Oppermann Regelgeräte KRM-1, KRM-2, KRM-2-MOD Technical Data Manual

Duct Smoke Sensor KRM®

Technical Data

Sensor: Scattering RM 3.3 (ALK-E)

Supply voltage KRM-1:

230 V AC ± 10 %, 50/60 Hz

Supply voltage KRM-2/KRM-2-MOD:

24 V AC/DC +15 % / -10 %

Rated current: KRM-1: 30 mA

KRM-2/KRM-2-MOD: 120 mA

Relay outputs: oating

Alarm relay locked: 1 changeover contact, 8 A,

250 V AC or 24 V DC

1 NC, 8 A, 250 V AC or 24 V DC

Contamination relay:

Operating temperature:

Permissible humidity:

Protection class:

(water resistant housing)

Approvals:

Sensing chamber and

air duct frames: VdS approval G210059

Tested:

according to FprEN54-27

LED display:

at > 70 %

LED in housing:

blue lack of air ow

yellow failure, electronics,

smoke detector defective,

low voltage

red smoke alarm, including

contamination > 99 %,

ashes at attempts to release

when the sensing chamber is

not empty

Adaptergehäuse: ABS

Air measuring tube:

shortest length 160 mm

standard length 600 mm

Dimensions:

Screw connection:

% contamination level ashes

257 x 166 x 77 mm (L x W x H)

1 NC contact, 6 A, 250 V AC or 24 V DC

-10 °C - +50 °C

10 - 95 % non-condensing

IP 54, IP 65 with WDG

green operating

Aluminium / plastic

3 x M16

• VdS certication (G210059)

• Patented single tube air sampling system

• Contamination display in %

and signalling at 100 %

• Electronic air ow control

• Externally operable reset button in the

housing

• Remote reset option via terminals

• Long service life, low contamination

Accessories

Mounting bracket: KS (for insulated / circular ducts)

Housing: waterresistant housing for outdoor

installation and increasing protection

class to IP 65

Function

The KRM duct smoke detector is designed for smoke detection

in ventilation ducts. It constitutes a combination of a smoke

detector with an adapter system, whose measuring tube and

housing have been specially adapted for optimal air ow through

the smoke detector.

The multi-chamber measuring tube in the air duct transports the

air within the air duct along the entire length of the tube, through

the sensing chamber and back into the air duct. Upon detection

of smoke, the sensor reacts immediately and triggers an alarm.

Over time, the sensor becomes contaminated. Because of alarm

threshold tracking, the sensitivity up to total pollution remains

the same. From 70 % contamination upwards, the sensor is triggered and indicates this by ashing. If the sensor is not replaced

the smoke alarm is triggered at 99 % contamination.

The contamination level is indicated in a two-line LED display; at

> 70 % it ashes.

To verify operability, the device is equipped with electronic air

ow monitoring, which lights a blue LED at < 1 m/s. The failure

LED illuminates when the smoke sensor or the electronics are

defective, in the absence of a smoke sensor, and with shortcircuits or cable breakage.

The smoke alarm must be released with the reset button.

A functionality test is also possible with the same button.

The operation functions like a smoke alarm.

Furthermore, the same function takes place on restart or when

the bridge circuit between terminals 9 and 10 is opened (remote

release).

Fire Protection | Data sheet No. 41300 | Version 01-2011 | 1 | 8

Duct Smoke Sensor KRM

10

9

11

12

13

8

6

5

7

1

14

Electrical connection

Power supply

230 V AC

Test/Reset

1

2

3

4

9

10

11

12

13

14

15

16

17

4

2

3

Power supply

230 V AC

Smoke alarm

Service signal

Contamination

14

11

9

10

Smoke alarm

Test/Reset

green

red

yellow

13

12

1 Adapter plate with gasket

2 Patented measuring tube (max. length 3 m)

3 End cap

4 Rubber bushing

(only for insulated or circular ducts)

