Optex HX-40/40AM Installation Insrtuctions

-1-

N219

INSTALLATION INSTRUCTIONS

No.59-1501-0

High Mount

Outdoor Detector

High Mount

Outdoor Detector

CONTENTS

By utilising the OPTEX’s unique pyro-element,

HX series achieves high reliable detection

performance against false and missed alarms.

HX series provides stable and accurate

detection in outdoor severe environmental

conditions.

•HX-40 : standard model with two PIRs

•HX-40AM : HX-40 with IR anti-masking

feature

HX -40/40AM

HX -40/40AM

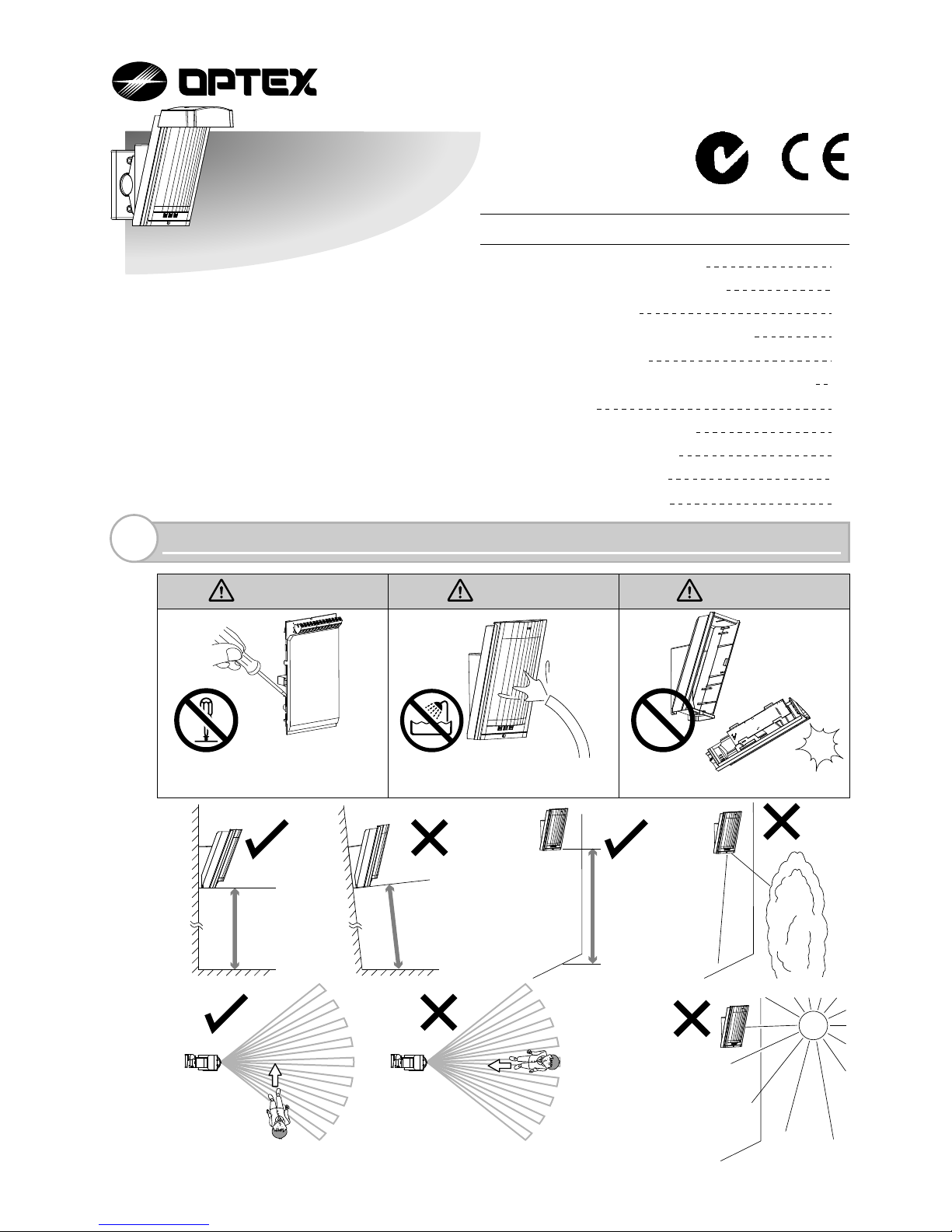

Warning Warning Caution

INSTALLATION HINTS

1

(1) INSTALLATION HINTS 1

(2) PARTS IDENTIFICATION 2

(3) KNOCKOUTS 2

(4) DETECTION AREA SETTING 3

(5) INSTALLATION 3

(6)

BRACKET INSTALLATION AND ADJUSTMENT

4

(7) WIRING 6

(8) FUNCTION SETTING 7

(9) OPERATION TEST 9

(10) LED FUNCTIONS 10

(11) SPECIFICATIONS 11

Parallel

2.5 - 3.0 m

(8.3 - 10 ft.)

