Optibelt ZRP, ZRM, ZRL, ZRL-M, ZRL-V Technical Manual

TECHNICAL MANUAL

OPTIBELT POLYURETHANE

TIMING BELT DRIVES

optibelt

ZRM: AT5 und AT10

optiflex:

Sortiment

Inklusive:

1

Technical Manual

for

Polyurethane Timing Belt Drives

Optibelt ZRM/ZRP/ZRL timing belts are made from

polyurethane and are especially suitable for use in

difficult environmental conditions

Endless Optibelt ZRM/ZRP timing belts, with corresponding Optibelt ZRS pulleys, provide non-slip,

synchronous transmission of power up to several

hundred kilowatts.

Where the requirement is for precise positioning in

linear drives and smoothly operating conveyor

systems, the open-ended and the joined endless

Optibelt ZRL timing belts provide the answer.

All essential information and the methods for calculating drives using Optibelt polyurethane timing belts are

contained in this manual. Should you have any further

questions, the free service provided by our application

engineers is readily available.

2

Produktionsstätten und Vertriebsorganisation der Arntz Optibelt Gruppe

Manufacturing and Distribution Organisation of the Arntz Optibelt Group

Produktionsstätten Factories

Arntz Optibelt GmbH

Postfach 10 01 32 · D-37669 Höxter/Germany

Corveyer Allee 15 · D-37671 Höxter/Germany

Tel. +49 (0) 52 71-6 21

Fax +49 (0) 52 71-97 62 00

A & M Belting Company Ltd.

Ballyraine Industrial Estate

Letterkenny Co. Donegal

Ireland

Tel. +353 (0) 74 91-2 50 66

Fax +353 (0) 74 91-2 50 61

a+m@optibelt.com

Optibelt Produktions GmbH & Co. KG

Carl-Vollrath-Straße 4

D-07422 Bad Blankenburg

Tel. +49 (0) 3 67 41-48 30

Fax +49 (0) 3 67 41-4 21 01

Arntz Belting Company Ltd.

Pennyburn Pass

Londonderry BT48 0AE

Northern Ireland

Tel. +44-28 71-26 12 21

Fax +44-28 71-26 33 86

abc@optibelt.com

Transac S.A.

54, Rue de la Gare

F-68520 Burnhaupt-le-Haut/France

Tél. +33-3-89 62 75 20

Fax +33-3-89 62 75 29

Vertriebsorganisation Deutschland Distribution Organisation Germany

Optibelt GmbH

Corveyer Allee 15

37671 Höxter

Tel. +49 (0) 52 71-6 21

Fax +49 (0) 52 71-97 62 00

info@optibelt.com

www.optibelt.com

Optibelt GmbH

Verkaufsbüro Nord

North Sales District

Corveyer Allee 15

D-37671 Höxter

Tel. +49 (0) 52 71-6 23 03

Fax +49 (0) 52 71-97 62 00

Optibelt GmbH

Verkaufsbüro Süd

South Sales District

Pfauhauser Straße 43

D-73240 Wendlingen

Tel. +49 (0) 70 24- 71 00

Fax +49 (0) 70 24-5 27 92

Vertriebsorganisation Europa Distribution Organisation Europe

Finnland Finland

Optibelt Finland Oy

PL 58

Lampputie 4

FIN-00751 Helsinki

Puh. +358-9-3 46 14 00

Faksi +358-9-3 46 15 00

optibelt@co.inet.fi

Großbritannien

United Kingdom

Optibelt (UK) Ltd.

5 Bishops Court

Winwick Quay

GB-Warrington WA2 8QY

Cheshire

Tel. +44-19 25-41 33 11

Fax +44-19 25-5737 51

optibelt@optibeltuk.co.uk

Frankreich France

Optibelt France S.A.S

54, Rue de la Gare

B.P. N° 13

F-68520 Burnhaupt-le-Haut

Tél. +33-3-89 62 75 10

Fax +33-3-89 62 75 19

optibelt-france@optibelt.fr

Polen Poland

Optibelt Polska Sp. z o.o.

ul. Budowlanych 11

PL-41-303 Da˛browa Górnicza

Tel. +48-32-260 1175/76

Faks+48-32-260 4208

biuro@optibelt.net.pl

Schweden Sweden

Optibelt Skandinaviska AB

Stadiongatan 60

S-21762 Malmö

Tel. +46-40-59 21 20

Direct +46-40-59 21 27

Fax +46-40-49 90 10

optibelt@optibelt.se

Niederlande Netherlands

Optibelt Nederland B.V.

Postbus 39

NL-2140 AA Vijfhuizen

Schipholweg 955

NL-2143 CE Boesingheliede

Tel. +31-23-5 55 16 51

Fax +31-23-5 55 19 26

t-online@optibelt.nl

Schweiz Switzerland

Optibelt AG

Bodenackerstrasse 70

CH-4657 Dulliken

Tel. +41-62-285 50 00

Fax +41-62-285 50 01

vertrieb@optibelt.ch

Ost-Europa

Eastern Europe GUS

Optibelt Russland

Varshavskoje Shosse,

125D, Korpus 1

113587 Moskau

Tel./Fax +7 09 59 95 05 41

Mobile +7 90 37 74 35 34

optibeltrus@ccs.ru

Dänemark Denmark

Optibelt Danmark A/S

International House

Center Boulevard

DK-2300 København S

Tlf. +45-32-47 32 34

Fax +46-40-49 90 10

optibelt@optibelt.dk

Belgien Belgium

Optibelt GmbH

Filiaal België

Cornelis Schutstraat 28

B-2100 Deurne

Tél. +32-3-3 25 22 75

Fax +32-3-3 26 09 55

optibelt@skynet.be

Spanien Spain

Optibelt España, S.A.

Apartado 1141

Rois de Corella, 12

E-08205 Sabadell

Tel. +34-93-7 20 79 60

Fax +34-93-7 11 64 90

administracion@optibelt.net

Südost-Europa

South Eastern Europe

Optibelt GmbH

Südost-Europa · Office Wien

Carlbergergasse 38

A-1230 Wien

Tel. +43-1-8 65 31 00 19

Fax +43-1-8 65 31 00 27

office@optibelt.at

Österreich Austria

Optibelt Österreich GmbH

Carlbergergasse 38

A-1230 Wien

Tel. +43-1- 8 65 43 97

Fax +43-1- 8 65 43 96

office@optibelt.at

Italien Italy

Optibelt AG

Via Dandolo, 1

I-20025 Legnano (Mi)

Tel. +39-0331-48 10 20

Fax +39-0331-48 10 75

optibeltitalia@libero.it

Vertriebsorganisation Nord- u. Südamerika Distribution Organisation North & South America

USA USA

Optibelt Corporation

1120 W. National Avenue

Addison, Illinois 60 101/USA

Tel. +1-630-628-84 00

Fax +1-630-628-61 75

optibelt@msn.com

Kanada Canada

Optibelt (Canada) Inc.

351 Steelcase Road West, Unit 8 & 9

L3R 4H9 Markham, Ontario/Canada

Tel. +1-905-477-8114

Fax +1-905-477-0857

info@optibelt.ca

Brasilien Brasil

Optibelt do Brasil Ltda.

Rua Henrique Monteiro Nr. 90

10 Andar-Pinheiros

CEP 05423-020 São Paulo-SP/Brasil

optibeltdobrasil@optibelt.com

Vertriebsorganisation Asien Distribution Organisation Asia

Singapur Singapore

Optibelt Asia Pacific Pte. Ltd.

No. 4 Loyang Way 1, # 01-02/03

Singapore 508708

Tel. +65-6545 4682

Fax +65-6545 4685

sales@optibelt.com.sg

China China

Optibelt Power Transmission (Shanghai) Co., Ltd.

# 55 Miaosan Road, Songjiang District

Shanghai 201612/P.R. China

Tel. +86-21-5768 7465

Fax +86-21-5768 7462

sales@optibelt.com.cn

2

3

Contents

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Manufacturing and Distribution Organisation of the Arntz Optibelt Group . . . . . . . . . . . . . . . . 2

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1 Product Description

1.1 Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Types and sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Special constructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Basics of Drive Design

2.1 Service factors, additional factors and formulae . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Symbols used in formulae . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 ZRM/ZRP Timing Belts

3.1 ZRM/ZRP resistance to chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 ZRM/ZRP optiflex timing belt range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 ZRM/ZRP belt selection graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4 ZRM/ZRP drive design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5 ZRM/ZRP tensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.6 ZRM/ZRP power rating table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4 Open-Ended and Joined Endless Optibelt ZRL Timing Belts for Linear Drives

and Conveying

4.1 ZRL timing belt range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2 ZRL graph of torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3 ZRL-M drive design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.4 ZRL-V drive design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.5 ZRL tensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.6 ZRL circumferential force and torque table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.7 ZRL resistance to chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5 Design Hints, Dimensions and Tolerances

5.1 Allowances, length tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2 Standard pulleys, flanged pulleys, idlers, clamping plates and minimum numbers of teeth . . 44

5.3 Operating, safety and maintenance hints, installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.4 Standards, pulley tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.5 Length measurement, width tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.6 Problems, causes, remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Taper Bushes, Timing Belt Pulleys and Clamping Plates

Taper bushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Timing belt pulleys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Recommended pulleys – special constructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Clamping Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

ZRM/ZRP Data Sheet and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

ZRL Data Sheet and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4

Introduction

Since the introduction of the first timing belt at the end of the 40’s,

this type of drive element has gained in importance for the

synchronous transmission of torque and power. The non-slip timing

belt has been successfully employed in many standard drives and

has provided economical design solutions in every sector of

mechanical engineering.

The position that the timing belt occupies today is due to the

development of tooth profiles and belt design. The Optibelt ZRM/

ZRP/ZRL single and double-section polyurethane timing belts are a

result of this progress. The properties specific to the polyurethane,

offer the following advantages:

● High resistance to abrasion

● Good to very good resistance to oil, grease and a

number of aggressive chemicals

● Colour fast

● Simple to weld, for attaching cleats and joining

endless to make belts of any length

● High resistance to tooth shear

● Good thermal tolerance (–30

°C to +80 °C)

● Good electrical insulation properties using poly-

urethane with Aramid tension cord

● Ageing resistant

● Ozone and UV resistant

Apart from the higher noise level at high belt speeds when

compared to V-belt drives, the timing belt has all of the advantages

of other drive mechanisms.

● Synchronous speed transmission, high angle and

positional accuracy due to the low-stretch tension

member and to the positive pulley/belt interlock.

● Double section belts permit multi-pulley arrange-

ments and contra-rotating pulleys.

● Belt flexibility allows high drive ratios requiring

minimum space.

● Low belt specific mass enables high belt speeds.

● Low-stretch tension cord means zero maintenance.

● High drive efficiency due to belt flexibility and lack

of slip.

● The low drive tension allows the use of smaller drive

bearings.

● No drive lubricant necessary, thus the drive is envi-

ronmentally friendly.

● Durable belt components ensure longer belt life.

1 Product Description

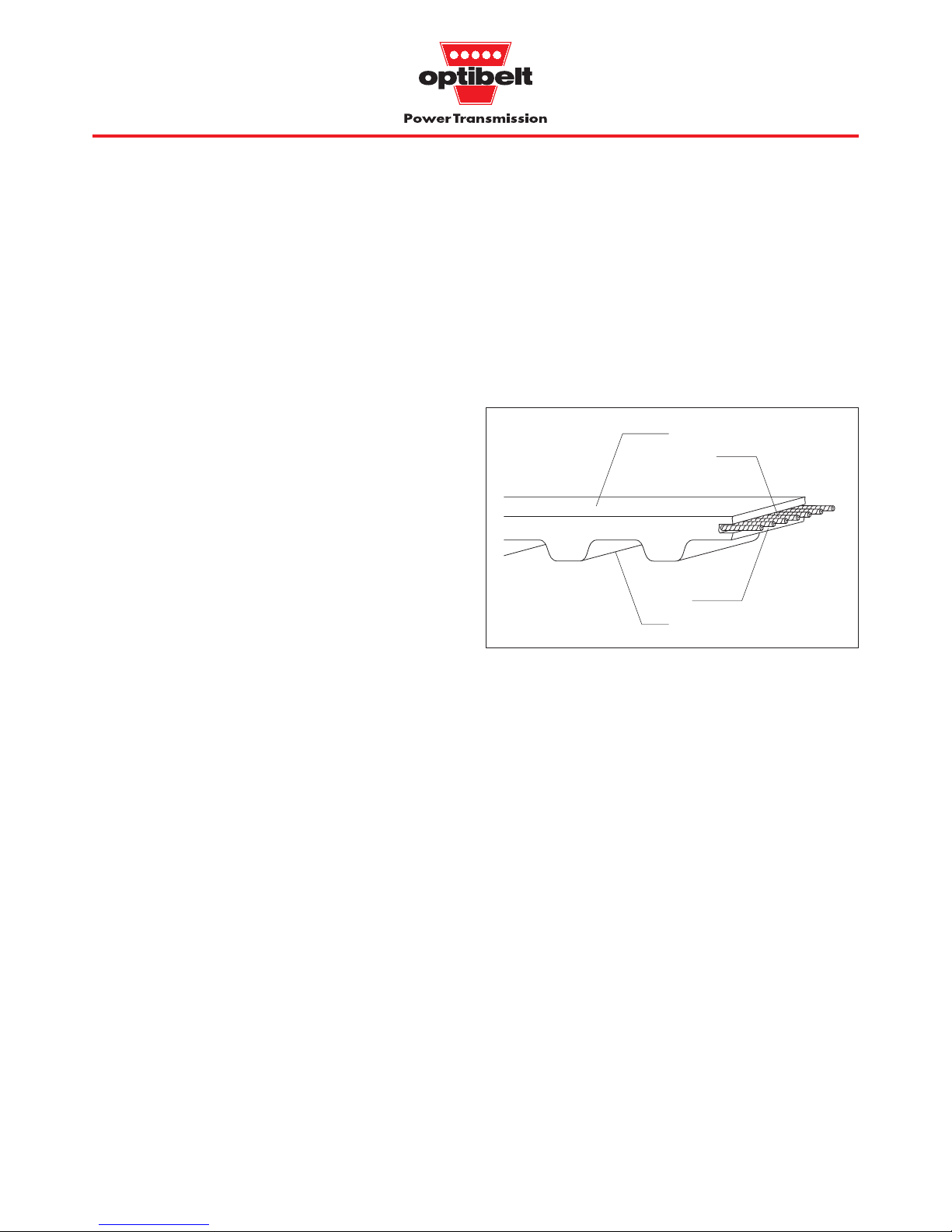

1.1 Construction

In addition to the features of the standard synchronised drive, the

Optibelt ZRM/ZRP/ZRL timing belts offer the additional advantages of polyurethane, as shown above, as a contribution to the

economical solution of design problems.

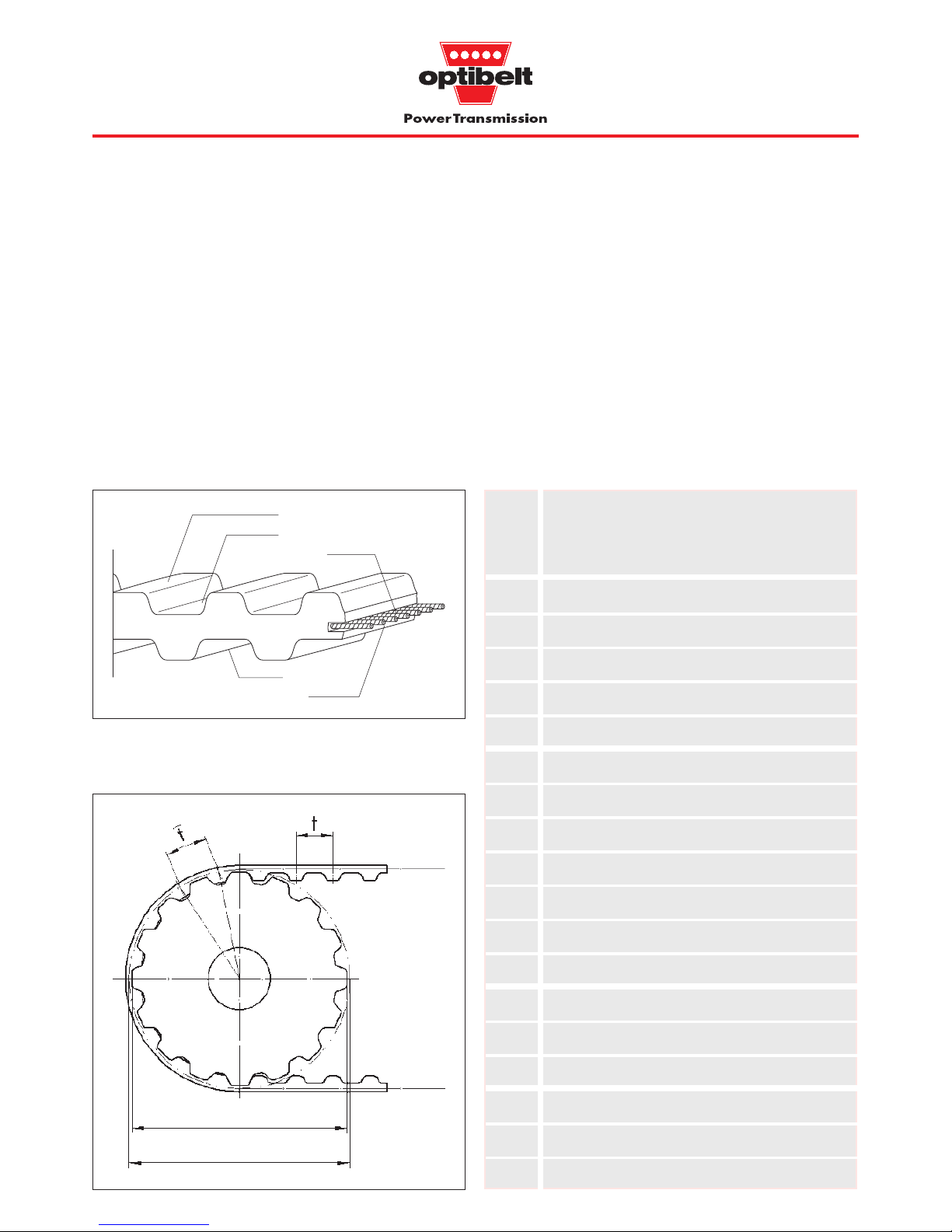

Top surface

Tension cord

Tooth

Base

Construction: Timing belts

Fig.1.1: Timing belts

a) Top surface

The top surface of the belt is polyurethane. Its function is to hold and

support the tension cord. This abrasion-proof, thin and extremely

flexible layer also protects the tension cord against wear and the

effects of ambient conditions.

b) Tension cord

The tension cord of the endless Optibelt ZRM/ZRP timing belt is

spirally wound steel cord. The teeth, base and top surface form a

unit so that the tension cord is enclosed in polyurethane.

The extremely strong, low stretch tension cord has a very small

cross section.

The open-ended Optibelt ZRL-M belting has parallel steel or

Aramid tension cords. This is also the case with the joined endless

Optibelt ZRL-V timing belt.

c) Teeth and base

The polyurethane teeth transfer power between the pulley teeth and

the belt tension cord, whilst the polyurethane base cushions the

tension cord against the abrasion from the top of the pulley teeth

(see Fig. 1.3).

The durable, shear resistant belt teeth are so formed and arranged

as to engage with the matching pulley with minimum friction and

maximum precision. When six teeth on the belt type ZRL-V, and

twelve teeth or more on the ZRM, ZRP and ZRL-M belts are in mesh

with the small pulley at any one time, their shear resistance exceeds

the maximum permitted circumferential force of the timing belt.

