OpenCell 0012TC19001 Users Manual

TRANSCEPT PROPRIETARY

TransCell 1900CB System

Installation Manual for Use with

Fiber and Coaxial Cable Networks

Document No. 1000070

Revision A

November 14, 2000

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF TRANSCEPT, INC, AND IS NOT TO BE

USED FOR ANY PURPOSE, EXCEPT IN ACCORDANCE WITH CONTRACTUAL NONDISCLOSURE

TERMS. THIS DOCUMENT IS NOT TO BE DUPLICATED IN WHOLE OR IN PART WITHOUT PRIOR

WRITTEN PERMISSION FROM A DULY AUTHORIZED REPRESENTATIVE OF TRANSCEPT, INC.

THE REVISION STATUS OF ALL PAGES IN THIS DOCUMENT IS THE SAME AS THAT STATED ON THIS

COVER.

Copyright 1999, 2000 Transcept, Inc

All rights reserved.

TRANSCEPT PROPRIETARY

TRANSCEPT PROPRIETARY

TransCell 1900CB System

Installation Manual for Use with

Fiber and Coaxial Cable Networks

REVIEW AND CONCURRENCE

STEVE DALE, APPLICATION ENGINEERING DATE

MATTHEW HUBBARD, APPLICATION ENGINEERING

CHRISTOPHER COLE, DIRECTOR, PRODUCT

MANAGEMENT

ERIK DEVINNEY, CONTINUATION ENGINEERING

MANAGER

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF TRANSCEPT, INC, AND IS NOT TO BE

USED FOR ANY PURPOSE, EXCEPT IN ACCORDANCE WITH CONTRACTUAL NONDISCLOSURE

TERMS. THIS DOCUMENT IS NOT TO BE DUPLICATED IN WHOLE OR IN PART WITHOUT PRIOR

WRITTEN PERMISSION FROM A DULY AUTHORIZED REPRESENTATIVE OF TRANSCEPT, INC.

DATE

DATE

Document No. 1000070

Revision A:

TRANSCEPT PROPRIETARY

TRANSCEPT PROPRIETARY

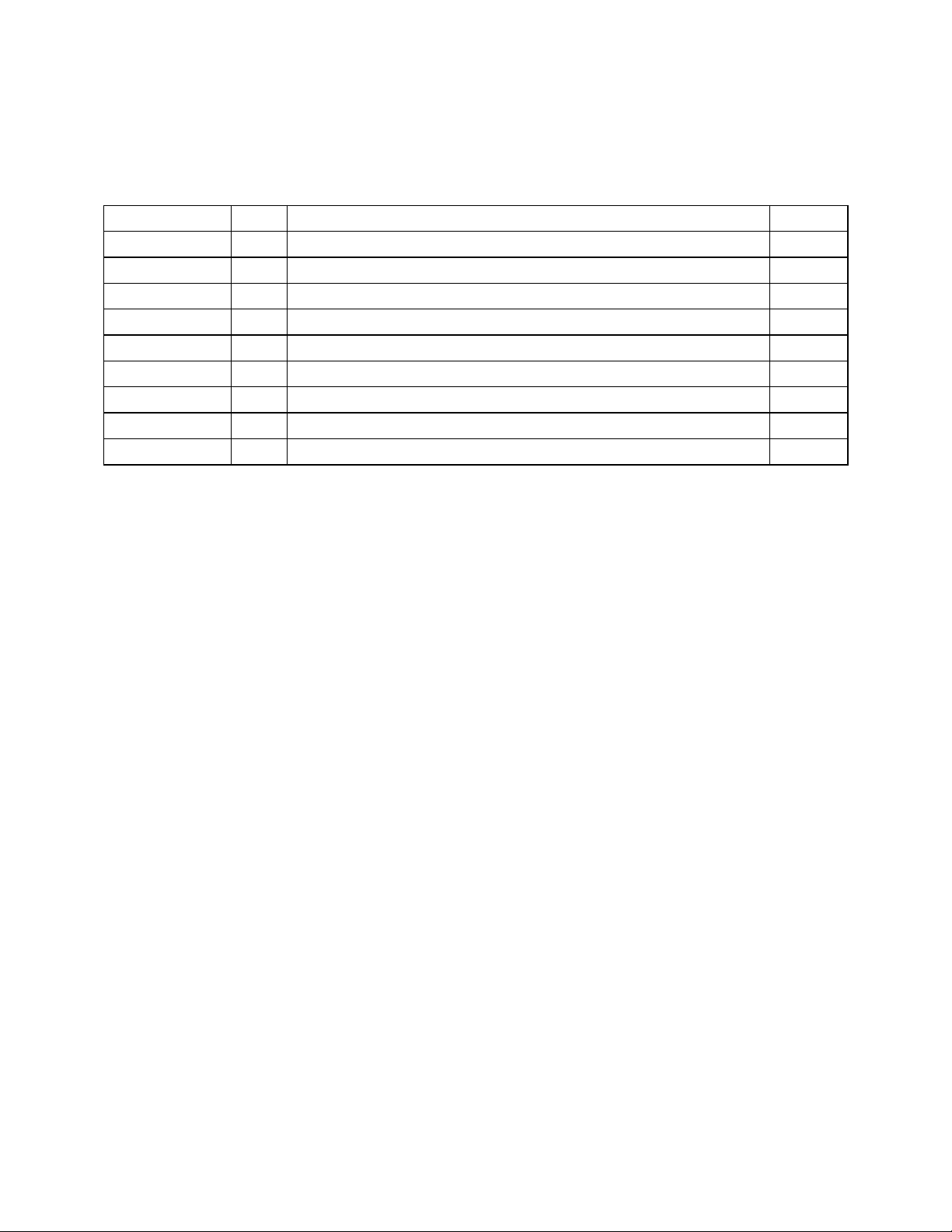

DRAWING NO. 1000070

DOCUMENT CHANGE HISTORY

DATE REV DESCRIPTION APPD

11/14/00 A Released to ECO control per RN001114 km/ED

TRANSCEPT PROPRIETARY

TransCell 1900CB Installation Manual Document No. 1000070A

TABLE OF CONTENTS

Paragraph Page

1 INTRODUCTION...............................................................................................................1-1

1.1 SCOPE...........................................................................................................................1-1

1.2 TERMINOLOGY, ACRONYMS, AND ABBREVIATIONS.............................................................1-2

1.2.1 TransCell 1900CB Terminology .............................................................................1-2

1.2.2 Acronyms and Abbreviations..................................................................................1-2

1.2.3 Notation Conventions in this Manual......................................................................1-3

1.3 REFERENCE DOCUMENTATION.........................................................................................1-3

1.4 SYSTEM OVERVIEW ........................................................................................................1-4

1.4.1 Hub Equipment (HE) Enclosure Configurations .....................................................1-5

1.4.1.1 Hub Control Unit (HCU) ..................................................................................1-5

1.4.1.2 RF Interface Assembly (RFIA)........................................................................1-6

1.4.1.3 Hub Interface Converter (HIC)........................................................................1-6

1.4.1.4 Hub Fiber Interface (HFI)................................................................................1-6

1.4.1.5 Cable Assemblies...........................................................................................1-6

1.4.1.6 Equipment enclosure......................................................................................1-7

1.4.1.7 +24 VDC Power Supply Assembly (Optional)..................................................1-7

1.4.2 Remote Fiber Interface (RFI) .................................................................................1-7

1.4.3 Cable Microcell Integrator (CMI) ............................................................................ 1-7

1.4.3.1 Power Extractor ..............................................................................................1-8

1.4.3.2 Internal Fiber Transceiver...............................................................................1-8

1.4.3.3 Transceiver.....................................................................................................1-9

1.4.3.4 Power Supply................................................................................................1-10

1.4.3.5 Power Amplifier.............................................................................................1-10

1.4.4 CMI Antennas ......................................................................................................1-10

1.4.5 Outdoor Enclosure Unit).......................................................................................1-10

2 HUB PRIMARY/EXPANSION RACK INSTALLATION......................................................2-1

2.1 INSTALLATION TASKS ......................................................................................................2-1

2.2 TOOLS, TEST EQUIPMENT, AND SUPPLIES........................................................................2-1

2.3 INSTALLATION PARTS LIST...............................................................................................2-2

2.4 POWER REQUIREMENTS..................................................................................................2-3

2.4.1 Typical Prime Power Requirements .......................................................................2-3

2.4.2 Protective Earth Grounding....................................................................................2-3

2.5 HUB EQUIPMENT CONFIGURATION AND SPACE REQUIREMENTS..........................................2-3

2.5.1 Suggested Floor Space Requirements...................................................................2-3

2.5.2 Floor Loading Requirements..................................................................................2-3

2.5.3 Typical Enclosure Configuration.............................................................................2-3

2.6 INSTALLATION OF ASSEMBLIES IN EQUIPMENT ENCLOSURE............................................2-5

2.6.1 Hub Enclosure Installation......................................................................................2-5

2.6.1.1 Hub +24 VDC Power Supply Installation.........................................................2-5

2.6.1.2 Hub Control Unit (HCU) Installation ................................................................2-6

2.6.1.3 +24 VDC Prime Power Installation..................................................................2-8

2.6.1.4 Initial Prime Power Test..................................................................................2-8

2.6.1.5 Initial HCU Test...............................................................................................2-8

2.6.1.6 RF Interface Assembly (RFIA) Installation ......................................................2-9

2.6.1.7 Hub Fiber Interface (HFI) (Option)..................................................................2-9

2.6.1.8 Hub Interface Converter (HIC) Installation....................................................2-10

2.6.1.9 Digital Communications Wiring Installation...................................................2-11

i

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

2.7 HUB EQUIPMENT CABLE INSTALLATION...........................................................................2-11

2.7.1 10/15 MHz Reference cable Installation between RFIA and HIC..........................2-12

2.7.2 Remote User Interface.........................................................................................2-13

2.7.3 HCU Modem ........................................................................................................2-13

2.8 INSTALLATION CHECKOUT - INITIAL TURN-ON..................................................................2-14

2.8.1 Reverse Link Input from Network Infrastructure...................................................2-14

2.8.2 HIC Initial Turn-on and Communication Test........................................................2-15

2.8.3 HCU Setup for HIC Checkout...............................................................................2-15

2.8.4 HIC Activation ......................................................................................................2-17

2.8.5 HIC Reference and Control Tone Output .............................................................2-19

3 CMI INSTALLATION.........................................................................................................3-1

3.1 CMI INSTALLATION REQUIREMENTS .................................................................................3-1

3.1.1 Tools, Test Equipment and Supplies......................................................................3-1

3.1.2 CMI Configurations ................................................................................................3-2

3.1.3 Transcept-Furnished Items for CMI Installation......................................................3-2

3.1.4 Customer-Furnished Items for CMI Installation ......................................................3-2

3.1.5 CMI External Connector Identification....................................................................3-4

3.2 SITE PREPARATION.........................................................................................................3-5

3.3 CMI HARDWARE INSTALLATION GUIDE.............................................................................3-6

3.3.1 CMI Access............................................................................................................3-6

3.3.1.1 Opening the Assembly....................................................................................3-6

3.3.1.2 Closing the Assembly......................................................................................3-6

3.3.2 CMI Port and Power Extractor Configuration Options ............................................3-7

3.3.2.1 CMI CATV Port Configurations.......................................................................3-7

3.3.2.2 Power Extractor Options.................................................................................3-9

3.3.3 Coaxial or Fiber Network Interface to the CMI .....................................................3-11

3.3.4 Power Extractor Reverse Link/Forward Link RF Attenuation (Coaxial Installation)3-11

3.3.5 Installing the CMI .................................................................................................3-11

3.3.5.1 Attaching CMI to Messenger Strand .............................................................3-11

3.3.5.2 Attaching Antennas to Messenger Strand.....................................................3-13

3.3.5.3 Installing and Routing Cables .......................................................................3-14

3.3.5.4 Protective Earth Grounding...........................................................................3-14

3.3.5.5 Antenna Cables ............................................................................................3-15

3.3.6 Power and CDMA SIGNAL Cables ...................................................................... 3-16

3.3.7 CMI Power Check................................................................................................3-16

3.4 MEASUREMENT TEST POINTS ........................................................................................3-16

3.5 FORWARD LINK CMI INSTALLATION MEASUREMENTS AND ADJUSTMENTS .............................3-17

3.5.1 CMI Forward Link Reference and Control Tone Input Level Check......................3-18

3.6 REVERSE LINK CMI INSTALLATION MEASUREMENTS AND ADJUSTMENTS..........................3-19

3.6.1 Activate CMI.........................................................................................................3-19

