Prod uct Bul le tin OP294

June 1996

GaA lAs Plas tic In fra red Emit ting Di ode

Types OP294, OP299

Fea tures

• Characterized at 5mA for battery

operated systems or other low drive

current systems

• Wide irradiance pattern (OP294) or

narrow irradiance pattern (OP299)

• Significantly higher power output than

GaAs at equivalent drive currents

• Wavelength matched to silicon’s peak

response

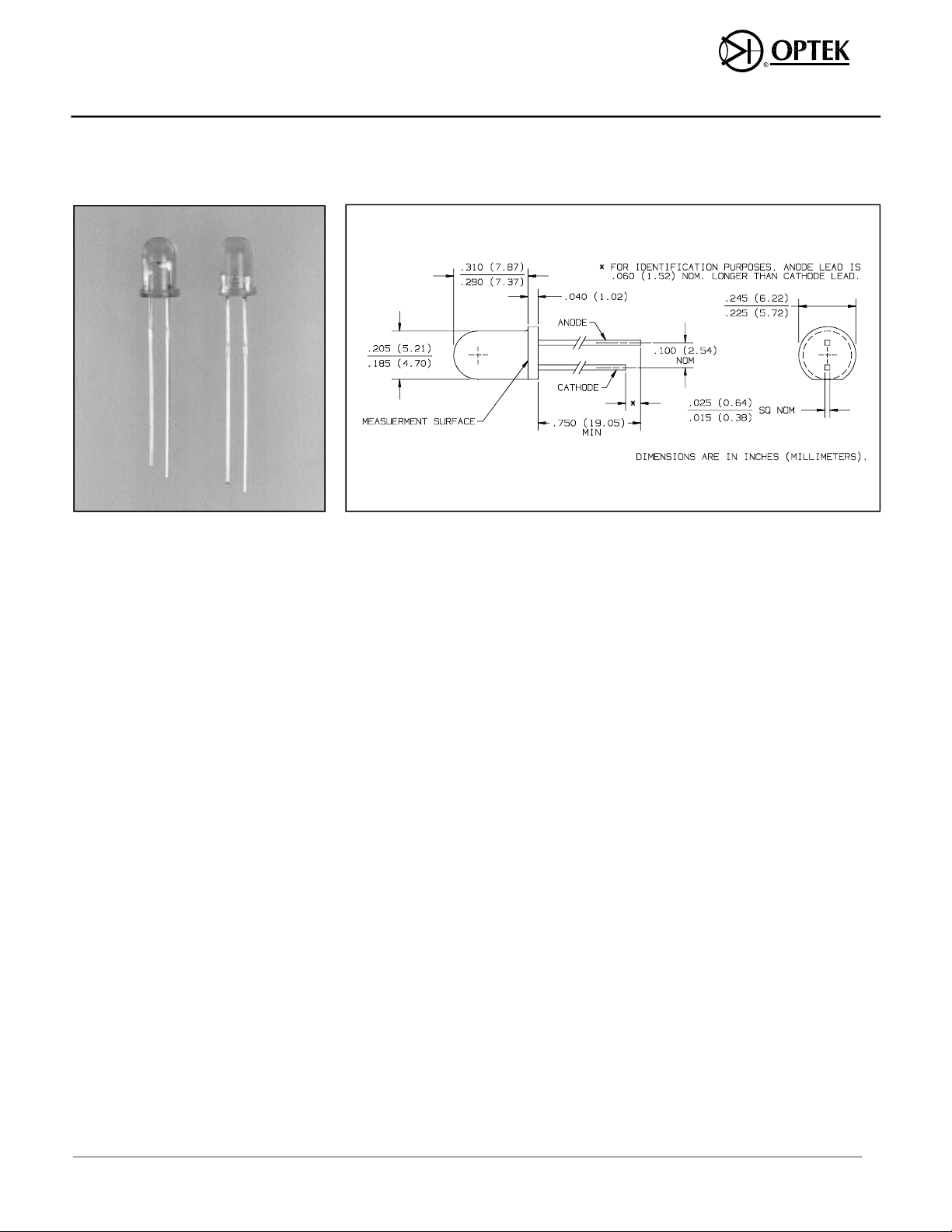

• T-1 3/4 package

De scrip tion

The OP294 and OP299 are gallium

arsenide infrared emitting diodes

designed for low current or power limited

applications (such as battery supplies).