Tilt

Never repair or modify product

Do not pour water over the

product

Mount securely

Mount the detector so that a majority of traffic flow is across the detection pattern.

-2-

䎃

䎃

䎃

䎃

䎃

䎃

䎃

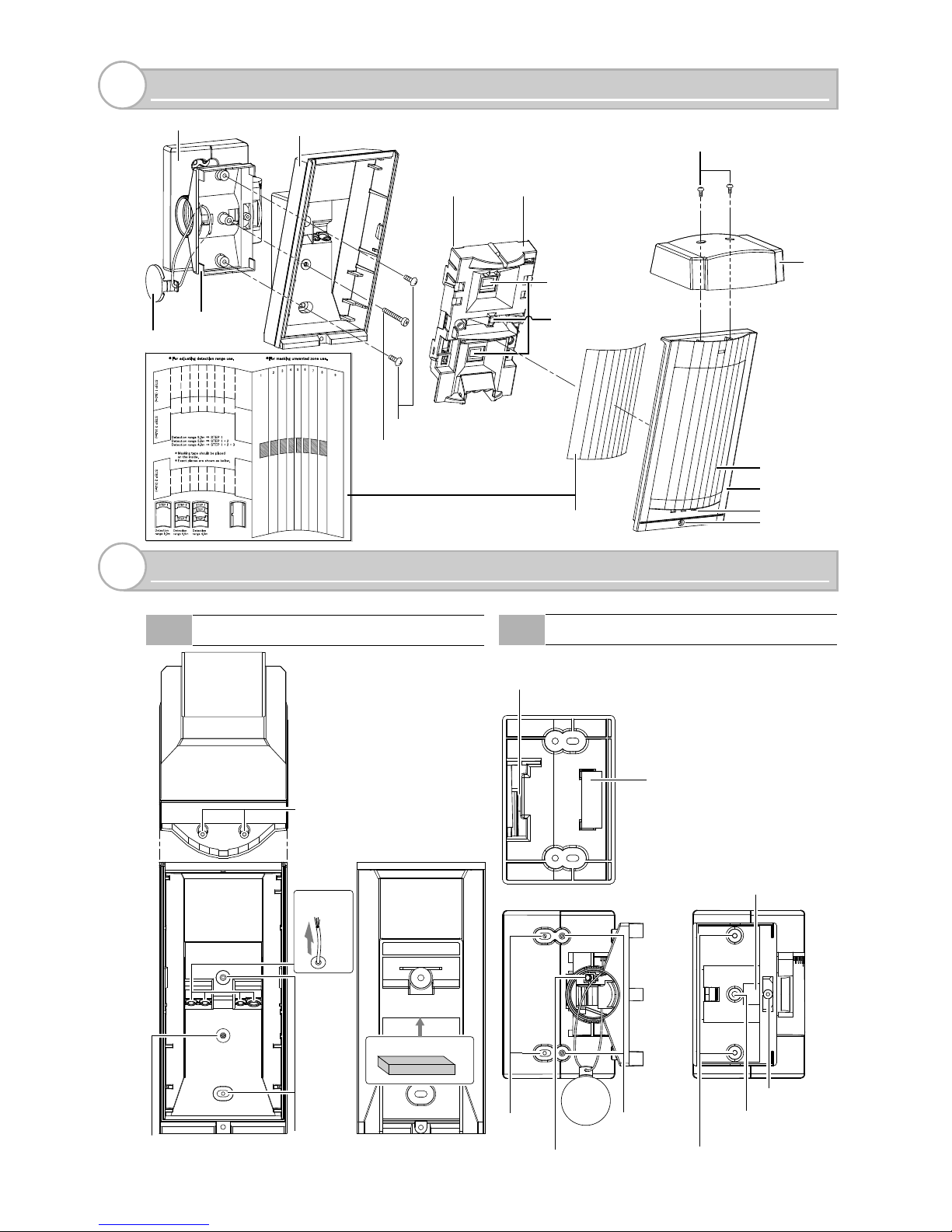

PARTS IDENTIFICATION

2

Hood

Screw (3×10 mm)

Screw (4×20 mm)

Bracket

Shaft cover

Lock screw (M4×35 mm)

Base

Bracket base

Main unitTerminals

Cover

Lock screw

Lens

LED indicator

Area

masking seal

PIR sensor

(Don not touch)

Anti-masking infrared LED

(HX-40AM only)

For wall

fastening

Wiring Hole

Wiring Hole

(Off-the-shelf) magnet switch

installation position

Adjustment screw

For switch

box fastening

For main unit fastening

Up-down

lock screw

Don’t touch

3-B Bracket

KNOCKOUTS

3

3-A Main unit

For wall fastening/bracket fastening

(installation pitch 83.5 mm (3.3 inch))

