TRANSCEPT PROPRIETARY

TransCell 1900TM System

Operation and Maintenance Manual

Document No. 1000497

Revision A

08 March 2001

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF TRANSCEPT, INC. AND IS

TO BE USED ONLY IN ACCORDANCE WITH THE NONDISCLOSURE AGREEMENT UNDER

WHICH THIS DOCUMENT IS PROVIDED. THIS DOCUMENT IS NOT TO BE DUPLICATED IN

WHOLE OR IN PART WITHOUT PRIOR WRITTEN PERMISSION FROM A DULY AUTHORIZED

REPRESENTATIVE OF TRANSCEPT, INC.

THE REVISION STATUS OF ALL PAGES IN THIS DOCUMENT IS THE SAME AS THAT

STATED ON THIS COVER.

Copyright 1999, 2001 Transcept, Inc.

All rights reserved.

TRANSCEPT PROPRIETARY

TRANSCEPT PROPRIETARY

TransCell 1900TM

Operation and Maintenance Manual

REVIEW AND CONCURRENCE

C. STRAW, TDMA TECHNICAL LEAD DATE

S. Maniglia, TDMA Project Manager DATE

P. Yelle, TDMA Product Manager DATE

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF TRANSCEPT, INC. AND IS NOT TO BE USED

FOR ANY PURPOSE, EXCEPT IN ACCORDANCE WITH CONTRACTUAL NONDISCLOSURE TERMS . THIS

DOCUMENT IS NOT TO BE DUPLICATED IN WHOLE OR IN PART WITHOUT PRIOR WRITTEN PERMISSION

FROM A DULY AUTHORIZED REPRESENTATIVE OF TRANSCEPT.

Document No. 1000497

Revision A: 08 March 2001

TRANSCEPT PROPRIETARY

TRANSCEPT PROPRIETARY

DRAWING NO.

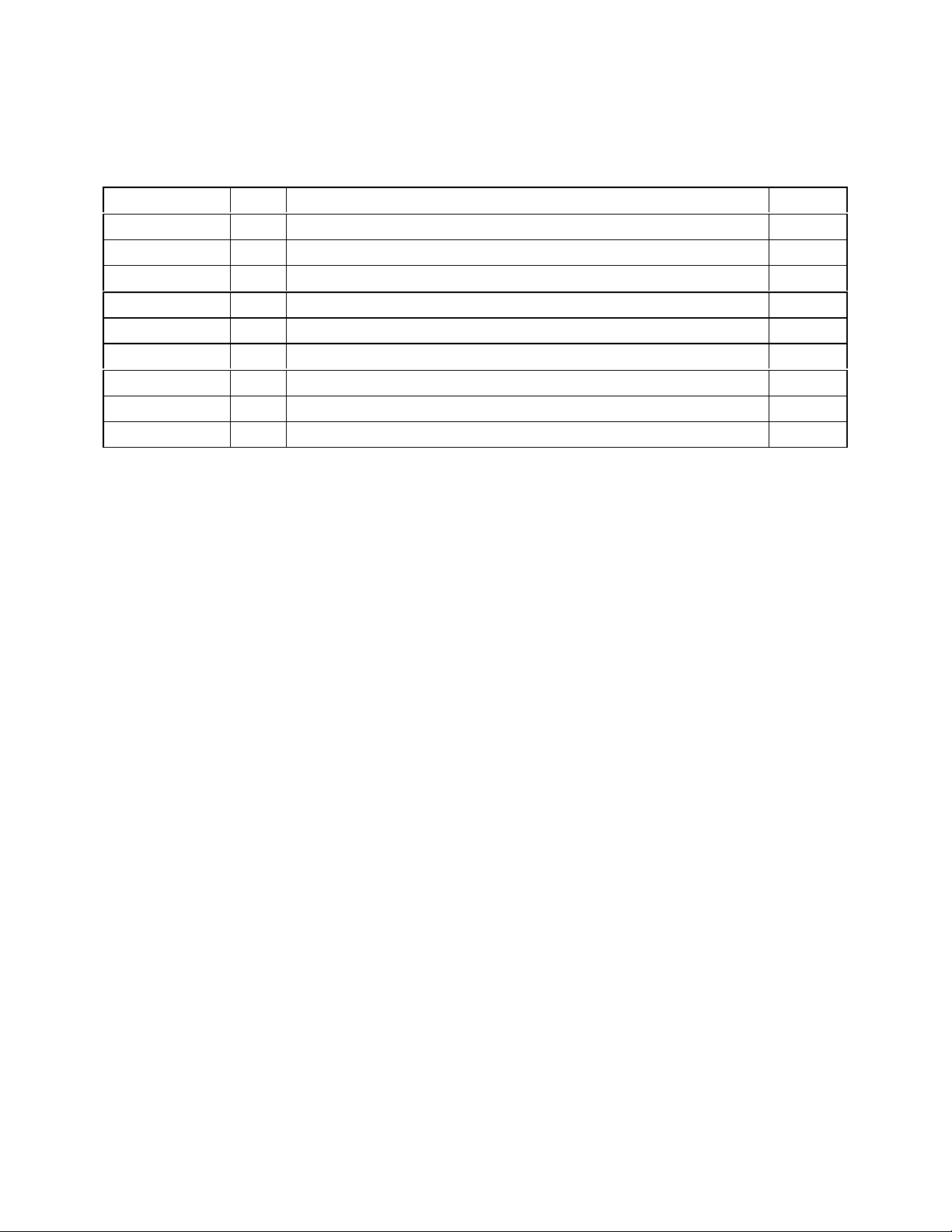

DOCUMENT CHANGE HISTORY

DATE REV DESCRIPTION APPD

03/08/01 A Rel to ECO control per RN 010308 km/CS

TRANSCEPT PROPRIETARY

TransCell 1900TM Operation and Maintenance Manual 1000497A

TABLE OF CONTENTS

Section Page

1.0 INTRODUCTION.......................................................................................................... 1-1

1.1 ABOUT THIS MANUAL ..........................................................................................................1-1

1.1.1 Scope.........................................................................................................................1-1

1.1.2 Manual Organization..................................................................................................1-1

1.2 TERMINOLOGY, A CRONYMS, AND ABBREVIATIONS...............................................................1-2

1.2.1 Notation Conventions ................................................................................................1-2

1.2.2 Acronyms and abbreviations.....................................................................................1-2

1.3 REFERENCE DOCUMENTATION............................................................................................1-3

1.4 SYSTEM O VERVIEW............................................................................................................. 1-4

1.4.1 System Configuration................................................................................................1-4

1.4.2 Physical Description..................................................................................................1-5

1.4.3 Hub Subsystem Assemblies......................................................................................1-7

1.4.3.1 Data Link Module (DLM) ....................................................................................1-7

1.4.3.2 Hub Transceiver Module (HTM)........................................................................1-8

1.4.3.3 Signal Processing Module (SPM) ......................................................................1-9

1.4.3.4 Hub Interface Tray Assy.....................................................................................1-9

1.4.3.5 Low Voltage Power Supply (LVPS).................................................................1-10

1.4.3.6 Microwave Antenna ..........................................................................................1-10

1.4.3.7 Cable Assemblies ............................................................................................1-11

1.4.4 Remote Subsystem Assemblies .............................................................................1-11

1.4.4.1 Remote Transceiver Module (RTM).................................................................1-12

1.4.4.2 Data Link Module..............................................................................................1-13

1.4.4.3 Remote Power Supplies ..................................................................................1-13

1.4.4.4 Remote Interface Tray Assembly....................................................................1-14

1.4.4.5 Transmitter Tray Assembly..............................................................................1-15

1.4.4.6 Tower Top Alarm Module (TTA).......................................................................1-15

1.4.4.7 Microwave Antenna ..........................................................................................1-16

1.4.4.8 Cable Assemblies ............................................................................................1-16

1.4.5 Communication Interfaces.......................................................................................1-16

1.4.5.1 Hardware/Software Platform Requirements for HRP User Interface..............1-16

1.4.5.2 Network Interface.............................................................................................1-16

1.4.5.3 System Element Manager (SEM) Interface.....................................................1-17

1.4.5.4 HRP User Interface (HUI).................................................................................1-17

1.4.5.5 HRP Command Language...............................................................................1-18

1.5 SEM STARTUP...................................................................................................................1-18

1.5.1 User Access.............................................................................................................1-18

