MET SERIES

OPTIKA

MICROSCOPES

®

ITALY

3

Inspection & Industrial

Metallurgical Microscopes

3

Metallurgical Microscopy

Metallography is the study of the physical structure and components of metals, by using microscopy.

Many different microscopy techniques are used in metallographic analysis.

Prepared specimens should be examined with the unaided eye after etching to detect any visible areas that have responded to the etchant

differently from the norm as a guide to where microscopical examination should be employed. Light optical microscopy (LOM) examination

should always be performed prior to any electron metallographic (EM) technique, as these are more time-consuming to perform and the

instruments are much more expensive.

Inspection & Industrial

Further, certain features can be best observed with the LOM, e.g., the natural color of a constituent can be seen with the LOM but not with EM

systems. Also, image contrast of microstructures at relatively low magnifications, e.g., <500X, is far better with the LOM than with the scanning

electron microscope (SEM), while transmission electron microscopes (TEM) generally cannot be utilized at magnifications below about 2000

to 3000X. LOM examination is fast and can cover a large area. Thus, the analysis can determine if the more expensive, more time-consuming

examination techniques using the SEM or the TEM are required and where on the specimen the work should be concentrated.

Brightfield and darkfield microscopy

Most LOM observations are conducted using bright-field (BF) illumination, where the image of any flat feature perpendicular to the incident

light path is bright, or appears to be white. But, other illumination methods can be used and, in some cases, may provide superior images

with greater detail. Dark-field microscopy (DF), is an alternative method of observation that provides high-contrast images and actually greater

resolution than bright-field. In dark-field illumination, the light from features perpendicular to the optical axis is blocked and appears dark while

the light from features inclined to the surface, which look dark in BF, appear bright, or “self-luminous” in DF. Grain boundaries, for example, are

more vivid in DF than BF.

Polarized light microscopy

Polarized light (PL) is very useful when studying the structure of metals with non-cubic crystal structures (mainly metals with hexagonal

close-packed (hcp) crystal structures). If the specimen is prepared with minimal damage to the surface, the structure can be seen vividly in

cross-polarized light (the optic axis of the polarizer and analyzer are 90 degrees to each other, i.e., crossed). In some cases, an hcp metal

can be chemically etched and then examined more effectively with PL. Tint etched surfaces, where a thin film (such as a sulfide, molybdate,

chromate or elemental selenium film) is grown epitaxially on the surface to a depth where interference effects are created when examined with

BF producing color images, can be improved with PL. If it is difficult to get a good interference film with good coloration, the colors can be

improved by examination in PL using a sensitive tint (ST) filter.

Differential interference contrast microscopy

Another useful imaging mode is differential interference contrast (DIC), which is usually obtained with a system designed by the Polish physicist

Georges Nomarski. This system gives the best detail. DIC converts minor height differences on the plane-of-polish, invisible in BF, into visible

detail. The detail in some cases can be quite striking and very useful. If an ST filter is used along with a Wollaston prism, color is introduced.

The colors are controlled by the adjustment of the Wollaston prism, and have no specific physical meaning, per se. But, visibility may be better.

Oblique illumination

DIC has largely replaced the older oblique illumination (OI) technique,

which was available on reflected light microscopes prior to about 1975.

In OI, the vertical illuminator is offset from perpendicular, producing

shading effects that reveal height differences. This procedure reduces

resolution and yields uneven illumination across the field of view.

Nevertheless, OI was useful when people needed to know if a second

phase particle was standing above or was recessed below the planeof-polish, and is still available on a few microscopes. OI can be created

on any microscope by placing a piece of paper under one corner of

the mount so that the plane-of-polish is no longer perpendicular to the

optical axis.

