ooznest WorkBee CNC Assembly Manual

WorkBee CNC

Full Kit Assembly Instructions

WorkBee CNC 1

Table of Contents

1.0 Getting Started 3

1.1 About The Kit 4

1.2 Check Product Contents 4

1.3 Tools Required 4

1.4 Notes on Assembly 4

2.0 Drag Chains Assembly 6

2.1 Y-Axis 7

2.1.1 Y-Axis Fixed End Assembly ........................................................... 7

2.1.2 Y-Axis Fixed End Mounting............................................................ 8

2.1.3 Y-Axis Moving End Assembly......................................................... 9

2.1.4 Y-Axis Moving End Mounting ....................................................... 10

2.1.5 Y-Drag-Chain............................................................................ 11

2.2 X-Axis 12

2.2.1 X-Axis Fixed End Mounting ......................................................... 12

2.2.2 X-Axis Moving End Assembly ...................................................... 13

2.2.3 X-Axis Moving End Mounting....................................................... 14

2.2.4 X-Drag-Chain ........................................................................... 15

3.0 Power Supply Assembly 16

3.1 Output 17

3.1.1 Securing XT60-Male Outputs ...................................................... 17

3.1.2 Inserting LED-Volt-Meter ............................................................ 18

3.2 Input 19

3.2.1 IEC-Inlet Wires ......................................................................... 19

3.2.2 Attaching IEC-Inlet.................................................................... 20

3.3 Connecting PSU-Cover 21

3.3.1 Connecting Wires ...................................................................... 21

3.3.2 Attaching PSU-Cover ................................................................. 23

3.3.3 Testing .................................................................................... 24

4.0 Limit Switches & Wire Routing 25

4.1 Limit Switches 26

4.1.2 Z-Axis Limit Switch.................................................................... 28

4.2 Wire Routing 29

4.2.2 Screw Driven - Gantry Wire Routing ............................................ 30

4.2.3 Belt Driven - Gantry Wire Routing ............................................... 31

4.2.4 Screw Driven - Y-Axis Wire Routing - Part 1 .................................. 32

4.2.5 Screw Driven - Y-Axis Wire Routing - Part 2 .................................. 33

4.2.6 Belt Driven - Y-Axis Wire Routing ................................................ 34

5.0 CNC xPro Assembly 35

5.0.1 Terminal-Block Attachment......................................................... 36

5.0.2 Fan Mount Assembly.................................................................. 37

5.0.3 Attaching The CNC-xPro ............................................................. 38

5.0.4 Fans Wiring.............................................................................. 39

5.0.5 Mounting the CNC-xPro Assembly................................................ 40

6.0 Wiring & Commissioning 42

6.1 CNC-xPro Wiring 43

6.2 Software & Machine Settings 44

6.2.1 Installing Universal G-Code Sender (UGS) .................................... 44

6.2.2 Configuring The Firmware .......................................................... 45

WorkBee CNC 2

6.3 Testing 46

6.4 Wire Tidying 48

6.5 Complete 49

7.0 Appendix 51

7.1 Appendix A - Kit Contents 52

8.0 Appendix B 59

8.1 Recommended GRBL Settings 60

8.2 Invert Mask Table 63

9.0 Appendix C 64

9.1 Common Trouble Shooting Questions 65

WorkBee CNC Getting Started 3

1.0 Getting

Started

WorkBee CNC Getting Started 4

1.1 About The Kit

This manual is for the full kit version of the WorkBee CNC Machine. Ideally, this manual

should be started straight after completing the mechanical assembly. This manual will turn

the mechanical portion of the WorkBee into a working moving machine.

Our WorkBee CNC Machine has a very large community of users, who can mostly be found

at http://openbuilds.com. It is free to sign up to this community and it will allow you to

share your builds, interact with other members, and download useful community created

resources. We have a specific build thread for the WorkBee, and we would love to see your

machines and what you make with them: https://openbuilds.com/builds/workbee-cncmachine.5626/.

1.2 Check Product Contents

When you receive your kit, the first thing you should do is check the contents against the

list in Appendix A. The majority of the parts will be separated into boxes that correspond

to the subsections in this manual. Additional spare small parts will be included. If anything

is missing or damaged (or if you have any other problems) please contact us at

sales@ooznest.co.uk and we will aim to resolve the issue as quickly as possible.

1.3 Tools Required

• The list below shows the main tools that will be required to complete this build:

• 2.5mm Allen Key

• 3.0mm Allen Key

• 4.0mm Allen Key

• 5.5mm Spanner

• 7.0mm Spanner

• 8.0mm Spanner

• Hammer

• Selection of Philips Screwdrivers

• Selection of Flathead Screwdrivers

• Tweezers

• Wire Cutters/Strippers

1.4 Notes on Assembly

This manual has been written for the construction of a 750 x 750mm screw driven version

of the WorkBee. If you have a different version everything is exactly the same, with the

exception of longer V-Slot extrusions and wire routing.

The assembly has been split into 5 sections: Drag Chains Assembly, Power Supply

Assembly, Limit Switches & Wire Routing, CNC xPro Assembly, Wiring & Commissioning.

To make locating parts quicker, leave the parts in the boxes they came in when carrying

out the build.

WorkBee CNC Getting Started 5

It is recommended that you read through the whole manual before beginning the build in

order to get a full picture of the assembly process. Before beginning each step, make

sure you have studied the diagram and have the required parts in front of you. A PDF

version of the manual is available on our website and this will allow you to zoom in on the

diagrams if needed.

Be very careful to not over tighten the nuts and bolts on the plastic parts, otherwise they

may crack. Everything should easily fit together, and so if it isn’t, take a step back and

re-read the instructions.

Assembly of this kit involves the use of electricity and therefore you should take appropriate precautions to ensure you are assembling the kit in a safe manner. When following

wiring diagrams, double check that everything is connected correctly. Before carrying out

any work on the electrics make sure that the machine is switched off.

The polarity is indicated by the color of the wire, not by the color of the connectors at each

end. For the AC IEC input, the live wire is brown, neutral blue, and earth is green and yellow. For the DC Wiring of the machine a positive wire is red, negative is black, and earth

is green and yellow.