1.5.2 SEM and HUI Workstation Initialization...................................................................1-18

1.5.3 SEM Workstation Shutdown....................................................................................1-18

1.5.4 HUI Workstation Shutdown ......................................................................................1-18

2.0 CONTROLS AND INDICATORS..................................................................................... 2-1

2.1 HUB ENCLOSURE CONFIGURATIONS....................................................................................2-1

2.1.1 Front and Rear Panels...............................................................................................2-1

2.1.2 Hub Subsystem Enclosure External Connectors......................................................2-4

2.1.3 Hub Transceiver Module (HTM) ................................................................................2-6

2.1.3.1 HTM Front panel.................................................................................................2-7

2.1.4 Data Link Module (DLM)............................................................................................2-8

2.1.4.1 DLM Front Panel................................................................................................2-8

Page i

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

2.1.4.2 DLM Rear View ..................................................................................................2-8

2.1.5 Signal Processing Module (SPM)..............................................................................2-9

2.1.5.1 SPM Front Panel................................................................................................2-9

2.1.6 Low Voltage Power Supply (LVPS).........................................................................2-11

2.1.7 Hub Interface Tray Assembly..................................................................................2-12

2.2 REMOTE SUBSYSTEM CONFIGURATION .............................................................................2-13

2.2.1 Front and Rear Panels.............................................................................................2-13

2.2.2 Remote Subsystem Enclosure External Connectors..............................................2-15

2.2.3 Remote Transceiver Module (RTM)........................................................................2-16

2.2.3.1 RTM Front Panel..............................................................................................2-16

2.2.4 TTA Module (TTA)..................................................................................................2-18

2.2.4.1 TTA Front Panel...............................................................................................2-18

2.2.5 Remote Interface Tray Assembly ............................................................................ 2-19

2.2.5.1 Remote Interface Tray Assembly Front View..................................................2-19

2.2.6 Transmitter Unit Assembly......................................................................................2-21

2.2.6.1 Transmitter Unit Assembly Top View...............................................................2-21

2.2.6.2 Transmitter Unit Assembly Circuit Breaker Power Cable Connection............2-23

2.2.7 Power Amp Power Supply (PAPS)..........................................................................2-23

2.3 TRANSCELL 1900TM OPERATING INSTRUCTIONS ................................................................ 2-24

2.3.1 Operating Menus .....................................................................................................2-24

2.3.2 Operating Procedures and System Software Functions........................................2-24

2.3.3 Maintenance Instructions.........................................................................................2-24

3.0 OPERATING PROCEDURES.......................................................................................... 3-1

3.1 HUB EQUIPMENT POWER-ON/POWER-OFF.........................................................................3-1

3.1.1 Energizing/De-energizing Hub Subsystem...............................................................3-1

3.1.1.1 Power-On Procedure.........................................................................................3-1

3.1.1.2 Power-Off Procedure.........................................................................................3-1

3.2 REMOTE EQUIPMENT POWER-ON/POWER-OFF...................................................................3-2

3.2.1 Energizing/De-energizing Remote Subsystem.........................................................3-2

3.2.1.1 Power-on Procedure..........................................................................................3-2

3.2.1.2 Power-Off Procedure.........................................................................................3-2

3.3 SEM WORKSTATION POWER-ON/POWER-OFF...................................................................3-2

3.3.1 SEM Workstation Power-On Procedure...................................................................3-2

3.3.2 SEM Workstation Power-off Procedure....................................................................3-3

3.4 SYSTEM SOFTWARE M ENUS............................................................................................... 3-3

3.5 TRANSCELL 1900TM SYSTEM SETUP .................................................................................. 3-3

3.6 TRANSCELL 1900TM SYSTEM OPERATIONS.......................................................................3-3

3.6.1 Autonomous Software Functionality..........................................................................3-4

3.6.1.1 Alarm Polling.......................................................................................................3-4

3.6.1.2 Autolevel Functionality.......................................................................................3-5

3.6.1.3 Autosync Functionality.......................................................................................3-5

3.6.1.4 Reverse Autogain Functionality.........................................................................3-6

3.6.1.5 Forward Continuity.............................................................................................3-6

3.6.1.6 Reverse Continuity.............................................................................................3-6

3.6.2 Software System Maintenance ..................................................................................3-6

3.6.2.1 Defining the Maintenance Window....................................................................3-6

3.6.2.2 Changing and adding TDMA channels..............................................................3-7

3.6.2.3 Querying System Status....................................................................................3-8

3.6.2.4 Toggling Transmitter State.................................................................................3-8

4.0 MAINTENANCE AND TROUBLESHOOTING ...................................................... 4-1

Page ii

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

4.1 SCHEDULED M AINTENANCE.................................................................................................4-1

4.1.1 Hub/Remote Inlet Filter .............................................................................................. 4-1

4.1.1.1 Hub /Remote Inlet Filter Cleaning/Replacement Procedure.............................4-1

4.1.2 Equipment Connectors..............................................................................................4-2

4.2 HUB SUBSYSTEM ASSEMBLY REPLACEMENT I NSTRUCTIONS...............................................4-2

4.2.1 TDMA HUB Card Cage Assembly Replacement Procedures..................................4-2

4.2.1.1 Card Cage Fan Replacement Procedure..........................................................4-2

4.2.1.2 Low Voltage Power Supply (LVPS) Replacement Procedure...........................4-3

4.2.1.3 Hub Transceiver Module (HTM) Replacement Procedure................................4-4

4.2.1.4 Signal Processing Module (SPM) Replacement Procedure.............................4-6

4.2.1.5 Data Link Module (DLM) Replacement Procedure............................................4-7

4.2.2 Power/Surge Suppressor Strip Replacement Procedure.........................................4-8

4.2.3 Hub Subsystem Enclosure Lightning Arrester Replacement Procedures................4-9

4.2.3.1 PCS Port Lightning Arrester Gas Capsule Replacement Procedure................4-9

4.2.3.2 Lightning Arrester Replacement Procedure....................................................4-10

4.3 REMOTE SUBSYSTEM ASSEMBLY REPLACEMENT I NSTRUCTIONS.......................................4-11

4.3.1 TDMA Card Cage Assembly Replacement Procedures.........................................4-11

4.3.1.1 Card Cage Fan Replacement Procedure........................................................4-11

4.3.1.2 Remote Low Voltage Power Supply Replacement Procedure........................4-12

4.3.1.3 Remote Transceiver Module Replacement Procedure...................................4-12

4.3.1.4 Signal Processing Module (SPM) Replacement Procedure...........................4-13

4.3.1.5 Data Link Module (DLM) Replacement Procedure..........................................4-13

4.3.1.6 TTAM Replacement Procedure.......................................................................4-14

4.3.2 Remote Interface Tray Replacement Procedure....................................................4-15

4.3.3 Power/Surge Strip Replacement Procedure...........................................................4-16

4.3.4 Remote Subsystem Lightning Arrester Replacement Procedures.........................4-16

4.3.4.1 Lightning Arrester Gas Capsule Replacement Procedure..............................4-16

4.3.4.2 Lightning Arrester Replacement Procedure....................................................4-16

4.3.5 Remote Transmitter Assemb ly Replacement Procedures.....................................4-17

4.3.5.1 Remote Transmitter Breaker Box Replacement Procedure............................4-18

4.3.5.2 Remote Transmitter Power Amplifier Replacement Procedure......................4-19

4.3.5.3 Transmitter Fan Assembly Replacement Procedure......................................4-20

4.3.6 Remote Power Amplifier Power Supply (PAPS) Replacement Procedure............4-20

4.4 TROUBLESHOOTING..........................................................................................................4-21

4.4.1 Reverse and Forward Link System Power Levels..................................................4-21

4.4.2 Alarms......................................................................................................................4-22

4.4.2.1 Software Fault Detection..................................................................................4-23

4.4.2.2 Alarm Displays .................................................................................................4-25

4.4.2.3 Alarm Reporting................................................................................................4-25

4.4.2.4 Alarm Logging..................................................................................................4-26

4.4.2.5 Alarm Closing...................................................................................................4-26

4.4.2.6 Alarm List ..........................................................................................................4-27

Page iii

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

LIST OF ILLUSTRATIONS

Figure Page

FIGURE 1-1. TYPICAL TRANSCELL 1900TM SYSTEM CONFIGURATION...........................................1-5

FIGURE 1-3. H UB SUBSYSTEM(SINGLE) ......................................................................................... 1-7

FIGURE 1-4. DATA LINK M ODULE (DLM) ........................................................................................ 1-8

