Page 1

Biopel v9

User manual

Biopel pellet boilers are boilers fulfilling stringent requirements for ecological heating with low combustion

emissions. It allows you to operate all electrical heating system components and connection of many types of

additional devices operated by boiler control unit. You can find full list of possible accessories inside this manual.

User manual includes all needed information about installation, startup and maintenance of all types of Biopel

boilers, from 10 to 200kW of power. Information included in this manual are intended to both installer and end user.

Chapters are written chronologically, starting with boiler installation, first start up and proper setup, to regular

maintenance. Read all information included inside this manual carefully.

Each Biopel boiler can be connected to our online server to use remote control features for both boiler and heating

system components. Online features are for free included in basic package of Biopel boilers. For more information,

ask your supplier about how to connect your boiler to the internet.

We believe that you will be satisfied with our product for its long working life. For more information about this boiler

and our company use not only this manual but also our network of representatives in your country as well as main

staff of OPOP, Czech Republic.

Page 2

CONTENT

1. INTRODUCTION ......................................................................................................................................................... 4

2. BASIC DESCRIPTION OF BIOPEL LINE BOILERS .......................................................................................................... 4

3. MAIN PARAMETERS .................................................................................................................................................. 5

3.1. Biopel 10 - 40kW ............................................................................................................................................... 5

3.2. Biopel 60 - 80kW ............................................................................................................................................... 6

3.3. Biopel 100 - 200kW ........................................................................................................................................... 7

3.4. Burner ............................................................................................................................................................... 8

3.5. Pellet tank ......................................................................................................................................................... 8

3.6. External feeder .................................................................................................................................................. 8

4. BASIC COMPONENTS OF BIOPEL INSTALATION ........................................................................................................ 9

4.1. Biopel 10 - 40kW ............................................................................................................................................... 9

4.2. Biopel 60 - 80kW ............................................................................................................................................. 10

4.3. Biopel 100 - 200kW ......................................................................................................................................... 11

4.4. Burner ............................................................................................................................................................. 13

4.5. Pellet hopper ................................................................................................................................................... 14

4.6. External feeder ................................................................................................................................................ 14

5. INSTALTION PROCESS.............................................................................................................................................. 15

5.1. Biopel 10 – 80kW ............................................................................................................................................ 17

5.2. Biopel 100 – 200kW ........................................................................................................................................ 18

5.3. Pellet tank ....................................................................................................................................................... 19

5.4. Burner ............................................................................................................................................................. 19

5.5. External feeder ................................................................................................................................................ 20

5.6. Control unit v9 and connection board ............................................................................................................ 20

5.7. Electrical connections ..................................................................................................................................... 21

6. CONTROL UNIT v9 ................................................................................................................................................... 24

6.1. Basic navigation .............................................................................................................................................. 24

6.2. Main operation modes .................................................................................................................................... 25

7. CONTROL UNIT’S MENU LAYOUT ............................................................................................................................ 26

7.1. First start ......................................................................................................................................................... 26

7.2. Ignition / Extinction ......................................................................................................................................... 26

7.3. Main settings ................................................................................................................................................... 26

7.4. Fitters menu .................................................................................................................................................... 28

7.5. Service menu ................................................................................................................................................... 36

7.6. Language selection .......................................................................................................................................... 38

8. FIRST START ............................................................................................................................................................. 39

9. COMBUSTION ADJUSTMENT .................................................................................................................................. 42

9.1. Flame parameters ........................................................................................................................................... 42

9.2. Change fan speed ............................................................................................................................................ 42

Page 3

9.3. Change operation time of external feeder ..................................................................................................... 43

9.4. Non standard installation ................................................................................................................................ 44

10. HEATING SYSTEM EXAMPLES .................................................................................................................................. 45

10.1. One CH circuit + DHW ................................................................................................................................. 45

10.2. Two CH circuits + DHW ............................................................................................................................... 46

11. REGULAR MAINTENANCE ........................................................................................................................................ 49

11.1. Biopel 10 - 80kW ......................................................................................................................................... 49

11.2. Biopel 100 - 200kW ..................................................................................................................................... 50

11.3. Burner 10 - 200kW ...................................................................................................................................... 50

12. BIOPEL ONLINE ........................................................................................................................................................ 51

13. FIRMWARE UPDATE ................................................................................................................................................ 51

14. OPERATIONAL AND ALARM MESSAGES .................................................................................................................. 52

15. SOLUTIONS TO SPECIFIC SITUATIONS ..................................................................................................................... 53

16. FACTORY SETTINGS ................................................................................................................................................. 56

17. WARRANTY CONDITIONS, GENERAL INFORMATION .............................................................................................. 58

18. STANDARDS AND REGULATIONS ............................................................................................................................ 59

19. WARRANTY CARD .................................................................................................................................................... 60

Page 4

1. INTRODUCTION

Reed this manual step by step, each chapter from the beginning to the end, to make sure installation and start-up is made

properly. You make sure your boiler runs at its best if you read all information included in this manual. Chapters describe first

boiler installation, than chronologically accessories connection and activation and boiler maintenance. Manual describes all

important steps and describes practical information for each chapter, so it helps customer to understand activity of all boiler and

heating system components.

In the second half of this manual is full heating system examples including electrical components such as pups and mixing valves

and step by step description how to connect and activate these components inside v9 controller menu. Use this manual to

connect and setup all accessories properly so boiler operation will be in in accordance with user manual.

If you need more information about boiler function, do not hesitate to contact OPOP business partners in your country or

directly OPOP staff. We will gladly tell you all the information you want to know.

2. BASIC DESCRIPTION OF BIOPEL LINE BOILERS

Biopel boilers are produced in several sizes, from 10 to 200kW. Boiler is operated by v9 control unit which regulates also all

electrical components of heating system, if connected into the connection board in the front of the boiler. There are many

advanced features implemented inside v9 controller which allows customer to use his boiler as he requires.

V9 controller allows following:

2 mixing valves operation.

2 room thermostats for 2 separate heating circuits.

5 pumps – central heating pump (CH pump), domestic hot water pump (DHW pump), valve pump 1, valve pump 2,

additional pump with configurable settings.

Weather compensation based on the outside temperature sensor.

CH temperature time control - programmable weekly operation mode.

Buffer tank operation with use of 2 temperature sensors.

Online remote control by our OPOP online server: opop.emodul.eu.

Firmware update via USB key to upload new features.

Additional output for boiler activation by solar heating device.

Despite this, v9 controller allows connection of wide range of additional devices, which makes boiler operation and maintenance

more automatic. List of all additional accessories is listed below:

RT10 room thermostat, displaying information of full hydraulic system connection.

Compressor cleaning of burner, extending significantly intervals for manual cleaning.

Automatic ash removal, extracting ash from bottom part of the boiler into the external container. You don’t need to

remove ash from the boiler to often if you install this device.

Automatic exchanger cleaning, which moves turbulators inside the boiler up and down and cleans heat exchanger. All

the ash drops down to the ashtray and can be removed automatically by automatic ash removal system.

Lambda sensor, measuring remaining oxygen inside the boiler and adjusting combustion to make it more efficient.

GSM module, which can change boiler operation by sending sms messages on sim card inside this module.

Vacuum transport, transferring pellets from external silo inside standard pellet tank next to the boiler.

Cascade controller, allowing you to operate up to 4 boilers connected together and make big boiler rooms more

efficient.

Exhaust fan, to increase chimney draft if chimney is not high enough to support proper boiler operation.

These devices can be installed anytime, even after boiler installation. Ask your installer for more information about each

accessories if you consider using these with your boiler. We will also gladly help you to explain and suggest possibilities how to

make your boiler even more automatic and efficient.

Page 5

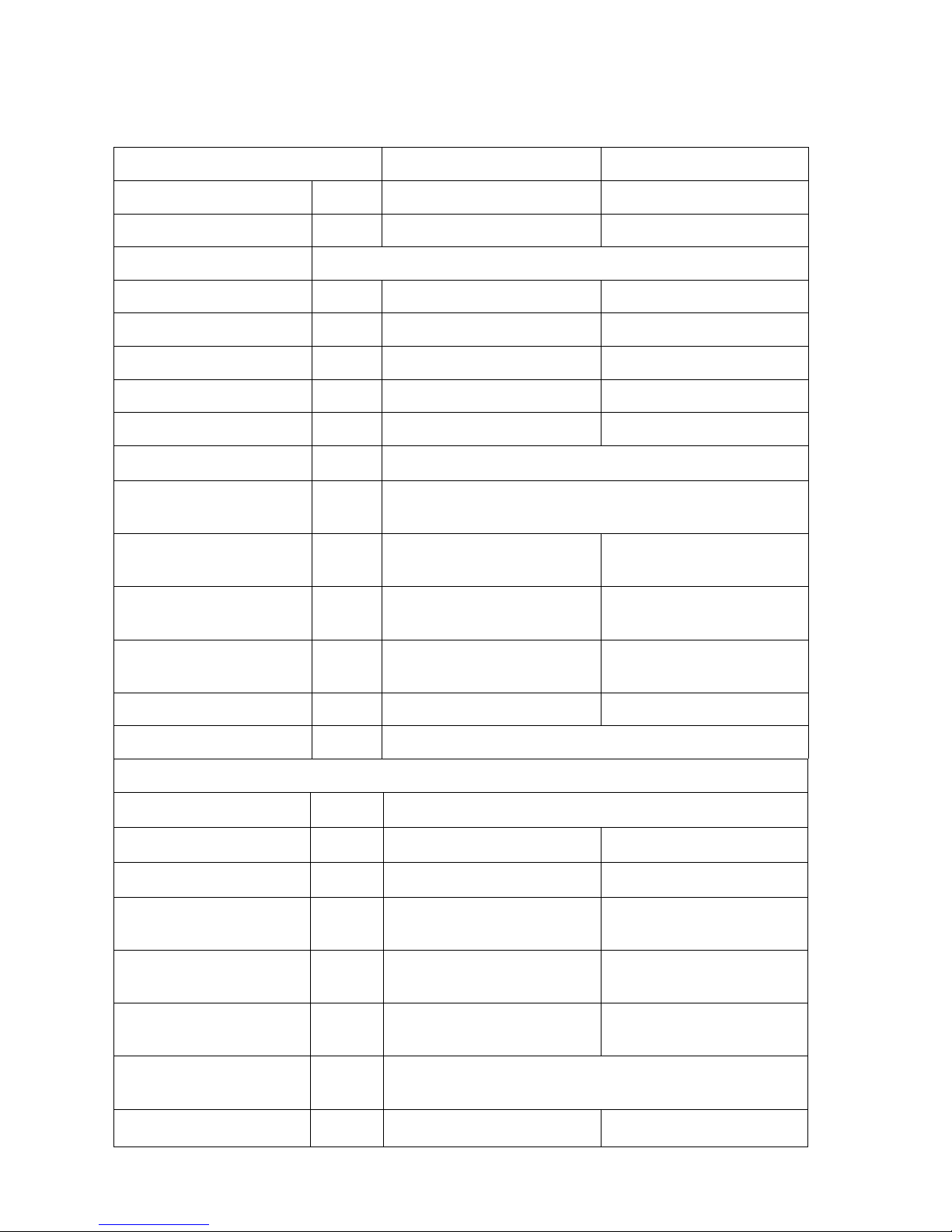

3. MAIN PARAMETERS

Main components of basic installation are boiler, burner and fuel storage tank. You can find main parameters for each

component down below, including also diameters and other important values.

3.1. Biopel 10 - 40kW

Boiler body is always different according its maximum power. Main differences are external dimensions, connection outlets

and inlets, flue gas outlet diameter, heat exchanger size and number of doors attached on the boiler body.

