Optikon Keratron Scout Operating manual

Cod. 161204EN

2008-12-03 Rev.B

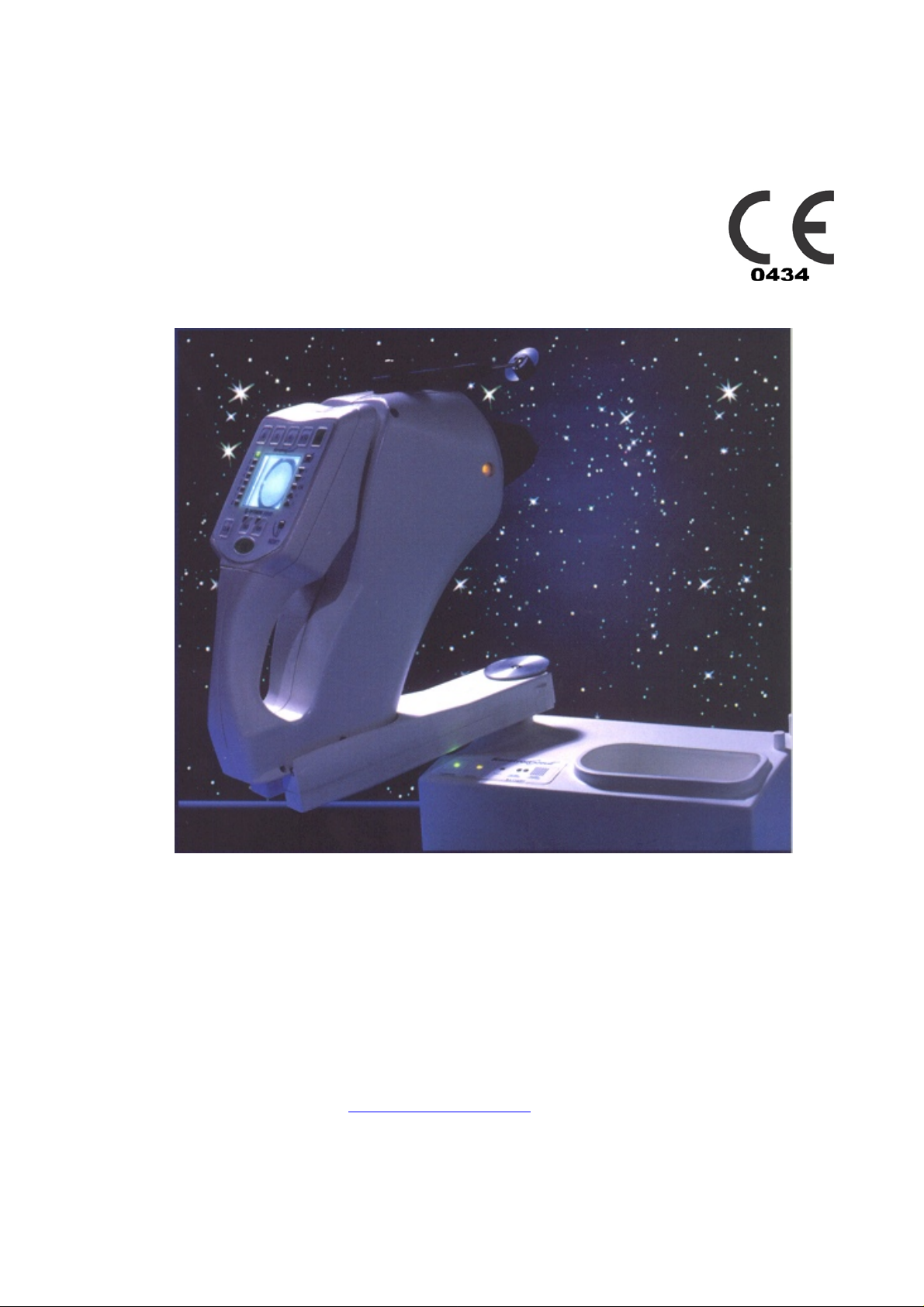

KERATRON® SCOUT

Videokeratoscope

INSTALLATION AND OPERATING MANUAL

OPTIKON 2000 S.p.A.

