Page 1

EN-1

CONTENTS

1 INTRODUCTION

1-1 PREPARATION........................................................................................... 1

1-2 PRECAUTIONS .......................................................................................... 1

1-3 PARTS IDENTIFICATION........................................................................... 2

1-4 DETECTION AREA..................................................................................... 2

1-5 INSTALLATION WORK FLOWCHART....................................................... 2

2 MOUNTING TYPE AND ASSEMBLY OPTIONS

2-1 MOUNTING TYPE ...................................................................................... 3

2-2 DISASSEMBLY ........................................................................................... 4

2-3 ASSEMBLY OPTIONS................................................................................ 4

3 BEFORE INSTALLATION

3-1 REMOVING THE FRONT COVER ............................................................. 6

3-2 MOUNTING THE FRONT COVER ............................................................. 6

3-3 REMOVING THE LASER WINDOW ........................................................... 6

3-4 MOUNTING THE LASER WINDOW ........................................................... 6

3-5 WIRING CABLE ENTRY ............................................................................. 6

3-6 INSTALLING NETWORK CABLE ............................................................... 7

4 INSTALLATION AND ANGLE ADJUSTMENT

4-1 WALL OR CEILING MOUNTED.................................................................. 7

4-2 ANGLE ADJUSTMENT ............................................................................... 7

4-3 LASER AREA CONFIRMATION ................................................................. 7

5 PARTS LAYOUT INSIDE AND THEIR FUNCTIONS

5-1 WIRING ....................................................................................................... 8

5-2 PROGRAMMABLE SIGNAL OUTPUT........................................................ 8

5-3 PROGRAMMABLE SIGNAL INPUT (RLS-2020S only) .............................. 8

5-4 ETHERNET PORT (PoE)............................................................................ 8

5-5 MAINTENANCE SECTION ......................................................................... 8

5-6 MAINTENANCE PORT ............................................................................... 8

5-7 POWERING ON .......................................................................................... 8

5-8 INITIALIZATION TO FACTORY DEFAULT ................................................ 8

5-9 LED INDICATOR......................................................................................... 8

6 SETTING

6-1 OVERVIEW ................................................................................................. 9

6-2 DETECTION CONFIGURATION ................................................................ 9

6-4 NETWORK OPTIONS............................................................................... 10

6-5 AUTHENTICATION..................................................................................

. 10

6-6 MAINTENANCE ........................................................................................ 11

6-7 REDWALL EVENT CODE......................................................................... 11

7 DIMENSIONS

7-1 DIMENSIONS............................................................................................ 11

8 SPECIFICATIONS

8-1 SPECIFICATIONS .................................................................................... 11

8-2 OPTIONS .................................................................................................. 12

9 APPENDIX

9-1 REPAINTING ............................................................................................ 12

FEATURES

1

INTRODUCTION

1-1

PREPARATION

• Read this instructions carefully prior to installation.

• This instructions uses the following warning indications to provide information

regarding correct usage of the product to prevent harm and damages to assets.

These warning indications are described below.

Ensure these precautions before reading the rest of this instructions.

Install the product so that the detection

area is not influenced by interference

from tall grass or tree branches waving

in the wind.

Do not install or leave the product in a

location exposed to heat, vibrations or

impacts.

Do not use the product in an

environment where solvent fumes or

corrosive gases are present.

NO. 59-2408-6

INSTALLATION INSTRUCTIONS

Indoor/Outdoor model

Indoor only

RLS-2020S

Laser Scan Detector

Laser Scan Detector

RLS-2020S

RLS-2020

RLS-2020

This symbol indicates prohibition.

The specific prohibited action is provided in and/or around the figure.

This symbol requires an action or gives an instruction.

This product is not a safety component as per the machinery directive.

Do not use it for the purpose of machine safety.

Do not touch the unit base or power terminals of the product with a wet

hand (do not touch when the product is wet with rain, etc.). It may cause

electric shock.

Never attempt to disassemble or repair the product. It may cause fire or

damage to the devices.

Do not exceed the voltage or current rating specified for any of the

terminals, doing so may cause fire or damage to the devices.

Ensure the power is turned off before wiring.

Confirm the type of each terminal to ensure wiring is carried out correctly.

Whenever a commercial switching regulator is used, be sure to connect

PE (Protective Earth Terminal).

Clean and check the product periodically for safe use.

If any problem is found, do not attempt to use the product as it is.

When disposing of this product, be sure to follow the waste-disposal

regulations of the country or region where it is used.

Hold the main unit securely when you install or service it. Exercise care

not to bump the product against nearby objects or drop it inadvertently.

This product is not capable of detecting objects in the dead zone of the

laser scan.

Do not use this product for an application where it is not capable of

covering the detection area required by the task.

Please note that the product can malfunction, including producing an

irregular output and committing a detection error, if it is exposed to

unfavorable environmental conditions such as strong ambient light,

electronic noises or mechanical vibrations.

Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

This product is intended to detect an intruder(s) and is not designed to

prevent theft, disasters or accidents. The manufacturer shall not be held

liable for any damage to user’s property resulting from theft, disasters or

accidents.

Do not use this product in environments where there may be oil mist particles

which may contaminate the window of the detector; thus causing detection errors

and possible corrosion which may lead to product failure.

There should not be any obstructs (e.g. lighting equipment, fire detectors,

cameras, poster, etc.) in the laser area.

After installation, any obstructs should not be carried/moved into the detection area.

• 20 x 20 m (65 x 65 ft.), 95 degrees detection area

• Vertical and Horizontal detection area

• Multi-angle Adjustment Shell Structure (M.A.S.S.)

• Automatic area setting function

• Advanced area setting

• 4 adjustable detection areas on IP connection

• Total 3 outputs can be assigned for analog connection

• Anti-masking, Anti-rotation, Soiling, Device trouble, Tamper output (selectable)

• Paintable housing

• Supporting multiple network protocols

RLS-2020S

• Indoor and Outdoor use

• Indoor high resolution mode

• Indoor throw-in mode

• Area selection

• Environmental disqualification circuit (DQ)

1-2

PRECAUTIONS

mini

The check mark indicates recommendation.

Caution

Warning

EN

(UL) 59-2408-4 1703-01

Failure to follow the instructions provided with this indication and

improper handling may cause death or serious injury.

Failure to follow the instructions provided with this indication and

improper handling may cause injury and/or property damage.