Technical parameters:

Biopel 10

Biopel 15

Biopel 20

Biopel 30

Biopel 40

Maximum power

kW

10,32

14,5

19,43

31,5

42,48

Minimum power

kW

2,99

3,7

4,7

8,5

11,4

Warranty fuel

Wood pellets 6-8 mm

Fuel consumption (max power)

kg/h

2,5

3,4

4,4

7,2

9,96

Fuel consumption (min power)

kg/h

0,71

0,85

1,1

1,9

2,66

Emmision class *1

5

Efficiency *1

%

89,94

91,4

92,82

92,2

91,41

Water volume

L

43

59,3

83

Recommended chimney draft

Pa

5-10

5-12

5-15

10-20

10-20

Maximum water pressure

during operation

Bar

2

Maximum water temperature

in the boiler

°C

85

Minimum return water

temperature

°C

65

Flue gas temperature (durning

max. boiler power)

°C

70

73

77

87

97

Weight

kg

198

198

228

228

300

Supply voltage

V/Hz

230V/50Hz ±10%

Dimensions:

Boiler height

mm

1054

1154

Boiler width

mm

455

555

655

Boiler depth

mm

773

838

936

Flue gas outlet position from

the ground

mm

708

808

Inlet water position from the

ground

mm

178

Outlet water position from the

ground

mm

868

968

Counnecting diameters of

water outlet and inlet

DN

G1 1/4"

Flue gas outlet diameter

mm

130

150

*

1

Emission parameters are measured according the EN 303-5 standards.

Page 6

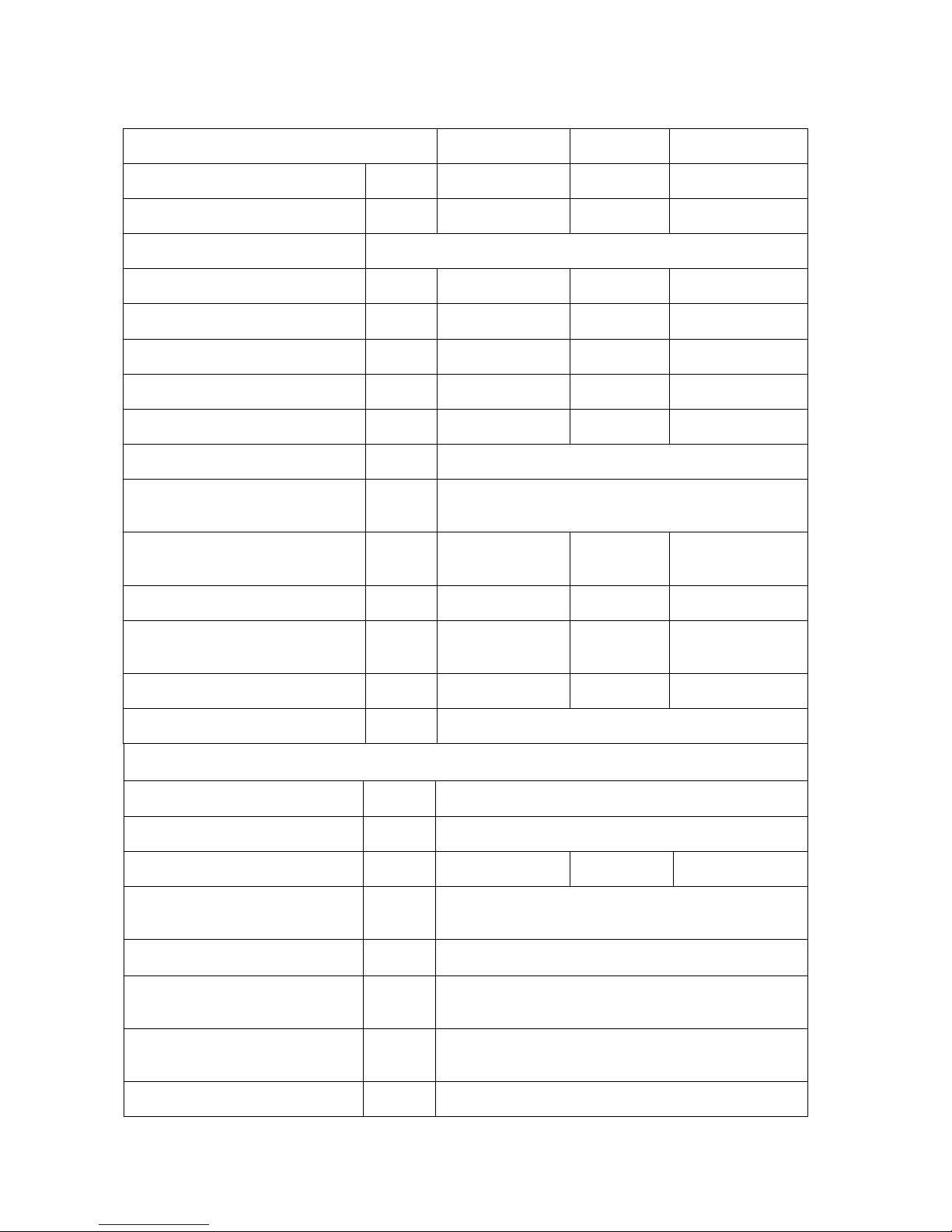

3.2. Biopel 60 - 80kW

Boiler body is always different according its maximum power. Main differences are external dimensions, connection outlets

and inlets, flue gas outlet diameter, heat exchanger size and number of doors attached on the boiler body. Biopel 60-80kW

can be installed only with external version of pellet tank.

Technical parameters:

BIOPEL 60

BIOPEL 80

Maximum power

kW

63,5

84,4

Minimum power

kW

15,5

19,96

Warranty fuel

Wood pellets 6-8 mm

Fuel consumption (max

kg/hod

15,1

20,1

Fuel consumption (min

kg/hod

3,9

5,2

Emmision class *1

5

5

Efficiency *1

%

90,6

90,1

Water volume

l

95

130

Recommended chimney draft

Pa

10-15

Maximum water pressure

during operation

Bar

2

Maximum water temperature

in the boiler

°C

85

85

Minimum return water

temperature

°C

65

65

Flue gas temperature (durning

max. boiler power)

°C

117,8

131,9

Weight

kg

385

480

Supply voltage

V/Hz

230V/50Hz ±10%

Dimensions:

Boiler height

mm

1312

Boiler width

mm

641

743

Boiler depth

mm

949

1049

Flue gas outlet position from

the ground

mm

1007

1007

Inlet water position from the

ground

mm

90

90

Outlet water position from

the ground

mm

1171

1164

Counnecting diameters of

water outlet and inlet

DN

G1 1/4"

Flue gas outlet diameter

mm

150

178

*

1

Emission parameters are measured according the EN 303-5 standards.

Page 7

3.3. Biopel 100 - 200kW

This size of Biopel has horizontal pipe type of heat exchanger. Its dimensions, way of installation and connection diameters

of water inlet and outlet are also different than Biopel 10-80kW. Read exact values in the table below.

Technical parameters:

BIOPEL 100

BIOPEL 150

BIOPEL 200

Maximum power

kW

107,1

154,5

201,4

Minimum power

kW

28,7

44,5

59,9

Warranty fuel

Wood pellets 6-8 mm

Fuel consumption (max power)

kg/hod

25,2

35,2

45

Fuel consumption (min power)

kg/hod

6,7

10,3

13,9

Emmision class *1

4 5 5 Efficiency *1

%

90,9

91,8

95,5

Water volume

l

690

950

1190

Recommended chimney draft

Pa

10-15

Maximum water pressure during

operation

Bar

2

Maximum water temperature in the

boiler

°C

85

85

85

Minimum return water temperature

°C

65

65

65

Flue gas temperature (durning max.

boiler power)

°C

95,8

92,6

93,5

Weight

kg

1414

1740

2133

Supply voltage

V/Hz

230V/50Hz ±10%

Dimensions:

Boiler height

mm

1919

Boiler width

mm

1560 / 1198

Boiler depth

mm

1660

2060

2460

Flue gas outlet position from the

ground

mm

1886

Inlet water position from the ground

mm

606 / 70

Outlet water position from the

ground

mm

676 / 217

Counnecting diameters of water

outlet and inlet

DN

G 1 1/2" / G 2 1/2"

Flue gas outlet diameter

mm

199

*

1

Emission parameters are measured according the EN 303-5 standards.

Page 8

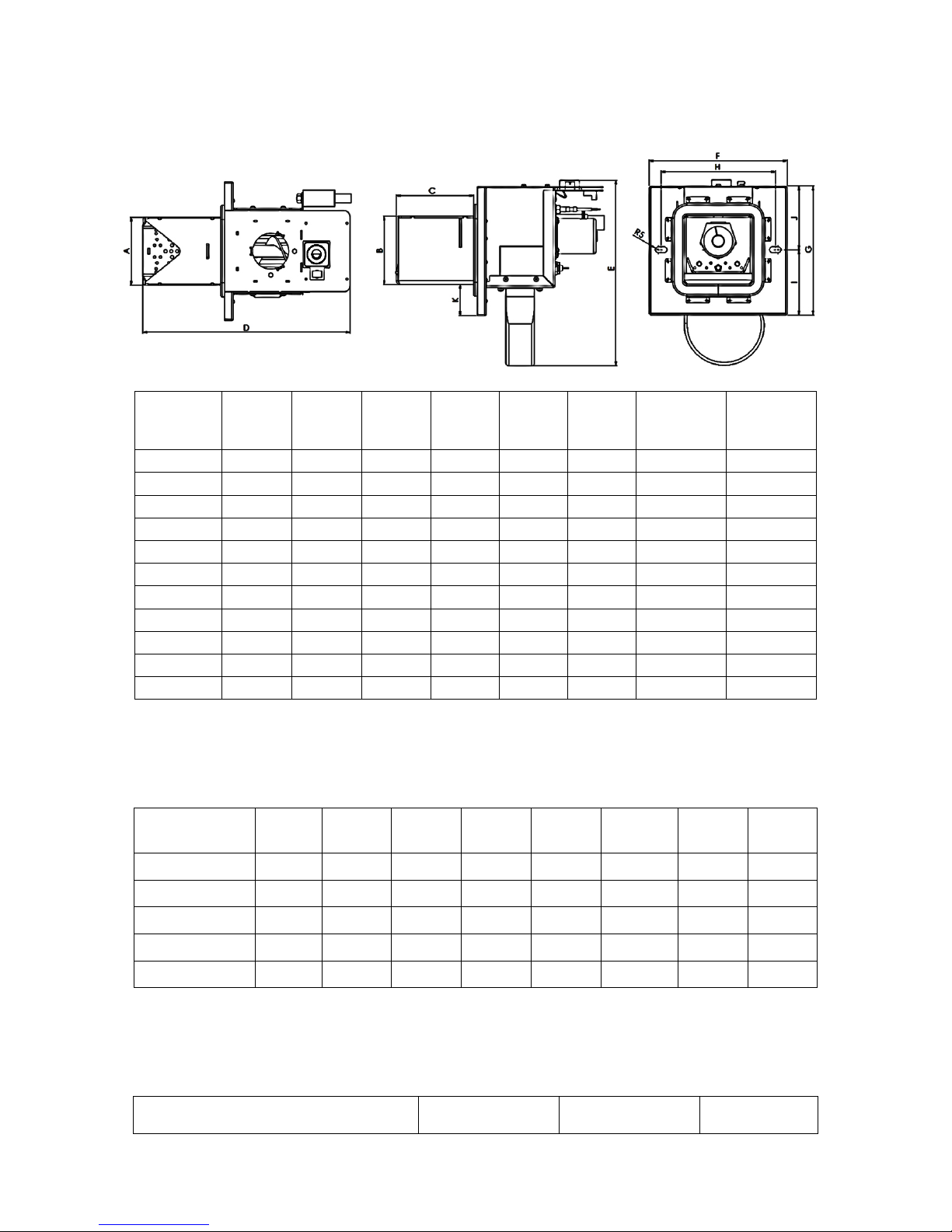

3.4. Burner

Pellet burner is different the same way as a boiler body, according to the maximum power. Differences are mainly in burner

dimensions, types of electrical components and types of burner grates which are also different according to the burner size.