These LEDs are similar in design to the

OP290 and OP295 but use a smaller

chip which increases output

efficiency at low current levels by

increasing current density. Light output

can be maximized with continuous (d.c.)

forward current up to 100mA or with

pulsed forward current operation up to

750 mA. The chip is mounted in an IR

transmissive plastic package and has

been designed and tested for use with

OP593/598 phototransistors or similar

photodetector.

Ab so lute Maxi mum Rat ings (TA = 25o C un less oth er wise noted)

Re verse Volt age . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.0 V

Con tinu ous For ward Cur rent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mA

Peak For ward Cur rent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 750 mA

Stor age and Op er at ing Tem pera ture Range . . . . . . . . . . . . . . . . . . -40o C to +100o C

Lead Sol der ing Tem pera ture [1/16 inch (1.6 mm) from case for 5 sec. with sol der ing

iron] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260o C

Power Dis si pa tion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180 mW

Notes:

(1) RMA flux is recommended. Duration can be extended to 10 sec. max. when flow soldering.

A max. of 20 grams force may be applied to the leads when soldering.

(2) Derate linearly 1.80 mW/o C above 25o C.

(3) E

(4) E

(5) Cathode lead is 0.070" nominal shorter than anode lead.

is a measurement of the average apertured radiant energy incident upon a sensing

e(APT)

area 0.250" (6.35 mm) in diameter, perpendicular to and centered on the mechanical axis of

the lens, and 1.429" (36.3 mm) from the measurement surface. E

uniform within the measured area.

is a measurement of the average apertured radiant energy incident upon a sensing

e(APT)

area 0.250" (6.35 mm) in diameter, perpendicular to and centered on the mechanical axis of

the lens, and .500" (12.7 mm) from the measurement surface. E

uniform within the measured area.

is not necessarily

e(APT)

is not necessarily

e(APT)

(1)

(2)

Op tek Tech nol ogy, Inc. 1215 W. Crosby Road Car roll ton, Texas 75006 (972) 323- 2200 Fax (972) 323- 2396

2-56

Types OP294, OP299

Elec tri cal Char ac ter is tics (TA = 25o C un less oth er wise noted)

SYM BOL PA RAME TER MIN TYP MAX UNITS TEST CON DI TIONS

µA

2

IF = 5 mA

2

IF = 5 mA

VR = 2 V

IF = 10 mA

E

e(APT)

V

I

λp

Apertured Radiant Incidence OP294

OP299

Forward Voltage 1.50 V IF = 5 mA

F

R

Reverse Current

Wavelength at Peak Emission

0.50

0.15

1.50

mW/cm

0.45

mW/cm

10

890 nm

B Spectral Bandwidth Between Half Power Points 80 nm IF = 10 mA

∆λp/∆T

θ

HP

t

r

t

f

Spectral Shift with Temperature

Emission Angle at Half Power Points OP294

OP299

+0.18 nm/o C

50

20

Deg.

Deg.

Output Rise Time 500 ns I

Output Fall Time 250 ns

IF = Constant

IF = 10 mA

IF = 10 mA

F(PK)

PW = 10 µs, D.C. = 10%

(4)

(3)

= 100 mA,

Op tek re serves the right to make changes at any time in or der to im prove de sign and to sup ply the best prod uct pos si ble.

Op tek Tech nol ogy, Inc. 1215 W. Crosby Road Car roll ton, Texas 75006 (972)323- 2200 Fax (972)323- 2396

2-57