Optex Prosafe OA-1V, Prosafe OA-2VF, Prosafe OA-205V-1, Prosafe OA-2V, Prosafe OA-205V-2 Operation Manual

Page 1

12345678

ON

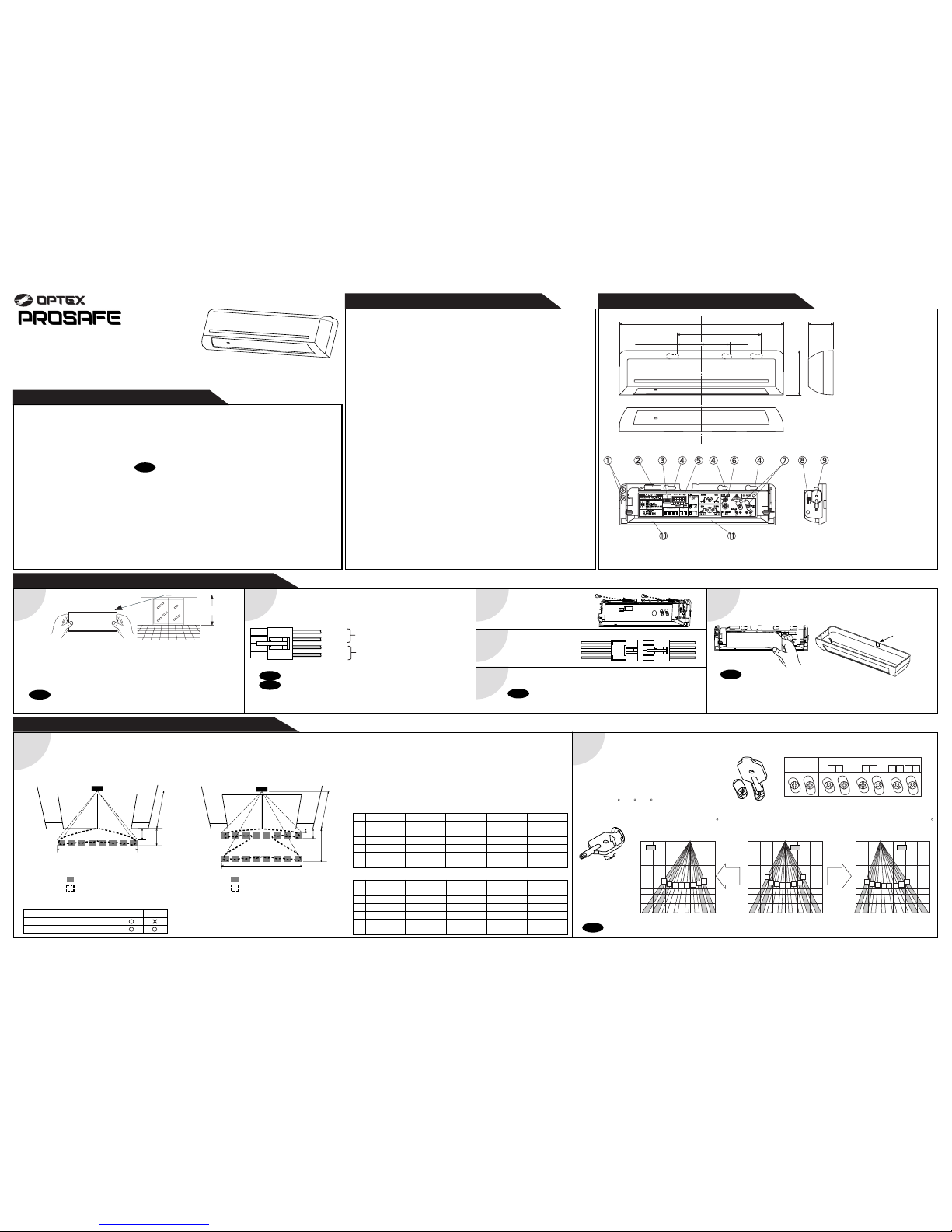

245 ( 9 5/8" )

125 ( 4 15/16" )

36 ( 1 7/16" )

68 ( 2 11/16" )

37 ( 1 7/16" )

43 ( 1 11/16" )

01.0m 1.0m 2.0m

3.0m

2.8m

2.6m

2.4m

2.2m

2.0m

1.0m

3.0m

2.8m

2.6m

2.4m

2.2m

2.0m

1.0m

01.0m2.0m 1.0m

3.0m

2.8m

2.6m

2.4m

2.2m

2.0m

1.0m

01.0m 1.0m

18

2

7

3

6

45

1

2

3

4

8

7

6

5

7

6

45

1

2

3

8

MANUFACTURER’S STATEMENT

Read this Operation Manual carefully before use, to ensure proper operation of this Optex sensor.