3.6.2 Reverse Link Gain Adjustment.............................................................................3-22

3.6.2.1 Setting CMI Reverse Link Signal Level Setpoint at HIC................................3-22

3.6.2.2 Measure CMI Reverse Link Control Tone at HIC..........................................3-23

3.6.3 Adjusting Reverse Gain at the HIC ......................................................................3-24

4 BTS INTERFACE AND NETWORK OPTIMIZATION........................................................4-1

4.1 INTRODUCTION ...............................................................................................................4-1

4.2 MEASUREMENT/CALCULATION OF CMI DELAYS ................................................................4-1

4.2.1 Sector Dedicated to TransCell 1900CB - Timing Equal..........................................4-1

4.2.1.1 Description......................................................................................................4-1

ii

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

4.2.1.2 Basic BTS Settings for Dedicated Sector with Equal Timing...........................4-2

4.2.2 Sector Dedicated to TransCell 1900CB - Timing Unequal......................................4-4

4.2.2.1 Description......................................................................................................4-4

4.2.2.2 Basic BTS Settings for Dedicated Sector with Unequal Timing.......................4-5

4.2.3 Simulcasting with a Tower - Timing Equal Within TransCell 1900CB.....................4-6

4.2.3.1 Description......................................................................................................4-6

4.2.3.2 Basic BTS Settings for Shared Sector with Equal Timing ...............................4-6

4.2.4 Split Sector - Timing Unequal Within TransCell 1900CB........................................4-7

4.2.4.1 Description......................................................................................................4-7

4.2.4.2 Basic BTS Settings for Shared Sector with Unequal Timing ...........................4-8

4.3 ASSESSMENT OF BTS SECTORS......................................................................................4-9

4.4 PHYSICAL INTERFACES WITH BTS...................................................................................4-9

4.4.1 Measurement of HIC Reverse Link Output...........................................................4-12

4.4.1.1 HIC CDMA Reverse Link Output to BTS.......................................................4-13

4.4.2 CDMA Forward Link Input from BTS....................................................................4-14

4.4.3 CDMA Forward Link Output to Coaxial Network ..................................................4-15

4.4.3.1 HIC Forward Link CDMA Pilot Level .............................................................4-16

4.5 INITIAL SETTING OF BTS PARAMETERS ..........................................................................4-19

4.5.1 Initial Conditions...................................................................................................4-19

4.5.2 Guidelines for Initial Setting of Parameters ..........................................................4-19

4.6 OPTIMIZING BTS PARAMETER SETTINGS .........................................................................4-20

APPENDIX A RADIO FREQUENCY INTERFACE ASSEMBLY (RFIA) CONFIGURATION

PROCEDURE......................................................................................................................... A-1

RADIO FREQUENCY INTERFACE ASSEMBLY (RFIA) CONFIGURATION PROCEDURE.. A-2

APPENDIX B PCS CHANNEL NUMBER-TO-FREQUENCY CROSS-REFERENCE...........B-1

APPENDIX C HIC CHANNEL NUMBER-TO-FREQUENCY CROSS-REFERENCE ............ C-1

ENCLOSURE/HIC DATA SHEET...........................................................................................C-1

CMI DATA SHEET ..................................................................................................................4-1

iii

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

LIST OF ILLUSTRATIONS

Figure Page

FIGURE 1-1. TRANSCELL 1900CB SYSTEM FUNCTIONAL BLOCK DIAGRAM ...................................1-4

FIGURE 2-1. RECOMMENDED HUB EQUIPMENT FLOOR SPACE......................................................2-4

FIGURE 2-2. TYPICAL ENCLOSURE CONFIGURATION....................................................................2-4

FIGURE 2-3. +24 VDC POWER SUPPLY REAR PANEL..................................................................2-5

FIGURE 2-4. TYPICAL INDOOR ENCLOSURE CONFIGURATION........................................................2-7

FIGURE 2-5. HCU COMPUTER REAR VIEW .................................................................................2-7

FIGURE 2-6. HIC REAR PANEL.................................................................................................2-10

FIGURE 2-7. HIC POWER WIRING HARNESS 1000062G1..........................................................2-10

FIGURE 2-8. THREE HIC CONTROL INTERCONNECT DIAGRAM (NOT TO SCALE)............................2-11

FIGURE 2-9. HIC COMMUNICATION WIRING HARNESS P/N 8339969G1.....................................2-11

FIGURE 2-10. BTS/HIC/COAXIAL NETWORK RF CABLING DIAGRAM (15MHZ FROM RFIA SHOWN)2-12

FIGURE 2-11. CONFIGURATION OPTIONS DIALOG..............................................................2-16

FIGURE 2-12. HUB CONTROL PANEL: USER DIALOG...........................................................2-16

FIGURE 2-13. TYPICAL ADD HIC DIALOG.................................................................................2-18

FIGURE 2-14. REFERENCE AND CONTROL TONES DIALOG...............................................2-20

FIGURE 3-1. CMI CHASSIS RIGHT END VIEW ..............................................................................3-4

FIGURE 3-2. CMI CHASSIS LEFT END VIEW ................................................................................3-4

FIGURE 3-3. CMI BOLT TIGHTENING SEQUENCE .........................................................................3-6

FIGURE 3-4. TYPICAL HOUSING-TO-HARDLINE CONNECTOR INTERFACE .......................................3-7

FIGURE 3-5. PROCEDURE FOR CUTTING CATV PORT CENTER CONDUCTOR TO LENGTH...............3-7

FIGURE 3-6. ASSEMBLY OF TYPICAL HOUSING TO HARD-LINE/POWER CONNECTORS ....................3-8

FIGURE 3-7. POWER EXTRACTOR.............................................................................................3-10

FIGURE 3-8. POWER SUPPLY INPUT CONNECTOR......................................................................3-10

FIGURE 3-9. CMI BRACKET INSTALLATION................................................................................3-12

FIGURE 3-10. ANTENNA INSTALLATION (OPTION 1)....................................................................3-13

FIGURE 3-11. ANTENNA INSTALLATION (OPTION 2)....................................................................3-14

FIGURE 3-12. CMI ASSEMBLY REAR VIEW................................................................................3-15

FIGURE 3-13. CMI TEST POINT ACCESS AND SUBASSEMBLY LAYOUT.........................................3-17

FIGURE 3-14. TYPICAL HUB CONTROL PANEL DIALOG .........................................................3-19

FIGURE 3-15. TYPICAL HIC CONTROL PANEL DIALOG...........................................................3-21

FIGURE 3-16. TYPICAL ADD CMI DIALOG.................................................................................3-22

FIGURE 3-17. TYPICAL CMI CONTROL PANEL DIALOG ..........................................................3-25

FIGURE 4-1. SECTOR DEDICATED TO TRANSCELL 1900CB WITH EQUAL TIMING LINKS .................4-2

FIGURE 4-2. SECTOR DEDICATED TO TRANSCELL 1900CB WITH UNEQUAL TIMING LINKS .............4-5

FIGURE 4-3. TOWER SECTOR SPLIT WITH TRANSCELL 1900CB - TIMING EQUAL..........................4-6

FIGURE 4-4. TOWER SECTOR SPLIT WITH TRANSCELL 1900CB - TIMING UNEQUAL.....................4-8

FIGURE 4-5. TYPICAL FORWARD LINK LEVELS; SINGLE CARRIER ...............................................4-10

FIGURE 4-6. TYPICAL FORWARD LINK LEVELS; THREE CARRIER ................................................4-10

FIGURE 4-7. TYPICAL REVERSE LINK LEVELS; SINGLE CARRIER.................................................4-11

FIGURE 4-8. TYPICAL REVERSE LINK LEVELS; THREE CARRIER .................................................4-11

FIGURE 4-9. HIC CONTROL PANEL: DIALOG.........................................................................4-12

FIGURE 4-10. HIC REAR PANEL...............................................................................................4-13

FIGURE 4-11. RFIA REAR PANEL.............................................................................................4-14

FIGURE 4-12. HIC FORWARD POWER DIALOG.....................................................................4-17

FIGURE C-1. RF INTERFACE PLATE ASSEMBLY .......................................................................... C-3

LIST OF TABLES

iv

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

Table Page

TABLE 2-1. ENCLOSURE INSTALLATION TOOLS AND TEST EQUIPMENT ..........................................2-1

TABLE 2-2. HUB EQUIPMENT ENCLOSURE ASSEMBLY INSTALLATION KIT.......................................2-2

TABLE 3-1. CMI INSTALLATION SUPPORT NEEDS ........................................................................3-1

TABLE 3-2. CMI CONFIGURATIONS.............................................................................................3-2

TABLE 3-3. OPTIONAL TRANSCEPT-FURNISHED ITEMS FOR CMI INSTALLATION.............................3-2

TABLE 3-4. CUSTOMER-FURNISHED ITEMS FOR CMI INSTALLATION..............................................3-3

TABLE 3-5. CMI EXTERNAL CONNECTIONS .................................................................................3-5

TABLE 4-1. SEARCH WINDOW SIZES ..........................................................................................4-4

TABLE 4-2. RECOGNIZED ALARM LIST.......................................................................................4-18

v

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

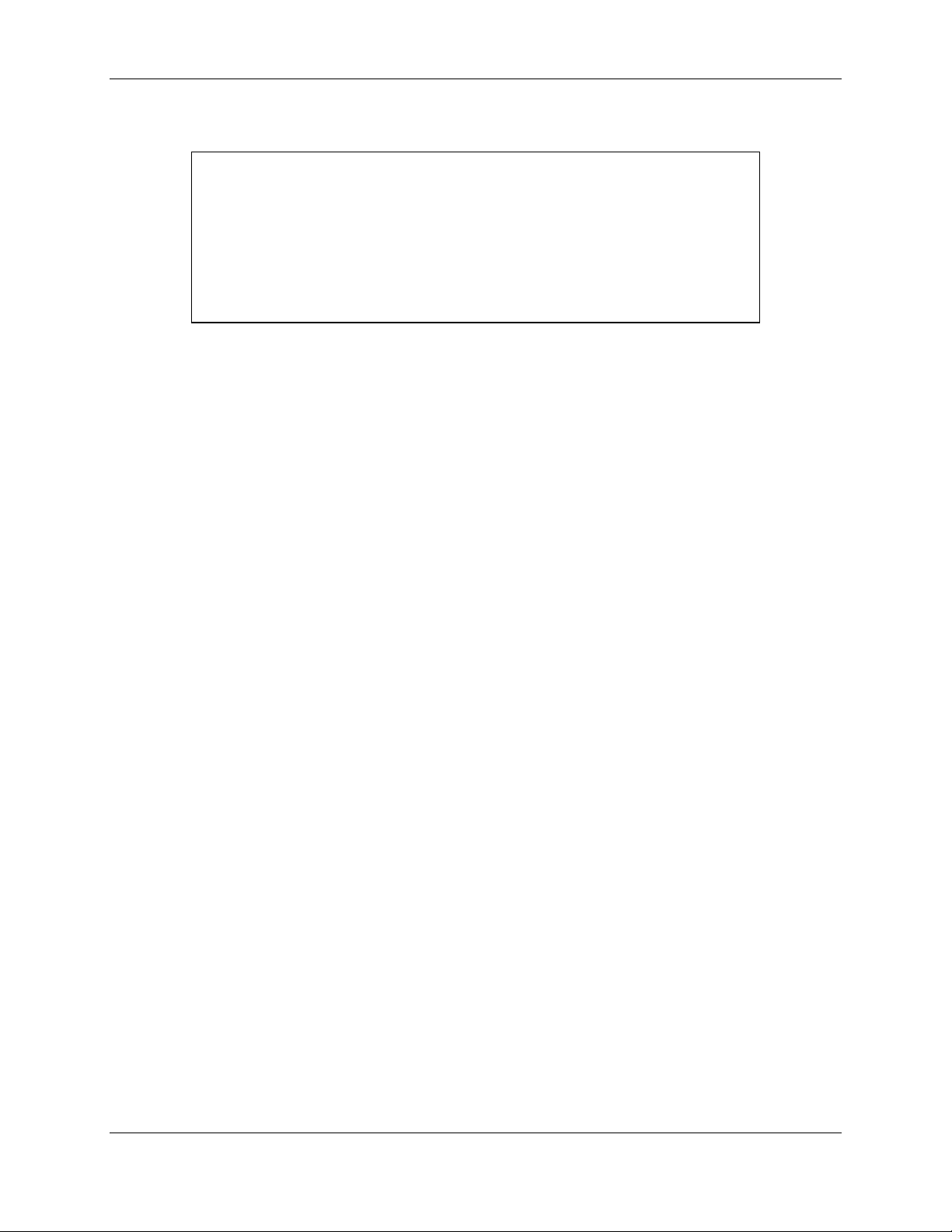

♦ High leakage current: The Hub rack, internal or external (environmental) enclosure

must be connected to Protective Earth ground before any connection is made to +24

VDC prime power.