FIGURE 1-5. H UB TRANSCEIVER MODULE (HTM)...........................................................................1-9

FIGURE 1-5. SPM FRONT PANEL...................................................................................................1-9

FIGURE 1-6 H UB INTERFACE TRAY...............................................................................................1-10

FIGURE 1-7. LOW VOLTAGE POWER SUPPLY................................................................................1-10

FIGURE 1-8. MICROWAVE ANTENNA.............................................................................................1-11

FIGURE 1-9. REMOTE SUBSYSTEM...............................................................................................1-12

FIGURE 1-10. REMOTE TRANSCEIVER M ODULE (RTM) ................................................................ 1-13

FIGURE 1-11. POWER AMP POWER SUPPLY.................................................................................1-14

FIGURE 1-12. REMOTE TRANSMITTER TRAY.................................................................................1-15

FIGURE 1-13. TTA FRONT PANEL...............................................................................................1-15

FIGURE 1-14. N ETWORKING REQUIREMENTS ...............................................................................1-17

FIGURE 2-1. H UB SUBSYSTEM (SINGLE) ASSEMBLY LOCATIONS ....................................................2-2

FIGURE 2-2. H UB SUBSYSTEM ENCLOSURE CONNECTOR SIDE......................................................2-5

FIGURE 2-3. HTM FRONT PANEL...................................................................................................2-7

FIGURE 2-4. DLM FRONT PANEL...................................................................................................2-8

FIGURE 2-5. DLM REAR VIEW .......................................................................................................2-9

FIGURE 2-6. SPM FRONT PANEL ...................................................................................................2-9

FIGURE 2-7. LOW VOLTAGE POWER SUPPLY................................................................................2-11

FIGURE 2-8 HUB INTERFACE TRAY ASSEMBLY............................................................................2-12

FIGURE 2-9. REMOTE SUBSYSTEM ASSEMBLY LOCATIONS...........................................................2-14

FIGURE 2-10. REMOTE SUBSYSTEM ENCLOSURE CONNECTOR SIDE ...........................................2-15

FIGURE 2-11. RTM FRONT PANEL...............................................................................................2-17

FIGURE 2-12. TTA FRONT PANEL................................................................................................2-18

FIGURE 2-13. REMOTE I NTERFACE TRAY (G2) ASSEMBLY FRONT PANEL..................................... 2-19

FIGURE 2-14. REMOTE I NTERFACE TRAY ASSEMBLY REAR VIEW.................................................2-20

FIGURE 2-15. TRANSMITTER UNIT ASSEMBLY TOP VIEW..............................................................2-22

FIGURE 2-16. POWER AMPLIFIER POWER SUPPLY.......................................................................2-24

FIGURE 4-1. H UB AND REMOTE INLET FILTER LOCATIONS..............................................................4-1

FIGURE 4-2. H UB SUBSYSTEM TDMA CARD CAGE........................................................................4-3

FIGURE 4-3. LOW VOLTAGE POWER SUPPLY..................................................................................4-4

FIGURE 4-4. HTM FRONT PANEL...................................................................................................4-6

FIGURE 4-5. SPM FRONT PANEL...................................................................................................4-7

FIGURE 4-6. DLM DIPLEXER CONFIGURATION, HUB ......................................................................4-8

FIGURE 4-7. H UB POWER/SURGE SUPPRESSOR STRIP..................................................................4-9

FIGURE 4-8. REMOTE SUBSYSTEM TDMA CARD CAGE................................................................4-11

FIGURE 4-9. REMOTE TRANSCEIVER M ODULE (RTM) FRONT PANEL............................................4-13

FIGURE 4-10. DLM DIPLEXER CONFIGURATION, REMOTE.........................................................4-14

FIGURE 4-11. TTAM FRONT PANEL.............................................................................................4-15

FIGURE 4-12. REMOTE I NTERFACE TRAY FRONT PANEL.............................................................4-16

FIGURE 4-13. REMOTE TRANSMITTER ASSEMBLY.........................................................................4-17

FIGURE 4-14. POWER AMPLIFIER POWER SUPPLY......................................................................4-21

Page iv

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

LIST OF TABLES

Table Page

TABLE 1-1. MAJOR ASSEMBLIES FOR HUB SUBSYSTEM CONFIGURATIONS.........................................6

TABLE 1-2. MAJOR ASSEMBLIES FOR REMOTE SUBSYSTEM (P/N 1000102).......................................6

TABLE 1-6. PLATFORM REQUIREMENTS FOR HRP U SER INTERFACE SOFTWARE .............................16

TABLE 2-1. HUB SUBSYSTEM ASSEMBLIES.........................................................................................3

TABLE 2-2. HUB SUBSYSTEM ENCLOSURE EXTERNAL CONNECTORS................................................6

TABLE 2-3. HTM FRONT PANEL CONNECTORS AND I NDICATORS.......................................................7

TABLE 2-4. DLM FRONT PANEL CONNECTORS..................................................................................8

TABLE 2-5. SPM FRONT PANEL CONNECTORS AND I NDICATOR .......................................................10

TABLE 2-6. HUB POWER SUPPLY CONNECTORS AND I NDICATORS....................................................11

TABLE 2-7. HUB I NTERFACE TRAY ASSEMBLY CONNECTORS ...........................................................13

TABLE 2-8. REMOTE SUBSYSTEM CONTROL AND I NDICATOR LOCATIONS .........................................14

TABLE 2-9. REMOTE SUBSYSTEM ENCLOSURE EXTERNAL CONNECTORS.........................................15

TABLE 2-10. RTM FRONT PANEL CONNECTORS AND I NDICATORS...................................................17

TABLE 2-11. TTA ASSEMBLY FRONT PANEL CONNECTORS..............................................................18

TABLE 2-12. REMOTE I NTERFACE TRAY ASSEMBLY FRONT PANEL CONNECTORS............................20

TABLE 2-13. REMOTE I NTERFACE TRAY ASSEMBLY REAR PANEL CONNECTORS..............................21

TABLE 2-14. TRANSMITTER UNIT ASSEMBLY TOP VIEW CONNECTORS.............................................23

TABLE 2-15. POWER AMP POWER SUPPLY CONNECTORS AND I NDICATORS.....................................24

TABLE 3-1. LVPS OUTPUT WIRING CHART....................................................................................3-1

TABLE 3-2. AUTONOMOUS SYSTEM SOFTWARE SETTINGS .............................................................3-4

TABLE 3-3. TIA/EIA-136-280 TABLE 2 BORDER CHANNELS..........................................................3-8

TABLE 4-1. SUBSYSTEM ACCEPTANCE TEST POWER LEVELS.......................................................4-22

TABLE 4-2 FAULT BITMASKS BY MODULE.....................................................................................4-23

TABLE 4-3. ALARM FORMAT DESCRIPTION ...................................................................................4-26

TABLE 4-3. HRP ALARM M ESSAGES AND CORRECTIVE ACTION ................................................... 4-28

Page v

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

♦ High leakage current: The Hub and Remote environmental enclosures must be connected to

Protective Earth ground before any connection is made to AC prime power.

♦ High voltages (115 Vac and 220 Vac) are present within the Hub and Remote environmental

enclosures, respectively. Use extreme caution when working inside the enclosures.

♦ High voltages may exist close to the Hub or Remote environmental enclosure location; use

standard industry safety practices when working on an installed enclosure.

ESD CAUTION

The Hub Transceiver Assembly, Remote Transceiver Assembly, and

11-Mbps TDMA Chassis Assembly contain circuit card assemblies

(CCAs) that are sensitive to Electrostatic Discharge (ESD) damage.

Whenever handling these assemblies, use ESD precautionary

procedures to minimize the risk of permanent ESD damage to the

CCAs. Low relative humidity levels increase the potential for damage

to ESD-sensitive devices.

FCC License Data

The Hub and Remote assemblies are in the process of being licensed by the Federal Communications

Commission for operation in the frequency band as noted on the product label affixed to the

enclosure.

Any changes or modifications to this equipment (including software) must be expressly approved by

Transcept. Failure to do so may void the user’s authority to operate this equipment. This equipment

complies with FCC rules when the antennas and cables having characteristics and part numbers as

specified below are used with the system. The user is responsible for ensuring that only the specified

antennas and cables are used and properly installed.

♦ PCS Antenna: Maximum gain 21 dBi

This system is designed to be used exclusively for fixed, point-to-point operations, as defined in

47CFR15.247. The user is responsible for ensuring that the system is installed and operated in the

manner described herein. Operation of this equipment in a manner other than fixed, point-to-point

may constitute a violation of the FCC rules.