Failure to read this Operation Manual may cause improper sensor operation and may result in

serious injury or death. This product is a non-contact activating switch intended for mounting on the

header of an automatic door. Do not use it for any other applications; otherwise proper operation

and safety cannot be guaranteed.

Cautions:

1.

Follow the instructions (especially Note ) in this Operation Manual when installing and

adjusting the sensor.

2. When setting the sensor's area pattern, make sure there is no traffic around the installation site.

3. Before turning the power on, check the wiring to prevent damage or malfunction of equipment

that is connected to the sensor.

4. Do not wash, disassemble, rebuild or repair the sensor by yourself; otherwise it may cause

electric shock or breakdown of the sensor.

5. Only use the sensor as specified in the supplied instructions.

6. Be sure to install the sensor in accordance with the local laws and standards of your country.

7. Before leaving the jobsite, be sure that this sensor is operating properly and instruct the

building owner/operator on proper operation of the door and this sensor.

1 : Mounting Screws

2 : Connector

3 : Sensitivity Switch

4 : Mounting holes

5 : Dipswitches

6 : Area Adjustment Screw

7 : Width Adjustment Shutters

8 : Base Angle Scale

9 : Area Adjustment Tool

10: Operation Indicator

11: Detection Window

mm (inch)

*The specifications herein are subject to change without prior notice due

to improvements.

Model

Cover color type

Mounting Height

Detection Area

Detection Method

Detection Angle

Adjustments

Detection Width

Adjustments

Power Supply

Current Draw

Power Consumption

Operation Indicator

Output

Relay Hold Time

Response Time

Operating Temperature

Weight

Accessories

:

OA-1V / OA-2V / OA-2VF / OA-205V-1 / OA-205V-2

: Silver / Black

: 2.0m (6’6”) to 3.0m (9’10”)

: See “ADJUSTMENT - 1. Detection Area”

: Active Infrared Reflection Method

: Base Angle: -2° to 10° for OA-1V/OA-205V-1

0° to 10° for OA-2V/2VF/OA-205V-2

Adjustment Screw Angle: ±4° adjustable by 1°

every one click (Deep / Shallow)

: Adjustment Screw Angle: ±7° adjustable by 3.5°

every one click (Right / Left)

: 12 to 110V AC / DC (50/60Hz)

: 160mA Max. (at 12V AC)

: 4.0VA Max. (at 100V AC)

: Green / Stand-by

Red / 1st Row Detection Active

Orange / 2nd Row Detection Active

(OA-1V/OA-205V-1 has no 2nd Row.)

: “Form A” relay 50V 0.1A Max. (Resistance Load)

: 0.5 sec.

: < 0.3 sec.

: -20°C to +55°C (-4°F to +131°F)

: 230g (8.2oz)

: 1 Cable 3m (9’10”), 2 Mounting Screws

1 Operation Manual, 1 Mounting Template

1 Area Adjustment Tool, 1 Protection sheet

5

4

32

INSTALLATION

1. Affix the Mounting Template to the mounting surface.

2. Drill two mounting holes (ø 3.4mm or 1/8”).

3. To carry through the wire to the header, drill a wiring hole

(ø 8mm or 5/16”).

4. After drilling the holes, remove the Mounting Template.

Note Be sure that the mounting height is within the value

of those in "SPECIFICATIONS."

Remove the cover

and attach the

sensor with screws.

Plug the Connector

for the sensor to

that for the cable.

Supply power to the sensor. Adjust the detection area and

set the various Switches. (See “ADJUSTMENT.”)

Note Make sure that you connect the cable correctly to the

Control Unit of the door before turning the power on.

1.Stick a protection sheet on the sensor.

2. Put back the cover on the sensor.

3. If wiring is to be exposed, break the Knockout.

Yellow Output : “Form A” relay

Yellow 50V 0.1A Max. (Resistance Load)

Grey Power Supply

Grey 12 to 110V AC / DC (50/60Hz)

Note Connect the cable when main power is turned off.

Note When passing through the cable to the hole, make sure

not to tear shield: otherwise it may cause electric shock

or breakdown of sensor.

6

Note

Do not use the sensor without the cover. Install the sensor indoors

, or use the rain-cover (Optional), when using the Knockout,

otherwise it may cause electric shock or breakdown of sensor.

