Page 1

N219

CONTENTS

1 INTRODUCTION

1-1 BEFORE INSTALLATION ................2

1-2 PARTS IDENTIFICATION ................3

1-3 DETECTION AREA..........................4

2 INSTALLATION

2-1 WIRING DIAGRAM..........................4

2-2 TRANSMITTER PREPARATION .....5

2-3 BEFORE WALL MOUNTING ...........6

2-4 STACKING METHOD ......................7

2-5 SIDE-BY-SIDE AND

TOP-TO-BOTTOM METHOD ........11

3 WALK TEST

3-1 WALK TEST ...................................13

4 DIP SWITCH SETTING

4-1 WALK TEST MODE .......................14

4-2 BATTERY SAVING TIMER ............14

4-3 ALARM & TROUBLE OUTPUT ......14

4-4 LED ................................................15

4-5 PIR SENSITIVITY ..........................15

4-6 ANTI-MASKING .............................15

5 OTHERS

5-1 WALL TAMPER (OPTION)

CONNECTION...............................16

5-2 LED LIGHT PATTERN ...................16

6 BATTERY

6-1 HOW TO REPLACE BATTERY .....17

6-2 BATTERY LIFE ..............................18

7 SPECIFICATIONS

7-1 SPECIFICATIONS .........................19

7-2 DIMENSIONS ................................20

FTN-R Battery operated model with 2 PIRs

FTN-RAM FTN-R

with anti-masking

Long battery life

Easy wiring by a connector

Multi fixing transmitter box

Compact design

190° adjustable bracket

Intelligent AND logic

Digital anti-masking (RAM model)

Wall tamper (option)

•

•

•

•

•

•

•

•

N

O.59-1646-0 091201

INSTALLATION INSTRUCTIONS

Compact outdoor

detector

Compact outdoor

detector

fit series

fit series

- 1 -

Page 2

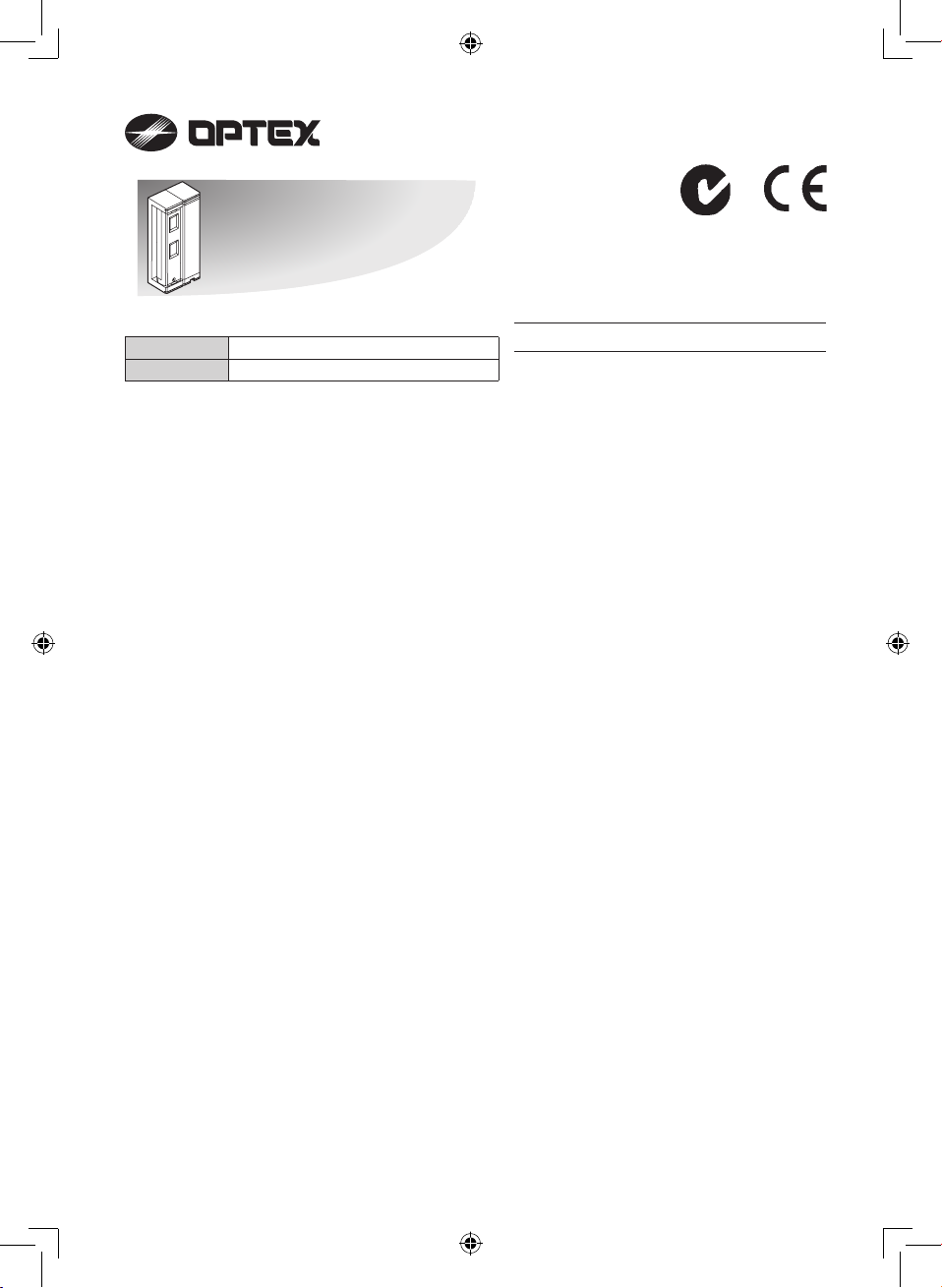

1

INTRODUCTION

1-1

BEFORE INSTALLATION

Warning

Failure to follow the instructions provided with this indication and improper

handling may cause death or serious injury.