♦ High Voltages (110/220 VAC and 24 VDC) are present within the Hub rack or

environmental enclosure. Use extreme caution when working inside the

rack/enclosure.

♦ High voltages may exist close to the CMI location; use standard electrical industry

safety practices when working on an installed CMI.

♦ High voltages (110/220 VAC RMS) exist on the AC power input to the CMI. Use

extreme caution when removing the AC power cable to avoid coming in contact with

the center conductor.

♦ Laboratory tests conducted in accordance with ANSI/IEEE C95.1-1992 show that a

transmitting CMI poses no radiation hazard to persons in close proximity to the

transmitting antenna. However, for added safety when working near a CMI,

maintain a minimum distance of 12 inches from the transmitting antenna.

ESD CAUTION

The CMI contains circuit card assemblies that are sensitive to

Electrostatic Discharge (ESD) damage. Whenever handling the CMI, use

ESD precautionary procedures to minimize the risk of permanent ESD

damage to circuit card components. Low relative humidity level increases

the potential for damage to ESD-sensitive devices.

FCC License Data

The CMI is licensed by the Federal Communications Commission for operation in the

frequency band as noted on the product label affixed to the CMI Chassis.

National Recognized Test Laboratories (NRTL) Data

Cable Microcell Integrator (CMI), Models 1000000G1-33, 1000501G1-6, 1000601G1-33, and

1000701G1-6: Listed as Communications Service Equipment NRTL 1950

Hub Equipment Racks (Models 1000023P1 and 1000025P1) with the Hub Interface

Converters (Models 1000604G1-3 and 8334760G1-3) and Hub Control Unit Model

(1000015P1): Basic Listing as Information Technology Equipment, Complementary

Listing as Professional Video Equipment

vi

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

SECTION 1

INTRODUCTION

1 INTRODUCTION

1.1 SCOPE

This manual contains installation and checkout instructions for the components of the

TransCell 1900CB system. The TransCell 1900CB system provides the means to distribute

wireless Personal Communications Services (PCS) telephony signals encoded with the

Code Division Multiple Access (CDMA) protocol over fiber or coaxial cable infrastructures.

This manual addresses the TransCell 1900CB installation for both fiber and coaxial

networks, and for both indoor and outdoor Hub equipment, distinguishing the unique

requirements for each case as needed. The manual is organized as follows:

♦ Section 1, Introduction - terminology definitions, brief descriptions of the TransCell

1900CB system and its major components

♦ Section 2, Hub Indoor/ Outdoor Rack Installation - installation and checkout of the

Hub Equipment (HE) rack configurations; installation of the Hub Control Unit

(HCU), and the Hub Interface Converter (HIC)

♦ Section 3, CMI Installation - Cable Microcell Integrator (CMI) installation and

checkout of the outside cable network at selected remote locations in the service

area

♦ Section 4, BTS Interface and Network Optimization - measurement and adjustment

procedures for optimal integration of the TransCell 1900CB system with the Base

Transceiver Stations (BTS), with variations according to BTS manufacturer

♦ Appendix A, Radio Frequency Interface Unit (RFIA) Installation - installation of the

RFIA, to provide a cable transition at the HIC, provide a stable 10 or 15 MHz

reference signal for the HICs in the primary or expansion racks and the duplexing

of signals between the HICs and the BTS

♦ Appendix B, PCS channel-number-to-frequency cross-reference table

♦ Appendix C, HIC Channel Number-to-frequency cross-reference table

1-1

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

1.2 TERMINOLOGY, ACRONYMS, AND ABBREVIATIONS

1.2.1 TransCell 1900CB Terminology

The following words and phrases are used throughout this manual when referring to signal

flow over the fiber/cable network, between the subscriber’s PCS handset and the wireless

telephony network’s BTS:

♦ Forward Link – direction of the fiber/cable network from the HIC to the CMI,

supporting communications from the BTS to subscriber units.

♦ Forward Path - the physical/electrical path for forward link signals

♦ Reverse Link – direction of the fiber/cable network from the CMI to the HIC,

supporting communications from subscriber units to the BTS.

♦ Reverse Path - the physical/electrical path for reverse link signals

1.2.2 Acronyms and Abbreviations

AWG American Wire Gage NOCC Network Operation Control Center

BTS Base Transceiver Station NRTL National Recognized Test Lab

CDMA Code Division Multiple Access OA&M Operation, Administration, and

Maintenance

CMI Cable Microcell Integrator PCS Personal Communications Services

CRT Cathode Ray Tube PEGND Protective Earth Ground

Ctl Control PN Pseudo Noise

EIA Electronic Industries Association POTS Plain Old Telephone Service

ESD Electrostatic Discharge RBW Resolution Bandwidth

FCC Federal Communications Commission RCV Receive

FWD Forward (BTS to Subscriber) Ref Reference

HCU Hub Control Unit REV Reverse (Subscriber to BTS)

HE Hub Equipment RFIA Radio Frequency Interface Assembly

HFC Hybrid Fiber Coax Infrastructure RTN Return

HIC Hub Interface Converter Rx Receive

IF Intermediate Frequency SMIU Sector Management Interface Unit

kbps Kilobits Per Second Tx Transmit

LED Light Emitting Diode UL Underwriters Laboratories

MHz Megahertz XMIT Transmit

1-2

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

1.2.3 Notation Conventions in this Manual

This manual assumes that the user has a basic knowledge of the Windows NToperating

system. Several typographic conventions and standard Windows NT terms are used in

this manual when discussing the TransCell Network Manager software. They are as

follows:

Mouse Commands - The TransCell Network Manager software uses only the left mouse

button:

♦ “click” - press and release the left mouse button

♦ “double-click” - press and release left mouse button twice in quick succession

Menu Commands - Menu commands are bolded with each command level separated from

the previous one by a slash (/) mark, e.g., “Select Privileges/Modify Privileges.”

Button Names – Command button names in dialogs are underlined, e.g., “To confirm

selection, click OK.”

Key Names - Key names are spelled out and appear in small, bold capital letters, e.g.

ENTER, ESCAPE, AND CONTROL.

Dialogs and Messages - Dialog and message titles appear in all upper case (capital) letters,

and generally the name is referenced exactly as shown on the title bar, e.g., the PCS

FREQUENCY dialog. However, in cases where the dialog title varies according to privilege

level, enclosure, or sector, the title is shortened to exclude this variable information unless

the variable is important. If a dialog title is referenced that includes a specific HIC or CMI

number, the number is represented by the bracketed letter n: e.g., CMI CONTROL

PANEL: ALPHA SECTOR, CMI [n].

Dialog Options - Dialog options (text boxes and radio buttons) are shown in italics, e.g.,

“Type in the desired PCS Frequency.” All instructions to “select” or “choose” an option

imply clicking on that option, although options can be selected via the keyboard as well.

Keyboard Input - Instructions for keyboard entries start with “Type in...”, and anything

that should be typed in verbatim is shown in a contrasting font. For example, “Type in

config01.dtb in the File Name box.”

Displayed Text - Text displayed in a dialog box is shown in another contrasting font, e.g.,

“The CONFIGURATION OPTIONS dialog displays the query “Do you Want To Restore

a Pre-existing Configuration?”.

1.3 REFERENCE DOCUMENTATION

♦ Hub Control Unit (HCU)-associated vendor hardware/software documentation

(Computer, Monitor, Watchdog Timer, etc.) Transcept Document No. 1000015P1

♦ TransCell 1900CB System Acceptance Test Procedure Requirements, Transcept

Document No. 1000095

♦ Mobile Station-Base Station Compatibility Std for Wideband Spread Spectrum

Cellular Systems, TIA/EIA-95-B

1-3

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

• Fiber/

Coaxial Infrastructure

MOBILE

MOBILE

• Fiber/

Coaxial

infrastcr.

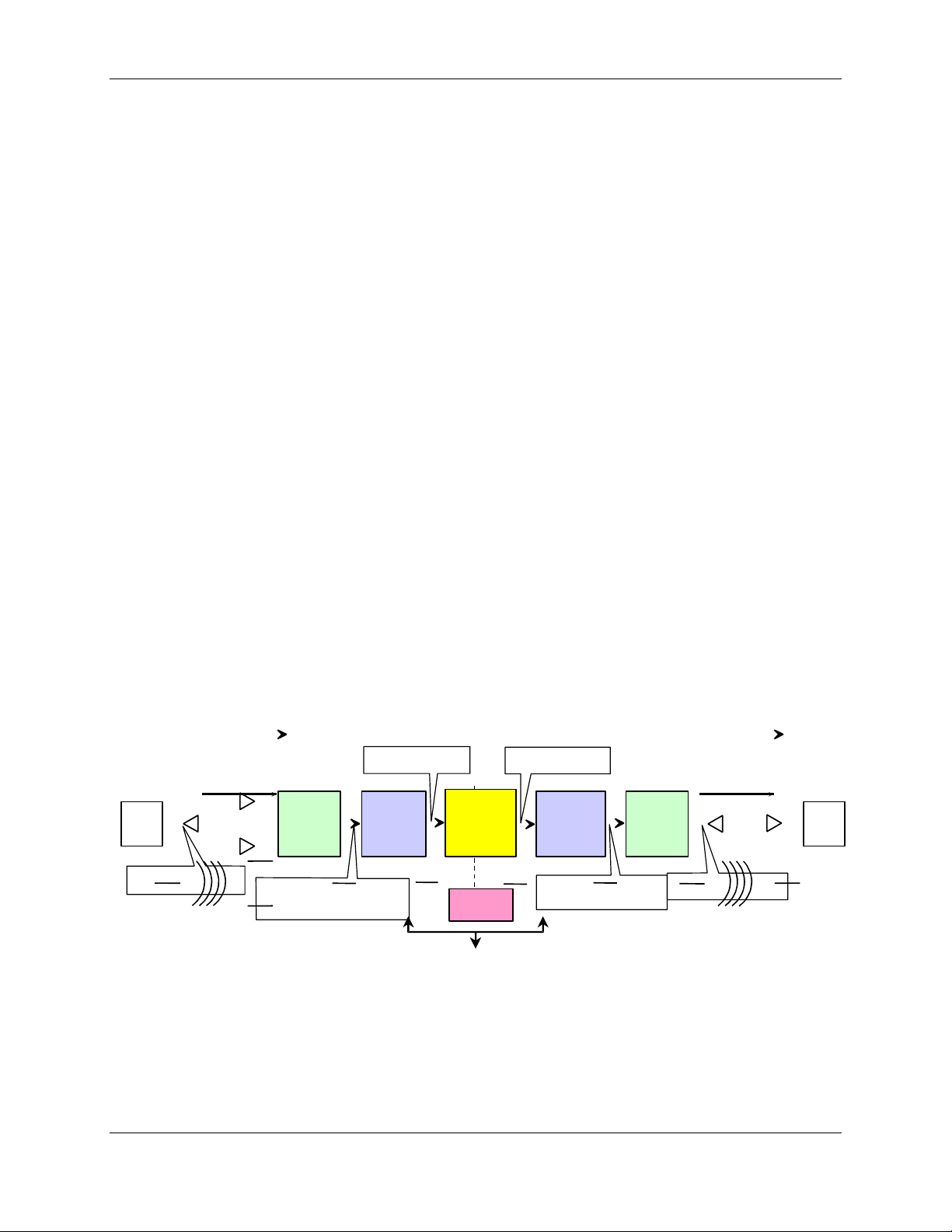

1.4 SYSTEM OVERVIEW

The TransCell 1900CB system permits the transport of CDMA PCS signals between a Base

Transceiver Station (BTS) and mobile users over fiber/coaxial cable infrastructures. The

cable network (fiber, coax, or hybrid) is used to distribute the PCS signals between the

cable Hub or hub facility and attached remote locations throughout the service area.

