OOOZNEST WorkBee CNC Assembly Manual

WORKBEE CNC

Mechanical Assembly Instructions

Screw Driven

WorkBee CNC 1

Contents

1.0 Getting Started ...................................................................................................... 2

1.1 About The Kit ................................................................................................. 2

1.3 Tools Required ................................................................................................ 2

1.4 Notes on Assembly .......................................................................................... 2

2.0 Assembly ............................................................................................................ 4

2.1 Wheel Assembly .............................................................................................. 4

2.2 Y-Plate Assembly ............................................................................................ 5

2.2.2 Y Wheels & Y-Plate-Inner ...................................................................... 6

2.2.3 Stepper Motor ...................................................................................... 8

2.2.4 Repeat ................................................................................................ 9

2.3 X-Carriage Assembly ..................................................................................... 10

2.3.2 Z ACME Nut Block ............................................................................... 12

2.3.3 X ACME Nut Blocks ............................................................................. 13

2.3.4 X Wheels & X-Plate-Front .................................................................... 14

2.3.5 X & Z Mating ...................................................................................... 16

2.3.6 Z Extrusion ........................................................................................ 17

2.3.7 Z Stepper Motor ................................................................................. 18

2.3.8 Z ACME Screw.................................................................................... 19

2.4 X-Gantry Assembly........................................................................................ 21

2.4.2 X-Carriage & Y-Plate-Left Assembly ...................................................... 22

2.4.3 X ACME Screw.................................................................................... 23

2.4.4 Angle Corners .................................................................................... 24

2.5 Base Assembly.............................................................................................. 25

2.5.2 End Plates ......................................................................................... 26

2.5.3 Stepper Motors .................................................................................. 27

2.5.4 Y ACME Screws .................................................................................. 28

2.5.5 End Caps ........................................................................................... 29

2.6 Spoiler Board Support Extrusions - Method 1 .................................................... 30

2.6.2 Y-End-Plate Final Bolts & Angle Corners ................................................ 31

2.6.3 Spoiler Board Support Brackets ............................................................ 32

2.6.4 Attaching Spoiler Board Supports ......................................................... 33

2.7 Spoiler Board Support Extrusions - Method 2 .................................................... 34

2.7.2 Spoiler Board Support Brackets ............................................................ 35

2.7.3 Spoiler Board Support Assembly ........................................................... 36

2.7.4 Attaching Spoiler Board Supports ......................................................... 37

2.8 Complete ...................................................................................................... 38

3.0 Appendix ............................................................................................................ 39

3.1 Appendix A - Kit Contents .............................................................................. 39

WorkBee CNC 2

1.0 Getting Started

1.1 About The Kit

The WorkBee CNC is an open source design designed and introduced by OOOZNEST and is an offspring

of the OX CNC Machine designed by Mark Carew of Open Builds

. 1.2 Check Product Contents

The first thing you should do when you receive your kit is to check the contents against the list in

Appendix A. If anything is missing or damaged (or you have any other problems), please contact us

and we will aim to resolve the issue as quickly as possible.

1.3 Tools Required

The list below shows the main tools that are required to complete this build:

• Set of Allen Keys

• 8.0mm Spanner

• M5Tap

1.4 Notes on Assembly

We recommend that you read through the whole manual before beginning the build, as this enables

you to get a rough idea of how it all goes together. Before starting each step make sure you have

studied the diagram and fully understand what you are doing. A PDF version of the manual is available

on our website, allowing you to zoom in on the diagrams if needed.

When attaching parts, make sure they are properly squared and aligned, and everything should easily

fit together. If a part is requiring significant force to attach, stop, take it off, re-read the instructions,

and try again. Do not over tighten bolts, as you may strip the threads.

If you forget to insert a Tee-Nut when instructed, there is no need to undo any of the work you have

done. We have included spare M5-Drop-In-Tee-Nuts in the kit for this situation. M5-Drop-In-Tee-Nuts

do not have to be inserted from the end of the extrusion - simply place them in the V-Slot, then screw

in the bolt. This will turn them and engage them into the underside of the V-Slot.