Via del Casale di Settebagni, 13 - 00138 Rome Italy

Phone +39 06 8888355 - Fax. +39 06 8888440

e-mail

mailto:sales@optikon.com - www.optikon.com

Optikon 2000 SpA is an ISO 9001 and ISO 13485 certified company

which manufactures surgical and diagnostic devices for ophthalmology.

Its products are manufactured to satisfy the requirements of 93/42/EEC

Medical Devices Directive.

TABLE OF CONTENTS

Page

DISCLAIMER ................................................................1-1

1

2 LIMITED WARRANTY CONDITIONS.......................................2-1

3 WARNINGS .................................................................3-1

4 SYMBOLS ...................................................................4-1

5 GENERAL INFORMATION.................................................. 5-1

5.1 SYSTEM DESCRIPTION .............................................................................. 5-1

5.2 TECHNICAL SPECIFICATIONS ...................................................................... 5-2

5.3 EMC TABLES ......................................................................................... 5-5

5.3.1 ELECTROMAGNETIC EMISSIONS................................................................ 5-5

5.3.2 ELECTROMAGNETIC IMMUNITY ................................................................ 5-6

5.3.3 RECOMMENDED SEPARATION DISTANCES .................................................... 5-7

5.4 CIRCUIT DIAGRAMS ................................................................................. 5-8

5.5 COMPOSITION ....................................................................................... 5-8

5.6 ACCESSORIES ........................................................................................ 5-9

5.7 UPGRADE KITS......................................................................................5-10

5.8 NOT SUPPLIED ACCESSORIES.....................................................................5-11

5.9 DISCONTINUED CODES ............................................................................5-12

6 INSTALLATION.............................................................6-1

6.1 INTRODUCTION...................................................................................... 6-1

6.2 UNPACKING AND INSPECTION..................................................................... 6-1

6.3 INSTALLATION PROCEDURE ....................................................................... 6-2

6.3.1 CONFIGURATION ON THE SLIT LAMP ......................................................... 6-2

6.3.2 “PORTABLE” (BATTERY OPERATED) CONFIGURATION..................................... 6-4

6.3.3 INTRA-OPERATORY CONFIGURATION......................................................... 6-6

6.4 SOFTWARE INSTALLATION......................................................................... 6-7

6.4.1 INTRODUCTION .................................................................................. 6-7

6.4.2 DOWNLOAD THE KERATRON SCOUT FROM THE WEB....................................... 6-8

6.4.3 KERATRON SCOUT SOFTWARE INSTALLATION............................................... 6-9

6.4.4 IMPORTING OLD KERATRON® TESTS .......................................................... 6-9

6.4.5 KERATRON SCOUT SOFTWARE ANATOMY...................................................6-11

6.4.6 SCOUT CUSTOMIZATION.......................................................................6-12

6.4.7 USB DRIVERS INSTALLATION ..................................................................6-12

6.4.8 CONFIGURING KERATRON SCOUT SOFTWARE..............................................6-15

6.4.9 UNINSTALL KERATRON SCOUT SOFTWARE..................................................6-16

7 SCREEN AND COMMANDS DESCRIPTION ................................ 7-1

7.1 INTRODUCTION...................................................................................... 7-1

7.2 CALIBRATION........................................................................................ 7-1

7.3 HOW TO ACQUIRE A GOOD IMAGE ............................................................... 7-2

7.3.1 THE SLIT LAMP CONFIGURATION.............................................................. 7-2

7.3.2 THE PORTABLE CONFIGURATION.............................................................. 7-3

7.4 HOW TO PROCESS, PRINT AND SAVE IMAGES................................................... 7-6

7.5 PUPILLOMETRY...................................................................................... 7-7

8 CLEANING, STERILIZATION AND MAINTAINANCE...................... 8-1

8.1 CLEANING AND DISINFECTION .................................................................... 8-1

8.2 STERILIZATION ...................................................................................... 8-1

9 TROUBLESHOOTING ......................................................9-1

9.1 SOFTWARE INSTALLATION......................................................................... 9-1

9.2 THE SCOUT.INI FILE ................................................................................ 9-1

9.3 SHARING KERATRON® SCOUT WITH OTHERS.................................................... 9-2

9.4 CHANGING THE PC ................................................................................. 9-2

9.5 MISCELLANEOUS PROBLEMS....................................................................... 9-3

10 INDEX...................................................................10-1

11 APPENDIX ..............................................................11-1

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

1 DISCLAIMER

OPTIKON 2000 S.p.A. requires the user of this system to carefully read specific

warnings found in this manual. It is responsibility of the user to provide its personnel