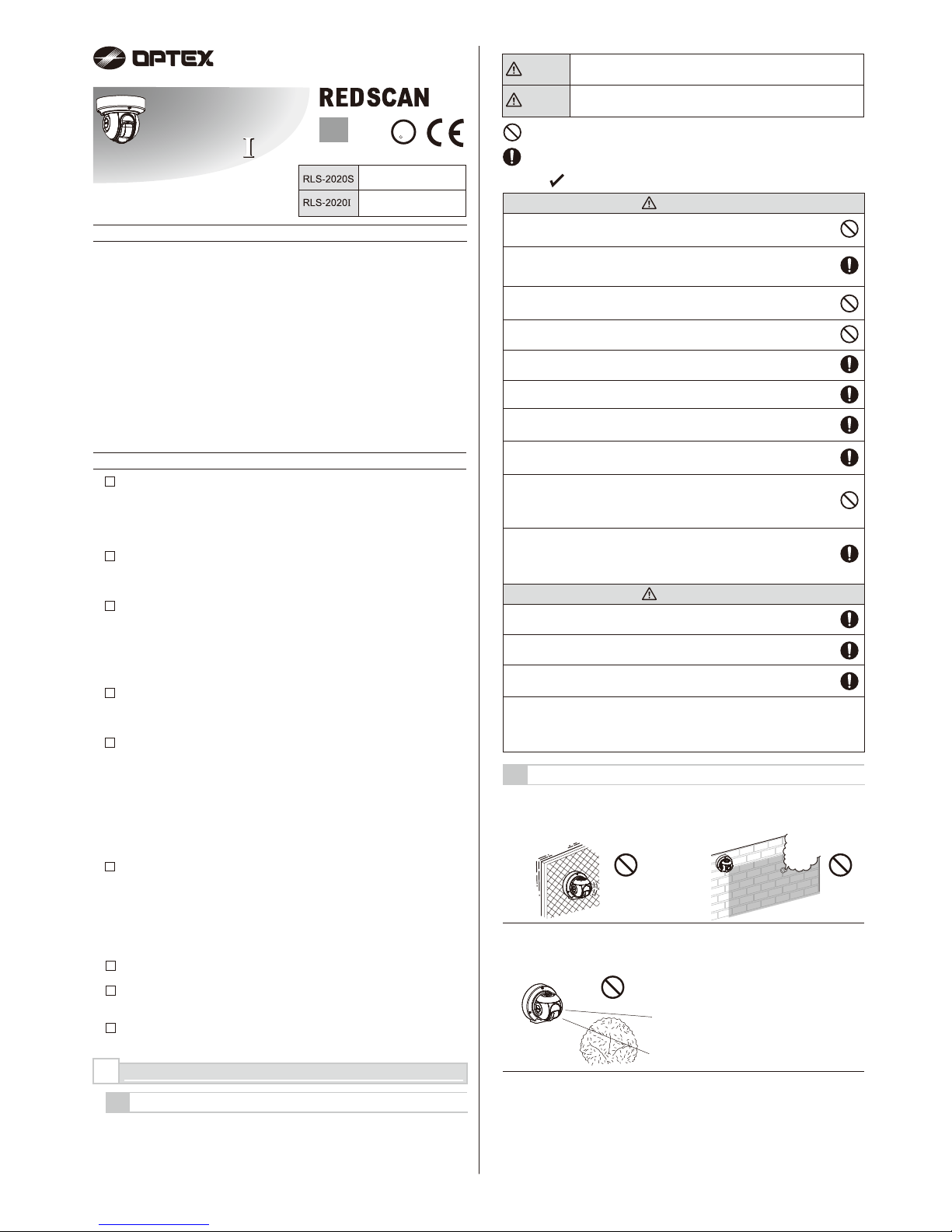

Install the product only on a solid

surface.

Do not install the product on an

uneven surface.

Avoid mounting near vents or devices

which cause high levels of smoke or

condensation.

Warning

Caution

SECURITY

U

L

LISTED

R

6-3 NETWORK CONFIGURATION................................................................. 10

Page 2

EN-2

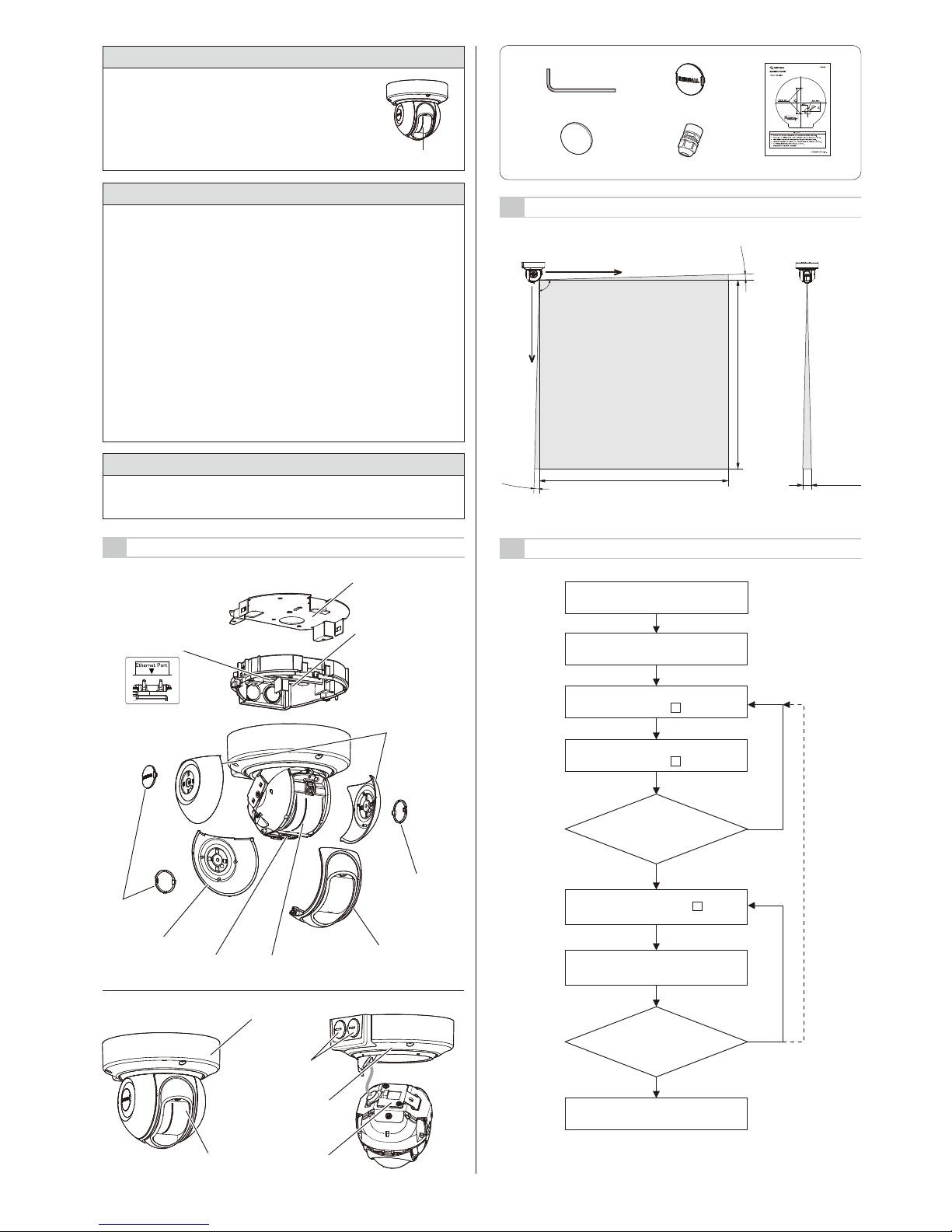

1-5

INSTALLATION WORK FLOWCHART

1-4

DETECTION AREA

1-3

PARTS IDENTIFICATION

Clean the laser window using a damp cloth.

A smeared laser window can limit the detection area due to

the reduced laser sensitivity. In addition, heavy soiling of the

window can induce detection errors.

Cleaning the Product

Laser window

This product is categorized as a Class 1 product in terms of the Safety

Standard.

Average Power : Max. 0.021 mW (AEL)

Wavelength : 905 nm

Pulse Width : 4 ns

Emission period : 35 μs

Standard : IEC 60825-1

Class 1 of the Laser Safety Standard means that the safety of laser products

belonging to this class is warranted under normal operating conditions

(reasonably predictable operating conditions). The product is marked to indicate

that it is laser equipment. No additional safety measures are necessary.

Complies with 21 CFR 1040.10 and 1040.11 except for deviations pursuant to

Laser Notice No.50, dated June 24, 2007.

