Optimanufacturing T60-1001-C8-1A, T60-1001-C9-1A, T60-1002-C8-00, T60-1002-C9-00 Service Manual

OPERATION & SERVICE MANUAL FOR

CABLE TENSIOMETER

T60 SERIES

PART NUMBERS:

T60-1001-C8-1A (NSN: 6635-00-530-1128)

T60-1001-C9-1A (NSN: 6635-00-530-1129)

T60-1002-C8-00 (BRITISH MODEL FOR CWT CABLES)

T60-1002-C9-00 (BRITISH MODEL FOR CWT CABLES)

SOP-TN-002 Rev. Q

T60 Operations and Service Manual

TABLE OF CONTENTS

INTRODUCTION AND DESCRIPTION .................................................................................................................................... 2

1-1. INTRODUCTION ...................................................................................................................................... 2

1-2. PURPOSE - .............................................................................................................................................. 2

1-3. DESCRIPTION - ....................................................................................................................................... 2

1-4. WARRANTY - ........................................................................................................................................... 2

Table 1- Type Identification .............................................................................................................................................. 2

SPECIAL SERVICE TOOLS .................................................................................................................................................... 3

2-1. SPECIAL SERVICE TOOLS .................................................................................................................... 3

PREPARATION FOR USE, STORAGE, and SHIPMENT ........................................................................................................ 3

3-1. PREPARATION FOR USE ...................................................................................................................... 3

3-2. PERFORMANCE – .................................................................................................................................. 3

3-3. STORAGE ................................................................................................................................................ 3

3-4. SHIPMENT - ............................................................................................................................................. 3

Figure 1.1- Wrist Band ...................................................................................................................................................... 3

Figure 1- Cable Tensiometer, Typical ............................................................................................................................... 4

SECTION IV ................................................................................................................................................................ 4

OPERATION INSTRUCTIONS ................................................................................................................................................ 4

4-1. GENERAL INSTRUCTIONS .................................................................................................................... 4

4-2. OPERATING INSTRUCTIONS - .............................................................................................................. 5

4-3. MEASURING CABLE DIAMETERS ......................................................................................................... 5

Figure 2- T60 Cable Diameters ........................................................................................................................................ 5

4-4. TAKING CABLE TENSION READINGS, TYPE C8 ................................................................................. 6

Figure 3- Preset Instructions, Type C8 ............................................................................................................................. 6

4-5. TAKING TENSION READINGS, TYPE C9 - ............................................................................................ 7

Figure 3.5- Preset Instructions, Type C9 .......................................................................................................................... 7

4-6. DIFFICULT LOCATIONS ......................................................................................................................... 7

4-7. ACCURACY - ........................................................................................................................................... 7

Table 2- T60 Accuracy Tolerance..................................................................................................................................... 7

4-8. TYPE OF CABLE - ................................................................................................................................... 8

4-9. USE OF CALIBRATION BAR - ................................................................................................................ 8

Figure 4- Calibration Bar Instruction ................................................................................................................................. 8

4-10. OVERLOAD - ........................................................................................................................................... 8

SECTION V ................................................................................................................................................................. 9

PERIODIC INSPECTION, MAINTENANCE, AND LUBRICATION ........................................................................................... 9

5-1. GENERAL - .............................................................................................................................................. 9

Table 3- Lubrication Chart ................................................................................................................................................ 9

SECTION VI ................................................................................................................................................................ 9

TROUBLE SHOOTING ............................................................................................................................................................ 9

6-1. GENERAL - .............................................................................................................................................. 9

6-2. SERVICE TROUBLES AND REMEDIES - .............................................................................................. 9

Table 4- Trouble Shooting Chart ...................................................................................................................................... 9

SECTION VII ............................................................................................................................................................. 10

CALIBRATION ....................................................................................................................................................................... 10

7-1. EQUIPMENT REQUIRED - .................................................................................................................... 10

7-2. DISASSEMBLY PRIOR TO CALIBRATION - ........................................................................................ 10