5

1 Product Description

1.1 Construction

Fig.1.3: Timing belt / pulley relationship

Fig.1.2: Double section timing belt

Section

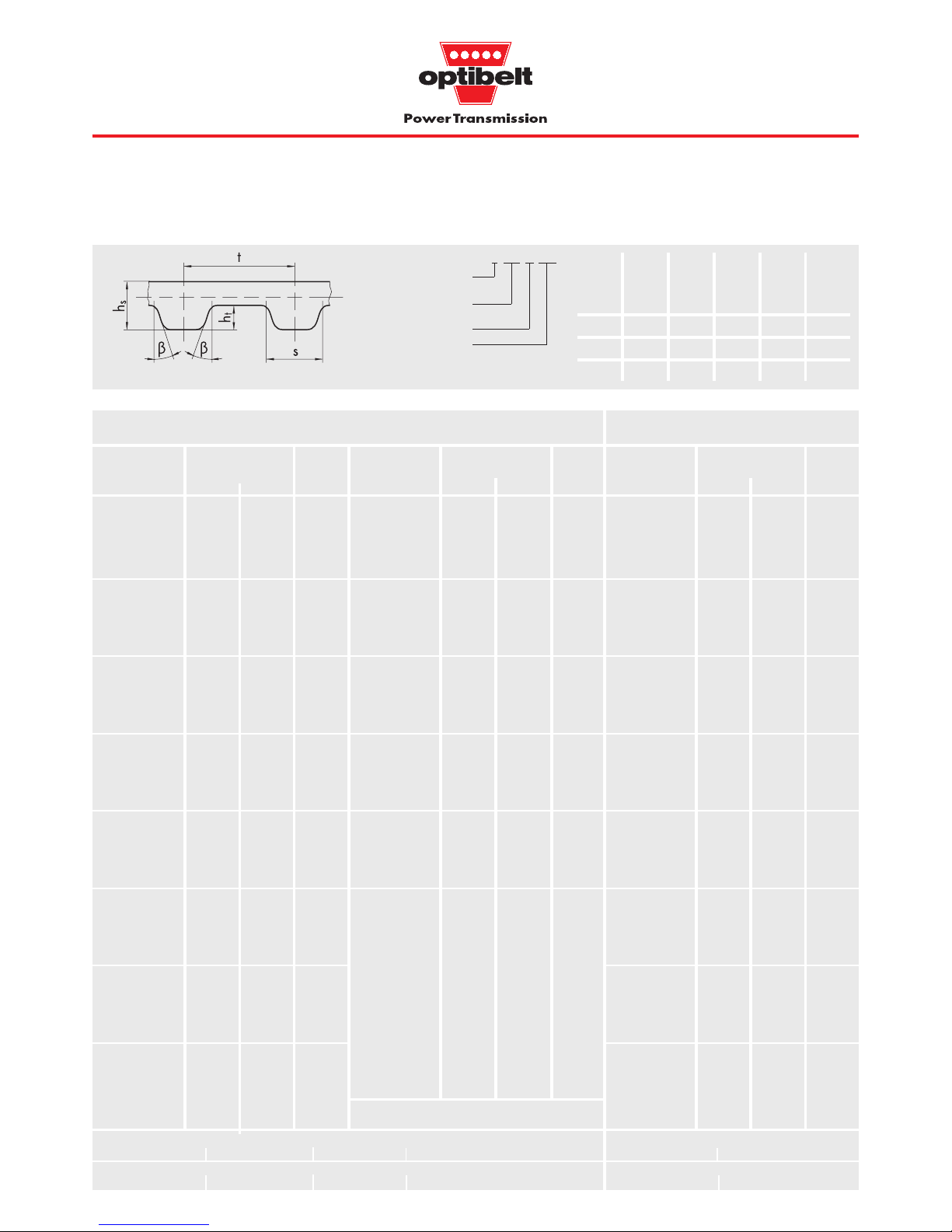

Overall

belt

thickness

h

s1

(mm)

Tooth

angle

2 β

(°)

Tooth

depth

h

t

(mm)

Tooth

width

at top

b

(mm

)

Tooth

pitch

t

(mm)

Overall

belt

thickness

h

s

(mm

)

Tooth

width

at base

s

(mm)

Table 1.1: Section dimensions, sections see Fig. 1.5, page 8,

Standards see Table 5.6, page 48

MXL 2.032 1.14 — 0.51 1.14 — 40

XL 5.080 2.30 — 1.27 2.57 — 50

L 9.525 3.60 — 1.91 4.65 — 40

H 12.700 4.30 — 2.29 6.12 — 40

XH 22.225 11.20 — 6.35 12.57 — 40

T2.5 2.500 1.30 — 0.70 1.50 — 40

T5 5.000 2.20 — 1.20 2.65 — 40

T5D 5.000 — 3.4 1.20 2.65 — 40

T10 10.000 4.50 — 2.50 5.30 — 40

T10D 10.000 — 7.0 2.50 5.30 — 40

T20 20.000 8.00 — 5.00 10.15 — 40

T20D 20.000 — 13.0 5.00 10.15 — 40

AT5 5.000 2.70 — 1.20 — 2.50 50

AT10 10.000 5.00 — 2.50 — 5.00 50

AT20 20.000 9.00 — 5.00 — 10.00 50

5M 5.000 3.60 — 2.10 — — —

8M 8.000 5.60 — 3.38 — — —

14M 14.000 10.00 — 6.10 — — —

The tooth pitch ‘t’ is the distance between two corresponding points

on adjacent teeth on either the belt or the pulley effective diameter.

When the timing belt is laid flat the tooth pitch ‘t’ can be measured

from tooth centre to centre.

When the belt is bent around a pulley the tooth pitch ‘t’ is measured

at the level of the tension cord, also called the effective radius. The

effective diameter ‘d

d

’ thus describes a circle which lies outside the

perimeter of the pulley (d

d

> da).

Construction of the double section timing belt

The construction of the double section timing belt is similar to the

normal timing belt already described. The number and spacing of

the teeth are identical on both sides of the belt, but the two sides

are offset to each other (see Fig. 1.2).

The tension cord and its position relative to the base and teeth are

the same. The maximum permitted power of the double section

timing belt is therefore not doubled but is the same as for the

corresponding normal belt. The power can be transmitted by both

sides of the belt as required.

Base

Tooth

Tooth

Base

Tension cord

d

a

d

w

6

1 Product Description

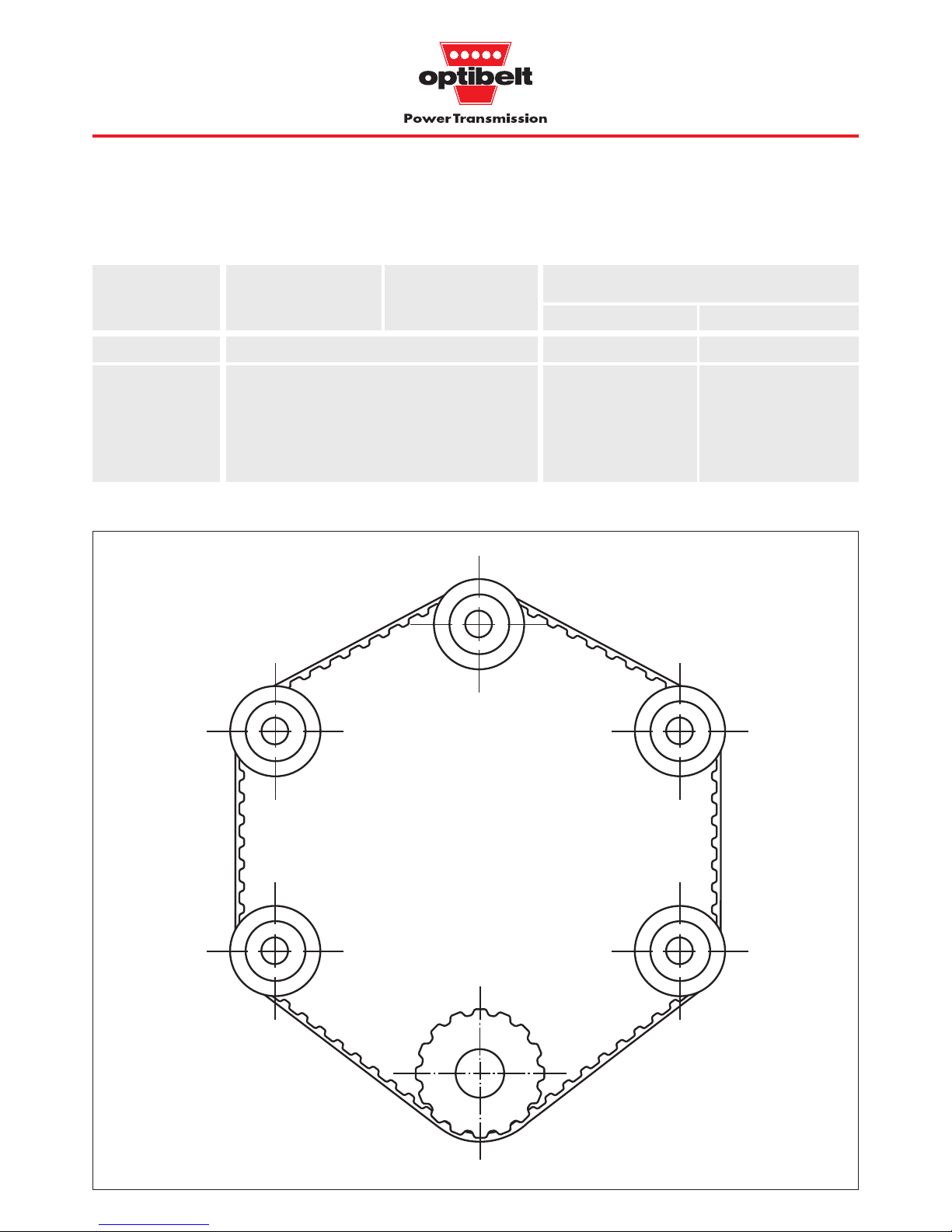

1.2 Applications

Table 1.2: Types and applications

Type ZRM ZRP ZRL

ZRL-M ZRL-V

Applications Synchronous power transmission Linear drives Conveying

Examples: Machine tools Doors and door drives Conveyor systems

Textile machines Washing systems Ram conveyors

Printing presses Reciprocating drives Feeding systems

Packaging machines Mechanical handling Haul-off belts

Domestic appliances equipment Drives with large

Office machines Robots centre distances

Medical equipment Positioning drives

Fig. 1.4.1: Synchronous power transmission

Multi-spindle drives

• •

•

•

• •

•

•

• •

•

•

• •

•

•

• •

•

•

7

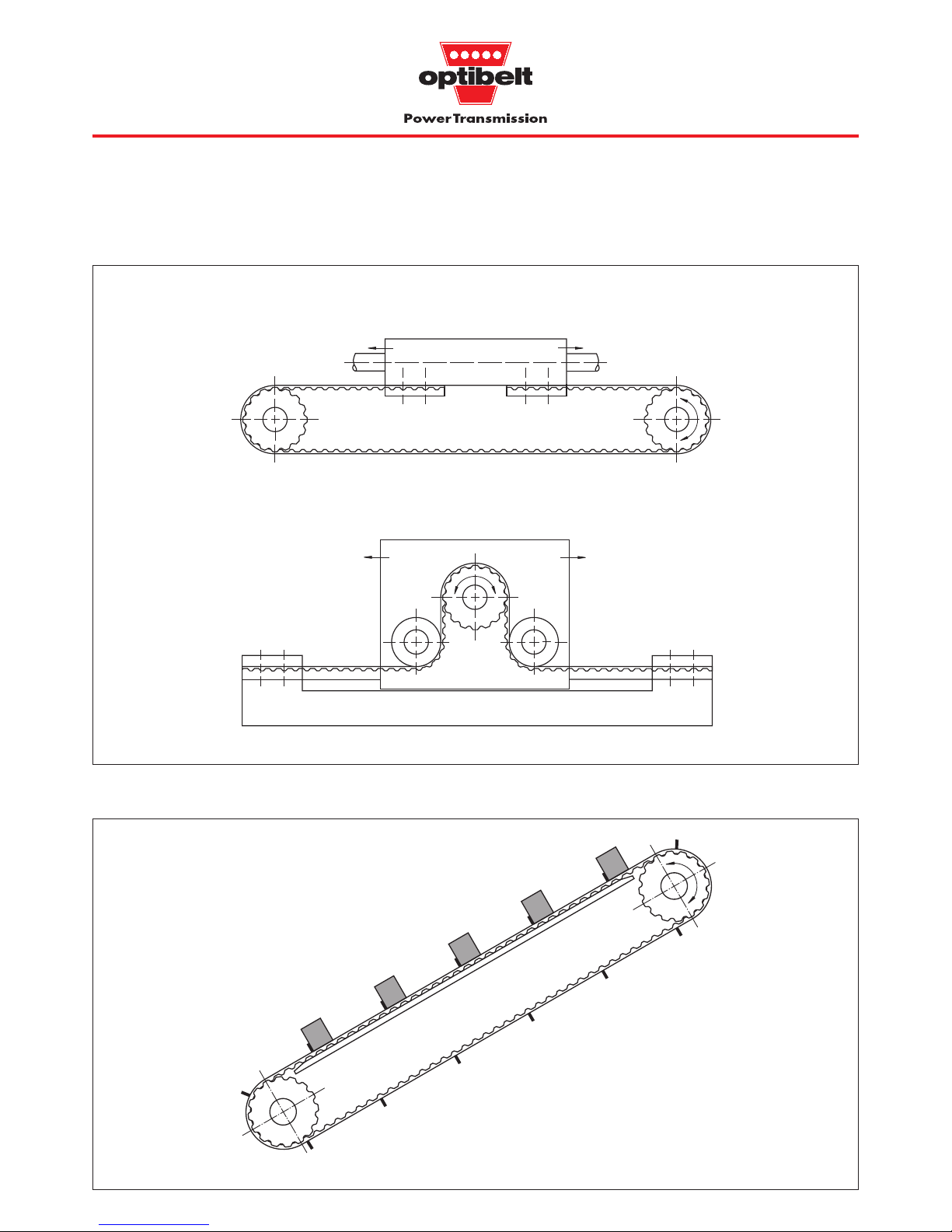

1 Product Description

1.2 Applications

Fig. 1.4.2: Linear drives

Fig. 1.4.3: Conveying

Inclined conveyors with cleats

Trolley drives

Positioning drives

•

•

•

•

•

•

•

•

•

•• •

•

•

•

•

••• •

•

•

•

•

•

•

• • • • • ••

•••

•

•

•

•

•

•

•

•

•••

•

•

•

•••

•

•

•

•

••

••

•

•

•

•

8

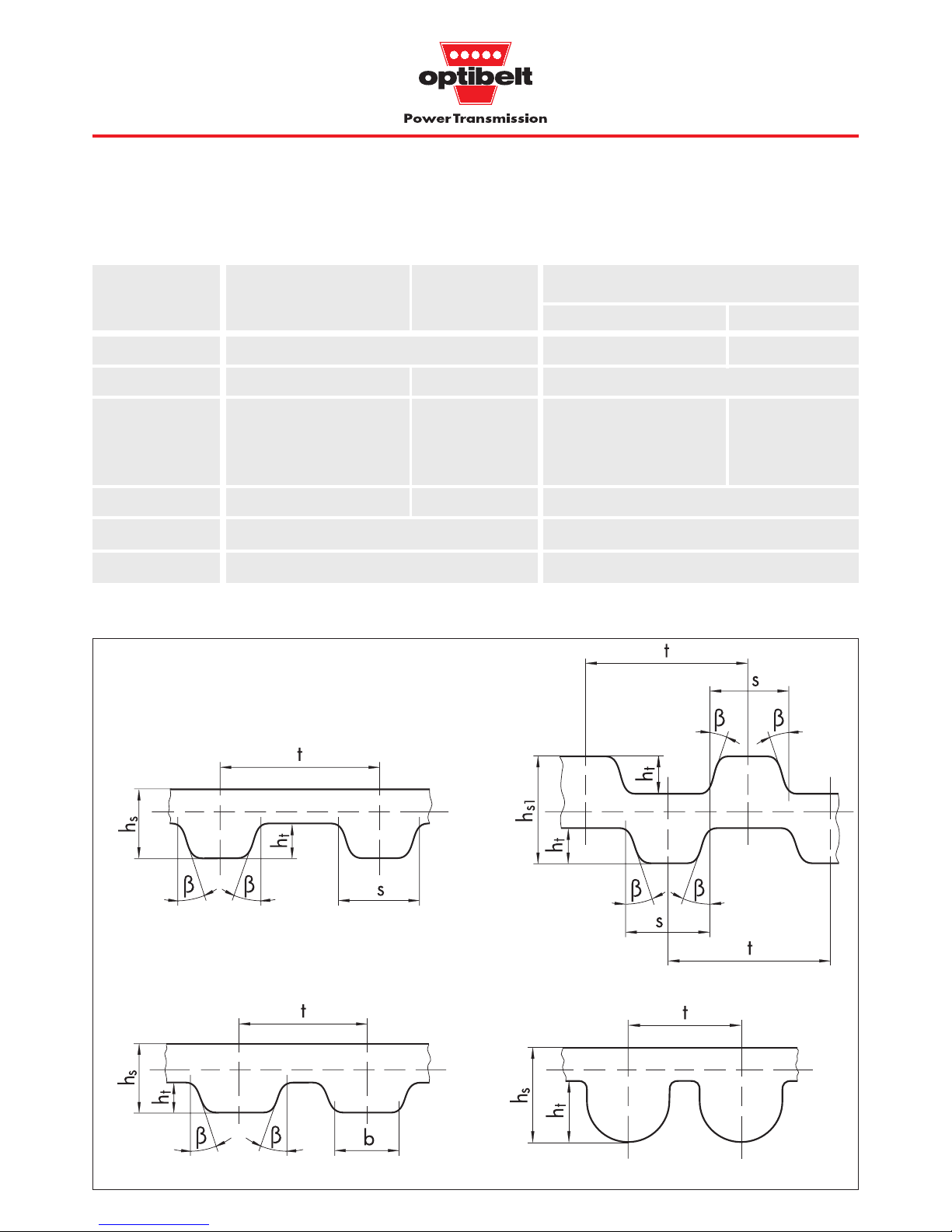

1 Product Description

1.3 Types and sections

Type ZRM ZRP ZRL

ZRL-M ZRL-V

Construction manufactured endless open-ended joined endless

metric inch metric and inch

Section T2.5 MXL* T5 AT5 XL T5 AT5 XL

T5 T5D AT5* XL 5M* L L

T10 T10D AT10* L T10 AT10 8M* H T10 AT10 H

T20* T20D* AT20* T20 AT20* 14M* XH T20 XH

5M 8M 14M

Verzahnung ??? single, double (D) single single

Standard tension cord

steel (St), MXL = Aramid (AR) steel (St), Aramid (AR)

Special tension cord Aramid (AR) —

Table 1.3: Types and sections

∗ Non stock (8M and 14M with steel tension cord can be supplied from stock)

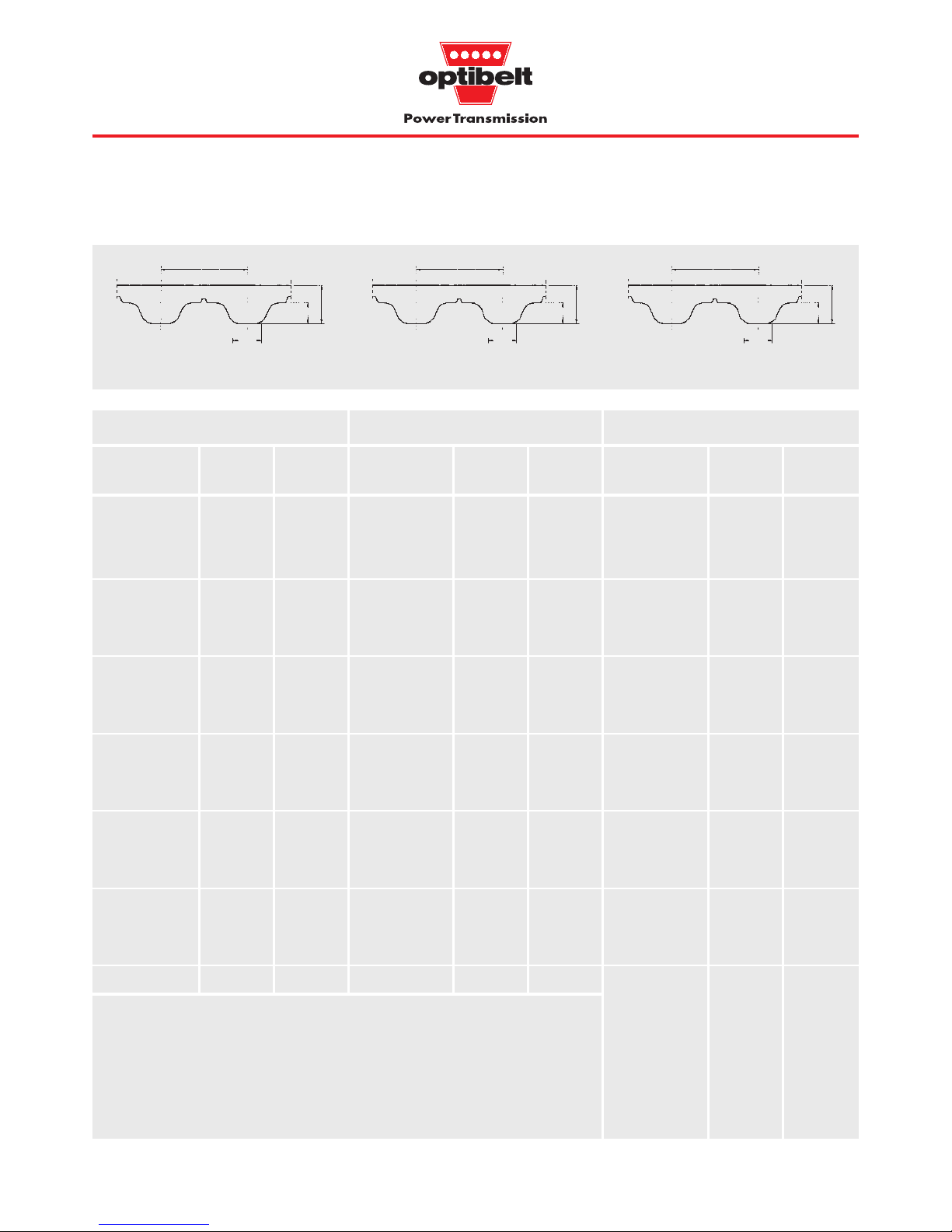

Sections AT5; AT10; AT20 Sections 5M; 8M; 14M

Fig. 1.5: Sections, section dimensions see Table 1.1, page 5

Sections MXL; XL; L; H; XH; T2.5; T5; T10; T20

Sections T5D; T10D; T20D

Measurement/

identification units

•

•

•

•

•••••

•

•

•

•

•

•

••

•• •

•

•

•

•

•

•

•

•

•

•

•••••••

•

•

•

•

•

•

••• •

•

•

•

9

1 Product Description

1.4 Special constructions

Table 1.4: Additional top surfaces

Linatex, Natural 40 – 30 to patterned (to 1.2; 1.6; no furniture industry,

red rubber + 60 1.6 mm thick), 2.4; 3.2; haul-off and

smooth (from 4.8; 6.4; conveying systems

2.4 mm thick), 8.0;

very good coef- 10.0;

ficient of friction, 12.7

abrasion resistant

Supergrip, PVC 40 – 30 to coarse structure, 4.5 conditionally woodworking

blue-green + 80 good coefficient industry,

of friction, inclined transport

abrasion resistant

under certain

conditions

HV 1-film, Poly- 85 – 30 to smooth, 1.0; yes food industry,

HV 2-film, urethane + 80 very good 2.0 glass transport

transparent abrasion

resistance,

superior wear

resistance

Foam PUR 40 – 30 to fine grain, 1.0; 2.0; yes packaging industry

Vulkolan, foam + 80 good coefficient 3.0; 4.0; (lightweight goods),

beige of friction, 5.0; 6.0 transport of

good abrasion sharp-edged objects

resistance,

cut resistant

Solid Poly- 70 – 30 to fine grain, 2.0; 3.0; yes packaging industry

Vulkolan, urethane + 80 good coefficient 5.0; 6.0 (heavy goods),

beige of friction, transport of

good abrasion sharp-edged objects

resistance,

superior wear

resistance

Porol, Cellular 25 – 30 to fine grain, 2.0; 3.0; yes transport of

black rubber + 90 very good coef- 5.0; 8.0; impact-sensitive

ficient of friction, 10,0 goods,

abrasion resistant suction systems

under certain (lightweight materials)

conditions,

cut resistant

PU 06, Poly- 50 – 30 to very fine grain, 2.0; 3.0; yes glass industry,

yellow or grey urethane + 80 high density, 4.0; 5.0; packaging industry,

good coefficient 8.0 transport of

of friction, sharp-edged objects

good abrasion

resistance,

cut resistant

Studs, PVC 65 – 30 to coarse structure, 1.5 yes food industry,

white + 80 good coefficient woodworking industry

of friction,

abrasion resistant

under certain

conditions

Intermediate thicknesses can be made by doubling or grinding the top surface cover.