The TransCell 1900CB system has four primary components: Cable Microcell Integrator

(CMI), Hub Interface Converter (HIC), RF Interface Assembly (RFIA), and Hub Control

Unit (HCU) and two fiber optic peripherals: Hub Fiber Interface (HFI) and Remote Fiber

Interface (RFI). The HICs and CMIs provide the carrier frequency translation and signal

conditioning needed for the CDMA signal (single carrier or three-carrier) interfaces

between mobile user, BTS, and fiber/coaxial network. The HCU provides the operation,

administration, and maintenance (OA&M) functions for the system. The RFI and HFI

provide the conversion between light and RF energy.

As shown in Figure 1-1, in the reverse path a CMI at a remote location receives a CDMA

signal from a mobile PCS unit via the receive antennas, converts its PCS carrier frequency

to an IF frequency and sends the signal to the associated HIC at the Hub. The HIC

converts the signal carrier back to the PCS frequency and routes the signal to the BTS. The

BTS then switches the signal into the telephone network.

In the forward path, the process is inverted. The HIC receives the CDMA signal from the

BTS, translates the carrier frequency to an IF frequency and sends the signal to the CMI.

The CMI translates the signal carrier back to the PCS frequency, amplifies the signal, and

radiates it via the transmit antenna for capture by the mobile PCS unit. One HIC provides

the BTS interface for up to three CDMA sectors and may control as many as 30 CMIs.

The HICs and CMIs normally handle the transport of PCS traffic over the fiber/coaxial

network without assistance from the HCU. The HCU is used to set up frequency,

attenuation, and fault reporting parameters and to change those parameters as needed. In

normal operation, the HCU allows operators to monitor system operational status and

alarms.

CONNECTION

TO

TELEPHONE

REVERSE FORWARD

• 1850 to 1910 MHz

• CDMA

HIC

REVERSE

LINK

PCS

UNIT

• 1850 to 1910 MHz

• Band Specific Filters

CMI

PCS

RECEIVE

FUNCTION

• Basic - 5 to 52 MHz

NETWORK

BASE

TRANSCEIVER

STATION

(BTS)

HCU

• 1930 to 1990 MHz

• CDMA

HIC

FORWARD

LINK

• 450 to 750 MHz

CMI

PCS

TRANSMIT

FUNCTION

• 1930 to 1990 MHz

• Band Specific Filters

PCS

UNIT

Figure 1-1. TransCell 1900CB System Functional Block Diagram

1-4

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

For installations with existing environmentally controlled indoor Hub or hub facilities, the

typical TransCell 1900CB configuration consists of up to three Hub Equipment (HE)

enclosures stacked, containing a HCU, three Hub Fiber Interface Units (HFIs), three RF

Interface Assemblies (RFIAs), and three HICs. Additional enclosures may be purchased

when more than three HICs are required at a given site. Each HIC is connected to several

CMIs which are installed on the outside fiber/coaxial network.

For ruggedized outdoor installations, the HCU and HICs are housed in an outdoor

environmental controlled enclosure.

Either the indoor or outdoor system installation may also include a network interface unit

to remote the HCU for centralized monitoring and control of PCS network operation.

1.4.1 Hub Equipment (HE) Enclosure Configurations

The HE enclosure contains these major components:

♦ Hub Control Unit (HCU)

♦ RF Interface Assembly (RFIA)

♦ Hub Interface Converters (HICs)

♦ Hub Fiber Interface Unit (HFI) (Optional)

♦ +24 VDC Power Supply (Optional)

There are three stackable enclosure configurations available. One enclosure houses the

HCU (PC, Monitor, and Keyboard). The second enclosure houses an RFIA, HIC, HFI

(optional), Power Supply (Optional), and a network interface box (remote configuration

only). The third enclosure houses two RFIAs, two HICs, and two HFIs (Optional). Section

2 of this manual contains a detailed assembly list for each enclosure configuration. The

following paragraphs describe the major assemblies that are normally installed in the

configurations along with some optional assemblies.

1.4.1.1 Hub Control Unit (HCU)

The HCU is installed in one Hub equipment enclosure. A single HCU supports up to 26

HICs. The HCU may also be installed in a central location (NOCC) and remoted to an

outside enclosure. This configuration is used for those installations in uncontrolled

environments. The major HCU hardware components are:

♦ Computer chassis

♦ Color CRT Monitor

♦ Keyboard/Touchpad/Mouse

The HCU is the monitoring and control device for the attached HIC units and their

assigned CMIs. It monitors various system parameters to verify that these units are

operational and that signal power is being maintained at the proper levels. The HCU

communicates with the HICs over an RS-485 interface via a LonWorks® card located in the

computer, and through the HICs it communicates with the CMIs. The HCU interprets all

faults reported by the HICs and CMIs into alarms, which are logged and displayed. The

computer also contains one or more modems for remote monitoring and control of the HCU

located at a central control point.

1-5

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

The major HCU software components are:

♦ Microsoft® Windows NT

♦ pcANYWHERE Version 8.0 or later (optional)

♦ TransCell Network Manager software

♦ Software drivers for custom HCU functions

1.4.1.2 RF Interface Assembly (RFIA)

The RFIA provides a transition from the larger and more rigid cables from the BTS and

cable plant to smaller and more flexible cables for connecting the HICs. It also provides a

stable 10 or 15-MHz reference signal for the HICs.

Depending on the site requirements these RFIA configurations provide duplexing of the RF

signals between the HIC and the BTS and the cabling between the HIC and HFI or

Fiber/Coaxial Network. One RFIA is required for each HIC installed in the enclosure(s).

Each RFIA requires +24 VDC for operation. For more detailed description and installation

instructions, see Appendix A.

1.4.1.3 Hub Interface Converter (HIC)

The HIC is the direct interface between the RFIA and Fiber/Coaxial network. It processes

up to three forward link sector of CDMA PCS signals (single carrier or three carriers) and

up to three pairs of diversity reverse link CDMA PCS signals (single carrier or three

carriers). The HIC converts the PCS frequencies from the BTS to an intermediate

frequency (IF) suitable for transmission over fiber/coaxial cable to its associated CMIs, and

it converts the IF signals from the CMIs to PCS frequencies for the BTS. The HIC uses

rear panel connectors to interface with the RFIA and HFI or coaxial cable network. Each

HIC supports up to 10 CMIs on each of three CDMA sectors (up to 30 CMIs total per HIC).

The HIC assigns each CMI its frequency and gain levels.

Each HIC consists of two-circuit card assemblies that contains the components for the

three sector interfaces and the digital circuitry. A DC-operated fan cools the HIC by pulling

air into the front and exhausting the air via the rear side panels.

1.4.1.4 Hub Fiber Interface (HFI)

The HFI is an interface unit that converts IF CDMA signals to/from light and interfaces

the HIC with the fiber network. The HFI contains three independent fiber optic

transceivers that may be configured to support multiple fiber optic networks. Typical

configurations are one HFI per HIC since one sector is typically designated to a

geographical area and each HIC supports three sectors. The HFI power source

requirements is +24VDC. Each fiber optic transceiver unit contains a separate laser on/off

lockable switch located on the front panel of the unit.

1.4.1.5 Cable Assemblies

Cable assemblies provided with each enclosure interconnect the installed assemblies

within the enclosure. Cable assemblies are not provided for external interconnection

between the enclosure and BTS or fiber/cable network. Refer to Section 2 for a list of cable

assemblies provided with each enclosure configuration.

1-6

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

1.4.1.6 Equipment enclosure

The indoor and outdoor equipment enclosure is a standard EIA design that holds and

secures standard 19-inch-wide enclosure-mounted assemblies. The equipment enclosure

dimensions are:

Indoor Enclosure Outdoor Enclosure

♦ Height 24 inches 39 inches (minus lift brackets)

♦ Depth 25 inches 26 inches

♦ Width 20 inches 24 inches

1.4.1.7 +24 VDC Power Supply Assembly (Optional)

For installation sites where an external +24 VDC prime power source is unavailable, an

optional +24 VDC Power Supply is available for enclosure installation. The +24 VDC Power

Supply operates on either 110 or 220 VAC. The +24 VDC Power Supply will be used to

power all three of the HICs installed in an enclosure.

1.4.2 Remote Fiber Interface (RFI)

The RFI is a fiber node. The unit contains a fiber optic transceiver and an AC

(110/220VAC) to DC power supply. The RFI resides at the demarcation point, between the

Hub HFI and a network of Coaxial CMIs, where the fiber no longer is available and coaxial

cable must be extended to the CMIs.

1.4.3 Cable Microcell Integrator (CMI)

The CMI is the communications link between the PCS handset and the fiber/cable network.

It processes a single forward link and single pair of diversity reverse link CDMA PCS

carriers (single carriers or three-carriers). Each CMI is controlled by its assigned HIC. The

CMI is comprised of the following major hardware assemblies:

♦ Power Extractor - routes the tapped coaxial IF CDMA signals to/from the RF

Transceiver in a coaxial CMI.

♦ Internal Fiber Interface – converts light to/from the IF frequencies to/from the RF

transceiver in a fiber CMI.

♦ Transceiver - responds to control messages from the assigned HIC and converts the

CDMA signals to the appropriate transmission frequencies.

♦ Power Amplifier - enabled/disabled by the assigned HIC; boosts the CDMA signal

sent to the PCS handset via an antenna.

♦ Power Supply - converts the 110/220VAC power to the DC voltages required by the

Transceiver, Internal Fiber Interface, and Power Amplifier.

♦ CMI Housing Assembly - environmentally sealed fireproof enclosure for all of the

four CMI assemblies.

♦ Antennas – one transmit and two receive, typically omnidirectional. Antennas are

optionally available from Transcept, depending on customer preference.

1-7

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

1.4.3.1 Power Extractor

The CMI Power Extractor is available in two configurations:

♦ Single (or Combined) Mode, Sub-Split: Basic frequency range - 5 to 42 MHz

♦ Single (or Combined) Mode, Mid-Split: Extended frequency range - 5 to 52 MHz

The Power Extractor routes the following signals:

♦ Reverse link signals from the Transceiver module, 5 to 42 MHz (basic) or 5 to 52

MHz (extended)

♦ Forward link signals to the Transceiver module, 450 to 750 MHz

NOTE

References to reverse link frequency range in this manual imply a range of 5

to 52 MHz. However, if a single mode sub-split (basic) Power Extractor

module is installed in a CMI, the range for that CMI will be 5 to 42 MHz.

The relationship between the Power Extractor configuration and the way in which the CMI

is electrically connected to the coaxial cable is as follows:

♦ The Single Mode is configured to operate with both the forward and reverse link

signals on a single interface port (FWD/REV). The CMI is configured in this mode

by installing the Single Mode, Sub-Split (basic frequency range) or the Single Mode,

Mid-Split (extended frequency range) Power Extractor module.

The Power Extractor accommodates field-replaceable, plug-in attenuator pads for both the

forward and reverse paths, and a field-replaceable, plug-in equalizer (should be zero for

typical installations) in the forward path. These component locations are accessible when

the CMI housing cover is open, without the need to remove the Power Extractor. The CMI

is shipped with no pads or equalizer installed. It will accept Scientific Atlanta model

numbers PP-0 to PP-10 attenuator pads, or equivalent, and Scientific Atlanta model

number EQ750 equalizers, or equivalent.

1.4.3.2 Internal Fiber Transceiver

The Internal Fiber Transceiver converts 1310nm-laser light to IF energy that feeds the RF

Transceiver in the forward direction. In the reverse direction, the unit converts IF energy

from the RF Transceiver to 1550nm light (2mW max). The power interface to the Internal

Fiber Interface is DC power coming from the power supply. The fiber optic cable is

connected to the fiber network via a coupler and passes through a housing interface and

connected directly to the Internal Fiber Transceiver.

1-8

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

1.4.3.3 Transceiver

The Transceiver contains a dual receiver and a transmitter, and incorporates both analog

and digital signal processing and control. Reverse link RF signals, originating in the PCS

wireless domain, are received by both the primary and diversity receivers, processed and

sent, via the coaxial/fiber network, to a Hub location. Forward link signals, originating at

the Hub, travel via the coaxial/fiber network to the CMI where they are processed by the

transmitter and sent to the Power Amplifier.

