Page 1

General Specifications

Tamper Resistant Outdoor

Dome Camera

Camera Installation

model no.

Please carefully read these instructions before using this product.

CM-305

CM-305-H

Save this manual for future use.

29713AB

Model No.

Image Sensor

Imaging DSP

IP Rating

Type / Format

Wide Dynamic Range

Minimum Illumination

Day / Night

Horizontal TVL

Service Monitor Jack

S/N Ratio

Focal Length

Iris Control

Synchronization

Video Output

White Balance

Auto White Balance Range

Backlight Compensation

Auto Gain Control

Operating Temperature

Heater

Power Consumption

Rated Amperature

Input Voltage

Weight

Dimensions

Housing / Dome Cover

CM-305 CM-305-H

1/3” Sony SuperHAD

Sony HQ-1

0.6 lux @ F1.2 (50 IRE)

Day: 540 TVL / Night: 570 TVL

Yes, 2.5 mm (3/32) T/S Jack

3.3 ~ 12 mm

1.0Vpp, 75Ω BNC Unbalanced

AWB, AWB-EX

2500 K ~ 11000 K (AWB-EX 2000 K ~ 18000 K)

Central Area

AGC-EX, AGC Normal

14ºF ~ 122ºF (-10ºC ~ 50ºC)

Optional

4.2W

0.35A (12vDC) / 0.18A (24vAC)

12vDC / 24vAC (±10%)

1.98 lbs (0.9 kg)

Dome : ø3.9" (100 mm) x H: 1.7" (45 mm)

Housing: ø5.3" (135 mm) x H: 1.9" (50 mm)

Gray / Clear

IP66

NTSC

No

Yes

>50dB

DC Drive

INT / LL

-58ºF ~ 122ºF (-50ºC ~ 50ºC)

Yes

13W

0.54A (24vAC)

24vAC (±10%)

• 1/2” Rubber Grommet

• 3/4” Rubber Grommet

• Screw Pack

• Torx Driver

• Wire-ended Power Adaptor lead

• Quick Install Adaptor (Optional)