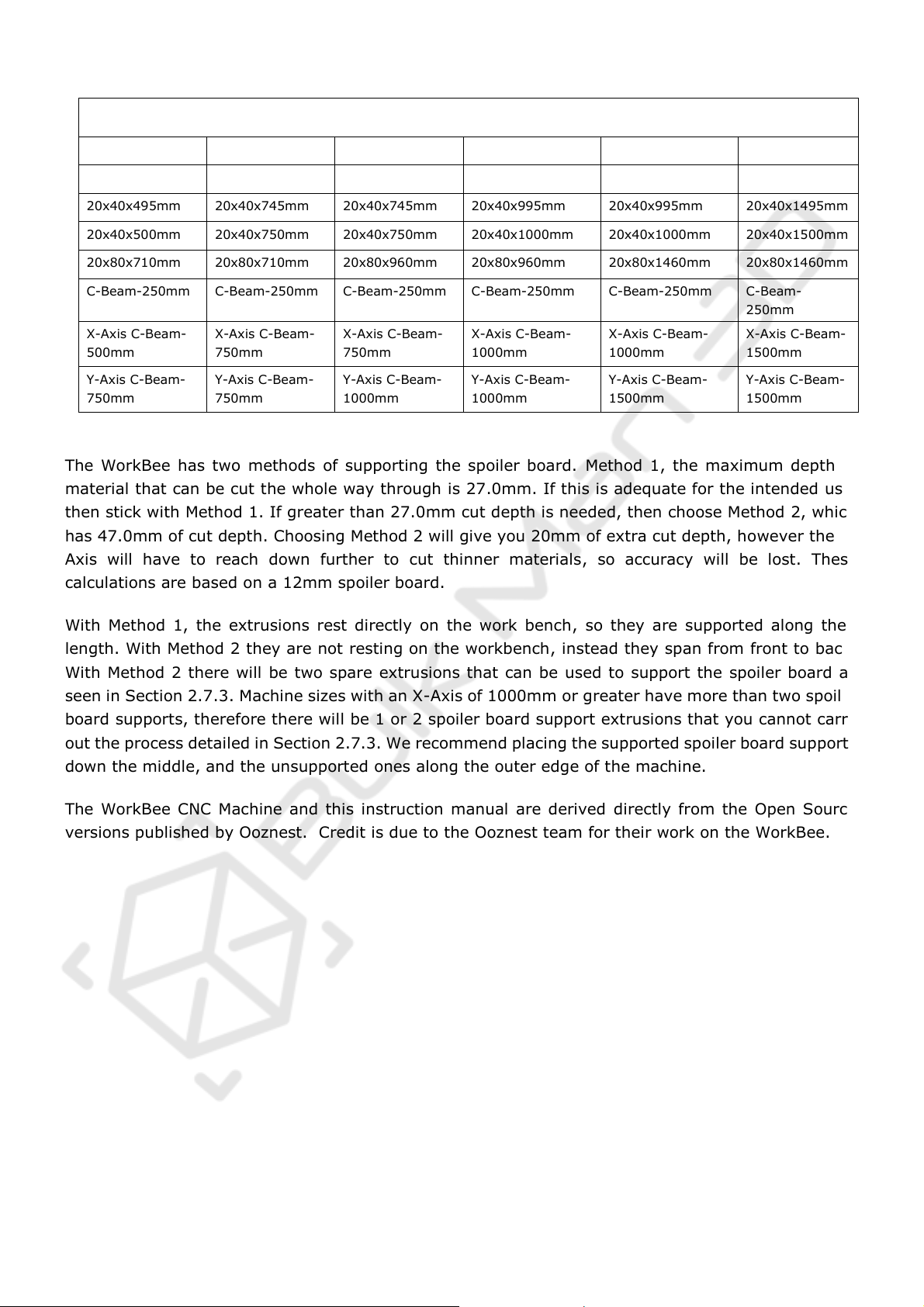

This manual has been written for the construction of a 1500 x 1500 mm screw driven version of the

WorkBee. If you have a different version, everything is the same, except you will be working with

shorter V-Slot extrusions and ACME Lead screws. Use the table below to convert V-Slot dimensions in

this manual to the sizes for your machine.

Check to see if all the V-Slot and C-Beam Extrusion has been tapped, if not then tap to a depth of

around 10mm.