328

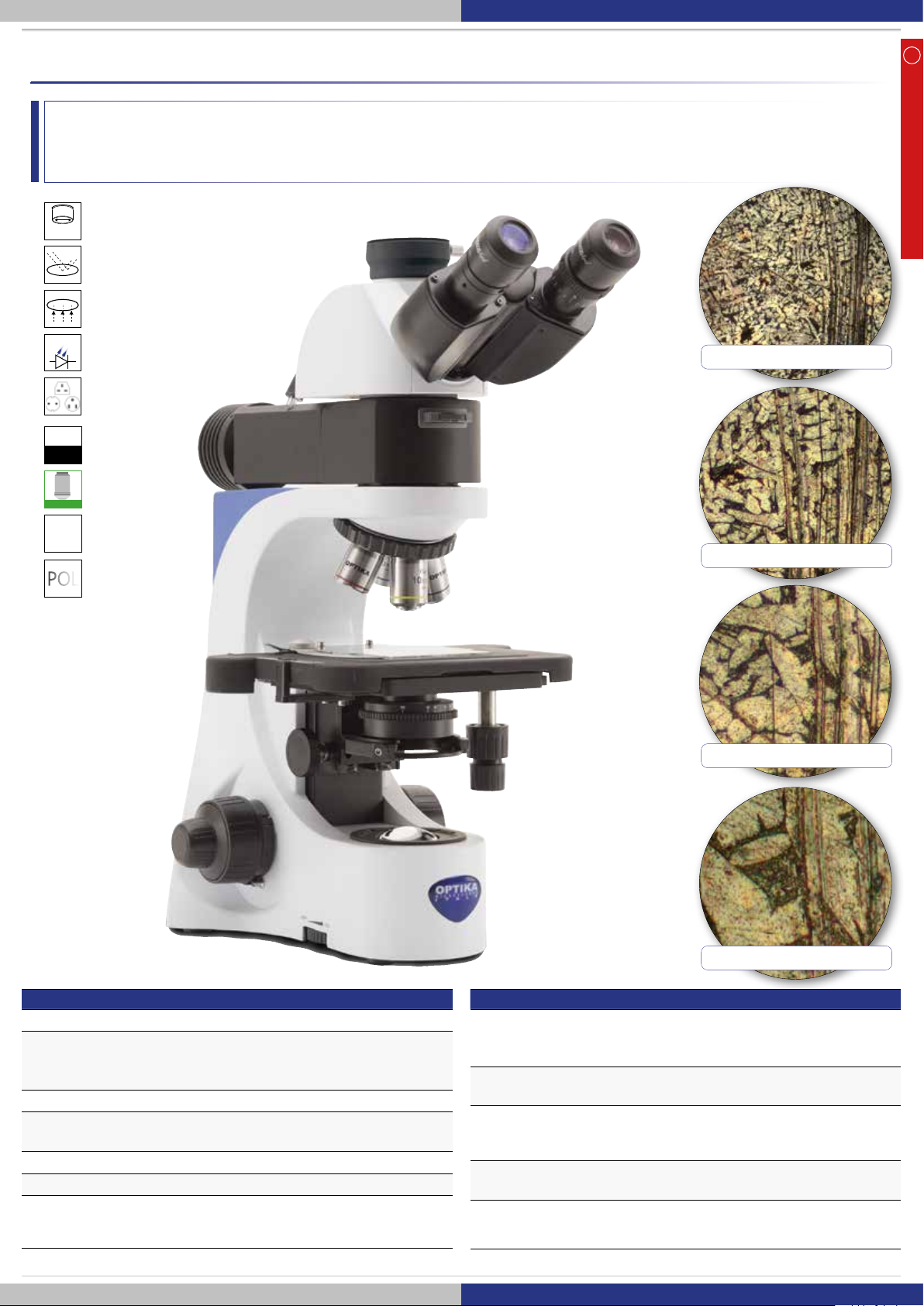

B-383MET - Metallurgical Microscope

3

Brightfield upright microscope with IOS W-PLAN MET objectives and metallurgical attachment combining the exclusive X-LED3 lighting source both for incident

and transmitted illumination. The NCG (no cover glass) objectives are especially designed for microscopy use without a cover slip ideal for metallographic

samples and other opaque specimens.

20

33

X-LED

4x

IOS

∞

W-PLAN

MET

10x

POLPOL

Inspection & Industrial

Part Description

Observation mode: Brightfield, incident polarized light.

Epi-illumination and

polarizing filters:

Head: Trinocular (fixed 50/50), 30° inclined, 360° rotating.

Interpupillary

distance:

Dioptric adjustment: On the left eyepiece tube.

Eyepieces: WF10x/20 mm, high eye-point and secured by screw.

Nosepiece: Quintuple revolving nosepiece, rotation on ball

3

X-LED

with white 3.6 W LED (6.300 K) with brightness

control. Field and aperture diaphragms, polarizer &

analyzer filters.

Adjustable between 48 and 75 mm.

bearings.

20x

50x

Part Description

Objectives

(strain-free):

Specimen stage: Double layer rackless mechanical stage, 233x147 mm,

Focusing:

Condenser:

Transmitted illumination

(Fixed Koehler type):

IOS W-PLAN MET 5x/0.12 IOS W-PLAN MET 10x/0.25

IOS W-PLAN MET 20x/0.40 IOS W-PLAN MET 50x/0.75

All with anti-fungus treatment.