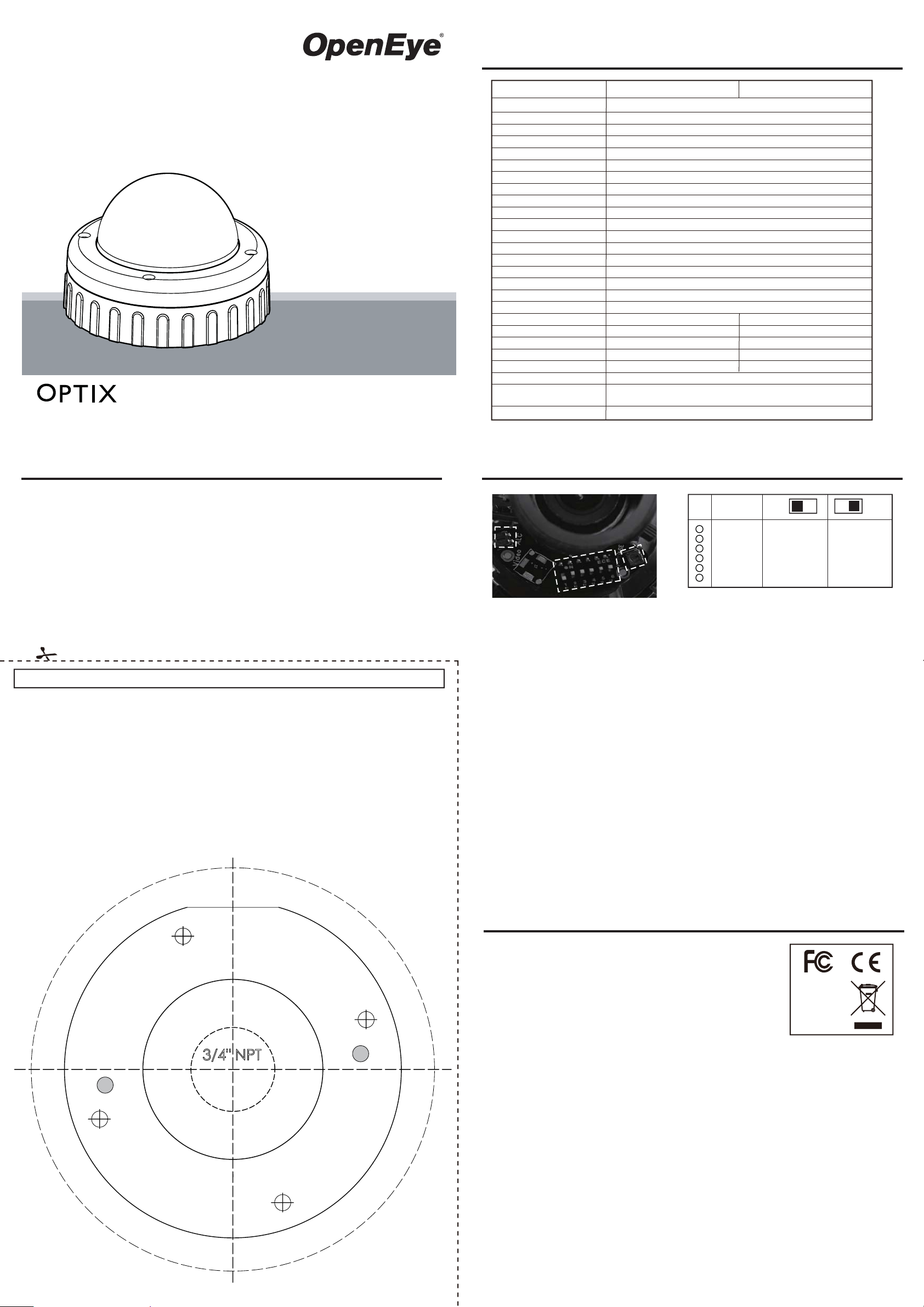

Template

Surface Mount (on a wall or ceiling)

Using Quick Install Adaptor:

Create an aperture in the mounting surface to a

diameter of 1.5” (38 mm) as indicated by “T2”.

Using Locking Arms:

Create an aperture in the mounting surface to a

diameter of 4.3” (110 mm) as indicated by “T3”.

Using Screws:

Create four holes at template positions ‘T1’, use the

screws and plugs provided in the screw kit where the

mounting surface is appropriate.

Cable Access Using Base Cable Entry

When the cables are threaded through the mounting

surface, create a 3/4” (19 mm) hole as indicated

“T4”.

Note: When mounting the dome on a surface with

the four T1 screws, use one of the side knock-outs

as indicated for cable entry

(see installation guide overleaf ).

Note: When mounting on a US Single Gang Box,

use the pre-drilled securing holes in the dome base

as indicated “T5”.

Do Not Open the holes at position “T5”.

Camera AdjustmentsHardware Kit Contents

OFF NONOITCNUF

ALC

V-Phase

DIP Switches

The bank of DIP switches allows the following settings to be made:

Line Lock (INT/LL)

In LL Mode, the V-Phase may be adjusted to compensate for connected supply phase differences. Only applicable

for 24vAC supply. When using a 12vDC power supply, the camera should be operated with INT (internal) sync.

DAY/NIGHT Mode (D/N)

When this switch is set to ON the camera will produce color images under normal lighting conditions. In reduced

light the camera will switch to Monochrome mode.

Auto White Balance (AWB Normal/AWB-EX)

AWB: The camera operates in the normal AWB range (2700 K ~ 11000 K).

AWB-EX: The camera operates in the extended AWB range (2000 K ~ 18000 K).

Flickerless Mode (FL/ON)

The camera reduces flicker in the image under fluorescent lighting.

Back Light Compensation (BLC)

When set to ON, this option improves the camera’s response to strong, unwanted lighting effects behind the

desired subject.

Low Light Sensitivity (AGC-EX/AGC Norm)

When set to EX, sensitivity in low light will automatically increased.

Selecting NORMAL will remove noise from the image, but will also limit the camera’s sensitivity.

Vertical Phase Adjustment (V-Phase)

Use this adjustment when using an 24vAC supply to align the camera phase with that of the power supply.

DC-IRIS Adjustment (ALC)

This is factory preset. It should not normally require adjustment.

1

L.L.

2

D/N

3

AWB

4

FL

5

BLC

6

AGC

INT

OFF

NORMAL

OFF

OFF

EX

LL

ON

EX

ON

ON

NORMAL

T3

T5

US Single Gang Box

T1

T1

Cable Access

T2

T1

T4

T1

US Single Gang Box

T5

Regulatory Compliance

Emissions

Immunity

FCC COMPLIANCE:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will no occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocated the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced Radio/TV technician for help.

CISPR 22 WARNING:

This is a Class B product. In a domestic environment this product may cause radio interference which case the

user may be required to take adequate measures.

POWER SUPPLY REQUIREMENTS:

For use with listed Audio/Video product and only connected to 15W or less power supply.

*Power supply should be a NEC Class 2 / LPS Supply.

EQUIPMENT MODIFICATION CAUTION:

Equipment changes or modifications not expressly approved by the manufacturer, the party responsible for FCC

compliance, could void the user’s authority to operate the equipment and could create a hazardous condition.

FCC part 15 Class B

CE: EN55011

ICES-003

EN55022

CISPR 11

CISPR 22

ANSI C63.4

CE: EN50130-4

RoHS

This class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Page 2

Installation

1. Remove the dome cover and the camera module

Use the supplied large torx driver to loosen the four cover

screws. The screws are captive and will remain in the

cover (image A).

