Page 1

General Specications Camera Overview Camera OSD Menu

High Resolution Indoor

Dome Camera

Camera Installation & Conguration

model no: CM-306 Rev B

Please carefully read these instructions before using this product.

23221 E Knox Ave

Liberty Lake, WA 99019

1.888.542.1103

www.openeye.net

Precautions

• Do not attempt to dismantle the camera module mounted within the dome. There

are no user serviceable parts in the camera module. Refer servicing to a qualied

professional.

• Handle the camera with care. Do not abuse the camera. Avoid striking or shaking

it. Improper handling and storage could damage the camera.

• Do not operate the camera beyond its temperature or power source rating. Refer to

the environmental information provided in this document.

Emissions

• FCC COMPLIANCE: This equipment complies with Part 15 of the FCC rules for

intentional radiators and Class B digital devices when installed and used in accordance with the instruction manual. Following these rules provides reasonable

protection against harmful interference from equipment operated in a commercial

area. This equipment should not be installed in a residential area as it can radiate

radio frequency energy that could interfere with radio communications, a situation

the user would have to x at their own expense.

Save this document for future use.

30832AC

Model No. CM-306 Rev B

Image Sensor 1/3” Sony CCD

Imaging DSP Sony Efo-E 2

IP Rating IP66

Type / Format NTSC

Wide Dynamic Range Yes, Digital Wide Dynamic Range

Minimum Illumination 0.3 Lux @ 50 IRE, 0.15 Lux @ 30 IRE

Day / Night Digital Day / Night

Resolution 700 TVL

Service Monitor Jack Yes

S/N Ratio >50dB

Focal Length 3.3 ~ 12 mm

Iris Control Auto

Synchronization Internal

Video Output 1.0Vpp 75Ω BNC Unbalanced

White Balance ATW, Manual, Push, Push Lock, User, Anti CR

Auto White Balance Range 2700K ~ 9700K

Backlight Compensation Full Range

Auto Gain Control 44.8 dB

Operating Temperature 14˚ ~ 122˚ F (-10˚ ~ 50˚C)

Heater Yes

Power Consumption 12W

Rated Amperage 0.5 A (24vAC)

Input Voltage 12vDC / 24vAC (± 10%)

Weight 1.12 lbs (0.51 kg)

Dimensions ø5.35” (136 mm) x H: 3.7” (94.2 mm)

Housing / Dome Cover White / Clear

Hardware Kit Contents

• Wall anchors (x4)

• T3 1/4 screws (x4)

• Rubber washers (x4)

• Rubber caps (x4)

• ¾” threaded cable entry sealing plug (½” sealing plug tted to enclosure)

• ½” cable entry grommets (¾” grommet tted to enclosure)

• External OSD service board

• Torx Driver

• Wire-Ended Power Adapter Lead

Regulatory Compliance

Emissions FCC part 15 Class B

CE: EN55011

ICES-003

EN55022

CISPR 11

CISPR22

ANSI C63.4

Immunity CE: EN50130-4

FCC COMPLIANCE:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in as

residential installation. This equipment generates uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation.

If this equipment does harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try \to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced Radio/TV technician for help.

CISPR 22 WARNING:

This is a Class B product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

POWER SUPPLY REQUIREMENTS:

For use with listed Audio/Video product and only connected to 15W or less power supply.

*Power supply should be a NEC Class 2 / LPS Supply.

EQUIPMENT MODIFICATION CAUTION:

Equipment changes or modications not expressly approved by the manufacturer, the party responsible for FCC

compliance, could void the user’s authority to operate the equipment and could create a hazardous condition.