WorkBee CNC 3

Machine Size

500x750mm

750x750mm

750x1000mm

1000x1000mm

1000x1500mm

1500x1500mm

20x40x415mm

20x40x665mm

20x40x665mm

20x40x915mm

20x40x915mm

20x40x1415mm

20x40x495mm

20x40x745mm

20x40x745mm

20x40x995mm

20x40x995mm

20x40x1495mm

20x40x500mm

20x40x750mm

20x40x750mm

20x40x1000mm

20x40x1000mm

20x40x1500mm

20x80x710mm

20x80x710mm

20x80x960mm

20x80x960mm

20x80x1460mm

20x80x1460mm

C-Beam-250mm

C-Beam-250mm

C-Beam-250mm

C-Beam-250mm

C-Beam-250mm

C-Beam-

250mm

X-Axis C-Beam-

500mm

X-Axis C-Beam-

750mm

X-Axis C-Beam-

750mm

X-Axis C-Beam-

1000mm

X-Axis C-Beam-

1000mm

X-Axis C-Beam-

1500mm

Y-Axis C-Beam-

750mm

Y-Axis C-Beam-

750mm

Y-Axis C-Beam-

1000mm

Y-Axis C-Beam-

1000mm

Y-Axis C-Beam-

1500mm

Y-Axis C-Beam-

1500mm

The WorkBee has two methods of supporting the spoiler board. Method 1, the maximum depth of

material that can be cut the whole way through is 27.0mm. If this is adequate for the intended use,

then stick with Method 1. If greater than 27.0mm cut depth is needed, then choose Method 2, which

has 47.0mm of cut depth. Choosing Method 2 will give you 20mm of extra cut depth, however the ZAxis will have to reach down further to cut thinner materials, so accuracy will be lost. These

calculations are based on a 12mm spoiler board.

With Method 1, the extrusions rest directly on the work bench, so they are supported along their

length. With Method 2 they are not resting on the workbench, instead they span from front to back.

With Method 2 there will be two spare extrusions that can be used to support the spoiler board as

seen in Section 2.7.3. Machine sizes with an X-Axis of 1000mm or greater have more than two spoiler

board supports, therefore there will be 1 or 2 spoiler board support extrusions that you cannot carry

out the process detailed in Section 2.7.3. We recommend placing the supported spoiler board supports

down the middle, and the unsupported ones along the outer edge of the machine.

The WorkBee CNC Machine and this instruction manual are derived directly from the Open Source

versions published by Ooznest. Credit is due to the Ooznest team for their work on the WorkBee.

