Optex HX-40, HX-40AM Installation

-1-

N219

High Mount

High Mount

Outdoor Detector

Outdoor Detector

HX -40/40AM

HX -40/40AM

By utilising the OPTEX’s unique pyro-element,

HX series achieves high reliable detection

performance against false and missed alarms.

HX series provides stable and accurate

detection in outdoor severe environmental

conditions.

•HX-40 : standard model with two PIRs

•HX-40AM : HX-40 with IR anti-masking

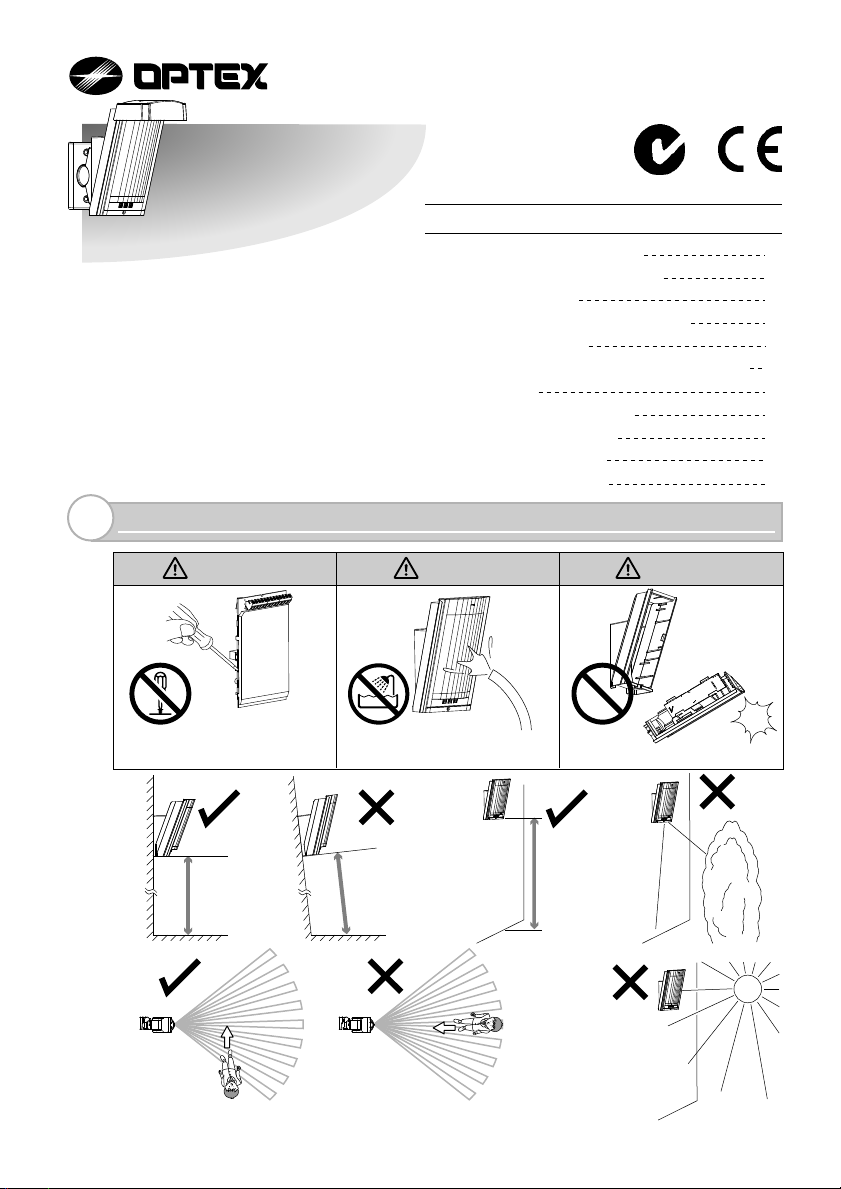

INSTALLATION HINTS

1

feature

Warning Warning Caution

No.59-1501-0

INSTALLATION INSTRUCTIONS

CONTENTS

(1) INSTALLATION HINTS 1

(2) PARTS IDENTIFICATION 2

(3) KNOCKOUTS 2

(4) DETECTION AREA SETTING 3

(5) INSTALLATION 3

(6)

BRACKET INSTALLATION AND ADJUSTMENT

(7) WIRING 6

(8) FUNCTION SETTING 7

(9) OPERATION TEST 9

(10) LED FUNCTIONS 10

(11) SPECIFICATIONS 11

4

Never repair or modify product

Parallel

Mount the detector so that a majority of traffic flow is across the detection pattern.