Page vi

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

SECTION 1

INTRODUCTION

1.0 INTRODUCTION

1.1 ABOUT THIS MANUAL

1.1.1 Scope

This manual contains instructions for operating and maintaining the TransCell 1900TM

System, which consists of a Hub and a Remote subsystem. The major components and

assemblies of the Hub/Remote Pair (HRP) are:

⇒ TDMA Hub Subsystem (Master)

Hub Transceiver Module (HTM)

Data Link Module (DLM)

Signal Processing Module(SPM)

Low Voltage Power Supply (LVPS) (2 each)

Microwave Data Link Antenna

Hub Interface Tray

TDMA Remote Subsystem

Remote Transceiver Module (RTM)

Data Link Module (DLM)

Signal Processing Module(SPM)

Low Voltage Power Supply(LVPS) (2 each)

Power Amp Power Supply (PAPS)

Tower Top Alarm (TTA) Module

Microwave Data Link Antenna

Transmitter Unit Assembly

Remote Interface Tray Assembly

TransCell 1900TM Operating software

♦ Linux Operating System

♦ Executive Control and Monitoring

The manual covers use of TransCell 1900TM operating software for normal system

operation and fault detection. It also covers the troubleshooting and repair of the enclosuremounted assemblies.

1.1.2 Manual Organization

This manual is organized into the following sections:

Section 1 - Provides general system information.

Section 2 - Defines the function of hardware front panel controls and indicators.

Section 3- Provides normal operating procedures.

Section 4 - Provides maintenance and troubleshooting procedures.

Page 1-1

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

1.2 TERMINOLOGY, ACRONYMS , AND ABBREVIATIONS

1.2.1 Notation Conventions

This manual assumes that the user has a basic knowledge of the Windows NT operating

system. Several typographic conventions and standard Windows NT terms are used in

this manual when discussing the TransCell 1900TM user interface software.

1.2.2 Acronyms and abbreviations

ESD ElectroStatic Discharge

A/D Analog-to-Digital

ADC Analog-to-Digital Converter

AGC Automatic Gain Control

ASCII American Standard Code for

Information Interchange

BER Bit Error Rate

BPSK Binary Phase Shift Keying

BTS Base Transceiver Station

BTU British Thermal Unit

CCA Circuit Card Assembly

CH Channel

CIC Carrier Ident ification Code

CCK Complimentary Code Keyed

CPU Central Processing Unit

D/A Digital-to-Analog

dB Decibel

DBPSK Differential Binary Phase Shift

Keying

DCCH Digital Control Channel

DDC Digital Down Converter

DIV Diversity

DLM Data Link Module

DPSK Digital Phase Shift Keying

DQPSK Differential Quadrature Phase Shift

Keying

DS0 Digital Signal, Level Zero – one

channel of a 24 channel T1 line

DSP Digital Signal Processor

DSSS Direct Sequence Spread Spectrum

DSU/CSU Digital Service Unit/Channel

Service Unit. Digital equivalent of

an analog modem.

DUC Digital Up Converter

Duplexer A device used to split a higher speed

source data stream into two

separate streams for transmission

over two data channels.

EEPROM Electronically Erasable

Programmable Read Only Memory

EVM Error Vector Magnitude

FCC Federal Communications

Commission

FPGA Field Programmable Gate Array

Fresnel The line of sight path

Zone between two microwave antennas.

FTP File Transfer Protocol

GFI Ground Fault Indicator

GUI Graphical User Interface

HTM Hub Transceiver Module

HRP HUB Remote Pair

H-RX Horizontal Receive

H-TX Horizontal Transmit or Transmitter

HUI HRP User Interface

Hz Hertz

I/F Interface

IF Intermediate Frequency

ISM Band Industrial Scientific Medical; a term

the FCC uses to name several

frequency bands in the spectrum.

ISM band = 902-928 MHz, 2.4 GHz,

5.8GHz

ITU International Telecommunications

Union

ITU-T International Telecommunications

Union – Telecommunication sector

LA Lightning Arrester

LED Light Emitting Diode

LNA Low Noise Amplifier

LUT Look Up Table

LVDS Low Voltage Differential Signaling

LVPS Low Voltage Power Supply

MAC Media Access Control

MBPS Mega Bits Per Second

Page 1-2

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

MSC Master Switch Center

MUX Multiplex or Multiplexer

NCO Network Control Office

NEMA National Electrical Manufacturers

Association

Nm Newton meter - unit of torque

NOC Network Operations Center

OA&M Operation, Administration, and

Maintenance

OSI Open Systems Interconnection, an

internationally accepted framework

of standards for communication

between different systems.

OSS Operation Support System

PA Power Amplifier

PAPS Power Amplifier Power Supply

PCS Personal Communications Service

PLL Phase Lock Loop

PRI Primary

PRISM™ An Intersil (Harris) trademark

denoting a chip set used to

implement wireless communications

using direct spread spectrum

technology.

QPSK Quaternary Phase Shift Keying or

Quadrature Phase Shift Keying

RSSI Receiver Signal Strength Indication

RXD Diversity Receive

RXP Primary Receive

SEM System Element Manager

SPM Signal Processing Module

SCCS Self Contained Cell Site

T-1 or T1 A digital transmission link with a

capacity of 1.544 Mbps.(24 digital 64

kbps voice channels)

TCP/IP Transmission Control

Protocol/Internet Program

TDMA Time Division Multiple Access

TEMS Test Equipment Mobile Station

TIA/EIA Telecommunications Industries

Association/Electronics Industries

Association (Now called TIA).

TMA Tower Mounted Amp

TTA Tower Top Alarm

TX Transmit or Transmitter

UL Underwriters Laboratories

V.35 ITU-T standard for trunk interface

between a network access device

and a packet network that defines

signaling for data rates greater than

19.2 kbps.

V-RX Vertical Receive

V-TX Vertical Transmit or Transmitter

WAN Wide Area Network

RTM Remote Transceiver Module

1.3 REFERENCE DOCUMENTATION

♦ TransCell 1900TM Installation and Integration Manual, Transcept Document No.

1000462

♦ TransCell 1900TM Product Specifications, Transcept Document No. 1000143

♦ TDMA Cellular PCS, TIA/EIA-136

♦ Installation and User Manual for SEM and HUI Subsystems, Transcept Document

No. 1000483

Page 1-3

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

1.4 SYSTEM OVERVIEW

The TransCell 1900TM System provides an economical means for building out both

coverage and capacity for TIA/EIA-136 TDMA wireless communications. The TransCell

1900TM System uses distributed RF elements to receive and transmit TDMA-based signals

at remote sites, and microwave data links for two-way transport. These signals between

the remote sites and the Base Transceiver Station (BTS) interface at the designated hub

site.

The system software oversees all elements of the TransCell 1900TM System and provides

operational data to a Network Operations Center (NOC). The software also provides the

means to remotely set all system operational parameters and to locally install software

upgrades. All user communications are conducted through an Ethernet® TCP/IP ASCII

interface.