WorkBee CNC 4

2.0 Assembly

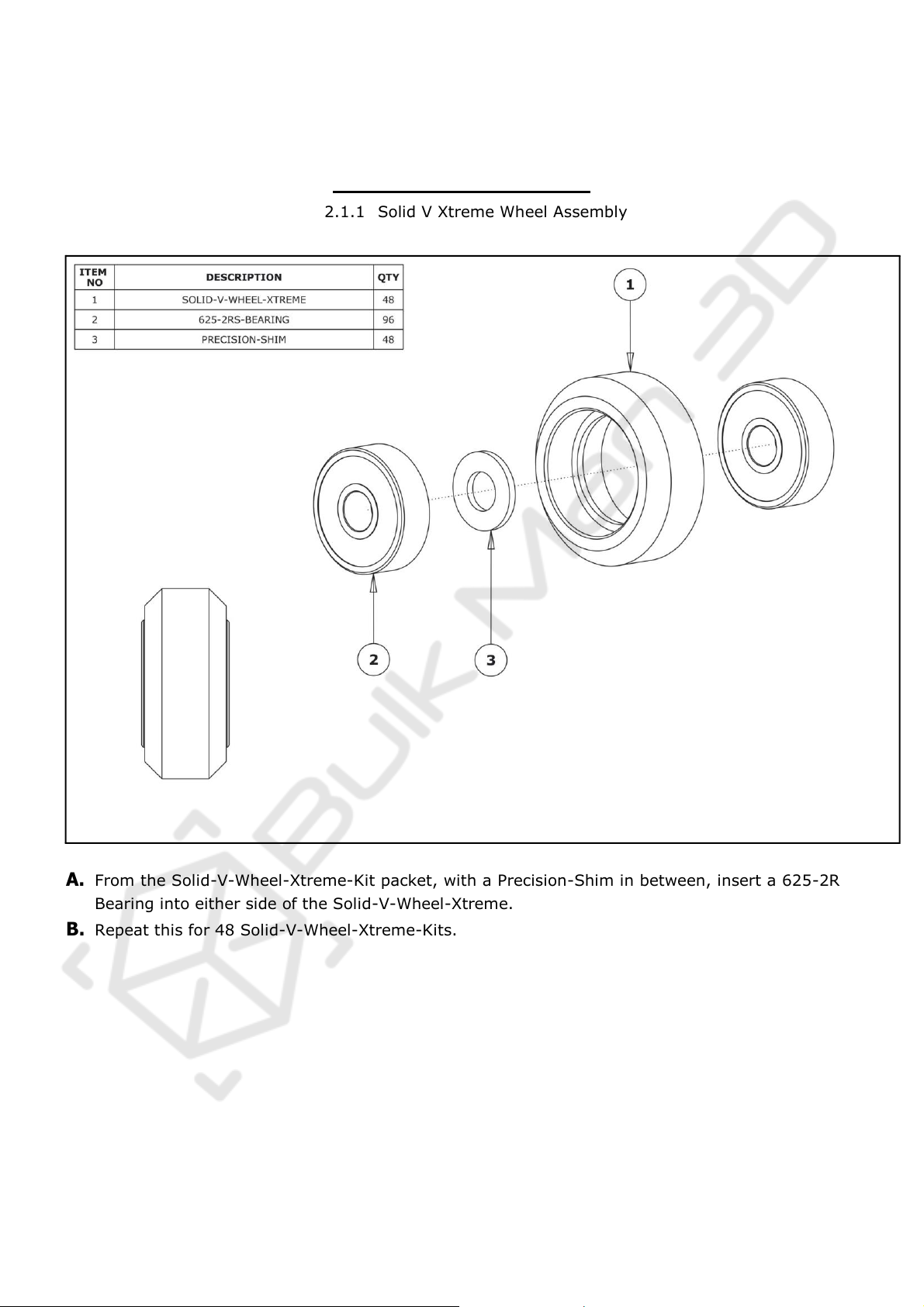

2.1 Wheel Assembly

A. From the Solid-V-Wheel-Xtreme-Kit packet, with a Precision-Shim in between, insert a 625-2RS-

Bearing into either side of the Solid-V-Wheel-Xtreme.