Class 1 laser product

Do not expose your eyes directly to the laser beam

On Safety of Laser

Warning: This is a class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take

adequate measures. (EN 55032)

CE Statement

Walk-test and confirm

the detection area.

(Refer to 4-3)

Change the assembly option according

to the mounting type. (Refer to 2-2, 2-3)

Mounting and angle adjustment.

(Refer to 4 )

Wiring and Power On

(Refer to 5 )

Laser area confirmation

(Refer to 4-3)

Area setting (Refer to 6 )

Configuration

Completion

OK

OK

NG

NG

Choose the detection area mode and

installation location. (Refer to 2-1)

X

Y

Side view Front view

20 m max.

20 m max.

Approx.

400 mm

90°

2.5°

2.5°

Cable gland: x1

Allen key: x1 Side cover cap: x3

Wall packing: x1

Accessories >>

Paper template: x1

Base

Ethernet port

Mounting bracket

Side cover S

Side cover L

Maintenance port

Front cover

Laser window

Side

cover cap

(Accessories)

Side

cover cap

(Accessories)

Base unit

Main unit

Base cover

Wiring cover

Blanking cap

Page 3

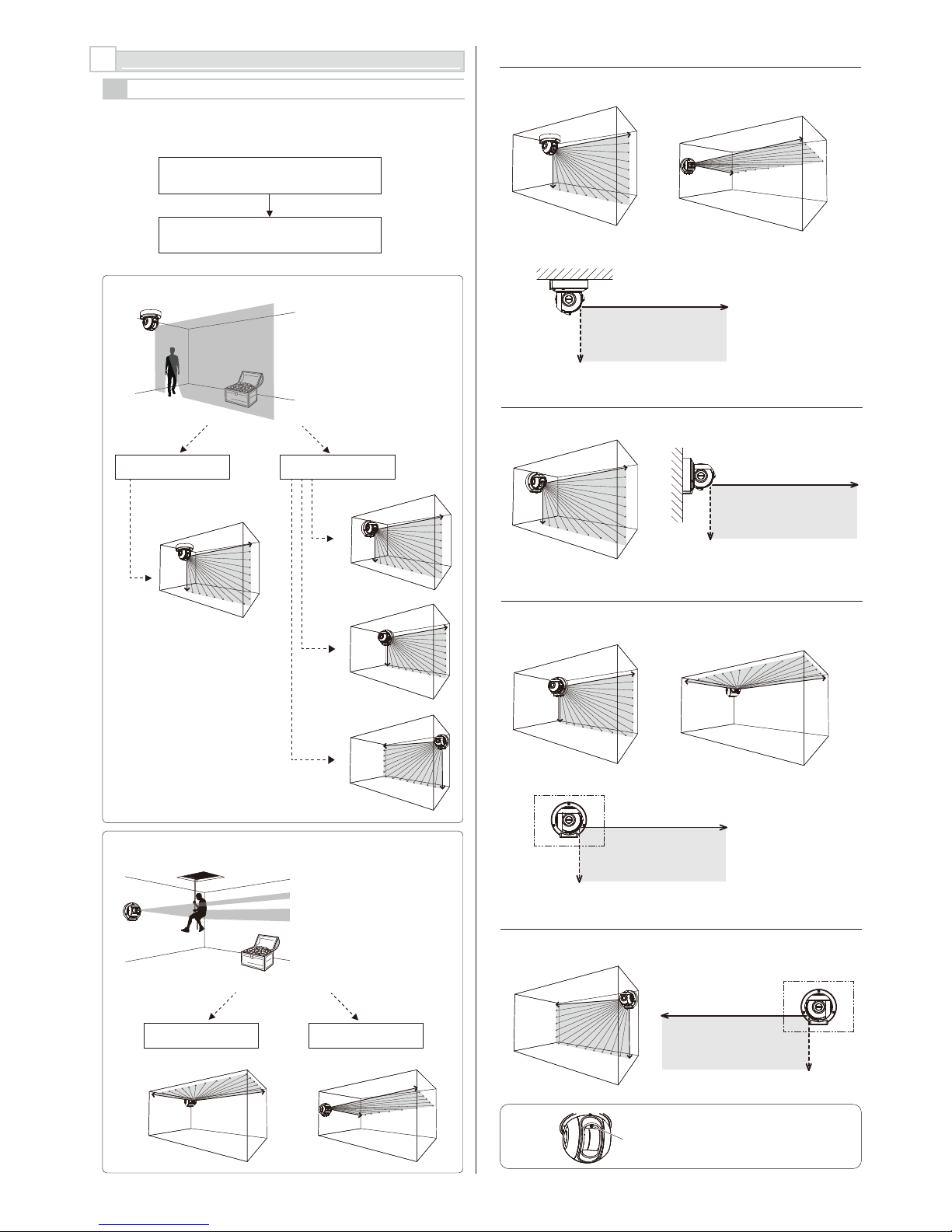

EN-3

-Type C

• Vertical area for wall mount

at the left corner

-Type D

• Vertical area for wall mount at the right corner

X

Y

Mounting surface

X

Y

Mounting surface

X

Y

Mounting surface

• Vertical area for ceiling mount

-Type A

-Type B

• Vertical area for wall mount

X

Y

Mounting surface

Caution >>

Fixing screw of

the front cover

The detection area should cover the

intruders approach.

Which detection area is appropriate,

Vertical or Horizonrtal?

Vertical Detection Area

CEILING MOUNT WALL MOUNT

Type C

Type D

Type B

Type A

Horizontal Detection Area

CEILING MOUNT WALL MOUNT

Type C

Type A

2

MOUNTING TYPE AND ASSEMBLY OPTIONS

2-1

MOUNTING TYPE

RLS-2020 has type A, B, C, and D to be installed.

Select the correct type of assembly to match the installation.

For the vertical detection area to

the mounting surface, be sure that

the fixing screw of the front cover is

placed on top.

The detector can create vertical

detection area.

Protect the asset from intruder who

across the detection area.

The detector can create horizontal

detection area.

Protect the asset from intruder who

across the detection area.

• Horizontal area for wall mount

• Horizontal area for ceiling mount

Detect!

Detect!