The Transceiver has four LED indicators on its outer surface, clearly visible when the CMI

cover is open. One LED is normally lit to indicate presence of +5 VDC power, while the

other three are normally unlit. These three LEDs light only to indicate particular

Transceiver fault conditions. The Transceiver is available in three different PCS frequency

band sets (A/D, B/E, C/F) (see Table 3-2); the desired band set is selected at the time of

order.

1-9

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

1.4.3.4 Power Supply

The Power Supply requires a 110/220VAC, 50/60-Hz voltage input. It produces four DC

voltages, +25V, +15V, +5V, and -15V, for use by the Transceiver and Power Amplifier. For

overcurrent protection, the Power Supply AC input is fused. The fuse is accessible with the

power supply cover removed.

1.4.3.5 Power Amplifier

The Power Amplifier operates in one of three 20-MHz pass bands corresponding to the

selected Transceiver frequency band for a single carrier CMI. For a multi-carrier (three)

unit, the power amplifier covers the entire 60MHz pass band. Power Amplifier parameters

include:

• Gain Approximately 60 dB

• Power Output +35.0 dBm/+39.0dBm max

• Power Output Dynamic Range 15 dB minimum

1.4.4 CMI Antennas

The CMI requires three antennas for operation: two receive and one transmit. For typical

aerial operation, 6-dBi gain antennas, approximately 8 inches in length, are used. The

receive antennas are installed on brackets and extend below a messenger strand. The

transmit antenna is installed on a bracket and extends above a messenger strand. A

separation of six feet between the diversity receive antennas is recommended to achieve

reasonable spatial diversity. The use of the 6-dBi gain antennas with a minimum transmitto-receive antenna distance of 36 inches will achieve the required transmit-to-receive

antenna isolation in excess of 40 dB. See the paragraph 3.3.5.2 for installation procedures.

1.4.5 Outdoor Enclosure Unit)

The outdoor enclosure configuration is a ruggedized equivalent of an indoor enclosure

without the HCU, used for installation in uncontrolled environments. The enclosure

accommodates a network interface unit, HIC, an RFIA (timing reference source), a

+24VDC power supply (optional), and a heating/cooling unit. All modules in the enclosure

are either rack mountable or mounted on 19-inch trays. The maximum footprint of the

pedestal is 24 x 26 inches. The maximum height of the cabinet is 45 inches (including lift

brackets). The enclosure conforms to NEMA 3R requirements.

1-10

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

SECTION 2

HUB ENCLOSURE INSTALLATION

2 HUB PRIMARY/EXPANSION RACK INSTALLATION

This section describes the installation of the Hub equipment and their constituent

components. Most of the component installation procedures are identical between the

indoor and outdoor configurations; differences are stated in the installation procedures.

2.1 INSTALLATION TASKS

Installing the Hub equipment involves the following major tasks:

♦ Preparing space for the individual enclosure

♦ Installing equipment in the enclosure

♦ Installing interconnecting cables in the rack

♦ Installing interconnecting cables between equipment and fiber/coaxial network

♦ Installing interconnecting cables between equipment and BTS

♦ Installing interconnecting cables between HIC and HFI

♦ Installation checkout

2.2 TOOLS, TEST EQUIPMENT, AND SUPPLIES

Table 2-1 lists the tools and test equipment needed (but not supplied) to support the

enclosure installation.

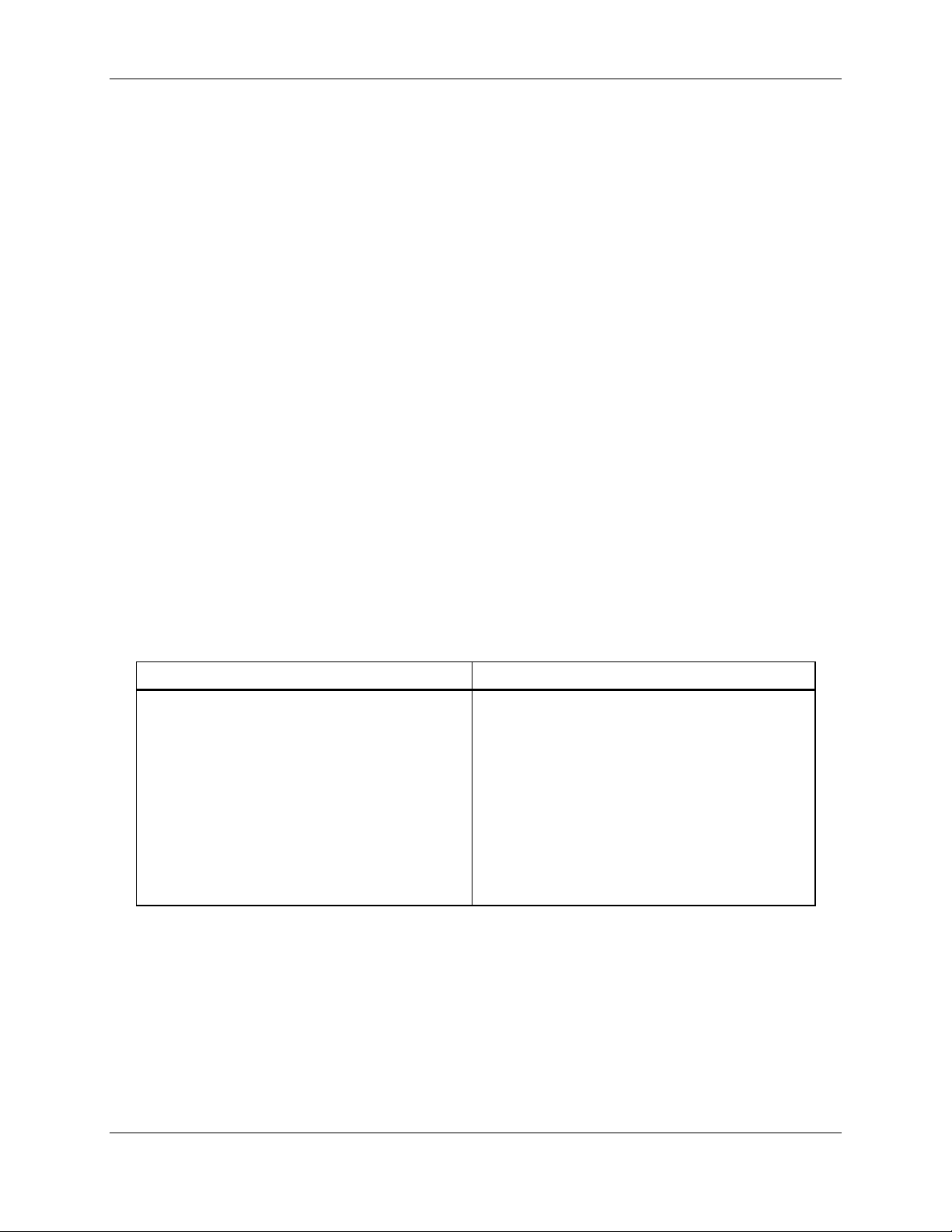

Table 2-1. Enclosure Installation Tools and Test Equipment

Hand Tools Test Equipment

• Philips Screwdriver # 2 head • Hand-held Digital Multimeter with test probes

• Flat Blade Screwdriver # 2 head • Spectrum Analyzer, HP 8593 or equivalent

• Wrench, 5/16 inch

• Wrench, 7/16 inch

• Wrench, 3/8 inch

• Nut Driver ¼ inch

• Tape Measure

• Torque Wrenches

• Cable Tie Installation Tool, Panduit GS2B,

or equivalent

2-1

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

2.3 INSTALLATION PARTS LIST

Table 2-2 lists the typical parts shipped for each Hub installation. Before proceeding with

the installation, inventory the kit contents to ensure all parts are present for the applicable

installation.

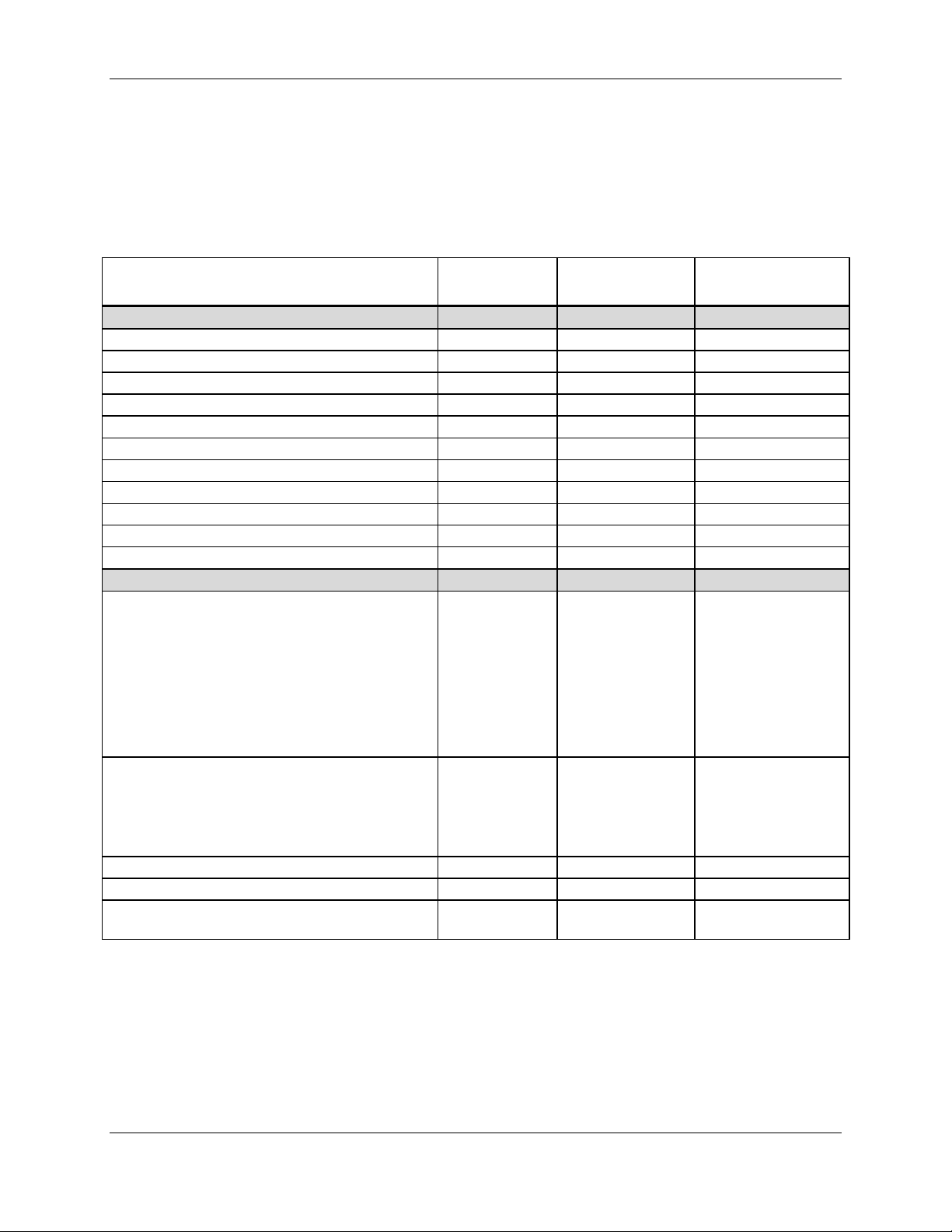

Table 2-2. Hub Equipment Enclosure Assembly Installation Kit

Indoor Enclosure

Assembly Item Part No.

Equipment enclosure

Indoor Hub Enclosure 1000023P1 Up to 3

Outdoor Hub Enclosure 1000025P1 1

Hub Enclosure Stacking Kit 1000059G1 Up to 2

Hub Enclosure Cable Kit 1000064G1 Up to 3 1

Hub Power Supply Assembly (Optional) 1000056G1 1 (Optional) 1 (Optional)

Communications Harness 1000063G1 1 1

Cable ties, 12 inches long PLT3S-C 12 12

Cable ties, 5.25 x 3.32 inches SST1.5I-C 10 2

Cable Tie Mount, Self Adhesive ABMM-AT-C 2 2

Cable Clamp, 3/8”, Nylon NAS1397P6N 5 2

Busbar Assembly P/O Enclosure Up to 3 1

Equipment

Hub Control Unit (HCU) Assembly

Computer, Pentium

Monitor, 14-inch color

PS/2 Keyboard with Touchpad,

Computer Power Cord

Monitor Power Cord

Rack Mounting Brackets

Windows NT, Version 4.0

PcANYWHERE, Version 8.0 (Optional)

Hub Interface Converter (HIC) 1000604G1,G2,

Hub Fiber Interface (HFI) (Optional) 1000014P2 Up to 3 (Optional) 1 (Optional)

Hub Power Supply Assembly (Optional) 1000056G1 1 (Optional) 1 (Optional)

RF Interface Assembly (RFIA) 1000035G1,G2,

1000022G1 1 N/A

or G3

OR

8334760G1,G2,

or G3

G3

1000023P1

Up to 3

OR

Up to 3

Up to 3 1

Outdoor Enclosure

8339254G1

1

2-2

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

2.4 POWER REQUIREMENTS

Both the indoor and outdoor enclosures require external 110/220 VAC, single phase, 50/60

Hz with use of power supply and HCU, or +24 VDC for prime power.