78x54 mm X-Y range. With tempered glass plate.

Coaxial coarse (adjustable tension) and fine focusing

mechanism with limit stop to prevent the contact

between objective and specimen.

Abbe N.A. 1.25, with objective-coded iris diaphragm,

focusable and centerable.

X-LED3 with white 3.6 W LED (6.300 K) with brightness

control. Multi-plug 100-240Vac/6Vdc external power supply.

329

3

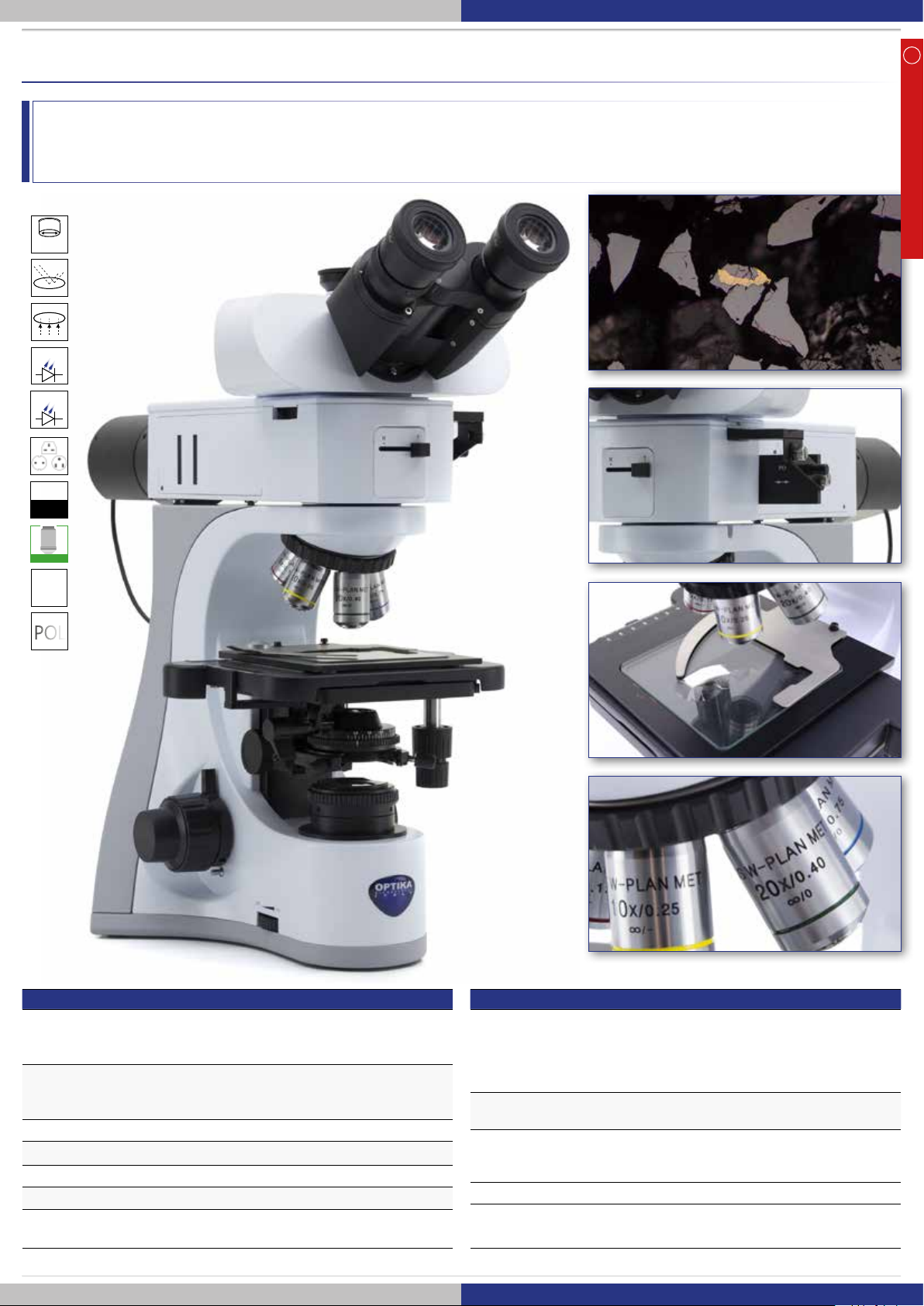

B-510MET - Metallurgical Microscope

Advanced routine laboratory microscope with IOS W-PLAN MET objectives and metallurgical attachment with the exclusive X-LED3 lighting source for incident

illumination only. The NCG (no cover glass) objectives are especially designed for microscopy use without a cover slip ideal for metallographic samples and other

opaque specimens.