with a thorough understanding of the equipment operation before use. In no event

shall Optikon 2000 S.p.A. be liable for any injury, incidental or consequential

damages incurred by the purchaser, users or patients as a result of operation of the

product.

Use of this system is a matter of professional medical judgment in all cases. Optikon

2000 S.p.A. is not responsible for any clinical problem resulting from mishandling this

equipment and makes no medical recommendations.

Optikon 2000 S.p.A. declares to be liable for safety, reliability and performance only

if:

• upgrades, calibrations, repairs are carried out by OPTIKON 2000 S.P.A.

authorized personnel

• the system is used in accordance with its instructions for use

• the mains electric installation to which the system is connected complies with

the IEC or UL Safety Regulations

IMPORTANT NOTICE

Every effort has been made to have all the illustrations and information

accurately represent the product and its operation as it actually was at the time

this operation manual was printed. Changes in some items may be made

during the life of this manual, so that we may effectively continue to meet the

requirements of users. On occasion, these changes may be made without

notice.

OPTIKON 2000 S.p.A.

Via del Casale di Settebagni, 13

00138 Rome Italy

Phone +39 06 8888355

Fax +39 06 8888440

e-mail

www.optikon.com

sales@optikon.com

NOTICE: Information contained in this manual is proprietary with Optikon 2000 S.p.A.

reproduction of any part or whole may only be performed with written permission from

OPTIKON 2000 S.p.A.

Cod. 161204EN 1-1 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

THIS PAGE IS INTENTIONALLY BLANK

Cod. 161204EN 1-2 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

2 LIMITED WARRANTY CONDITIONS

All OPTIKON 2000 S.P.A. equipment and accessories sold and installed in the

European Union are guaranteed against defective workmanship and faulty parts for

ONE YEAR, from the date of the invoice. Warranty on consumable materials is

limited to the first use

Please, inquire with your local Optikon Distributor for warranty conditions in countries

outside the European Union.

All items under warranty will be repaired or replaced free of charge.

Warranty includes the research of causes of the faults, reparation of the defect and a

final inspection of the unit, or part(s).

This warranty does not cover the results of misuse, accident, abuse and tampering or

alteration done by anyone other than personnel authorized by OPTIKON 2000 S.p.A.

OPTIKON 2000 S.P.A. reserves the right to ascertain, in case of faults, whether or

not the equipment and/or its accessories have been altered, tampered with, in any

way, or have been damaged by improper use.

.

OPTIKON 2000 S.P.A. also reserves the right to modify the equipment and/or its

accessories whenever operating techniques necessitate modification(s).

No warranty will be recognized if serial number of the equipment and/or accessories

attributed by OPTIKON 2000 S.P.A. is missing, tampered and/or not clearly readable.

Warranty does not include expenses for return shipment of equipment and

accessories: all expenses for transport, packing etc. are to be borne by the

purchaser.

In case of an expressly requested intervention of our technicians, all travel and hotel

expenses will be debited to the client.

OPTIKON 2000 S.P.A. cannot be held liable for damages caused by transportation. If

this is the case, the customer should apply at once to the carrier that handled the

consignment.

Cod. 161204EN 2-1 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

THIS PAGE IS INTENTIONALLY BLANK

Cod. 161204EN 2-2 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

3 WARNINGS

General

®

• The Keratron

eyes.The use and the evaluation of the Keratron

comply with this manual, or made by using surfaces having a reflectivity or a

shape which is far from those typical of human eyes (for example: contact

lenses, surfaces having discontinuity in the tangent or concavity in any of its

section profiles, or surfaces such to create multiple reflections or

disappearance of some mire) cannot insure to have the same degree of

accuracy and thus it is strongly discouraged.

