Page 1

OVS-6000

ENGLISH

MANUFACTURER'S STATEMENT

Read this installation instructions carefully before use to ensure proper operation of this product.

Failure to read this operation manual may cause improper operation and may result in serious injury or death of

a person.The meanings of the symbols are as follows.

5924371 FEB 2016

WARNING

CAUTION

NOTE

NOTE

1. This product is a non-contact switch intended for header mount or wall mount for vehicle detection.

Do not use for any other applications.

2. When setting the sensor's detection area, make sure that there is no traffic around the installation site.

3. Before turning the power ON, check the wiring to prevent damage or malfunction of equipment connected to

the product.

4. Only use the product as specified in the operation manual provided.

5. Be sure to install and adjust the sensor in accordance with the local laws and standards of the country in which

the product is installed.

6. Before leaving the installation site make sure that the product is operating properly and instruct the building

owner/operator on proper operation of the product.

7.The product settings can only be changed by an installer or service engineer. When changed, the

changed settings and the date shall be registered in the maintenance logbook.

Danger of electric shock

Disregard of the warning symbol can cause improper operation which may cause death

or serious injury.

Disregard of the caution symbol can cause improper operation which may cause injury of a

person or damage the object.

Special attention is required to the section of this symbol.

It is required to check the operation manual if this symbol is shown on the product.

WARNING

Do not wash, disassemble, rebuild or repair the sensor, otherwise

it may cause electric shock or breakdown of the equipment.