This class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

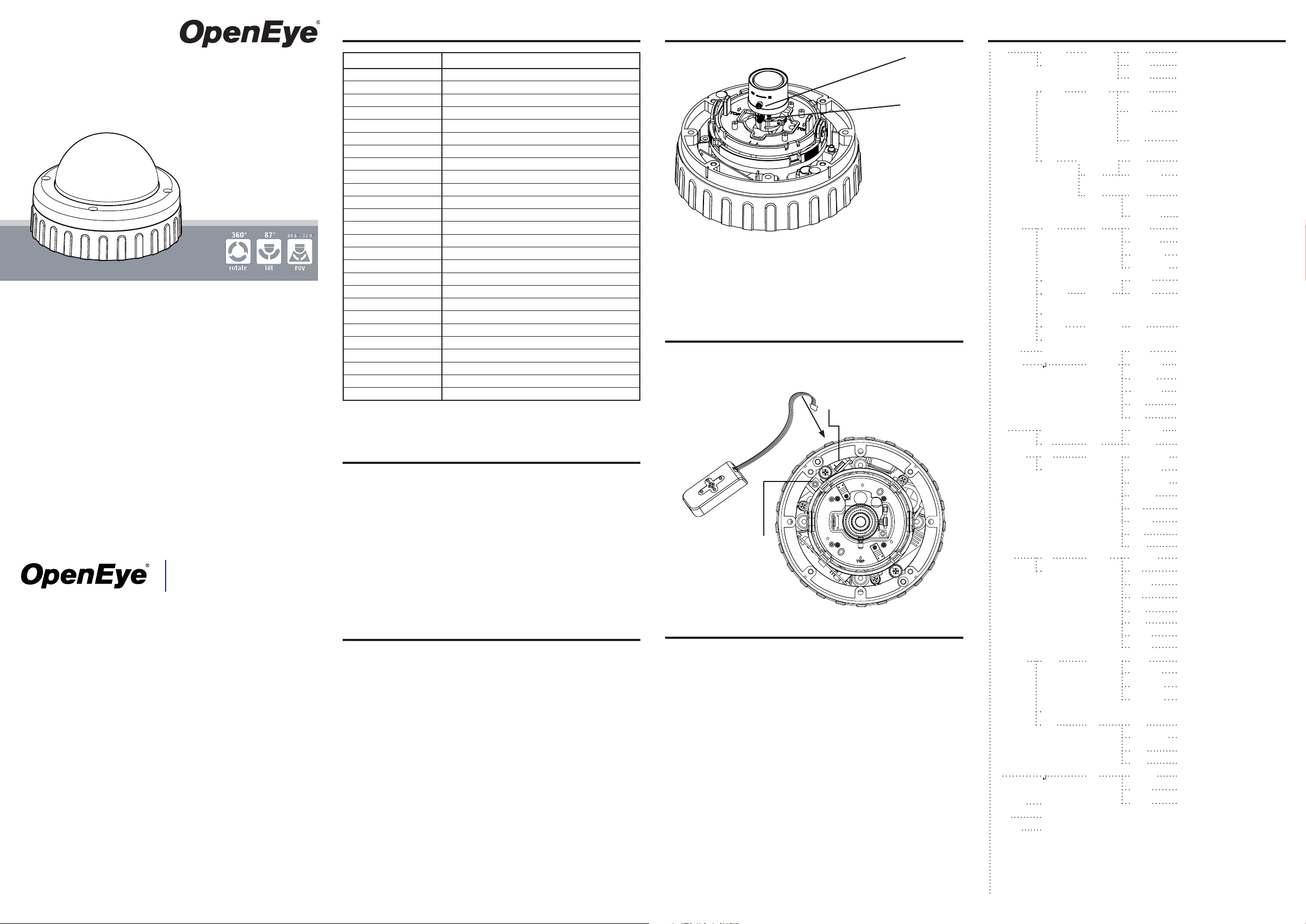

A

B

A: Focus adjuster

B: Field of view adjuster

Camera Adjustments

The following illustration shows the external service board which allows you to control

the On Screen Display (OSD) and make any programming changes required.

C: Service board connector

UP

Down

D: Service jack

Adjusting the Camera

With the exception of the Focus (A) and Field of View (B) controls on the camera, all

settings are made using the keys on the OSD Service Board. When making adjustments using the OSD Service Board, the camera must have power and be connected

to a video display.

1. Press ENTER to access the top level menu.

2. Use the arrow keys on the service board to navigate the OSD menu and use the

ENTER key to conrm your selections.