7-3. CALIBRATION - ..................................................................................................................................... 10

7-4. INDICATOR CABLE SIZE - .................................................................................................................. 11

Table 5- STD Cable Size to British (CWT) Cable Size Equivalents ................................................................................ 11

SECTION VIII ............................................................................................................................................................ 12

GROUP ASSEMBLY PARTS LIST......................................................................................................................................... 12

Figure 6- Cable Tensiometer, Type C8 and C9 .............................................................................................................. 12

Table 6 Part List ............................................................................................................................................................ 13

SOP-TN-002 Rev. Q

T60 Operations and Service Manual

1

SECTION I

TYPE

MFR’S

PART NUMBER CABLES

RANGE

Type C8

T60-1001-C8-1A

1/16”, 3/32”, 1/8”

10 to 200 lbs.-tension

5/32”, 3/16”

30 to 200 lbs.-tension

7/32”, 1/4”

80 to 200 lbs.-tension

British

T60-1002-C8-00

3 CWT, 5 CWT,10 CWT

10 to 200 lbs.-tension

15 CWT, 25 CWT

30 to 200 lbs.-tension

35 CWT, 45 CWT

80 to 200 lbs.-tension

Type C9

T60-1001-C9-1A

1/8”, 5/32”, 3/16”, 7/32”, 1/4”

150 to 450 lbs.-tension

British

T60-1002-C9-00

10CWT, 15CWT, 25CWT, 35CWT, 45CWT

150 to 450 lbs.-tension

INTRODUCTION AND DESCRIPTION

1-1. INTRODUCTION - This publication is issued as the basic Manual of Operation and Service

Instructions for Types C8 and C9 Cable Tensiometers manufactured by OPTI Manufacturing Corp.,

Luquillo, Puerto Rico USA. The equipment covered are listed in table 1. Instructions contained in this

1-2. PURPOSE - The cable Tensiometer are designed for use in accurate rigging of airborne control cables

1-3. DESCRIPTION - Used extensively, it is considered the standard of the industry in many countries,

1-4. WARRANTY - The T60 cable Tensiometer has a warranty to the original customer for a period of (1)

publication apply to both types listed, unless specifically noted otherwise.

and has proven it’s durably under long and continual service. Each instrument is suitable for use over a

wide range of tension measurements and different cable sizes.

Firm positive 3-point cable grip prevents dislodgement when instrument hanging free on control cable.

The T60 requires no alternate riser for the various size cables. There are no losable parts in the T60.

The instrument is always ready for instant use. An easy to operate, accurate, built-in gage eliminates

guess work as to size of cable to be tested. Simple, comfortable lever grip permits one hand operation

without operator fatigue. In severe cold, service mittens or gloves may be worm without any loss

efficiency of operation.

A simple lock holds dial pointer at exact reading on cables in areas where instrument cannot be seen.

A touch unlocks the pointer preparatory for the next reading. Large, clear numerals make readings

easy and accurate. Bezel is easily turned to the correct zero setting for the proper cable size,

determined by the gage in the handle head. The T60 is a durable precision instrument and is not

damaged by use on cable tensions beyond its range.