WorkBee CNC Drag Chains Assembly 6

2.0 Drag

Chains

Assembly

WorkBee CNC Drag Chains Assembly 7

2.1 Y-Axis

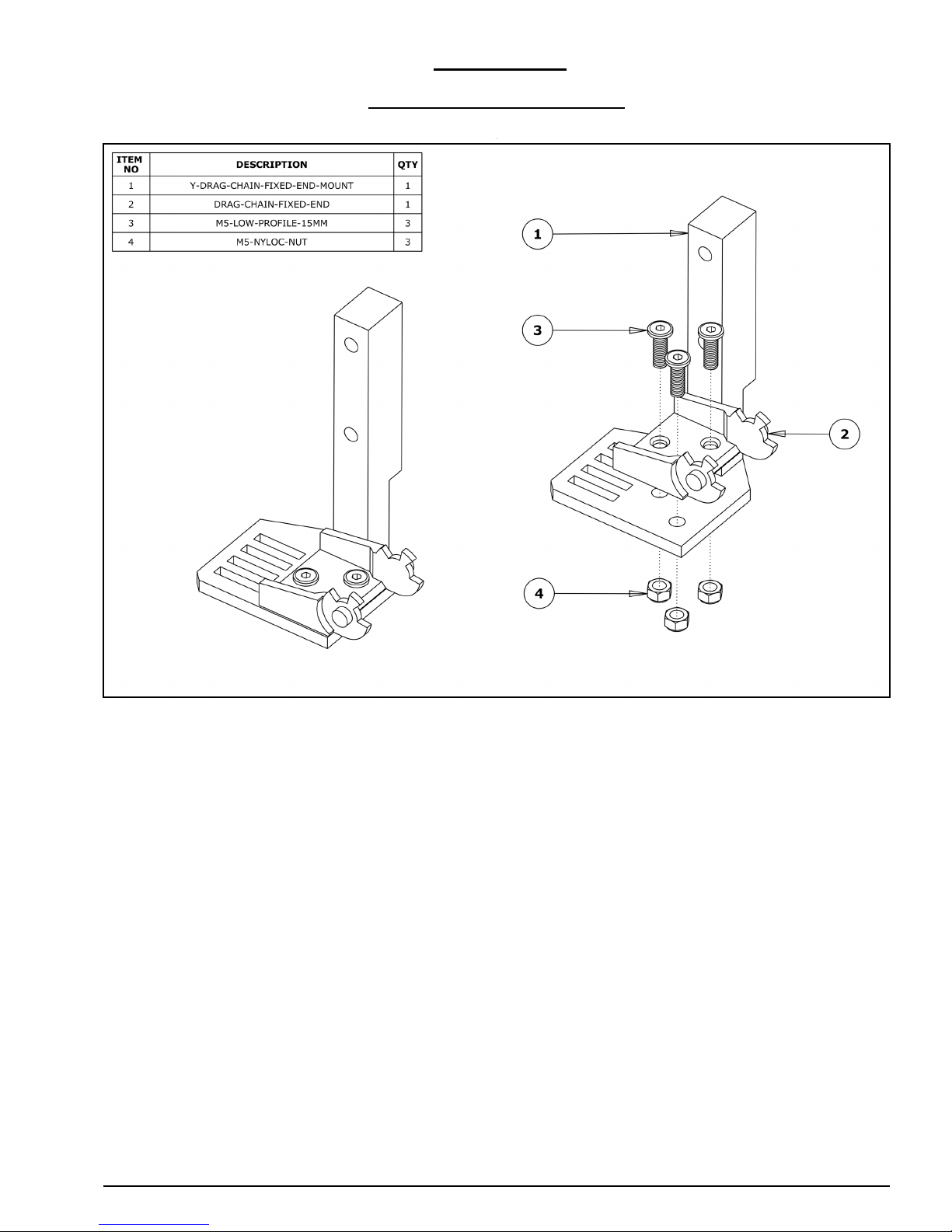

2.1.1 Y-Axis Fixed End Assembly

A. Attach a Drag-Chain-Fixed-End to the Y-Drag-Chain-Fixed-End-Mount in the orienta-

tion shown above, using 3 x M5-Low-Profile-15mm bolts and 3 x M5-Nyloc-Nut’s.

WorkBee CNC Drag Chains Assembly 8

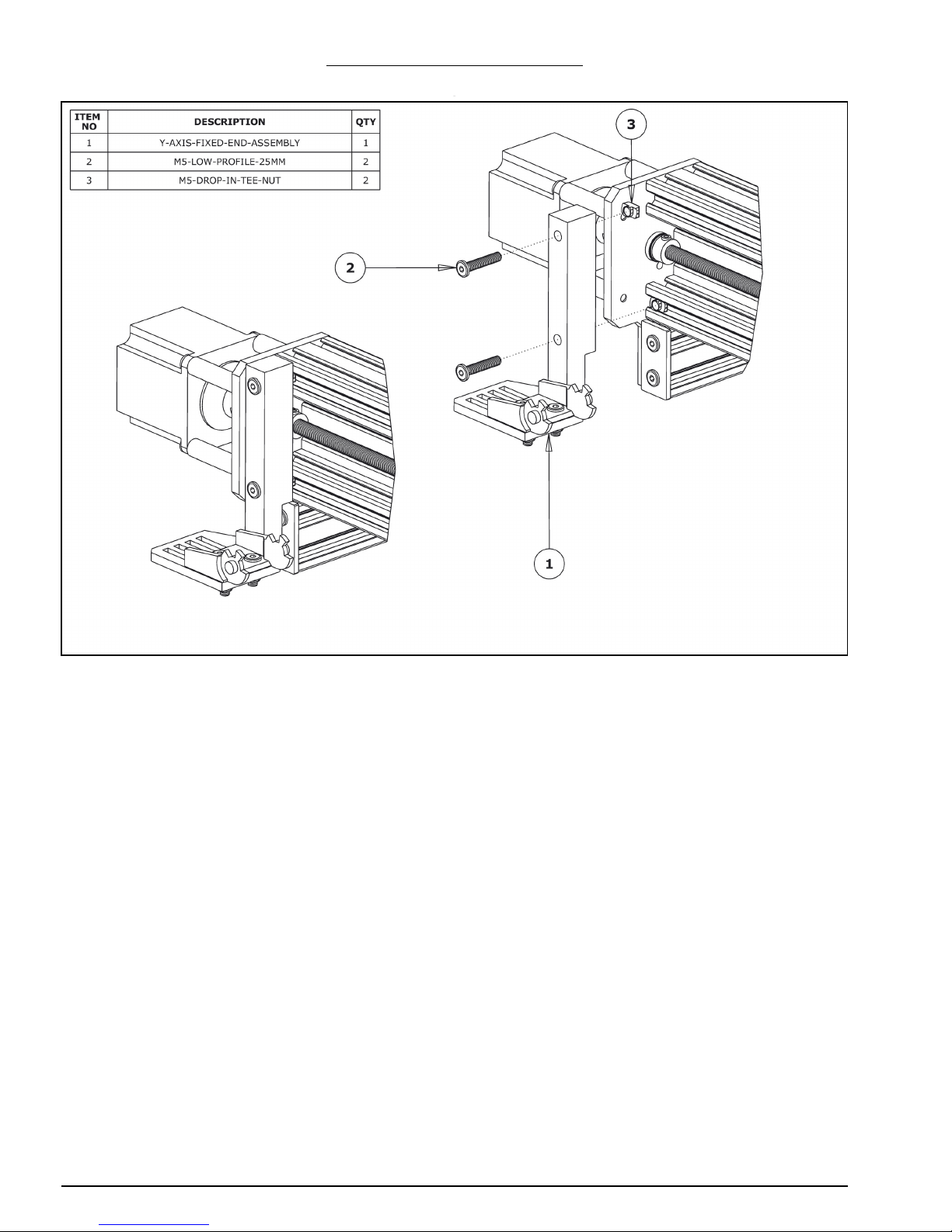

2.1.2 Y-Axis Fixed End Mounting

A. Position the Y-Axis-Fixed-End-Assembly to the back left corner of the WorkBee. It

should be flush with the end of the C-Beam-750mm. Secure it using 2 x M5-Low-Profile-25mm bolts and 2 x M5-Drop-In-Tee-Nuts.