B. Repeat this for 48 Solid-V-Wheel-Xtreme-Kits.

WorkBee CNC 5

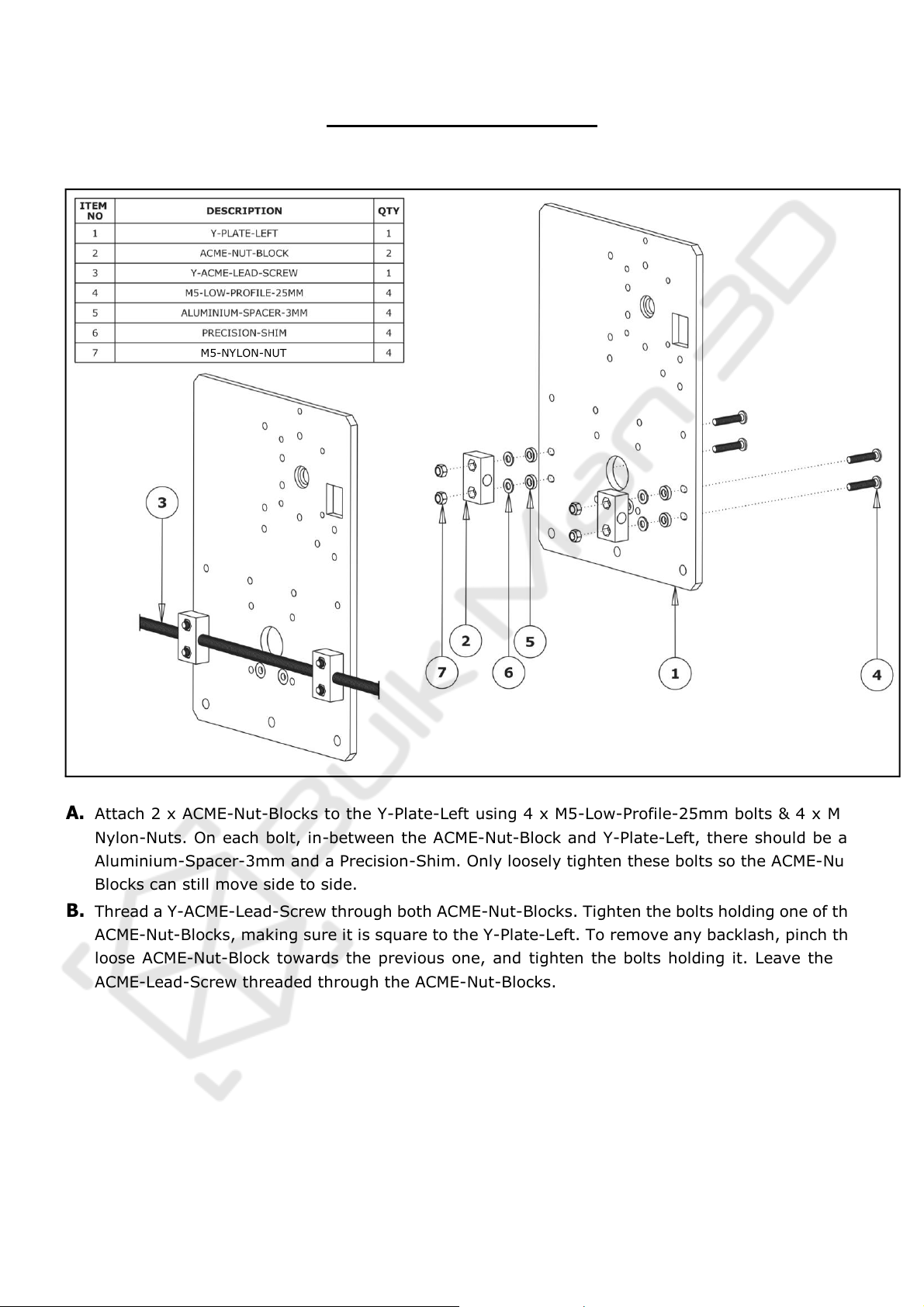

2.2 Y-Plate Assembly

A. Attach 2 x ACME-Nut-Blocks to the Y-Plate-Left using 4 x M5-Low-Profile-25mm bolts & 4 x M5-

Nylon-Nuts. On each bolt, in-between the ACME-Nut-Block and Y-Plate-Left, there should be an

Aluminium-Spacer-3mm and a Precision-Shim. Only loosely tighten these bolts so the ACME-Nut-

Blocks can still move side to side.

B. Thread a Y-ACME-Lead-Screw through both ACME-Nut-Blocks. Tighten the bolts holding one of the

ACME-Nut-Blocks, making sure it is square to the Y-Plate-Left. To remove any backlash, pinch the

loose ACME-Nut-Block towards the previous one, and tighten the bolts holding it. Leave the YACME-Lead-Screw threaded through the ACME-Nut-Blocks.