Caution

Failure to follow the instructions provided with this indication and improper

handling may cause injury and/or property damage.

The check

mark indicates recommendation.

The nix sign indicates prohibition.

Warning

Caution Caution

Do not remove the PCB. Do not remove the separate box

tamper.

Do

not touch the PCB except for the

DIP switch.

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

Mounting height. Keep the detector parallel to the

ground.

Consider the direction a person is

approaching from, as well as the

detection area.

Install the detector in a place where it is free from false alarm factors. For example:

Sunlight and reflection• Heat source• Objects moving in the wind •

0.8 – 1.2 m

(2'7

" – 3'11")

Parallel

Tilt

- 2 -

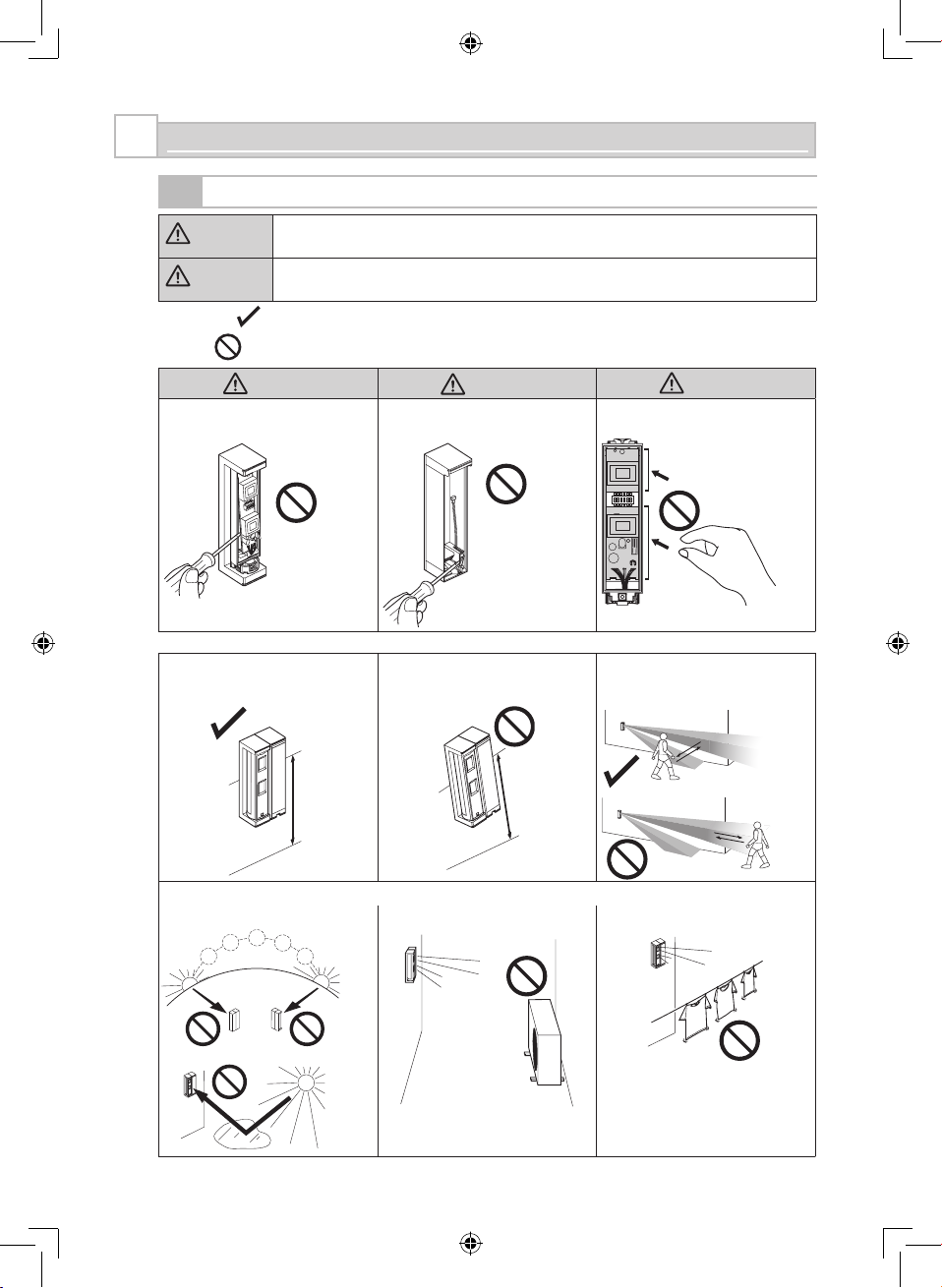

Page 3

Separate box

Separate box tamper

Main unit

Bracket

Fixture

Main

unit cover

Lens

1-2

PARTS IDENTIFICATION

Connector for POWER and ALARM

Connector for TROUBLE

Screw kit

For joint For wall mounting

Screw (M3 × 10 mm)

Plate nut

Screw (3 × 20 mm)

Note>>

Transmitter and battery are not included.