Do not pour water over the

product

Tilt

Mount securely

2.5 - 3.0 m

(8.3 - 10 ft.)

-2-

䎃

䎃

䎃

䎃

䎃

䎃

䎃

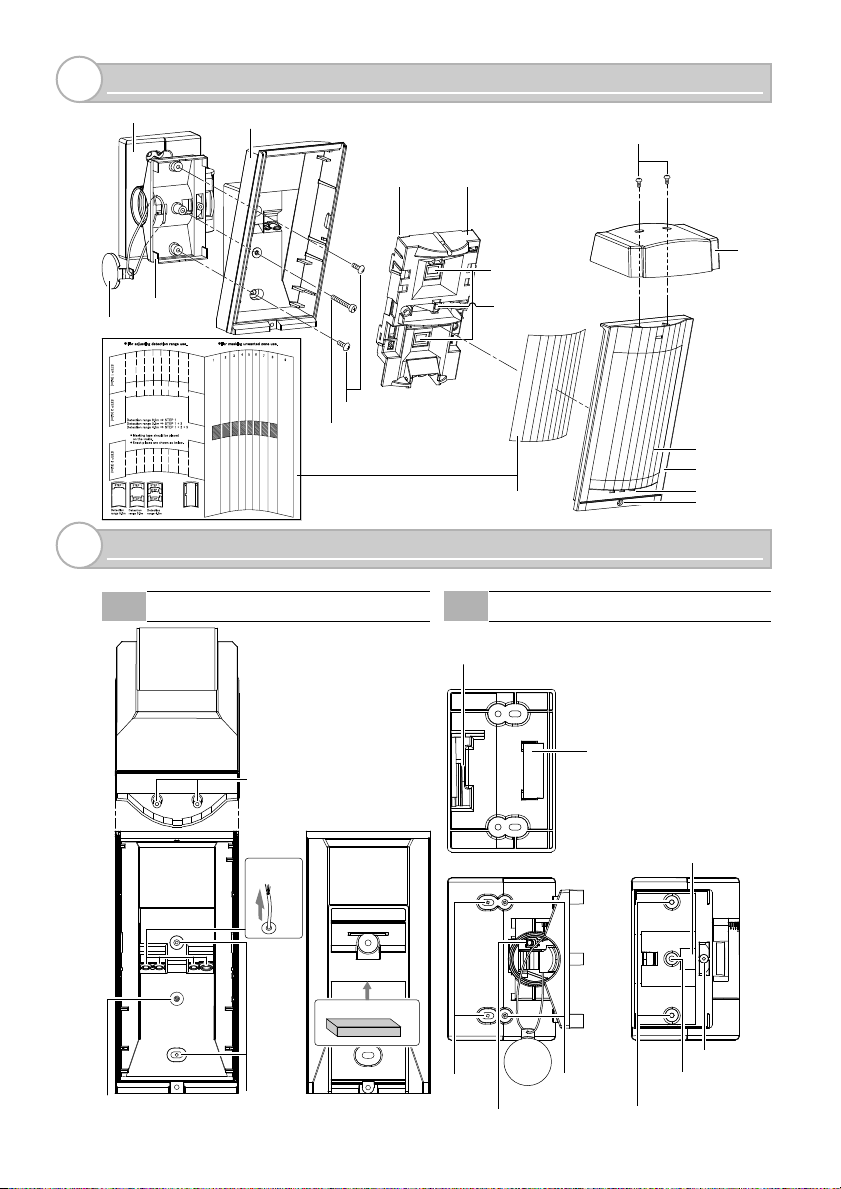

PARTS IDENTIFICATION

2

Hood

Screw (3×10 mm)

Screw (4×20 mm)

Bracket

Shaft cover

Lock screw (M4×35 mm)

Base

Bracket base

Main unitTerminals

Cover

Lock screw

Lens

LED indicator

Area

masking seal

PIR sensor

(Don not touch)

Anti-masking infrared LED

(HX-40AM only)

For wall

fastening

Wiring Hole

Wiring Hole

(Off-the-shelf) magnet switch

installation position

Adjustment screw

For switch

box fastening

For main unit fastening

Up-down

lock screw

Don’t touch

3-B Bracket

KNOCKOUTS

3

3-A Main unit

For wall fastening/bracket fastening

(installation pitch 83.5 mm (3.3 inch))