Top surfaces other than the examples given in Table 1.4 are also available.

noitangiseD

ruolocdnaruolocdna

ruolocdna

ruolocdnaruolocdna

lairetaM

ssendraH

.xorppa.xorppa

.xorppa

.xorppa.xorppa

)AerohS()AerohS(

)AerohS(

)AerohS()AerohS(

erutarepmeT

ecnatsiserecnatsiser

ecnatsiser

ecnatsiserecnatsiser

)C°(.ac)C°(.ac

)C°(.ac

)C°(.ac)C°(.ac

seitreporP

dradnatS

sessenkcihtsessenkciht

sessenkciht

sessenkcihtsessenkciht

)mm()mm(

)mm(

)mm()mm(

dnaliO

foorp-esaergfoorp-esaerg

foorp-esaerg

foorp-esaergfoorp-esaerg

noitacilppalacipyT

10

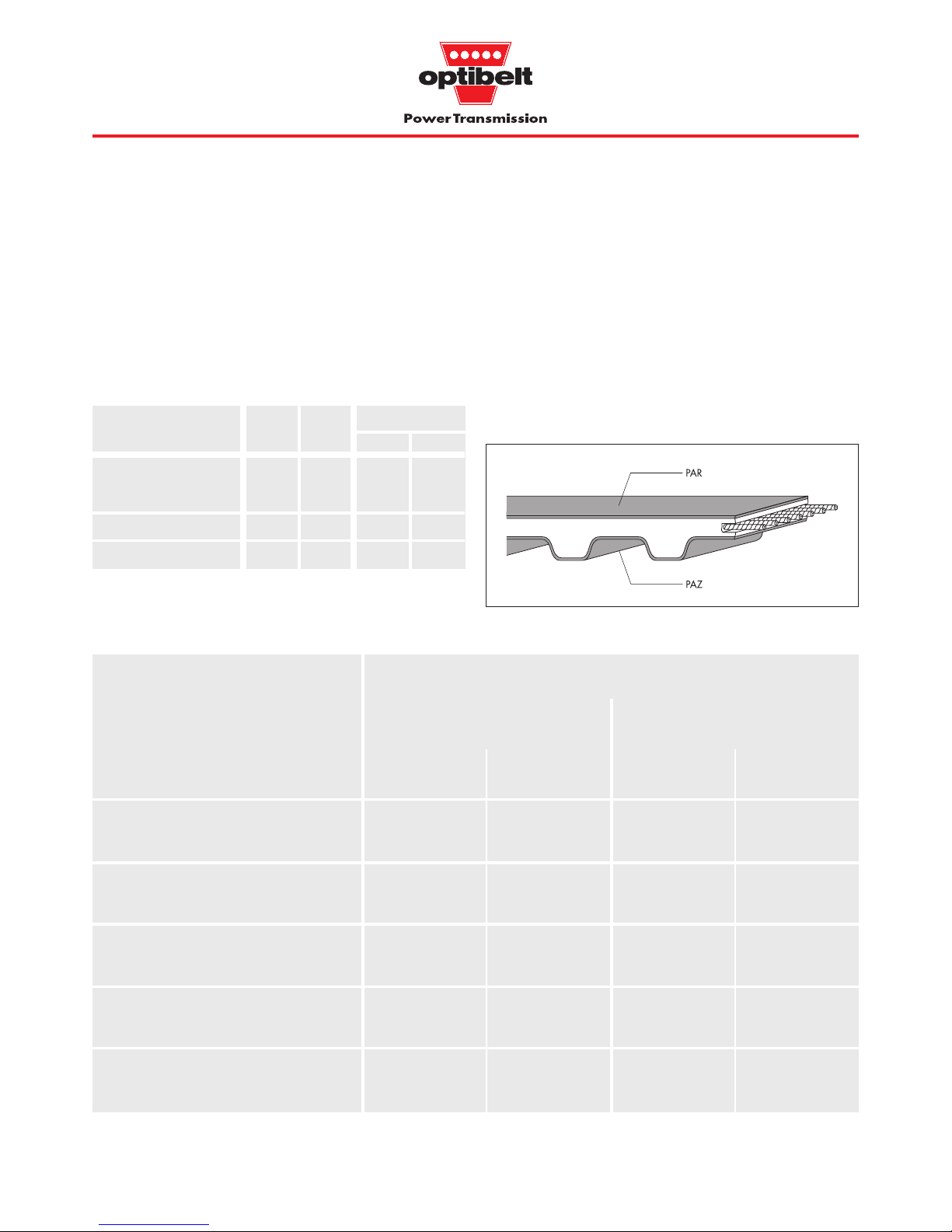

Fabric facing

Optibelt timing belts can be supplied with polyamide fabric on

either the top face or the toothed face of the belt. This fabric offers

less friction resistance than polyurethane and is ideally suited for

facing on belts (PAR) used on ram conveyor applications. Fabric

covering on the toothed face (PAZ) is used to reduce static and

sliding friction on belts which need to be supported on this face by

plastic or metal rails. Support rails are used primarily on belt hauloff and feeder sections where support idlers are widely spaced.

Fig. 1.6: Timing belt with fabric facing on both sides

1 Product Description

1.4 Special constructions

Optibelt timing belts can be adapted to the most varied of

applications in the conveying, control and handling fields, by the

appropriate choice of top surfaces, fabric facings and cleats.

The Optibelt ZRM/ZRP timing belts, intended for use for power

transmission can also be provided with an additional top surface.

Table 1.5: Special constructions

The special constructions shown in Table 1.5 can be combined with

one another.

Special ZRM ZRP ZRL

construction ZRL-M ZRL-V

Fabric facings

– top face (PAR) ●●

– toothed face (PAZ) ●●

Additional top surfaces ●●●●

Conveyor cleats ●●

* polyamide fabric is required where sliding friction is important

Which of the coefficients of friction is used depends upon whether

the conveyed components are static or sliding on the belt. The

coefficients of friction apply for dry conditions and can vary with

belt speed, heat dissipation rate and texture of the surface of the

materials in contact. The upper and lower limits of the coefficients

of sliding friction are based on a belt speed of 0.1 to 1.0 m/sec.

≥ 0.40 ≥ 0.25

≤ 0.70 ≤ 0.45

≥ 0.50 ≥ 0.20

≤ 0.90 ≤ 0.30

≥ 0.30 ≥ 0.20

≤ 0.50 ≤ 0.35

≥ 0.85* ≥ 0.30

≤ 1.00* ≤ 0.50

≥ 0.50 ≥ 0.20

≤ 0.85 ≤ 0.35

µ

0

µµ

0

µ

R

z

= 16 µm

R

z

= 6,3 µm

Table 1.6: Coefficients of friction

slairetamtcatnoC noitcirffostneiciffeoC

enahteruyloP

gnicafcirbafRAP/ZAPtuohtiw

enahteruyloP

gnicafcirbafRAP/ZAPhtiw

noitcirfcitatsnoitcirfgnidilsnoitcirfcitatsnoitcirfgnidils

,leetS

5554

,muinimulA

0553

enelyhteyloP

5252

,ssalG

htooms

0503

,dooW

niargehthtiw

5353.0

11

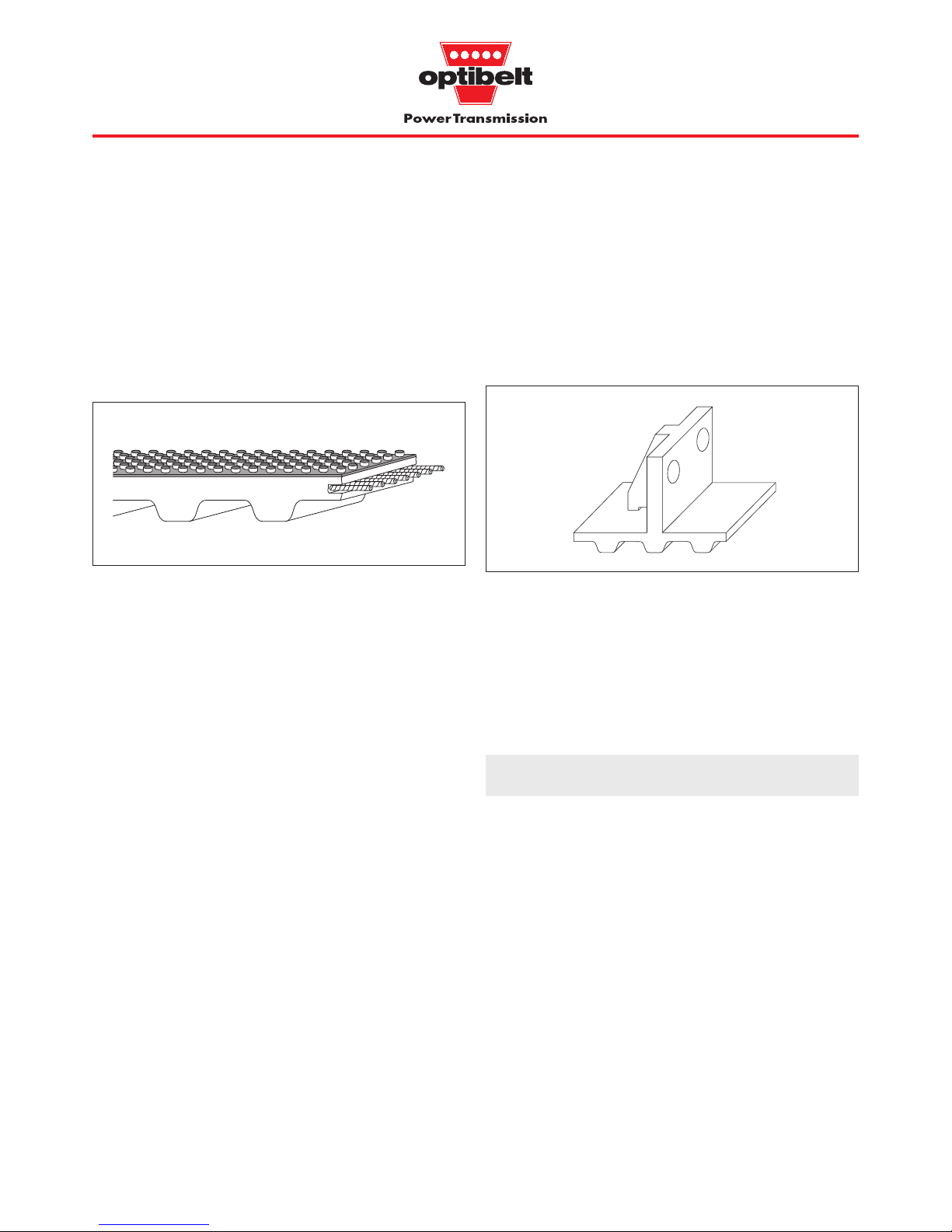

Additional top surfaces

The top surface materials listed in Table 1.4 on page 9 improve

conveying rates by increasing the coefficient of friction. They also

protect the top surface of the belt. They allow the belt to be used

on a small incline or on a haul-off arrangement in which the belt is

used to overcome level differences. Where stringent demands are

made on the uniformity of the surface or thickness, the top surface

can also be ground.

Fig.1.7: Additional top surfaces e.g. studs, white

Conveyor cleats

The belts in the Optibelt programme can be fitted with conveyor

cleats. Like the timing belt, they are made of polyurethane and are

welded to the back of the belt.

By making positive contact with the transported goods, the conveyor cleats extend the range of applications for ZRL timing belting

as follows:

● uniform feed e.g. for production and assembly lines

● conveying of bulky items using belts running in

parallel

● inclined and vertical conveying to bridge differences

in levels

● positioning and switching in handling and control

systems

1 Product Description

1.4 Special constructions

The shapes and sizes of the cleats are adapted to the function they

are required to carry out. They can, for example, be provided with

holes if fixtures are to be attached e.g. for vertical conveying.

Cleats with V-shaped grooves on their upper faces are suitable for

conveying in longitudinal and transverse directions.

Fig.1.8: Cleats with unwelded back supports for large loads and

with holes for fixtures

Cleats should be narrow in the area of the weld and are usually

arranged opposite a belt tooth. The original flexibility of the timing

belt is thus retained. In order to achieve this, the required cleat

spacing a

m

must coincide with the tooth pitch t, and the belt length

L

w

must be matched to the number nm of cleats required for the

length of the conveyor in question. With particularly long timing

belts, the length tolerance of the belt must be taken into consideration (see Table 5.2, page 43).

Lw = am · n

m

am = t · x x total number of teeth

12

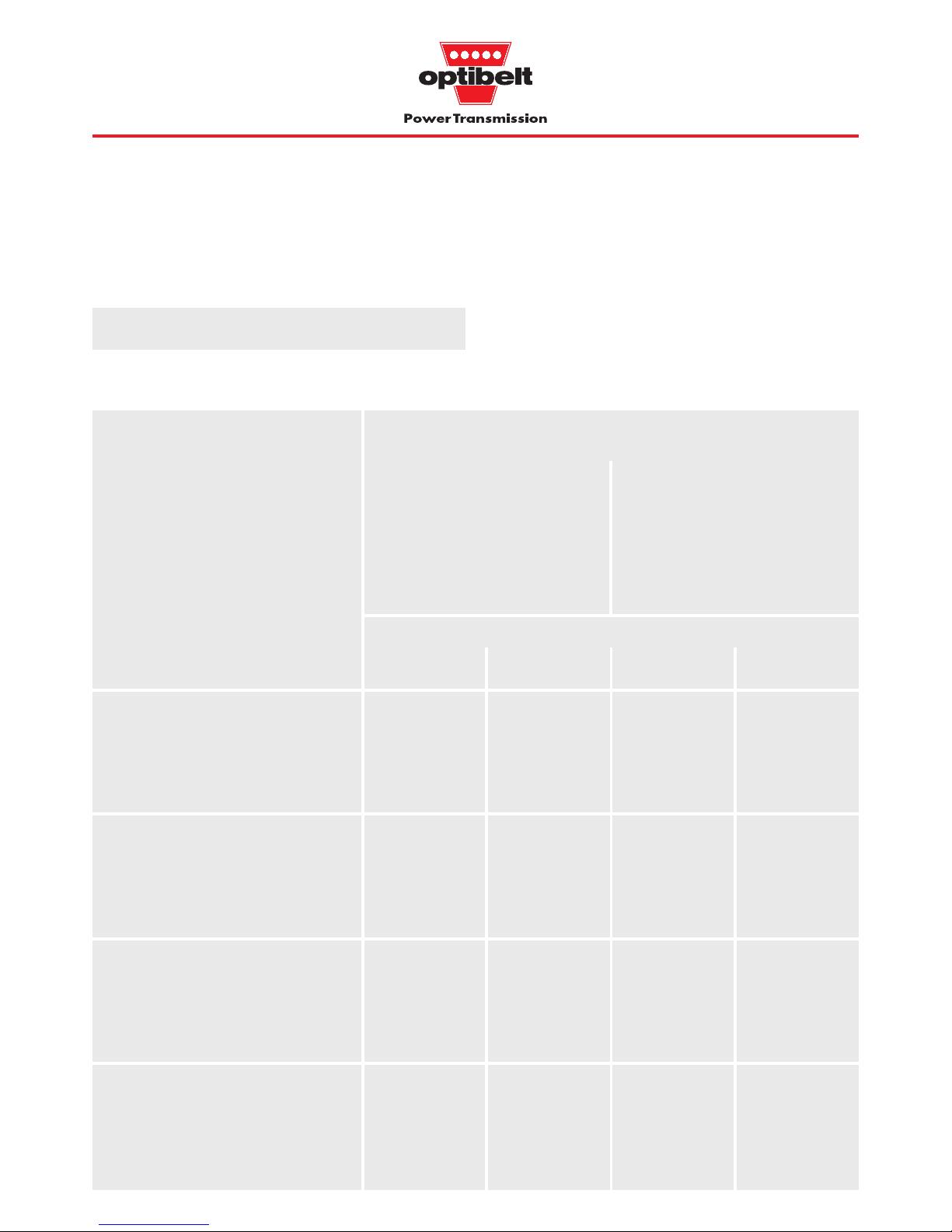

dnasnoitidnocecivreS

srevomemirpfoselpmaxesrevomemirpfoselpmaxe

srevomemirpfoselpmaxe

srevomemirpfoselpmaxesrevomemirpfoselpmaxe

h61otpuh61revoh61otpuh61revo

3.14.14.15.1

6.17.18.19.1

8.19.10.21.2

0.21.22.23.2

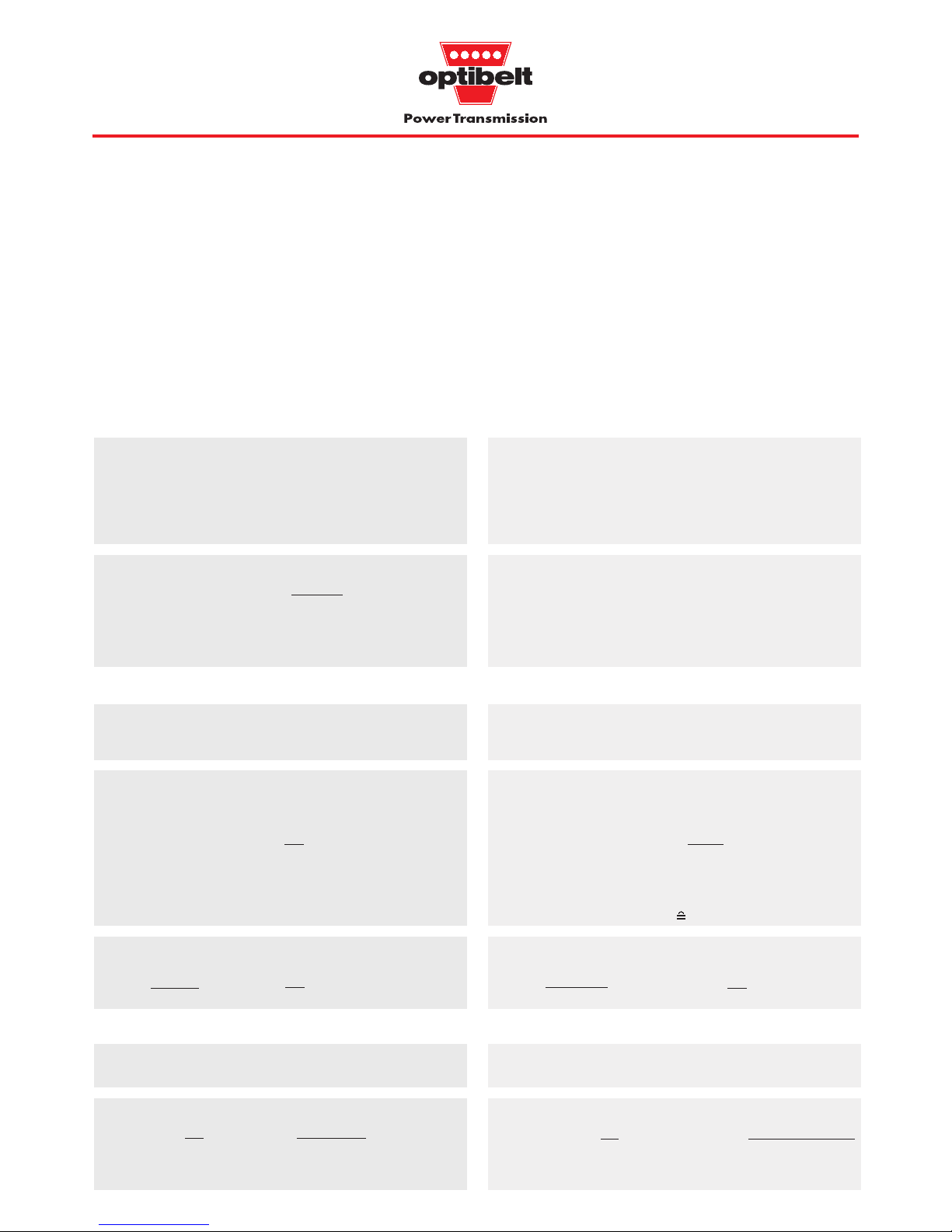

Total service factor c

2

The total service factor comprises the basic service factor c0 and

two further correction factors c

6

and c8.