-Optional accessories

Wall tamper (WRS-03)

•

Separate box cover

Sponge

Sponge

Sponge for transmitter

- 3 -

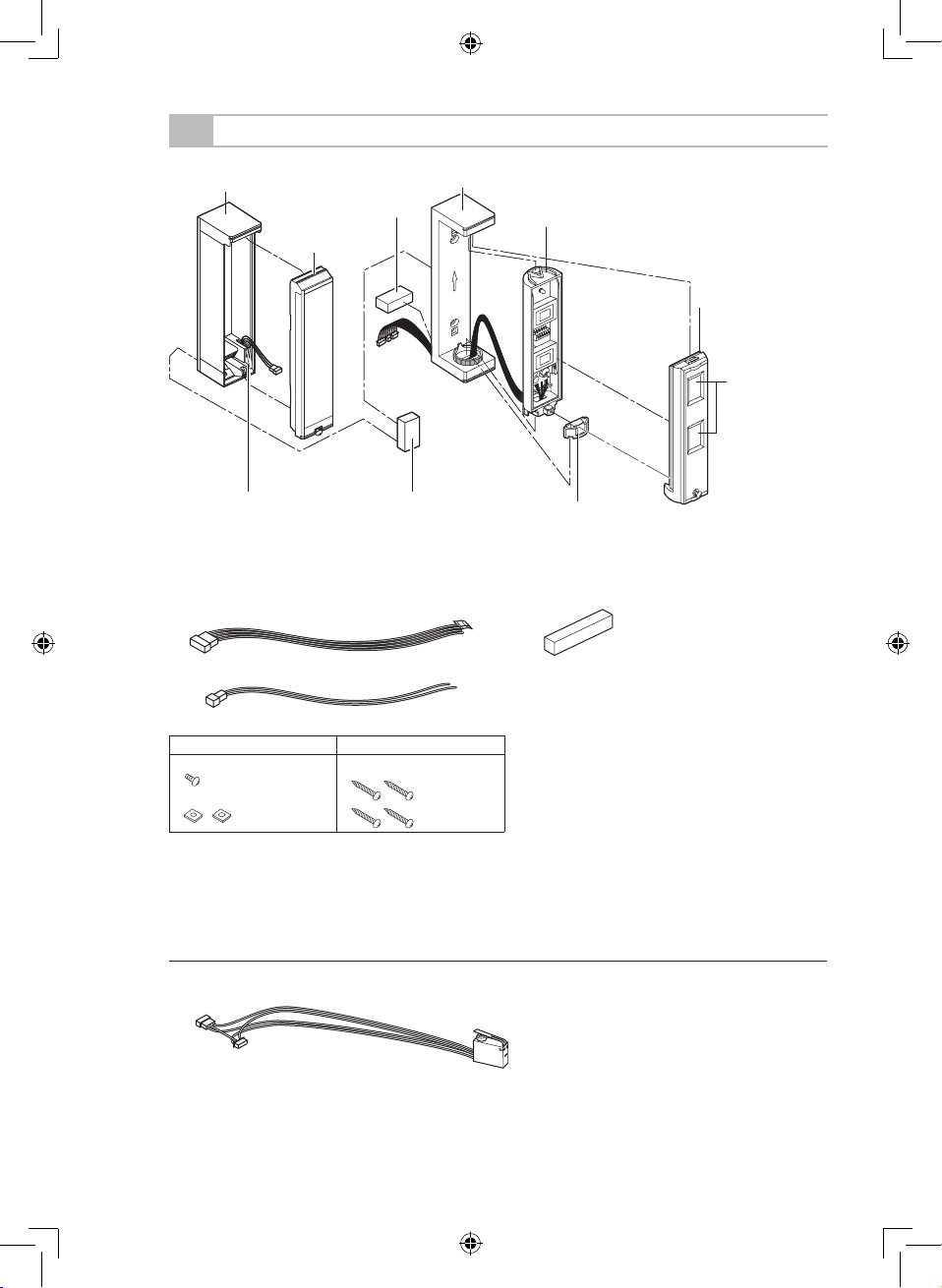

Page 4

0' 5' 10' 15'

0.8

0

(m)

1.0

1.2

2'7"

0'

(ft.)

3'3"

3'11"

10 2 3 4 5

(m)

(ft.)

0' 5' 10' 15'

0.8

0

(m)

1.0

1.2

10 2 3 4 5

(m)

2'7"

0'

(ft.)

3'3"

3'11"

(ft.)

0

10

0'0'5'

5'

5'

10'

10'

10'

15'

15'

15'

2 3 4 5

1

1

1

2

3

4

5

(m)

(ft.)

(ft.)

(m)