22

Inspection & Industrial

88

X-LED

IOS

∞

W-PLAN

MET

POLPOL

Part Description

Observation mode: Brightfield, simple polarized light, oblique illumination

on incident light.

Epi-illumination and

polarizing filters:

Head: Trinocular (fixed 50/50), 30° inclined, 360° rotating.

Interpupillary distance:

Dioptric adjustment: On the left eyepiece tube.

Eyepieces: WF10x/22 mm, high eye-point and with rubber cups.

Nosepiece:

330

8

X-LED

with white 8 W LED (6.300 K) with brightness

control. With aperture and field diaphragms, and

oblique illumination system. With polarizer and analyzer.

Multi-plug 100-240Vac/6Vdc external power supply.

Adjustable between 50 and 75 mm.

Quintuple revolving nosepiece, rotation on ball bearings.

Part Description

Objectives

(strain-free):

Specimen stage: Double layer rackless mechanical stage, 233x147 mm,

Focusing:

IOS W-PLAN MET 5x/0.12

IOS W-PLAN MET 10x/0.25

IOS W-PLAN MET 20x/0.40

IOS W-PLAN MET 50x/0.75

All with anti-fungus treatment.

78x54 mm X-Y range.

Coaxial coarse (adjustable tension) and fine focusing

mechanism with limit stop to prevent the contact

between objective and specimen.

B-510METR - Metallurgical Microscope

3

Advanced routine laboratory microscope with IOS W-PLAN MET objectives and metallurgical attachment with the exclusive X-LED3 lighting source for both

transmitted and incident illumination. The NCG (no cover glass) objectives are especially designed for microscopy use without a cover slip ideal for metallographic

samples and other opaque specimens.

22

33

X-LED

88

X-LED

IOS

Inspection & Industrial

∞

W-PLAN

MET

POLPOL

Part Description

Observation mode: Brightfield on transmitted light.

Brightfield, simple polarized light, oblique illumination

on incident light.

Epi-illumination and

polarizing filters:

Head: Trinocular (fixed 50/50), 30° inclined, 360° rotating.

Interpupillary distance:

Dioptric adjustment: On the left eyepiece tube.

Eyepieces: WF10x/22 mm, high eye-point and with rubber cups.

Nosepiece: Quintuple revolving nosepiece, rotation on ball

8

X-LED

with white 8 W LED (6.300 K) with brightness

control.

With aperture and

oblique illumination system. With polarizer and analyzer.

Adjustable between 50 and 75 mm.

bearings.

field diaphragms, and

Part Description

Objectives

(strain-free):

Specimen stage: Double layer rackless mechanical stage, 233x147 mm,

Focusing:

Condenser:

Transmitted illumination

(Full Koehler type):

IOS W-PLAN MET 5x/0.12

IOS W-PLAN MET 10x/0.25

IOS W-PLAN MET 20x/0.40

IOS W-PLAN MET 50x/0.75

All with anti-fungus treatment.

78x54 mm X-Y range. With tempered glass plate.

Coaxial coarse (adjustable tension) and fine focusing

mechanism with limit stop to prevent the contact

between objective and specimen.

Swing-out N.A. 0.2/0.9, with iris diaphragm, focusable and centerable.

X-LED3 with white 3.6 W LED (6.300 K) with brightness

control. Multi-plug 100-240Vac/6Vdc external power supply.