Loosen the gimbal securing screws to remove the camera

module (image B).

2. Open the required cable entry

Use either the base cable entry (C1) for the side cable

entry (C2) as required. When surface mounting and using

the side cable entry (C2), open the large (C3) or small (C4)

knock-out on the outer ring to required size by cutting

away excess material. Rotate the outer ring so that the

knock-out aligns with the side cable entry. Seal an unused

side cable entry with a sealing plug (C5). Use the supplied

rubber grommet (C6) to prevent dust penetration when

using the base cable entry. For external applications,

conduit should be used to carry cables into the housing.

3. Mount the camera base

Mount the camera base, using screws, on a US single

gang box, using the flush mount locking arms, or using the

quick install adaptor. See the individual instructions below

and at right.

4. Connect the wiring

Feed the pre-connected main lead through one of the

cable access points and connect it to your video output and

power input cables. A wire-ended adaptor lead (E1) is

suppled for use with power supply cables that are not

terminated with the appropriate power connector.

For 12VDC operation: Connect the red lead to positive and

the black lead to negative.

E

Video Output

E1

Wire-ended adaptor lead

12VDCGND

Power Input

Red: +12VDC

Black: 0VDC

A

B

C

C3

large

knock-out

D

rubber grommet

C6

cable entry

C2

C5

sealing plug

Mounting Surface

T1

T1

small knock-out

C4

C1

base

cable entry

side

Cable Entry

T1

T1

3/4”

Rubber Grommet

Flush Mount Using Locking Arms

Cut a 4.3” (110mm) hole in the mounting surface as indicated by the template marking T3. Insert the dome

base and turn the silver-colored screws counter-clockwise by 180° to extend the locking arms and tighten

them against the mounting surface (image I).

Note: To protect against dust and moisture penetration, always use the large rubber gasket on the dome

base when installing.

I

Locking Arm

3/4”Base Cable Entry

1/2” Side Cable Entry

Rubber Gasket

Locking Arm

Locking Screw

Locking Arm

Extending the Locking arms with screw driver.

Using the Quick Install Adaptor

Cut a 1.5” (38mm) hole in the mounting surface using the T2 marking on the template. Insert the adapter

and turn the screws counter-clockwise one turn to extend the arms, then turn the screws clockwise to pull

the arms toward the flange and secure the adapter to the mounting surface (image J).

Push the cables through the opening and the 1/2” rubber grommet. Make sure the grommet is properly

installed on the adapter to prevent dust penetration (image K).

J

Locking Arms

K

Video-Power Cables

Mounting Surface

1/2”Rubber

Grommet

IMPORTANT: If the dome is mounted externally, use a suitable sealant aroung the cable entry hole to

ensure a moisture resistant seal. This prevents water vapour, from the connected conduit, from condensing

inside the housing.

5. Replace the Camera Module

Tighten the gimbal screws with a screw driver to re-install the camera module.

6. Adjust the camera position

Adjust the camera position by rotating and panning the camera base. The focus and range of the lens

can also be adjusted

7. Install the camera liner

Carefully fit the camera liner over the camera base so that it snaps into place

(image F). Do not obstruct the camera lens.

F

index mark

8. Replace the Dome Cover

Replace the dome cover using the index mars (image G)

to align it. Tighten the torx screws to secure the cover. Do

not overtighten.

The dome cover

The dome base

index mark

G

Mount Using Screws

When mounting the dome to a ceiling or wall using screws, knock out the four screw access holes on the

base that correspond to the template marks T1 using a phillips head screw driver (image D). Drill four

holes in the mounting surface using template marks T1 and cut a hole using template marking T4 for the

3/4” base cable entry.

Template

When flush mounting or surface mounting using the outer ring, ensure that the large rubber gasket

(image I) is in place under the lip of the dome enclosure.

IMPORTANT: If the dome is mounted externally using screws, use the suppled rubber o-rings over each of

the four mounting holes of the dome base to ensure a moisture resistant seal. Tighten the screws sufficiently

to compress the o-ring moisture seals located underneath the screwheads. Do not overtighten.

Mount on a US Single Gang Box:

When mounting the dome to a single gang box,

carefully remove the screws from the securing

position on the box. Insert the 3/4” rubber

grommet in the base cable entry to prevent dust

penetration and push the cables through the dome

base and grommet.

Mount the dome base using the two screws

removed earlier. Tighten the screws sufficiently to

secure the base to the box (position T5, image H).

K

Dome

Base

T5

T5

Rubbe

3/4”

r Grom

met

Securin

Positio

(T5)

Securin

Positio

(T5)

g

n

g

n

US Single

Gang

Box

Loading...

Loading...