WorkBee CNC Drag Chains Assembly 9

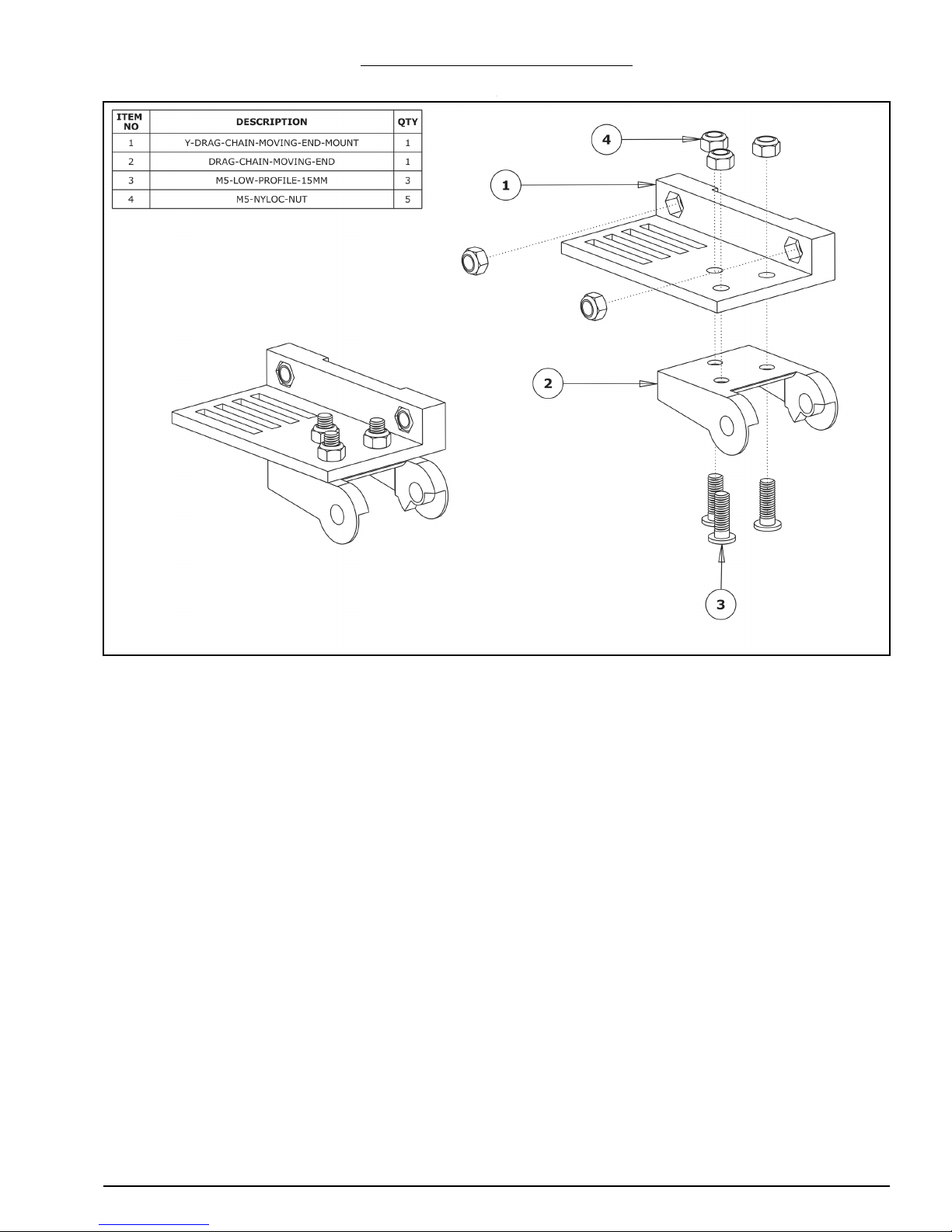

2.1.3 Y-Axis Moving End Assembly

A. Insert 2 x M5-Nyloc-Nuts into the insets on the Y-Drag-Chain-Moving-End-Mount.

They are a snug fit, so may require a light tap with a hammer.

B. Attach a Drag-Chain-Moving-End to the Y-Drag-Chain-Moving-End-Mount in the orien-

tation shown above using 3 x M5-Low-Profile-15mm bolts and 3 x M5-Nyloc-Nuts.