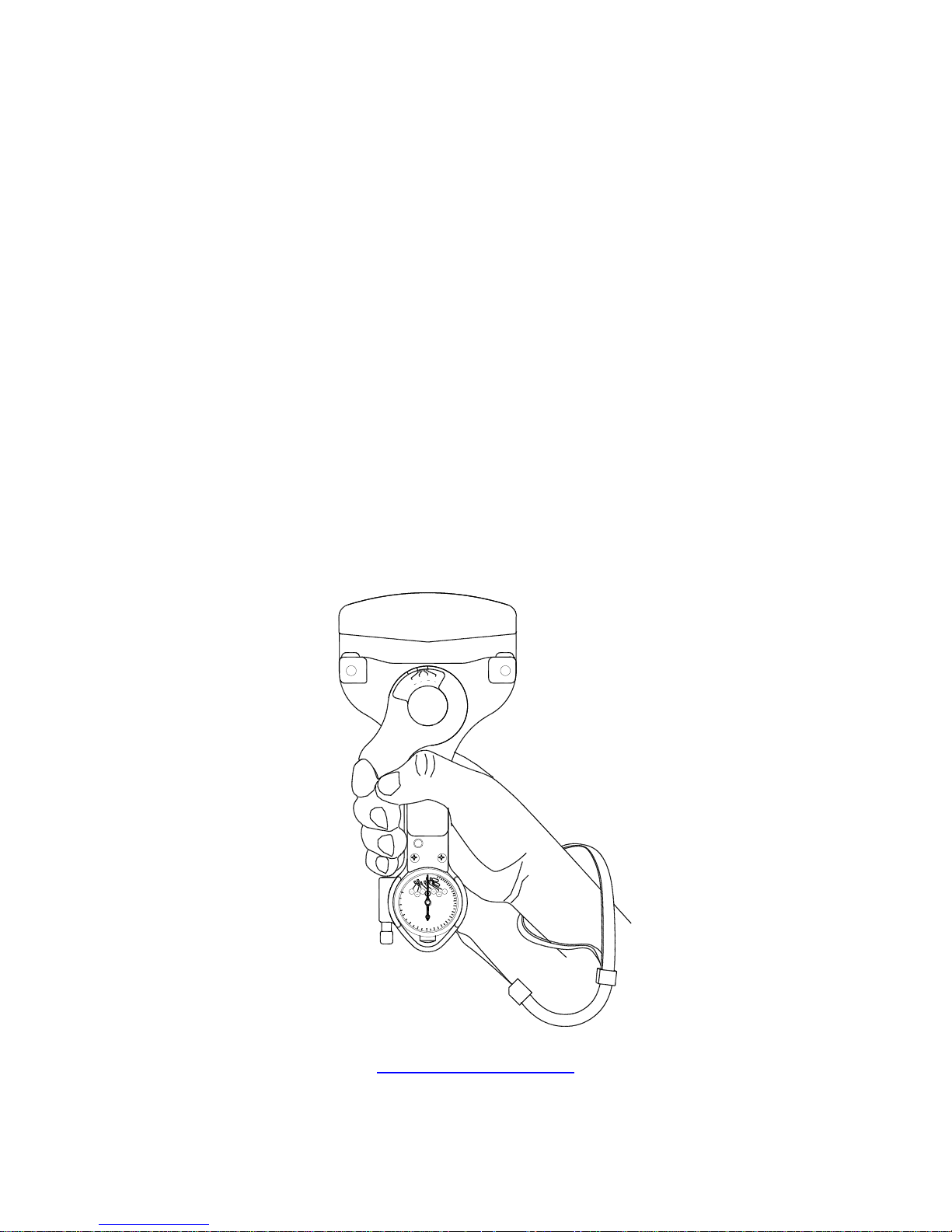

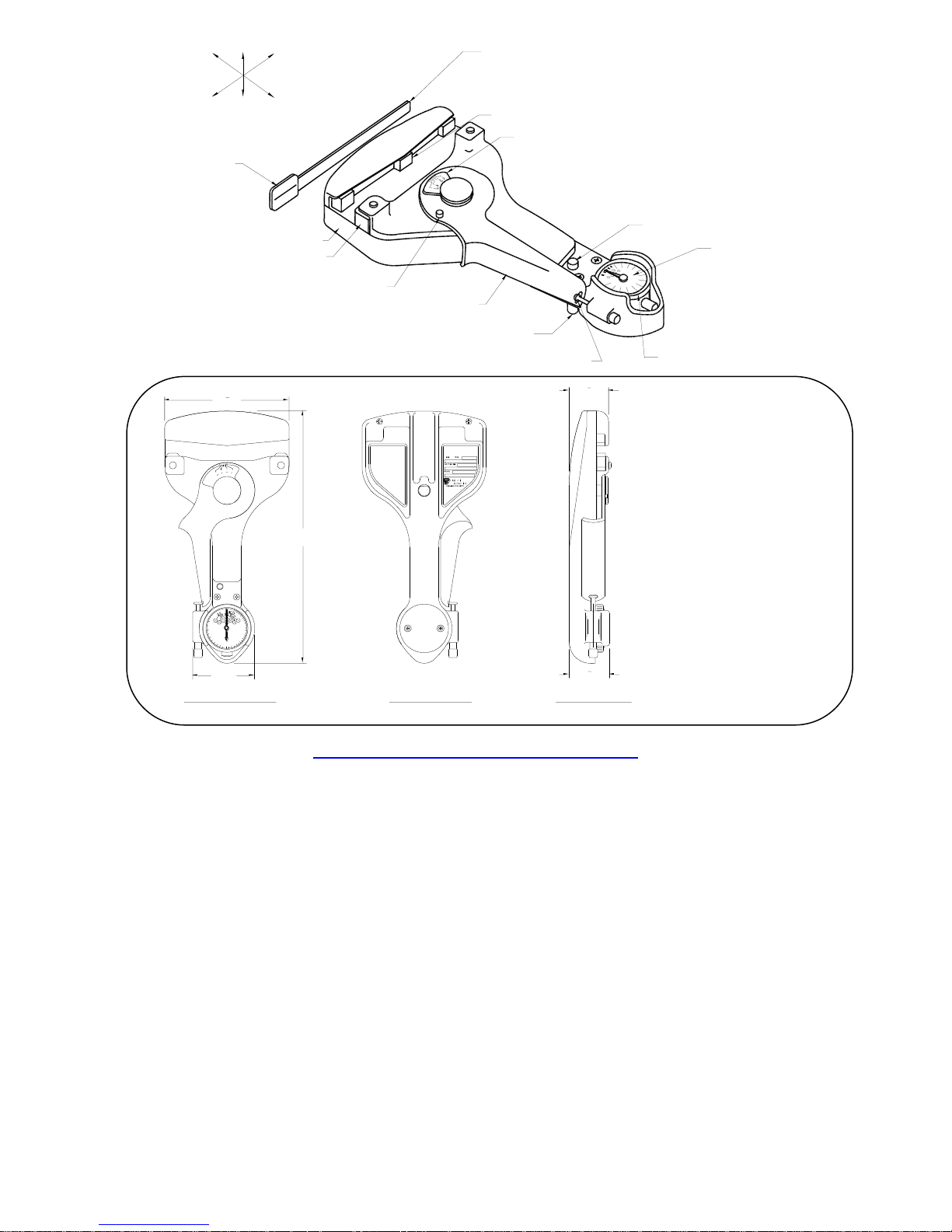

The cable Tensiometer is a hand-held instrument. A jaw is located at the top of instrument. Actual

contact on the cable is made by the riser block and the two sectors located in the jaw. A sliding yoke

slides up the frame of the instrument to provide a measuring force. A dial indicator is located at the

bottom of the instrument to give the actual tension indication. An actuating handle is pivoted at the

center of the instrument and is motivated by a trigger spring within the body of the Tensiometer. A

pointer lock button is situated just above the dial indicator and a handle latch is located on the left side

of the frame to engage the detent notch of the actuating handle. (See figure 1)

one year on new units and (6) six months for repaired units from the invoice date. This warranty is to

ensure the cable Tensiometer is free of defects in materials and workmanship under correct and

normal use. The warranty can be void if the unit has been tampered, altered, dropped or damaged by

an accident.

All returns must have a Return Material Authorization (RMA) number. In order to obtain a RMA, please

contact our Quality Department via email, jorge@optimanufacturing.com, or via fax: (787) 889-2805.

Table 1- Type Identification

SOP-TN-002 Rev. Q

T60 Operations and Service Manual

2

32

CABLE TENSIOMETER

PACIFIC SCIENTIFIC

1

16

3

32

1

8

3

16

7

32

1

4

POUNDS TENSION

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

200

125+

125-

5

1

4

3

16

1

16

1

8

SECTION II

SPECIAL SERVICE TOOLS

2-1. SPECIAL SERVICE TOOLS - No special tools are required for service or maintenance of the cable

Tensiometer.