331

3

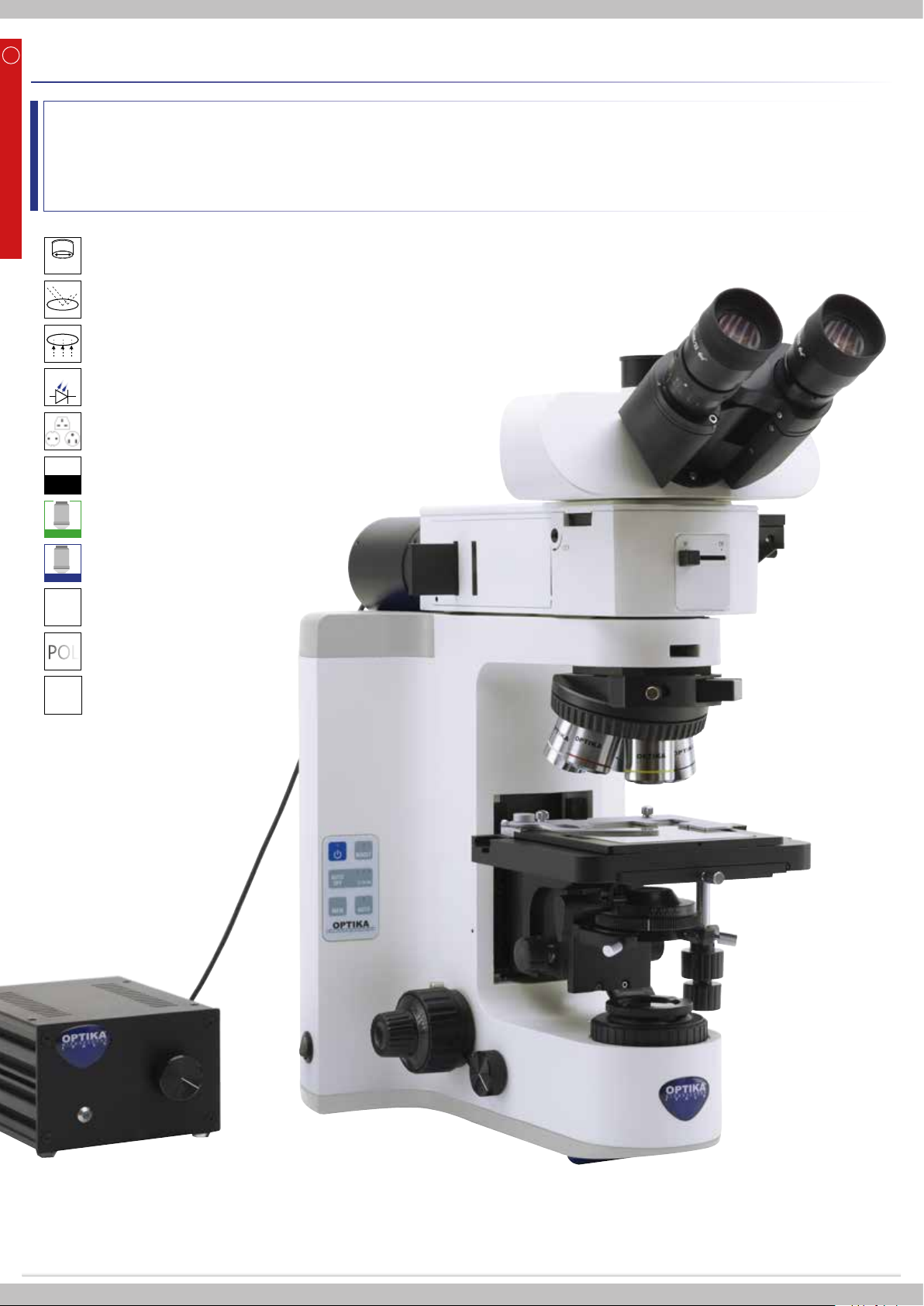

B-

1000MET

The modular OPTIKA B-1000 is available with brightfield and darkfield incident light, helping you working in a comfortable way during extended periods of

use and performing reliable, accurate and rapid diagnosis benefiting from modularity, which gives the chance to create customized configurations tailored on

customer needs. Versatile, robust, durable and sturdy, B-1000 offers premium quality optics, the state-of-the-art, exclusive

designed by OPTIKA and the Koehler diaphragm. Incident light through 100 W halogen lamp or 18 W LED illumination.

B-1000 gives multiple options as manual or motorized configuration.