WorkBee CNC Drag Chains Assembly 10

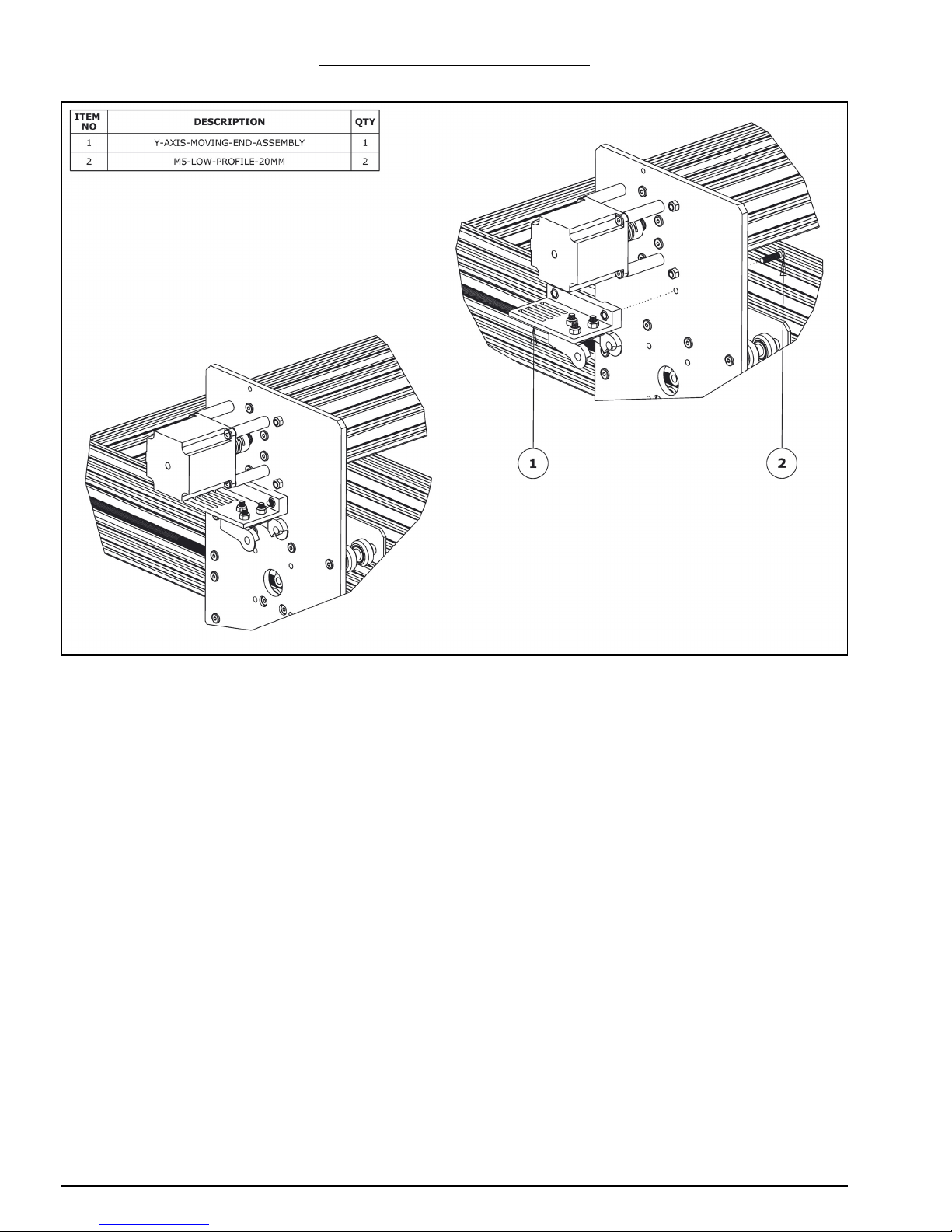

2.1.4 Y-Axis Moving End Mounting

A. Secure the Y-Axis-Moving-End-Assembly using 2 x M5-Low-Profile-20mm bolts and

the 2 x M5-Nyloc-Nuts already inserted into Y-Drag-Chain-Moving-End-Mount.

WorkBee CNC Drag Chains Assembly 11

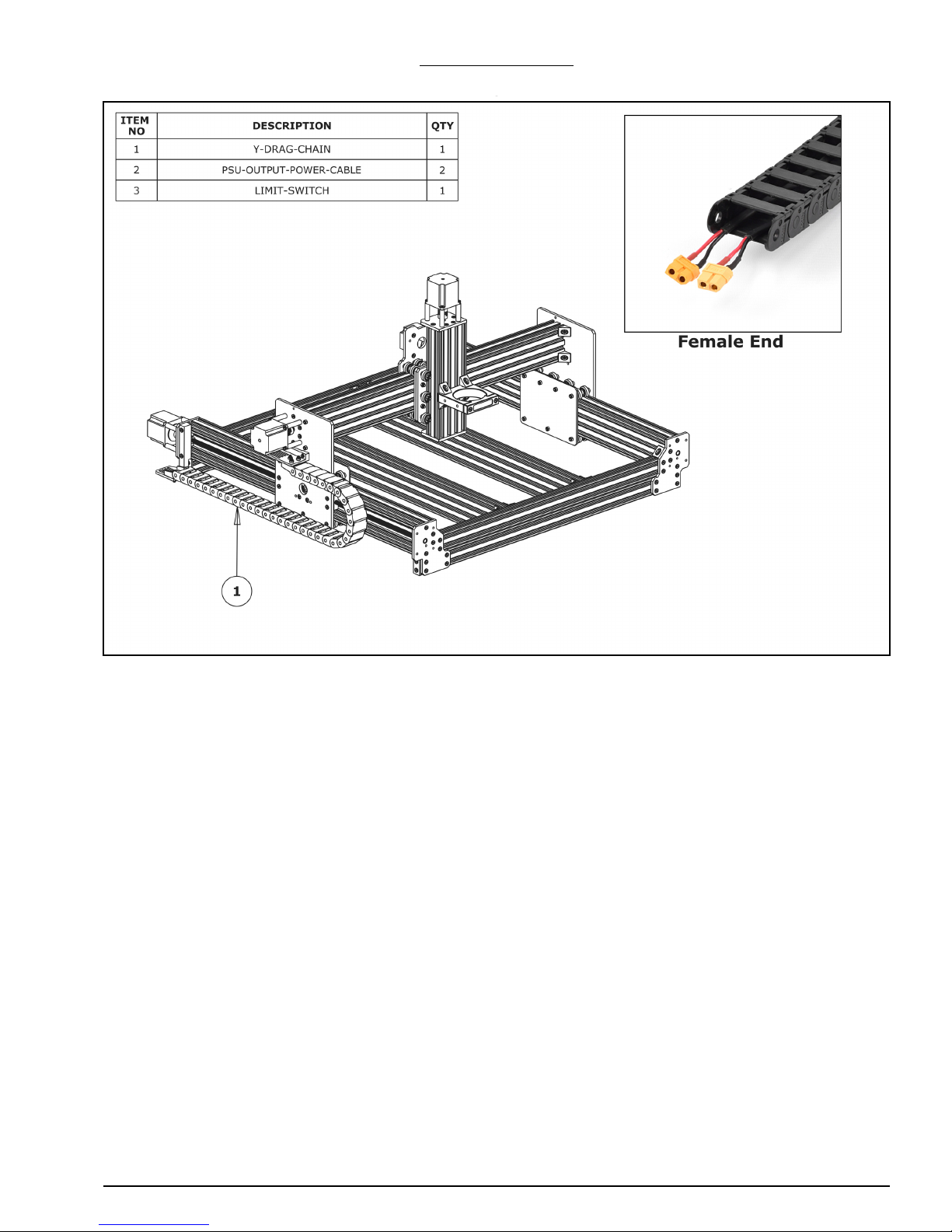

2.1.5 Y-Drag-Chain

A. Lay the Y-Drag-Chain flat on a table. Feed one of the PSU-Output-Power-Cables

through the whole length of the Y-Drag-Chain. Ensure that the end with the XT60Connector, is located at the female end of the Y-Drag-Chain (as shown above in the

‘Female End’ image). Repeat for a second PSU-Output-Cable. If the PSU-OutputPower-Cable gets snagged inside the Y-Drag-Chain, the tabs on the Y-Drag-Chain flip

open for access.