3. When you have completed the camera conguration, you must select EXIT to

save your changes.

4. If necessary, you can reset the camera to the factory default settings by selecting

RESET in the OSD menu.

Lens Manual Auto Iris Type DC / Video

Auto Mode Open / Close / Auto

Speed 0 ~ 255

Shutter / AGC Manual Manual

Auto Auto Setup Mode Shut + Auto Iris / Auto Iris

White Bal. ATW ATW Speed 0 ~ 255

Push B-Gain 0 ~ 255

User 1/2 User 1/2 WBR-Gain 0 ~ 255

Anti CR

Manual Manual WB Level 0 ~ 255

Push Lock

Backlight Off / BLC / HLC Mirror Off / On

Pict Adjust Pict Adjust Brightness 0 ~ 255

ATR Off Luminance Low / Md / High

On ATR Contrast Low / Mdlow / Md / Mdhigh / High

Motion Det On Motion Det Detect Sense 0 ~ 127

Off Block Disp Off / On / Enable

Privacy On Privacy Area Sel 1/4 ~ 4/4 (1/8 ~ 8/8**)

Off Top 0 ~ 244

Day / Night Auto Day / Night Burst Off / On

Color

B/W B/W Burst Off / On

NR NR NR Mode Off / Y / C / Y/C

Camera ID Off / On C Level 0 ~ 15

Sync Int

Language English / Chinese / Spanish / Portuguese / Russian / French / German / Japanese

Camera Reset

Exit

Next

Back

Save All

Setup

High

Luminance

Low

Luminance

Mode Shut + AGC

Shutter 1/50 (1/60*), 1/100 (1/120*), 1/250

AGC 6.00, 12.00, 18.00, 24.00, 30.00,

Brightness 0 ~ 255

Mode Off / AGC

Brightness X0,25 / X0.5 / X0.75 / X1.0

Delay Cnt 0~ 255

ATW Frame X0.5 / X1.0 / X1.5 / X2/0

Environment Indoor / Outdoor

Contrast 0 ~ 255

Sharpness 0 ~ 255

Hue 0 ~ 255

Gain 0 ~ 255

Monitor Area Off / On

Area Sel 1/4 ~ 4/4

Top 0 ~ 244

Bottom 0 ~ 244

Left 0 ~ 474

Right 0 ~ 474

Bottom 0 ~ 244

Left 0 ~ 474

Right 0 ~ 474

Color 1 ~ 8

Transp 0.00 / 0.50 / 0.75 / 1.00

Mosaic Off / On

Delay Cnt 0 ~ 255

Day - Night 0 ~ 255

Night - Day 0 ~ 255

IR Optimizer Off / On

Mode Auto / Center

Level 0 ~ 31

Y Level 0 ~ 15

1/500, 1/1000, 1/2000, 1/4000,

1/10000

36.00, 42.00, 44.80

Page 2

Installation

1

1. Loosen the four cover screws with the supplied Torx driver and remove the dome

2. Loosen the gimbal securing screws to remove the camera module.

3. Select a mounting method below--A, B, or C.

Prepare the dome for installation

cover.

C

C

A

C

B1

B1

C

AA

Flush mount using screws.

B

Flush mount using locking

B1

arms.

B1

C

Surface mount using outer

ring and rubber o-rings.

5

Fit camera assembly

2

Use template to prepare mounting area

Flush Mount

• Tape the template to the mounting surface and cut a 4.3” hole as indicated by T5

on the template.

A. Using Screws:

Using a ¼” (7mm) drill bit, drill two holes at template positions T2 and insert a

wall anchor in each hole. Use two (no. 12 x 1 ½”) screws to secure the camera to

mounting surface.

B. Using Locking Arms:

Place the camera (with the locking arms retracted) into the opening. Use a Phillips

head screwdriver to turn the silver-colored screws (B1) clockwise to rst extend

the locking arms and then tighten them against the mounting surface. Tighten the

screws sufciently to compress the o-ring seals under the screw heads, however -

DO NOT OVERTIGHTEN.