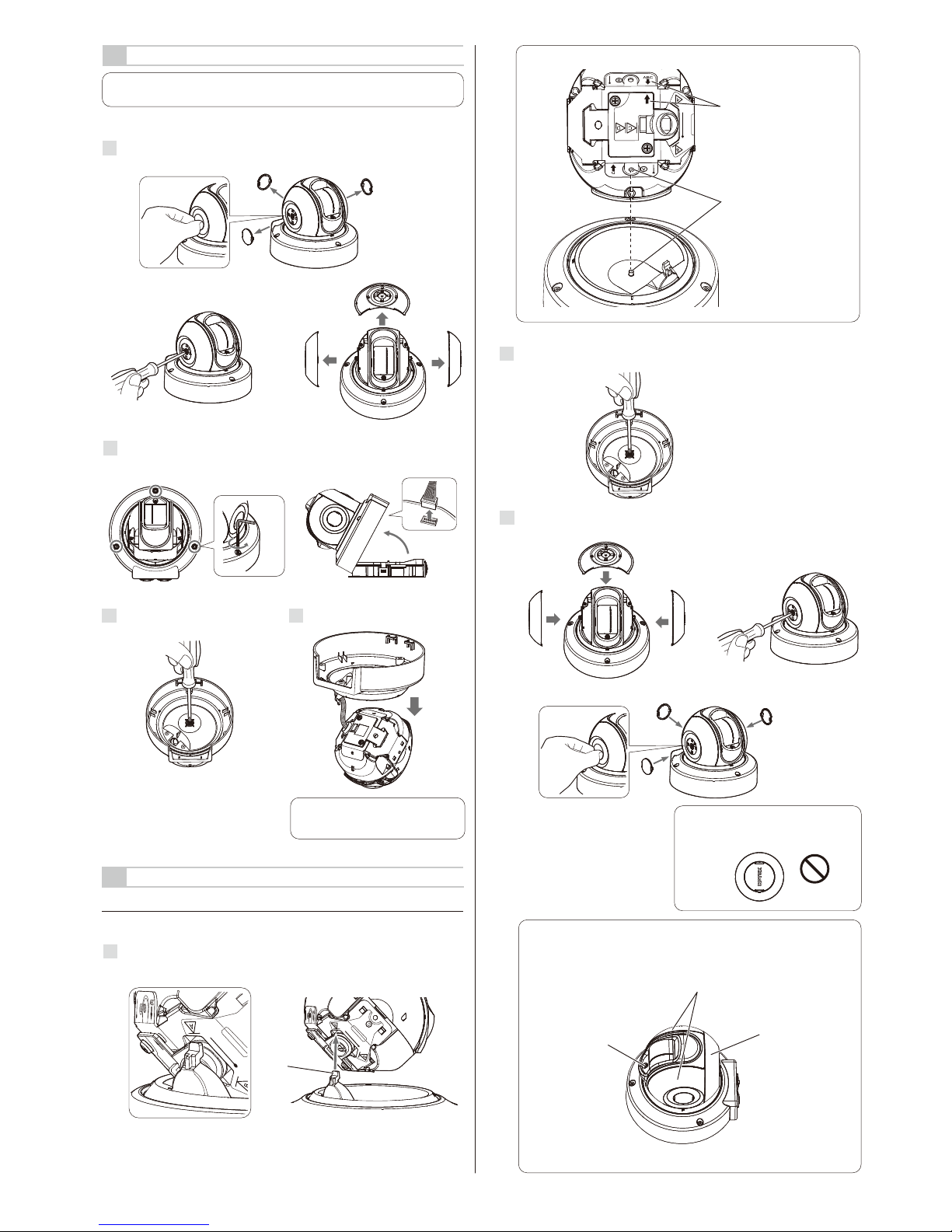

Page 4

EN-4

2-3

ASSEMBLY OPTIONS

Follow the procedure below to return to type A from other mounting types.

-Type A (Default)

1

Rotate the main unit and insert the hook of the base cover into the position

where the letter "A" is written on the wiring cover.

Hook

2-2

DISASSEMBLY

Disassemble the following parts in preparation.

1

Remove the side cover caps, side cover (L) and side covers (S).

2

Loosen 3 screws and remove the base.

3

Turn over the unit and remove the

screw at the center.

4

Remove the base cover.

Caution >>

Do not apply loads to the wiring.

Note >>

1.

2. 3.

Disassembling is not required to use type A. (factory default)

2

Turn over the unit and adjust the position of the screw hole, and tighten the

screw at the center.

3

Mount the side cover L, side cover S and side cover cap.

2.

1.

3.

Note >>

Mount the cover caps and the logo must

be displayed horizontally.

Note >>

1.

2.

Side cover L

Note >>

Before assembling, confirm

the arrow mark on the wiring

cover and the same with

ABC on the main unit face

each other.

Then, place the main unit

on the base unit, so as to

match the screw hole of

the main unit and the one

at the center of the base

cover as indicated.

The positions of the fixing screw and side cover are shown

below.

Fixing screw

Side cover S

Page 5

EN-5

2

-Type D

1

Loosen 2 screws and remove the wiring cover.

2

Rotate the wiring cover by 180 degrees and replace it.

1

Rotate the main unit and insert the hook of the base cover into the position

where the letter "B" is written on the wiring cover.

Note >>

2

Assemble parts just as step 2 to 3 for type A.

-Type C

1

Rotate the main unit and insert the hook of the base cover into the slot of the

wiring cover.

-Type B

Slot of the wiring cover

Hook

Then, place the main unit on

the base unit, so as to match

the screw hole of the main unit

and the one at the center of

the base cover as indicated.

Hook

3

Rotate the main unit and insert the hook of the base cover into the slot of the

wiring cover.

Slot of the wiring cover

Hook

4

Note >>

Then, place the main unit on

the base unit, so as to match

the screw hole of the main unit

and the one at the center of

the base cover as indicated.

Note >>

Note >>

Note >>

Note >>

Then, place the main unit on

the base unit, so as to match

the screw hole of the main unit

and the one at the center of

the base cover as indicated.

Side cover L

Fixing screw

The positions of the fixing screw and side cover are shown

below.

Side cover L

Fixing screw

The positions of the fixing screw and side cover are shown

below.

The positions of the fixing screw and side cover are shown

below.

Assemble parts just as step 2 to 3 for type A.

Assemble parts just as step 2 to 3 for type A.

Side cover S

Side cover S

Side cover L

Fixing screw

Side cover S

Before assembling, confirm

the arrow mark on the wiring

cover and the same with

ABC on the main unit face

each other.

Before assembling, confirm

the arrow mark on the wiring

cover and the same with

ABC on the main unit face

each other.

Before assembling, confirm

the arrow mark on the wiring

cover and the same with D

on the main unit face each

other.

Page 6

EN-6

3

BEFORE INSTALLATION

3-1

REMOVING THE FRONT COVER

Note >>

The procedure to open the front cover is required when connecting the LAN cable to

the maintenance port. (refer to 5-6)

Caution >>

Do not touch the laser window exept it’s frame.

Do not touch inside.

1

Loosen the screw on the front

cover and pull the front cover

forward with a snap.

2

Rotate the front cover at opposite

side of the screw upward and

remove the hooks (x2).

3-2

MOUNTING THE FRONT COVER

1

Snap the front cover into the main

unit.

2

Tighten the screw.

Note >>

The laser window needs to be

removed when pressing the

reset button or replacing it.

Caution >>

Be sure to turn OFF the

power supply when mounting

or removing the laser window.

Caution >>

Be sure to turn OFF the power supply when mounting

or removing the laser window.

3-3

REMOVING THE LASER WINDOW

As shown in the figure below, use the supplied allen key to put out the hook

upward in a leverage motion.

3-4

MOUNTING THE LASER WINDOW

As shown in the figure below, insert the foot of the laser window until it clicks.

3-5

WIRING CABLE ENTRY

Use a screwdriver to open a knockout.

2 wiring holes

Make a slit with a cutter.

-Wiring hole on the back side

Caution >>

Be sure to open a knockout to the

downward direction.

When performing wiring on the

back side, Apply the supplied

packing on the depression on

the back side of base.

Note >>

1. Loosen the screw.

2. Pull the cover

forward.

Tighten the screw.

1. Use the allen key

to remove the

hook.

2. Open it slightly

and then pull

out upward.

-Wiring hole on the side

Remove the blanking caps of the wiring holes on the side using a tool such as a

coin.

1.

2.

1 knockout

1. Insert the hook.

2. Push the unit until it clicks.

Pass the wiring through the slit of

the packing.

Page 7

EN-7

4-2

ANGLE ADJUSTMENT

4-3

LASER AREA CONFIRMATION

It is recommended that the optional Laser Area Checker(LAC-1) is used to

confirm the location of the laser plane.

Check that the laser beams are targeted to the desired areas.

Tips: Two units of LAC-1 (option) can make it easier to confirm

the detection area.

1

Slightly loosen 3 fixing screws.

2

Use the laser area checker to adjust the angle and then tighten

3 fixing screws.