Dimensions

mm

Biopel

burner

10

Biopel

burner

15

Biopel

burner

20

Biopel

burner

30

Biopel

burner

40

Biopel

burner

60

Biopel

burner 80-

100

Biopel

burner 150-

200

A

116

116

145

177

183

183

213

324

B

116,6

116,6

116,6

171

173,8

173,8

198,8

224

C

132

177

221

250,7

322,6

322,6

360,9

523,6

D

354

399

446,1

500

573

602

637

842,4

E

316,5

316,5

319,1

380,3

390,8

457,8

476,8

477,4

F

236

236

240

278

333

333

340

453

G

220

220

240

278

273

273

299

298

H

195

195

204

248

306

306

306

412

I

111,5

111,5

120

139

144

144

150

147,5

J

108,5

108,5

120

139

129

129

149

150,5

K

53

53

70,4

58,5

43

43

50

37

3.5. Pellet tank

Pellet tanks are divided to 2 main types. Compact version can be used with boilers from 10 to 40kW, external versions can

be used for all Biopel types.

Pellet tank type

cm

External

60x60

External

80x80

External

100x100

External

1420x80

Compact

big

Compact

middle

Compact

small

Volume of pellets

kg

110

220

300

350

250

150

60

Weight

kg

25

29

35

38

95

55

Height

mm

1300

1300

1300

1300

1210

1210

1210

Width

mm

600

815

1000

1420

653

507

507

Depth

mm

600

815

1000

815

1180

995

3.6. External feeder

External feeder is used only with external tank configuration. Compact tank has feeder already installed inside. You can

choose two sizes – 2 or 3m length.

External feeder type

m 2 3

Page 9

4. BASIC COMPONENTS OF BIOPEL INSTALATION

Biopel is produced in several sizes depending on maximum power, form 10 to 200kW. Each size has its differences, speaking not

only about dimensions, but also design of heat exchanger, doors, connection dimensions of inlets, outlets, flue gas outlets.

Boiler size is also influenced by burner dimensions, pellet tank type which you selected, external feeder size and other. You can

read about each main part of Biopel installation set below in next chapters.

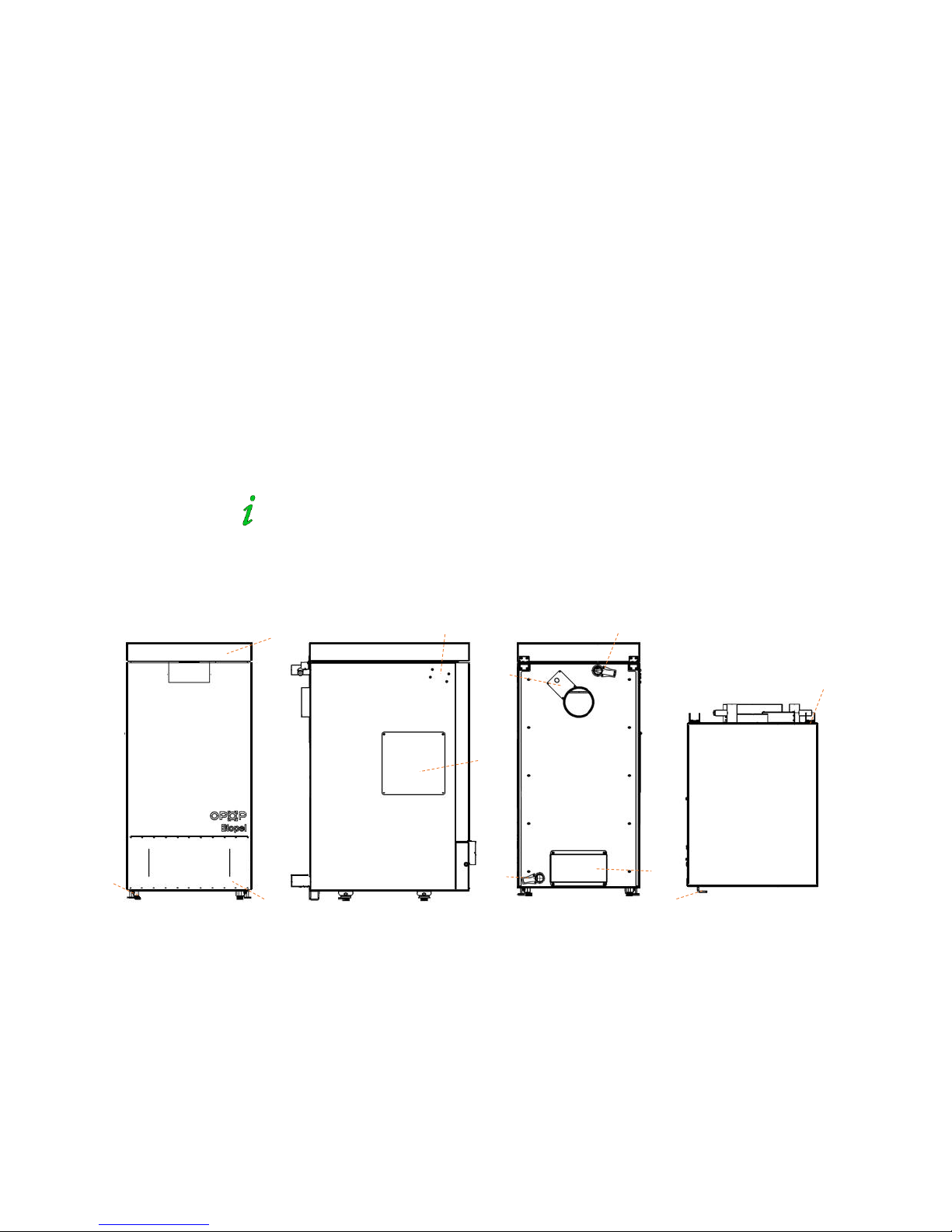

4.1. Biopel 10 - 40kW

You can find 3 doors on the boiler. Two doors on the top of the boiler, one door in the bottom front part of the boiler. There

is top lid on the top of the boiler for better isolation, which decreases the temperature loss. Cleaning doors on the top of

the boiler are removable to get inside the heat exchanger easily, to clean the inside of the boiler without problem.

On each side there is place for pellet burner, covered on one side by metal flap. So you can choose from which side you

insert pellet burner into the boiler. There is also attachement of motor for exchanger cleaning on the sides of the boiler and

also connecting holes for control unit holder attachemen if you use boiler with external type of pellet tank.

Pellet burner can be installed on the right or left side of the boiler body.

There are 2 inlets for temperature sensors on the back side of the boiler. Sink for CH and Termik temperature sensor is

attached on the outcomming water outlet on the top back side of the boiler. On the bottom ack side of the boiler is inlet for

incoming water from heating system into the boiler. Next to this inlet is filling valve outlet to fill up boiler with system

water. There are two covers on the back side of the boiler. First is placed next to the chimney flue path outlet, which covers

lambda sensor and chimney temperature sensor connection. Second cover is at the bottom back side of the boiler for

automatic ash removal motor (additional device). Chimney flue path outlet is positioned on the back side of the boiler as

well. Temperature sensors (CH, termik and Chimney flue gas) re connected on the back side of the boiler. There are shafts

for cables on the sides of the boiler.

On the bottom of the boiler there are adjustable legs, which can change the hight of the boiler to keep it at horizontal level

all the time. Hinges of the bottom front door are removable to make the opening of these dors on left or right side.

Hinges of the bottom front doors are removable. You can install them on the other

side and make to opening of the doors from other side.

There is ashtray inside the boiler and above there are turbulators inserted inside heat exchanger. The reason is to keep the

the heated air inside the boiler as long as possible, to inscrease boiler efficiency. Turbulators can be removed to access th e

heat exchanger easily and clean efficiently all the surface inside the boiler.

a) Top lid, under combustion and cleaning top

doors

b) Sidded bottom ash doors

c) Adjustable legs on bolts

d) Burner blanking flap on both sides of the

boiler

e) Blanking flap of aut. Exchanger cleaning

f) External control unit holder (only with

external pellet tank version)

g) Inlet for CH and termik temperature sensors

h) Inlet for for filling / drain valve and for return

water into the boiler

i) Blanking flap for lambda sensor connection

and chimney temperature sensor.

j) Blanking flap for aut. ash removal system

k) Hinges of top lid

l) Closing handle for ash door

a

b c d

e f g

h

ch

i j k

l

Page 10

Package content:

There are additional accessories inserted with mounting material inside the ashtray. Remove it for completing the

installation. Amount and types of additional parts can vary depending on the type of the boiler.

3pcs of cleaning tools (brush, brush handle,

scraper) – for cleaning the internal parts of

the boiler.

Filling valve – for filling water inside the boiler

and drainig if necessary.

2pcs of burner screws – installed on the

burner outlet to hold the burner at right

position.

Ash container – in the bottom part of the

boiler

Burner flange (for 20, 30 and 40kW boiler) –

installed on the boiler opening for the burner

attachement.

4 screws of the burner flange (for boilers 30

and 40kW) - for mounting flange on the boiler

opening for the burner attachement. Flange

for 20kW boiler is attached directly on the

burner screws.

2 pieces of wing nuts for burner attachement -

to ensure the tightness between the flange

and the burner. Mounted on the burner

screws.

2 washers – placed on the burner screws,

under the wing nuts.

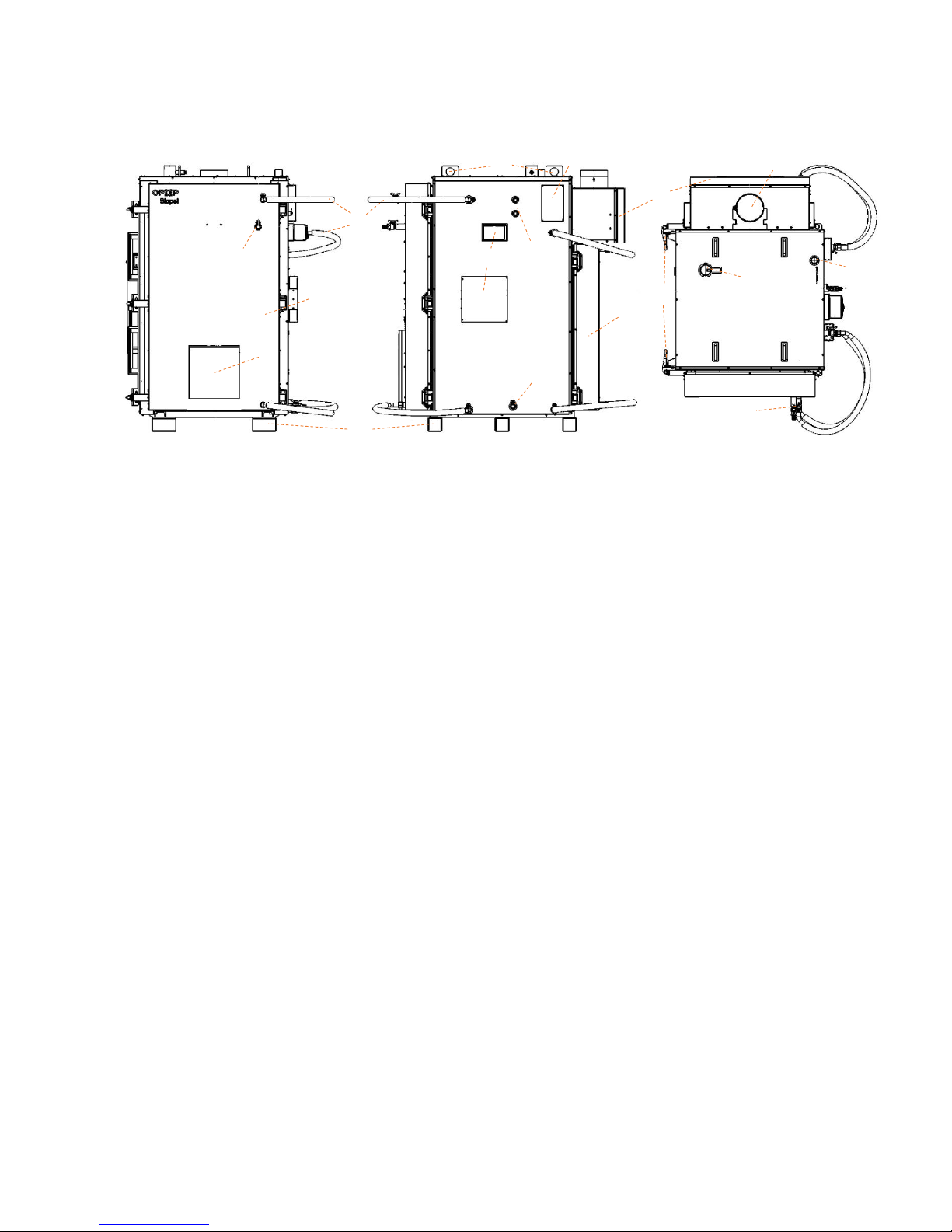

4.2. Biopel 60 - 80kW

The boiler is equipped with three doors. Stoking, cleaning and ash doors. The top of the boiler is, for better insulation, fitted

with a lid. Stoking and cleaning doors are fixed by wing nuts. Cleaning doors are also completely removable. On the sides,

see the burner openings (left and right) and mounting for the control unit.