For bracket

up-down lock screw

For hood fastening

Wiring

knockout

Wiring sponge pad

-3-

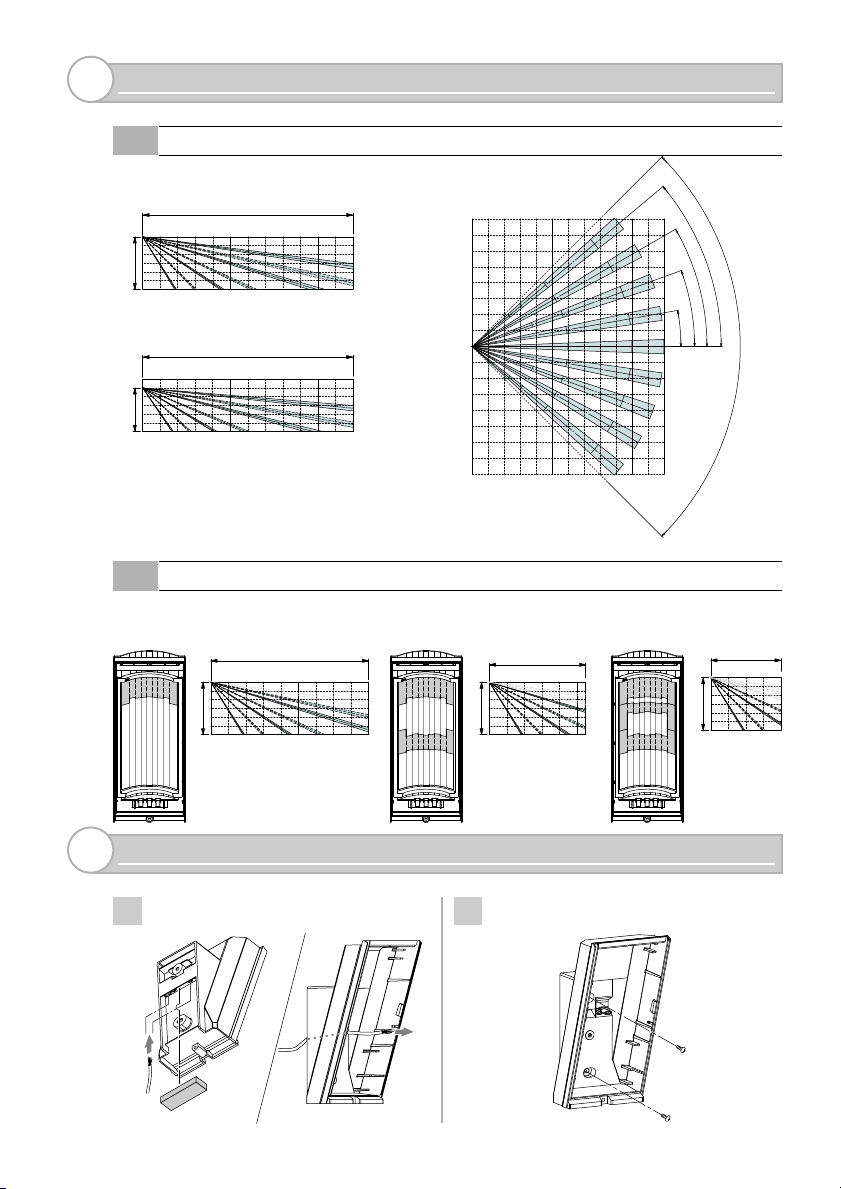

Side view of detection area

(Installation height 3.0 m (1 ft.) )

(Installation height 2.5 m)

To limit the detection distance, apply the appropriate masking seal. Note that there are three

different types of seal.

DETECTION AREA SETTING

4

4-B Detection Length Adjustment

4-A Detection Area

Top view of detection area

90°

4

0

°

30

°

20

°

10°

0

8 m

(26.7ft.)

8 m

(26.7ft.)

12 m (40 ft.)

12 m

(40 ft.)

3.0 m (10 ft.)

12 m (40 ft.)

2.5 m (8.3 ft.)

9.0 m (30 ft.)

3.0 m (10 ft.)

5.5 m (18.3 ft.)

3.0 m (10 ft.)

4.0 m (13.3 ft.)

3.0 m (10 ft.)