7

Insert the base hook in to the base cover and ensure that the fixing screw

does not jam against the cover.

Close the base cover, and then tighten the 3 screws to fix it.

-Vertical Detection Area

-Horizontal Detection Area

1

Adjust the detector's angle so that

the laser beam hits the farthest

position of the required area and

just the bottom of the detector.

2

Check that the entire area is

covered properly with laser area

checker (option: LAC-1).

Note >>

For detailed instructions refer to the

LAC-1 instruction manual.

Note >>

Align the markings of the base unit and main unit to be the guideline

for the direction of the detection area.

1.

2.

3.

Approx. 4° virtically and horizontally

4

INSTALLATION AND ANGLE ADJUSTMENT

4-1

WALL OR CEILING MOUNTED

Caution >>

Do not supply the power for this unit during wiring.

1

Remove the mounting bracket

from the base, using a tool such

as flathead screwdriver.

Methods for ceiling mounting and wall mounting are the same.

2

Place the supplied paper template

on the mounting surface and open

2 mounting holes.

3

Mount the mounting bracket to the

mounting surface.

Screws to fix the mounting bracket

are not included.

4

Attach the base into the mounting

bracket until it clicks.

5

Perform wiring. (See 5-1.)

6

Connect the base and main unit

with wiring. When the LED at the

side of the relay connecter is ON,

turn OFF the power supply before

connecting them.

Relay connector

Caution >>

The LAN cable with the cover on cannot passes through the cable gland.

Be sure to remove the cover before use.

Caution >>

Do not install the cable gland upward than horizontal line. Doing so may reduce the

waterproof performance.

3-6

INSTALLING NETWORK CABLE

1

Disassemble the cable gland.

2

Pass the Ethernet plug with the correct order and direction. Put the seal from

the side.

Seal

Sensor side

±180°horizontally

Note >>

Pull the base to make sure that the

base is completely attached.

Note >>

Make sure that the arrow points upward

when mounting the detector on the wall.

180° 180°

Note >>

3.5 mm max.

Φ9.5 mm max.

4 mm

/ No.8

Page 8

EN-8

5-2

PROGRAMMABLE SIGNAL OUTPUT

5-3

PROGRAMMABLE SIGNAL INPUT (RLS-2020S only)

The three output terminals can be configured as NO/NC. They

are however fixed as open when the unit is not energized.

The outputs are programmable from options below.

Alarms

• Master alarm (MO)

• Zone alarm

(A1, A2, B1, B2)

Troubles

• Anti-masking (AM)

• Anti-rotation (AR)

• Soiling (SO)

• Environmental disqualification

(DQ)

• Device trouble (TR)

• Tamper output (TA)

5

PARTS LAYOUT INSIDE AND THEIR FUNCTIONS

5-1

WIRING

Inside the base

The length of the power wire

must be less than the figures

listed below.

Stripping length

m (ft)

Wire size

12VDC 24VDC

AWG18

(0.83 mm

2

)

AWG20

(0.52 mm

2

)

30

(100)

AWG16

(1.31 mm

2

)

Strip the cover of the

wiring about 9 mm.

9 mm

Cable

PoE (IEEE802.3 standard)

Cat5e or

above

50

(160)

80

(260)

790

(2590)

1260

(4130)

2000

(6560)

100

(320)

Relay connector

Signal input

(RLS-2020S only)

Signal output 3

Signal output 2

Signal output 1Power supply input

Wall tamper input

Ethernet port (PoE)

5-9

LED INDICATOR

Stand-by

Alarm

Anti-masking

Anti-rotation

Soiling

Environmental

disqualification

(DQ)

Red

Yellow

Green

Blink Light OFF

Detector condition

Warm-up

(apprpx. 60 s)

LED

*

* According to alarm status.

Motor error

Hardware error

Over heat

Others

(not fixed the laser

window properly, etc.)

Trouble condition

LED

Green blinks once. Yellow blinks once.

Green blinks once. Yellow blinks twice.

Green blinks once. Yellow blinks 3 times.

Green blinks once. Yellow blinks 4 times.

x 2

x 3

x 4

Green blinks once. Red blinks once.

Green blinks once. Red blinks twice.

x 2

Green blinks once. Red blinks 3 times.

x 3

Green blinks once. Red blinks 4 times.

x 4

REPEAT

REPEAT

REPEAT

REPEAT

REPEAT

REPEAT

REPEAT

REPEAT

Note >>

Some PoE netwok switches have a limit for wattage. Connect the detectors

to PoE network switches without exceeding the limit referring to their

instructions.

5-8

INITIALIZATION TO FACTORY DEFAULT

5-7

POWERING ON

Enter the DC power to the power supply input terminal.

Or, connect PoE power supply equipment to the ethernet port (PoE)

.

After power on, all the indicators are turned on for approx. 60 seconds and then

the status and alarm indicators are turned off.

During this period, REDSCAN mini itself performs initial settings.

Reset button

1. Turn Off the power supply. Remove

the front cover and laser window.

(refer to 3-1,3-3)

2.

Power On while pressing the reset button.

3. All LEDs turn On. Red LED turns Off

after 50 sec, and green LED turns Off

after 2 sec. And then, release the reset

button.

Yellow LED turns off after 3 sec.

4. Turn Off the power supply.

Attach the laser window and the front

cover. Then, Power On.

* As for wiring for UL application, refer to UL statement on the end of page 11.

5-4

ETHERNET PORT (PoE)

5-5

MAINTENANCE SECTION

The Ethernet port inside the base is for constant

connection. PoE is supported.

LED indicator Maintenance port

Default

IP address : 192.168.0.126

Subnet mask : 255.255.255.0

Default gateway : 192.168.0.1

Note >>

At a maintenance port, Use a light LAN

cable for indoor use. (Do not use the

heavy LAN cable for exterior use.)

This port is for maintenance purpose.

After maintenance, re-assemble the front

cover.

Note >>

Do not use the same subnet for the main Ethernet port and the Maintenance port.

Programmable input can be used for the following functions.

・

Signal Output 1 for confirmation of the function

・

Signal Output 2 for confirmation of the function

・

Signal Output 3 for confirmation of the function

When the signal input is closed, the signal output (1 to 3)

responds as change the status of output. It can be used for

confirmation that the detector is operated properly.

・ Switching to Next Masking / Allocating file

When the signal input is closed, the unit changes Masking/Area

Allocation pattern files. e.g. File 1 to File 2, File 2 to File 3, File 3

to File 4 and File 4 to File 1... It can be used for switching

Masking/Allocation pattern remotely without REDSCAN Manager.

・Area Set

When the signal input is closed, Area set is started.

It can be used for re-creating the detection area without

REDSCAN Manager.

For settings this function, the dedicated software, REDSCAN Manager is required.

If signal input is closed shorter time than the judgement time (Default 1 sec.,

adjustable range 1 to 10 sec), it will be ignored.

5-6

MAINTENANCE PORT

The Ethernet port on the maintenance section is

connected only for initial set-up. Do not use it for

constant connection.

Default

IP address : 192.168.1.126

Subnet mask : 255.255.255.0

Note >>

Do not use the same subnet for the main Ethernet port and the Maintenance port.

*Refer to UL statement

on the end of page11

Page 9

EN-9

The following setting items can be configured. Use pull-down menu or enter a

value. Items that are unavailable for setting are grayed out, depending on a model

or mode.

6-2

DETECTION CONFIGURATION

6-1

OVERVIEW

There are two options to setup the unit with WEB browser for simple setting and

optional setup software, Redscan Manager software for advanced configuration.