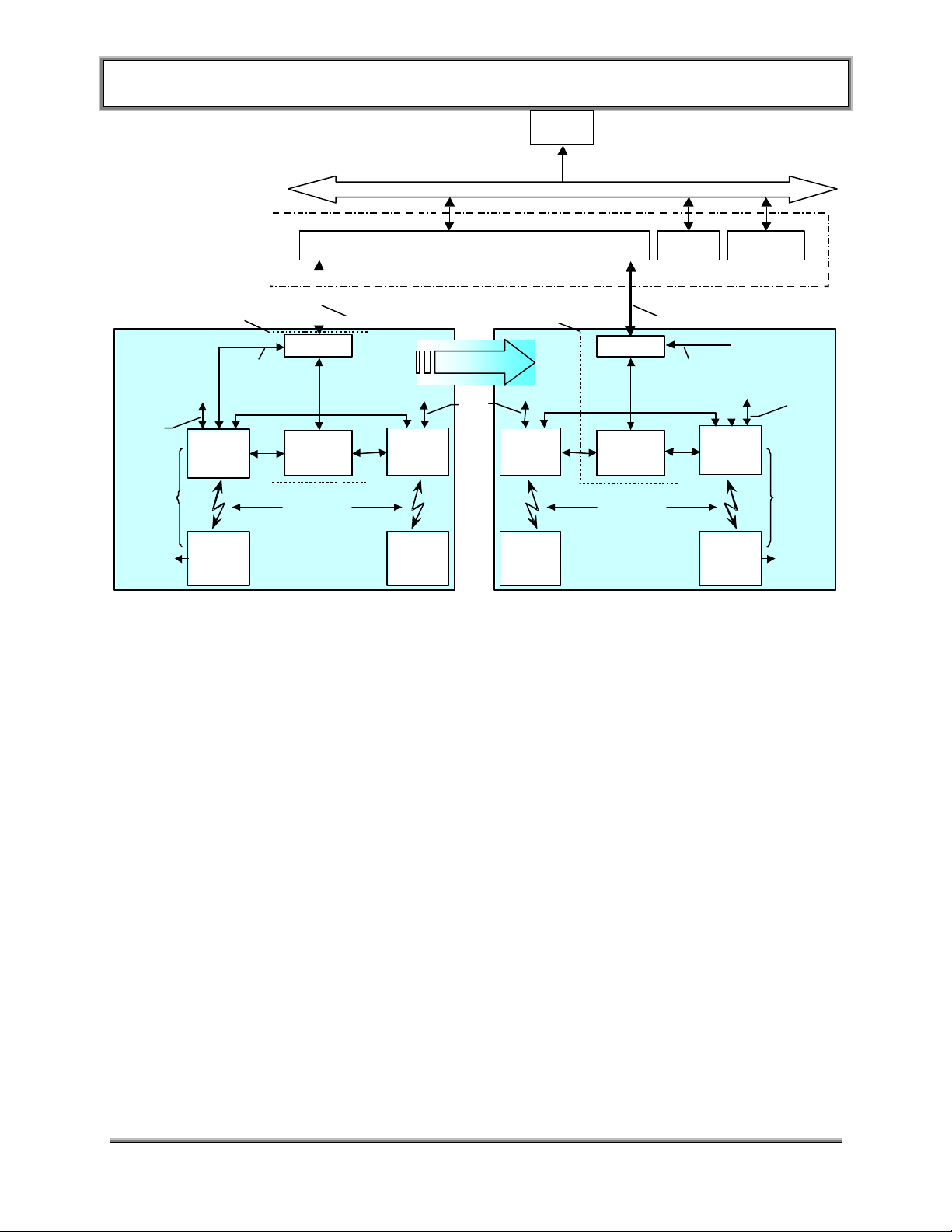

1.4.1 System Configuration

A typical TransCell 1900TM System configuration is shown in Figure 1-1. The basic system

configuration is a Hub/Remote Pair (HRP). Each HRP consists of a Hub Subsystem (either

a Master or Slave) and a Remote Subsystem connected with a microwave data link. Each

Hub Subsystem (Hub 1 through Hub n) is directly connected to a BTS.

Monitoring and control access to the TransCell 1900TM System is provided both locally and

remotely. Local access for monitoring and control of each HRP is provided at both the Hub

and the Remote subsystems in the form of an Ethernet port. Any computer meeting the

minimum configuration requirements (see paragraph 1.4.5.1) with the HRP User Interface

(HUI) software installed and the appropriate list of Internet Protocol (IP) addresses can be

connected for password-controlled access.

At the NOC, the System Element Manager (SEM) software, installed on an appropriately

configured computer, continuously captures alarm data from the Wide Area Network

(WAN) for each HRP. The alarm data is displayed for review and acknowledgment via the

SEM user interface, and it is made available to the NOC’s Operation Support Services

(OSS). A computer with the HUI software installed also may be activated at the NOCC for

monitoring and control access to operating parameters of each HRP.

Page 1-4

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

OSS

Combined Alarm Data

Customer Wide Area Network

HRP

User Interface

Hub N

Slave

Local

10baseT

Access

Local

10baseT

Access

Local

10baseT

Access

Hub-Remote

Pair (HRP)

Local

10baseT

Access

SCCS

Hub 1

Master

Remote 1

V.35

DS0

CSU/DSU

Serial

BTS

3 Sector

Microwave Link

T1

Hub

Slave 2

Remote 2

DS0 Extraction

Local

10baseT

Access

SCCS

Hub N-1

Master

Remote

N-1

MSC

CSU/DSU

Serial

BTS

Microwave Link

T1

SEM

V.35

DS0

Remote N

Figure 1-1. Typical TransCell 1900TM System Configuration

1.4.2 Physical Description

The Hub/Remote Subsystem enclosures are intended for outdoor use, primarily to provide a

degree of protection against corrosion, wind-blown dust and rain. The Hub and Remote

enclosures are made of steel with access via a single door on the front of the cabinets. Each

has two lifting eyes at the top for cable attachment when moving and positioning the

enclosures. The two enclosure configurations are based on similar hardware.

The Hub enclosure dimensions are:

♦ Height: 78 in. (198 cm) includes 6 in. base

♦ Depth: 24 in. (61.0 cm)

♦ Width: 24 in. (61.0 cm),

♦ Weight: Single Hub 325 lb. (147.6 kg); Dual 450 lb. (202.0 kg)

The Remote enclosure dimensions are:

♦ Height: 81 in. (205.5 cm) includes 6 in. base

♦ Depth: 24 in. (61.0 cm)

♦ Width: 36 in. (92.0 cm),

♦ Weight: 510 lb. (232.0 kg)

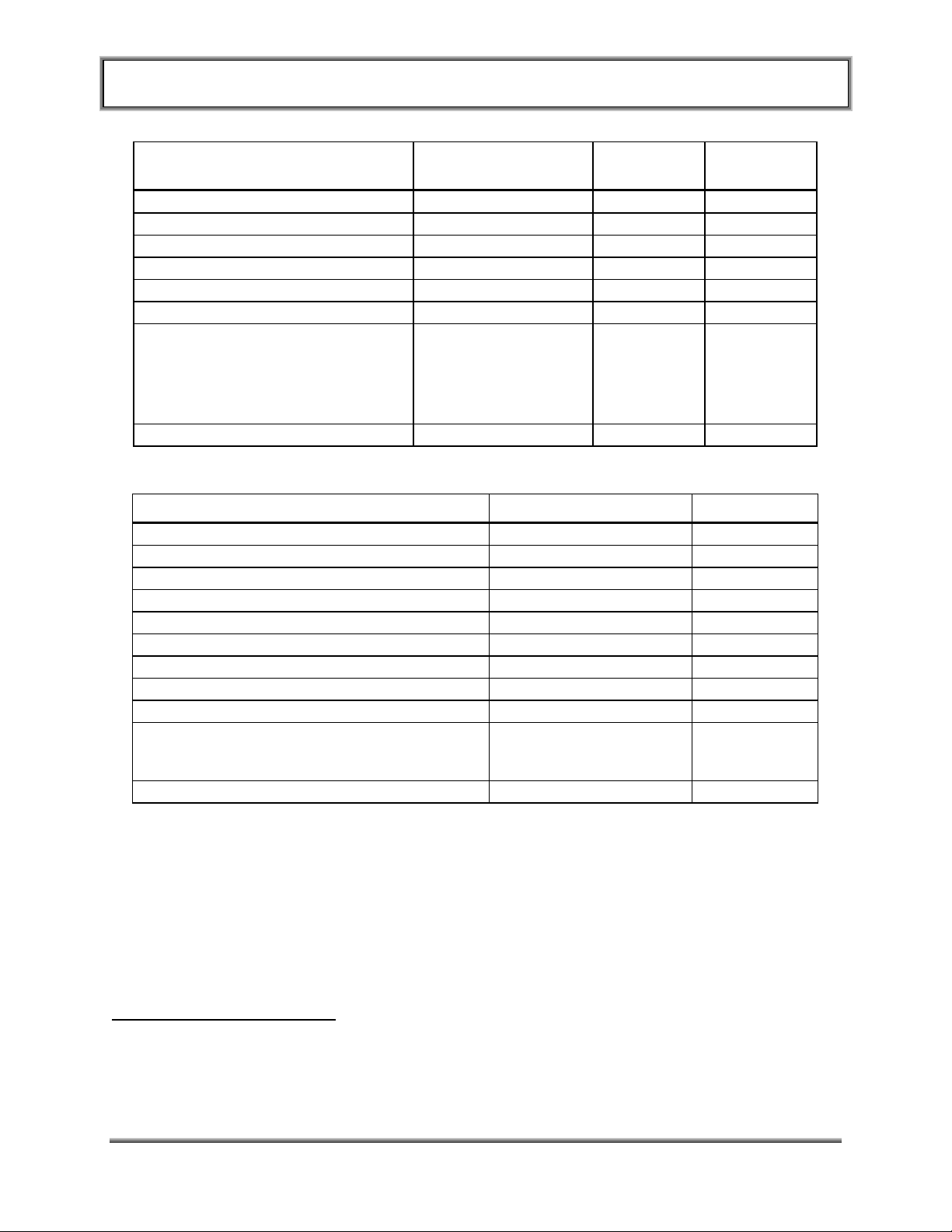

Table 1-1 lists the major assemblies and components installed for the Dual Hub (P/N

1000225) and Single Hub (P/N 1000101) Subsystems. Table 1-2 lists the major assemblies

and components installed for the Remote Subsystem (P/N 8344086G1). For a detailed

assembly list for each enclosure, refer to Section 2.