5 Lower housing with seal

6 Electronics

7 Optical smoke sensor

8 Upper casing with seal

9 Red LED: alarm / reset button

10 Yellow LED: interference

11 LED display: % of sensor contamination

12 LED green: in operation

13 LED blue: air ow under 1 m / s

14 Opening for test gas

15 Air duct

10

11

12

13

14

15

16

17

1

2

3

4

9

Power supply

230 V AC

Smoke alarm

Smoke alarm

Service signal

Contamination

Power supply

24 V AC/DC

Test/Reset

green

Test/Reset

red

yellow

blue

Power supply

24 V AC/DC

Test/Reset

KRM-2-MOD, 24 V

10

11

12

13

14

15

16

17

1

2

3

4

5

6

7

8

9

KRM-1

Bus B

Bus B

Bus A

Bus A

Power supply

24 V AC/DC

Smoke alarm

Smoke alarm

Service signal

Contamination

Test/Reset

blue

green

red

yellow

KRM-2, 24 VKRM-1, 230 V

KRM-2

Programming the Bus address for the KRM-2-Mod:

Press buttons T3+T4 on the circuit board (to the right, next to the

display) at the same time, so that the display changes from contamination level to show the bus address (the display will ash).

Press button T3 or T4 to adjust the desired address (1-99). The last

set bus address is automatically saved. The display resets automatically after 3 seconds or by simultaneously pressing T3+T4.

Contact depictions are with the

power o (alarm)

KRM-2-MOD

Notes: The oating switching contacts (terminals 11-17) are uniformly assigned to an installation category according to EN 60730-1.

blue

These switching contacts are only to be used for 230 V AC or 24 V AC/DC, a combination is not permitted.

A mixed connection of safety extra-low voltage (SELV) and low voltage must not occur. The assembly may only be operated on one mains

phase.

2 | 8 | Fire Protection | Data sheet No. 41300 | Version 01-2011

Duct Smoke Sensor KRM

Installation Instructions

Install the detector where ow meters, etc. are normally xed,

so that the air ow can run in a laminar manner with the measuring tube. Follow the installation instructions. All work must be

carried out by suciently qualied craftsman.

Current local rules and regulations (e.g. building regulations,

elecrical/VDE guidelines, etc.) are to be observed. Installers

and operators are required to be adequately informed before

operation. We assume no liability for misprints and changes

after printing. Compliance with operating and installation

instructions is also included within the regulations of intended

use. We assume no liability for damages caused by improper

use. Operating licenses and guarantees and all warranty claims

will be voided in the event of unauthorized modications or any

tampering with the device.

Maintenance

Targeted maintenance can be carried out since the smoke

detector is equipped with a contamination indicator. From a

70 % contamination level or higher the smoke sensor must

be changed. There is a contact available for this signal, and it

should be connected to the automation station.