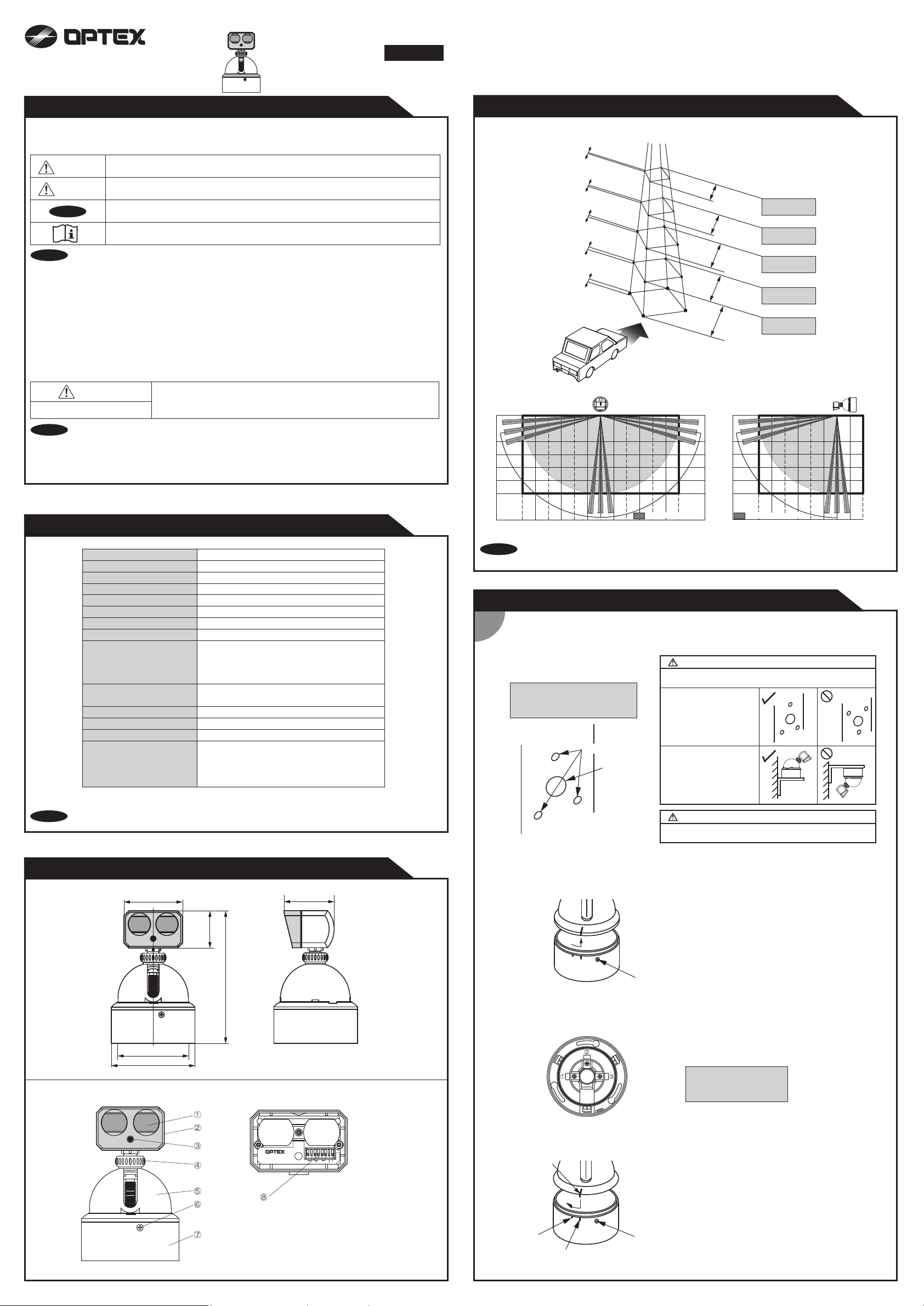

DETECTION AREA

3 15/16"

(100)

5 7/8"

(150)

7 7/8"

(200)

9 13/16"

(250)

11 13/16"

(300)

FRONT VIEW SIDE VIEW

1'4 9/16"

(420)

2' 13/16"

(630)

2' 9 1/16"

(840)

3' 5 5/16"

(1050)

4' 1 5/8"

(1260)

6' 6 3/4"(2m)

9' 10 1/8"(3m)

13' 1 1/2"(4m)

16' 4 7/8"(5m)

19' 8 1/2"(6m)

[feet, inch(mm)]

NOTE

The following conditions are not suitable for sensor installation.

-Fog or exhaust emission around the detection area

-Wet floor

-Vibrating header or mounting surface

-Moving objects, steel plate, emergency lights or illumination in the detection area or in vicinity

-Highly reflecting floor or highly reflecting objects around the detection area

SPECIFICATIONS

Detection range

Detection method

Detection range (Vertical)

Detection range (Right & Left)

Detection range (right & left)

Power supply

Power consumption < 2.5W (24VDC)

Current consumption

Operation indicator

Output

Relay hold time

Operating temperature

Weight

Accessories 1 Operation manual

OVS-6000Model

6' 6 3/4" to 19' 8 1/2" (2.0 to 6.0m)

Active infrared reflection method

-80° to +80° (Deep/Shallow)

360°

24VDC

< 105mA (24VDC)

Stand-by

Detection(Only one area)

Detection(Any areas)

Infinite detection

: LED ON

: LED OFF

: LED Slow Blinking

: LED Fast Blinking

"Form A" relay 100VAC 1A

30VDC 0.1A Max.

Approx. 1.0sec.

-4 to 131°F (-20 to +55°C)

290g (10.2oz)

2 Mounting screws

1 Mounting template

1 Cable 9'10"(3m)

9' 10 1/8"

NOTE

16' 4 7/8"

(5m)

The actual detection area may become smaller depending on the ambient light, the color / material of

the object or the floor as well as the entry speed of the object.

(3m)

3' 9/32"

(1m)

INSTALLATION

Install Sensor

1

(1-1) Drill three mounting holes.

Affix the mounting template put “up side”

sign up and make holes. Drill a wiring hole

when you pass the cable into the wall.

・Mounting screw holes : ø1/8"(3.3mm)

(Three positions)

・Wiring hole : ø19/32"(15mm)

(One in center)

Mounting screw holes

3' 9/32"

0

(1m)

Wiring holes

: Actual detection area

9' 10 1/8"

16' 4 7/8"

(3m)

6' 6 3/4"

(2m)

9' 10 1/8"

(3m)

13' 1 1/2"

(4m)

16' 4 7/8"

(5m)

19' 8 1/2"

(6m)

:

Actual detection area

16' 4 7/8"

(5m)

(5m)

CAUTION : Risk of product failure.

Do not install sensors upside down.

Otherwise rain water makestroubles.

Right position of the

mounting screw holes when

install on the side pole.

Right sensor position

whenuse a angle.