Page 1-5

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

Table 1-1. Major Assemblies for Hub Subsystem Configurations

Dual Hub

Assembly Item Part Number

Data Link Module (DLM) 1000428G1 2 1

Signal Processing Module (SPM) 1000115G1 2 1

Hub Transceiver Module (HTM) 1000361G1 2 1

Low Voltage Power Supply 1000107P1 4 2

Hub Interface Tray 1000425 2 1

Microwave Antenna 1(2, 3 or 4 foot

dish)

Cable Assemblies Various X X

1920006P004 (2 foot)

1920006P005 (3 foot)

1920006P001(4 foot)

10000225

2 1

Single Hub

1000101

Table 1-2. Major Assemblies for Remote Subsystem (P/N 1000102)

Assembly Item Part Number Qty.

Data Link Module (DLM) 1000428G1 1

Signal Processing Module (SPM) 1000115G1 1

Remote Transceiver Module (RTM) 1000362G1 1

Low Voltage Power Supply 1000107P1 2

Power Amp Power Supply 1000106P1 4

Remote Interface Tray Assembly 1000210 1

Tower Top Alarm Module 1000217G1 1

Transmitter Unit Assembly 1000104 2

Power Amplifier 1000103P1 6

Microwave Antenna 1(2, 3 or 4 foot dish) 1920006P004 (2 foot)

1920006P005 (3 foot)

1920006P001(4 foot)

1

Cable Assemblies Various

1

Size of antenna is dependant the on configuration of cell site. Refer to Transcept Product Spec (Spec.

No.1000143) for details.

Page 1-6

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

Figure 1-2. Hub Subsystem (Single)

1.4.3 Hub Subsystem Assemblies

The following paragraphs describe the major Hub Subsystem assemblies listed in Table 1-1.

A typical Single Hub Subsystem is shown in Figure 1-2 with the major assemblies installed.

1.4.3.1 Data Link Module (DLM)

The Data Link Module is a 5.8 GHz Spread Spectrum Transmitter/Receiver that provides

the microwave link to/from the remote unit. The DLM converts the digital data to/from the

SPM to/from 5.8GHz microwave data. The interface to and from the SPM is an 11 Mbps

RS485 serial interface. The data rate over the microwave link is 11 Mbps in both the

transmit and receive directions. The general performance specifications are shown in Table

1-3. Figure 1-3 shows the front panel of the DLM.

Page 1-7

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

Table 1- 3. DLM General Performance Specifications

Parameter Units Spec Comments

Frequency MHz 5725

to

5850

Channels 4 One transmit and one receive

Receiver sensitivity dBm -83 Minimum, for <1e-5 BER

Transmitter output dBm 30

Transmitter

Rate

Receiver

Rate

Mbps 11

Mbps 11

Unlicensed, Industrial, Scientific, and

Medical band, FCC Section 15.247

Figure 1-3. Data Link Module (DLM)

1.4.3.2 Hub Transceiver Module (HTM)

The HTM provides the interface to the BTS for both forward and reverse paths to the

TransCell 1900TM System. The HTM converts the forward PCS signals received from the

BTS to a digital IF signal for Digital Down Conversion on the SPM. In the reverse path

the HTM converts a digital IF signal from the Digital Up Converters on the SPM to a

reverse PCS signal and transmits to the BTS. The general performance specifications are

shown in table 1-4. Figure 1-4 shows the front panel of the HTM.

Table 1-4 HTM General Performance Specifications

Parameter Units Spec Comments

Output Carrier

frequency

(reverse path)

Input IF

(reverse path)

Output Power

(reverse path)

Input Carrier

Frequency

(forward path)

Input Power

(forward path)

Output IF

(forward path)

MHz 1850 – 1910 In accordance with

TIA/EIA-136-110-A, Table

3

MHz 12 – 19.5 Split band configuration

dBm -110 to –20

MHz 1930 – 1990 In accordance with

TIA/EIA-136-110-A,

Table 3

dBm

MHz 3.5 – 18.5

-18 ± 10 dB

Per Carrier.

Page 1-8

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

Figure 1-4. Hub Transceiver Module (HTM)

1.4.3.3 Signal Processing Module (SPM)

The SPM consists of a processor, digital IF interfaces, data communication interfaces,

Digital Down Converters (DDC) and Digital Up Converters(DUC). The processor uses a

Motorola Power PC that runs Linux OS.

The digital IF interface transmits/receives digital IF data to/from the RTM or the HTM and

provides the channelization of the wideband data. The interface to the DLM consists of

digital baseband receive and transmit data at an 11 Mbps rate. Figure 1-5 shows the SPM

Front Panel.

The communications interfaces consist of the following:

• Cell 2 and 3 RS232 Serial interface for dual and triple Hub configuration

• RS-485 serial interface to the Power Amplifier

• Power Amp and Low Voltage Power Supply Interfaces (I2C)

• A v.35 interface that provides the interface to a DSU/CSU connection on a host

network. This interface provides for status and health monitoring of the

TransCell 1900TM system.

• Maintenance RS-232 and Ethernet ports

Figure 1-5. SPM Front Panel

1.4.3.4 Hub Interface Tray Assy

This assembly, Figure 1-6, contains high power duplexers that provide the duplexed Rx and

Tx signals to and from the HTM. This assembly is only required in configurations that

support duplexed transmit and receive RF interfaces such as the Nortel and Lucent

basestations. Basestations that have separate receive and transmit interfaces do not

require this interface tray, such as the Ericsson basestation.

Page 1-9

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

Figure 1-6 Hub Interface Tray

1.4.3.5 Low Voltage Power Supply (LVPS)

The LVPS operates using 115 VAc, 60 Hz as its input and provides +12, and +8 VDc to the

front panel mounted bus bar for distribution to the other modules in the Hub. Two power

supplies are installed for redundancy. If the main power supply fails the back up power

supply will supply the necessary voltage and current to maintain operation of the system

without loss of service. The power supply provides fault status to the SPM via an I2C serial

interface. The LVPS front panel is shown in Figure 1-7.

Figure 1-7. Low Voltage Power Supply

1.4.3.6 Microwave Antenna

The microwave antenna (data link antenna), shown in Figure 1-8 is used for

communication between a Hub and a Remote site is available in a two, three or a four foot

version. The mechanical specifications of the microwave antenna are:

♦ Diameter: 4 feet (1.2 meters)

♦ Weight: 60 pounds (27.2 kilograms) without radome

70 pounds (31.8 kilograms) with radome

Page 1-10

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

♦ Elevation Range: ± 25° (Course)

±15° (Fine)

♦ Azimuth Range: ± 180° (Course)

±15° (Fine)

♦ Polarization: Horizontal and vertical

Figure 1-8. Microwave Antenna

1.4.3.7 Cable Assemblies

Cable assemblies provided with the Hub Subsystem interconnect the installed assemblies

within the enclosure. The external V.35 cable assembly, for interconnection between the

Hub and the BTS and all other external-interfacing cables at the site are not provided as

part of the TransCell 1900TM system.

1.4.4 Remote Subsystem Assemblies

The following paragraphs describe the major assemblies listed in Table 1-2 that are

installed in the Remote Subsystem. A typical Remote Subsystem is shown in Figure 1- with

the major assemblies installed. Refer to Section 2 for more information concerning installed

assemblies in the Remote Subsystem.

Page 1-11

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

Figure 1-9. Remote Subsystem

1.4.4.1 Remote Transceiver Module (RTM)

The RTM provides the RF up conversion from digitized IF to the PCS frequencies and down

conversion from PCS frequencies to IF frequencies. In the forward path there are 6

individual carriers that are transmit to the high power amplifiers. The reverse path

consists of a primary and diversity carrier that are transmitted to the SPM. The general

performance specifications are shown in Table 1-5. Figure 1-10 shows the front panel of the

RTM.