The cable is arranged to connect to the door controller

properly as shown below.

Adjusting the Pattern Width

Pattern when changed 7

to Left

Pattern when Standard

ADJUSTMENT

: Erasable

Area

: Erasable

Area

Setting the Width

adjustment shutters

Adjusting the Width Angle Left or Right :

between 0 to 7 (3.5 per click)

1278

78

12

to Right

A 2.00 2.20 2.50 2.70 3.00

*The values of the chart blow is of the Emitting Spots, but not of

the Detection Area.

The actual Detection Area may become smaller depending on

the ambiance light and the colour / material of object and the

floor as well as the entry speed of object.

[m]

After adjustment, turn the power off and on again, be sure to walktest all of detection areas.

Detection Area

2

1st Row

2nd Row

OA-1V/OA-205V-1

OA-2V/OA-2VF/OA-205V-2

C

D

A

F

E

A

B

G

SPECIFICATIONS OUTER DIMENSIONS

5911961 2005.07

1

1

1st Row

to Left

[m]

: Detection Area

: Emitting Spots

B

: Detection Area

: Emitting Spots

Pattern when changed 7

to Right

Note Setting the pattern for exact door opening may give a slow response to side approaching traffic.

Presence Detection

Motion Detection

Provided Detection Row type 1st 2nd

: Erasable

Area

Knockout

Mounting

Template

2m to 3m

( 6’6" to 9’10")

F 0.27 0.29 0.33 0.36 0.40

B 2.10 2.30 2.60 2.80 3.10

C 0.73 0.80 0.91 0.98 1.09

D 0.85 0.93 1.06 1.14 1.27

E 0.16 0.18 0.20 0.22 0.25

G 1.34 1.47 1.68 1.81 2.01

Eliminate Eliminate Eliminate

Opens

All Areas

to

Left

to

Right

OA-2VF does not have 1st Row Spots

during stand-by.

Refer to "4-Setting of Dipswitches" in detail.

Area arrangement changes with models. Please adjust after taking into consideration.