This instructions mention for the setting with WEB browser. For setting with

Redscan Manager, please refer to the help of the software.

A web browser can be used to configure the Redscan mini settings.

The ethernet port on the base unit and the maintenance port on the main unit can

be used for configuration.

The main port is for the operation and settings, the maintenance port is for

settings by web browser or REDSCAN Manager.

Recommend web browser: Chrome.

< Default setting >

Main Ethernet port IP address : 192.168.0.126

Subnet Mask : 255.255.255.0

Default gateway : 192.168.0.1

Maintenance port IP address : 192.168.1.126

Subnet Mask : 255.255.255.0

MTU : 1500

ID : REDSCAN

Password : OPTEX

When connected, the start page appears:

Described below are menu displayed on the screen left:

• Output/Input Status

Indicates statuses of the device output/input, REDWALL Event Code and

Soiling ratio of laser window. Outputs can be triggered manually.

.

• Detection Configuration

Configures detection settings.

• Network Configuration

Configures network settings.

• Authentication

Configures user ID and password.

• Maintenance

Shows MAC address and licences. Updates firmware and reboots the unit.

6

SETTING

• Area Set

After installation and angle adjustment of the laser beam, press this button before

starting the setting adjustment. The unit learns background and adjusts detection

area. No human body must enter the area to be configured as a detection area.

Otherwise the area may not be configured properly.

• Area Set Information

To indicate the date of area setting.

• Save Config.

Transfers and saves the setting configured on the browser. Press this button

after configuring the setting.

• Detection Mode

Four modes are available:

[ Indoor mode ] (RLS-2020I and RLS-2020S)

For general indoor applications. (Default)

Can make vertical detection area or horizontal detection area according to the

mounting direction.

[ Outdoor mode ] (RLS-2020S only)

This option can be selected for general outdoor applications.

In this mode, the special algorism works to reduce false alarms by weather

conditions (e.g. rain, snow and fog).

In order to reduce the false alarms under harsh environment, the environmental

resistance function can be set as enable.

[ Indoor high resolution mode ] (RLS-2020S only)

By increasing detection resolution, the unit can detect small object at longer

distance. In regular indoor mode, the resolution is 0.25 degree.

In this high resolution mode, it gets 0.125 degree.

Thus, the same small size object can be detected at the double distance. But,

fastest response time can be within 100 ms in this mode, the unit may not detect

fast movement object. This mode shall be use for only indoor application.

[ Indoor throw-in mode ] (RLS-2020S only)

This mode can work to detect the object which is thrown into the detection area.

Response time is the minimum within 25ms.

This mode shall be use for only indoor application.

• Detection Area

Three options are available:

[ Horizontal ]

Creating a detection area in parallel with the ground, such as ceiling protection.

[ Vertical ]

Creating a detection area perpendicular to the ground, such as wall protection.

[ Auto ] (Default)

For automatic selection by a sensor direction.

• Environmental Resistance (RLS-2020S only)

Erroneous reports under a bad environment such as a fog can be reduced when

outdoor mode is selected.

[ Disable ]

Configure this when a report without a delay is required for an application of

PTZ camera linkage.

This setting may cause an erroneous report under a bad environment such as a

fog or snow.

[ Enable ] (Default)

False alarm due to a fog or snow can be reduced with balanced high detection

ability.

[ Enhanced ]

Reduction of erroneous reports due to a fog or snow can be maximized. It may

result in a longer response time.

In addition, detection may fail under certain environments.

Normal Indoor high resolution

0.25 degree 0.125 degree

*Refer to UL statement on the end of page 11.

• Network Options

Configures network options.

REDSCAN mini Configuration Page RLS-2020 Version. 2.1.0 (07 aug2018)

Output/Input

Status

Detection

Configuration

Network

Configuration

Network Options

Authentication

Maintenance

Area Set

Area Set

Information

Save Config

REDSCAN mini Configuration

Detection Mode

Detection Area

Environmental Resistance

Sensitivity

Minimum Target Size

(Width)

Target Height for Vertival

Area

* Ignoring Area from Ground

Non-Detection Zone for

Vertical Area

* Ignoring Area from Ceiling

Detection Range 1

* For vertical detection area, input “detection length”

* For horizontal detection area, input “detection width”

Detection Range 2

* For vertical detection area, input “detection length”

* For horizontal detection area, input “detection width”

Offset

Length mm, m inch, ft.

Indoor mode

Auto

Disable

H M L Custom

150 msec. (75-9 000 000)

150 mm (10-1 000)

250 mm (1-1 000)

0.1 m (0-20)

20 m (1-20)

20 m (1-20)

100 mm (0-1 000)

REDSCAN mini Configuration Page RLS-2020 Version. 2.1.0 (07 aug2018)

Output/Input

Status

Detection

Configuration

Network

Configuration

Network Options

Authentication

Maintenance

IP Communication

<REDWALL Event Code (R.E.C.)>

Soiling Ratio of Laser Window

0%

Analog Connection <Terminal

Status>

Input

Output1Output2Output3

(S Model Only)

Duration Activating Terminal

sec.

5 (1- Output1 Output2 Output3

1 800)

Page 10

EN-10

IDs and passwords can be changed.

• Change authentication

[ New user ID ] Default : REDSCAN

[ New password ] Default : OPTEX

To reflect the setting, press [Save Config] button to send and save the setting to

the detector.

When losing the ID and password, the detector must be initialized.

(Refer to 5-8 Initialization to factory default.)

6-5

AUTHENTICATION

The unit's main communication port can be configured.

• Network Configuration of Main Ethernet Port

Configuration Type: Default “STATIC”

Select “STATIC” or “DHCP”

IP address: Default 192.168.0.126

Subnet Mask : Default 255.255.255.0

Default gateway : Default 192.168.0.1

MTU : 1500

• Network Configuration of Maintenance Port

IP address : Default 192.168.1.126

Subnet Mask : Default 255.255.255.0

• Event Code Configuration

[ Transmission Mode ] : Can be select from the following option

UDP-Broadcast, UDP-Unicast, TCP, UDP-Broadcast & TCP and

UDP-Unicast & TCP

[ Heartbeat for Device Monitoring ] : Can transmit a device monitoring

code to external devices for alive monitoring ( Default : Off )

[ Destination IP Address and Port number ]

UDP IP Address : Default 192.168.0.1

Port Number : Default 1234

TCP IP Address : Default 192.168.0.1

Port Number : Default 1234

6-3

NETWORK CONFIGURATION

Note >>

For further setting changes (Detection area shape, Area selection and Input/Ouputs

configuration), the optional setup software, Redscan Manager Software can be used.

• Target height for vertical area : Default 250 mm (10 inch.)

Enter 1 to 1,000 mm (0.04 to 40 inch)

• Non-Detection zone for vertical area

Default : Indoor / Indoor high resolution / Indoor throw-in mode 0.1m (0.3 ft),

Outdoor mode 1.5 m (5 ft)

In a vertical detection area, protruding objects on the ceiling can be excluded from the

detection area by disabling the upper part of the area by a specified distance.

Enter a desired length to disable.

The width is narrowed by a specified distance from the front direction from the main unit.

• Detection Range 1 Default : 20 m (65 ft.), 1 to 20 m (3.3 to 65 ft.)

For a vertical detection area, enter a length of an area to be detected. For a

horizontal detection area, enter a width of an area to be detected.

• Detection Range 2 Default : 20 m (65 ft.), 1 to 20 m (3.3 to 65 ft.)

For a vertical detection area, enter a height of an area to be detected. For a

horizontal detection area, enter a depth of an area to be detected.