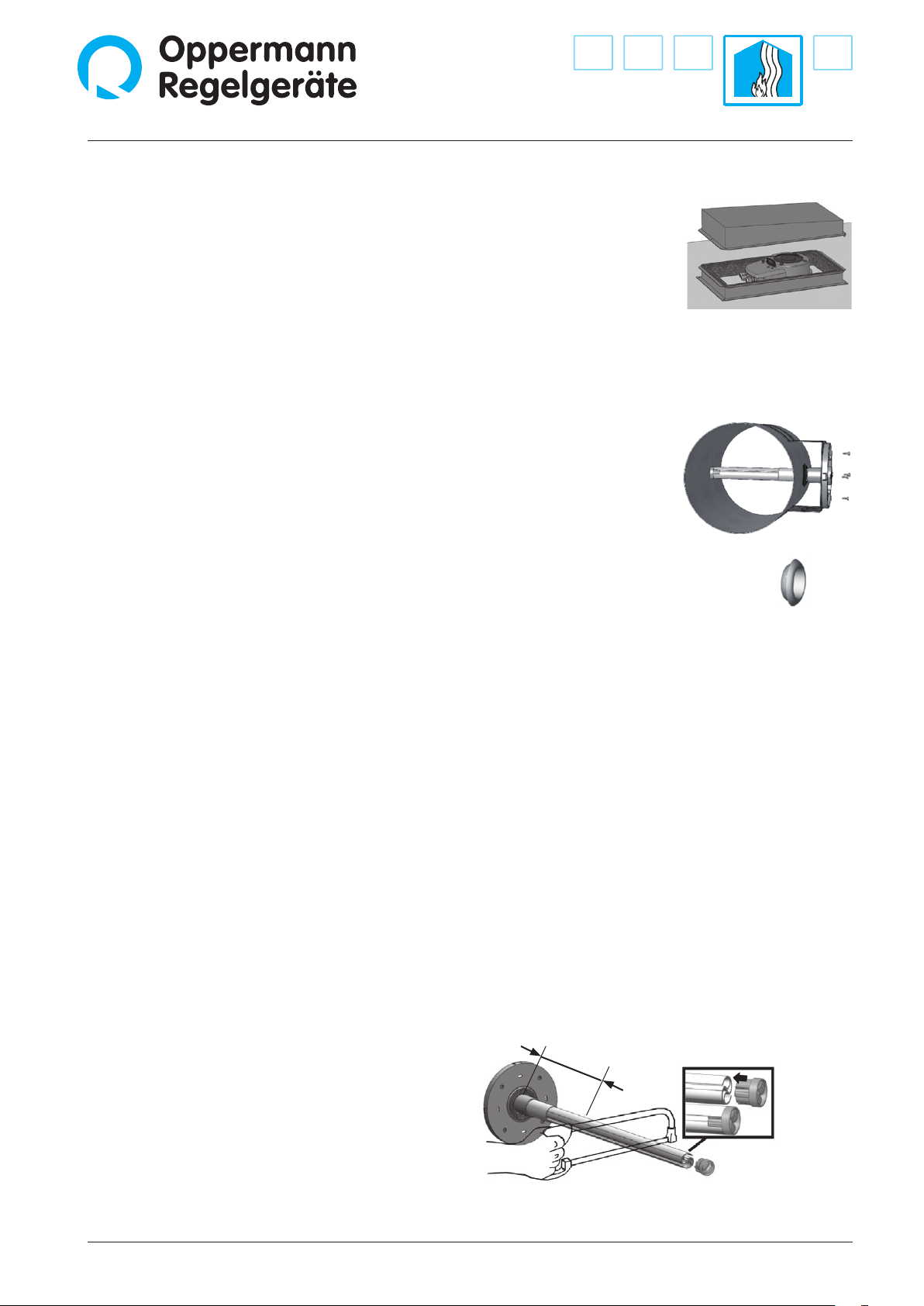

Accessories

Splash-proof housing (type

WDG) for outdoor installation

to prevent condensation. The

housing is lined with insulating foam.

Mounting bracket

Type KS is required if the duct smoke sensor must be mounted on round air ducts. The

bracket can also be used with

insulated rectangular ducts.

For this the adapter is mounted with the air measuring

tube before insulation.

Installation and positioning

1.

We recommend that the duct smoke detector be installed at the

same distance to heating, cooling and humidity equipment and

be mounted similarly to ow sensors. The distance of the smoke

sensor to ttings, valves, lters, etc., should be 3 times the diagonal length of the cross-section of the duct when going against

the air ow, and 5 times the diagonal length with the ow.

2.

Drill a hole of 43-44 mm in diameter at the intended mounting

location.

Note: Installation of the TurboTube measuring tube is possible

either from the top, bottom or side of the channel for all duct

cross-sections (for round ducts as well).

Fire Protection | Data sheet No. 41300 | Version 01-2011 | 3 | 8

3.

• Determine how long the measuring tube must be.

The TurboTube measuring tube must be inserted into the

duct at least to the middle of the duct‘s cross-section.

• If necessary, shorten the tube. Minimum length 160 mm.

• Deburr the cutting face and put the end plug back on up

to the stop collar.

Min. 160 mm Attention:

Operation without

end plug not

permitted.

Loading...

Loading...