2

4

5

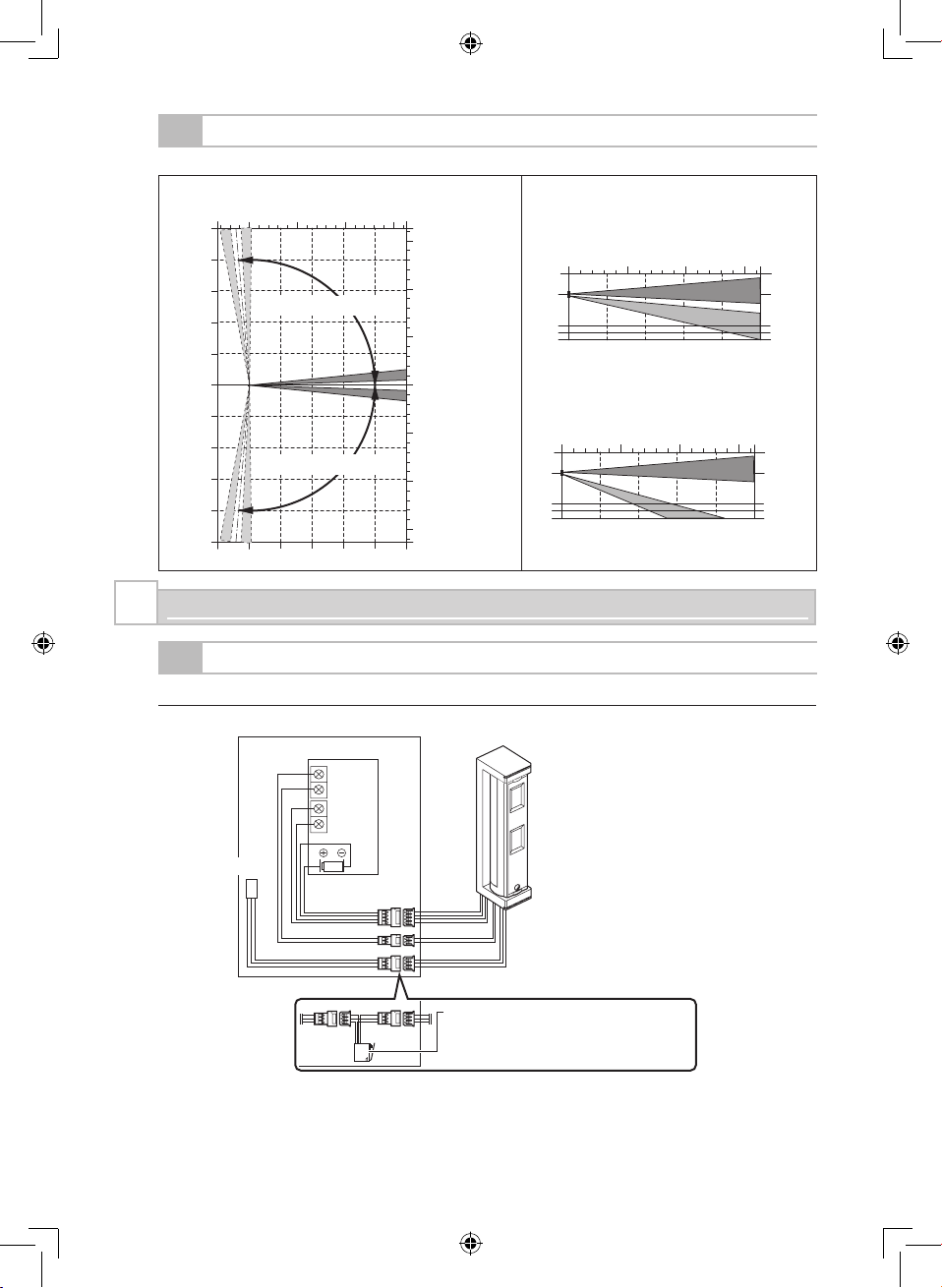

3

Separate box tamper

Trouble

Alarm

Wall tamper (option)

*For wall tamper wiring (option), refer to page

16.

Separate

box

Main unit

Transmitter

1-3

DETECTION AREA

Top view Side view

2 m detection length

5 m detection length

Adjustable range: 95° (by 5° pitch)

Adjustable range: 95° (by 5° pitch)

2

INSTALLATION

2-1

WIRING DIAGRAM

-Overall wiring diagram

Notes>>

The battery in the transmitter is shared with the detector.

Connection for TROUBLE is used when monitoring for Tamper and Anti Mask.

•

•

- 4 -

Page 5

35 (1.38")

130 (5.12")

30 (1.18")

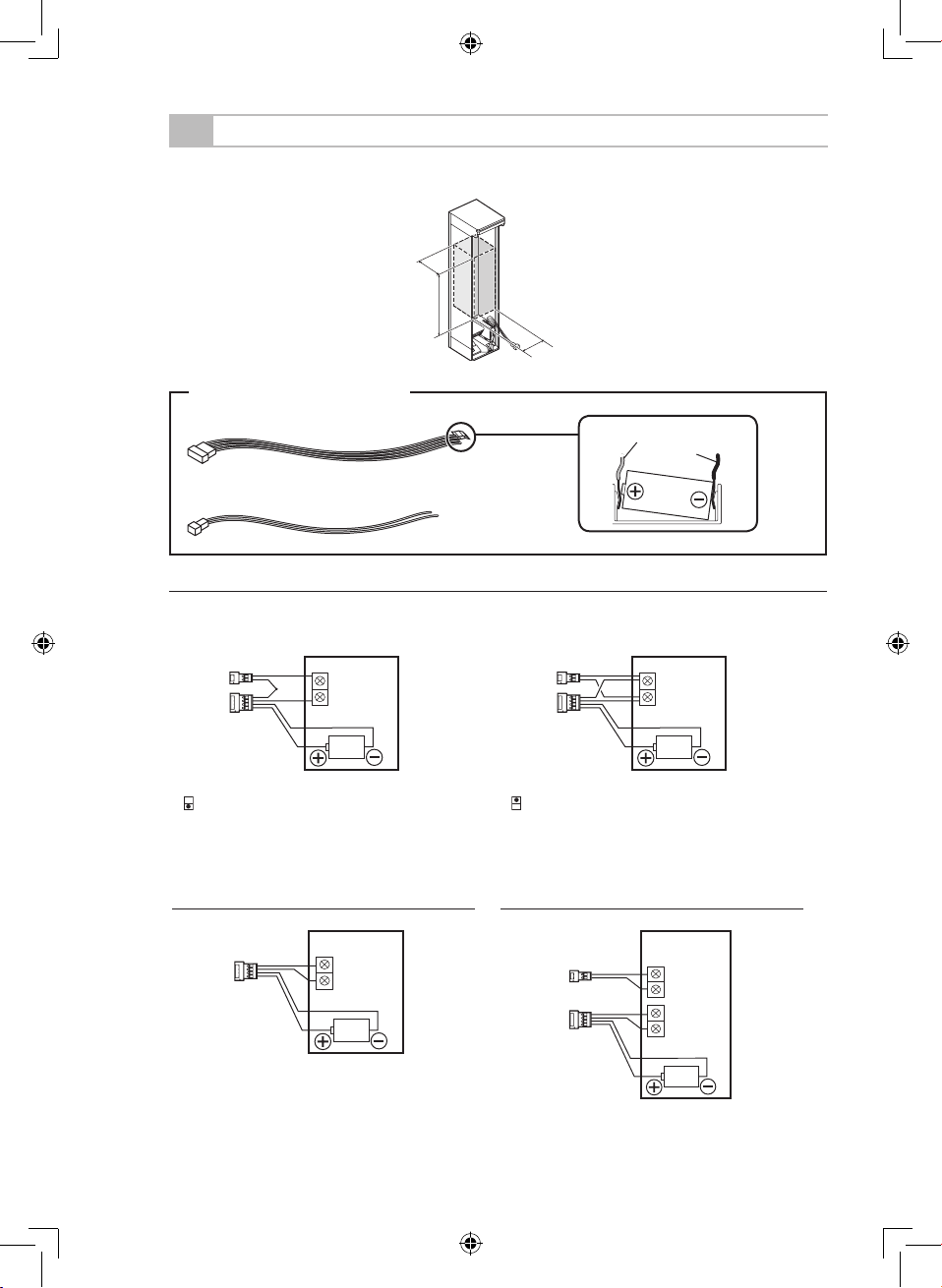

2-2

TRANSMITTER PREPARATION

The transmitter used should have the internal dimensions of H 130 × W 30 × D 35 mm.