Installation is possible only with an external type of pellet hopper.

You see two main pipes in the rear part of the boiler. In the upper part of the back side of the boiler is outlet for

outcomming water from the boiler, fitted with two sensors – CH and Termik. In the bottom rear part of the boiler is inlet for

incoming water to the boiler, fittet with filling valve. Flue outlet and opening for the ash removal system (optional, only for

10-60kW) are also located in the rear side of the boiler.

a) Top lid, underneath stoking and cleaning

doors

b) Ash door

c) Boiler legs

d) Burner opennings on both sides

e) Mounting for the control unit

f) Outlet for outcomming water from the boiler,

fitted with two sensors – CH and Termik

g) Inlet for incoming water to the boiler, fittet

with filling valve

h) Connection of Lambda probe and the flue gas

temperature sensor

i) Opening for the ash removal system

j) Upper lid hinges

k) Ashtray door handle

a

b

c

d

e

f

g

h

i jk

Page 11

Package content:

There are additional accessories inserted with mounting material inside the ashtray. Remove it for completing the

installation. Amount and types of additional parts can vary depending on the type of the boiler.

3pcs of cleaning tools (brush, brush handle,

scraper) – for cleaning the internal parts of

the boiler.

Filling valve – for filling water inside the boiler

and drainig if necessary.

2pcs of burner screws – installed on the

burner outlet to hold the burner at right

position.

Ash container – in the bottom part of the

boiler. There could be one or two section

ashtray.

Burner flange – installed on the boiler opening

for the burner attachement.

Burner flange gasket - installed between the

burner opening on the boiler and burner

flange.

4 screws of the burner flange - for mounting

flange on the boiler opening for the burner

attachement.

2 pieces of wing nuts for burner attachement -

to ensure the tightness between the flange

and the burner. Mounted on the burner

screws.

2 washers – placed on the burner screws,

under the wing nuts.

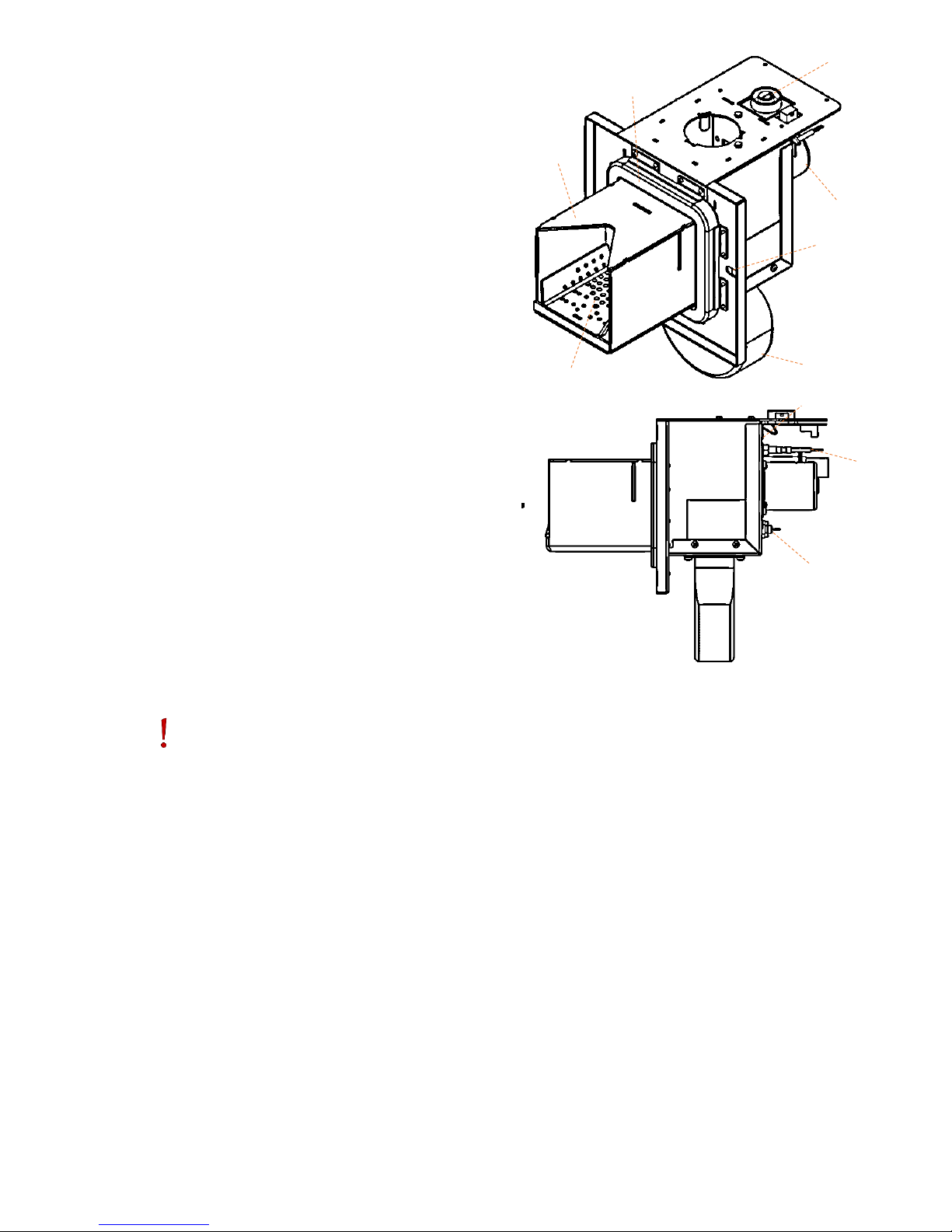

4.3. Biopel 100 - 200kW

These boilers include a two-tier heat exchanger located in the upper part of the boiler. Exchanger pipes are located in a

horizontal position above the opening for the burner installation. Exchanger tubes have 2 diameter sizes for better air flow

in the boiler. In each of the tubes are turbulators, which are designed to reduce the temperature in the flue path so that the

resulting boiler efficiency is maximized. Turbulators are removable for easier access to the heat exchanger during cleaning.

For cleaning of heat exchanger tubes use the handle and plug brush, with which you can clean each of the exchanger tubes.

Be sure to place the turbulators back into each of the tubes after cleaning. The purity of the heat exchanger is critical to

ensure maximal heat transfer from the heated air into the water in the boiler and heating system.

Biopel 100 to 200 kW is equipped with two horizontal multilevel tube heat exchanger.

Biopel 100-200 kW is equipped with two main doors, front and rear. Pellet burner is attached in to the opening which is on

the front doors. Burner flange is attached to this opening as well. The burner is fitted into the hole with two burner screws

and two wing nuts. Proper tightness is important for preventing leackage of air in the boiler or to prevent leackage of fumes

from the boiler out. The door can be opened together with the burner for inspecting the inner parts of the boiler and burner

grate without having to remove the burner of the boiler. To open the door with the burner you must dismantle the PVC

hose between the burner and the feeder so that the external feeder doesn’t stay in the way of door opening.

Caution: Never open the front door with a burner when the flame is in the boiler. For the

flame inspection use always rear door.

Front and rear doors are attached to the boiler using solid hinges and on the other side by closing handles. The tightness of

the closure can be adjusted. Ensure tight closing of both doors and the correct adjustment of closing handles to prevent

accidental opening of the door or leakage of smoke into the room through leaky doors closing. The front and rear doors are

filled with flowing heating system water. Water is pumped through the door through the cooling hoses. Each hose is fitted

with a ball valve. Doors can be separated from system water in the body of the boiler, if need of doors removal, repair etc.

In the upper part of the boiler are water inlet and outlet for connection of the boiler into the heating system. Smaller is inlet

water to the boiler, bigger is outlet water from the boiler. Furthermore, the upper section provides outlet for flue gases.

You can find an opening for connecting the Lambda sensor (optional) on the flue gas outlet.

Boiler handling is provided in two ways, either by increased base in the bottom of the boiler,

or using a hoks in the upper part of the boiler.

Inlet for filling valve is located on the side of the boiler, bottom part. When filling the boiler, chack that all connections are

sealed properly so water cannot leak out of the connections anywhere on the boiler. Especially check cooling hoses

connections and do not forget to open all ball valves on each cooling hose so water can flow inside and outside the frontal

and rear doors.

Electrical parts are installed in the front of the boiler (control unit v9 and connection board). There are also two outlets for

temperature sensor installation (CH and Termik sensor) on the side of the boiler. All cables must be positioned so nothing

can damage cables during operation of the boiler or when opening front or rear doors. It is also important that cables

doesn’t touch metal surface of boiler body (surface under the boiler covers) and that cables do not lay down on the ground

without fixing. Hot ash can permanently damage electrical cabeling. Make sure that cables are fixed on the position and

cannot fall or move into the boiler when doors are opened. Bottom of the boiler is shaped so you can clean inside of the

boiler easily. Use cleaning tools to remove all ash out of the bottom surface of the boiler. Clean all parts of the boiler

Page 12

regularly and check ash content each day during first two weeks of operation. Quality of pellets directly influences how

often you need to clean inside of the boiler (to clean heat exchanger, inside bottom of the boiler, flue path and burner). Set

for your self how often is necessary to clean all mentioned parts according the real pellet consumption and ash creation

during first two weeks of operation. Each boiler room is different. Check chapter Cleaning for more information about

proper way of maintenance.

a) Frontal door

b) Burner opening

c) Cooling hoses with ball valves

d) Automatic exchanger cleaning

e) Bottom support for boiler handling

f) Top support for boiler handling

g) Inlets for CH and Termik temperature sensors

h) V9 control unit and connection board

placement

i) Lambda controller placement (accessories).

j) Rear door

k) Cleaning door for flue outlet cleaning with

ashtray inside

l) Filling valve inlet

m) Flue gas outlet

n) CH water inlet

o) CH water outlet

p) Adjustable door closing mechanism

q) Ball valves for each of cooling hoses

Package content:

You can find following parts for boiler and burner installation inside the boiler. Content can vary considering exact boiler

and burner size. Use thise accessories for completing the installation and move on to the next chapter to start boiler

properly.

3pc cleaning tools (brush, handle, scraper).