OA-1V OA-205V-1

OA-2V OA-205V-2

OA-2VF

Base Angle: 0°, Adjustment Screw Angle: 0°

Base Angle: 10°, Adjustment Screw Angle: 0°

A 2.00 2.20 2.50 2.70 3.00

C 1.25 1.38 1.56 1.69 1.88

D 1.41 1.55 1.76 1.90 2.12

E 0.51 0.56 0.64 0.69 0.77

F 0.65 0.72 0.81 0.88 0.98

G 2.05 2.26 2.56 2.77 3.08

B 2.40 2.64 3.00 3.24 3.60

Page 2

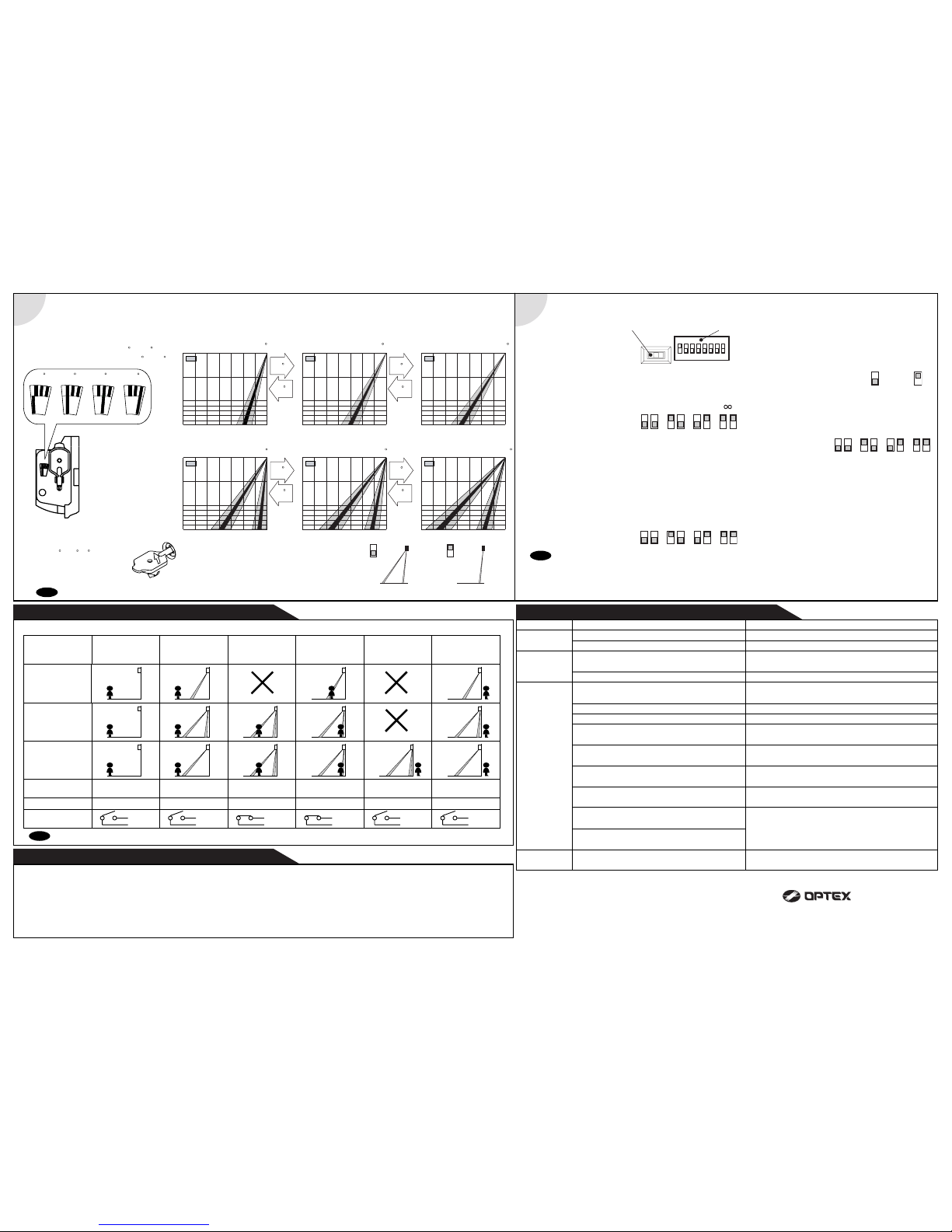

03.0m 2.0m 1.0m

3.0m

2.8m

2.6m

2.4m

2.2m

2.0m

1.0m

03.0m 2.0m 1.0m

3.0m

2.8m

2.6m

2.4m

2.2m

2.0m

1.0m

03.0m 2.0m 1.0m

3.0m

2.8m

2.6m

2.4m

2.2m

2.0m

1.0m

03.0m 2.0m 1.0m

3.0m

2.8m

2.6m

2.4m

2.2m

2.0m

1.0m

03.0m 2.0m 1.0m

3.0m

2.8m

2.6m

2.4m

2.2m

2.0m

1.0m

03.0m 2.0m 1.0m

3.0m

2.8m

2.6m

2.4m

2.2m

2.0m

1.0m

3

3. Setting the Row with the

Dipswitch 8

(for only OA-2V/OA-205V-2).

Pattern when Base Angle 10

Adjusting the Pattern Depth

Setting the Sensitivity

Normally set to “M.”

“H” increases the sensitivity and “L” lowers the sensitivity.

Setting the Presence timer

1st Row from door provide

the presence detection.

(1) Select the presence timer.

(2) Turn the power off and on again. Otherwise it may leave

door open for the duration of the presence time set.

(3) After making sure that the door closes, wait for 10

seconds before entering the detection area to set the

Presence timer.

Setting the Frequency Function

(Interference Prevention)

Four different frequencies

can be set by adjusting

the Dipswitch 3 and 4.

Note

When two or more sensors are installed close to each other,

it is possible that they interfere. When that happens,

change the Frequency.

Setting the immunity mode

Set the Dipswitch5 if the

sensor is used in a region

with snow or a lot of insects.

2. Setting the Depth Angle

between -4

to 4 (1 per click)

by Adjustment Screw.

Shallow

Depth

Setting the 1st Row detectable timer

(For only OA-2VF)

Select the 1st Row

detection time

by adjusting the

Dipswitch 7 and 8.

Note The door may close when this sensor broke down.

Entry motion

Power OFF

Outside the

Detection area

OA-1V

OA-205V-1

(image)

Sensor status

Power OFF Stand-by

Motion Detection

Active

Entry into 2nd Row Entry into 1st Row

Outside the

Detection area

Motion or Presence

Detection Active

Stand-by

Orange Red Green

Output

Operation indicator

GreenOFF

Yellow

Yellow

CHECKING

Check the operation according to the chart below.