(H 5.12" × W 1.18" × D 1.38")

- When monitoring ALARM and TROUBLE using the transmitter with 1 external input

External input is N.C. External input is N.O.

3

... DIP switch 3: OFF (N.C.)

3

... DIP switch 3: ON (N.O.)

-To monitor only the ALARM using a

transmitter with 1 external input

-To monitor the ALARM and TROUBLE

using a transmitter with 2 external inputs

Connectors to be used

Connector for POWER and ALARM

Connector for TROUBLE

Red

Black

How

to position a battery

Connector for POWER

and ALARM

Connector for

TROUBLE

Connector

for

POWER and ALARM

N.C.

N.O.

Unit: mm (inch)

- 5 -

Page 6

3

Hold the top of the bracket and

remove the main unit.

Note>>

Be sure to keep connectors installed

through the bottom part of bracket after

main unit is removed.

•

Bracket

Main unit

2

1

Bracket

Main unit

2

1

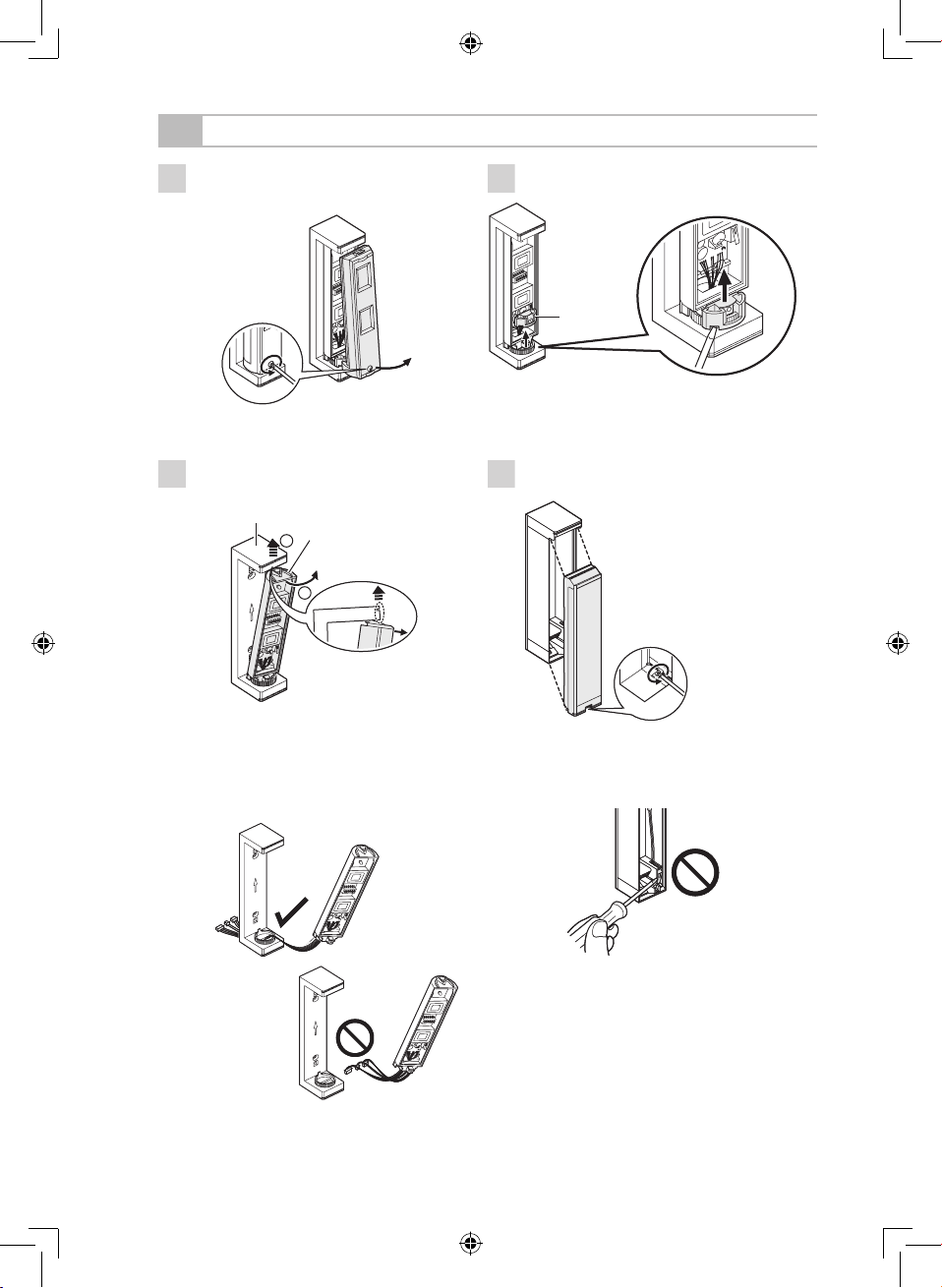

2-3

BEFORE WALL MOUNTING

1

Open the main unit cover.

2

Remove the fixture.

FixtureFixture

4

Open the separate box.