2.4.1 Typical Prime Power Requirements

When both 110/220 VAC, single phase, 50/60 Hz and +24 VDC are available at the

installation site, an enclosure with 3 HICs/HFIs installed requires approximately 8

amperes of +24 VDC power. The HCU requires approximately 2.0 amperes of 110 VAC,

50/60 Hz (or approximately 1.0 ampere of 220 VAC, 50/60 Hz), single phase power.

2.4.2 Protective Earth Grounding

The Hub Equipment Enclosures must be properly grounded to protect installers and

operators from electrical shock. For this purpose there are two-1/4 in. x 20 ground studs

located on the left and right rear of the enclosure floor panel. These studs are used to

ground the internal components to the enclosure and to connect the enclosure to the site

ground. The site grounding cable should consist of UL-approved wire of no less than 14

gauge. The wire should attach to one of the ground stud by means of a properly sized ring

terminal. The enclosure is supplied with a split washer and a 1/4-in. x 20 nut to secure the

grounding cable ring terminal to the stud.

2.5 HUB EQUIPMENT CONFIGURATION AND SPACE REQUIREMENTS

2.5.1 Suggested Floor Space Requirements

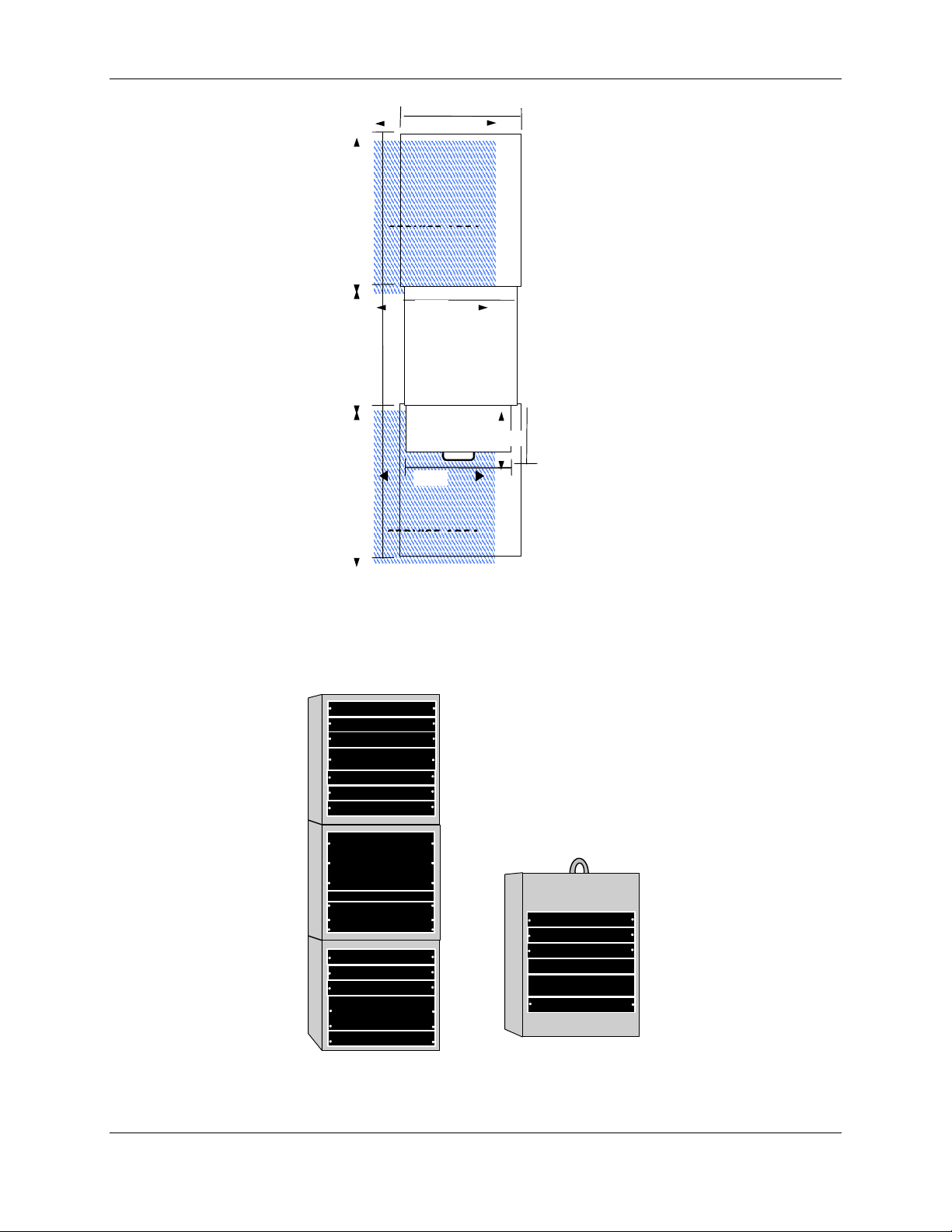

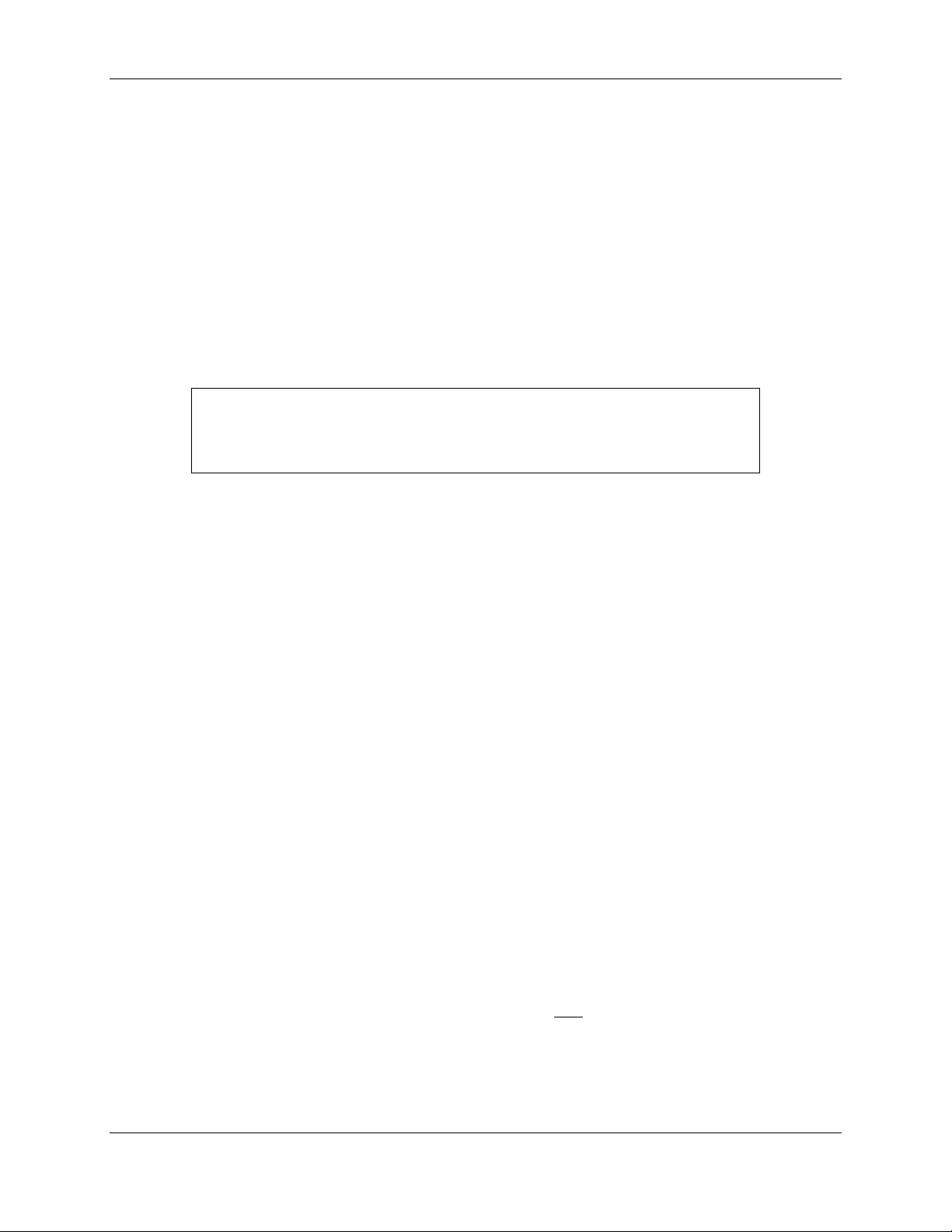

Figure 2-1 shows the suggested floor space to support the Indoor Hub Equipment enclosure

installation, operator workspace, and service area.

2.5.2 Floor Loading Requirements

In order to safely support the weight of a fully loaded enclosure unit, the floor of the

installation site must be rated for a load of 150 pounds per square foot or more .

2.5.3 Typical Enclosure Configuration

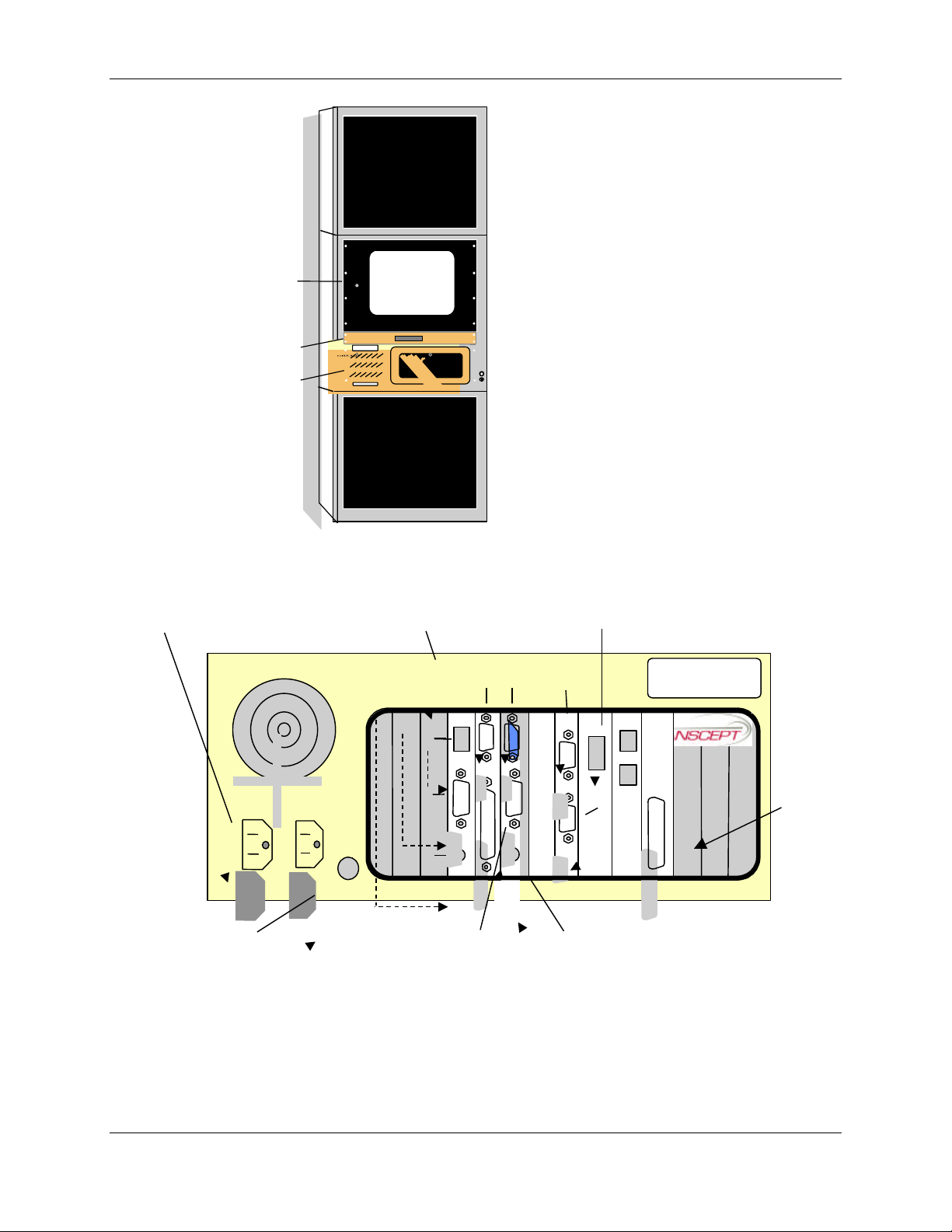

Figure 2-2 shows a typical enclosure configuration as it appears before installation of the

rack-mounted assemblies. The indoor enclosure configurations use the same enclosures

and are stackable up to three high. Each individual enclosure is 24 inches high, 25 inches

deep, and 20 inches wide (outside dimensions). A minimum of 36 inches of clear space

behind the enclosure is recommended for servicing and proper ventilation. The HCU

contains an extendable keyboard tray, which adds another 36 inches of clearance

requirement in front of the enclosure for operator workspace. The enclosures are bolted

together via the “Hub Enclosure Stacking Kit; PN 1000059G1” and it is recommended that

the enclosure be bolted to the floor.