9' 10 1/8"

(3m)

3' 9/32"

(1m)

3' 9/32"

0

(1m)

6' 6 3/4"

(2m)

9' 10 1/8"

(3m)

13' 1 1/2"

(4m)

16' 4 7/8"

(5m)

19' 8 1/2"

(6m)

NOTE

The specifications herein are subject to change without prior notice due to improvements.

OUTER DIMENSIONS AND PART NAMES

OVS-6000

2 3/4"(70)

Mounting pitch ø85 (x3)

ø100

"

44.5)

1 3/4

(

6 1/4"(158.5)

Without sensor head cover

2 3/4"(70)

[inch(mm)]

WARNING : Danger of electric shock.

Make sure to remove burr in mounting holes otherwise

damaged cable may cause electric shock.

(1-2) Put attached screws into mounting holes temporary.

(1-3) Break off basement from sensor unit.

Sensor

Basement

Lock screw

(1-4) Set basement onto temporary screws of (1-2)

(1-5) Wiring onto basement (refer to 3-1)

Wiring should be allowed sign of basement.

① Power supply ••• Red

② GND ••• Black

③ Signal ••• White

(1-6) Set sensor unit on basement.

1, Loose the lock screw of basement full well.

2, Basement can break off when rotate anticlockwise.

OVS-6000

Operation

indicator

Presence Sensitivity

Frequency Indicator

On delay

① Detection window

② Sensor head

③ LED indicator

Sensor adjust

joint mark

Sensor

Basement

1, Push sensor unit onto basement adjust joint mark.

2, Rotate sensor clockwise to prescribed position.

3, Tight up the lock screw.