• Offset Default : 100 mm (4 inch.), 0 to 1,000 mm (0 to 39 inch.)

For a vertical detection area, reflection from the ground or floor can generate noise for

the detector. Also, plants and small animals can cause a false alarm.

An offset can exclude a detect

ion area by a specified distance from the ground or floor.

• Minimum Target Size (Width)

Enter a width of an object to be detected.

(Default value depends on detection mode)

[ Indoor mode ] (Default: 150 mm (6 inch))

Enter 10 to 1,000 mm (0.4 to 40 inch)

[ Outdoor mode ] (Default: 250 mm (10 inch))

Enter 10 to 1,000 mm (0.4 to 40 inch)

[ Indoor high resolution mode ] (Default: 50 mm (2 inch))

Enter 10 to 1,000 mm (0.4 to 40 inch)

[ Indoor throw-in mode ] (Default: 150 mm (6 inch))

Enter 10 to 1,000 mm (0.4 to 40 inch)

Detectable range based on a target size

When configuring a target size smaller than 200 mm ( 8 inch), a distance to detect

an object with the size gets shorter.

• Sensitivity

Can be set from the options, H (High), M (Medium), L (Low), or Custom (Enter

required response time).

[ Indoor mode ] (Default M: 150 ms, H: 75ms, L: 500 ms)

Custom: Can be set from 75 to 900,000 ms (15 min.)

[ Outdoor mode ] (Default M: 150 ms, H: 75 ms, L: 500 ms)

Custom: Can be set from 75 to 900,000 ms (15 min.)

[ Indoor high resolution mode ] (Default M: 200 ms, H: 100 ms, L: 500 ms)

Custom: Can be set 100 to 900,000 ms (15 min.)

[ Indoor throw-in mode ]

Fixed to 0 ms. every scan report alarm.

Indoor/Outdoor/Indor throw-in mode

Target size

25 mm (1 in.)

50 mm (2 in.)

100 mm (4 in.)

150 mm (6 in.)

200 mm (8 in.)

300 mm (12 in.)

Black plate

-

4.0 m (13 ft.)

7.8 m (26 ft.)

11.4 m (37 ft.)

15.0 m (49 ft.)

21.0 m (69 ft.)

White plate

-

5.0 m (16 ft.)

8.8 m (29 ft.)

12.6 m (41 ft.)

16.4 m (54 ft.)

23.4 m (77 ft.)

Indoor high resolution mode

Target size

25 mm (1 in.)

50 mm (2 in.)

100 mm (4 in.)

150 mm (6 in.)

200 mm (8 in.)

300 mm (12 in.)

Black plate

-

4.4 m (14 ft.)

6.9 m (23 ft.)

12.6 m (41 ft.)

17.6 m (58 ft.)

22.0 m (72 ft.)

White plate

-

5.4 m (18 ft.)

8.9 m (29 ft.)

15.8 m (52 ft.)

22.0 m (72 ft.)

28.0 m (92 ft.)

* Reflectivity of Black plate: 10%

* Reflectivity of White plate: 90%

* Detectable range depends on the reflectivity of target and its shape.

Need to confirm the detectable range with actual target at the installation location.

[ Connection test ] : Can confirm the connection to the destination IP address

and port number.

You can configure multiple advanced network protocol options.

Consult your network system administrator when you use these options.

•

Web Server Configuration

Configure Web Server details.

• SNMPConfiguration

Configure SNMP details.

• Discovery

Enable/Disable WsDiscovery.

• DNS Configuration

Configure DNS details.

6-4

NETWORK OPTIONS

REDSCAN mini Configuration Page RLS-2020 Version. 2.1.0 (07 aug2018)

Output/Input

Status

Detection

Configuration

Network

Configuration

Network Options

Authentication

Maintenance

Save Config

Network Configuration of Main Ethernet Port

Configuration Type

IP Address

Subnet Mask

Default Gateway

MTU

Indoor mode

192.168.0.126

255.255.255.0

192.168.0.1

1500 (1000-1500)

Network Configuration of Maintenance Port

IP Address

Subnet Mask

192.168.0.126

255.255.255.0

UDP Broadcast

Event Code Configuration

Transmission Mode

Heartbeat for Device

Monitoring

Detector ID

Use an arbitrary number

Detector ID

UDP

Destination IP Address

Destination Port Number

TCP

Destination IP Address

Destination Port Number

000 (000-999)

192.168.0.1

1234

Connection Test

192.168.0.1

1234

Connection Test

REDSCAN mini Configuration Page RLS-2020 Version. 2.1.0 (07 aug2018)

Output/Input

Status

Detection

Configuration

Network

Configuration

Network Options

Authentication

Maintenance

Save Config

Web Server Configuration

Web Server Protocol

HTTP Port

HTTPS Port

Current Certification

HTTP

80 (0-65535)

443 (0-65535)

RLS-2020

Show Detail Information Show CSR Information

Select CRT Install CRT Create Self-certification

SNMP Configuration

Enable SNMPv1

Enable SNMPv2

Enable SNMPv3

Changes SNMPv3 Authorization

Authorization Method

Encryption

New User ID

New Password

New Password Again

MD5

DES

(Max 32 characters)

(8-12 characters)

(8-12 characters)

Discovery

Enable WsDiscovery

DNS Configuration

DNS Server Address

Domain Name

Primary DNS Server

Secondary DNS Server

STATIC

(Max 243 characters)

0.0.0.0

0.0.0.0

REDSCAN mini Configuration Page RLS-2020 Version. 2.1.0 (07 aug2018)

Output/Input

Status

Detection

Configuration

Network

Configuration

Network Options

Authentication

Maintenance

Save Config

Change Authentication

New User ID

New Password

New Password Again

Valid characters. A-Z/a-z/0-9 (Max 20 characters)

Valid characters. A-Z/a-z/0-9 (Max 20 characters)

Page 11

• Update software

Can update the firmware of the unit. If necessary, click Choose File button to

select the firmware file, and push Update button.

• MAC address

Shows MAC addresses for Main Ethernet Port and Maintenance Port.

• License

Click to show licenses of free open source software.

• Reboot

Can reboot the unit.

6-6

MAINTENANCE

EN-11

7

DIMENSIONS

7-1

DIMENSIONS

8

SPECIFICATIONS

8-1

SPECIFICATIONS

* Specifications and design are subject to change without prior notice.

Model

Installation location

Detection method

Indoor Indoor/Outdoor

Infrared Laser Scan

Laser protection class Class 1

Power input 10.5-30 VDC, PoE (IEEE 802.3af/at compliant)

Ceiling mount, Wall mount, Tripod mount,

Pole mount (Option), Recess mount (Option)

20 ×20 m (approx. 65×65 ft.), 95 degree

Current draw

Detection area

500 mA max. (12 VDC), 250 mA max. (24 VDC),

6 W max. (PoE)

Mounting method

Communication port

Detection range

Radius 1 to 21 m (approx. 3.3 to 68 ft.) at 10% reflectivity

Detection resolution/

Response time

Ethernet RJ-45

10BASE-T/100BASE-TX (Auto negotiation)

Protocol

Output

TCP/IP, UDP/IP, DHCP, DNS, HTTP, HTTPS,

FTP, SNMPv1/v2c/v3, ICMP, ARP

Input

Approx. 2 second delay timer

1 Non-voltage contact input

Alarm period

-40°C to 50°C degree

(-40°F to 122°F degree)

Operating temperature

IP66IP rating

146 × 160 × 160 mm (5.8 ×6.3 ×6.3 inch)Dimensions (H×W×D)

1.0 kg (2.2 Lbs)Weight

0.25 degrees

/ within 75 ms to 1 minute

0.25 degrees

/ within 25 ms to 1 minute

0.125 degrees

/ within 100 ms to 1 minute

(for indoor high resolution mode)

Mounting height

(Vertical mode)

2 m (6.7 ft.) or higher

Indoor: 2 m (6.7 ft.) or higher

Outdoor: 4 m (13 ft.) or higher

(Recommended)

Unit: mm (inch)

83.5

(3.29)

(Single Gang Box)

Φ160

(6.3)

160

(6.3)

146

(5.7)

1/4 -20UNC

84.9

(3.34)

(4’ Electrical Box)

84.9

(3.34)

3 outputs, 28 VDC 0.2 A

max. N.O./N.C. Selectable

(3 from Master alarm, Zone

alarm, Trouble, Tamper)

3 outputs, 28 VDC 0.2 A

max. N.O./N.C. Selectable

(3 from Master alarm, Zone

alarm, Trouble, Tamper, DQ)

< Purpose >

RLS-2020 generates original ASCII event codes which can be used by an NVR or

VMS software to control PTZ cameras and other devices.