B. If you have a screw driven WorkBee only feed two stepper motor wires through the Y-

Drag-Chain. The end of the stepper motor wires with the black connector should be at

the female end of the Y-Drain-Chain - same as Step A. Further to this, one of the stepper motor cables will be considerably longer than the other three - this cable should

be one of the two which go inside the Y-Drag-Chain.

C. For all WorkBee Variants, feed the wires on a Limit-Switch, through the Y-Drag-Chain.

The switch portion of the Limit-Switch should be at the female end of the Y-DragChain.

D. Lay the Y-Drag-Chain flat along the left side of the WorkBee. The female end of the Y-

Drag-Chain should be at the back of the machine, and the male end at the front.

E. Attach the female end of the Y-Drag-Chain to the Drag-Chain-Fixed-End on the Y-Axis-

Fixed-End-Assembly. It will take some force to click it into the Drag-Chain-Fixed-End.

F. Bring the male end of the Y-Drag-Chain to the Y-Axis-Moving-End-Assembly and

attach it to the Drag-Chain-Moving-End. It will take some force to click it into the

Drag-Chain-Moving-End.

WorkBee CNC Drag Chains Assembly 12

2.2 X-Axis

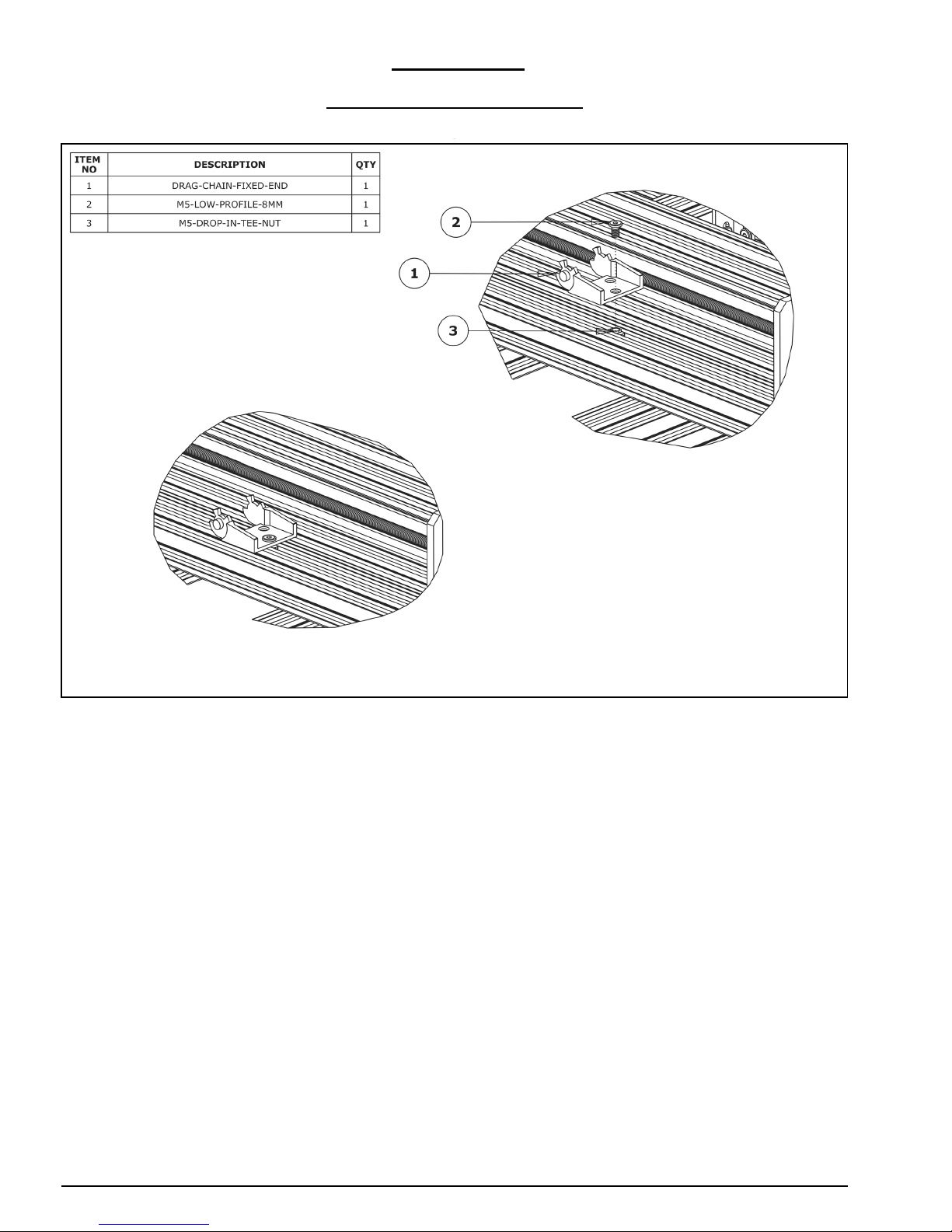

2.2.1 X-Axis Fixed End Mounting

A. Attach a Drag-Chain-Fixed-End to the V-Slot-2040-750mm using an M5-Low-Profile-

8mm and an M5-Drop-In-Tee-Nut. Ensure it is orientated as above; it should be

located 150mm from right hand end of the V-Slot-2040-750mm if looking from the

back. Ensure that it is parallel with the V-Slot-2040-750mm.

WorkBee CNC Drag Chains Assembly 13

2.2.2 X-Axis Moving End Assembly

A. Attach a Drag-Chain-Moving-End to the X-Drag-Chain-Moving-End-Mount in the ori-

entation shown above using 3 x M5-Low-Profile-15mm bolts and 3 x M5-Nyloc-Nuts.