For bracket

up-down lock screw

For hood fastening

Wiring

knockout

Wiring sponge pad

-3-

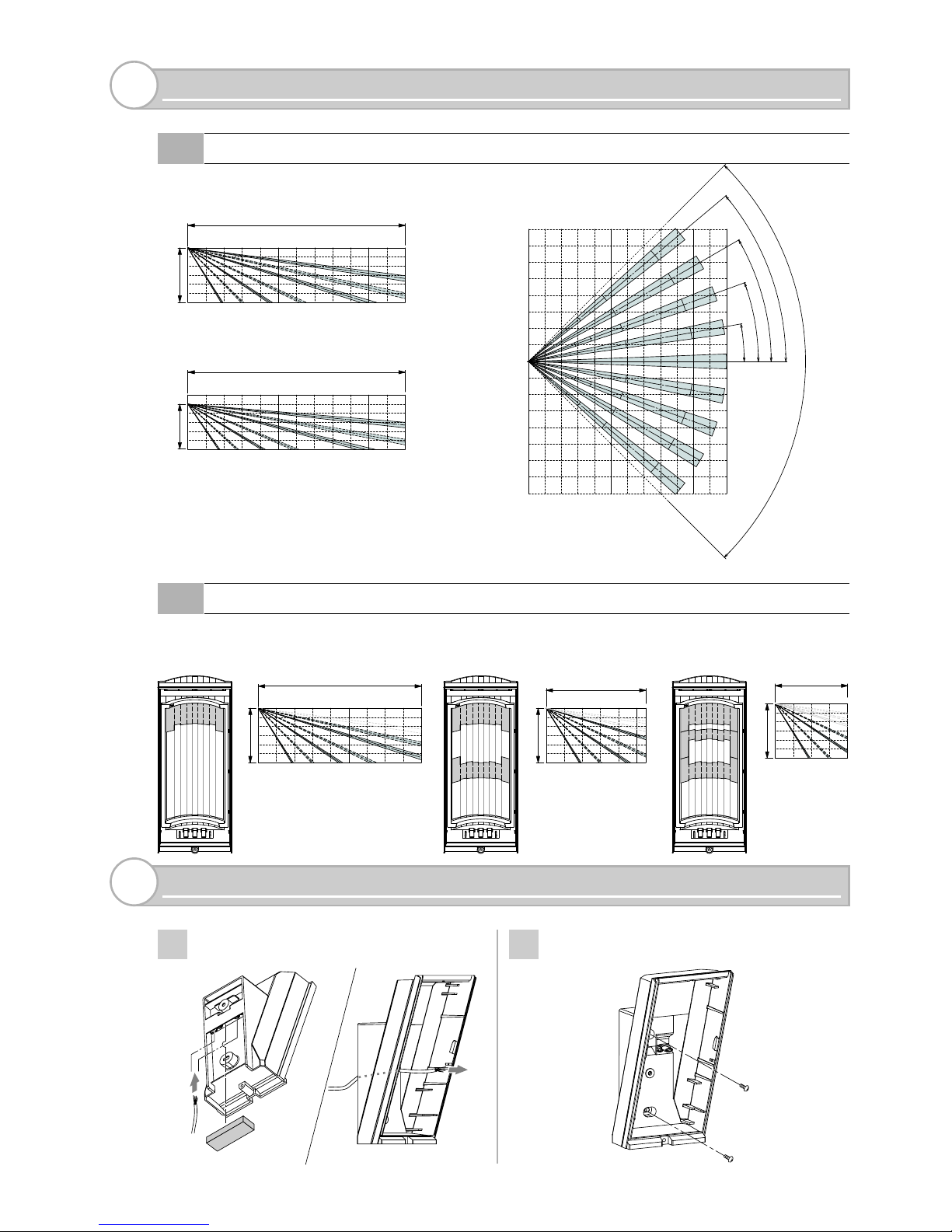

Side view of detection area

(Installation height 3.0 m (1 ft.) )

(Installation height 2.5 m)

To limit the detection distance, apply the appropriate masking seal. Note that there are three

different types of seal.

DETECTION AREA SETTING

4

4-B Detection Length Adjustment

4-A Detection Area

Top view of detection area

90°

4

0

°

30

°

20

°

10°

0

8 m

(26.7ft.)

8 m

(26.7ft.)

12 m (40 ft.)

12 m

(40 ft.)

3.0 m (10 ft.)

12 m (40 ft.)

2.5 m (8.3 ft.)

9.0 m (30 ft.)

3.0 m (10 ft.)

5.5 m (18.3 ft.)

3.0 m (10 ft.)

4.0 m (13.3 ft.)

3.0 m (10 ft.)