Inspection & Industrial

22

88

X-LED

IOS

∞

- Metallurgical Microscope

8

X-LED

(8 W) illumination system,

W-PLAN

U-PLAN

MET

POLPOL

DFDF

332

B-

1000MET

- Configuration Chart

3

PL10x/22 eyepiece, high eyepoint,

with micr

ometric scale (10mm/100um)

& rubber cup (retractable)

Trinocular head, three positions

(100/0, 50/50, 0/1

M-1021M

Main body with focus system

and X-LED

8

illumination,

for metallurgical model

Build the microscope that suites your needs by choosing among the components

M-781

M-1011

00)

M-1035

Metallurgical attachment, 100 W Halogen

M-1021M+M-1156*+M-1149

Main body with motorized focus system

and X-LED

8

illumination,

for metallurgical model

M-1001

PL10x/22 eyepieces (pair),

high eyepoint, with rubber cup

(r

etractable)

Metallurgical attachment, 18 W LED

Main body with focus system,

for metallur

M-1036

M-1022M

gical model with

incident light only

M-1003

PL15x/16 eyepieces (pair),

high eyepoint

M-1012

Binocular ERGO head

M-1022M+M-1156*+M-1149

Main body with motorized focus

system, for metallurgical model with

Inspection & Industrial

incident light only

Sextuple reversed nosepiece,

M-1042

for RMS objectives with DIC slot

IOS LWD W-PLAN MET

LWD

W-PLAN

MET

∞

M-1099 2.5x

Sextuple motorized reversed nosepiece,

M-1043+M-1156*

for RMS objectives with DIC slot

IOS LWD U-PLAN MET IOS LWD U-PLAN F MET

LWD

U-PLAN

MET

∞

M-1100 5x

M-1101 10x

M-1102 20x

M-1103 50x

M-1104 100x

LWD

U-PLAN F

MET

∞

M-1171 5x

M-1172 10x

M-1173 20x

M-1174 50x

M-1175 100x

M-1148

Mechanical stage with glass,

for metallur

gical model

Quintuple reversed nosepiece for

M-1045

darkeld MET objectives, with 3 adater

rings for RMS objectives

IOS LWD W-PLAN MET BD

LWD

W-PLAN

MET BD

M-1109 5x

M-1110 10x

M-1111 20x

M-1112 40x

∞

M-1113 50x

100x

M-1114

IOS LWD U-PLAN MET BD IOS LWD U-PLAN F MET BD

LWD

U-PLAN

MET BD

∞

M-1147+M-1156*

Motorized mechanical stage

Quintuple motorized reversed nosepiece

M-1046+M-1156*

for darkeld MET objectives, with 3

adater rings for RMS objectives

M-1094 5x

M-1095 10x

M-1096 20x

M-1097 50x

M-1098 100x

LWD

U-PLAN F

MET BD

∞

M-1180 5x

M-1181 10x

M-1182 20x

M-1183 50x

M-1184 100x

0.70 N.A. swing-out MET condenser

M-1154

* Code M-1156 must be added only once for any motorized configuration

333

3

IM-3MET- Metallurgical Microscope

Routine inverted microscope with IOS LWD U-PLAN MET objectives for material science and metallographic applications, combining a sturdy yet compact structure

with dedicated components required in this field, like the NCG (no cover glass) objectives working without cover slide ideal for metallographic samples and other

opaque specimens. A particularly simple and ingenious optical design allows stable alignments and smooth and accurate movements.