Page 1-12

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

Table 1-5 RTM General Perfromance Specifications

Parameter Units Requirement Comments

Output Carrier

frequency

(forward path)

Input IF

(forward path)

Output Power

(forward path)

Input Carrier

Frequency

(reverse path)

Input Power

(reverse path)

Output IF

(reverse path)

MHz 1930-1990 In accordance with

TIA/EIA-136-110-A, Table

3

MHz

dBm 5

MHz 1850 – 1910 In accordance with

dBm -88 to -90

MHz 3.5 – 18.5

12 – 15.75

Max

TIA/EIA-136-110-A,

Table 3

Figure 1-10. Remote Transceiver Module (RTM)

1.4.4.2 Data Link Module

The DLM in the Remote is identical to the DLM in the Hub refer to paragraph 1.4.3.1 for a

description of the module

1.4.4.3 Remote Power Supplies

The Remote unit contains two sets of power supplies. The LVPS is identical to the unit

used in the Hub. Refer to paragraph 1.4.3.5 for a description of the module. The Power

Amp Power Supply (PAPS) operates using 220 Vac, 60 Hz and provides +24 Vdc to the

transmitter tray and TTA module. The power supply contains four replaceable modules.

The power supply is shown in Figure 1-11.

Page 1-13

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

Figure 1-11. Power Amp Power Supply

1.4.4.4 Remote Interface Tray Assembly

The Remote Interface Tray houses various RF components used in the TransCell 1900TM

System. The major components of the Remote Transmitter are:

• Integrated LNA-Combiner

(2)

• PCS Duplexers (4 for 2

sector, 6 for 3 sector

configuration)

Page 1-14

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

The Remote Interface tray provides the necessary two or three sector combining and

duplexing of the forward and reverse PCS carriers.

1.4.4.5 Transmitter Tray Assembly

A transmitter tray, Figure 1-12, contains up to four high power amplifiers, high power

combiner and an associated fuse box. The power amplifiers amplify the forward signals

from the RTMs for transmission by the PCS antennas. The power amplifiers each contain

an RS485 serial interface for communications to and from the SPM.

Figure 1-12. Remote Transmitter Tray

1.4.4.6 Tower Top Alarm Module (TTA)

The TTA module provides an interface to the Tower Mounted Amplifiers (TMA).

The TTA module supplies +15Vdc to the TMA and provides for fault monitoring of

pulsed or steady state alarms generated from the TMAs. Additionally it provides a

fault status indicator for each of the high power amplifiers. Figure 1-13 shows the

front panel of the TTA.

Figure 1-13. TTA Front Panel

Page 1-15

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

1.4.4.7 Microwave Antenna

The Remote Microwave Antenna is identical to the Hub Microwave Antenna. Refer to

paragraph 1.4.3.6 for the description.

1.4.4.8 Cable Assemblies

Cable assemblies provided with the Remote Subsystem interconnect the installed

assemblies within the enclosure. Cable assemblies for external Remote Subsystem

connections at the site are provided by the customer.

1.4.5 Communication Interfaces

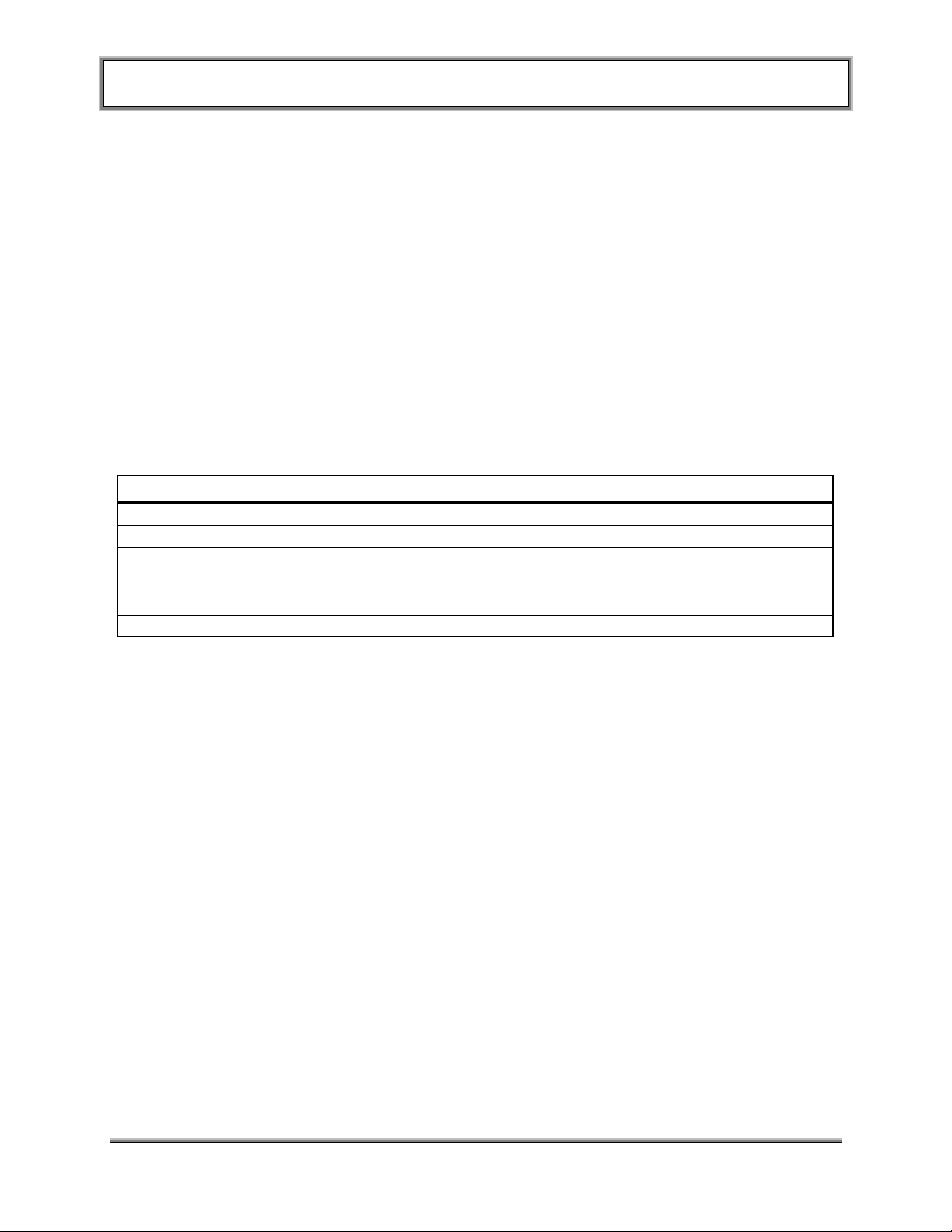

1.4.5.1 Hardware/Software Platform Requirements for HRP User Interface

Any personal computer configured per Table 1-6 may serve as the platform for the HRP

User Interface (HUI) software application.