④ Sensor head lock nut

⑤ Main unit

⑥ Base lock screw

⑦ Basement

⑧ Mode setting switch

Fixed position

Lock screw

Mounting basement

adjust joint mark

Page 2

INSTALLATION

HOW TO WIRING

2

CHECKING

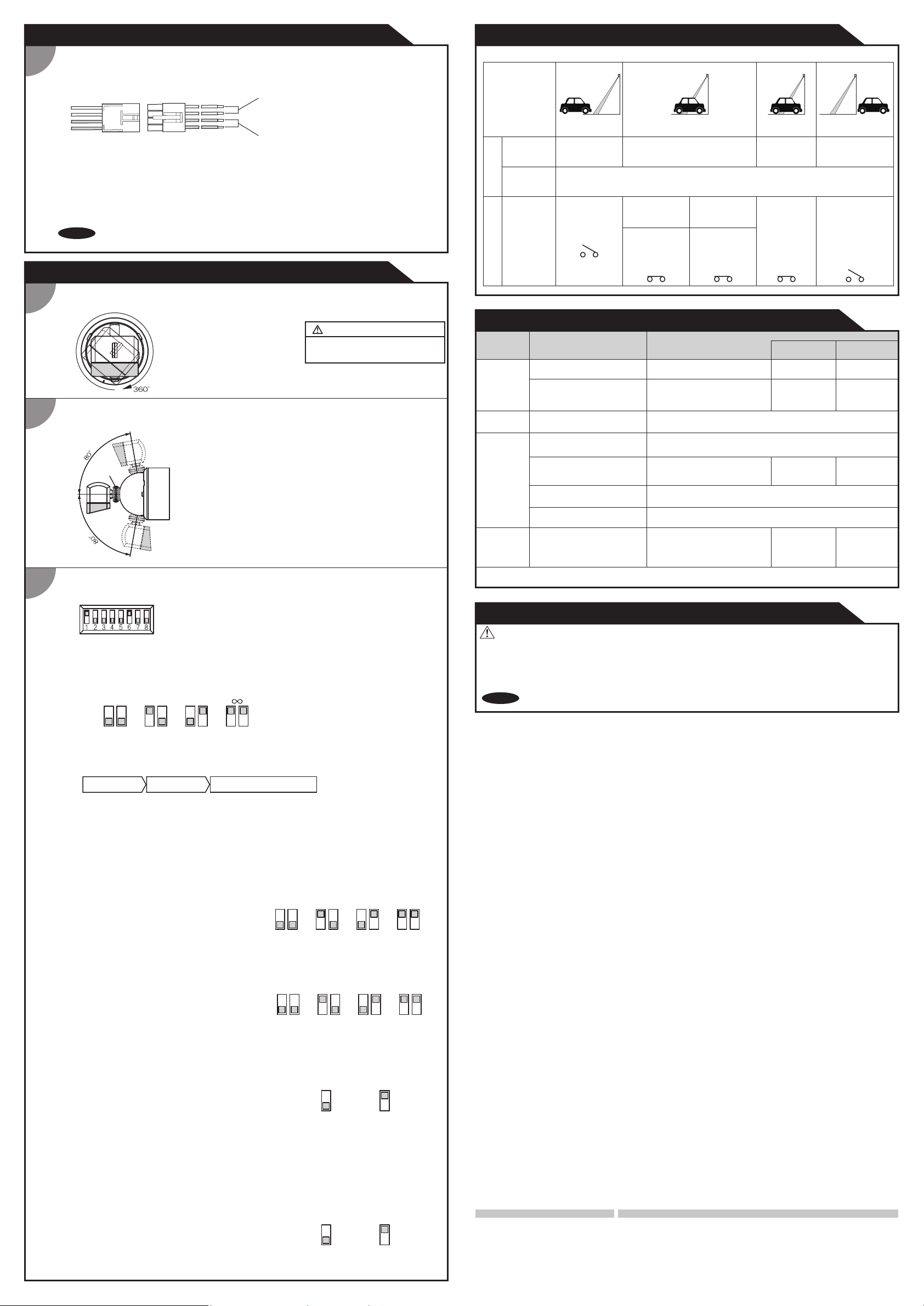

Check the operation in the operation mode according to the chart below.

< Wiring to the controller > Signal output (Yellow)

Relay output (N.O. / Non voltage contact.)

100VAC 1A, 30VDC under 0.1A

Power supply (Gray) 24VDC

Penetrate conector to the end.

If connector plugged not enough, signal will not stable.

< Sensor connecting cable setting >

Take care following matter when connect sensor cable.

NOTE Sensor cable sensor to sensor : Please use VCTF cable 0.75mm

Cable length : Please use cable within 32' 9 11/16"(10m) long between sensor to sensor.

ADJUSTMENTS

Adjust detection area of right & left direction.

1

Rotate sensor head angle which

position you want.

It can be revolved 360˚.

Horizontal angle of detection area

adjustment is as left picture.

Adjust detection area of vertical direction.

2

1, Loose sensor head lock nut to anticlockwise direction.

2, Move sensor head angle which you want. And tighten lock nut.

Lock nut

Adjust mode switches.

3

Adjust mode switch is found pull out sensor head cover. Please set dip switches.

(3-1) Adjust presence detection time setting

Adjust presence time by mode switch [1] & [2]

Attention : All detection area are adjusted.

2 sec. 60 sec.15 sec.

1 2 1 21 2

< Presence detection >

After power ON, please wait 10 sec without moving object in the detection area.

Presence detect function will be done by this.

Power ON Wait 10 sec Presence detection mode

It can be moved up to 80 degrees and down to 80 degrees.

[1] & [2], Presence detection timer. (Sec.)

[3] & [4], Frequency switch setting.

[5] & [6], Adjust detection area length. (Sensitivity)

[7], Adjust LED indicator setting.

[8], Adjust On delay.

Other than Infinity, will be changed to the presence

time is 10 minutes when the area has multiple

1 2

detection.

2

.

CAUTION : Risk of product failure.

Never rotate sensor head over three

rounds otherwise cable will be broken.

Entrance

(Image)

Stopped in the

area

OFF or

Blinking

Within

presence

time

Passed the area

ON

1.0sec. after

passing

OFF

OFF at

detection

setting

Always turn

setting

OVS-6000

Output Indicator

ON

Outside of the

area

ON

OFF

Entry into the area

OFF or Blinking

On delay

detection:

Normal setting

Entry into

the area

ON

ON

On delay

detection:

3sec. setting

Stopped 3 sec. or

more in the area

ON ON

TROUBLESHOOTING

Problem Possible countermeasures

Does not work

Does not work

sometime.

It works on

normal

operation.

Sensor signal

keep on.

If the trouble cound not solve, please call installar or service staff.

Possible cause

Power voltage

Wire disconnection, connect

trouble.