• Situations that create mires jamming can happen on human eyes in limited

areas. This must be

acquisitions (see in particular the chapters dedicated to the eye acquisition and

the last page of this manual), and eventually corrected by properly using “Photo

Process” Editing functions. Therefore, you can either adjust mires detection

parameters or eventually discard artefacts . In any case, the user must

individually check that the mires reconstruction has been adequate before

accepting the topographic resulting data as valid.

Scout has been developed and optimised to measure human

®

Scout in conditions that not

prevented by insuring a good tearing and good image

• Use of accessories and cables other than those provided with the unit may

result in an increase of the emissions or in decreased immunity of the system.

Portable and mobile communications equipment can affect the performance of

the unit.

• Carefully follow the instructions when installing and using the unit , in order to

prevent harmful interferences with other devices in the vicinity. If the unit causes

harmful interferences to other devices (determined by turning the unit off and

on), the user is encouraged to try to correct the interference by one or more of

the following measures:

• Reorient or relocate the other devices.

• Increase the distance between the equipment.

• Connect the unit into an outlet on a circuit different from that to which the other

devices are connected.

• Consult your local distributor or OPTIKON 2000 technical assistance.

Environmental

Cod. 161204EN 3-1 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

Recycle the Ni-Cd batteries or dispose properly

• Do not dispose of Keratron® Scout as unsorted municipal waste. Collect it

separately according to the local laws/regulations on disposal of waste electrical

and electronic equipment.

Electrical

• NiCd batteries: Warning!

o The batteries inside this module can explode or leak if put on fire

o Do not open the Battery Module and do not short-circuit its electric

contacts.

o Do not wet or put into water. You could have electrical shocks or

hazard.

• Caution when inserting/ de-inserting the Docking Base-VK cable

To insert the cable:

o

Turn the base off before plugging the cable to VK.

o Check the connector orientation.

o Insert perpendicularly.

o Tight the blocking screws.

To unplug:

• Turn the instrument off before unplugging the cable to the VK.

• Loose the blocking screws.

• Remove without teasing.

Cod. 161204EN 3-2 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

• Plug the power chord only of a PC having an insulation class II of

EN60950 (shortly represented with the symbol ), i.e.: compliant EN

60601-1 standard and then lock it by screwing the Perspex Plate in its

place

The Mains socket-outlet of the OR trolley must be used only to energize

equipment compliant with EN 60601-1 standard (or class II of EN60950). The

risks that are encountered when equipment, whose compliance with EN 606011 is unknown, is connected to the trolley are:

• the EARTH LEAKAGE CURRENT of the equipment could lead to

an excessive EARTH LEAKAGE CURRENT of the system, in

normal condition;

• the ENCLOSURE LEAKAGE CURRENT of the equipment could

lead to an excessive ENCLOSURE LEAKAGE CURRENT of the

system, in single fault conditions (interruption of common protective

earth conductor).

Mechanical

•

Block the handle before removing the Videokeratoscope from the staff The arm

of the OR trolley base is weight-balanced for an average weight of the Scout VK.

Prior to remove the VK, you should block the spring mechanism within the arm by

the proper handle, or the staff can hurt your face.

•

Insert the pin of the Slit Lamp Adaptor into the Slit Lamp hole before tightening

the hand-wheel. Tightening of the knob with the pin only partly inserted can

permanently deform it.