Note>>

Do not remove the separate box

tamper.

•

- 6 -

Page 7

5

Select the mounting method.

Stacking method

(Page 7)

Side-by-side method

(Page 11)

Top-to-bottom method

(Page 11)

Note>>

Be sure to mount the main

unit on the top.

•

2-4

STACKING METHOD

For the side-by-side method and the top-to-bottom method, refer to page 11.

6

Open the knockout.

Separate box

Separate box cover

Joint screw

knockout

W

all mounting

knockout

W

all mounting

knockout

Wiring knockout

Joint screw

knockout

Separate box

Separate box cover

Joint screw

knockout

W

all mounting

knockout

W

all mounting

knockout

Wiring knockout

Joint screw

knockout

7

Pull the connectors through the wiring

knockout.

- 7 -

Page 8

8

Attach the separate box cover and the bracket.

Notes>>

Be careful not to attach separate box cover upside down.

Be careful not to pinch wires.

•

•

Screw (3 × 10 mm)

Screw (3 × 10 mm)

Sponge

Plate

nut

Wiring

Sponge

Plate nut

Double-sided tape for

temporary fixing

Screw (3 × 10 mm)

Screw (3 × 10 mm)

Sponge

Plate

nut

Wiring

Sponge

Plate nut

Double-sided tape for

temporary fixing

9

Hold the top part of the bracket and

mount the main unit.

1

3

2

1

3

2

10

Mount the separate box on the wall.

Screw (3 × 20 mm)

Screw (3 × 20 mm)

Mounting height:

0.8 – 1.2 m (2'7" – 3'11")

Screw (3 × 20 mm)

Screw (3 × 20 mm)

Mounting height:

0.8 – 1.2 m (2'7" – 3'11")

100 mm

(3.94")

- 8 -

Page 9

13

Determine the horizontal detection

angle and attach the fixture.

Note>>

To make adjustments, remove the

fixture.

•

Angle pitch: 5°

95°

95°

Angle pitch: 5°

95°

95°

Note>>

Check that the fixture and bracket

engage correctly.

•

Note>>

Check that the fixture and bracket

engage correctly.

•

11

Connect the connectors.

Separate box side

Main unit side

Red

Black

White

Yellow

Red:

Power input (+)

Black: Power input (-)

White: Alarm

Yellow: Alarm

Green: Trouble

Blue:

Trouble

Brown: Tamper

Orange: Tamper

Grey:

Tamper

Green

Blue

Brown

Orange

Grey

Separate box side

Main unit side

Red

Black

White

Yellow

Red:

Power input (+)

Black: Power input (-)

White: Alarm

Yellow: Alarm

Green: Trouble

Blue:

Trouble

Brown: Tamper

Orange: Tamper

Grey:

Tamper

Green

Blue

Brown

Orange

Grey

Notes>>

The tamper output is not exclusive. The

Anti-masking and Tamper circuits share

the Trouble output.

For the wall tamper wiring connection

(option), refer to page 16.

To detect cutoff of tamper

input wires (3 wire

line) as shown in the

illustration, cut the orange

jumper wire provided for

purpose of detection.

In

this case, be sure to

use the connector of the separate box

tamper. Otherwise, the trouble output

will remain on.

•

•

•

12

Install the transmitter and attach the

separate box cover.

Note>>

Please use the sponge for transmitter

when needed.

•

1

2

3

Transmitter

1

2

3

Transmitter

- 9 -

Page 10

14

Determine the detection length. (2 m or 5 m)

If 2 m is required, rotate the lower lens

180 degrees.

Note>>

Do not remove the upper lens.•

5 m detection length

(Factory default)

2 m detection length

Side view

0' 5' 10' 15'

0.8

0

(m)

1.0

1.2

2'7"

0'

(ft.)

3'3"

3'11"

10 2 3 4 5

(m)

(ft.)

0' 5' 10' 15'

2'7"

0'

(ft.)

3'3"

3'11"

0.8

0

(m)

1.0

1.2

(ft.)

10 2 3 4 5

(m)

Side view

15

Attach the main unit cover.

Note>>

To prepare for walk test, check that DIP

switch 1 (WALK TEST MODE) is set to

“ON (TEST)” before attaching main unit

cover.

•

16

Perform walk test.

For details, refer to page 13.

17

After walk test is complete, set DIP

switch 1 (WALK TEST MODE) from

“ON” to “OFF”.

Note>>

The battery life will be shortened unless

the DIP switch 1 is set to “OFF”.

•

- 10 -

Page 11

6

Open the knockout.

Wiring knockout

(For side-by-side method)

Main unit

(Back

surface)

Wiring knockout

(For top-to-bottom

method)

Separate box

(Back surface)

Wiring knockout

(For side-by-side method)

Main unit

(Back

surface)

Wiring knockout

(For top-to-bottom

method)

Separate box

(Back surface)

Separate box

Wall mounting

knockout

W

all mounting

knockout

Wiring

knockout

Separate box

Wall mounting

knockout

W

all mounting

knockout

Wiring

knockout

2-5

SIDE-BY-SIDE AND TOP-TO-BOTTOM METHOD

For the stacking method, refer to page 7.

7

Pull the wire connectors through

wiring knockout.

8

Mount the bracket and the separate box to the wall.

Wiring

Side-by-side

method

Screw (3 × 20 mm)

Screw (3 × 20 mm)

Top-to-bottom

method

Double-

sided tape

Sponge Sponge

Mounting

height:

0.8

– 1.2 m

(2'7" – 3'11")

83.5 mm

(3.29")

Note>>

Be careful not to pinch wires.•

Wiring

Side-by-side

method

Screw (3 × 20 mm)

Screw (3 × 20 mm)

Top-to-bottom

method

Doublesided tape

Sponge Sponge

Mounting

height:

0.8

– 1.2 m

(2'7" – 3'11")

83.5 mm

(3.29")

Note>>

Be careful not to pinch wires.•

10 0 mm

(3.94")

Double-sided tape

- 11 -

Page 12

9

Hold the top part of the bracket and

mount the main unit.