1

3

2

11

2

In

Out

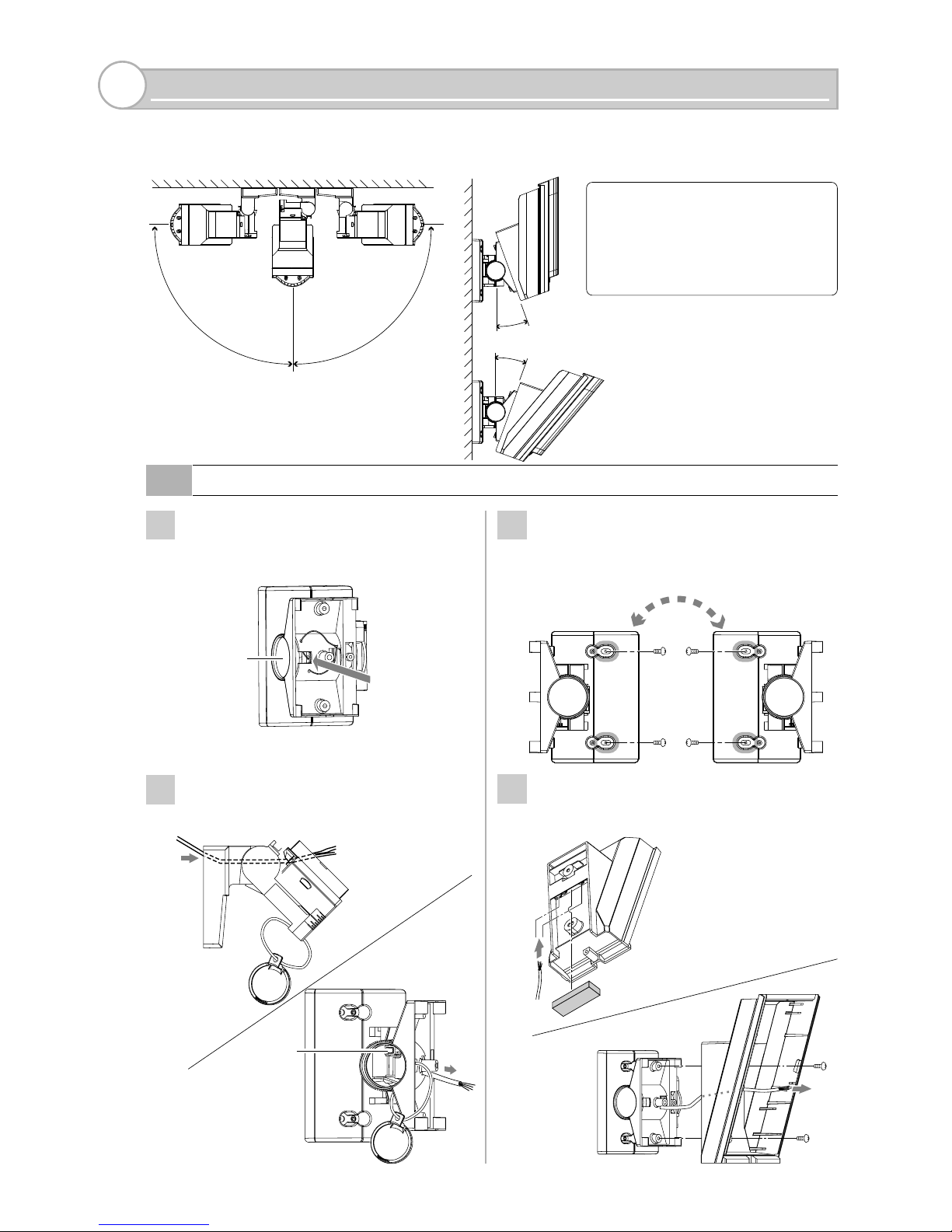

Pass the wire through the base knockout.

Fasten the base to the wall.

INSTALLATION

5

1

2

Wiring sponge pad

-4-

In

In

Out

Out

Wiring sponge pad

1

2

3

4

Push the shaft cover clip outwards to

remove the cover.

Loosen the adjustment screw, tilt the

bracket about 45° and pass through the

wire.

Fasten the bracket to the wall.

Change the bracket direction according

to whether the Main unit is to face left

or right.

Pass the wire through the base

knockout and install the base on the

bracket.

Adjustment

screw

BRACKET INSTALLATION AND ADJUSTMENT

6

20°

20°

90°

90°

6-A Bracket installation

Shaft cover

Push

Using the bracket makes it possible to adjust the unit through 180° degree.

In cases where the ground is uneven and therefore not parallel with the base of the unit, it is

possible to adjust the unit vertically by +/- 20 degree (see section 6-B)

Do not change the detection

distance with bracket.

Use the masking seal to

adjust the detection distance.

Caution>>

Loading...

Loading...