Filling valve – for filling boiler with central

heating water.

2pcs of burner screws – installed on the

burner outlet to hold the burner at right

position.

Příruba hořáku – instaluje se na otvor hořáku.

Burner flange – installed on the boiler opening

for the burner attachement.

4 screws of the burner flange - for mounting

flange on the boiler opening for the burner

attachement.

2 pieces of wing nuts for burner attachement -

to ensure the tightness between the flange

and the burner. Mounted on the burner

screws.

2 washers – placed on the burner screws,

under the wing nuts.

a b c

d e f g h i j

k

l

m

n o p

k

Page 13

4.4. Burner

Pellet burner sizes vary from 10 to 200kW, each burner is

different size. The difference between burners is not only the

dimensions, but also different electrical components, grates, etc.

Maximal burner power determinates also the external

dimensions of each burner. Burner is attache by following

components:

a) internal pellet feeder (motor and spiral),

b) fan,

c) ignitor,

d) fotosenzor,

e) safety burner temperature sensor is indicating actual

burner temperature,

f) burner printed circuit board (burner PCB),

g) removable grate,

h) grenamatová plate (30-200kW),

i) sealig cord,

j) openings for burner screws attachement.

Burner pipe is connected on the top of the boiler and fixed by

two small screws. There is also a sealing circle between the

burner pipe and the burner. Two socets for control unit

connection are located also on the top of the burner. Smaller

socet is transferring signal of safety temperature sensor and

fotosensor. Bigger socket is for 230V power supply of all main

electrical components on the burner (fan, motor and ignitor). Fan

and motor is also connected to the capacitors which are

responsible for smooth start of each of the components. Both

condensators are attached on the burner.

Burner body and grate are stainless steel, so they can resist high

temperatures inside the boiler reaching 1100°C. Burner grate can

be removed for proper cleaning. Holes inside the grate should be

always clean for best combustion quality.

Ignitor and sealing cord are consumable parts and must be changed in regular intervals.

Ignitor provides automatic ignition, which takes from 3 to 5min. When flame is created, fotosensor detects light of the

flame and boiler stansfers operation from ignition to PID work. Fotosensor together with safety burner temperature sensor

are responsible for shutting down the boiler when burner temperature is higher than 60°C (safety temp. sensor is

responsible) or when there is no flame inside the boiler (fotosensor is responsible).

Sealing cord must lay on the burner flange all around its surface, so no heat escapes from the burner outside. There is a high

risk of damage when burner is not connected properly. Check the connection always, when burner was removed for

cleaning or other service.

Burner is hearth of heating system and it needs proper regular maintenance. Pay high coution when you clean the grate and

make sure that position of grate is as it should be. More information about cleaning and grate position is written in chapter

Regular maintenance.

Package content:

Burner 10 – 200kW

Burner cover

Burner pipe

2ks screws 4M, for burner pipe fixing

Sealing circuit – for sealing the connection

between burner and burner pipe.

PVC hose – connect feeder and brner pipe

Control unit v9 – attached on the side of the

boiler oron the top of the compact hopper.

2ks wing nuts – for fixing the burner

2ks washers for burner screws

f

i a b d c

e

g

h

j

Page 14

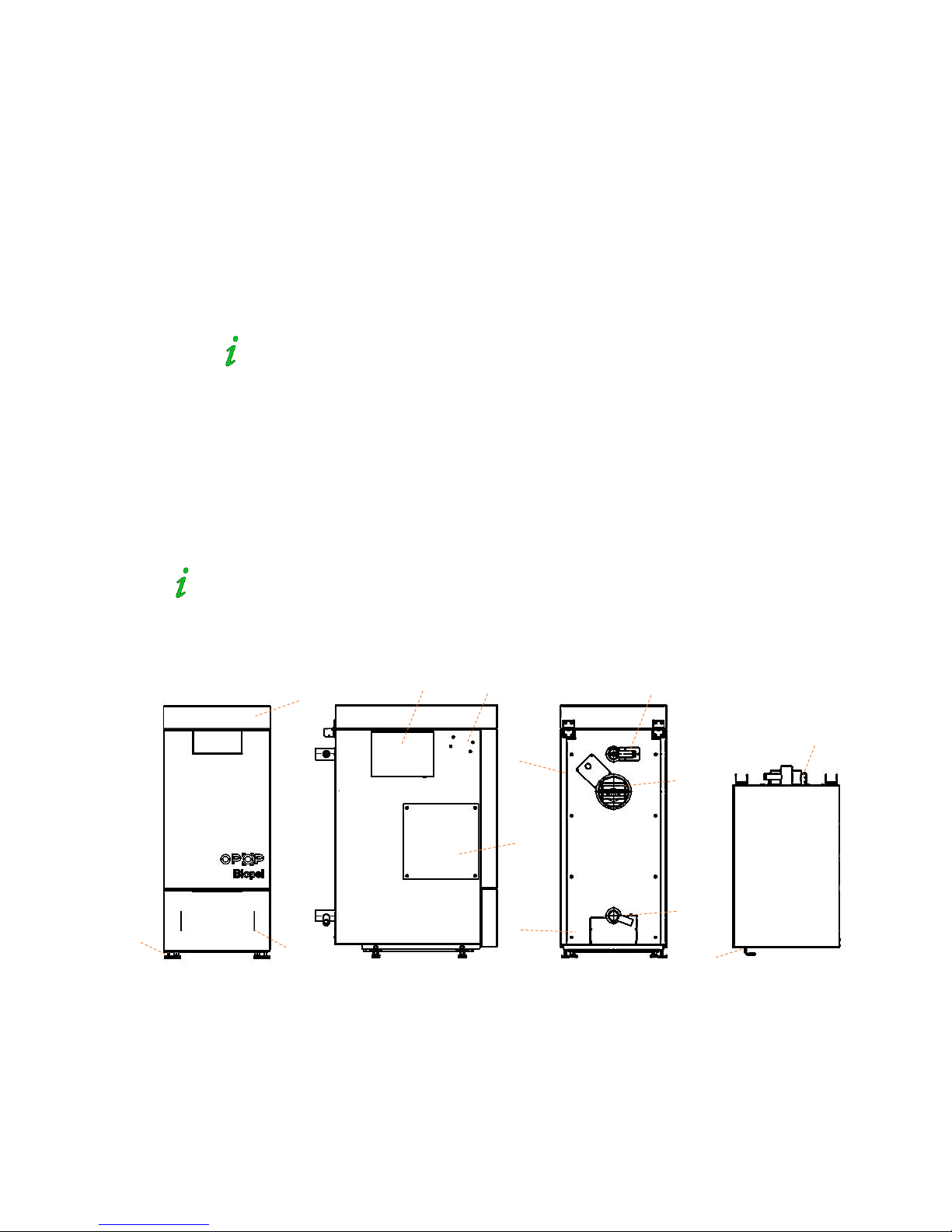

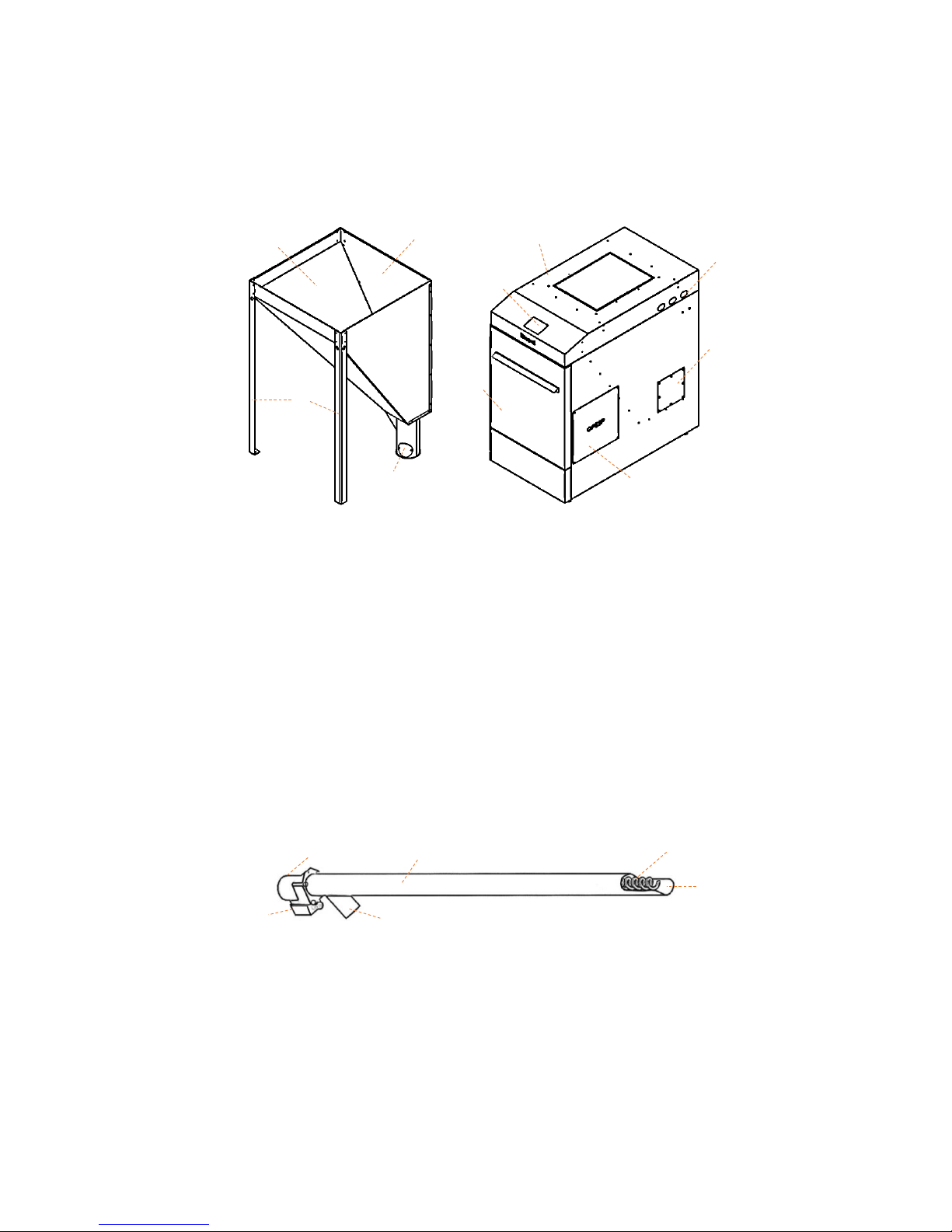

4.5. Pellet hopper

Two types of pellet hoppers are sown below. External and Compact versions. Compact hopper can be used with Biopel 1040kW, External hopper can be used with all Biopel boilers. External hopper is assembled during boiler installation; Compact

hopper is assembled in OPOP. Read chapter Installation process to se how to assemble External hopper properly.

Compact version is on the right side of the picture, all electrical components, including buner are hidden inside Compact

hopper. External hopper is on the left side of thi piture and is used only with 2 or 3m External feeders.

a) External hopper

b) 3 legs

c) External feeder connection into the hopper

d) Clening hole fro removing dust out of the

hopper

e) Filling openening – can be attached by cover

f) Compact hopper

g) Front door

h) Cleaning hole for removing the dust out of the

hopper

i) Cable shaft for electrical wiriing

j) Control unit v9

k) Opening for burner installation on both sides

4.6. External feeder

External feeder is used to transfer pellets from external hopper into the burner. It is used only with externl hopper.

Compact hopper already has external feeder inside. External feeder is defferent type for each boiler power. Check the

sticker on the external feeder to see, if it is the right speed for your boiler power. Use only external feeders for proper type

of boiler.

a) Motor with capacitor – iger boiler you have,

faster feeder you use

b) PVC pipe

c) Feeder spiral

d) Pellet inlet into the feeder

e) Pellet outlet to the burner

f) 230V socket – or electrical connection

a

f

c

d

e g h

i

j

k

a b c d e

f

Page 15

5. INSTALTION PROCESS

Instalation process varies considering the boiler size, pellet hopper type. You can see full installation explanation down below.