Basic service factor c

0

The basic service factor c0 takes into account the daily duration of

operation, the type of prime mover and the type of driven machine.

As it is virtually impossible to cover every combination of prime

mover/machine/operating condition in a single standardised

summary, the basic service factors must be taken as guides only.

The final drive will depend upon the loads involved in each case.

Table 2.1: Basic service factor c

0

Type of service and examples of

machine applications

Service factor c

0

at number of operating hours per day

Very heavy duty drives, continuous

operation with high shock loading

Grinding mills

Calenders

Extruders

Piston pumps and compressors

Lifting gear

Heavy duty drives, intermittent

operation with medium to high

shock loading

Machine tools

Woodworking machines

Eccentric drives

Belt conveyor systems (heavy goods)

Medium drives, intermittent operation

with low to medium shock loading

Mixing machines

Kitchen machines

Printing machines

Textile machines

Packaging machines

Belt conveyor systems (heavy goods)

Lightweight drives, shock-free and

steady running

Measuring equipment

Film cameras

Office machinery

Belt conveyor systems (lightweight goods)

2 Basics of Drive Design

2.1 Service factors, additional factors and formulae

c

0

Intermittent operation

Hydraulic motors

Low-speed turbines

Piston engines with small

number of cylinders

Steady operation

Electric motors

High-speed turbines

Piston engines with large

number of cylinders

c2 = c0 + c6 + c

8

13

Correction factors c6 and c

8

Like the basic service factor c0, the factors to be added for pulleys

and idlers c

6

and for start/stop frequency under load c8 are to be

taken as approximations only. These factors are allowances to

be made for unusual operating conditions and are added where

applicable to the basic service factor c

0

.

Table 2.2: Correction factors c6 and c8 for special operating

conditions

Type of operating Designation and Remarks

conditions value of

correction factor

Use of c

6

= 0.2 0.2 per idler

tensioning and to a maximum of

guide idlers 1.0

Start/stop c

8

= 0.1 ... 0.3 depending upon

and/or frequency, up to

reversing approx. 1.5 times

under load nominal torque

with low start-up

torque (e.g. star/

delta connection)

c8 = 0.3 ... 0.5 depending upon

frequency, above

approx. 1.5 times

nominal torque

with high start-up

torque

The correction factor c

6

applies when more than two pulleys are

used. Such use of additional pulleys must be separately checked at

the design stage.

Large drive torque of inertia should be classified as external loads.

2 Basics of Drive Design

2.1 Service factors, additional factors and formulae

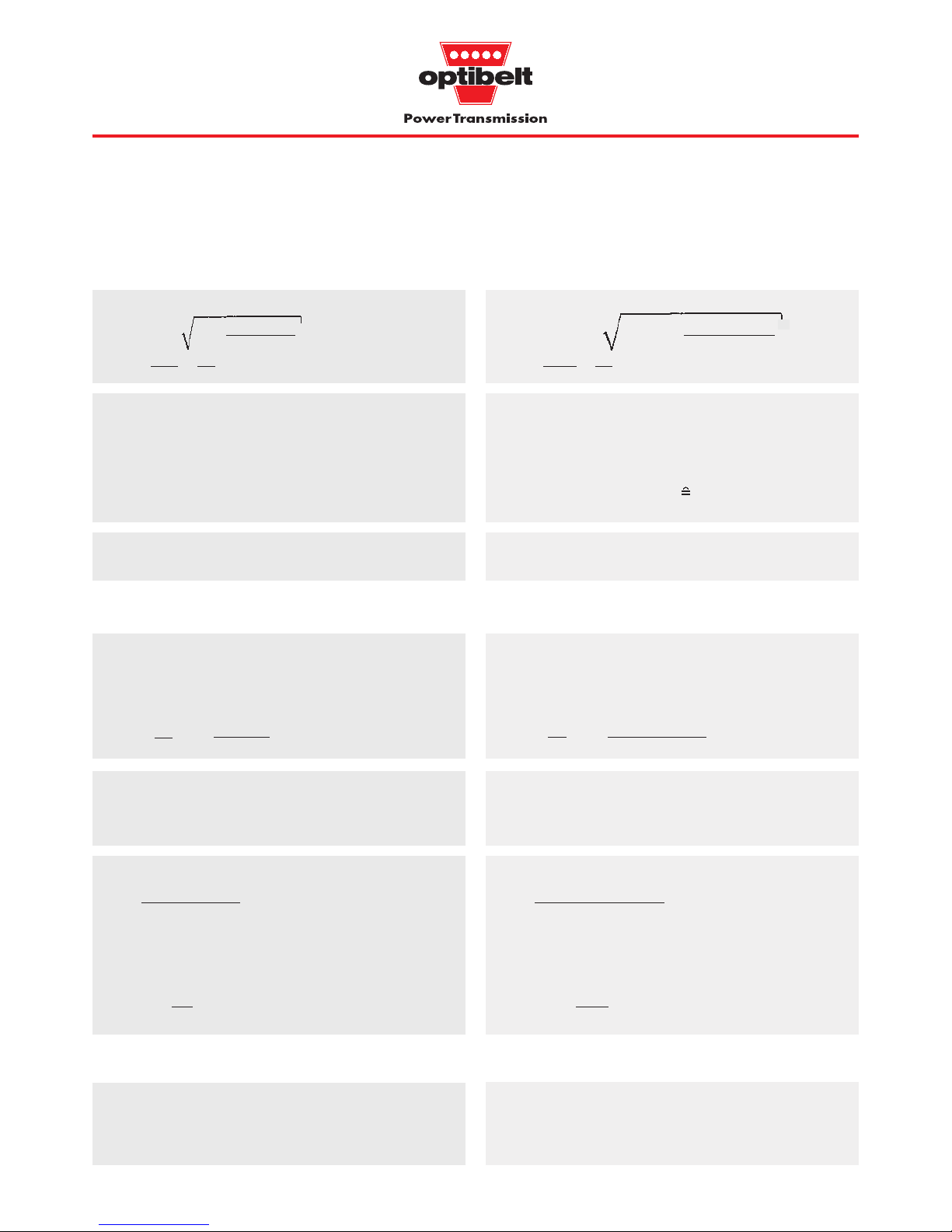

Length factor c3 for ZRM/ZRP belts

The approximate values for the length factor c3 are given in

Table 2.3 and apply only to rotating highly loaded drives fitted

with ZRM/ZRP timing belts.

The length factor c

3

takes into account the increase or decrease of

belt flexing when using a short or long belt.

Note the units used for the individual parts of the formulae. The formulae for the driven torque and driven power also apply for the driver

side using the formula symbols M

An

, PAn, dw1 and n1 in place of MAb, PAb, dw2 and n

2eff

.

General

For i = 1 or z = z

1

= z

2

Formulae for explanation of symbols see page 14

v

eff

==

i

eff

=== i =

d

w1

=d

w2

= (mm)

M

Ab

= (Nm) PAb = (kW)

M

Ab

= (Nm) PAb = (kW)

M

Ab

= (Nm) PAb = (kW)

MAb · n

2eff

9550

Sn3 · dw2 · n

2eff

19100 · 1000

Sn3 · v

eff

1000

Generaldriven torque and driven power

dw2 · S

n3

2000

9550 · P

Ab

n

2eff

dw2 · P

Ab

2 · v

eff

dw1 · n

1

19100

z1 · t

π

dw2 · n

2eff

19100

z2 · t

π

Drive calculation ZRM/ZRP see page 26

Drive calculation ZRL-M see page 34

Drive calculation ZRL-V see page 37

m

s

( )

Lw = 2 · a

nom

+ z · t (mm) a

nom

= t (mm) zR=

zR – z

2

L

w

t

z

2

z

1

d

w2

d

w1

n

1

n

2eff

n

1

n

2

Table 2.3: Length factor c3 for ZRM/ZRP belts

Section Pitch length L

w

Length factor

(mm) c

3

MXL; T2.5 ≤ 190 0.8

> 190 ≤ 260 0.9

> 260 ≤ 400 1.0

> 400 1.1

XL; T5 (D); AT5 ≤ 440 0.8

> 440 ≤ 555 0.9

> 555 ≤ 800 1.0

> 800 1.1

L; T10 (D); AT10 ≤ 600 0.8

> 600 ≤ 920 0.9

> 920 ≤ 1500 1.0

> 1500 1.1

T20 (D); AT20 ≤ 1260 0.8

> 1260 ≤ 1880 0.9

> 1880 ≤ 3000 1.0

> 3000 1.1

14

2 Basics of Drive Design

2.2 Symbols used in formulae

Table 2.4 defines the essential parameters and relevant units used

in the formulae listed on page 13, and the drive design process.

Table 2.4: Symbols

Symbol Description Unit

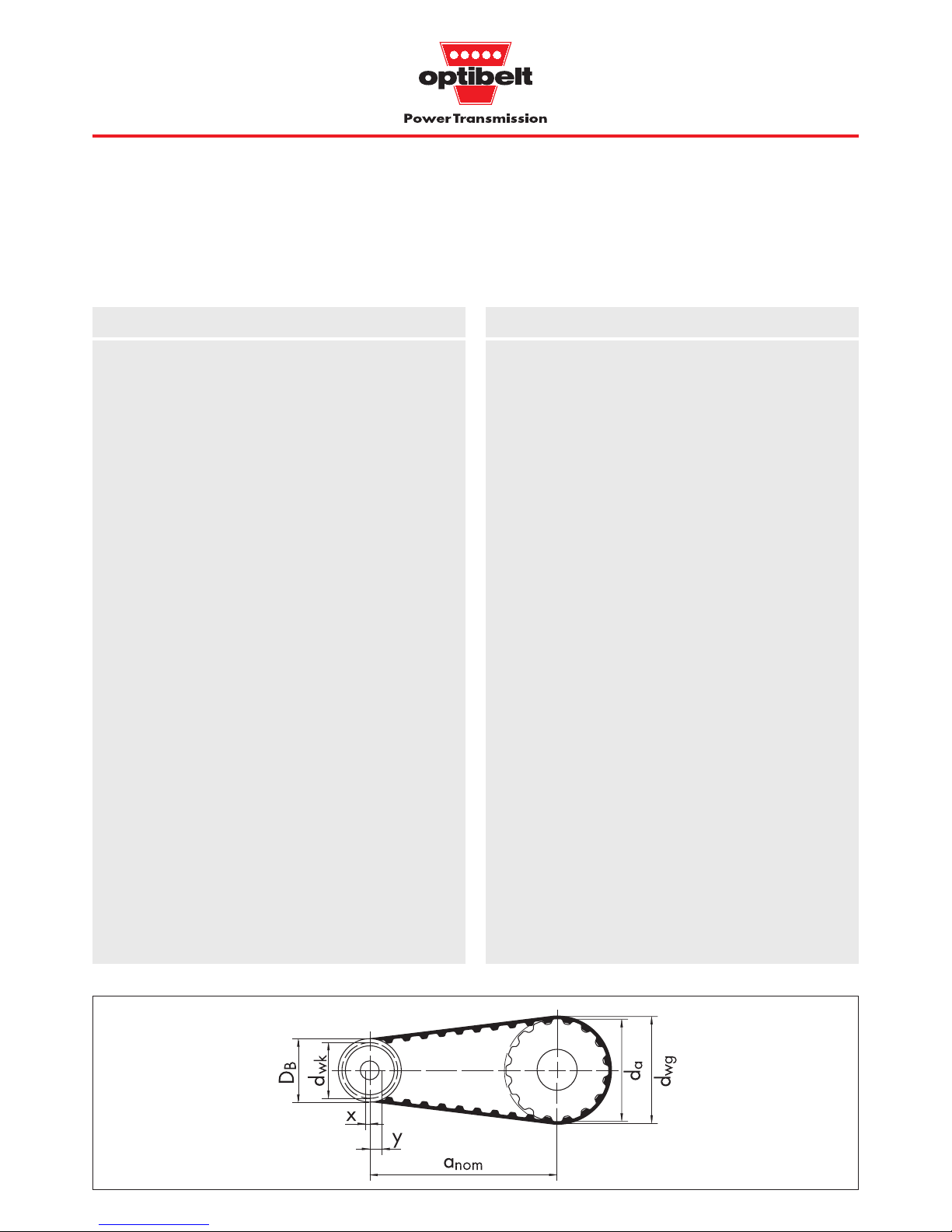

a Required drive centre distance (mm)

a

nom

Drive centre distance with standard belt length (mm)

b

St

Standard belt width (mm)

b

th

Theoretical belt width (mm)

cvTension factor

c

0

Basic service factor

c

2

Total service factor

c

2vorh

Actual service factor

c

3

Length factor

c

6

Pulley and idler correction factor

c8Correction factor for start/stop and

reversing under load

daOutside diameter of pulley (mm)

D

B

Outside diameter of pulley over flanges (mm)

d

wg

Pitch diameter of the large pulley (mm)

dwkPitch diameter of the small pulley (mm)

d

w1

Pitch diameter of the driver pulley (mm)

d

w1th

Theoretical pitch diameter of the driver pulley (mm)

d

w2

Pitch diameter of the driven pulley (mm)

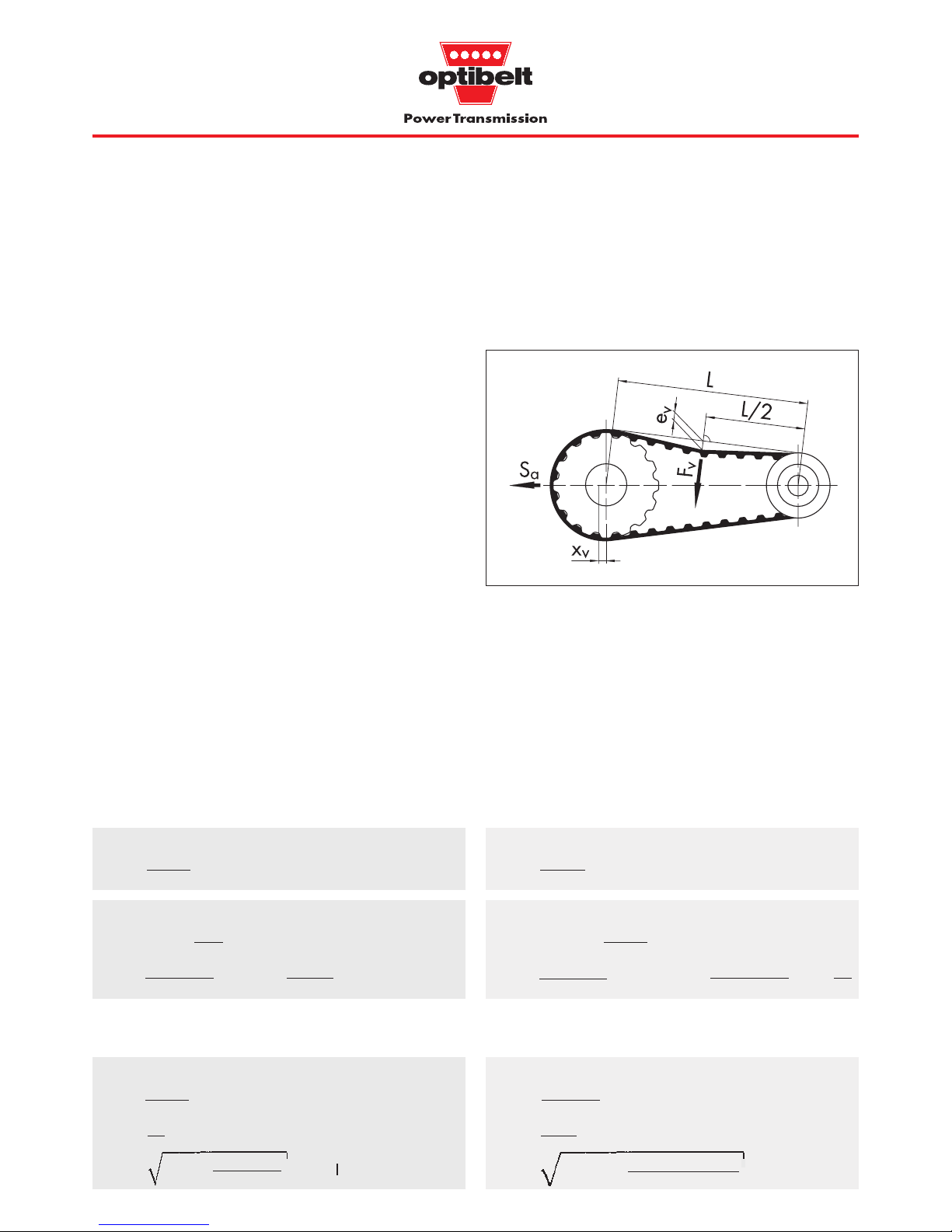

e

v

Belt deflection for checking belt tension (mm)

FvLoad used to set belt tension (N)

i Ratio required

i

eff

Ratio calculated from the number of pulley teeth

L Span length (mm)

L

wnom

Pitch length of joined endless/open ended (mm)

timing belts (ZRL-V/ZRL-M)

L

wSt

Standard pitch length of endless (mm)

timing belts (ZRM/ZRP)

L

wth

Theoretical pitch length of timing belts (mm)

M

Ab

Torque (Nm)

M

Abth

Theoretical torque (Nm)

M

An

Driver torque (Nm)

M

B

Design torque including service factor (Nm)

M

Bth

Theoretical design torque (Nm)

M

spez

Transferrable torque per engaged tooth (Nm/cm)

and 10 mm belt width

n

k

Speed of small pulley (min-1)

n

1

Speed of driver pulley (min-1)

n

2

Required speed of driven pulley (min-1)

n

2eff

Speed of driven pulley calculated from (min-1)

the number of teeth

P

An

Driver power (kW)

P

Ab

Driven power (kW)

P

B

Design power including total service factor (kW)

P

spez

Power per engaged tooth, 10 mm belt width (W/cm)

and 1 tooth of the small pulley

S

a

Static shaft loading at correct tension (N)

S

Bn3

Design circumferential force including (N)

total service factor

S

n3

Circumferential force (N)

S

spez

Transferrable circumferential force per (N)

engaged tooth and 10 mm belt width

S

zul

Transferrable circumferential force at (N)

maximum standard width

t Tooth spacing (mm)

v Required belt speed (m/s)

v

eff

Actual speed (m/s)

x Allowance for centre distance adjustment (mm)

a

nom

for belt tensioning

x

v

Deflection at correct tension (ZRL-M/ZRL-V) (mm)

y

1/2/3

Allowance for centre distance adjustment (mm)

a

nom

for belt installation, determined from

pulley arrangement

z

e

Number of teeth in mesh with the small pulley –

for power transmission calculation

z

emax

Maximum number of teeth in mesh with the small

pulley – for power transmission calculation

z

enom

Number of teeth in mesh with the small pulley – actual

z

k

Number of teeth on the small pulley

z

R

Number of teeth on the timing belt

z

1

Number of teeth on the driver pulley

z2Number of teeth on the driven pulley

Symbol Description Unit

Fig.2.1: Drive arrangement

•

•

•

•

•

••

•

•

•

•

•

•

•

•

••

•

•

•

•

•

•

•

•

•

•

•

15

The data given on the chemical resistance of the Optibelt ZRM/ZRP

timing belts refers to the material polyurethane and is based on

laboratory figures arrived at under ideal conditions.