1

3

2

11

2

In

Out

Pass the wire through the base knockout.

Fasten the base to the wall.

INSTALLATION

5

1

2

Wiring sponge pad

-4-

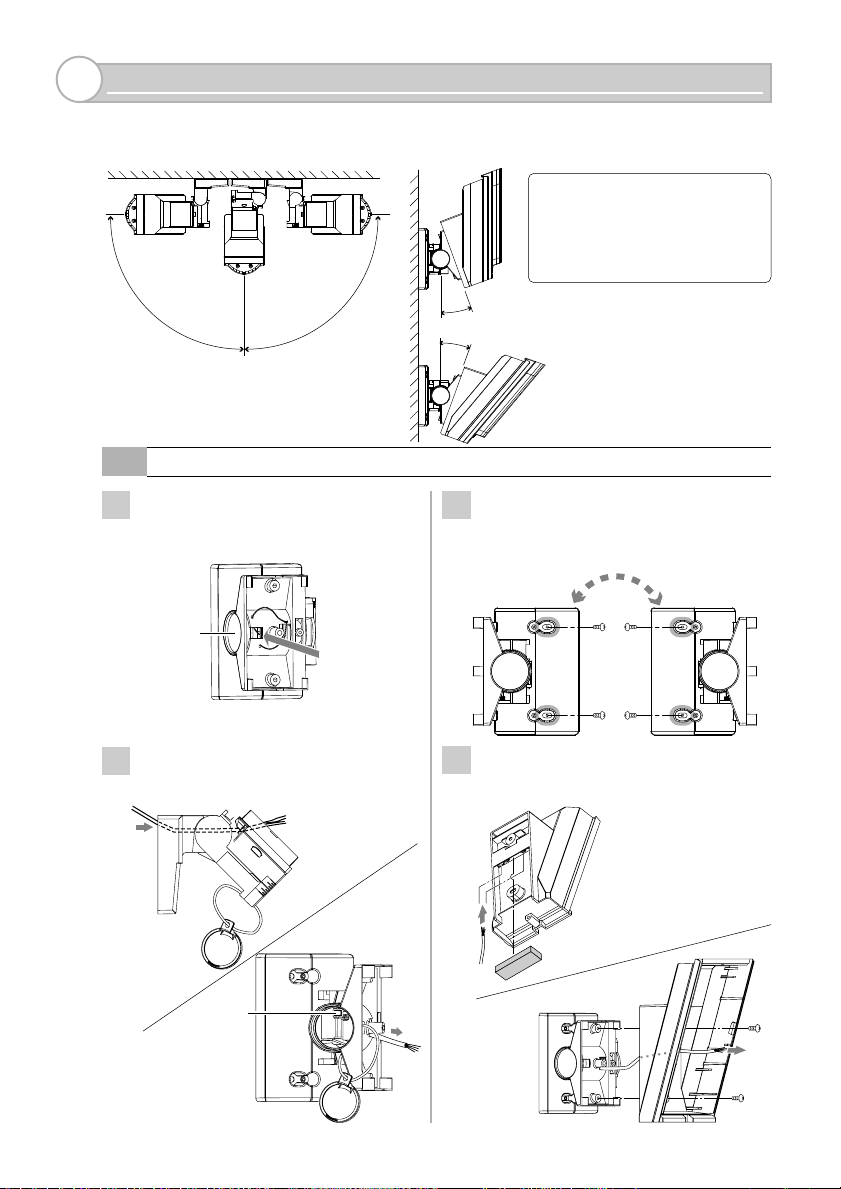

BRACKET INSTALLATION AND ADJUSTMENT

6

Using the bracket makes it possible to adjust the unit through 180° degree.

In cases where the ground is uneven and therefore not parallel with the base of the unit, it is

possible to adjust the unit vertically by +/- 20 degree (see section 6-B)

Caution>>

Do not change the detection

distance with bracket.

Use the masking seal to

adjust the detection distance.

90°

6-A Bracket installation

Push the shaft cover clip outwards to

1

remove the cover.

Shaft cover

Push

Loosen the adjustment screw, tilt the

2

bracket about 45° and pass through the

wire.

In

90°

20°

20°

Fasten the bracket to the wall.

3

Change the bracket direction according

to whether the Main unit is to face left

or right.

Pass the wire through the base

4

knockout and install the base on the

bracket.

Adjustment

screw

In

Wiring sponge pad

Out

Out

Loading...

Loading...