1

3

2

1

3

2

10

Connect the connectors.

Notes>>

The tamper output is not exclusive. The

Anti-masking and Tamper circuits share

the Trouble output.

For the wall tamper wiring connection

(option), refer to page 16.

To detect cutoff tamper

input wires (3 wire

line) as shown in the

illustration, cut the orange

jumper wire provided for

purpose of detection.

In

this case, be sure to

use the connector of the separate box

tamper. Otherwise, the trouble output

will remain on.

•

•

•

Separate box side

Main unit side

Red

Black

White

Yellow

Red:

Power input (+)

Black: Power input (-)

White: Alarm

Yellow: Alarm

Green: Trouble

Blue:

Trouble

Brown: Tamper

Orange: Tamper

Grey:

Tamper

Green

Blue

Brown

Orange

Grey

Separate box side

Main unit side

Red

Black

White

Yellow

Red:

Power input (+)

Black: Power input (-)

White: Alarm

Yellow: Alarm

Green: Trouble

Blue:

Trouble

Brown: Tamper

Orange: Tamper

Grey:

Tamper

Green

Blue

Brown

Orange

Grey

11

Install the transmitter and attach the

separate box cover.

Transmitter

1

2

3

Transmitter

1

2

3

12

For the subsequent procedure, refer

to steps 13 to 17 (page 9 to 10).

- 12 -

Page 13

1

Set the DIP switch 1 (WALK TEST

MODE) to “ON (TEST)”.

Note>>

The switch is set to “ON (TEST)” by

factory default.

•

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

DIP switch

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

DIP switch

3

Set the DIP switch 1 (WALK TEST

MODE) to “OFF (NORM)”.

Notes>>

The battery life will be shortened unless

the DIP switch 1 is set to “OFF”.

To use the LED in normal operating

condition, set the DIP switch 4 to “ON”.

•

•

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

DIP switch

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

DIP switch

3-1

WALK TEST

3

WALK TEST

2

Check that LED lights for 2 seconds

when the intended object is detected.

Detected

Not detected

- 13 -

Page 14

Note>>

The detector will not generate

alarms at intervals shorter

than the specified time.

•

4-1

WALK TEST MODE

DIP switch 1

FTN-R

FTN-RAM

ON

1 2 3 4 5 6

TEST

NORM

Position Function

TEST

(Factory

default)

The LED lights irrespective of the DIP

switch 4 (LED) setting.

The DIP switch 2 (BATTERY SAVING

TIMER) setting is inactive.

•

•

NORM

The

LED lights depending on the DIP

switch 4 (LED) setting.

The DIP switch 2 (BATTERY SAVING

TIMER) setting is active.

•

•

4-2

BATTERY SAVING TIMER

DIP switch 2

FTN-R

FTN-RAM

ON

1 2 3 4 5 6

5S

120S

Position Function

5S 5

sec.

120S

(Factory

default)

120 sec.

4-3

ALARM & TROUBLE OUTPUT

DIP switch 3

FTN-R

FTN-RAM

ON

1 2 3 4 5 6

N.O.

N.C.

Position Function

N.O. N.O.

output

N.C.

(Factory

default)

N.C. output

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

●: Factory default

DIP switch

1 WALK TEST MODE

2 BATTERY SAVING TIMER

3 ALARM & TROUBLE OUTPUT

4 LED

5 PIR SENSITIVITY

6 ANTI-MASKING

Do not touch the

PCB except for the

DIP switch.

4

DIP SWITCH SETTING

- 14 -

Page 15

4-4

LED

DIP switch 4

FTN-R

FTN-RAM

ON

1 2 3 4 5 6

ON

OFF

Position Function

ON LED

ON

OFF

(Factory

default)

LED OFF

Note>>

If the LED lights, check the DIP

switch 1 (WALK TEST MODE)

setting.

•

4-5

PIR SENSITIVITY

DIP switch 5

FTN-R

FTN-RAM

ON

1 2 3 4 5 6

Position Function

STD

(Factory

default)

Normal sensitivity

LOW Low

sensitivity

4-6

ANTI-MASKING

DIP switch 6

FTN-R

FTN-RAM

ON

1 2 3 4 5 6

Position Function

ON

(Factory

default)

ANTI-MASKING ON

OFF ANTI-MASKING

OFF

-ANTI-MASKING function

When

masking condition continues more than 3 minutes, TROUBLE will be generated.

TROUBLE is generated after 20 seconds under the anti-masking test mode.

STD

LOW

ON

OFF

Teaching mode starts when both the separate box cover and the main unit cover are

attached.

Please

be careful not to leave any object within 1 m from the unit.

ANTI-MASKING test mode

The trouble is output after 20 seconds.

Normal mode

The trouble is output after 3 minutes.

10 minutes1 minute

Teaching

- 15 -

Page 16

5-1

WALL TAMPER (OPTION) CONNECTION

Connect the tamper connector as shown below when connecting a wall tamper (option).

Mounting position

Stacking method Side-by-side method and top-to-bottom method

Separate box

Bracket

5

OTHERS

Separate box side

Main unit side

Wall tamper (option)

WRS-03

Sponge

Sponge

5-2

LED LIGHT PATTERN

The following explains the LED light pattern.

Detector condition LED indicator

Warm-up

Note>>

The LED blinks even if the DIP

switch 4 (LED) is set to “OFF”.

•

Blinks for approx. 120 seconds.

Alarm

Lights for 2 seconds.

Masking detection

(FTN-RAM only)

Blinks 3 times and then repeats.

LED

Blink Light OFF

- 16 -

Page 17

1

Open the separate box, and

disconnect the transmitter connector.

(It is not necessary for the main unit

to be opened.)