Classification of chemical resistance

1. No impairment of physical properties and working life

2. Minor impairment of physical properties and working life

3. Clearly visible swelling/disintegration, reduced physical

properties and shortened working life

4. Rapid disintegration

Copper sulphate, aqueous solution 20 1

Methanol 20 4

Methanol/petrol mixture 15 : 85 20 4

Methylene chloride 20 3

Methylethylketone 20 4

Mineral oil 80 3

n-Heptane 20 1

n-Hexane 50 1

Naphtha 20 2

Sodium carbonate,

saturated aqueous solution 20 2

Sodium chloride,

saturated aqueous solution 20 2

Sodium hydroxide, 1-N aqueous solution 20 2

Sodium phosphate, aqueous solution 20 1

Sodium soap, 20% aqueous solution 80 4

Sodium soap fat 20 3

Oleic acid 20 1

Palmitic acid 20 1

Phosphoric acid,

20-70% aqueous solution 20 1

Phosphoric acid, 85% aqueous solution 20 3

Mercury 20 1

SAE-10 oil 70 1

Nitric acid, 20% aqueous solution 20 4

Hydrochloric acid, 20% aqueous solution 20 2

Hydrochloric acid, 37% aqueous solution 20 4

Grease 20 2

Sulphuric acid, 20% aqueous solution 20 4

Sulphuric acid, 5% aqueous solution 20 2

Sulphurous acid 20 4

Seawater 20 2

Soap solution, aqueous 20 1

Soya oil 20 1

Stearic acid 20 1

Tannic acid, 10% aqueous solution 20 1

Turpentine 20 4

Carbon tetrachloride 20 4

Tetrahydrofuran 20 4

Toluol 20 4

Trichlorethane 20 4

Tricresyl phosphate 20 2

Water 100 4

Water 90 3

Water 20 1

Hydrogen 20 1

Plasticising oils 20 2

Xylol 20 4

3.1 ZRM/ZRP resistance to chemicals

Resistance of endless

optibelt

ZRM/ZRP timing belts

Table 3.1: ZRM/ZRP chemical resistance

Aluminium chloride,

5% aqueous solution 20 2

Formic acid 20 4

Ammonia 10% aqueous solution 20 2

Aniline 20 4

ASTM oil No. 1 80 3

ASTM oil No. 2 80 3

ASTM oil No. 3 80 3

Acetone 20 4

Petrol, “normal” 20 3

Petrol, “super” 20 3

Benzol 20 4

Borax solution 20 1

Boric acid, aqueous solution 20 1

Butane 20 1

Butanol 20 2

Butyl acetate 20 4

Calcium chlorate (I),

5% aqueous solution 20 4

Calcium chloride, aqueous solution 20 1

Calcium hydrogen sulphide,

aqueous solution 20 1

Chlorine, gaseous 20 4

Chromic acid

10 : 50% aqueous solution 20 4

Cyclohexane 20 2

Cyclohexanol 20 1

Diesel fuel 20 2

Dimethyl formamide 20 4

Ferric (III) chloride, 5% aqueous solution 40 3

Acetic acid, 20% aqueous solution 20 3

Ethanol 20 3

Ethyl acetate 20 4

Ethyl ether 20 3

Formaldehyde, 37% aqueous solution 20 3

Freon-11 20 2

Freon-113 20 1

Freon-12 54 1

Freon-22 20 3

Glycerine 20 1

Hydraulic fluid 20 2

Iso-octane 70 1

Iso-propanol 20 3

Potassium hydroxide,

1-N aqueous solution 20 3

Kerosene 20 2

Carbon dioxide 20 1

Copper chloride, aqueous solution 20 1

Medium

Temperatur

(°C)

Beständig-

keit

Medium

Temperatur

(°C)

Beständig-

keit

16

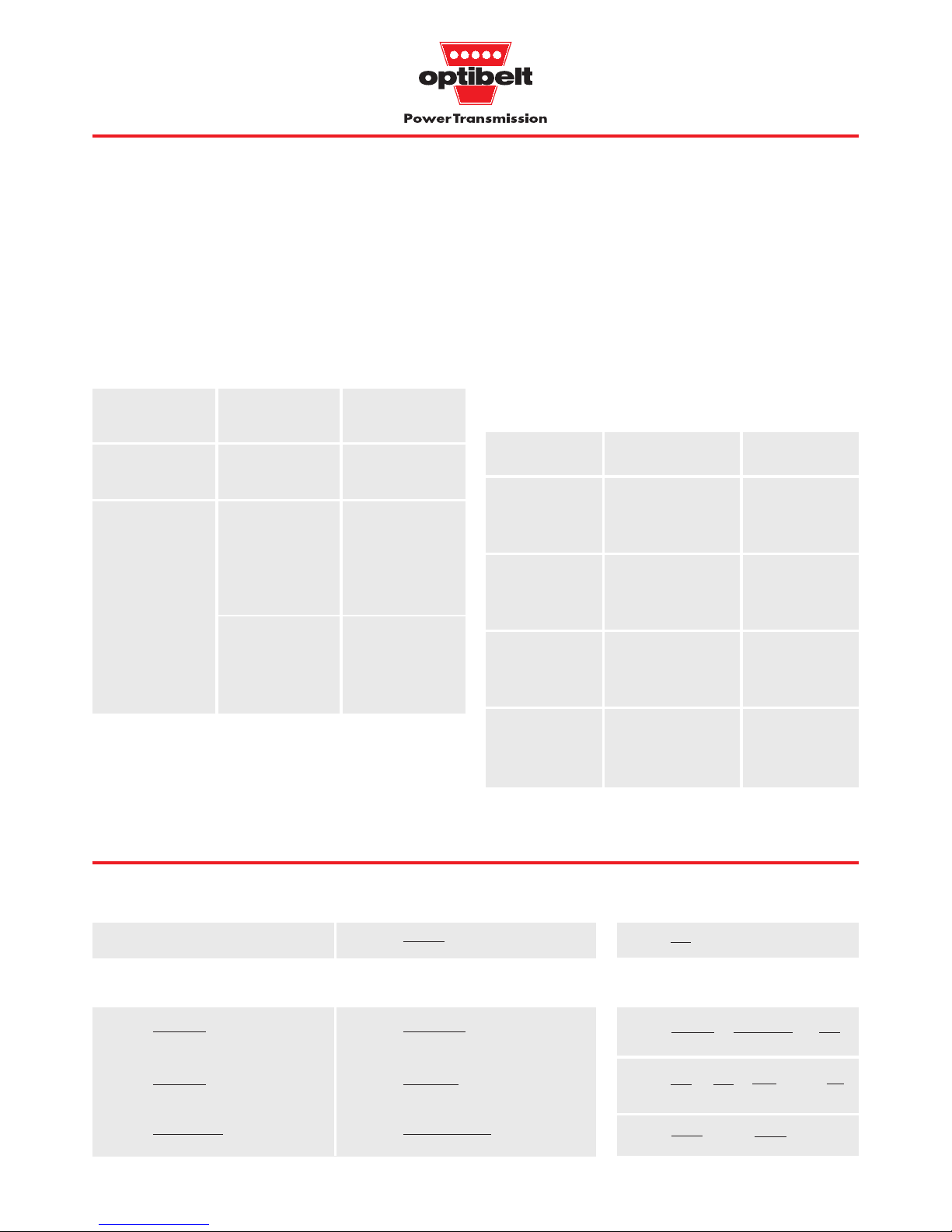

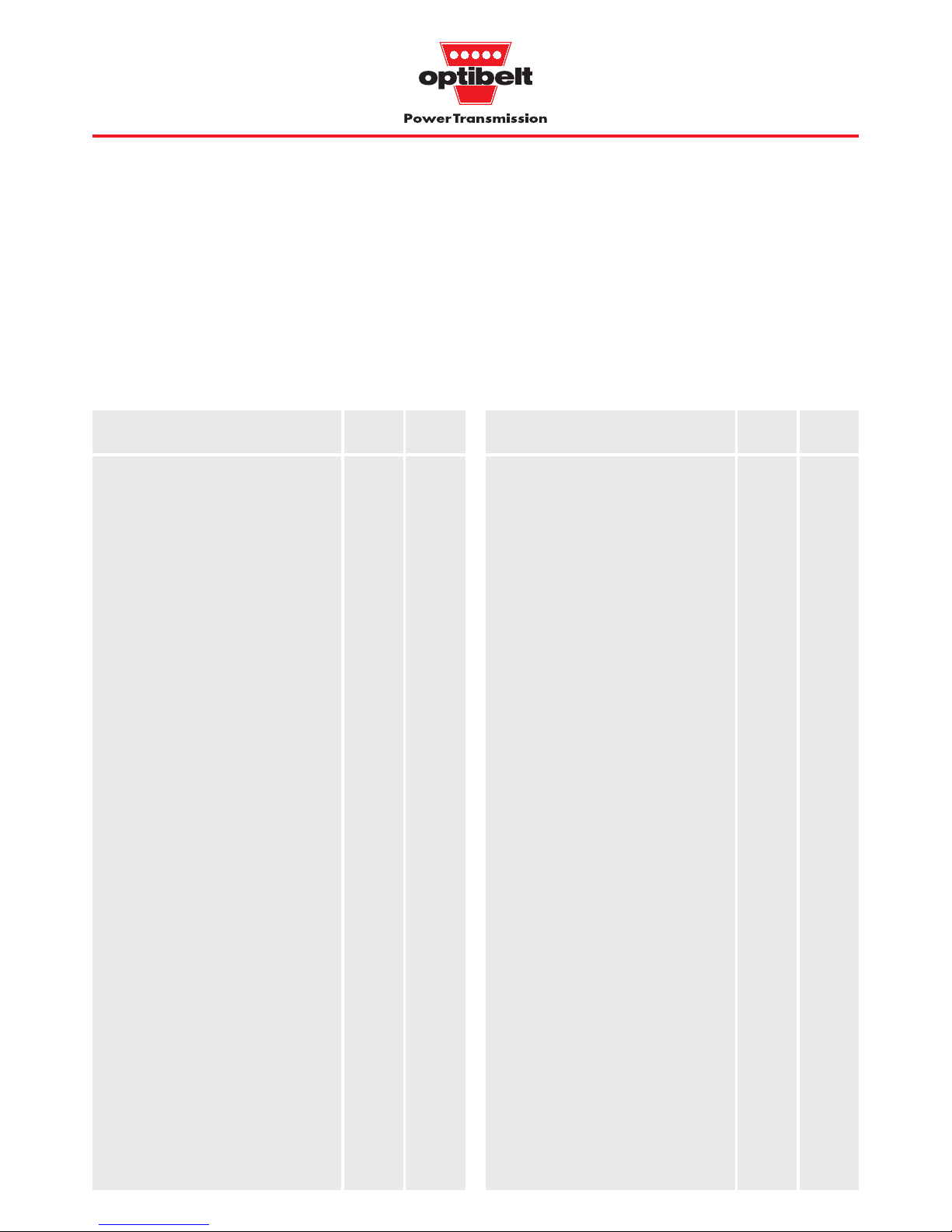

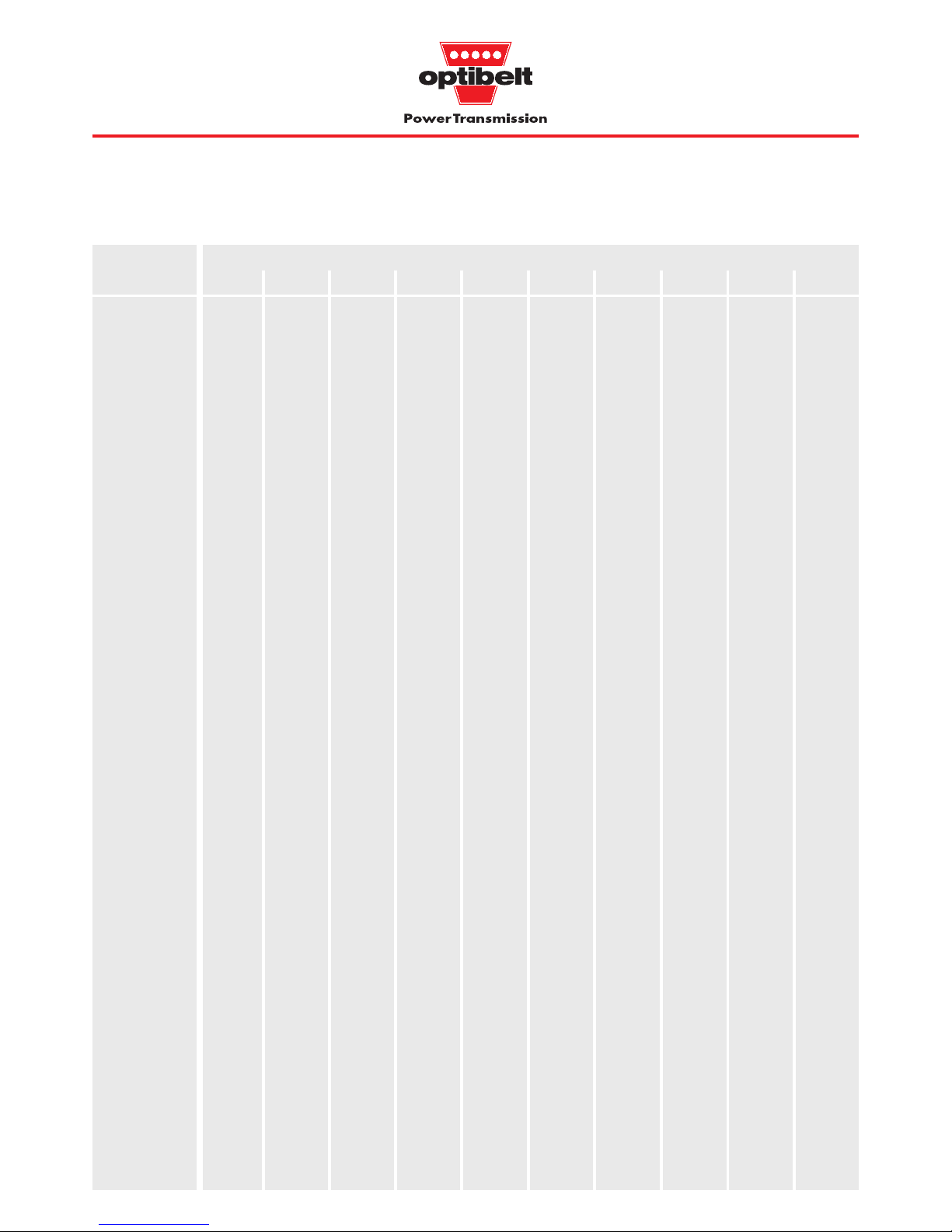

–5.2TnoitceS

mm5.2hctipmm5.2hctip

mm5.2hctip

mm5.2hctipmm5.2hctip

mm5hctip–5TnoitceS mm01hctip–01TnoitceS

.oNtleB

hctiP

)mm(

.oN

hteetfo.oNtleB

hctiP

)mm(

.oN

hteetfo.oNtleB

hctiP

)mm(

.oN

hteetfo.oNtleB

hctiP

)mm(

.oN

hteetfo

Standard widths bSt (mm):

4, 6, 8, 10, 12

Standard widths bSt (mm):

6, 8, 10, 12, 16, 20, 25

Standard widths bSt (mm):

10, 12, 16, 20, 25, 32, 50

3.2 ZRM/ZRP timing belt range

optibelt

ZRM timing belts, metric sizes

Further sizes on request. * Non stock

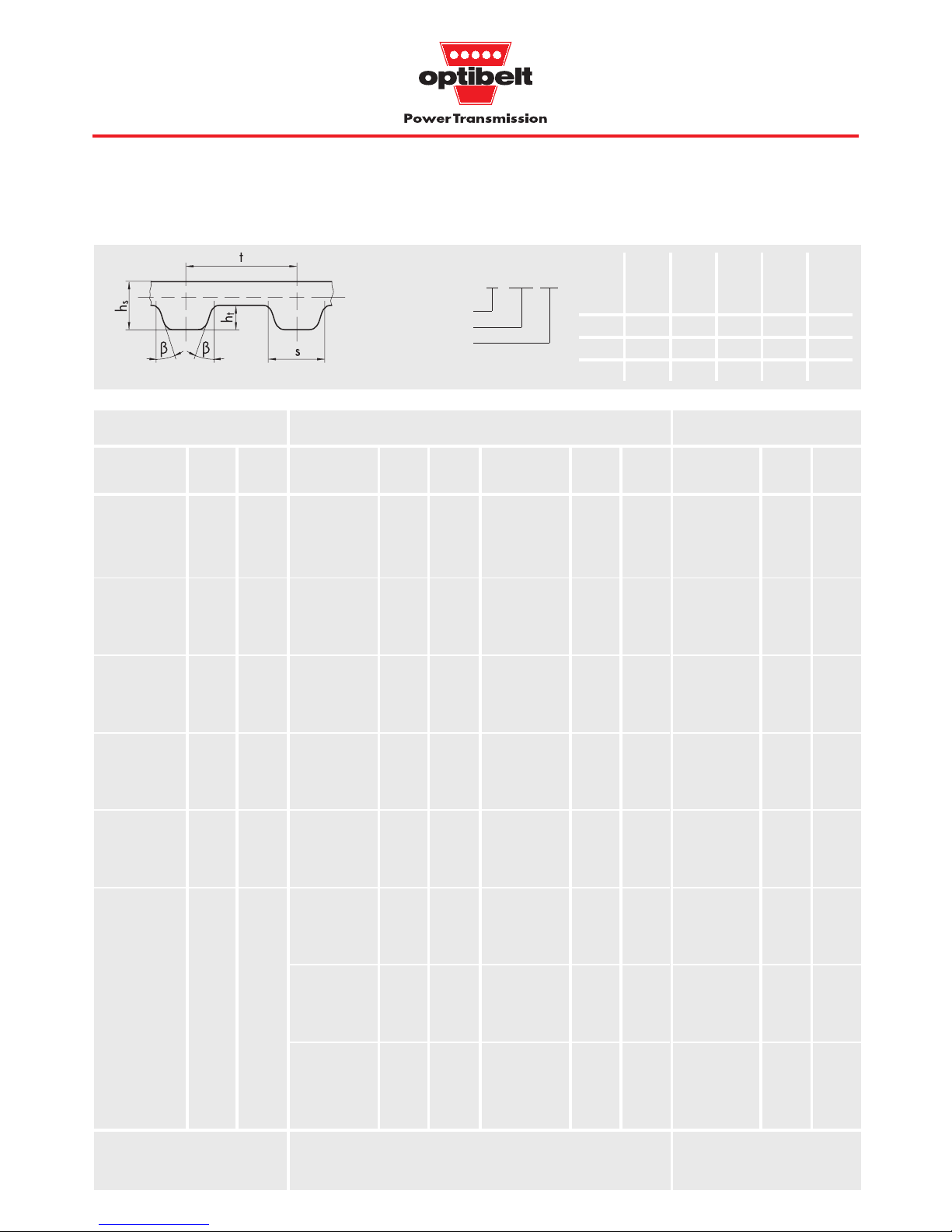

Section Pitch Tooth Overall Tooth Tooth

depth belt width angle

thickness

th

t

h

s

s2 β

(mm) (mm) (mm) (mm) (°)

T2.5 2.5 0.70 1.30 1.50 40

T5 5.0 1.20 2.20 2.65 40

T10 10.0 2.50 4.50 5.30 40

Construction: polyurethane with steel tension cord

Table 3.2: ZRM timing belt range

L

wSt

T2.5/120 120.0 48

T2.5/160 160.0 64

T2.5/177.5 177.5 71

T2.5/200 200.0 80

T2.5/230 230.0 92

T2.5/245 245.0 98

T2.5/265 265.0 106

T2.5/285 285.0 114

T2.5/305 305.0 122

T2.5/317.5 317.5 127

T2.5/330 330.0 132

T2.5/380 380.0 152

T2.5/420 420.0 168

T2.5/480 480.0 192

T2.5/500 500.0 200

T2.5/540 540.0 216

T2.5/600 600.0 240

T2.5/650 650.0 260

T2.5/780 780.0 312

T2.5/915 915.0 366

T2.5/950 950.0 380

T5/165 165.0 33

T5/185 185.0 37

T5/200 200.0 40

T5/215 215.0 43

T5/220 220.0 44

T5/225 225.0 45

T5/245 245.0 49

T5/250 250.0 50

T5/255 255.0 51

T5/260 260.0 52

T5/270 270.0 54

T5/275 275.0 55

T5/280 280.0 56

T5/295 295.0 59

T5/300 300.0 60

T5/305 305.0 61

T5/325 325.0 65

T5/330 330.0 66

T5/340 340.0 68

T5/350 350.0 70

T5/355 355.0 71

T5/360* 360.0 72

T5/365 365.0 73

T5/375 375.0 75

T5/390 390.0 78

T5/400 400.0 80

T5/410 410.0 82

T5/420 420.0 84

T5/425 425.0 85

T5/440* 440.0 88

T5/445* 445.0 89

T5/450 450.0 90

T5/455 455.0 91

T5/460* 460.0 92

T5/475 475.0 95

T5/480 480.0 96

T5/500 500.0 100

T5/510 510.0 102

T5/525 525.0 105

T5/545 545.0 109

T5/ 550 550.0 110

T5/ 560 560.0 112

T5/ 575 575.0 115

T5/ 590* 590.0 118

T5/ 600 600.0 120

T5/ 610 610.0 122

T5/ 620 620.0 124

T5/ 625* 625.0 125

T5/ 630 630.0 126

T5/ 640 640.0 128

T5/ 650 650.0 130

T5/ 660 660.0 132

T5/ 675* 675.0 135

T5/ 690 690.0 138

T5/ 700 700.0 140

T5/ 720 720.0 144

T5/ 725 725.0 145

T5/ 750 750.0 150

T5/ 780 780.0 156

T5/ 800* 800.0 160

T5/ 815 815.0 163

T5/ 840 840.0 168

T5/ 850 850.0 170

T5/ 860* 860.0 172

T5/ 900 900.0 180

T5/ 940 940.0 188

T5/ 990 990.0 198

T5/1000 1000.0 200

T5/1075 1075.0 215

T5/1100 1100.0 220

T5/1115* 1115.0 223

T5/1140* 1140.0 228

T5/1215 1215.0 243

T5/1350* 1350.0 270

T5/1380 1380.0 276

T5/1440 1440.0 288

T10/ 260 260.0 26

T10/ 370 370.0 37

T10/ 400 400.0 40

T10/ 410 410.0 41

T10/ 440 440.0 44

T10/ 450 450.0 45

T10/ 500 500.0 50

T10/ 530 530.0 53

T10/ 550* 550.0 55

T10/ 560 560.0 56

T10/ 600 600.0 60

T10/ 610 610.0 61

T10/ 630 630.0 63

T10/ 650 650.0 65

T10/ 660 660.0 66

T10/ 690 690.0 69

T10/ 700 700.0 70

T10/ 720 720.0 72

T10/ 750 750.0 75

T10/ 780 780.0 78

T10/ 800* 800.0 80

T10/ 810 810.0 81

T10/ 840 840.0 84

T10/ 850* 850.0 85

T10/ 880 880.0 88

T10/ 890 890.0 89

T10/ 900 900.0 90

T10/ 910 910.0 91

T10/ 920 920.0 92

T10/ 950 950.0 95

T10/ 960 960.0 96

T10/ 970 970.0 97

T10/ 980 980.0 98

T10/1000* 1000.0 100

T10/1010 1010.0 101

T10/1050 1050.0 105

T10/1080 1080.0 108

T10/1100 1100.0 110

T10/1110 1110.0 111

T10/1140 1140.0 114

L

wSt

L

wSt

L

wSt

z

R

z

R

z

R

z

R

Order example for ZRM: 10 T2.5/200

Width (mm)