Cod. 161204EN 3-3 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

THIS PAGE IS INTENTIONALLY BLANK

Cod. 161204EN 3-4 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

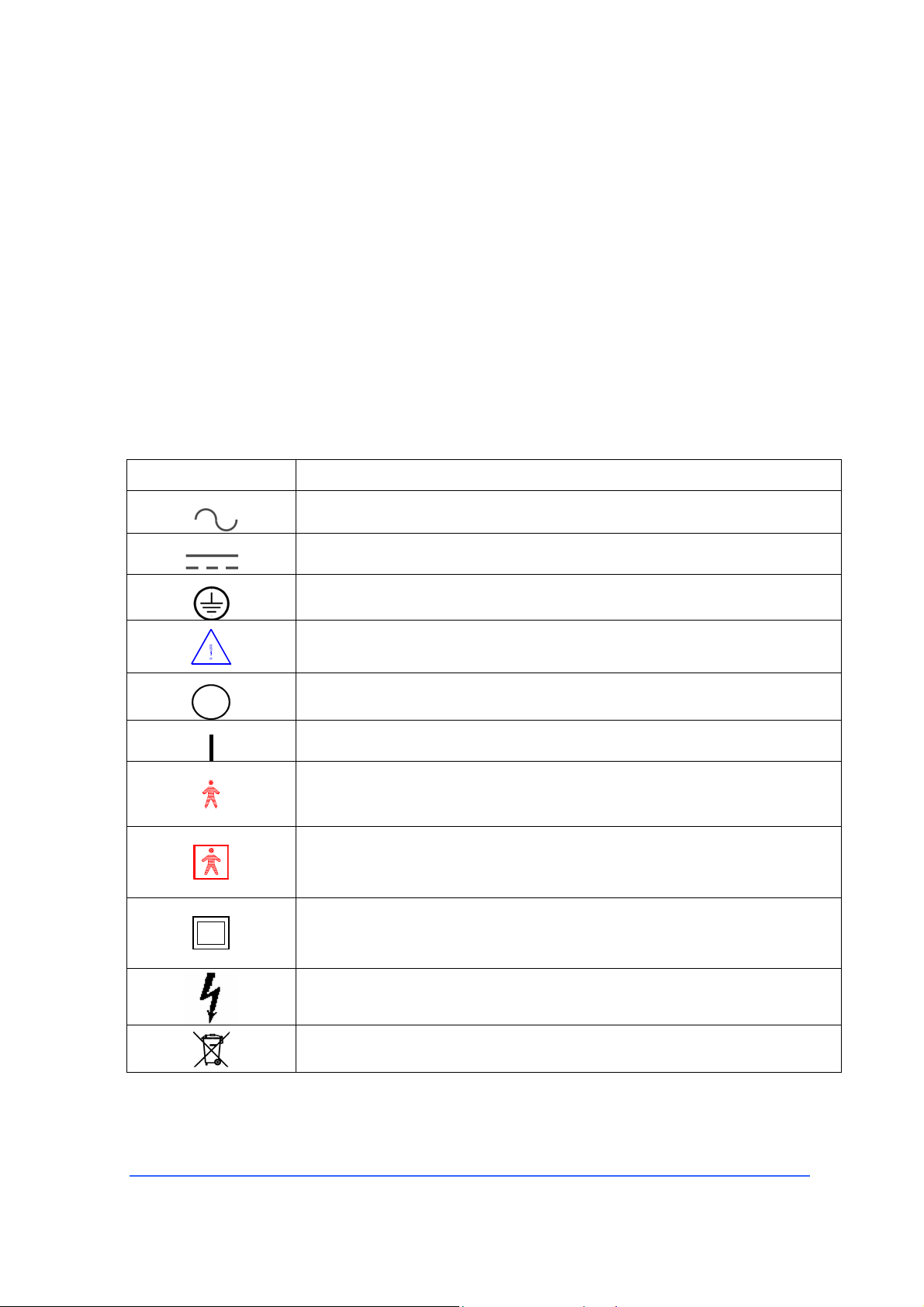

4 SYMBOLS

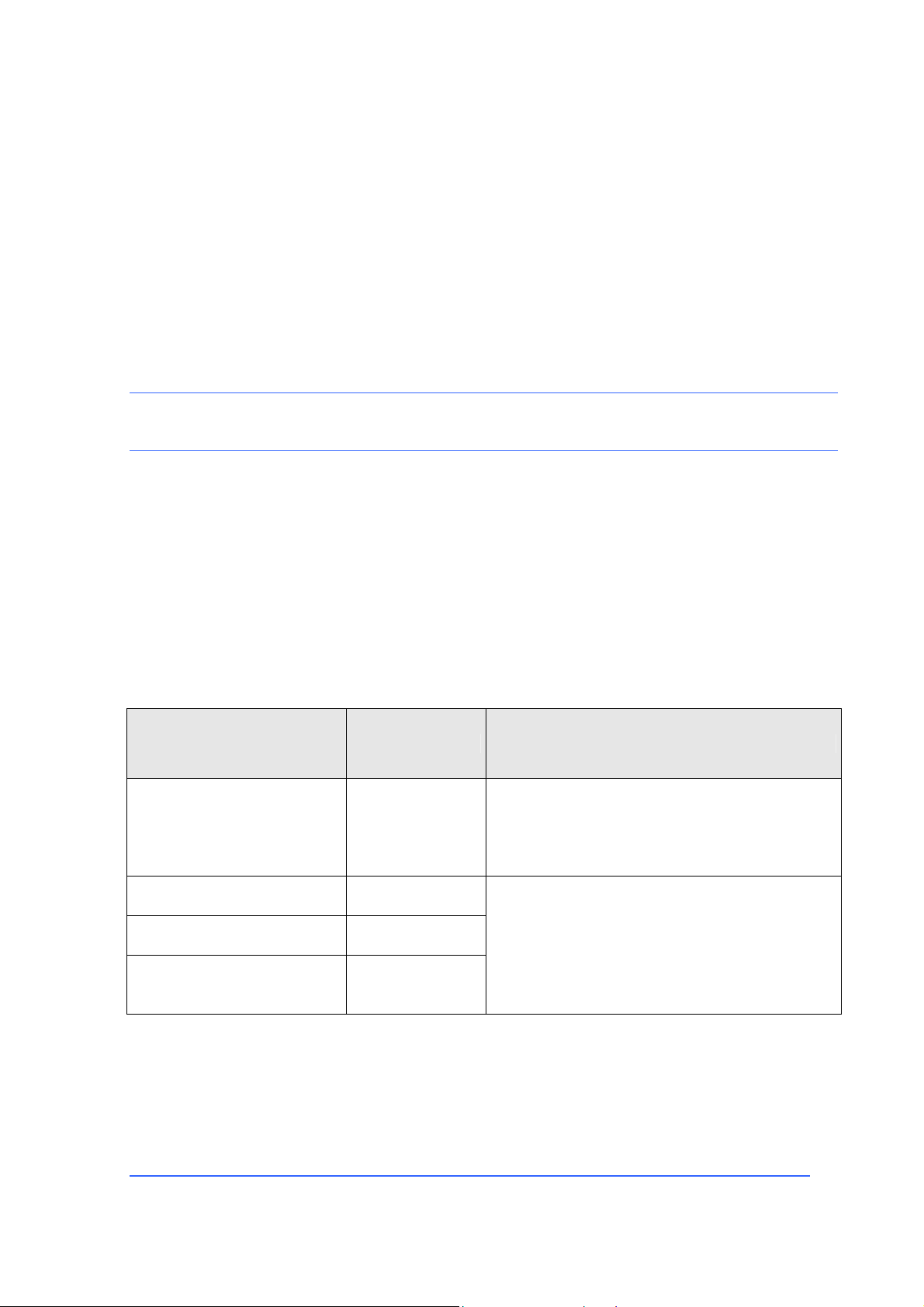

Table shown below reports some symbols approved by I.E.C. and their meaning.

When there is not enough room, they are frequently used on medical equipment to

enable an easy and fast communication of information and warnings. Sometimes two

or more symbols may be assembled to obtain a special meaning.

These symbols are used in the Keratron

starting to use the units, you should familiarize yourself with them and their definitions

shown in the table.