Dirty on the window.

Moving object or light source in

the detection area.

Detective area of other sensor

is lapped over.

There is some noisy machine

near sensor.

Water droppes on the window.

Change the floor condition

during presence mode.

Title No.

Set to the stated voltage.

Check the wireing and connector.

Clean up the dirty on the window.

Adjuct detection area or put out the moving object.

Change frequency switch by each

sensors.

Please take the noisy machne away from sensor.

Please re-install in order to avoide the rain water.

Please turn OFF the power and

ON again.

SPECIFICATIONS

INSTALLATION

ADJUSTMENTS

ADJUSTMENTS

(1-5)

Wiring onto

basement

(3-2)

Adjust frequency

switch setting

(3-1)

Adjust presence

detection time

setting

INFORM BUILDING OWNER / OPERATOR OF THE FOLLOWING ITEMS

WARNING

1. Always keep the detection window clean. If dirty, wipe the window with a damp cloth. Do not use any cleaner / solvent.

2. Do not wash the sensor with water.

3. Do not disassemble, rebuild or repair the sensor yourself, otherwise an electric shock may occur.

4. Always contact your installer or service engineer when changing the settings.

5. Do not paint the detection window.

NOTE

1. When turning the power ON, always walk-test the detection area to ensure the proper operation.

2. Do not place any objects that move or emit light in the detection area. (e.g. plant, illumination, etc.)

< Infinity mode switch setting >

When Infinity presence deteation mode is on, LED indicator is [Fast Blinking], and keep detection during

the object is in the detection area.

< CAUTION : When you use infinity mode on >

If the reflection ratio of floor condition will be changed by sudden rain or heavy snow, sensor will be filure

and keep detection.

If happen above situation, please cut power OFF and ON again. (Reset sensor)

(3-2) Adjust frequency switch setting

Mode switch [3] & [4] could adjust four kinds of

frequency position.

< Frequency switch setting >

When using more than one sensor close to each other, set the frequency different for each sensor.

(3-3) Adjust sensor detection area length (Sensitivity)

Mode switch [5] & [6] could adjust detection area

length (Sencitivity).

Set the sensitivity according to the mounting height.

Values below dipswitch are reference only.

< Detection area length switch setting >

[Detection area length] is lough indication. Depend on object or enviroment the effectual sensitivity will be

changed. Please re-adjust the swcitch position.

(3-4) Adjust LED indicator setting

Mode switch [7] turn on the LED indicator in usual.

1 2 3 4

3 4 3 4 3 4 3 4

L: 2~4m M: 3~5m H: 4~6m

5 6 5 6 5 6 5 6

When sensor

detect object LED

light turn off.

7 7

When sensor

detect object LED

light turn on.

Reserved

< Adjust indicator switch setting >

・

Turn on when detect : When sensor detect object LED light turn off. LED light indicator is on when waiting.

・Always turn on: LED light indicator is always turn on wheneven sensor detect object or not.

When you getting close to the detection point centor on the floor, you can find the LED indicator light is

more bright. To use this function, [Always turn on] mode can help to check the detection area on the floor.

After check and adjust the detection area, please set the switch to [Turn on when detect] mode.

(3-5) On delay setting

Mode switch [8] could On delay setting.

< On delay setting >

・Normal detection mode: When sensor detect object relay will be on.

・

On delay mode:

When detect objec the sensor relay will be turned on, after keep stay in the area 3 sec.

OFF 3sec.

8

8

Manufacturer

OPTEX Co.,LTD.

5-8-12 Ogoto Otsu 520-0101, Japan

TEL.: +81(0)77-579-8700

FAX.: +81(0)77-579-7030

WEBSITE:

www.optex.co.jp/as/eng/index.html

North and South America Subsidiary

OPTEX INCORPORATED

18730 S. Wilmington Avenue, Suite 100

Rancho Dominguez CA 90220 U.S.A

TEL.: +1-800-877-6656

FAX.: +1(310)898-1098

WEBSITE: www.optextechnologies.com

East coast office

8510 McAlpines Park Drive, Suite 108

Charlotte, NC 28211 U.S.A.

TEL.: +1-800-877-6656

FAX.: +1(704)365-0818

WEBSITE: www.optextechnologies.com

Loading...

Loading...