M5-NYLON-NUT

WorkBee CNC 6

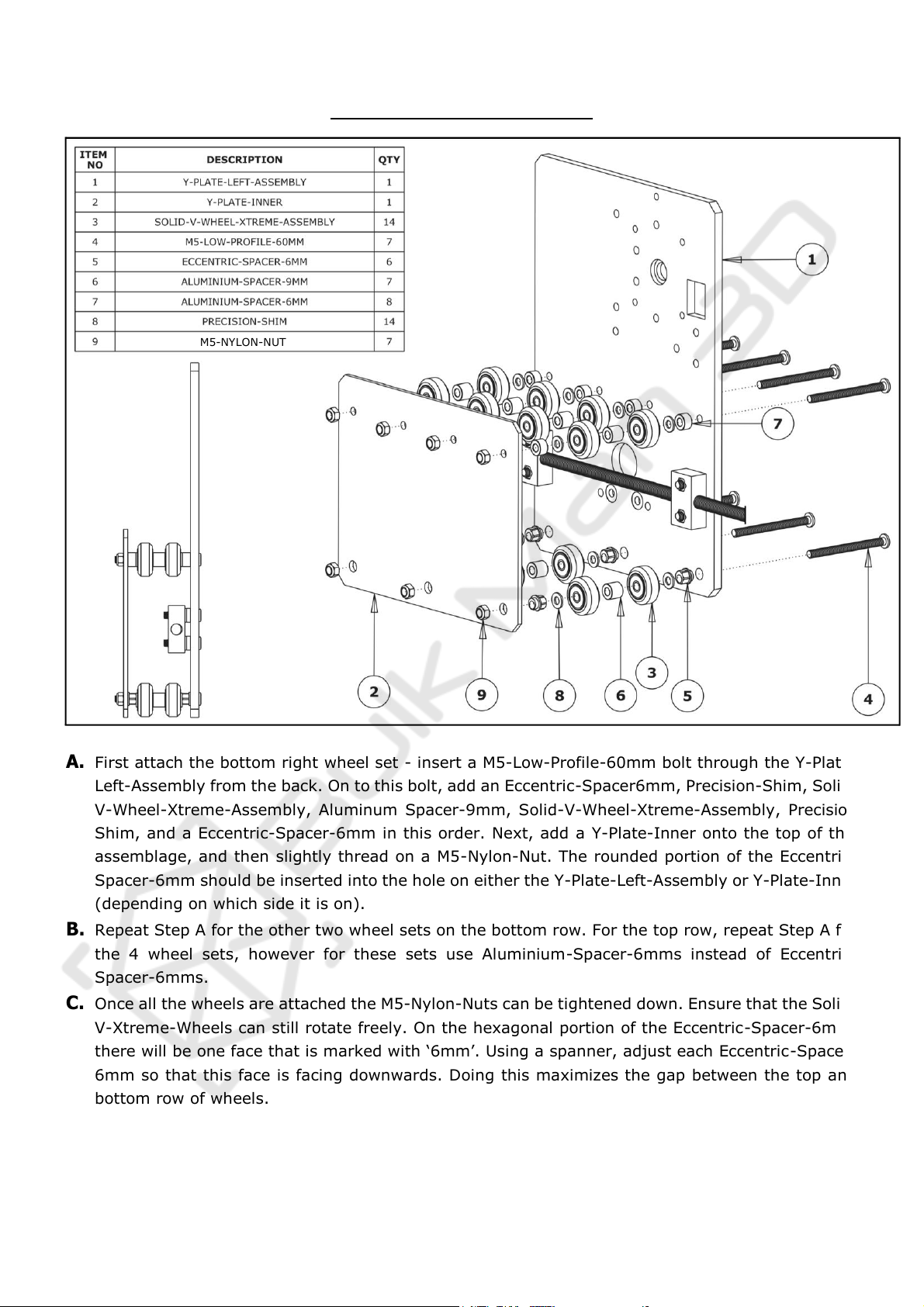

2.2.2 Y Wheels & Y-Plate-Inner

A. First attach the bottom right wheel set - insert a M5-Low-Profile-60mm bolt through the Y-Plate-

Left-Assembly from the back. On to this bolt, add an Eccentric-Spacer6mm, Precision-Shim, Solid-

V-Wheel-Xtreme-Assembly, Aluminum Spacer-9mm, Solid-V-Wheel-Xtreme-Assembly, Precision

Shim, and a Eccentric-Spacer-6mm in this order. Next, add a Y-Plate-Inner onto the top of this

assemblage, and then slightly thread on a M5-Nylon-Nut. The rounded portion of the EccentricSpacer-6mm should be inserted into the hole on either the Y-Plate-Left-Assembly or Y-Plate-Inner

(depending on which side it is on).

B. Repeat Step A for the other two wheel sets on the bottom row. For the top row, repeat Step A for

the 4 wheel sets, however for these sets use Aluminium-Spacer-6mms instead of Eccentric-

Spacer-6mms.

C. Once all the wheels are attached the M5-Nylon-Nuts can be tightened down. Ensure that the Solid-

V-Xtreme-Wheels can still rotate freely. On the hexagonal portion of the Eccentric-Spacer-6mm,

there will be one face that is marked with ‘6mm’. Using a spanner, adjust each Eccentric-Spacer-

6mm so that this face is facing downwards. Doing this maximizes the gap between the top and

bottom row of wheels.

D. Run any piece of C-Beam extrusion in between the two rows of wheels. Initially, the C-Beam will

wobble between the wheels. Turn the assembly upside down so the C-Beam is sitting on the row

of wheels with the Aluminium-Spacer-6mms. Starting with an outside pair of wheels, adjust both

Eccentric-Spacer-6mms down onto the C-Beam Extrusion until there is a small amount of friction

between both wheels and the C-Beam Extrusion. When adjusting the pair of Eccentric-Spacer-

M5-NYLON-NUT

WorkBee CNC 7

6mms ideally they should be adjusted identically. However, sometimes one will need to be

adjusted slightly more than the other to get both wheels engaged with the C-Beam extrusion.

Repeat this for the other outside pair of wheels, and then again for the middle pair.

E. Slide the C-Beam extrusion back and forth through the wheels. This should require a small amount

of force, and all wheels should spin as it rolls. Also check there is no wobbling of the extrusion.