SYMBOLS PUBLISHED BY THE IEC

SYMBOL

®

Scout and Docking Base labels. Before

DESCRIPTION

ALTERNATING CURRENT

DIRECT CURRENT

PROTECTIVE EARTH (GROUND)

ATTENTION, CONSULT ACCOMPAINING DOCUMENTS

OFF (POWER: DISCONNECTION FROM THE MAINS)

ON (POWER: CONNECTION TO THE MAINS)

FLOATING PART APPLIED TO THE PATIENT (BODY-

PART APPLIED TO THE PATIENT (BODY)

CLASS II EQUIPMENT

TYPE B

TYPE BF

FLOATING)

DANGEROUS VOLTAGE

SEPARATE COLLECTION OF WASTE ELECTRICAL/ELECTRONIC

EQUIPMENT

Cod. 161204EN 4-1 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

THIS PAGE IS INTENTIONALLY BLANK

Cod. 161204EN 4-2 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

5 GENERAL INFORMATION

5.1 SYSTEM DESCRIPTION

The KERATRON® SCOUT is a Modular “Computer Assisted

VideoKeratographer” (also said CAVK in the literature) that, just like the

KERATRON

symbolic colour map of the corresponding axial or refractive powers, of its local

curvatures or of its elevations in several formats (corneal topography).

The KERATRON

• a Videokeratoscope (VK), for the acquisition of the image of mires reflected

on the eye,

®

, is designed to measure the shape of the cornea and to represent it as

®

SCOUT is made of:

• either a table-top Docking Base or a OR Trolley base for intra-operative use,

to power supply the VK and to communicate via Universal Serial Bus (USB) of

any PC (not included) to the VK itself

• a selection of Adapters i.e. a Slit Lamp Adapter and Cable, a Battery

Module, and an Head Rest.

These modules, with some additional accessories like a Scout “far” Mires Cone

and Sterile Sleeves, can create a system to allow to get a corneal topography in one

or more of the following operating conditions:

• On a generic Slit Lamp, with the Slit Lamp Adapter inserted into the hole for

accessories of the slit lamp itself and a supplied cable inserted between the

VK and the Docking base

• Portable, with a specific battery module inserted under the VK and in the

docking base, and a head-rest inserted onto the VK.

• Intra-operative, inserting the VK into a staff of the OR Troll base, with a weight

balanced arm, which both supports and power supply it

The VK carries 28 mires, which are shaped as back-lighted concentric rings,

alternatively 14 black and 14 whites, arranged into the internal conical surface of a

cone, made of transparent perspex, called Mires Cone which is removable and

which carries a opto-electronic couple, made of an IRED and a photo-transistor, set

at two opposite sides of its external edge.

Cod. 161204EN 5-1 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

The Cone is back illuminated by the Lamp Board which contains a tight array of

LEDS. Behind the Lamp Board there are the fixation led, focused at a large distance,

and the TV Camera.

The photoelectric couple at the edge of the optical head intercepts the eye vertex

when this is at the preset distance from the optical head. An electronic circuit (EPCS)

eliminates the background light and measures the “degree of coverage”, which is

used to accept the acquisition only within a preset range. An array of 5 LEDS at the

right hand side of the TV monitor of the VK, indicates the operator how to move forth

and back towards the eye. If the eye is not at the right distance the image capture will

be inhibited.

The operator thus can only take images, by pressing a footswitch or the OK

pushbutton, only when the patient eye is at a preset distance, which is the same

distance at which the instrument was formerly calibrated on a sphere having a known

curvature radius.

During a test, 2 or 3 photos are usually taken on each eye, then they are processed

by algorithms to reconstruct the shape of the cornea at more than 7000 points

arranged at the crossways between the 28 black-to-white and white-to-black mire

borders and 256 radials or “meridians”.

Graphic routines then interpolates and traces this values in the form of color maps.

The center of the rings is the corneal vertex, that is the point of the cornea which is

closer to the observing TV-camera, and that is an important reference point for all

corneal maps. The entrance pupil is also detected.

5.2 TECHNICAL SPECIFICATIONS

PARAMETER SPECIFICATION

Manufacturer:............................... OPTIKON 2000 S.p.a.

via del Casale di Settebagni, 13

00138 Rome - Italy

®

Model:.......................................... Keratron

Regulatory compliance: .............. 93/42/EEC Medical Devices Directive (MDD)

Technical standards: EN 60601-1 ; EN 60601-1-1 ;

EN 60601-1-2

Scout

Cod. 161204EN 5-2 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

PARAMETER SPECIFICATION

ENVIRONMENTAL SPECS

Storage:....................................... temp range -10°C to +60°C,

humidity 0-100% (cond.included)

atm. pressure 500 to 1060 hPa

Operation:.................................... temp range 0°C to +40°C,

humidity 0-90% (non condensing)

atm. pressure 700 to 1060 hPa

ELECTRICAL SPECS

DOCKING BASE AND OR TROLLEY

Input voltage:............................... 100/120/220/230-240 V A.C. select.