Surface Mount

C. Surface Mount:

Tape the template to the mounting surface and using a ¼” (7mm) drill bit, drill four

holes at template positions T1 and insert a wall anchor in each hole. Use four (no.

12 x 1 ½”) screws to secure the camera to mounting surface. If you are installing the camera outside, use a rubber o-ring with each screw to ensure moisture

resistance.

Note When ush mounting or surface mounting using the outer ring, ensure that the

large rubber gasket (E6) is in place under the lip of the dome enclosure.

6

Remove camera liner

3

• There are two cable entry options: base cable entry (E1), or side cable entry (E3).

• For surface mount, use E3 to go with either E4 or E5.

• Rotate the outer ring as necessary to align knock-outs with side cable entry.

• Unused cable entries should be blocked with sealing plugs (E8).

• For indoor installations without conduit, the cable entry grommet (E9) should be

• For outdoor installations, conduit should be used to carry cables to the housing.

E7

E6

Open the necessary cable entry

used to prevent dust ingress.

E7

E2

E3

E1

E7

E4

E5

E1: Threaded base cable entry

E2: Washer and screw cable retainer

E3: Threaded side entry (with ½”

E7

E4: Outer ring large knock-out for

E5: Outer ring small knock-out for

E6: Large rubber gasket

E7: Cover index slots

E8: Cable entry sealing plugs

E9: Cable access grommet

(¾” sealing plug (E8) and cable

entry grommet (E9) supplied

sealing plug (E8) tted

conduit entry

cable only entry

E8 E9

4

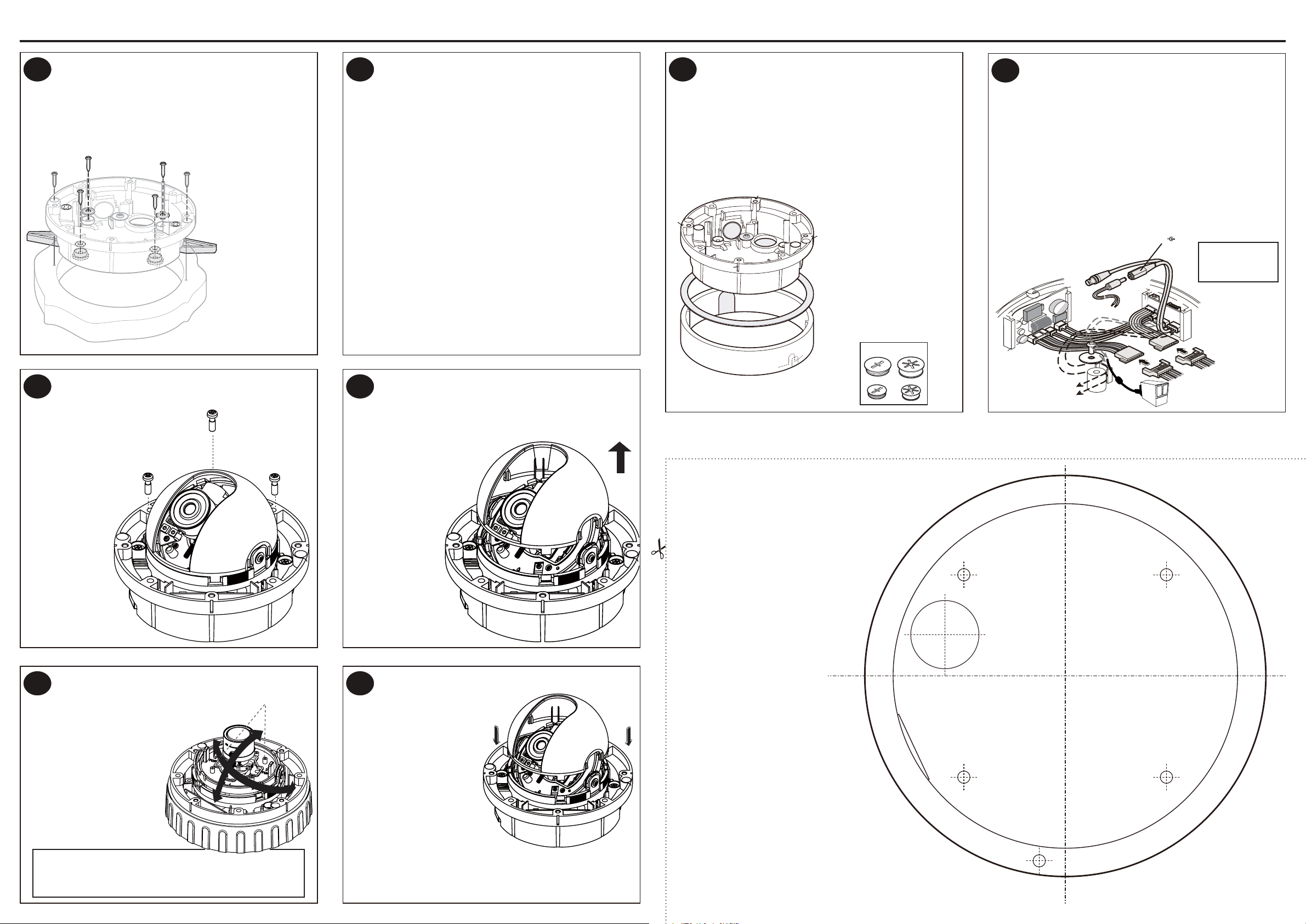

1. Connect F1 and F2 to your video-out and power-in cables.

2. If needed, use F8 (wire-ended adapter lead) with power supply cables.

3. Connect the camera to F4.

4. To focus the camera, use F3, a service jack for temporary video connection.

F1: Video output

F2: Power 12vDC or 24vAC input

F3: Service jack

F4: Camera lead y connector

F5: Cable trap pillar, washer and screw

Connect the wiring

Note 12vDC: connect the red lead to +ve and black lead to -ve.

24vAC: Connect either way, polarity is not important.

F6: RS-485 / Alarm / Light

F7: OSD controller connector