2-3

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

SUGGESTED

SUGGESTED

Monitor

Computer

HIC

RFIA

HFI

Blank

HIC

RFIA

HFI

HIC

RFIA

HFI

Blank

HIC

RFIA

HFI

Network I/F Unit

Blank

24 IN.

36 IN.

26 IN.

Hub Enclosure

PULL-OUT KEYBOARD

TRAY WITH TOUCHPAD

36 IN.

NOTES

1. Suggested work area for installation

2. Suggested work area to support

1

20 IN.

12 IN.

17 IN.

2

and maintenance

installation and operation

Figure 2-1. Recommended Hub Equipment Floor Space

Keyboard

Power Supply (Optional)

Power Supply (Optional)

Indoor Unit

Outdoor Unit

Figure 2-2. Typical Enclosure Configuration

2-4

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

2.6 INSTALLATION OF ASSEMBLIES IN EQUIPMENT ENCLOSURE

Paragraph 2.6.1, Indoor and outdoor enclosure installation, provides step-by-step

instructions for installing hardware assemblies, cables, wiring, etc.

2.6.1 Hub Enclosure Installation

For installation sites that do not provide an external +24 VDC power source, an optional

internal +24 VDC Power Supply, part number 1000056G1, must be installed in the

enclosure. If an external +24 VDC power source is available, skip to paragraph 2.6.1.2.

2.6.1.1 Hub +24 VDC Power Supply Installation

If the +24 VDC Power Supply has been procured as an option, install as follows:

a. Connect Power Supply Input Cable (supplied with unit) to an AC outlet/source as

follows:

Black wire to Line AC (L1) terminal

White wire to Neutral AC (L2) terminal

Green wire to ground terminal

b. Verify polarity of wires, then connect ring terminal ends of Power Supply Output

Cable P/N 1000056G1 to V1 (+) and (–) terminals.

NOTE

See 2.6.1.3 for connecting the output of the +24 VDC Power Supply to the

Prime Power Panel.

c. Connect ring terminal of PEGND cable P/N 1000060G1 to ¼-inch ground stud on

back of the +24 VDC Power Supply.

d. Install +24 VDC Power Supply into rack in the bottom of the lower enclosure unit.

e. Secure +24 VDC Power Supply to rack with two 10-32 in. x 0.50 screws and

washers.

f. Connect FASTON connector of PEGND cable to PEGND leg of busbar at a position

adjacent to +24 VDC Power Supply.

g. Ensure that input power switch on the Power Supply is off, before connecting power

to Power Supply.

DC Terminals

GND

AC

Terminals

Figure 2-3. +24 VDC Power Supply Rear Panel

2-5

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

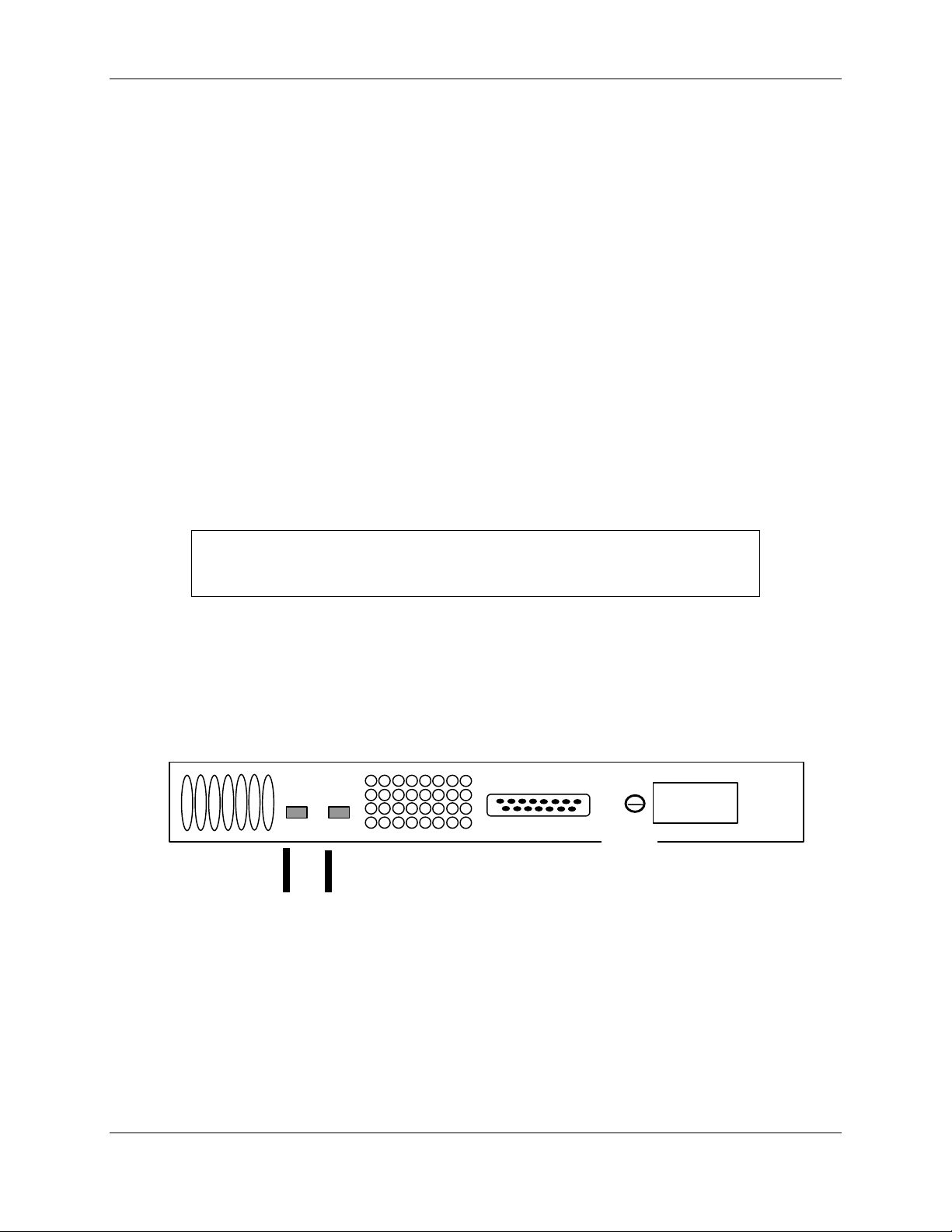

2.6.1.2 Hub Control Unit (HCU) Installation

The HCU, Keyboard, and Computer will take up one entire enclosure. For the outside

enclosure, these items are replaced with a network interface unit (PN 1000057G1) and the

HCU is remote from the outside enclosure. The following procedure is for the indoor

enclosure configuration.

NOTE

Both fixed and sliding sections of the keyboard slides are installed in the rack

at the factory. As part of the HCU installation, the sliding (keyboard tray)

section of each slide is removed from the rack and installed on the keyboard

tray.

a. Using a short cable tie, secure both touchpad cable and keyboard cable to cable tie

mount at rear of left slide.

b. Using six short cable ties, secure both touchpad cord and keyboard cable along

length of cable retractor. Do not over-stretch keyboard cable coils.

c. Locate two HCU rack-mounting brackets packed with HCU software media.

d. Remove hardware from bracket mounting holes on left and right sides toward front

of computer.

e. Using hardware removed, attach two brackets to chassis and tighten.

f. Insert computer into enclosure at location shown in Figure 2-4.

g. Slide computer onto angle rails and secure to rack using four 10-32 in. x .50

mounting screws and washers.

h. Connect keyboard cable to KEYBOARD connector at rear of HCU computer chassis

(Figure 2-5).

i. Connect touchpad cable to MOUSE connector at rear of HCU computer chassis

(Figure 2-5).

j. While supporting front and back of HCU monitor, carefully insert monitor into front

of rack at location shown in Figure 2-4.

k. Secure HCU monitor to rack using eight mounting screws and washers supplied

with monitor.

l. Connect HCU monitor video cable to video connector at rear of HCU computer

chassis (Figure 2-5).

2-6

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

LP

CO

M

PH

LI

BT

HCU

Monitor

HCU

Keyboard

Tray

HCU

Computer

Power

Reset

HDD

KB-LK

KB-LK

I

0

Connect Power Cable

to AC input connector

Connect Keyboard Cable

to Keyboard connector

Figure 2-4. Typical Indoor Enclosure Configuration

Network Interface

Card (Ethernet)

10base2

10base 5

10baseT

KEYBOARD

Connect Monitor Cable

to Video connector

Connect the HIC Communication

Cable P1 to the RS-485 connector

COM 2COM 1

T 1

MOUSE

COM 3

M1

COM 4

O

DE

M

C

A

O

NE

NE

S

AL

AR

M

Connect Touchpad Cable

to Mouse connector

Figure 2-5. HCU Computer Rear View

2-7

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

2.6.1.3 +24 VDC Prime Power Installation

The +24 VDC interface for the Indoor Enclosures are terminal blocks located on the inside

of each enclosure on the upper rear panels. The terminal block accepts two wires (+24VDC

and RTN) and distributes the power through busbars. Wire sizes accepted by the terminal

block range from AWG #14 to AWG # 4.

a. Before connecting power to enclosure, ensure that internal or external +24 VDC

power is OFF.

b. Secure +24 VDC input wires from the Power Supply or external power source to

Input Terminal Block with compression screws. Using a flat blade screwdriver, back

off the two screws on input section of Input Terminal Block.

NOTE

For enclosures using the optional +24 VDC Power Supply, use power supply

output cable P/N 1000056G1 in place of the on-site external +24 VDC power

cabling.

2.6.1.4 Initial Prime Power Test

This test requires a multimeter capable of measuring +24 VDC, and associated test probes.

The external or internal +24 VDC supply should be energized at this time. Perform the

following procedure to verify the voltage:

Using a multimeter, measure and record busbar voltage. (The Enclosure/HIC data

sheet at the end of this manual may be reproduced and used for recording.) Verify that

voltage is between +20 and +28 VDC and that polarity matches labels on busbar

mounting brackets.

2.6.1.5 Initial HCU Test

a. At the HCU front panel, set monitor power switch to ON and observe that power

indicator lights. (The monitor power may be from the computer.)

b. Set computer power switch to ON and observe that power indicator lights. If

monitor is powered from computer, monitor power indicator will also light.

c. Observe that computer boots up within 45 seconds and monitor displays Windows

NT desktop screen.

d. Pull out keyboard tray and operate touchpad to verify cursor control.

e. Place cursor on Start button on Windows NT desktop and click left mouse button. A

pop up menu appears.

f. Place cursor on Shut Down … selection and click left mouse button. A

SHUTDOWN WINDOW dialog appears.

g. Click on Shut down the computer? Then click on Yes button. The computer begins

an orderly shutdown process. Wait until a screen message appears indicating that it

is safe to remove power from computer.