Frequency:................................... 50/60 Hz

Power consumption:.................... 60 VA

Line fuses: ................................... 220/240 Volt: 1 A T

100/120 Volt: 2 A T

KERATRON® SCOUT

Input voltage:............................... 14-18 Vdc supplied by the Docking Base, by the Battery

or by the OR Trolley

Power consumption:.................... 28 VA

ACCURACY

Simulated K-Readings:................Within +/- 0.25D on a normal cornea.

Focusing......................................BFS deviation: with Slit Lamp Adapter typical within+/0.15D

Within +/- 0.25D handheld.To be checked by the

“repeatability check” function.

Misalignement..............................Mean deviation on the map: +/- 0.1 with misalignement up

to 1mm.

EQUIPMENT CLASSIFICATION ACCORDING TO IEC 60601-1

Type of protection against electric shock :

Docking Base............................... Class I

OR Trolley.................................... Class I

Keratron

®

Scout........................... Class II

Cod. 161204EN 5-3 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

Degree of protection against electric shock:

Docking Base............................... Type B

OR Trolley.................................... Type B

®

Keratron

Scout........................... Type BF

Degree of protection against harmful ingress of water:

Docking Base............................... Ordinary

OR Trolley.................................... IPX1

®

Keratron

Scout........................... Ordinary

OR Footswitch............................. IPX8

NOTE

The switches located inside the footswitch are immersion-proof (protection class:IPX8), therefore this

accessory is suitable for use in operating room environment

Degree of safety of application in the presence of a flammable

anaesthetic mixture:..................... not protected

Mode of operation........................ Continuos operation

DIMENSIONS

DOCKING BASE

Height: ......................................... 80 mm

Width:........................................... 250 mm

Depth:.......................................... 150 mm

Weight:......................................... about 2200 g

KERATRON® SCOUT

Height: ......................................... 240 mm

Width:........................................... 280 mm

Depth:.......................................... 100 mm

Weight:......................................... about 1000 g

BATTERY MODULE

Height: ......................................... 95 mm

Width:........................................... 260 mm

Cod. 161204EN 5-4 2008-12-03 Rev.B

Keratron® Scout Installation and Operating Manual

OPTIKON 2000

Depth:.......................................... 120 mm

Weight:......................................... about 500 g

OR TROLLEY BASE

Height: ......................................... 1400 mm

Width:........................................... 600 mm (900 with max arm extension)

Depth:.......................................... 600 mm (900 with max arm extension)

Weight:......................................... about 35 Kg

NOTE:

1) Weight and dimensions shown are approximate.

2) Specifications are subject to change without notice

5.3 EMC TABLES

5.3.1 GUIDANCE AND MANUFACTURER’S DECLARATION –

ELECTROMAGNETIC EMISSIONS

The Keratron® Scout is intended for use in the electromagnetic environment

specified below. The customer or the user of the Keratron® Scout should assure

that it is used in such an environment.

Emissions test Compliance Electromagnetic Environment – Guidance

®

Scout uses RF energy only for its

®

Scout is suitable for use in all

RF emissions

CISPR 11

RF emissions

CISPR 11

Harmonic emissions

IEC 61000-3-2

Voltage fluctuations/Flicker

emissions

IEC 61000-3-3

Group 1

Class B

Class A

Complies

The Keratron

internal function.

Therefore, its RF emissions are very low and are

not likely to cause any interference in nearby

electronic equipment.

The Keratron

establishments including domestic

establishments and those directly connected to

the public low voltage supply network that

supplies buildings used for domestic purposes.

Cod. 161204EN 5-5 2008-12-03 Rev.B

Loading...

Loading...