22

Inspection & Industrial

IOS

∞

U-PLAN

MET

POLPOL

CAST IRON CAST IRON

BRIGHTFIELDBRIGHTFIELD

CAST IRON CAST IRON

POLARIZED LIGHTPOLARIZED LIGHT

334

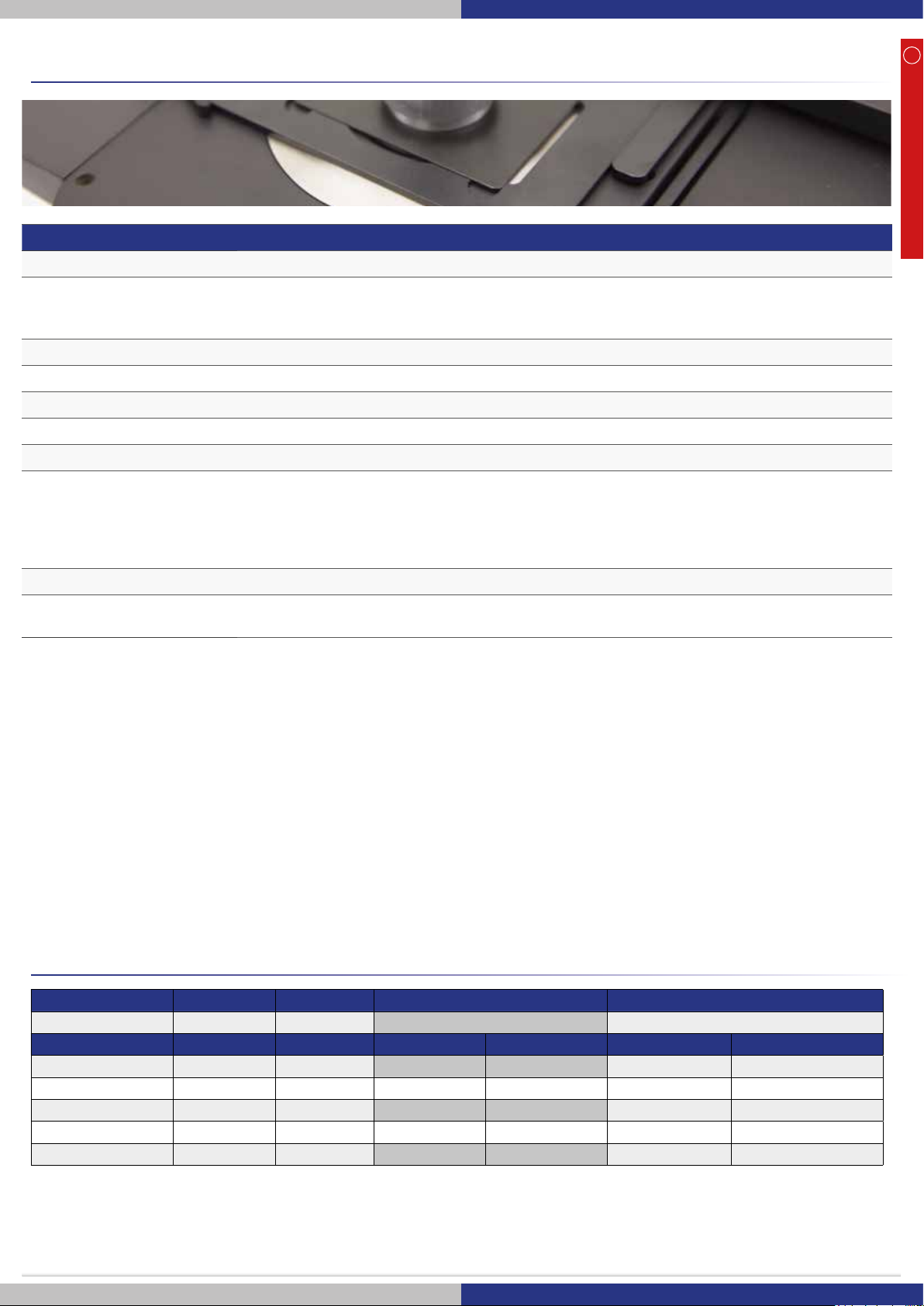

IM-3 Series - Specifications

Part Description

Observation mode: Brightfield, simple polarized light on incident light.

Epi-illumination and polarizing

filters:

Head: Trinocular (2-position 100/0, 50/50), 45° inclined.

Interpupillary distance: Adjustable between 50 and 75 mm.

Dioptric adjustment: On the left eyepiece tube.

Eyepieces: WF10x/22 mm, high eye-point and with rubber cups.

Nosepiece:

Objectives IOS LWD U-PLAN MET 5x/0.15

Halogen 12 V/50 W with brightness control.

With aperture and eld (centrable) diaphragms.

With polarizer and analyzer.

Quintuple revolving nosepiece, rotation on ball bearings.

IOS LWD U-PLAN MET 10x/0.30

IOS LWD U-PLAN MET 20x/0.45

IOS LWD U-PLAN MET 50x/0.55

All with anti-fungus treatment.

3

Inspection & Industrial

Specimen stage: Fixed stage, 250x160 mm, with metal stage insert.

Focusing: Coaxial coarse (adjustable tension) and fine focusing mechanism with limit stop to prevent the contact between objective

and specimen.

IM-3 Series - Optical performance

Eyepiece 10x (M-780) 15x (M-601)

Field number (mm) 22 16

Objective N.A. W.D. (mm) Total magnication Field of view (mm) Total magnication Field of view (mm)

5x

10x

20x

50x 0.55 7.90 500x 0.44 750x 0.32

100x 0.80 2.10 1000x 0.22 1500x 0.16

0.15 10.80

0.30 10 100x 2.20

0.45 4 200x 1.10

50x

4.40 75x 3.20

150x 1.60

300x 0.80

335

3

IM-5MET - Metallurgical Microscope

Industrial and materials science inverted microscope especially designed for opaque specimens (including metals microstructure

investigation and studies such as grain size, grain boundaries, phases, transformation, inclusions, and non-metals, as well as

sample preparation and treatment) in metallography labs. Freely configurable lenses according to customer ’s preferences ,

FN 24 high eyepoint, infinity corrected optical system, coaxial focusing, mechanical stage, and epi-illumination attachment

powered by halogen 12 V/100 W with brightness control. Sturdy and incredibly reliable, it is equipped with all the main controls

in ergonomic position and with long lasting, efficient LED illumination to provide over 20 years of use.