Section

Pitch length (mm)

•

•

•

•

•••••••

•

17

deunitnoc,01TnoitceSmm5hctip–D5TnoitceSmm01hctip–D01TnoitceS

.oNtleB

hctiP

)mm(

.oN

hteetfo.oNtleB

hctiP

)mm(

.oN

hteetfo.oNtleB

hctiP

)mm(

.oN

hteetfo

Standard widths bSt (mm):

10, 12, 16, 20, 25, 32, 50

Standard widths bSt (mm):

6, 8, 10, 12, 16, 20, 25

Standard widths bSt (mm):

10, 12, 16, 20, 25, 32, 50

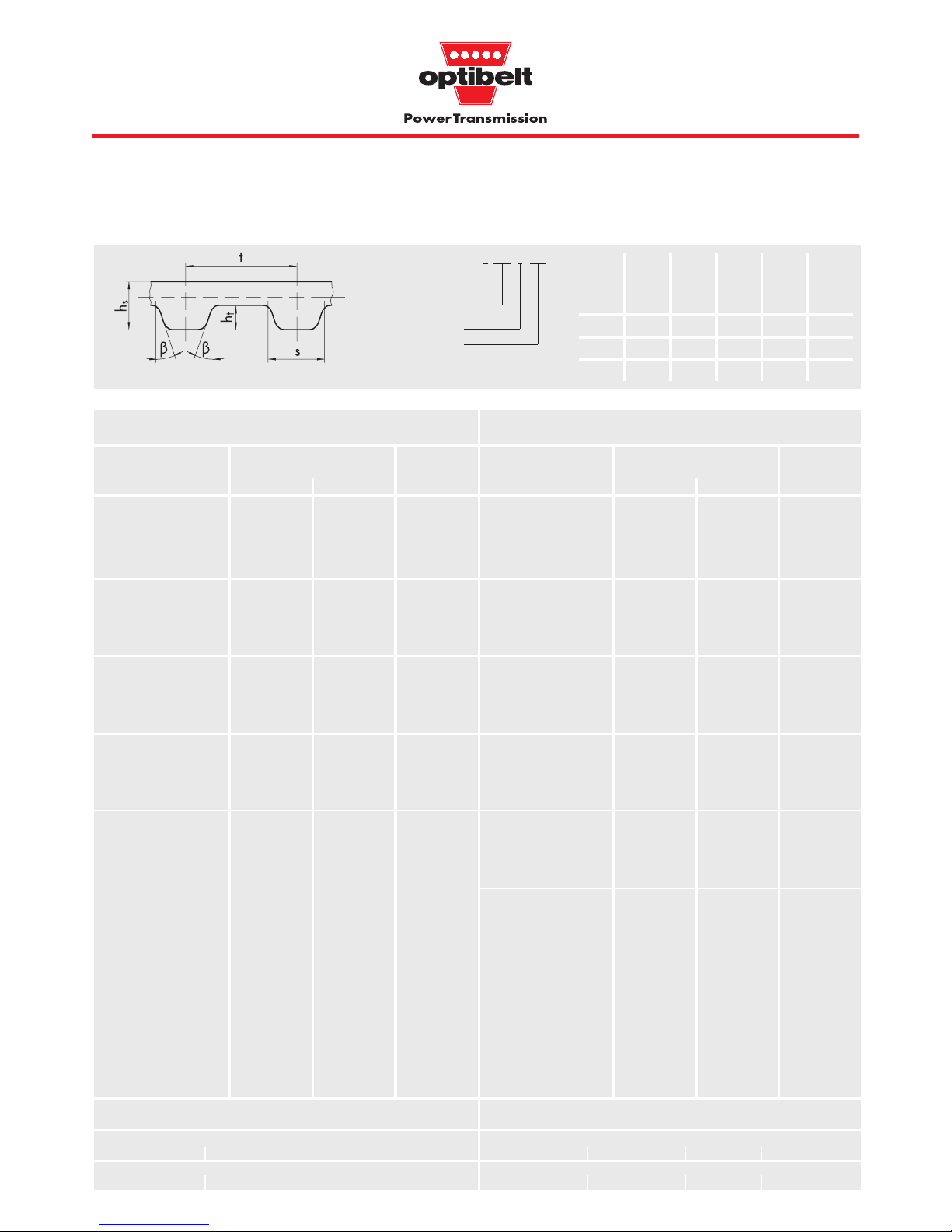

Section Pitch Tooth Overall Tooth Tooth

depth belt width angle

thickness

th

t

hs1s2 β

(mm) (mm) (mm) (mm) (°)

T5D 5.0 1.20 3.40 2.65 40

T10D 10.0 2.50 7.00 5.30 40

3.2 ZRM/ZRP timing belt range

optibelt

ZRM double section timing belts, metric sizes

Further sizes on request. * Non stock

Table 3.2 continued

L

wSt

z

R

L

wSt

z

R

z

R

L

wSt

T10/1150 1150.0 115

T10/1200 1200.0 120

T10/1210 1210.0 121

T10/1240 1240.0 124

T10/1250 1250.0 125

T10/1300 1300.0 130

T10/1320 1320.0 132

T10/1350 1350.0 135

T10/1390 1390.0 139

T10/1400 1400.0 140

T10/1420 1420.0 142

T10/1440 1440.0 144

T10/1450 1450.0 145

T10/1460 1460.0 146

T10/1500 1500.0 150

T10/1560 1560.0 156

T10/1600 1600.0 160

T10/1610 1610.0 161

T10/1700 1700.0 170

T10/1750 1750.0 175

T10/1780 1780.0 178

T10/1800* 1800.0 180

T10/1880 1880.0 188

T10/1960 1960.0 196

T10/2250 2250.0 225

T5/ 300 D* 300.0 60

T5/ 350 D* 350.0 70

T5/ 400 D* 400.0 80

T5/ 410 D 410.0 82

T5/ 450 D* 450.0 90

T5/ 460 D 460.0 92

T5/ 480 D 480.0 96

T5/ 500 D 500.0 100

T5/ 515 D 515.0 103

T5/ 550 D 550.0 110

T5/ 590 D 590.0 118

T5/ 600 D* 600.0 120

T5/ 620 D 620.0 124

T5/ 650 D 650.0 130

T5/ 700 D 700.0 140

T5/ 750 D 750.0 150

T5/ 800 D 800.0 160

T5/ 815 D 815.0 163

T5/ 850 D* 850.0 170

T5/ 860 D 860.0 172

T5/ 900 D 900.0 180

T5/ 940 D 940.0 188

T5/1100 D 1100.0 220

T10/ 260 D 260.0 26

T10/ 530 D 530.0 53

T10/ 600 D 600.0 60

T10/ 630 D 630.0 63

T10/ 660 D 660.0 66

T10/ 700 D 700.0 70

T10/ 720 D 720.0 72

T10/ 750 D 750.0 75

T10/ 800 D 800.0 80

T10/ 840 D 840.0 84

T10/ 900 D 900.0 90

T10/ 980 D 980.0 98

T10/1000 D* 1000.0 100

T10/1100 D 1100.0 110

T10/1200 D* 1200.0 120

T10/1210 D 1210.0 121

T10/1240 D 1240.0 124

T10/1250 D 1250.0 125

T10/1300 D* 1300.0 130

T10/1320 D 1320.0 132

T10/1350 D 1350.0 135

T10/1400 D 1400.0 140

T10/1420 D 1420.0 142

T10/1500 D 1500.0 150

T10/1600 D* 1600.0 160

T10/1610 D 1610.0 161

T10/1700 D 1700.0 170

T10/1800 D 1800.0 180

T10/1880 D 1880.0 188

Order example for ZRM D: 50 T 10/1420 D

Width (mm)

Section

Pitch length (mm)

Double section timing belts

T20 and AT sizes

on request

Construction:

polyurethane with steel tension cord

•

•

•

••

•• •

•

•

•

•

•

•

•

18

mm230.2hctip–*LXMnoitceS mm80.5hctip–LXnoitceS

.oNtleB

.oN

hteetfo.oNtleB

.oN

hteetfo.oNtleB

.oN

hteetfo

)hcni()mm()hcni()mm()hcni()mm(

Further sizes on request. * Non stock: minimum order 1 sleeve

3.2 ZRM/ZRP timing belt range

optibelt

ZRP timing belts, inch sizes

Section Pitch Tooth Overall Tooth Tooth

depth belt width angle

thickness

th

t

h

s

s2 β

(mm) (mm) (mm) (mm) (°)

MXL 2.032 0.51 1.14 1.14 40

XL 5.080 1.27 2.30 2.57 50

L 9.525 1.91 3.60 4.65 40

Table 3.3: ZRP timing belt range

Construction: polyurethane with Aramid (MXL) or steel tension cord (XL, L)

K 240 MXL 2.40 60.96 30

K 280 MXL 2.80 71.12 35

K 320 MXL 3.20 81.28 40

K 360 MXL 3.60 91.44 45

K 400 MXL 4.00 101.60 50

K 440 MXL 4.40 111.76 55

K 480 MXL 4.80 121.92 60

K 520 MXL 5.20 132.08 65

K 560 MXL 5.60 142.24 70

K 600 MXL 6.00 152.40 75

K 640 MXL 6.40 162.56 80

K 680 MXL 6.80 172.72 85

K 720 MXL 7.20 182.88 90

K 760 MXL 7.60 193.04 95

K 800 MXL 8.00 203.20 100

K 840 MXL 8.40 213.36 105

K 880 MXL 8.80 223.52 110

K 920 MXL 9.20 233.68 115

K 960 MXL 9.60 243.84 120

K 1000 MXL 10.00 254.00 125

K 1040 MXL 10.40 264.16 130

K 1080 MXL 10.80 274.32 135

K 1120 MXL 11.20 284.48 140

K 1160 MXL 11.60 294.64 145

K 1200 MXL 12.00 304.80 150

K 1240 MXL 12.40 314.96 155

K 1280 MXL 12.80 325.12 160

K 1320 MXL 13.20 335.28 165

K 1360 MXL 13.60 345.44 170

K 1400 MXL 14.00 355.60 175

K 1440 MXL 14.40 365.76 180

K 1480 MXL 14.80 375.92 185

K 1520 MXL 15.20 386.08 190

K 1560 MXL 15.60 396.24 195

K 1600 MXL 16.00 406.40 200

K 1640 MXL 16.40 416.56 205

K 1680 MXL 16.80 426.72 210

K 1720 MXL 17.20 436.88 215

K 1760 MXL 17.60 447.04 220

K 1800 MXL 18.00 457.20 225

K 1840 MXL 18.40 467.36 230

K 1880 MXL 18.80 477.52 235

K 1920 MXL 19.20 487.68 240

K 1960 MXL 19.60 497.84 245

K 2000 MXL 20.00 508.00 250

K 2040 MXL 20.40 518.16 255

K 2080 MXL 20.80 528.32 260

K 2120 MXL 21.20 538.48 265

K 2160 MXL 21.60 548.64 270

K 2200 MXL 22.00 558.80 275

K 2240 MXL 22.40 568.96 280

K 2280 MXL 22.80 579.12 285

K 2320 MXL 23.20 589.28 290

K 2360 MXL 23.60 599.44 295

K 2400 MXL 24.00 609.60 300

K 2480 MXL 24.80 629.92 310

K 2560 MXL 25.60 650.24 320

K 2640 MXL 26.40 670.56 330

K 2720 MXL 27.20 690.88 340

K 2800 MXL 28.00 711.20 350

K 2880 MXL 28.80 731.52 360

K 2960 MXL 29.60 751.84 370

K 3040 MXL 30.40 772.16 380

K 3120 MXL 31.20 792.48 390

K 3200 MXL 32.00 812.80 400

z

R

Pitch length

L

wSt

z

R

Pitch length

L

wSt

z

R

Pitch length

L

wSt

K 60 XL* 6.00 152.40 30

K 70 XL* 7.00 177.80 35

K 76 XL* 7.60 193.04 38

K 80 XL* 8.00 203.20 40

K 84 XL* 8.40 213.36 42

K 90 XL* 9.00 228.60 45

K 94 XL* 9.40 238.76 47

K 96 XL* 9.60 243.84 48

K 100 XL 10.00 254.00 50

K 102 XL* 10.20 259.08 51

K 104 XL* 10.40 264.16 52

K 106 XL* 10.60 269.24 53

K 110 XL 11.00 279.40 55

K 114 XL* 11.40 289.56 57

K 116 XL* 11.60 294.64 58

K 120 XL 12.00 304.80 60

K 124 XL* 12.40 314.96 62

K 126 XL* 12.60 320.04 63

K 128 XL* 12.80 325.12 64

K 130 XL 13.00 330.20 65

K 136 XL* 13.60 345.44 68

K 140 XL 14.00 355.60 70

K 150 XL 15.00 381.00 75

K 152 XL* 15.20 386.08 76

K 154 XL* 15.40 391.16 77

K 160 XL 16.00 406.40 80

K 166 XL* 16.60 421.64 83

K 170 XL 17.00 431.80 85

K 180 XL 18.00 457.20 90

K 186 XL* 18.60 472.44 93

K 190 XL 19.00 482.60 95

K 200 XL 20.00 508.00 100

K 210 XL 21.00 533.40 105

K 212 XL* 21.20 538.48 106

K 220 XL 22.00 558.80 110

K 230 XL 23.00 584.20 115

K 240 XL 24.00 609.60 120

K 250 XL 25.00 635.00 125

K 254 XL* 25.40 645.16 127

K 260 XL 26.00 660.40 130

Sleeve width: 127 ± 10 mm

Order example for ZRP: K 120 XL 037

K = plastic

(polyurethane)

Pitch length code

Pitch length (inch x 10)

Section

Width code

Width (inch x 100)

Standard widths bSt:

1/8" = 3.175 mm 3/16" = 4.764 mm 1/4" = 6.35 mm 5/16" = 7.94 mm

Code No.:

012 019 025 031

Standard widths bSt, continued on page 19:

1/4" = 6.35 mm 5/16" = 7.94 mm

Code No.:

025 031

•

•

•

•

•••••••

•

19

3.2 ZRM/ZRP Timing Belt Range

optibelt

ZRP timing belts, inch sizes

Section Pitch Tooth Overall Tooth Tooth

depth belt width angle

thickness

th

t

h

s

s2 β

(mm) (mm) (mm) (mm) (°)

MXL 2.032 0.51 1.14 1.14 40

XL 5.080 1.27 2.30 2.57 50

L 9.525 1.91 3.60 4.65 40

Further sizes on request. * Non stock: minimum order 1 sleeve

Table 3.3, continued:

Construction: polyurethane with Aramid (MXL) or steel tension cord (XL, L)

K 270 XL 27.00 685.80 135

K 290 XL 29.00 736.60 145

K 300 XL 30.00 762.00 150

K 320 XL* 32.00 812.80 160

K 330 XL 33.00 838.20 165

K 360 XL* 36.00 914.40 180

K 376 XL* 37.60 955.04 188

K 384 XL* 38.40 975.36 192

K 390 XL 39.00 990.60 195

K 414 XL* 41.40 1051.56 207

K 460 XL* 46.00 1168.40 230

K 480 XL* 48.00 1219.20 240

K 512 XL* 51.20 1300.48 256

K 550 XL* 55.00 1397.00 275

K 564 XL* 56.40 1432.56 282

K 630 XL* 63.00 1600.20 315

K 670 XL* 67.00 1701.80 335

K 124 L 12.40 314.30 33

K 150 L 15.00 381.00 40

K 165 L* 16.50 419.10 44

K 173 L* 17.30 439.42 46

K 187 L 18.70 476.20 50

K 210 L 21.00 533.40 56

K 225 L 22.50 571.50 60

K 240 L 24.00 609.60 64

K 255 L 25.50 647.70 68

K 270 L 27.00 685.80 72

K 285 L 28.50 723.90 76

K 300 L 30.00 762.00 80

K 322 L 32.20 819.10 86

K 345 L 34.50 876.30 92

K 367 L 36.70 933.40 98

K 375 L* 37.50 952.50 100

K 390 L 39.00 990.60 104

K 420 L 42.00 1066.80 112

K 427 L* 42.70 1084.58 114

K 450 L 45.00 1143.00 120

K 480 L 48.00 1219.20 128

K 510 L 51.00 1295.40 136

K 525 L* 52.50 1333.50 140

K 540 L 54.00 1371.60 144

K 600 L 60.00 1524.00 160

Pitch length

L

wSt

z

R

Pitch length

L

wSt

z

R

Sleeve width: 150 ± 10 mmSleeve width: 150 ± 10 mm

Order example for ZRP: K 480 L 150

K = plastic

(polyurethane)

Pitch length code

Pitch length (inch x 10)

Section

Width code

Width (inch x 100)

Standard widths bSt, continued for page 18:

3/8" = 9.53 mm 1/2" = 12.7 mm

Code No.:

037 050

Standard widths bSt:

1/2" = 12.7 mm 3/4" = 19.05 mm 1" = 25.4 mm 1 1/2" = 38.1 mm

Code No.:

050 075 100 150

•

•

•

•

•••••••

•

deunitnoc,mm80.5hctip–LXnoitceS mm525.9hctip–LnoitceS

.oNtleB

.oN

hteetfo.oNtleB

.oN

hteetfo

)hcni()mm()hcni()mm(

20

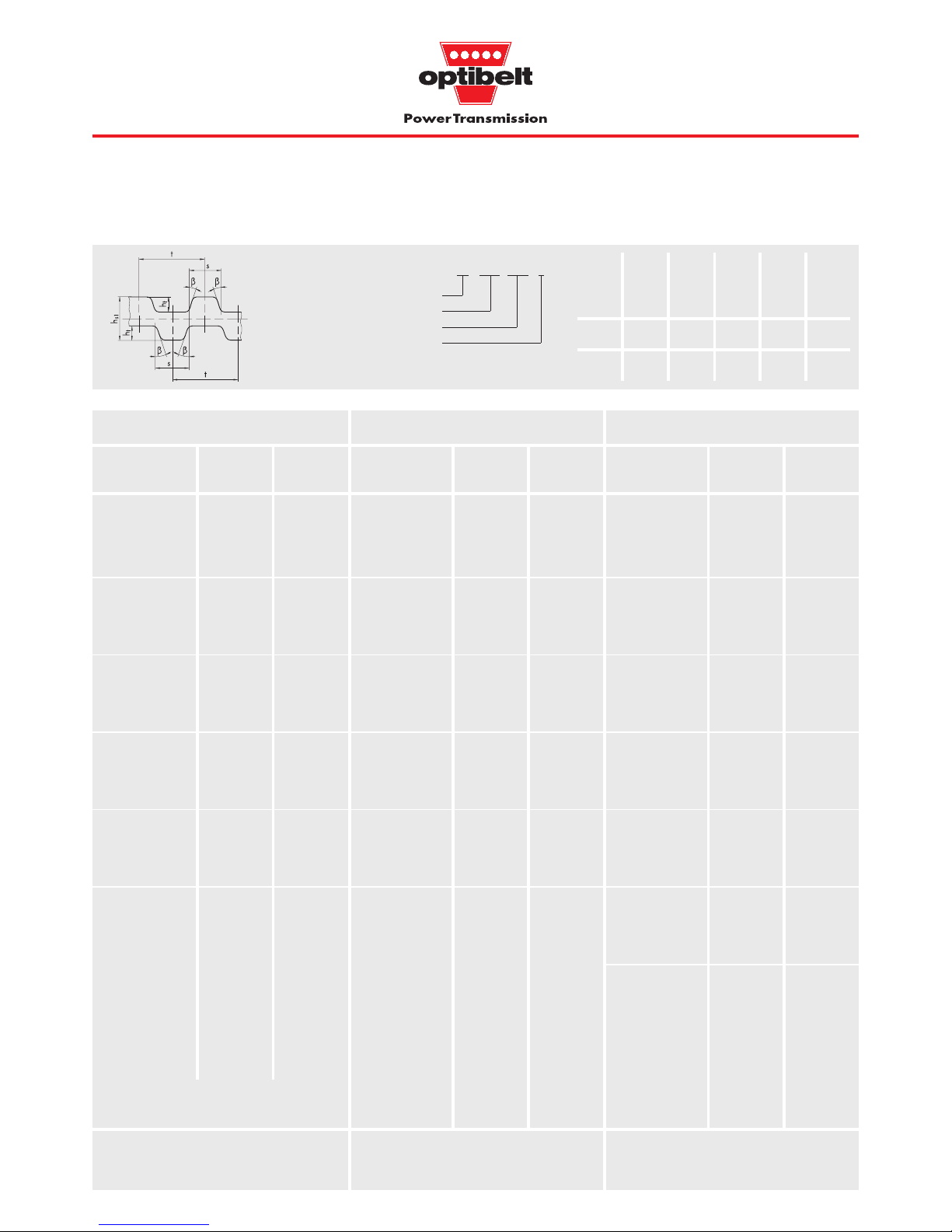

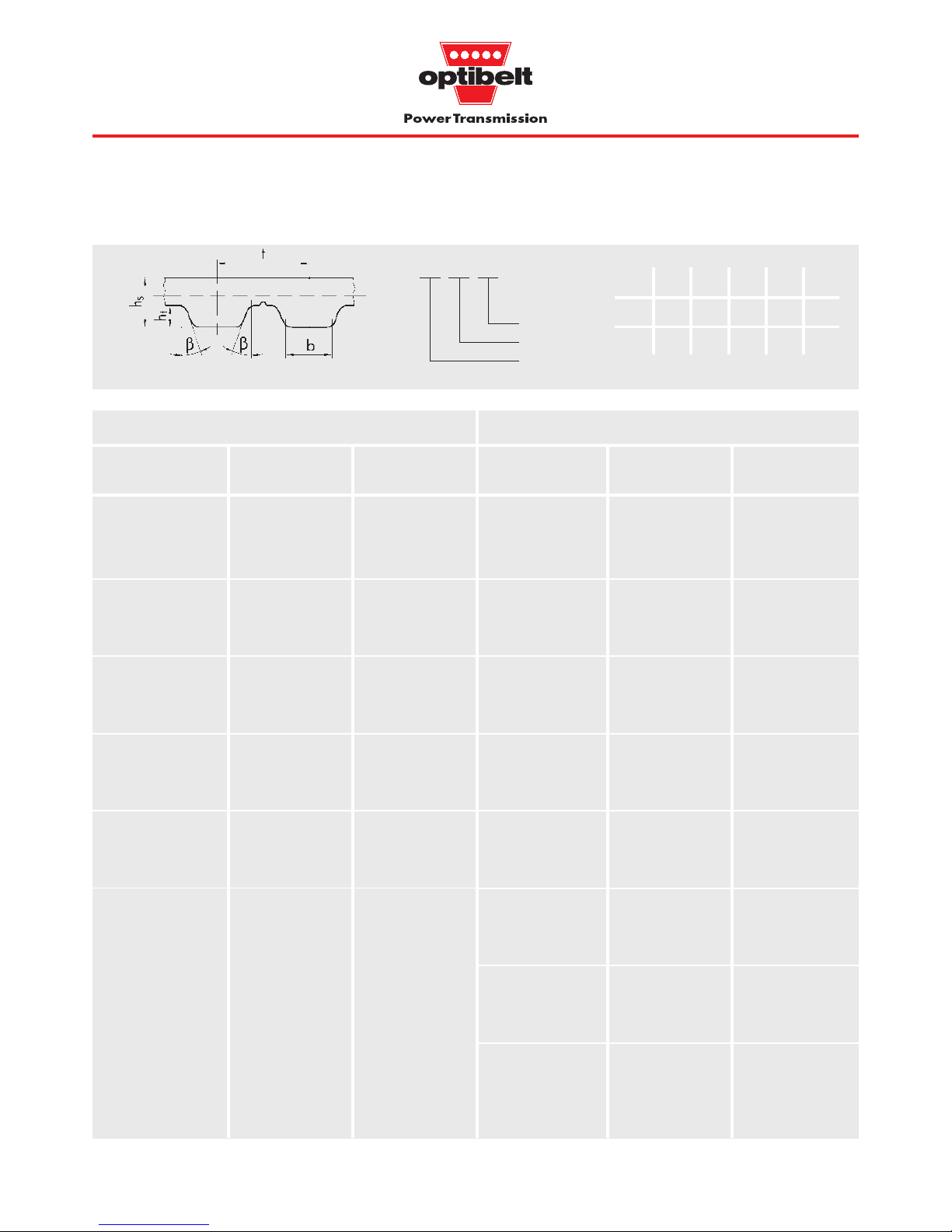

Type AT5 – pitch 5 mm

Belt No.

Pitch length

(mm)

Number

of teeth

Belt No.

Pitch length

(mm)

Number

of teeth

Type AT10 – pitch 10 mm

Standard widths:

6 mm – Code 6; 8 mm – Code 8; 10 mm – Code 10; 12 mm – Code 12;

16 mm – Code 16; 20 mm – Code 20; 25 mm – Code 25.

Standard widths:

10 mm – Code 10; 12 mm – Code 12; 16 mm – Code 16; 20 mm – Code 20;

25 mm – Code 25; 32 mm – Code 32; 50 mm – Code 50.

Construction: polyurethane with steel-wire cord

AT5 / AT10

10 /AT5 300

Type

ββ

ββ

β

AT5 5.0 1.20 2.70 2.50 50°

AT10 10.0 2.50 5.00 5.00 50°

th

t

hsb

(mm) (mm) (mm) (mm)

Pitch length (mm)

Pitch (5␣ mm)

Width (mm)

Further sizes on request.

AT5/ 225 225.00 45

AT5/ 255 255.00 51

AT5/ 280 280.00 56

AT5/ 300 300.00 60

AT5/ 340 340.00 68

AT5/ 375 375.00 75

AT5/ 390 390.00 78

AT5/ 420 420.00 84

AT5/ 450 450.00 90

AT5/ 455 455.00 91

AT5/ 500 500.00 100

AT5/ 545 545.00 109

AT5/ 600 600.00 120

AT5/ 610 610.00 122

AT5/ 660 660.00 132

AT5/ 710 710.00 142

AT5/ 720 720.00 144

AT5/ 750 750.00 150

AT5/ 780 780.00 156

AT5/ 825 825.00 165

AT5/ 860 860.00 172

AT5/ 975 975.00 195

AT5/1050 1050.00 210

AT5/1125 1125.00 225

AT5/1500 1500.00 300

AT10/ 500 500.00 50

AT10/ 560 560.00 56

AT10/ 600 600.00 60

AT10/ 610 610.00 61

AT10/ 660 660.00 66

AT10/ 700 700.00 70

AT10/ 730 730.00 73

AT10/ 780 780.00 78

AT10/ 800 800.00 80

AT10/ 840 840.00 84

AT10/ 890 890.00 89

AT10/ 920 920.00 92

AT10/ 960 960.00 96

AT10/ 980 980.00 98

AT10/1000 1000.00 100

AT10/1010 1010.00 101

AT10/1050 1050.00 105

AT10/1080 1080.00 108

AT10/1100 1100.00 110

AT10/1150 1150.00 115

AT10/1200 1200.00 120

AT10/1210 1210.00 121

AT10/1250 1250.00 125

AT10/1280 1280.00 128

AT10/1300 1300.00 130

AT10/1320 1320.00 132

AT10/1350 1350.00 135

AT10/1360 1360.00 136

AT10/1400 1400.00 140

AT10/1420 1420.00 142

AT10/1480 1480.00 148

AT10/1500 1500.00 150

AT10/1600 1600.00 160

AT10/1700 1700.00 170

AT10/1720 1720.00 172

AT10/1800 1800.00 180

AT10/1860 1860.00 186

AT10/1940 1940.00 194

3.2 ZRM/ZRP timing belt range

optibelt

ZRM timing belts, metric

Table 3.4

21

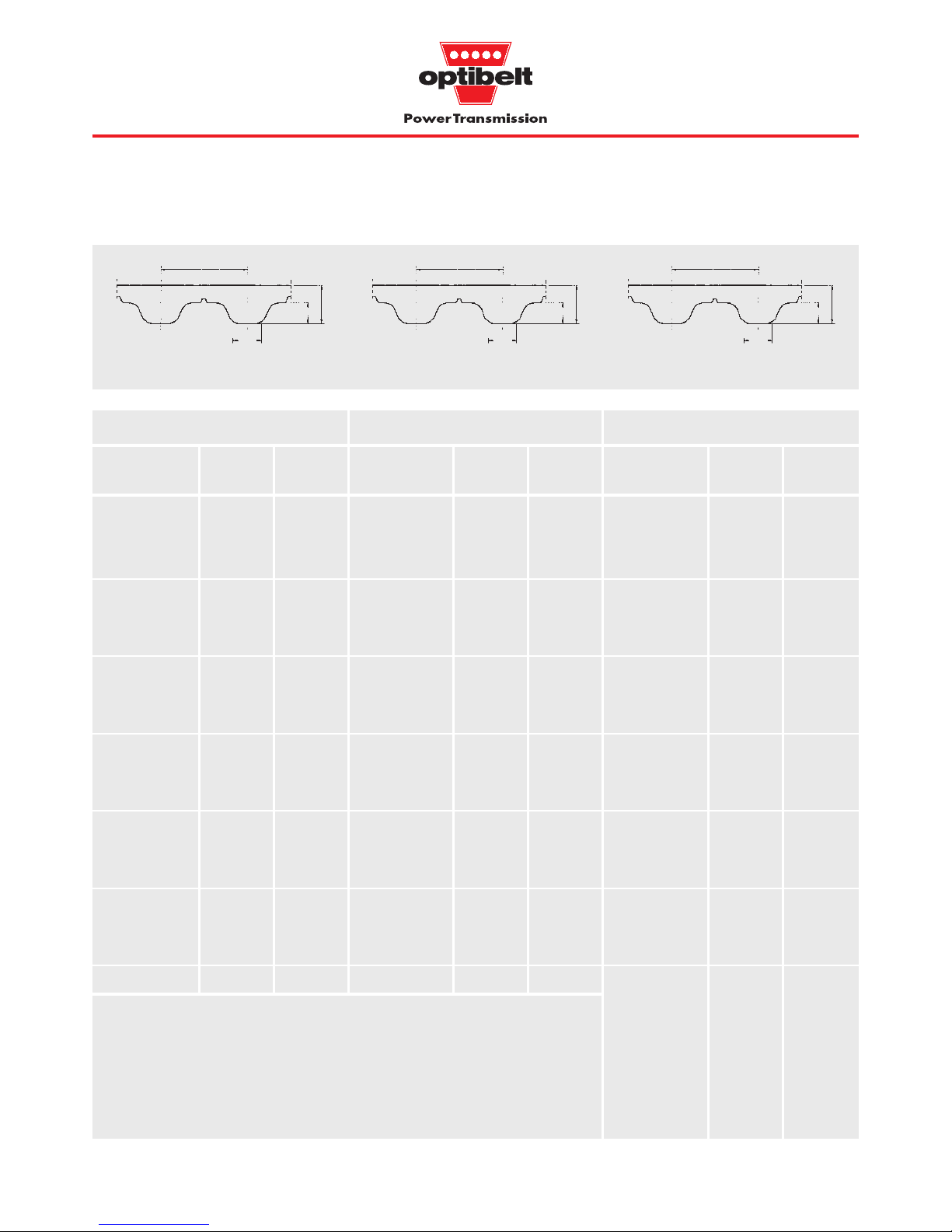

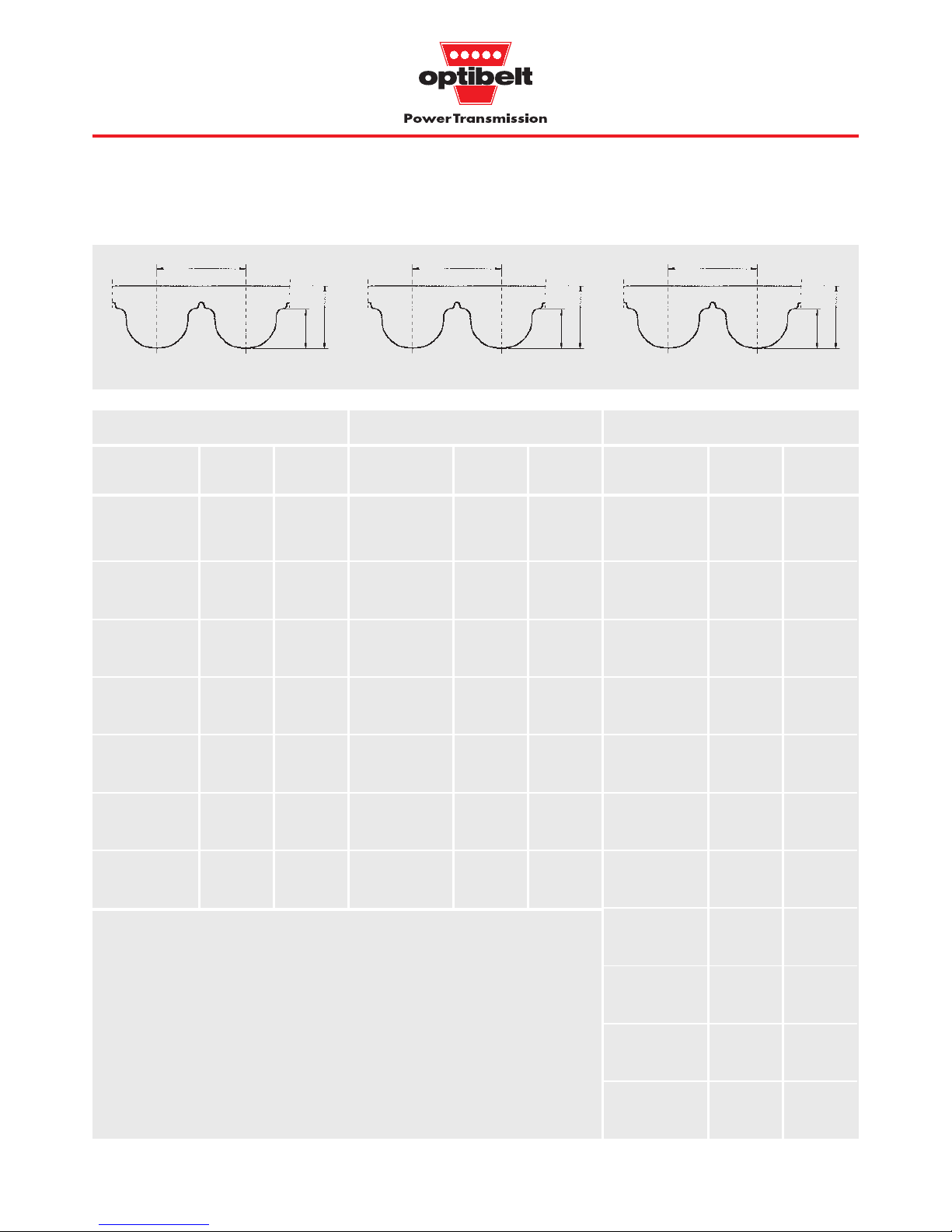

Construction: polyurethane with steel-wire cord

5.0

1.8

1.2

2.2

10.0

3.5

2.5

4.5

20.0

6.5

5.0

8.0

Standard widths:

16 mm – Code 16; 25 mm – Code 25; 32 mm – Code 32; 50 mm – Code 50; 75 mm – Code 75; 100 mm – Code 100.

3.2 ZRM/ZRP timing belt range

optiflex

timing belts, endless manufactured

T5/1500• 1500.00 300

T5/1600• 1600.00 320

T5/1700• 1700.00 340

T5/1800• 1800.00 360

T5/1900• 1900.00 380

T5/2000• 2000.00 400

T5/2100• 2100.00 420

T5/2200• 2200.00 440

T5/2300• 2300.00 460

T5/2400• 2400.00 480

T5/2500• 2500.00 500

T5/2600• 2600.00 520

T5/2700• 2700.00 540

T5/2800• 2800.00 560

T5/2900• 2900.00 580

T5/3000• 3000.00 600

T5/3200• 3200.00 640

T5/3400• 3400.00 680

T5/3600• 3600.00 720

T5/3800• 3800.00 760

T5/4000• 4000.00 800

T5/4200• 4200.00 840

T5/4400• 4400.00 880

T5/4600• 4600.00 920

T5/4800• 4800.00 960

T5/5000• 5000.00 1000

T5/5200• 5200.00 1040

T5/5400• 5400.00 1080

T5/5600• 5600.00 1120

T5/5800• 5800.00 1160

T5/6000• 6000.00 1200

T10/1500• 1500.00 150

T10/1600• 1600.00 160

T10/1700• 1700.00 170

T10/1800• 1800.00 180

T10/1900• 1900.00 190

T10/2000• 2000.00 200

T10/2100• 2100.00 210

T10/2200• 2200.00 220

T10/2300• 2300.00 230

T10/2400• 2400.00 240

T10/2500• 2500.00 250

T10/2600• 2600.00 260

T10/2700• 2700.00 270

T10/2800• 2800.00 280

T10/2900• 2900.00 290

T10/3000• 3000.00 300

T10/3200• 3200.00 320

T10/3400• 3400.00 340

T10/3600• 3600.00 360

T10/3800• 3800.00 380

T10/4000• 4000.00 400

T10/4200• 4200.00 420

T10/4400• 4400.00 440

T10/4600• 4600.00 460

T10/4800• 4800.00 480

T10/5000• 5000.00 500

T10/5200• 5200.00 520

T10/5400• 5400.00 540

T10/5600• 5600.00 560

T10/5800• 5800.00 580

T10/6000• 6000.00 600

T20/1500• 1500.00 75

T20/1600• 1600.00 80

T20/1700• 1700.00 85

T20/1800• 1800.00 90

T20/1900• 1900.00 95

T20/2000• 2000.00 100

T20/2100• 2100.00 105

T20/2200• 2200.00 110

T20/2300• 2300.00 115

T20/2400• 2400.00 120

T20/2500• 2500.00 125

T20/2600• 2600.00 130

T20/2700• 2700.00 135

T20/2800• 2800.00 140

T20/2900• 2900.00 145

T20/3000• 3000.00 150

T20/3200• 3200.00 160

T20/3400• 3400.00 170

T20/3600• 3600.00 180

T20/3800• 3800.00 190

T20/4000• 4000.00 200

T20/4200• 4200.00 210

T20/4400• 4400.00 220

T20/4600• 4600.00 230

T20/4800• 4800.00 240

T20/5000• 5000.00 250

T20/5200• 5200.00 260

T20/5400• 5400.00 270

T20/5600• 5600.00 280

T20/5800• 5800.00 290

T20/6000• 6000.00 300

Type T5 – pitch 5 mm Type T10 – pitch 10 mm Type T20 – pitch 20 mm

Optiflex timing belts are available with PAZ fabric.

Length: 1500 mm - 24 000 mm

Minimum quantity: according to production capability (100 mm or 150 mm)

Double-toothed timing belts section T5D / T10D – on request.

Lengths over 6000 mm on request.

• Non stock items.

Belt No.

Pitch length

(mm)

Number

of teeth

Belt No.

Pitch length

(mm)

Number

of teeth

Belt No.

Pitch length

(mm)

Number

of teeth

22

Construction: polyurethane with steel-wire cord

Type AT5 – pitch 5 mm Type AT10 – pitch 10 mm Type AT20 – pitch 20 mm

5.0

2.5

1.2

2.7

10.0

5.0

2.5

4.5

20.0

10.0

5.0

8.0

Standard widths:

16 mm – Code 16; 25 mm – Code 25; 32 mm – Code 32; 50 mm – Code 50; 75 mm – Code 75; 100 mm – Code 100.