< Communication methods >

REDWALL EVENT CODE can be sent to the assigned port using UDP or TCP

protocol. The default port number is “1234”.

< Code format >

6-7

REDWALL EVENT CODE (R.E.C.)

ID number of the RLS-2020 unit consist 6 bytes as follows.

RLS + 3 bytes number (Default number is the last group of the host IP address.)

“RLS126 MO A1 AA CC DQ AR AM TR SO TA”

ID number of

the RLS-2020

Y1

Master

alarm

Y2

Latest

alarm

Y3

Multiple

alarm

Y4

Multiple

alarm

......... Y10

Tamper

Position

Command

Description

Y1 MO/CL

Y2

A1/A2

/B1/B2

Latest alarm.

Y3

AA-BB,

EA-EB,AL

It shows detected areas by 11 patterns. *

Y4 CC

Y10 TA/ta/DM

Tamper circuit activates/ Tamper circuit status is restored

/ “Heart beats” for device monitoring.

Y8 TR/tr Trouble condition / Trouble condition restored.

Y9 SO/so

Soiling on the laser window (Self checking function) /

Soiling on the laser window status is restored.

Y7 AM/am

Anti-masking function activates / Anti-masking status is restored.

Y5 DQ/dq

Environmental disqualification circuit activates

/ Environmental disqualification circuit status is restored.

Y6 AR/ar

Anti-rotation function activates / Anti-rotation status is resotred.

R.E.C.

AA

BB

BA

Ba

bA

ba

B2 B1 A1 A2

R.E.C.

EA

Ea

Eb

EB

AL

B2 B1 A1 A2

* Multiple alarm

Any alarm zone are triggered, Master alarm code, "MO"

code is generated. And, "CL" code is generated 10

seconds after master alarm was cleared.

The time can be changed by setting software.

Multiple alarm.

CC means that there are multiple detected areas.

Note >>

Contact to OPTEX to get more detailed specifications of REDWALL Event Code.

* Refer to UL statement on

the end of page 11.

-40°C to 60°C degree

(-40°F to 140°F degree)

* Refer to UL statement on

the end of page 11.

Update

REDSCAN mini Configuration Page RLS-2020 Version. 2.1.0 (07 aug2018)

Output/Input

Status

Detection

Configuration

Network

Configuration

Network Options

Authentication

Maintenance

Update Software

Select File Not Selected

MAC Address

Main Ethernet Port 00:1f:d1:1d:00:b3

Maintenance Port 00:1f:d1:1d:00:b4

License

Licence

Reboot

Reboot

Show License

Page 12

EN-12

Model/ Name

Place

Serial No.

Date

IP address/

Subnet mask/

Default gateway

Output 1

Output 2

Output 3

Input setting

Mode/

Parameter/

Others

< MEMO >

OPTEX INC./AMERICAS HQ (U.S.)

URL: www.optexamerica.com

OPTEX (EUROPE) LTD./EMEA HQ (U.K.)

URL: www.optex-europe.co m

OPTEX TECHNOLOGIES B.V.

(The Netherlands)

URL: www.optex.eu

OPTEX SECURITY SAS (France)

URL: www.optex-security.com

OPTEX SECURITY Sp.z o.o. (Poland)

URL: www.optex.com.pl

OPTEX PINNACLE INDIA,

PVT., LTD. (India)

URL: www.optex.net/in/en/sec

OPTEX KOREA CO.,LTD. (Korea)

URL: www.optexkorea.com

OPTEX (DONGGUAN) CO.,LTD.

SHANGHAI OFFICE (China)

URL: www.optexchina.com

OPTEX (Thailand) CO., LTD. (Thailand)

URL: www.optex.net/th/th

Copyri ght (C) 2018 OPTEX CO.,LTD.

OPTEX CO., LTD. (JAPAN)

URL: www.optex.net

■ EU contact information

Manufa cturer:

OPTE X CO., LTD.

5- 8-12 Ogoto, Ot su, Shiga ,

520- 0101 JAPAN

Author ised re prese ntative i n Europ e:

OPTE X (EUROPE) LTD./EME A HEADQUART ERS

Unit 13, Cord wallis Par k, Clivem ont Road,

Maiden head Berks hire, SL6 7BU U. K.

Remove the side cover cap, side cover L and side

cover Ss. (refer to 2-2 1 )

Remove the base cover. (refer to 2-2 2 3 4 )

Remove the front cover. (refer to 3-1)

Paint the following parts. (refer to marks as follows)

Use the suitable paint for poly-carbonate resin.

Note >>

Do not paint the front cover, the laser window or the base unit.

Painting the RLS-2020 S a dark color could raise the internal

temperature and cause a malfunction.

Painting should be avoided if there is any possibility that

the unit would be exposed to direct sunlight.

9

APPENDIX

9-1

REPAINTING

1

2

3

4

Note >>

Be careful not to lose the removed washer.

1.

2.

3.

8-2

OPTIONS

LAC-1 : Laser area checker

RLS-PB : Pole mounting bracket

RLS-RB : Recessed mount kit

RLS-LW : REDSCAN mini laser window

- In case of using DC power supply

UL required the main unit to be connected to a UL listed PoE injector or switch

and the PoE must be connected to a UL listed (UTRZ) UPS with output rating of

100-240 VAC, 1.0 A and 24 hours standby.

UL Statement

- For UL Listed installation applications

The relay outputs shall be connected to a compatible UL Listed control panel.

The equipment shall be installed in accordance with the National Electrical Code

NFPA 70.

- UL testing was conduted at temperature range of

0°C to 49°C for RLS-2020I, and -35°C to 66°C for RLS-2020S.

UL required the main unit to be connected to a UL listed power supply Class 2,

capable of providing a norminal input of 10.5-30 VDC 500 mA and battery standby

time of 4 hours.

- In case of using PoE injector or switch for power supply

UL testing was conducted with product powered from the following Listed POE:

Manufacturer: PHIHONG, Model: POE36U-1AT-R, Input: 100-240 VAC, 1.0 A, Output: 56 V - 0.6 A

UL approved the PoE connection as supplemental.

The PoE cannot be used to monitor the device.

- UL approved indoor modeandoutdoormodeonly.

Indoor high resolution mode and Indoor throw-in mode has not evaluated by UL.

The signal input cannot be connected to alarm output to reduce the risk of

false alarm.

EN 50131-1 Grades and Environmental Class:

Security Grade 3, Environment ClassII TS50131-2-11

Loading...

Loading...