WorkBee CNC Drag Chains Assembly 14

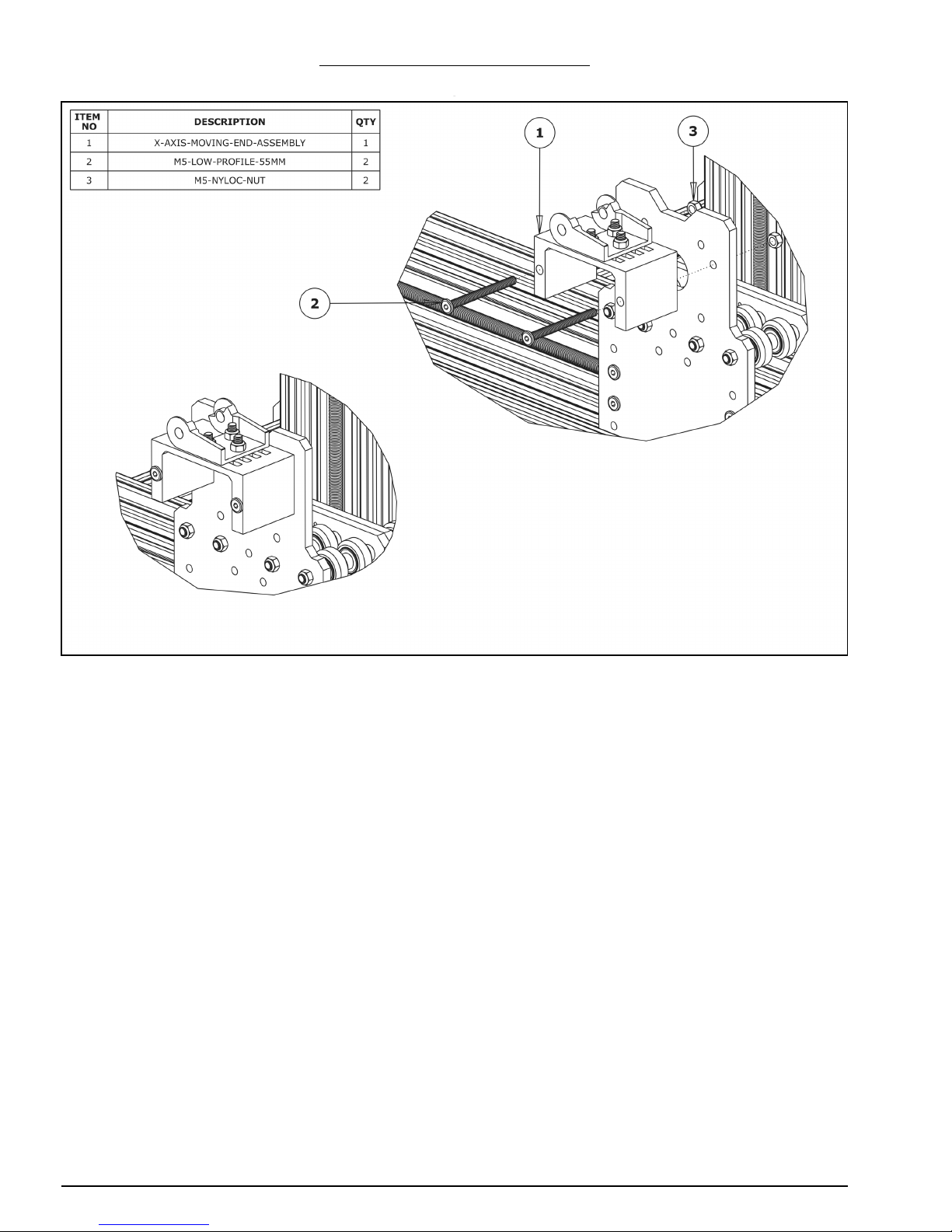

2.2.3 X-Axis Moving End Mounting

A. Secure the X-Axis-Moving-End-Assembly to the X-Plate-Back using 2 x M5-Low-Pro-

file-55mm bolts and 2 x M5-Nyloc-Nuts.

WorkBee CNC Drag Chains Assembly 15

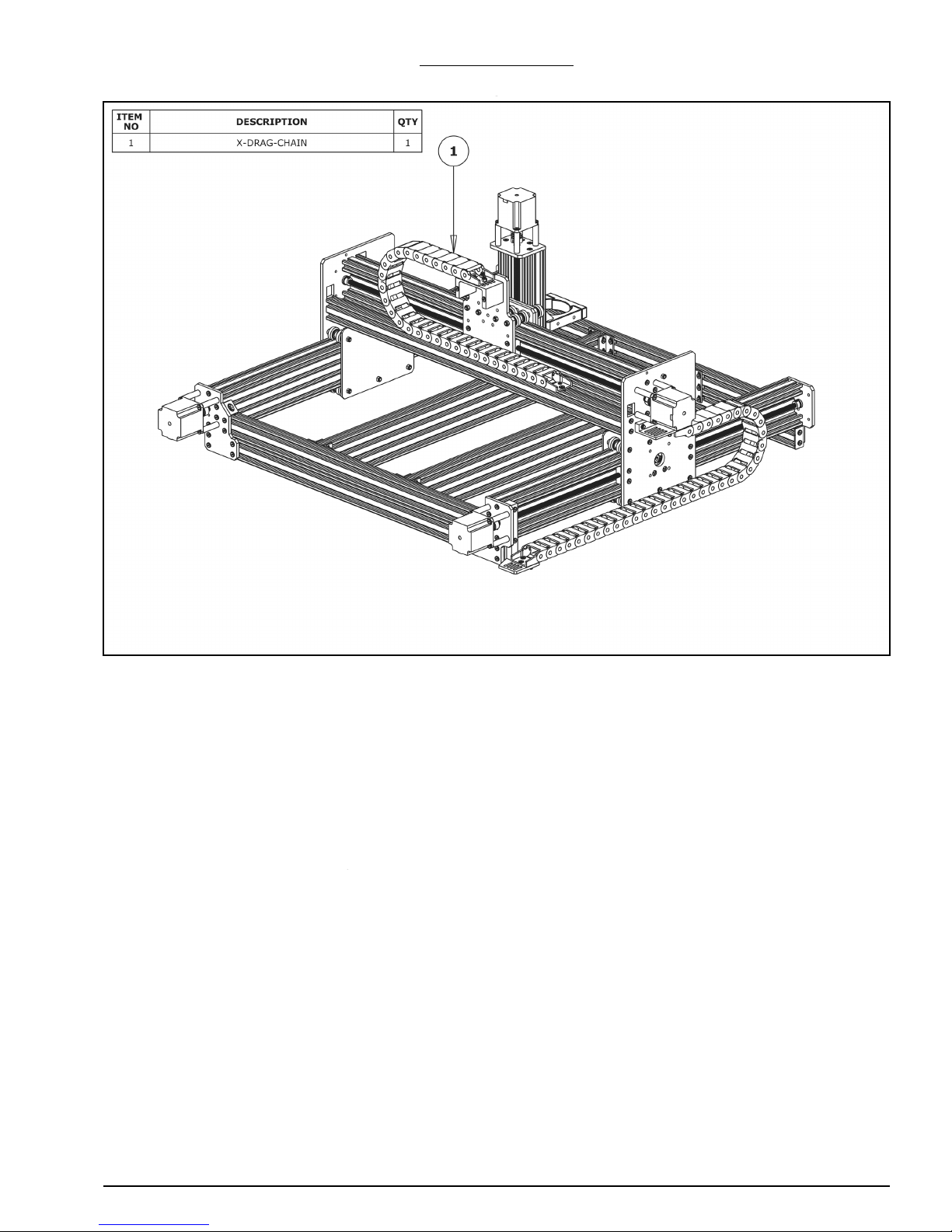

2.2.4 X-Drag-Chain

A. Like in Section 2.1.5 lay the X-Drag-Chain flat on a table. If you have a screw driven

WorkBee feed through one stepper motor wire. If you have a belt driven WorkBee feed

through two. The end of the stepper motor wires with the black connectors should be

at the male end of the X-Drag-Chain (opposite to Section 2.1.5).