Table 1-6. Platform Requirements for HRP User Interface Software

Computer

450 MHz (minimum) Pentium P3 laptop computer running Windows NT

RS-232 Serial ports, 9-pin

10BaseT Ethernet

56-kbps Modem

pcANYWHERE Version 8.0 or later

Console cable

1.4.5.2 Network Interface

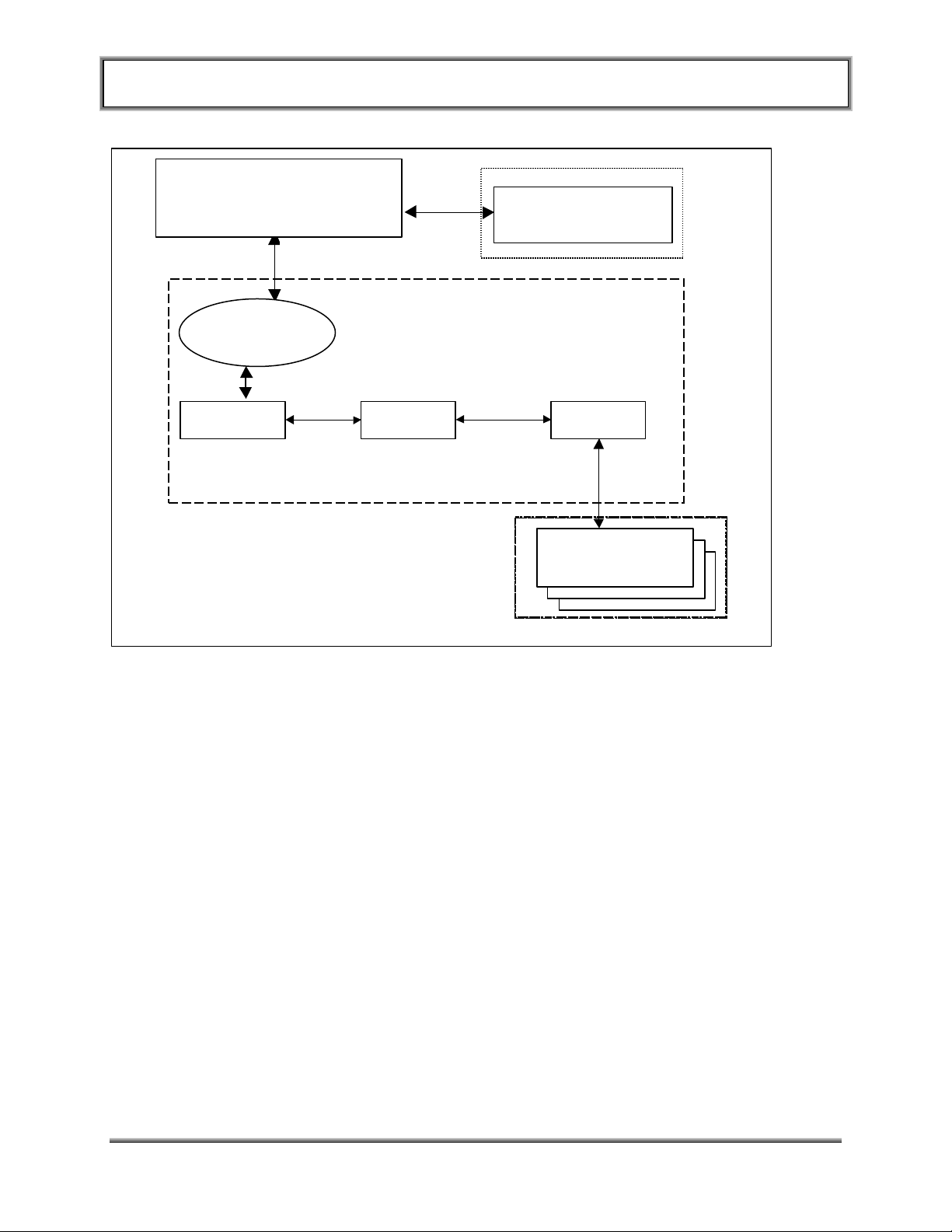

Figure 1-14 shows how the System Element Manager (SEM) and HRP User Interface (HUI)

communicate over the customer’s network with a Hub. The Hubs are connected to a customer provided

DSU/CSU via a V.35 serial connection. The DSU/CSU communicates over a DS0 slot in a T1 line to

another DSU/CSU at the customer’s switch. The DSU/CSU at the Switch is connected to a router over

another V.35 serial connection. A TCP/IP connection is established between the Transcept V.35 Master

SPM in the HRP and the Customer’s router at the Switch. Once this link has been established, the SEM

can connect to the Hub to monitor its health. Likewise a HUI located on the customer’s network can

connect to the HRP to view or change system settings. The Router must be programmed to pass traffic

for the IPs out of its V.35 serial port that is connected to the DSU/CSU.

Page 1-16

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

POTS

T1 DS0 slot

V.35

Hub/Remote Pairs

V.35

HUB / REMOTE

Ethernet

Remote Monitoring

System Element Manager

Customer’s

(SEM) and/or

HRP User Interface (HUI)

Interface

Interface

Customer’s Network and required

via PcAnywhere

equipment

WAN

Router DSU/CSU DSU/CSU

64Kbps

Pair

Figure 1-14. Networking Requirements

1.4.5.3 System Element Manager (SEM) Interface

The SEM software application can be configured to automatically connect to all HubRemote Pairs (HRPs) in the network for monitoring of alarm data. The SEM workstation

communicates with each HRP by connecting to an Ethernet network via a network

interface card.

The SEM Combined Alarm Port can be used to transmit alarms collected at the SEM to the

OSS at the Network Operations Center (NOC). See the Installation and User Manual for

SEM and HUI Subsystems, Transcept Document Number 1000483 for more detail.

1.4.5.4 HRP User Interface (HUI)

The HUI software provides access to the CLI on a HRP. The HUI software operates on the

users PC and communicates with the HRP over an Ethernet connection. A computer with

HUI software installed functions as a monitoring and control point for the TransCell

1900TM System. Remotely located computers may also use this interface to communicate

with the HRPs. See the Installation and User Manual for SEM and HUI Subsystems,

Transcept Document number 1000483 for more detail.

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

Page 1-17

TransCell 1900TM Operation and Maintenance Manual 1000497A

1.4.5.5 HRP Command Language

Command language in the form of ASCII text strings is used to send commands to and

receive messages from the HRP. For example, a command to set the forward attenuation of

Remote RTM carrier number 1 to 4 would be written in HRP Command Language as:

$ SET RTM FWATTEN 1 4

For a complete list of commands see the Installation and User Manual for SEM and HUI

Subsystems, Transcept Document number 1000483.

1.5 SEM STARTUP

1.5.1 User Access

The TransCell 1900TM System provides an operator log-in and log-out capability through

the HRP User Interface software. To log-in, the operator must enter a password, which

defines the authorized user privilege level: The User level typically allows only viewing of

operational parameters and status, while the Super-User level allows changing of

operational parameters. A valid password is comprised of up to eight alphanumeric

characters (no special characters). The HUI validates the password and allows the operator

to gain access to the menus to perform required functions.

The Super-User has the privileges necessary to monitor, control, and modify the system

parameters. See the Installation and User Manual for SEM and HUI Subsystems,

Transcept Document number 1000483 for more detail.

1.5.2 SEM and HUI Workstation Initialization

When power is applied to the SEM workstation, it executes its power-up diagnostics, and

then it starts all the necessary processes, initializes all communication interfaces, and

waits for input from the operator. The HUI requires the user to start the process. Once

started the HUI will start the necessary processes, initializes all communication interfaces,

and wait for input from the operator. See the Installation and User Manual for SEM and

HUI Subsystems, Transcept Document number 1000483 for more detail.

1.5.3 SEM Workstation Shutdown

Normally the SEM operates 24 hours a day, seven days a week. A system shutdown is only

necessary when a SEM workstation is to be replaced or new software is to be downloaded. A

shutdown of the system closes all logging functions, terminates communications links, and

closes all the SEM processes. Refer to Section 4 for a more detailed description.

1.5.4 HUI Workstation Shutdown

To shut down a HUI workstation, the user logs out and then exits from the HUI software in

a manner similar to most other Windows NT based programs, and powers down the

computer. See the Installation and User Manual for SEM and HUI Subsystems, Transcept

Document number 1000483 for more detail.

Page 1-18

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

SECTION 2

CONTROLS AND INDICATORS

2.0 CONTROLS AND INDICATORS

2.1 HUB ENCLOSURE CONFIGURATIONS

2.1.1 Front and Rear Panels

The front and rear views of the Hub are shown below in Figure 2-1. A Single Hub

configuration only is shown. A dual Hub configuration is very similar. In a dual Hub

configuration an additional chassis would be installed with the exact compliment of CCAs

that are in the single Hub chassis. Table 2-1 lists all of the major assemblies of a Hub.

Page 2-1

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

Figure 2-1. Hub Subsystem (Single) Assembly Locations

Page 2-2

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

TransCell 1900TM Operation and Maintenance Manual 1000497A

Table 2-1. Hub Subsystem Assemblies

Item Controls/Indicators Purpose

Hub Transceiver

Module(HTM)

Data Link Module

(DLM)

Signal Processing

Module (SPM)

Low Voltage Power

Supply

Hub Interface Tray See section 2.1.7. Contains high power duplexers that interface to a

See section 2.1.3 Converts PCS frequencies from BTS to IF in the

forward path and IF to PCS frequencies to the BTS in

the reverse path.

See Section 2.1.4. Provides the conversion to/from digital baseband

to/from 5.8 GHz data

See Section 2.1.5. Provides system control, fault monitoring and data

conversion from/to IF to/from baseband

See section 2.1.6. Generates +12 Vdc, and +8 Vdc for the Hub Modules

duplexed BTS. Not required for Non-Duplexed

Basestations

Page 2-3

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE

Loading...

Loading...