Once happy, double check the tightness of the M5-NylonNuts.

WorkBee CNC 8

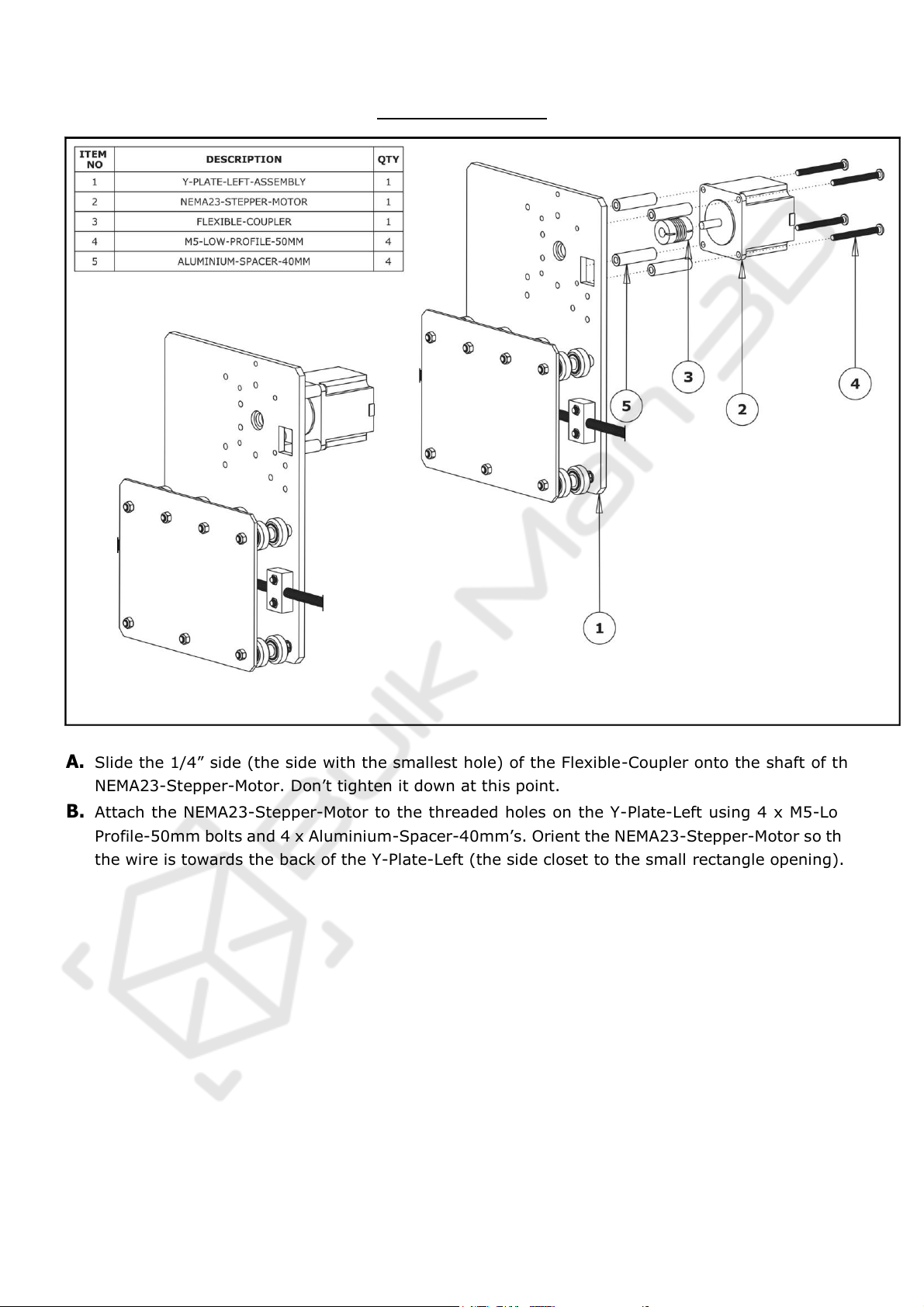

2.2.3 Stepper Motor

A. Slide the 1/4” side (the side with the smallest hole) of the Flexible-Coupler onto the shaft of the

NEMA23-Stepper-Motor. Don’t tighten it down at this point.