B. Attach the female end of the X-Drag-Chain to the Drag-Chain-Fixed-End on the V-

Slot-2040-750mm. It will take some force to click it into the Drag-Chain-Fixed-End.

C. Bring the male end of the X-Drag-Chain up to the X-Axis-Moving-End-Assembly and

attach it to the Drag-Chain-Moving-End. It will take some force to click it into the

Drag-Chain-Moving-End.

WorkBee CNC Power Supply Assembly 16

3.0 Power

Supply

Assembly

WorkBee CNC Power Supply Assembly 17

3.1 Output

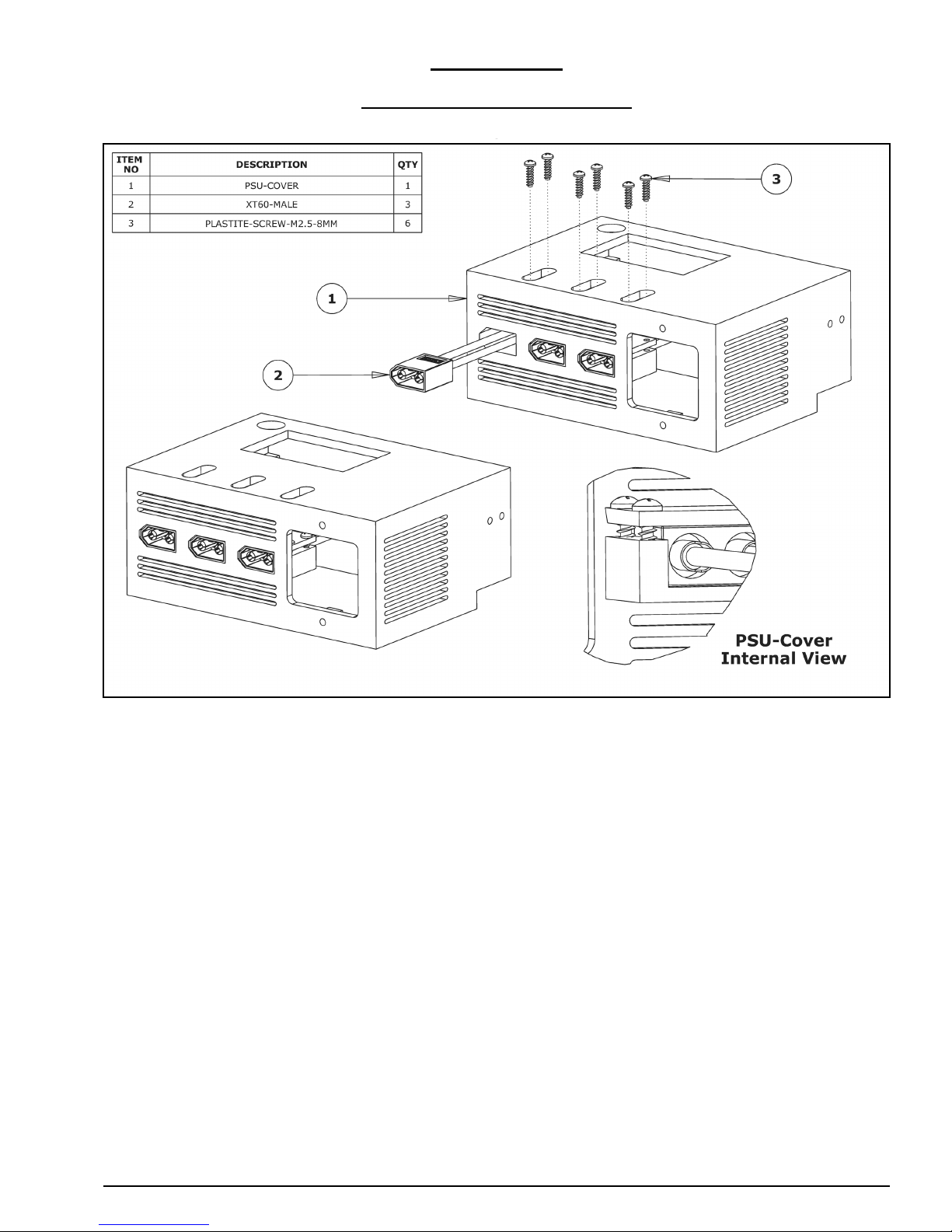

3.1.1 Securing XT60-Male Outputs

A. Insert the XT60-Male connectors into the provided insets on the PSU-Cover. They

should sit flush with the front of the PSU-Cover. Completion of this kit only requires 2

x XT60-Male connectors. The left-most XT60-Male connector is not needed for the

operation of this machine, but is included so you have the option to add additional

accessories. For safety reasons, if you do not intend to use it, do not attach it to the

PSU-Cover, and leave that inset empty.

B. Secure each XT-Male connector using 2 x Plastite-Screw-M2.5-8mm through the holes

provided on the securing tab as seen on the internal view. When initially placing the

screw, it is helpful to hold each screw in place using tweezers or long nose pliers.