Choose your type of boiler and pellet hoper and read all information carefully.

Full installation process can be devidet to following sections:

1. Boiler, burner, hopper, and external feeder installation (chapters 5.1 to 5.6)

2. Accessoriess installation (chapter 5.7)

3. First start (chapter 8)

4. Combustion adjustment (chapters 9.1 to 9.3)

5. Accessories operational values adjustment (chapter 7)

Basic installation type can be devided by the type of pellet hopper. Basic component configuration varies by used pellet hopper.

You can see first type of installation with compact pellet hopper. You can find burner, external feeder and control unit inside the

tank when installation is finished. Picture below is also presented with additional accessories for better illustration of all

possibilities which goes with Biopel boiler.

Biopel set with compact version of pellet hopper

a) Compact pellet hopper

b) Front door

c) Filling opening

d) Acuum transport (accessories)

e) Burner opening from both sides (burner is

inside the hopper)

f) Ash removal system (accessories)

g) Control unit v9

h) Cleaning hole for removing the dast out of the

hopper.

i) Shafts for electrical cables.

j) Connection board for accessories connection

is behind the front cover.

k) Biopel 10 – 40kW

Compact hopper is not connected to the boiler by any means. It is placed next to the boiler and can be moved easily any time.

When hopper is placed to the final position, next step is to attach urner inside the hopper. Open the front doors first. Hold the

front doors and move them up by 2cm first. Than pull back to remove the door completly.

You can connect burner from left or right side of the boiler. Choos the opening on the same side of the hopper as on the boiler.

Opening inside the hopper must be positioned roperly on the burner opening to connect burner easily. Control unit v9 is placed

on the top of tha hopper and connected by cable to the connection board in the front wall of the boiler. Connect this cable into

the connection board into the socket which is on the left side of the connection board. Use small oval openings which are on

both sides of pellet hopper to move the gable from control unit to the connction board.

All cables connected into the connection boards can be holded on the position by two fixing straps abowe the connection board.

a

b

c

d

e f g

h i k

Page 16

There is exteral feeder inside the pellet hoper. Its outlet must be attached by PVC hose to connect external feeder and burner

pipe. Connect cable into the External feeder socket for power supply.

Caution: PVC hose must be installed in a way that pellets fall down to the burner without any problem.

Otherwise you risk damage and back flame inside the hopper.

There is cable shaft on both top sides of the hopper to move cables from the front to the back side of the installation set. Cover

which protects the cables inside the hopper can be removed for easier cble installation. Cover must be placed back to cover

electrical wiring against dust inside the hopper.

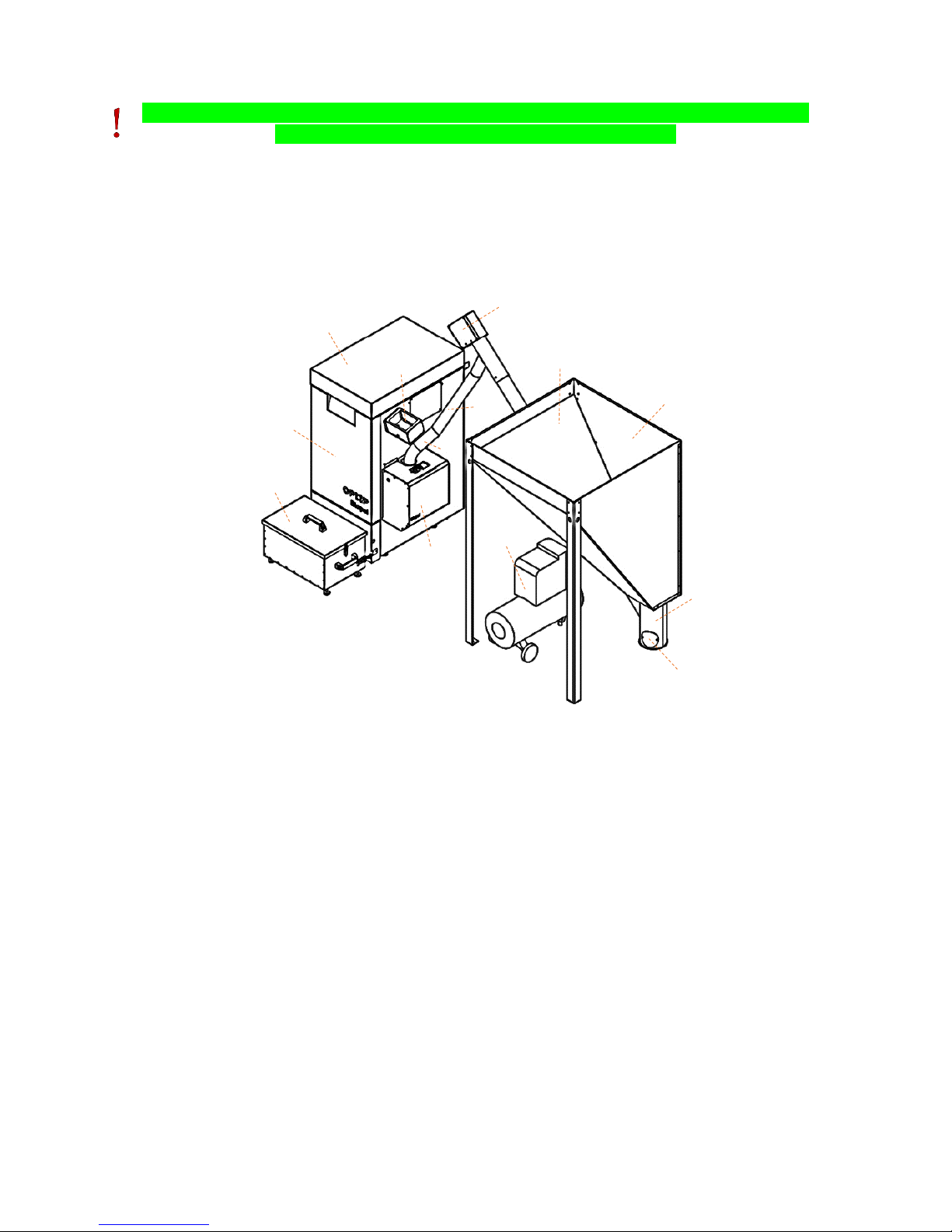

Second hopper version is external. External hopper can be used with all Biopel boilers from 10 to 200kW. However you have to

use this type of hopper with Biopel 60 – 200kW always. You can see boiler with external hopper in the picture below. Presented

set is also combined with additional accessories for better imagination what are the possibilities for biopel boilers.

Biopel set with external version of pellet hopper

a) External hopper

b) Filling opening

c) External feeder connetion to the hopper

d) Cleaning hole for dust removing out of the

hopper

e) External feeder (2 or 3m), 50° angle.

f) Ash removal (accessories)

g) Control unit v9

h) Pellet burner

i) PVC hose

j) Burner pipe

k) Compressor cleaning (accessories)

l) Connection board behind thefront cofer of the

boiler

m) Biopel 10 – 200kW

External hopper is assembled during boiler installation. It is ussualy delivered disassembled in one box. External feeder is moved

into the bottom leg of the hopper and fixed by chain to the top edge of the hopper. Check the angle of external feedr from the

ground, which should be 50°. External feeder is connected to the burner with help of PVC hose. PVC hose must be straight so

pellets cn fall down easily to the burner. Connect power supply cable from connection board into the external feeder socket.

External hopper can be placed anywhere inside the boiler room, but you need to achhhive non problem pellet supply from the

hopper to the burner. Check all connection, proper PVC hose installation and make sure that PVC hose doesn’t fall off the feeder

or that PVC hose doesn’t change its shape after some time.

External feeder motor has differen speeds considering feeder type. For each burner power we have different feeder (motor)

speed. Use only the external feeder which is for the same power as your boiler is.

a

b

c

d

f g h

i j k

l

m

e

Page 17

5.1. Biopel 10 – 80kW

This is step by step explanation how to install all biopel boilers from 10 to 80kW of power. Read all information careffuly and

continue chronologicaly, so all important steps during boiler installation are met.

1. Open the covers and remove boiler from plastic protection. During boiler manipulation keep in mind thet boiler has

electronics inside. Make sure that:

a. PIf you moow boiler with wooden protection, make sure that boiler cavers are not damaged by wood or

other parts of wooden covering. There are spikes inside the wood, so be carefull to not damge the boiler

during transportation.

b. Place boiler on strait floor with no deformation. Boiler must be placed horisontaly, no angle is possible.

c. Make sure that there is enough space around boiler and hopper so you can move around the installation

without problem.

d. Check if there is enough space to fully open ash doors and to remove ashtray out from the biler without

problem.

We recommend remove front boiler cover before any manipulation. Cover is not attaced on the

boiler with screws, it only hengs on the screws so be sure you do not damage this cover during boiler

transportation.

2. Remove all accessories out of the boier. Cleaning tools are inside the boiler, connection material is in the

ashtray.

3. Install filling valve on the outlet located in the back bottom side of the boiler.

4. Connect water outlet G1 1/4" to the heating system.

5. Connect water inlet G1 1/4" to the heating system.

6. Connect flue gas outlet to the chimney. Connection must be tight so no smoke escapes out of the flue pipe. Make

sure that:

a. Chimney connection cannot decrease chimney draft below the minimal level mentionad in chapter Main

parameters.

b. Chimney flue path diameter cannot by smaller than flue outlet on the back side of the boiler, so 130 or

178mm, depending on boiler type. Check mentioned value in chapter Main parameters.

c. Connection between flue outlet and flue pipe cannot hide lambda and chimney temperature sensors,

located inside flue outlet on the back side of the boiler.

d. When connection into the chimney is finished, check and measure chimney draft to make sure that

requirement for minimal chimney draft is met. If not we strictly recommend to install Chimney fan which is

optional device to boost natural chimney draft.

Good chimney draft is very important for good combustion, proper ash creation and for smoke

leackage prevention. If you see smoke leackage during operation, chimney draft is too low.

7. Connect water hose on the fillig valve and fill the boiler and full heating system with water. Ceck the maximal

pressure, whch should not increase abowe 2 bars during operation. So pressure should be lower when boiler is not

active and system water is cold.

8. When boiler is filled, close the filling valve and remove water hose.

9. Check tightnes of all pipe connections. If you detect some water leaking, epair it immediately, before you start the

boiler.

10. Check proper position of both CH and Termik temperature sensors, which are inside the sink on the water outlet.

Make sure thay are fixed properly and there is no possibility for the sensors to fall of the sink.

11. Check inside of the boiler, mainly. Proper turbulators positioning inside heat exchanger, chack burner flap below the

stocking doors and chack that there is no accessories left inside the boiler. Remove all parts which should not be

inside the boiler during operation.

12. Check tightnes of all doors. Thay can be damaged during boiler transportation. Sealing cords inside the doors must

tuch the boiler body all around properly, without any holes.

13. Choose the side wher burner will be installed, left or right. On the other side should be burner cover, to close the

opening for burner, if burner is connected from othe side.

14. Proceed to the next chapter if all mentioned steps are done. Next chapter is about pellet hopper and burner

installation. Read all information careffuly to connect both parts properly.

Page 18

5.2. Biopel 100 – 200kW

This is the installation procedure of Biopel boilers with outputs from 100 to 200 kW. The points below serve as a guide for

installing the boiler to the heating system. Individual points are listed chronologically. Read therefore the points

chronologically so you do not forget any of the fundamental points of the installation.