TROUBLESHOOTING

Inform the following items to the building owner/operator

1. When turning the power on, always walk-test the sensor pattern to ensure proper operation.

2. Always keep the detection window clean. If dirty, wipe the window with a damp cloth. (Do not use any cleaner or solvent.)

3. Do not wash the sensor with water.

4. Do not disassemble, rebuild or repair the sensor yourself; otherwise electric shock may occur.

5. Contact your installer or the sales engineer if you want to change the settings.

6. Do not place an object that moves or emits light in the detection area. (Ex. Plant, illumination, etc.)

7. Do not paint the Detection Window.

Contact your installer or the sales engineer if:

- you need to change the settings or replace the sensor.

- the trouble still persists after checking and remedying as described above.

Does not

operate

Dose not

operate

consistently

Operates by

itself

(Ghosting)

Power supply is not adequate.

Connection Failure.

Dirty detection window.

Sensitivity is Low.

There is an object that moves or emits light in the

detection area. (Ex. Plant, illumination, etc.)

Vibration of the header.

Sensitivity is high.

Waterdrops on detection window.

Detection area has interfered the area of another

sensor.

The detection 1st row spots are overlapping with

the door / header.

Door stay open

or closed

There is an reflected object in the detection area.

Solar light reflects.

Presence timer is Infinity. There was an abrupt

condition change in the detection area.

Adjust to stated voltage.

Check the wiring and the connector.

Wipe the detection window with a damp cloth. (Do not

use any cleaner or solvent.)

Set the Sensitivity Switch “H.”

Set the Sensitivity Switch “L.”

Remove the object.

Remove the object.

Secure the header. Or set the Sensitivity Switch “L.”

Install in a place keeping the waterdrops off. OR

use a rain-cover (Optional).

Set the different frequency position each other.

Adjust the detection area to deep (outside).

Turn the power off and on again.

Trouble Possible Cause Solution

There was a puddle left by rain or snow.

The floor has gotten wet.

The exhaust of the car and the fog penetrate into the

detection area.

This sensor is equipped with the anti-malfunction.

However, pay attention when installing as malfunction

may occur under the left conditions.

OPTEX CO., LTD.

(ISO 9001 Certified by LRQA)

5-8-12 Ogoto Otsu 520-0101, Japan

TEL.: +81 (0)77-579-8700 FAX: +81 (0)77-579-7030

WEBSITE: www.optex.co.jp

4

Setting of Sensitivity Switch and Dipswitches

Sensitivity Switch Dipswitches

1 2 3 4 5 6 7 8

ON

L M H

12

12

12

12

34

34

34

34

78

78

78

78

Depth angle can be set up by two kinds, a base and an adjustment screw.

1. Setting the Base Angle.

OA-1V/OA-205V-1: between -2

to 10 .

OA-2V/2VF/OA-205V-2: between 0 to 10 .

Pattern when Base Angle 5

Pattern when Base Angle -2

+5

-5

:Adjustable Area

by Adjustment

Screw ±4°

8

8

-2 0

5

10

2ROW

1ROW

:Adjustable Area

by Adjustment

Screw ±4°

:Adjustable Area

by Adjustment

Screw ±4°

:Adjustable Area

by Adjustment

Screw ±4°

:Adjustable Area

by Adjustment

Screw ±4°

:Adjustable Area

by Adjustment

Screw ±4°

+7

-7

+5

-5

+5

-5

OA-2V

OA-205V-2

(image)

OA-2VF

(image)

During 1st Row

detectable time ,after

leaving the Detection

area

Green

1st Row detectable Stand-by

Pattern when Base Angle 10

Pattern when Base Angle 5 Pattern when Base Angle 0

OA-1V/OA-205V-1

OA-2V/OA-2VF/OA-205V-2

Yellow

Yellow

Yellow

Yellow

Yellow

Yellow

Yellow

Yellow

Yellow

Yellow

5

5

Normal Immunity

2sec. 15sec. 180sec.

5sec. 10sec. 15sec. 20sec.

Position Position Position Position

1 2 3 4

Note Be aware of non-detection area by the door-rail when moving the emitting spots forward too much for deeper approach.

OA-2VF does not have 1st Row spots during

stand-by. Immediately after 2nd Row spots detects,

1st Row spots appear till the 1st Row detection time

set up.

When entry into 1st Row spots or 2nd Row spots

within 1st Row detection time, even if setting time

passes, 1st Row spots continue existing.

After leaving area, and passing 1st Row detection

time, 1st ROW spots are lost again.

Loading...

Loading...