SECTION III

PREPARATION FOR USE, STORAGE, and SHIPMENT

3-1. PREPARATION FOR USE - The cable Tensiometer is shipped by the manufacturer in its own

carrying case and is ready for use, for avoid damage on common use, the operator shall be use the

Wrist Band adjustable, see figure 1.1. Each time the cable Tensiometer is used it shall be removed

from the case and the serial number stamped on the nameplate checked against the serial number on

the tab of the calibration bar.

3-2. PERFORMANCE – The Tensiometer shall be capable for use under extreme conditions of heat or

cold without affecting the accuracy of readings, the operating temperature range are -65⁰F to 160⁰F

(-53⁰C to 71⁰C.)

3-3. STORAGE - When the cable Tensiometer is not in use it must be placed in its carrying case. There

are no special instructions or precautions relative to storage.

3-4. SHIPMENT - If the cable Tensiometer is to be shipped, it shall be placed in its carrying case and

packed in such a manner as to avoid damage by common carrier.

SOP-TN-002 Rev. Q

T60 Operations and Service Manual

Figure 1.1- Wrist Band

3

UP

DOWN

BOTTOM

RIGHT

TOP

LEFT

CALIBRATION BAR

RISER

CABLE GAGE

POINTER LOCK BUTTON

PRESET ACTUATING

DIAL FACE

RING

HANDLE LATCH

POINTER UNLOCK

BUTTON

ACTUATING HANDLE

CABLE GAGE STOP PIN

SECTOR

JAW BASE

TAB

32

CABLE TENSIOMETER

PACIFIC SCIENTIFIC

1

16

3

32

1

8

3

16

7

32

1

4

POUNDS TENSION

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

200

125+

125-

5

1

4

3

16

1

16

1

8

9"

228.6mm

4

1

2

"

114.3mm

2"

50.8mm

INSTRUCTIONS

1- PRESET DIAL TO

CABLE DIA.(NOTE

RANGE LARGER DIA.)

2- CLAMP ON CABLE

SEVERAL PLACES AND

AVERAGE READINGS.

3- TO KEEP DIAL

READING PRESS

BUTTON,

REVERSE

TO RELEASE

CABLE

TENSIOMETER

PATENTS:

2,592,868

D - 157032

MADE IN

U.S.A.

T60040

1

1

2

"

38.1mm

1

1

2

"

38.1mm

FRONT VIEW

Not Scale

REAR VIEW SIDE VIEW

Not Scale Not Scale

T60 TENSIOMETER

Net Weight: 1.58 lb. / .72 kg.

Shipping Weight: 3 lbs. / 1.36 kg.

Figure 1- Cable Tensiometer, Typical

4-1. GENERAL INSTRUCTIONS - Each time the instrument is removed from its case for use check the

serial number on the nameplate to ascertain that it agrees with the serial number on the calibration

Warning: Cable Tensiometers should not be used for adjusting the rig load in a cable system where an automatic

cable tension regulator is installed. All such cable systems should be rigged by adjusting them so that the

pointer on the cable tension regulator scale indicates the correct number based on the surrounding temperature

as indicated on the chart provided by the aircraft Maintenance Manual. The Tensiometer may be used to check

the tension so obtained, but it must be remembered that the actual cable tension will vary from the nominal

depending on the errors in the instrument itself, manufacturing tolerance of springs in the regulators, rate of the

regulator spring, and condition of the control cable. Cable tension readings taken on a regulated control system

therefore can be misleading and can result in damage through improper rigging.

SOP-TN-002 Rev. Q

T60 Operations and Service Manual

bar. Before using the instrument check the calibration by means of the calibration bar. (See paragraph

4-9.)

SECTION IV

OPERATION INSTRUCTIONS

4

Loading...

Loading...