6

BATTERY

The detector shares the battery with the transmitter. Check that the 2.5 to 10.0 V power battery is

used for the transmitter.

6-1

HOW TO REPLACE BATTERY

Stacking method

Side-by-side method and

top-to-bottom method

Separate box

Separate

box cover

Separate box

Separate box

cover

Black

Red

3

2

Replace the battery.

3

Connect the connector, and close the

separate box.

Note>>

Check that the warm-up period is

started.

•

- 17 -

Page 18

6-2

BATTERY LIFE

The values indicated are only for reference on condition that the detector is exceptionally

operated by the sole battery.

It is impossible to indicate the battery life under the normal operation as the battery in the

transmitter is shared with the detector.

Interval 120 sec Interval 5 sec

CR123A (3 V, 1300 mAh) Approx. 6 years Approx. 5 years

CR2 (3 V, 750 mAh) Approx. 4 years Approx. 3 years

1/2AA (3.6 V, 1000 mAh) Approx. 5 years Approx. 4 years

Note>>

Data shown here is when the LED is off, AM is on. Battery life becomes shorter when the

LED is on.

•

- 18 -

Page 19

7

SPECIFICATIONS

7-1

SPECIFICATIONS

Model FTN-R FTN-RAM

Detection method Passive infrared

PIR coverage 5 × 1 m (16'5" × 3'3")

Detection length limit 2 m, 5 m (6'7", 16'5")

Detectable speed 0.3 – 1.5 m/s (1' – 4'11"/s)

Sensitivity 2.0°C

(at 0.6 m/s) (3.6°F (at 2'/s))

Operation voltage 2.5 – 10 V DC

Power input 3 – 9 V DC (Lithium or Alkali Battery)

Current draw

9 μA (at stand-by)/3 mA

(max.)

(at 3 V DC)

10 μA (at stand-by)/3 mA

(max.) (at 3 V DC)

Alarm period 2.0 ±1.0 sec.

Warm-up period Approx. 120 sec. (LED blinks)

Alarm output

N.C./N.O. Selectable-Solid State Switch 10 V DC 0.01 A

(max.)

T

rouble output

N.C./N.O. Selectable-Solid State Switch 10 V DC 0.01 A

(max.)

LED

indicator

Enable:

During DIP switch 1 (WALK TEST MODE) or

DIP switch 4 (LED) ON

Disable: During normal operation

Light/Blink: Warm-up, alarm, masking detection

RF Interference No alarm 10 V/m

Operation temperature -20 – +60°C (-4 – +140°F)

Environment humidity 95% max.

Weatherproof IP55

Mounting W

all (Outdoor, Indoor)

Mounting height 0.8 – 1.2 m (2'7" – 3'11")

Weight 190

g (6.7 oz.)

Accessories

Connector

for POWER and ALARM,

connector

for TROUBLE, plate nut × 2,

screw

(M3 × 10 mm) × 2, screw (3 × 20 mm) × 4,

sponge

for transmitter

*Specifications and design are subject to change without prior notice.

- 19 -

Page 20

7-2

DIMENSIONS

Unit: mm (inch)

Unit: mm (inch)

35 (1.38") 42.5 (1.67") 35 (1.38") 42.5 (1.67")

155 (6.10")

155 (6.10")

Note>>

These units are designed to detect an intruder and activate an alarm control panel. Being

only a part of a complete system, we cannot accept responsibility for any damages or other

consequences resulting from an intrusion. These products confirm to the EMC Directive

2004/108/EC.

•

OPTEX INCORPORATED (USA)

TEL:+1-909-993-5770

Tech:(800)966-7839

URL:http://www.optexamerica.com/

OPTEX KOREA CO., LTD. (KOREA)

TEL:+82-2-719-5971

URL:http://www.optexkorea.com/

OPTEX SECURITY Sp. z o. o. (POLAND)

TEL:+48-22-598-06-55

URL:http://www.optex.com.pl/

OPTEX (DONGGUAN) CO., LTD.

SHENZHEN OFFICE (CHINA)

TEL:+86-755-33302950

URL:http://www.optexchina.com/

OPTEX CO., LTD. (JAPAN)

(ISO 9001 Certified)

(ISO 14001 Certified)

5-8-12 Ogoto Otsu

Shiga 520-0101

JAPAN

TEL:+81-77-579-8670

FAX:+81-77-579-8190

URL:http://www.optex.co.jp/e/

OPTEX (EUROPE) LTD. (UK)

TEL:+44-1628-631000

URL:http://www.optexeurope.com/

OPTEX SECURITY SAS (FRANCE)

TEL:+33-437-55-50-50

URL:http://www.optex-security.com/

OPTEX INCORPORATED (USA)

TEL:+1-909-993-5770

Tech:(800)966-7839

URL:http://www.optexamerica.com/

OPTEX KOREA CO., LTD. (KOREA)

TEL:+82-2-719-5971

URL:http://www.optexkorea.com/

OPTEX SECURITY Sp. z o. o. (POLAND)

TEL:+48-22-598-06-55

URL:http://www.optex.com.pl/

OPTEX (DONGGUAN) CO., LTD.

SHENZHEN OFFICE (CHINA)

TEL:+86-755-33302950

URL:http://www.optexchina.com/

OPTEX CO., LTD. (JAPAN)

(ISO 9001 Certified)

(ISO 14001 Certified)

5-8-12 Ogoto Otsu

Shiga 520-0101

JAPAN

TEL:+81-77-579-8670

FAX:+81-77-579-8190

URL:http://www.optex.co.jp/e/

OPTEX (EUROPE) LTD. (UK)

TEL:+44-1628-631000

URL:http://www.optexeurope.com/

OPTEX SECURITY SAS (FRANCE)

TEL:+33-437-55-50-50

URL:http://www.optex-security.com/

- 20 -

Loading...

Loading...