WorkBee CNC Power Supply Assembly 18

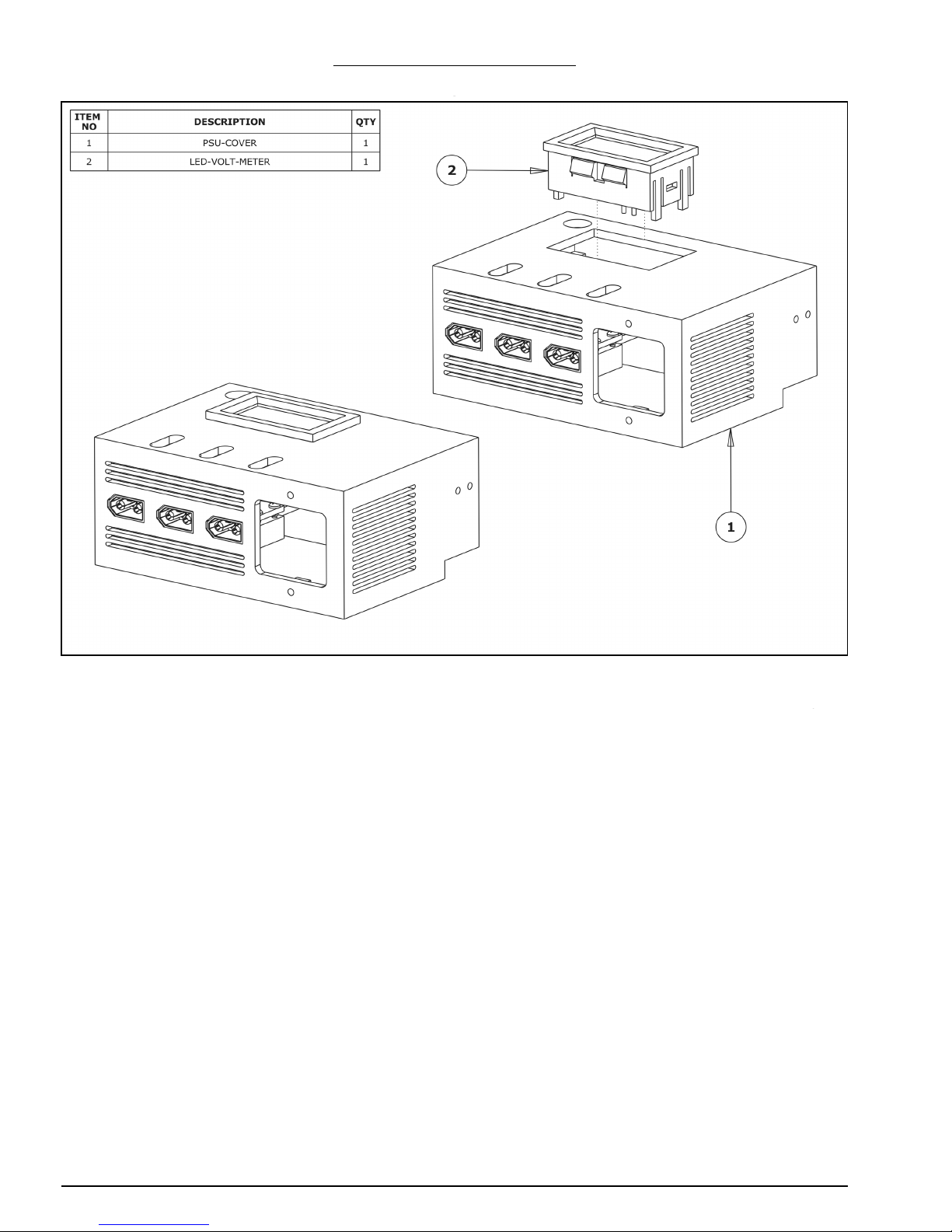

3.1.2 Inserting LED-Volt-Meter

A. Gently push the LED-Volt-Meter into the provided gap on the top of the PSU Cover.

The wires on the LED-Volt-Meter should be oriented to the front of the PSU-Cover.

WorkBee CNC Power Supply Assembly 19

3.2 Input

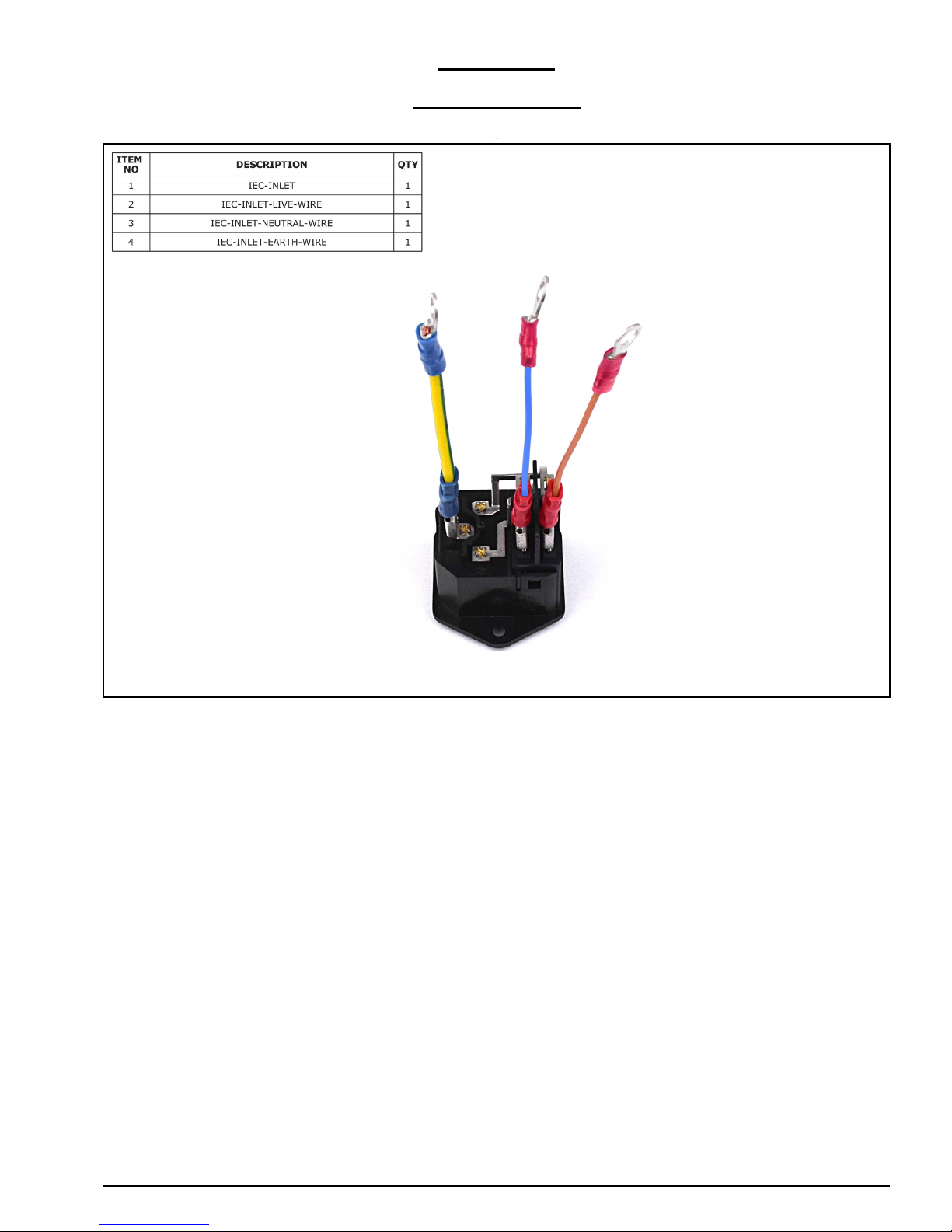

3.2.1 IEC-Inlet Wires

A. Attach the receptacle end of the IEC-Inlet-Live-Wire, IEC-Inlet-Neutral-Wire & IEC-

Inlet-Earth-Wire to their respective terminal tabs on the IEC-Inlet, as seen in the

above image.

Loading...

Loading...