2-8

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

2.6.1.6 RF Interface Assembly (RFIA) Installation

NOTE

It is highly recommended that the RFIAs be installed in the enclosure in the

following order so that the enclosure does not become top-heavy and unstable

if the enclosure is not bolted to the floor:

• The first RFIA should be installed in the top slot of the lower enclosure

below the keyboard.

• RFIAs 2 and 3 should be installed starting in the slot just above the bottom

slot of the top enclosure followed by one in the top slot of the top enclosure.

a. Install RFIAs in enclosure by sliding them onto angle brackets and securing them

with screws and washers.

b. Repeat step a for remaining RFIAs.

c. Locate +24VDC Power Wiring Harness P/N 1000062G1 (Figure 2-7) for each RFIA.

d. At a location parallel to RFIA PWR connector, connect +24VDC connector of wiring

harness to +24VDC busbar and +24VRTN connector to +24VRTN busbar.

e. Plug mating connector of power cable into RFIA PWR connector and tighten

connector retaining screws.

f. Repeat steps d and e for remaining RFIAs.

2.6.1.7 Hub Fiber Interface (HFI) (Option)

a. Install HFIs in enclosure by sliding them onto angle brackets and securing them

with screws and washers.

b. Repeat step a for remaining HFIs.

c. Locate +24VDC Power Wiring Harness P/N 1000074G1 for each HFI.

d. At a location parallel to HFI PWR connector, connect +24VDC connector of wiring

harness to +24VDC busbar and +24VRTN connector to +24VRTN busbar.

e. Plug mating connector of power cable into HFI PWR connector and tighten

connector retaining screws.

f. Repeat steps d and e for remaining HFIs.

2-9

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

2.6.1.8 Hub Interface Converter (HIC) Installation

NOTE

It is highly recommended that the HICs be installed in the enclosure in the

following order so that the enclosure does not become top-heavy and unstable

if the enclosure is not bolted to the floor:

• The first HIC should be installed in the slot below the RFIA of the lower

enclosure below the keyboard.

• HICs 2 and 3 should be installed starting in the lower slot of the top

enclosure followed by one in the upper part of the top enclosure below the

RFIA.

a. Install HICs in enclosure by sliding them onto angle brackets and securing them

with screws and washers.

b. Connect one end of GND Cable Assembly P/N 1000060G1 to ground studs on the

enclosures located on the bottom panel of the enclosure and the other end on to the

wing nut screw on the back of the HIC.

c. Repeat steps a and b for remaining HICs.

d. Locate +24VDC Power Wiring Harness P/N 1000062G1 (Figure 2-7) for each HIC.

e. At a location parallel to HIC PWR connector, connect +24VDC connector of wiring

harness to +24VDC busbar and +24VRTN connector to +24VRTN busbar.

f. Plug mating connector of power cable into HIC PWR connector and tighten

connector retaining screws.

g. Repeat steps d and f for remaining HICs.

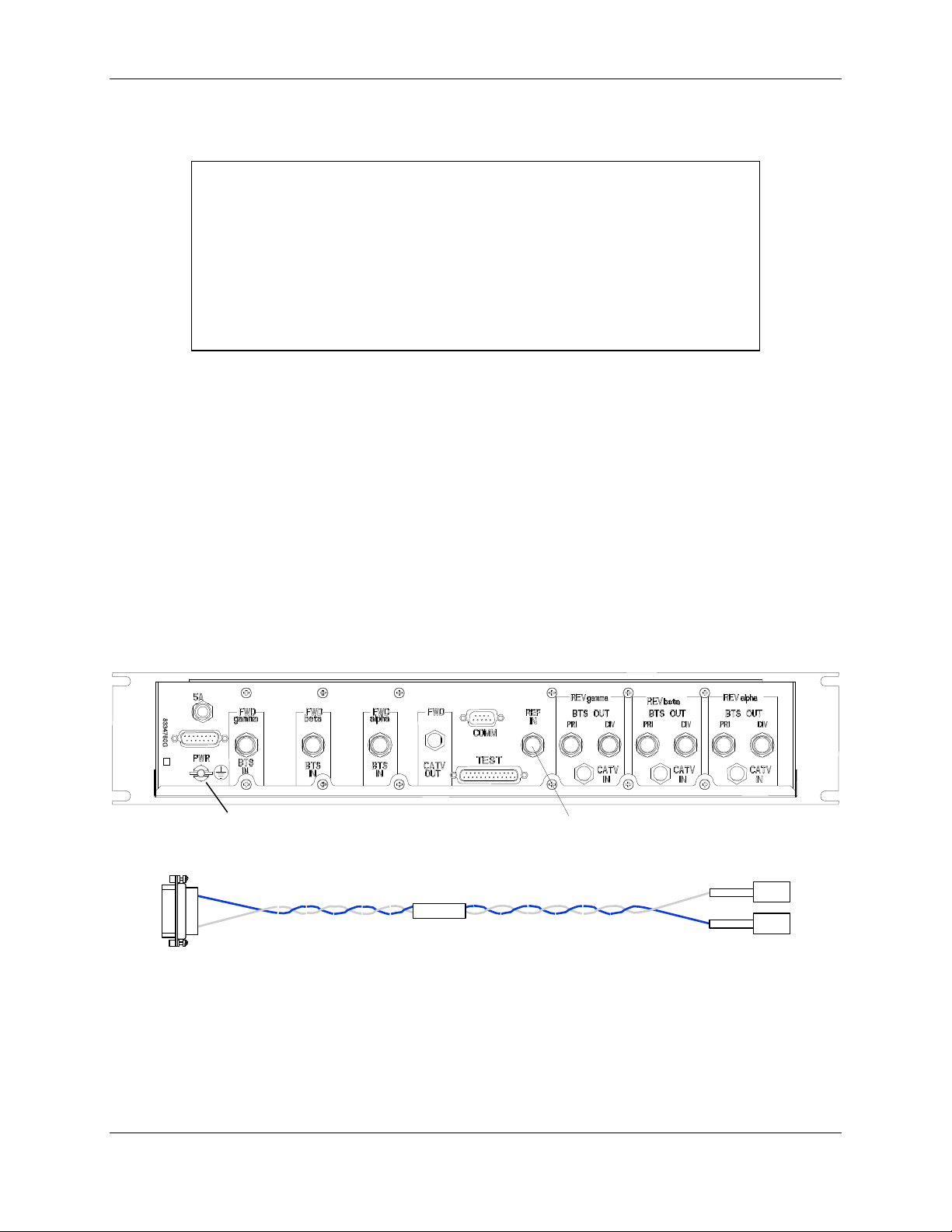

Ground Stud

10 or 15 MHz

Figure 2-6. HIC Rear Panel

P3

8337944

P2

+24RTN

+24VDC

P1

Figure 2-7. HIC Power Wiring Harness 1000062G1

2-10

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

TransCell 1900CB Installation Manual Document No. 1000070A

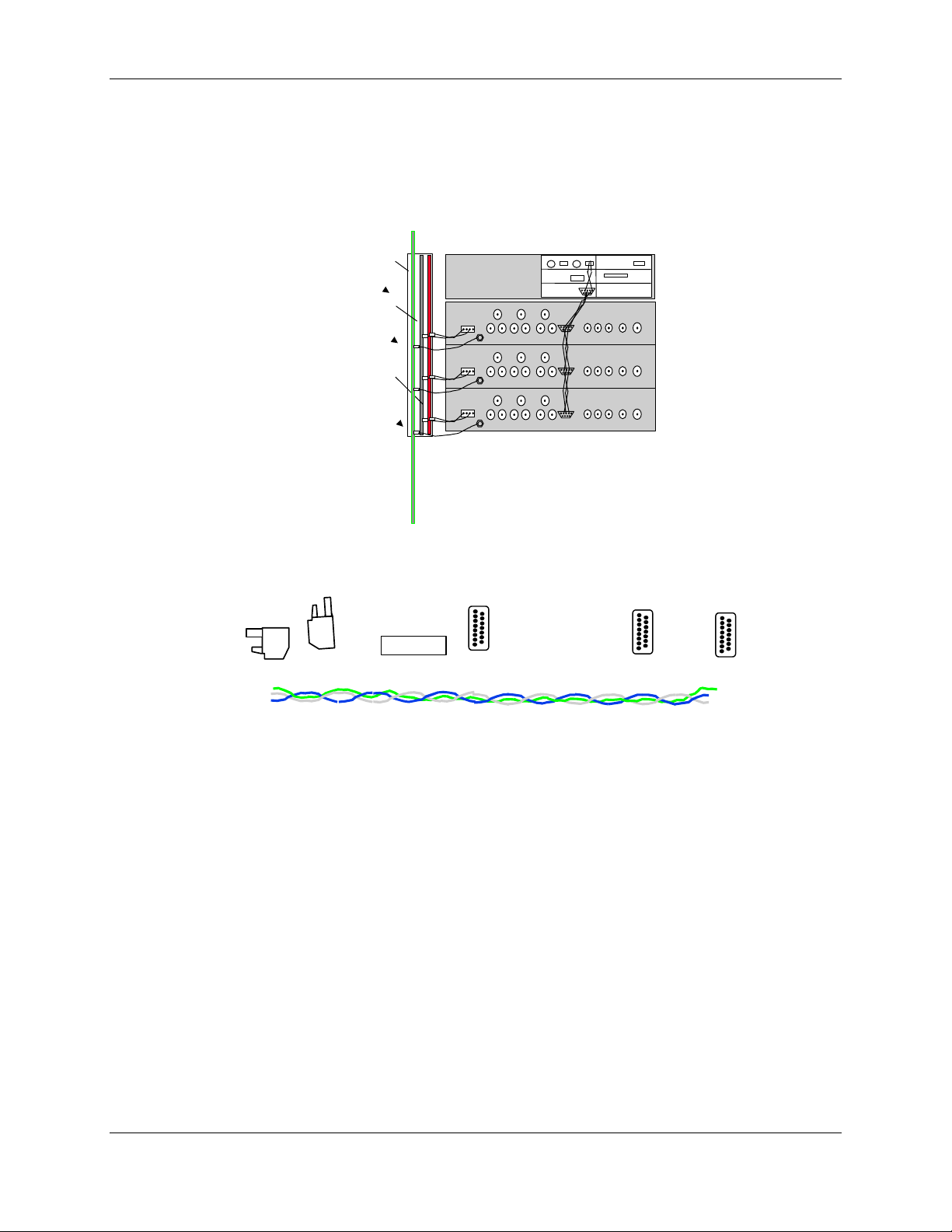

2.6.1.9 Digital Communications Wiring Installation

The HIC communicates with the computer via an RS-485 interface using a LonWorks®

protocol. The RS-485 interface uses twisted 3-wire 22-gauge wire, beginning at the

computer and connecting to the upper and lower HIC modules a RS-485 cable assembly PN

1000063G1. Figure 2-8.

GND

BUSBAR

+24VDC

RTN

BUSBAR

+24VDC

BUSBAR

CONTROL COMPUTER

LONWORKS

Figure 2-8. Three HIC Control Interconnect Diagram (not to scale)

a. Mate connector P1 of HIC Communication Wiring Harness P/N 1000063G1 (Figure

2-9) to RS-485 port on computer rear panel (Figure 2-5).

1000063

Figure 2-9. HIC Communication Wiring Harness P/N 8339969G1

b. Connect the other connector to the additional HICs.

2.7 HUB EQUIPMENT CABLE INSTALLATION

With the exception of the indoor and outdoor interface cables between the RFIA and HIC

and between the HIC and HFI, external RFIA interface cables are not provided with the

enclosures or HICs. The cables are provided locally by the user at the installation site. For

the Hub Equipment enclosures, the user must provide up to 14 cables for each RFIA/HIC

installed:

One cable to interface the 15 MHz Reference to the HIC (if using external reference), four

cables interface the HIC with the coaxial network (if applicable), three fiber cables

interface the HFI with the fiber network (if applicable), and nine cables interface the RFIA

with the BTS. Figure 2-10 shows the RF cable interconnections between a single installed

HIC, an RFIA, coaxial network, and BTS. If the HFI is required, configure the cables

between the HIC and HFI to meet the fiber network architecture.

2-11

TRANSCEPT PROPRIETARY - DATA ON THIS PAGE SUBJECT TO RESTRICTIONS CITED ON COVER AND TITLE PAGE

Loading...

Loading...