1. Unpack the boiler out of a paper protection. Remove transparent foil and place the body of the boiler to its final

position in the boiler room. When handling the boiler consider following precautions:

a. When handling, be careful about the casing and other components of the boiler. The boiler can be moved

only when the front and rear doors of the boiler are closed.

b. To manipulate boiler body use the trolley positioned under boiler, or crane with a chain attached from the

top of the boiler. Boiler must be always in horizontal position during the transport procedure.

c. Place boiler on strait floor with no deformation. Boiler must be placed horisontaly, no angle is possible.

d. Make sure that there is enough space around boiler and hopper so you can move around the installation

without problem.

e. Check if there is enough space to fully open front and rear doors and to remove ashtray out from the biler

without problem (some boilers are not sold with ashtray).

2. Remove all accessories out of the boier. Cleaning tools are inside the boiler, connection material is in the

ashtray.

3. Install the filling valve on the inlet at the bottom side of the boiler.

4. According to the size of the boiler, filling valve is mounted on the lower side of the boiler, or placed as an accessory

inside the boiler.

5. Connect water outlet G1 1/2" to the heating system.

6. Connect water inlet G1 1/2" to the heating system.

7. Connect flue gas outlet to the chimney. Connection must be tight so no smoke escapes out of the flue pipe. Make

sure that:

a. Chimney connection cannot decrease chimney draft below the minimal level mentionad in chapter Main

parameters.

b. Chimney flue path diameter cannot by smaller than flue outlet on the back side of the boiler, so 199mm.

Check mentioned value in chapter Main parameters.

c. Connection between flue outlet and flue pipe cannot hide lambda and chimney temperature sensors,

located inside flue outlet on the back side of the boiler.

d. When connection into the chimney is finished, check and measure chimney draft to make sure that

requirement for minimal chimney draft is met. If not we strictly recommend to install Chimney fan which is

optional device to boost natural chimney draft.

8. Install the cooling hoses with ball valves on the sleeves on the side of the boiler and on the front and rear doors. For

clarity of colling hoses connections, use image of Biopel 100 - 200kW in chapter Basic componnents of biopel

installation.

Caution: Ball Valves on each cooling hose must be set to open position. Otherwise you

risk overheating.

9. Connect water hose on the fillig valve and fill the boiler and full heating system with water. Ceck the maximal

pressure, whch should not increase abowe 2 bars during operation. So pressure should be lower when boiler is not

active and system water is cold.

10. When boiler is filled, close the filling valve and remove water hose.

Check tightness of all connections. Possible leackage must be repaired immediately

or before boiler start up.

11. Check the inside of the boiler, in particular: proper placement of turbulators in the heat exchanger, the correct

position of the ashtray in the cleaning space (below the flue outlet) and make sure that there are no accessories or

fasteners left inside the boiler.

12. Remove any parts that do not belong to the boiler.

13. Check the front and rear doors of the boiler. Check the correct settings of all closing handles, or adjust the position

of hooks of closing handles that doors are tightly connected to the boiler body when closed.

14. If all points are met, you can proceed to hopper and burner installation.

Page 19

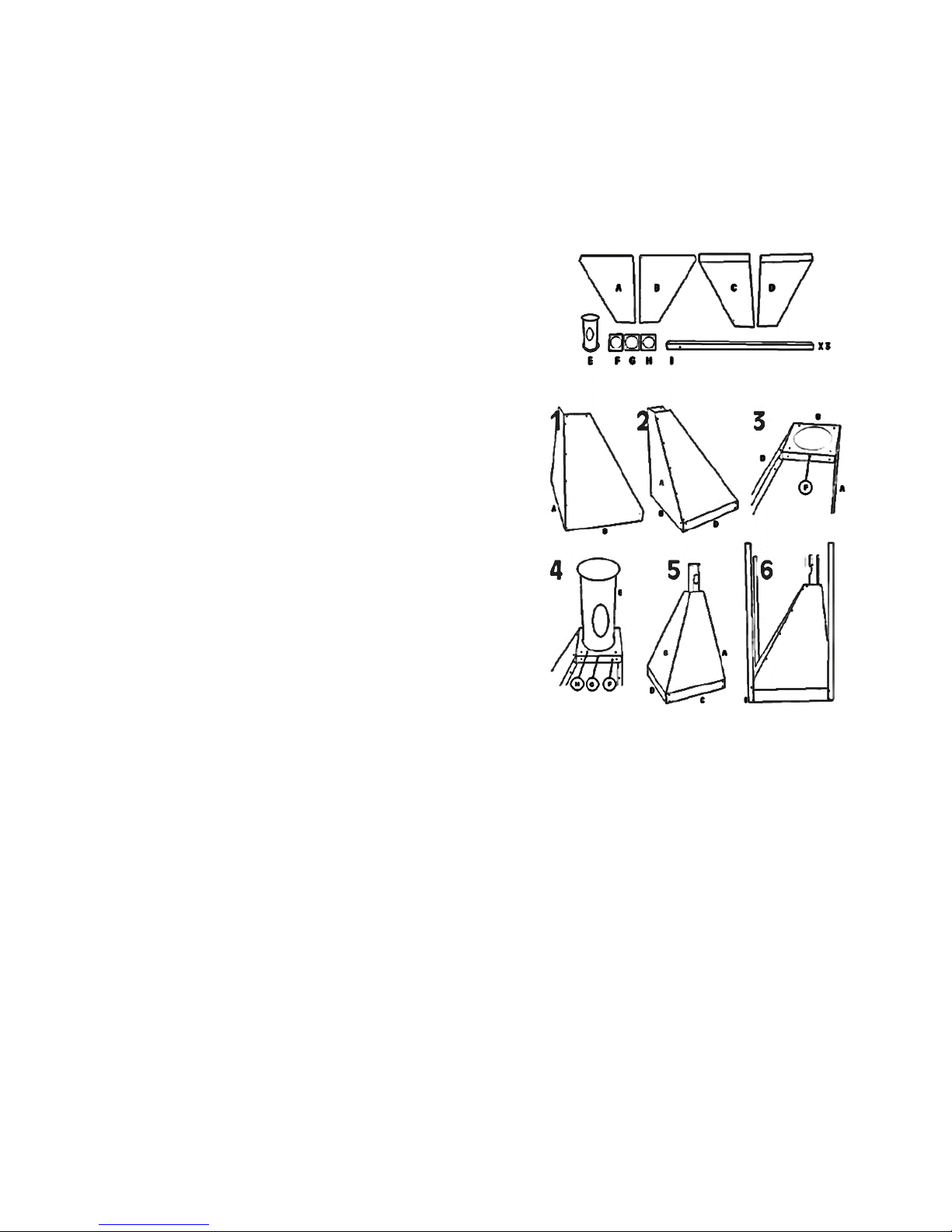

5.3. Pellet tank

The compact pellet hopper installation is very simple since it comes from the factory already assembled. So unpack the

hopper of the wooden cover, remove the foil and put the compact hoper in place next to the boiler side, where the burner

will be assembled. Revmove the burner opening cover form the boiler if necessary to install the burner, but do not forget to

pot this cover on the opposite side of the boiler to close the second burner opening (on the other side of burner position).

Be carefull during hopper transportation, wooden cover is attached with spikes which can damage the hopper surface. We

recommend to remove the cover first and than move he hopper. External hopper is assembled on the site, inside the boiler

room. It comes disassembled from the OPOP factory. You can see installation procedure down below. Follow these steps

carefully.

1. A and B connect together. You have part AB after

connection.

2. Connect D with AB part. You have ABD part after

connection.

3. Connect F with ABD part. You have ABDF part after

connection.

4. Connect parts H, G, E a F with part ABDF.

5. Than, connect C with remaining hopper body.

6. Connect 3 legs onto the hopper body.

7. You are done. Move the hopper on the final position,

next to the boiler and you are reddy to connect external

feeder.

If you are assembling 350kg external hopper, use additional plate

(B type) to extend the standard 220kg hoper. So the installation

procedure is the same as mentioned above only with one

additional B type plate.

Check inside space in the hopper to make sure, there are no

remaining parts, which should not be there during operation.

Leave hopper empty so nothing other than pellets gets to the

external feeder. Next step is burner installation. Read all steps to

attach burner on the boiler body properly.

5.4. Burner

Type and burner size always vary depending the boiler size and power. Burner installation is therefore different considering

the type of boiler and burner you use. Use this explanation as a general manual how to install burner the correct way. Full

brner installation is devided to following steps:

1. Unpack all parts of the burner package out of the box.

2. Install the burner flange on the burner opening on the boiler (left or right side of the boiler), if the burner fange is

part of the delivery (some boiler sizes doesn’t use burner flange and burner is installed directly on the burner

opening on the boiler body. Flange type varies according to the size of the burner and therefore the method of

installation on the boiler is also different:

a. Biopel 10-15kW: no burner flange

b. Biopel 20kW: flange is attached to the 2pc burner screws.

c. Biopel 30-80kW: flange is installed using 4 screws M5, burner package includes frame sealing for the flange.

d. Biopel 100kW: flange is attached to the 2pc burner screws.

e. Biopel 150-200kW: no burner flange

3. Burner must be attached on 2pc burner screws, which should be mounted on the burner flange or directly on the

burner opening on the boiler body (depends on mentioned boiler types above). Tighten this connection by 2pc wing

nuts to make sure, that there is no space between the boiler and burner, so no air can leak out of this connection.

Check the burner few times so it doesn’t move whan you push it up and down and tighten the wing nuts once again.

4. Done. If you moved the hopepr during burner installation, make sure that the pellet hoper is on its final position

befor you fill the hopper with pellets. Next step is External feeder installation, if you use Biopel with external

hopper.

Page 20

5.5. External feeder

External feeder installation must be done only if you use external hopper with your Biopel boiler. If this is your case follow

explanation below to make sure feeder is installed properly. If you use compact hopper, skip this chapter and move to

electrical connectition of external feeder and other electrical components.

1. Remove the paper cover from the top of the external feeder.

2. Make sure that there is no damage of feeder spiral or of PVC tupe inlet, where pellets go to the feeder. If there is

wissible deformation of PVC tupe inlet, there is a risk that spiral get stucked by damaged or angled feeder inlet. In

this case we do not recommend to install feeder with any wissible damage.

3. Move the bottom leg of external hopper towards the burner so external feeder inlet can fit inside.

4. Move the external feeder inlet inside the hopper leg opening.

5. Top part of the feeder should be attached onto the top edge of external hopper by chain. Use small holes inside

hopper legs to hang the feeder in right position.

6. Adjust chain lengt to make sure that external feeder is in 50° angle from the ground.If angle is smaller, feeder gives

more pellets and the opposite. So if the angle is different, make sure you do proper combustion adjustment,

describet in chapter Combustion adjustment.

Caution: Combustion adjustment must be done always, when external feeder angle is not 50°.

Smaller angle means more pellets inside the burner – Fitters menu, Coefficients – make proper

flame adjustment to correct the combustion!

External feeder is on the place. Now you need to connect this feeder to the burner. Folw steps below.

1. Put burner pipe inside the burner top outlet. Do not forget to place sealing circle between the bourner and burner

pipe.

2. Fix this connection by 2pc bolts so the connection is tight.

3. Use PVC hose to establish connection between burner pipe and external feeder. You can cut the PVC hose to the

length you need to make sure, that pallets can fall down to the burner without stucking inside the PVC hose.

5.6. Control unit v9 and connection board

External feeder is connected to the burner. No we need to connect all cables to supper 230V to all electrical components.

Following steps describes electrical wiring and control unit installation.

1. Remove front boiler cover. It hangs on two screws so move cover up by 2cm and tan push towards you to remove

the cover out of the boiler.

2. In case of compact tank, remove small cover on the side of the compact tank (side where burner and boiler is

placed). You will use this opening to move cables from the connection board into the hopper.