F8: Wire-ended power adapter lead

F9: OSD lead to camera

F2

12VDCGND

NEC Class 2 / LPS

F1

F3

F8

F5

F9

F6

F4

Supply Required

F7

• Place the complete camera assembly (G1) onto

the three mounting pillars (G2) and tighten the

gimbal screws.

G2

7 8

• Rotate and pan the camera chassis to the desired position

• To avoid damage to the lens

• Rotate and pan the camera chas-

Adjust camera position and test Replace camera liner & dome cover

and then tighten the camera chassis locking screws.

mount, tilt and pan the lens by

holding onto the two bars (I2) on

the disk. DO NOT USE THE LENS

TO POSITION THE CAMERA.

sis (I1) to the desired position.

G2

G2

G1

I2

I1

• Lift the camera liner (H1) from the chassis (H2)

• Carefully place the camera liner (J1)

to provide full access to the camera.

H1: Camera liner

H2: Camera chassis

over the focused camera so that it

ts fully on the top ring of the camera

chassis (J2) and provides an

unobstructed view for the camera

lens.

J1: Camera liner

J2: Camera chassis

Template

H1

H2

J1

Mounting Methods

There are three mounting methods available for this camera:

A: Flush Mount using screws

B: Flush Mount using locking arms

C: Surface Mount using the outer ring

Note Always use the template provided.

T1: Drill ¼” holes for Surface Mount

T2: Drill ¼” holes for Flush Mount (using screws)

T3: Location of base cable entry

T4: Location of side cable entry

T5: 4.3” hole for Flush Mount

T1

T3

T4

T1

J2

T2

T1

T5

T1

Note Do not attempt to adjust the camera position by holding the lens. This

will damage the camera. Make adjustments by tilting and rotating the

gimbal assembly. DO NOT rotate/tilt the disk beyond its maximum

allowed range (350/87 degrees), you may damage the camera.

• Replace the dome cover. Four small internal rigs in the cover align with four

corresponding index slots (E7) on the enclosure body. These restrict the cover to

only four possible orientations and ensure that the cover screw holds are correctly

aligned. Use the included Torx key to tighten the four cover screws. DO NOT

OVERTIGHTEN.

T2

Loading...

Loading...