AT5/1500• 1500.00 300

AT5/1600• 1600.00 320

AT5/1700• 1700.00 340

AT5/1800• 1800.00 360

AT5/1900• 1900.00 380

AT5/2000• 2000.00 400

AT5/2100• 2100.00 420

AT5/2200• 2200.00 440

AT5/2300• 2300.00 460

AT5/2400• 2400.00 480

AT5/2500• 2500.00 500

AT5/2600• 2600.00 520

AT5/2700• 2700.00 540

AT5/2800• 2800.00 560

AT5/2900• 2900.00 580

AT5/3000• 3000.00 600

AT5/3200• 3200.00 640

AT5/3400• 3400.00 680

AT5/3600• 3600.00 720

AT5/3800• 3800.00 760

AT5/4000• 4000.00 800

AT5/4200• 4200.00 840

AT5/4400• 4400.00 880

AT5/4600• 4600.00 920

AT5/4800• 4800.00 960

AT5/5000• 5000.00 1000

AT5/5200• 5200.00 1040

AT5/5400• 5400.00 1080

AT5/5600• 5600.00 1120

AT5/5800• 5800.00 1160

AT5/6000• 6000.00 1200

AT10/1500• 1500.00 150

AT10/1600• 1600.00 160

AT10/1700• 1700.00 170

AT10/1800• 1800.00 180

AT10/1900• 1900.00 190

AT10/2000• 2000.00 200

AT10/2100• 2100.00 210

AT10/2200• 2200.00 220

AT10/2300• 2300.00 230

AT10/2400• 2400.00 240

AT10/2500• 2500.00 250

AT10/2600• 2600.00 260

AT10/2700• 2700.00 270

AT10/2800• 2800.00 280

AT10/2900• 2900.00 290

AT10/3000• 3000.00 300

AT10/3200• 3200.00 320

AT10/3400• 3400.00 340

AT10/3600• 3600.00 360

AT10/3800• 3800.00 380

AT10/4000• 4000.00 400

AT10/4200• 4200.00 420

AT10/4400• 4400.00 440

AT10/4600• 4600.00 460

AT10/4800• 4800.00 480

AT10/5000• 5000.00 500

AT10/5200• 5200.00 520

AT10/5400• 5400.00 540

AT10/5600• 5600.00 560

AT10/5800• 5800.00 580

AT10/6000• 6000.00 600

AT20/1500• 1500.00 75

AT20/1600• 1600.00 80

AT20/1700• 1700.00 85

AT20/1800• 1800.00 90

AT20/1900• 1900.00 95

AT20/2000• 2000.00 100

AT20/2100• 2100.00 105

AT20/2200• 2200.00 110

AT20/2300• 2300.00 115

AT20/2400• 2400.00 120

AT20/2500• 2500.00 125

AT20/2600• 2600.00 130

AT20/2700• 2700.00 135

AT20/2800• 2800.00 140

AT20/2900• 2900.00 145

AT20/3000• 3000.00 150

AT20/3200• 3200.00 160

AT20/3400• 3400.00 170

AT20/3600• 3600.00 180

AT20/3800• 3800.00 190

AT20/4000• 4000.00 200

AT20/4200• 4200.00 210

AT20/4400• 4400.00 220

AT20/4600• 4600.00 230

AT20/4800• 4800.00 240

AT20/5000• 5000.00 250

AT20/5200• 5200.00 260

AT20/5400• 5400.00 270

AT20/5600• 5600.00 280

AT20/5800• 5800.00 290

AT20/6000• 6000.00 300

Optiflex timing belts are available with PAZ fabric.

Length: 1500 mm - 24 000 mm

Minimum quantity: according to production capability (100 mm or 150 mm)

Double-toothed timing belts section AT5D / AT10D – on request.

Lengths over 6000 mm on request.

• Non stock items.

3.2 ZRM/ZRP timing belt range

optiflex

timing belts, endless manufactured

Belt No.

Pitch length

(mm)

Number

of teeth

Belt No.

Pitch length

(mm)

Number

of teeth

Belt No.

Pitch length

(mm)

Number

of teeth

23

Standard widths:

15 mm – Code 15; 25 mm – Code 25; 50 mm – Code 50;

75 mm – Code 75; 100 mm – Code 100.

Type 5M – pitch 5 mm

Construction: polyurethane with steel-wire cord

5.0

2.2

3.7

Type 8M – pitch 8 mm Type 14M – pitch 14 mm

8.0

3.6

5.6

14.0

6.43

10.0

Standard widths:

20 mm – Code 20; 25 mm – Code 25; 30 mm – Code 30;

50 mm – Code 50; 85 mm – Code 85; 100 mm – Code 100.

Standard widths:

25 mm – Code 25; 40 mm – Code 40; 55 mm – Code 55;

85 mm – Code 85; 100 mm – Code 100.

5M/1500• 1500.00 300

5M/1600• 1600.00 320

5M/1700• 1700.00 340

5M/1800• 1800.00 360

5M/1900• 1900.00 380

5M/2000• 2000.00 400

5M/2100• 2100.00 420

5M/2200• 2200.00 440

5M/2300• 2300.00 460

5M/2400• 2400.00 480

5M/2500• 2500.00 500

5M/2600• 2600.00 520

5M/2700• 2700.00 540

5M/2800• 2800.00 560

5M/2900• 2900.00 580

5M/3000• 3000.00 600

5M/3200• 3200.00 640

5M/3400• 3400.00 680

5M/3600• 3600.00 720

5M/3800• 3800.00 760

5M/4000• 4000.00 800

5M/4200• 4200.00 840

5M/4400• 4400.00 880

5M/4600• 4600.00 920

5M/4800• 4800.00 960

5M/5000• 5000.00 1000

5M/5200• 5200.00 1040

5M/5400• 5400.00 1080

5M/5600• 5600.00 1120

5M/5800• 5800.00 1160

5M/6000• 6000.00 1200

8M/1504• 1504.00 188

8M/1600• 1600.00 200

8M/1704• 1704.00 213

8M/1800• 1800.00 225

8M/1904• 1904.00 238

8M/2000• 2000.00 250

8M/2104• 2104.00 263

8M/2200• 2200.00 275

8M/2304• 2304.00 288

8M/2400• 2400.00 300

8M/2504• 2504.00 313

8M/2600• 2600.00 325

8M/2704• 2704.00 338

8M/2800• 2800.00 350

8M/2904• 2904.00 363

8M/3000• 3000.00 375

8M/3200• 3200.00 400

8M/3400• 3400.00 425

8M/3600• 3600.00 450

8M/3800• 3800.00 475

8M/4000• 4000.00 500

8M/4200• 4200.00 525

8M/4400• 4400.00 550

8M/4600• 4600.00 575

8M/4800• 4800.00 600

8M/5000• 5000.00 625

8M/5200• 5200.00 650

8M/5400• 5400.00 675

8M/5600• 5600.00 700

8M/5800• 5800.00 725

8M/6000• 6000.00 750

14M/1512• 1512.00 108

14M/1596• 1596.00 114

14M/1694• 1694.00 121

14M/1750• 1750.00 125

14M/1806• 1806.00 129

14M/1904• 1904.00 136

14M/2002• 2002.00 143

14M/2100• 2100.00 150

14M/2198• 2198.00 157

14M/2296• 2296.00 164

14M/2394• 2394.00 171

14M/2450• 2450.00 175

14M/2506• 2506.00 179

14M/2604• 2604.00 186

14M/2702• 2702.00 193

14M/2800• 2800.00 200

14M/2898• 2898.00 207

14M/2996• 2996.00 214

14M/3094• 3094.00 221

14M/3150• 3150.00 225

14M/3206• 3206.00 229

14M/3304• 3304.00 236

14M/3402• 3402.00 243

14M/3500• 3500.00 250

14M/3598• 3598.00 257

14M/3696• 3696.00 264

14M/3794• 3794.00 271

14M/3850• 3850.00 275

14M/3906• 3906.00 279

14M/4004• 4004.00 286

14M/4102• 4102.00 293

14M/4200• 4200.00 300

14M/4298• 4298.00 307

14M/4396• 4396.00 314

14M/4494• 4494.00 321

14M/4550• 4550.00 325

14M/4606• 4606.00 329

14M/4704• 4704.00 336

14M/4802• 4802.00 343

14M/4900• 4900.00 350

14M/4998• 4998.00 357

14M/5096• 5096.00 364

14M/5194• 5194.00 371

14M/5250• 5250.00 375

14M/5306• 5306.00 379

14M/5404• 5404.00 386

14M/5502• 5502.00 393

14M/5600• 5600.00 400

14M/5698• 5698.00 407

14M/5796• 5796.00 414

14M/5894• 5894.00 421

14M/5950• 5950.00 425

14M/6006• 6006.00 429

Optiflex timing belts are available with PAZ fabric.

Length: 1500 mm - 24 000 mm

Minimum quantity: according to production capability (100 mm or 150 mm)

Double-Toothed Timing Belts Section D-5M – on request.

Lengths over

6000 mm on request (Section 5M / 8M).

6006 mm on request (Section 14M).

• Non stock items.

3.2 ZRM/ZRP timing belt range

optiflex

timing belts, endless manufactured

Belt No.

Pitch length

(mm)

Number

of teeth

Belt No.

Pitch length

(mm)

Number

of teeth

Belt No.

Pitch length

(mm)

Number

of teeth

24

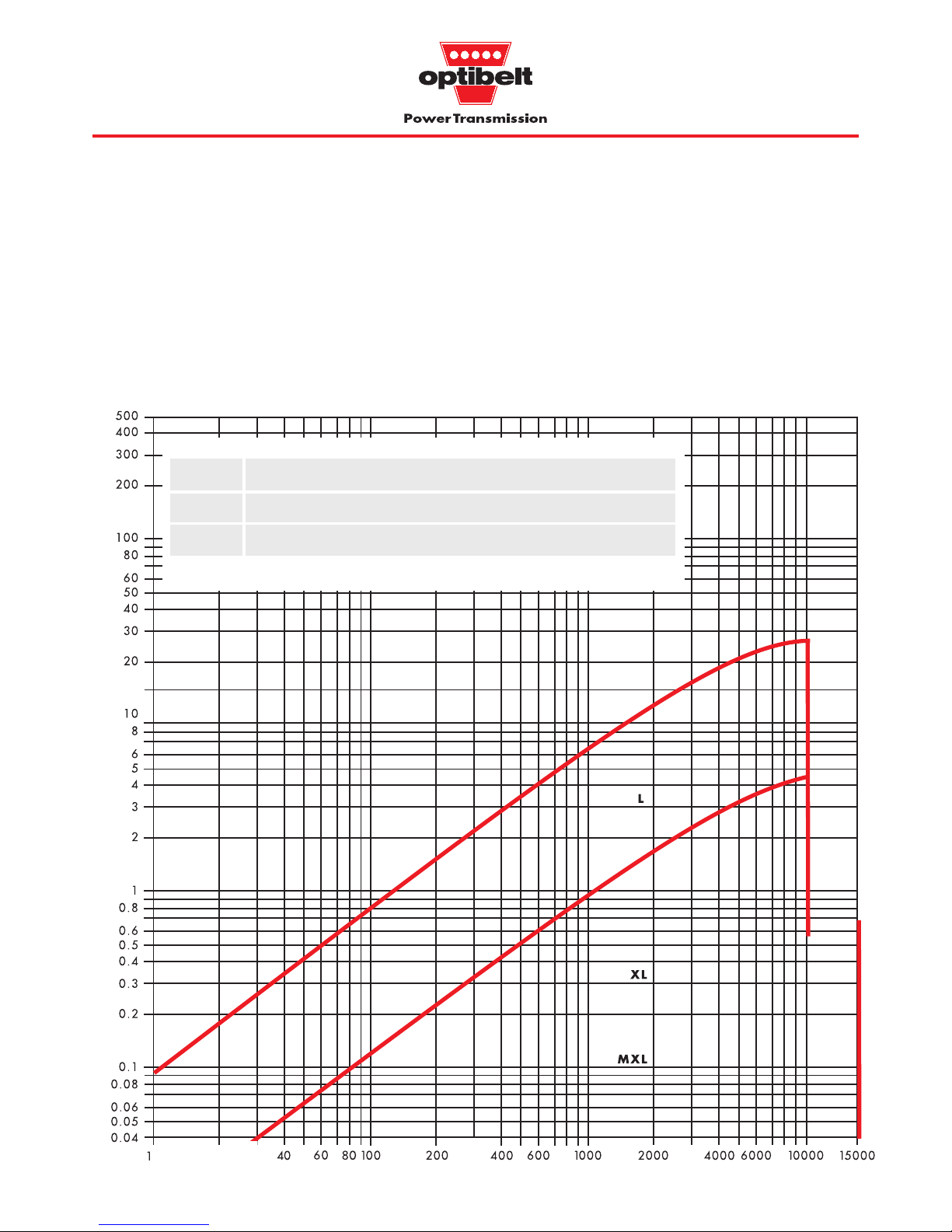

3.3 ZRM/ZRP belt selection graphs

Power rating graphs for section selection and maximum belt speeds for

optibelt

ZRM/ZRP timing belts, Z

emax

= 12

The maximum belt speeds for the individual timing belt sections in

these graphs are based on pulleys with 60 teeth, at least 12 of

which are in mesh. In addition each maximum width is based on

a combination of standard timing belts and standard pulleys (see

Table 3.4).

Wider belts can be used with special pulleys allowing increased

power transmission.

Specifying smaller pulley diameters, a smaller number of teeth in

mesh or narrower belts, will reduce the maximum power limits

proportionally.

Design power P

B

(kW) →

Speed of the small pulley nk (min

-1

) →

Graph 3.1: ZRP power ranges

Section

MXL* XL L T2.5 T5(D) T 10(D) T 20*(D)* AT 5* AT10* AT20*

bSt** (mm) 6.4 9.5 25.4 6 25 50 100 25 50 100

v

max

(m/s) 80 60 40 80 60 40 30 60 40 30

* Non stock

** Maximum width using a standard timing belt and a standard pulley

Table 3.4: Maximum standard width and speed

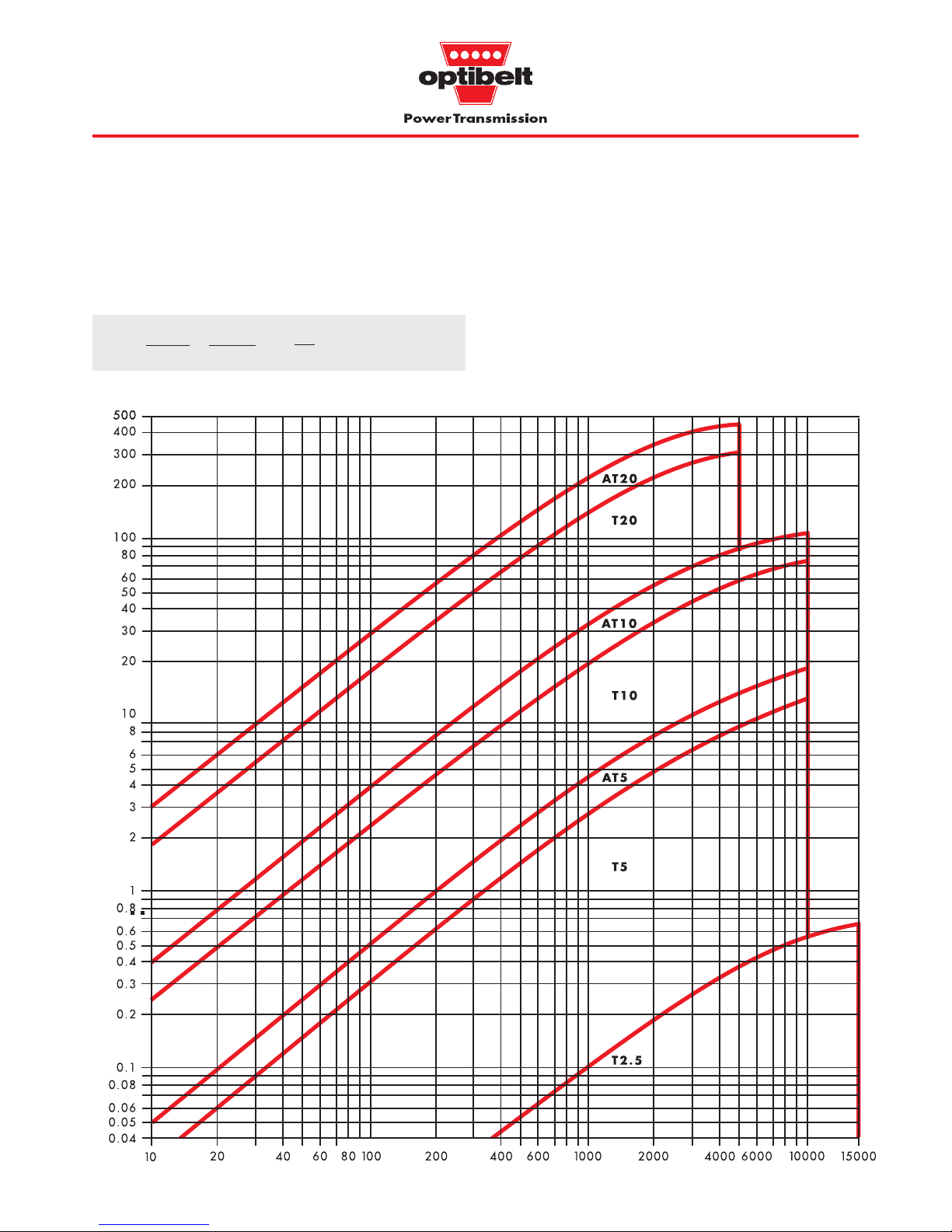

25

The belt speeds given in Table 3.4 should not be exceeded for the

standard drives. For belt speeds close to these maximum values,

increased belt tension is necessary.

3.3 ZRM/ZRP belt selection graphs

Power rating graphs for section selection and maximum belt speeds for

optibelt

ZRM/ZRP timing belts, Z

emax

= 12

The smaller of the two drive pulleys is used for the calculation

irrespective of whether it is used as a driver or a driven pulley.

The values given for the transmissible power P

spez

(W/cm) in Table

3.5, page 25 are based on one tooth in mesh, a 10 mm timing belt

width and one tooth of the small pulley.

These values are not based on the belt tension cord strength, but

on the shear strength of the teeth based on the particular mode of

operation.

Speed of the small pulley n

k

(min

-1

) →

Design power P

B

(kW) →

Graph 3.2: ZRM power ranges

v= =

dw1 · n

1

19100

dw2 · n

2

19100

( )

m

s

26

Prime mover

Prime mover: three-phase squirrel

cage electric motor

Power: PAn= 6.0 kW

Speed: n

1

= 1450 min

-1

Starting torque: MA= 2.0 M

N

Pulley clearance

diameter: as required

Drive width: b

1

, B␣ < 80 mm

Operating conditions

Daily operation: max. 16 hours

Starts/stops: approx.

150 per day

Ambient conditions: standard room

temperature, contact

with cutting oil

Drive centres: a = 410 ± 20 mm

Driven machine

Driven machine: drill

Absorbed power:PAb= 5.0 kW

Driven speed: n

2

= 600 ± 10 min

-1

Start condition: no load

Type of loading: intermittent operation with

average shock loading

Pulley clearance

diameter: < 300 mm

Width: b

1

, B as required

3.4 ZRM/ZRP drive design

Drive calculation for

optibelt

ZRM/ZRP timing belts, Z

emax

= 12

Formulae Calculation example

Design power and belt selection

Total service factor c

2

c2 = c0 + c6 + c

8

Basic service factor c0 Table 2.1, page 12

Pulley and idler factor c

6

Table 2.2, page 13

Start/stop factor c

8

Table 2.2, page 13

c2 = 1.8 + 0 + 0 = 1.8

c

0

= 1.8

c

6

= 0

c

8

= 0

Design power P

B

PB = PAb · c

2

PAb=

If P

Ab

unknown: PB= PAn · c2Formulae page 13

Select section from graph pages 24 and 25 using small pulley

speed n

k

PB = 5.0 · 1.8 = 9.0 kW

Section T10 nk = n1 = 1450 min

-1

Pulleys

For standard pulley ranges see pages 54 to 86,

For pulley materials and fitting see Table 5.3, page 44

T10 for standard pulleys see page 82

Number of teeth z1, z2, pitch diameter dw1, dw2 and

calculation of the drive ratio i

z

1

, dw1 see standard pulley range

z

2

= z1 · ii=

z

2

, dw2 see standard pulley range

Are clearance diameters and permissible sizes acceptable?

Clearance diameter including space to fit belt > da (resp. DB) + 2 · h

s

z1= 25 dw1= 79.58 mm see page 82

z

2

= 25 · 2.42 i = = 2.42

z

2

= 60 dw2= 190.98 mm see page 82

Bore: d

1

from 12 ... 30 mm d2 from 16 ... 60 mm

Clearance diam. >189.1 + 2 · 4.5 198.1 mm < 300 mm, hs see p. 5

1450

600

Driven speed n

2eff

and

drive ratio i eff

n

2eff

=i

eff

=

Pitch length and drive centres with allowances

Drive centres and pulley flange arrangements

0.5 · (D

Bk

+ dwg) + y < a < 2 · (dwg + dwk)

Flanges on small pulley, y

2k

see Table 5.1 page 43

0.5 · (83 + 190.98) + 10 = 147 mm 147 mm < a < 541 mm

L

wth

= 2 · 410 + · (190.98 + 79.58) +

L

wth

= 1252.6 mm

L

wSt

= 1250 mm for Section T10 see page 17

π

2

(dwg – dwk)

2

4 a

(190.98 – 79.58)

2

4 · 410

π

2

MAb · n

2

9550

n1 · z

1

z

2

n

2eff