3. Connect 230V AC power cord into the power supply socket.

4. Connect 230V AC power cord into the External feeder socket.

5. Connect burner cable into the burner sockets (2 sockets, small and bigger).

6. Connect control unit v9 into the connection board. There is a socket for this on the left top side of connection board.

Place control unit v9 on the position (on the compact tank, or mount it on the side of biopel boiler if you use

external hopper version.

Basic electrical connection is finished. If you plan to connect additional devices into the connection board, use cable safts on

the sides of the boiler to move cables from connection board to the back side of the boiler.

Boiler cannot be in operation if any doors are opened. There is a risk that heet coming out of

the opened door damages electrical wiring around the connection board. Make sure that

cables do not touch hot surface of the boiler.

Electrical connection for all additional devices can be finded in next chapter. Now ther is a time to connect all accessories

which will be used with the boiler. When alla electrical componnents installed, pust ON button (red button on the conection

board), close the connection board and put the front boiler cover back on its place on the boiler.

Before first start, read chapters Electrical connections and Control unit v9. This helps you to better understand control unit

and the way how boiler is operated. These chapters will help you to understand all features of v9 control unit you will be able

to navigate easily through the first boiler start up. First start should be the next chapter you should read to setup the boiler

operation properly. Keep in mind that all the setup can by changed any time inside the menu structure of V9 control unit.

Page 21

5.7. Electrical connections

Internet connection with

RJ45 cable

RS bus outputs for

accessories connection

(lambda, RT10, 431N,

cascade, exhaust fan)

Additonal sensor 4

United output for C4,C3

Additonal sensor 3

Additonal sensor 2

United output for C2,C1

Additonal sensor 1

Solar contact

Room thermostat 2

United output Room reg.1,2

Room thermostat 1

External (weather) sensor

Unitted uotput for weather and

return temp. sensors

Return water sensor

Valve sensor 2

Valve sensor 1

United output for Valve 1,2 sensors

DHW sensor

Chimney temp. sensor

Safety sensor Termik

CH sensor

Internal feeder temp. sensor (burner)

Fotosenzor (fire sensor)

United output for burner and fire

sensors

Vacuum transport

Compressor 1

Compressor 2

Voltage free output

Exchanger cleaning

Deashing

Heater

Feeder 1

Fan

Feeder 2

DHW pump

CH pump

Valve 1 pump

Aditional pump

Valve 2 pump

Valve 2

Valve 1

Page 22

This is the list of all functions inside the control unit which are connected with each electrical output. Use this list for better

orientation of accessories setup and activation. And also in case of alarm message, you can find easily which output is

responsippel for each alarm. It is simple to fid the source of alarm with help of this list, for example when some temperature

sensor is not connected but function inside the control unit connected ith this sensor has been activated.

RJR5 – Fitters menu:

Internet module

RS1 and 2 – Fitters menu:

Lambda

Room thermostat

Additional valve 1 and 2

GSM module

Cascade.

Additional sensor 4 and 3 – Fitters menu:

For possible future use

Additional sensor 2 and 1 - Fitters menu:

Additional pump

Buffer tank

Build in valve 1,2 – Select CH sensor type

Solar contact – Fitters menu:

Solar.

Room thermostat 1 and 2 – Fitters menu:

Room regulator – Regulator standard 1 and 2

Build in valve 1,2 – Room regulator – Regulator standard.

External (weather) sensor – Fitters menu:

Built in valve 1 and 2 – Weather regulation

Weather sensor calibration

Firing up locked

Return water sensor – Fitters menu:

Build in valve 1,2 – Return protection

Valve sensor 2 and 1 – Fitters menu:

Build in valve 1 a 2

DHW sensor – Main settings:

Working modes – Water heater priority, Parallel pumps or Summer mode.

– Service menu:

Dizinfection – Dizinfection temperature

Priority temperature

DHW hysteresis

Chimney sensor – Service menu:

Max. temp. exhaust

Safety sensor Termik – no associated function

CH sensor – Main settings:

CH temperature

CH boiler weekly control

Working modes – House heating

– Fitters menu:

Build-in valve 1,2 – Boiler protection

– Service menu:

CH pump emergency activation

Boiler alarm temperature

Pump switch on temperature

Min. boiler temperature

Boiler hysteresis

Internal feeder temperature sensor – Service menu:

Feeder alarm temperature

Fotosenzor – Service menu:

Pellet settings – Ignition parameters – Firing-up brightness

Pellet settings – Operation parameters – Operation controll

Page 23

Mixing valve 2 and 1 – Fitters manu:

Build-in valve 1,2

Additional pump – Fitters menu:

Additional pump

– Service menu:

Pump switch on temperature

Valve pump 2 and 1 – Fitters menu:

Build-in valve 1,2 – Valve pump 1,2

DHW pump – Main settings:

Working modes – Water heater priority, Parallel pumps or Summer mode.

– Service menu:

Pump switch on temperature

DHW hysteresis

CH pump – Main settings:

Working modes – Water heater priority, Parallel pumps or Summer mode.

– Service menu:

Pump switch on temperature

Internal (burner) feeder – Service menu:

Internal feeder coefficient

Pellet settings – Ignition parameters – Feeder operations and Feeding pauses

Pellet settings – Damping parameters – Feed time and Feed interval

External (tank) feeder – Service menu:

Pellet settings – Ignition parameters – Underpoor time

Pellet settings – Operation parameters – Min. power – Feeder operations and Feeding pauses

Pellet settings – Operation parameters – Max. power – Feeder operations and Feeding pauses

– Fitters menu:

Coefficients – Min and Max feeder coefficients

Fan – Main settings:

Burner cleaning

– Service menu:

Pellet settings – Ignition parameters – Blow out time, Blow out gear, Fan rotations 1,2, Fan delay

Pellet settings – Operation parameters – Min. power – Min. working fan

Pellet settings – Operation parameters – Max. power – Max. working fan

Pellet settings – Operation parameters – Cleaning period

Pellet settings – Damping parameters – Fan rotations

– Fitters menu:

Coefficients – Min and Max fan coefficients

Ignitor – Service menu:

Pellet settings – Ignition parameters – Heater protection and Minimum heater power

Freely programmable output – no associated function

Exchanger cleaning – (Fitters menu) – Exchanger cleaning

Ash removal – (Fitters menu) – Ash removal

Vacuum transport – (Fitters menu) – Vacuum

Compressor 2 and 1 – (Fitters menu) – Compressor 1, 2

Page 24

6. CONTROL UNIT v9

Control unit v9 is high resolution touch screen device. Type of the screen is properly selected in consideratio n of boiler room

environment. It is covered by pelxi glass shield which protects it against dust and scrathes. Conntrol unit is connected into the

connection board in fornt of the boiler by small plug and lay cable. Instalation takes just few seconds. After boiler activation, by

pushing main switch on the side of connection board, is v9 controller switched on and first procedure it takes is to check

firmware versions of v9 controller and external board. Firmware verisons are displayed below OPOP loge when you switch your

boiler on. Tjose numbers should be the same for prober boiler operation.

Next step is to select your language. To do so, click on Menu button, and than navigate yourselve to the right by clicking on right

arrow key to display Language selection. Click on this button and select your language version. Translantion is changed instantly.

We recommend to read carefully next chapters to understand better the way how boiler and control unit v9 operates.

6.1. Basic navigation

Basic navigation is simple mainle because of touch screen, which simplifies usage of this controller. Read basic controller and

Main screen description down below.

Main panel of v9 controller

a) Boiler temperature measured by CH sensor which

is connected into the sink on the water outlet in

the back of the boiler.

b) Selected boiler temperature. Can be changed in

Main settings, CH temperature. We recommend

to set this temperature in range from 65 to 80°C.

c) Real time operation state – Ignition, PID work or

Extinction are the main fases of operation.

d) Actual power in kW

e) Pellet supply correction, made in Fitters menu,

Coefficients.

f) Burner temperature, inside the external feeder.

Which should be from 15 to 55°C during PID

work.

g) Pannel showing component real time operation,

such as fan, feeders, ignitors, pumps and

activated accessories.

h) DHW temperature measured by DHW sensor,

which is connected into the “DHW sens” output

inside the connection board.

i) Selected domestic hot water temperature. Can

be changed in Main settings, DHW temperature.

Works only when one of the DHW modes is

activated in Main settings, Working modes.

j) Display of pump operational modes. Can be

changed in Main settings, Working modes. This

is basically which of CH and DHW pumps has

prority to start to operate first. Read Control

unit’s layout structure for more information.

k) Weather sensor temperature. Sensor is

connected into the „Weather sens.“ output

inside the connection board.

l) Chimney temperature sensor. Should be in

range from 70 to 110°C, by the size of the boiler.

m) Flame detection by fotosensor. If you see this

icon, flame is detected inside the boiler.

n) Room regulator indication, if activated in Fitters

menu, Room regulator.

o) Real time and date.

p) Menu button to access menu layout structure.

q) Change main panel layout to display variety of

information on the main panel. The possibilities

vary depending on the number of accessories

connected into the connection board. So you

can display basic information about each

accessory on the main panel.

a b c d e f g h i j k l m n o

p

q

Page 25

6.2. Main operation modes

Biopel during its operation changes its fases according to request from user or automatic modulation. Each operation mode

is displayed on the main screen. You can find more information about each operation mode down below, including sub

steps made by control unit duringeach mode of operation.

Ignition: automatic ignition of pellets layed on the grate. Maximum time for ignition is set to 12min. Boiler goes trough

several stages during this operational mode:

Preventilation – grate cleaning by a fan, factory settings (hereinafter referred to as FS) = 30s.

Underpoor time – pellet dosing by feeders, the internal feeder in the burner operates twice as long as external

feeder to move all of the pellets to the burner grate. FS = 12 – 15s

Fan delay – preheating ignitor before starting the fan. FS = 30s

Fan speed 1 – the fan speed during the first 6 minutes of ignition. The fan operates at low speed, to produce a

flame, while not cooling down the ignitor. FS: 3-8%.

Fan speed 2 - the fan speed during the second 6 min ignition. Maximum ignition cycle is 12 min. If pellets are not

ignited within first 6min of ignition, fan will increase its speed to create a flame. The standard ignition time is 3-6

min. FS: 5-16%.

Firiing up delay – flame was created, fotosensor detects light, followed by stabilization of the flame procedure. If

the flame detection by fotosensor is stable, boiler goes into PID work (normal operation). If the detection by

fotosensor is not good and stable, boiler remains at the stage of Ignition, until the flame is not large enough. If the

flame is not stable enough, it is followed by the second ignition (at least 12 additional minutes).

The output of the phase Ignition may be:

o Moving on to the PID work - normal operation of the boiler, or

o The alarm message – Failed ignition, pellets failed for some reason to ignite. Boiler performes 2 tries of

ignition before the announcement of this error condition appears. For more information, see chapter

Operating and error messages.

Caution: the indicated time intervals and other values are set at the factory. But they may be

changed in Service menu anytime.

PID work: normal operation of the boiler, indicated by current boiler power output and fan speed in %, which correspond

to a percentage of current power in kW. The PID works following operating states are listed below:

Min power – boiler starts its operation in the lower half of the power spectrum, from 0 to 50% of maximum power.

The reason is to not damage small flame by incomming pelelts after ignition. FS = 1-50% of maximal power, by the

size of the boiler.

Max power – burner is slowly increasing its power up to the maximal 100%. This can take from 5 to 15min.

depending on burner size. Power modulation is influenced only by set and measured CH temperature.

PID modulation – When measured Ch temperature is close enough to the set CH temperature, burner starts to

modulate power down to keep the CH temperature at level approximately +-5°C. Set CH temperature can be

overreached by 5°C, which is value set in Service manu, Supervission temperature. If CH temperature is higher for

more than 5°C than desired CH temperature, boiler is turned off – extinction pahse.

The output of the phase PID work may be:

o Transition to Extinction – set CH temperature is +5°C or higher than set CH temperature.