Inspection & Industrial

24

IOS

∞

U-PLAN

MET

POLPOL

DFDF

DDIICC

WAFER, POLARIZED WAFER, POLARIZED

LIGHTLIGHT

WAFER, DICWAFER, DIC

336

IM-5MET - Specifications

Part Description

Head: Trinocular (split ratio: 100/0, 50/50), 45° inclined.

Dioptric adjustment: Both eyepieces.

Eyepieces: WF10x/24 mm, high eyepoint, secured by screw and with retractable rubber cups.

Epi-illumination & lters: Halogen 12 V/100 W with brightness control. With eld and aperture diaphragms, polarizer and analyzer lters.

Nosepiece: Quintuple ball bearings revolving nosepiece, reversed.

Objectives: Selectable according to customer’s preferences. All with anti-fungus treatment.

Specimen stage:

Focusing: Coaxial coarse and ne focusing mechanism with limit stop to prevent the contact between objective and specimen.

Mechanical stage, 240x250 mm.

Adjustable tension of coarse focusing knob.

3

Inspection & Industrial

IM-5MET is freely configurable in terms of objectives, by choosing among:

MET Innity-corrected Plan-Achromatic, Long Working Distance

objectives, eld atness up to F.N. 25:

M-1100 IOS LWD U-PLAN MET objective 5x/0.15

M-1101 IOS LWD U-PLAN MET objective 10x/0.30

M-1102 IOS LWD U-PLAN MET objective 20x/0.45

M-1103 IOS LWD U-PLAN MET objective 50x/0.55

M-1104 IOS LWD U-PLAN MET objective 100x/0.80 (dry)

MET Innity-corrected Plan-Achromatic, Long Working Distance

objectives, for brighteld and darkeld, eld atness up to F.N. 25:

M-1094 IOS LWD U-PLAN MET BD objective 5x/0.15

M-1095 IOS LWD U-PLAN MET BD objective 10x/0.30

M-1096 IOS LWD U-PLAN MET BD objective 20x/0.45

M-1097 IOS LWD U-PLAN MET BD objective 50x/0.55

M-1098

IOS LWD U-PLAN MET BD objective 100x/0.80 (dry)

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

MET Innity-corrected Semi-Apochromatic, Long Working Distance

objectives, eld atness up to F.N. 25:

M-1171 IOS LWD U-PLAN F MET objective 5x/0.15

M-1172 IOS LWD U-PLAN F MET objective 10x/0.30

M-1173 IOS LWD U-PLAN F MET objective 20x/0.50

M-1174 IOS LWD U-PLAN F MET objective 50x/0.80

M-1175 IOS LWD U-PLAN F MET objective 100x/0.90 (dry)

MET Innity-corrected Semi-Apochromatic, Long Working Distance

objectives, for brighteld and darkeld, eld atness up to F.N. 25:

M-1180 IOS LWD U-PLAN F MET BD objective 5x/0.15

M-1181 IOS LWD U-PLAN F MET BD objective 10x/0.30

M-1182 IOS LWD U-PLAN F MET BD objective 20x/0.50

M-1183 IOS LWD U-PLAN F MET BD objective 50x/0.80

M-1184

IOS LWD U-PLAN F MET BD objective 100x/0.90 (dry)

Included n Optional

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

337

3

Inspection & Industrial

v 2.0 - OPTIKA reserves the right to make corrections, modications, enhancements, improvements and other changes to its products at any time without notice.

Headquarters and Manufacturing Facilities

OPTIKA S.r.l.

®

Via Rigla, 30 - 24010 Ponteranica (BG) - ITALY - Tel.: +39 035.571.392

- info@optikamicroscopes.com

Optika Sales branches

OPTIKA Spain

OPTIKA China

OPTIKA India

® ®

®

®

spain@optikamicroscopes.com

china@optikamicroscopes.com

india@optikamicroscopes.com

OPTIKA USA

OPTIKA Central America

®

usa@optikamicroscopes.com

camerica@optikamicroscopes.com

Loading...

Loading...