B. Attach the NEMA23-Stepper-Motor to the threaded holes on the Y-Plate-Left using 4 x M5-Low-

Profile-50mm bolts and 4 x Aluminium-Spacer-40mm’s. Orient the NEMA23-Stepper-Motor so that

the wire is towards the back of the Y-Plate-Left (the side closet to the small rectangle opening).

WorkBee CNC 9

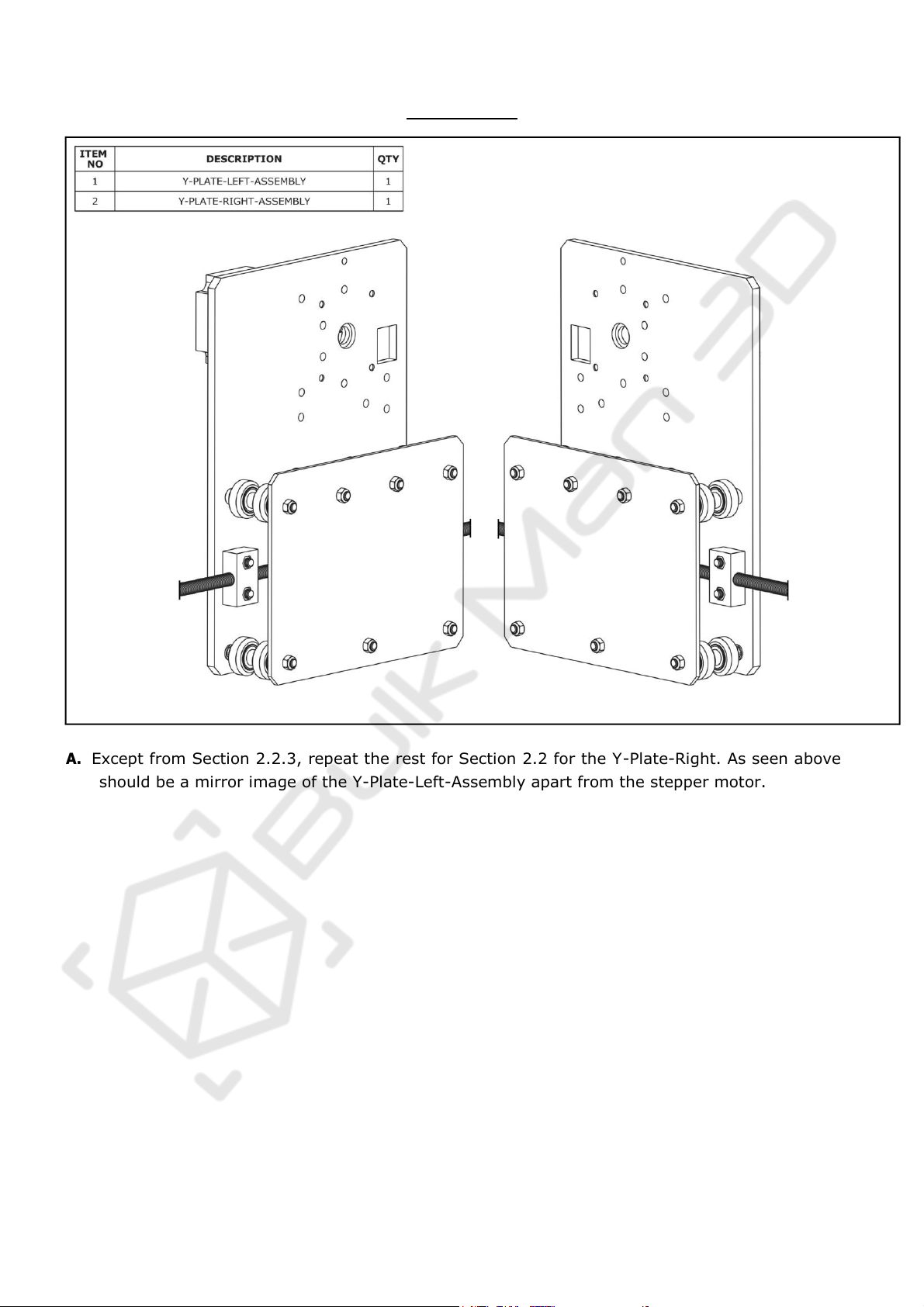

2.2.4 Repeat

A. Except from Section 2.2.3, repeat the rest for Section 2.2 for the Y-Plate-Right. As seen above it

should be a mirror image of the Y-Plate-Left-Assembly apart from the stepper motor.

WorkBee CNC 10

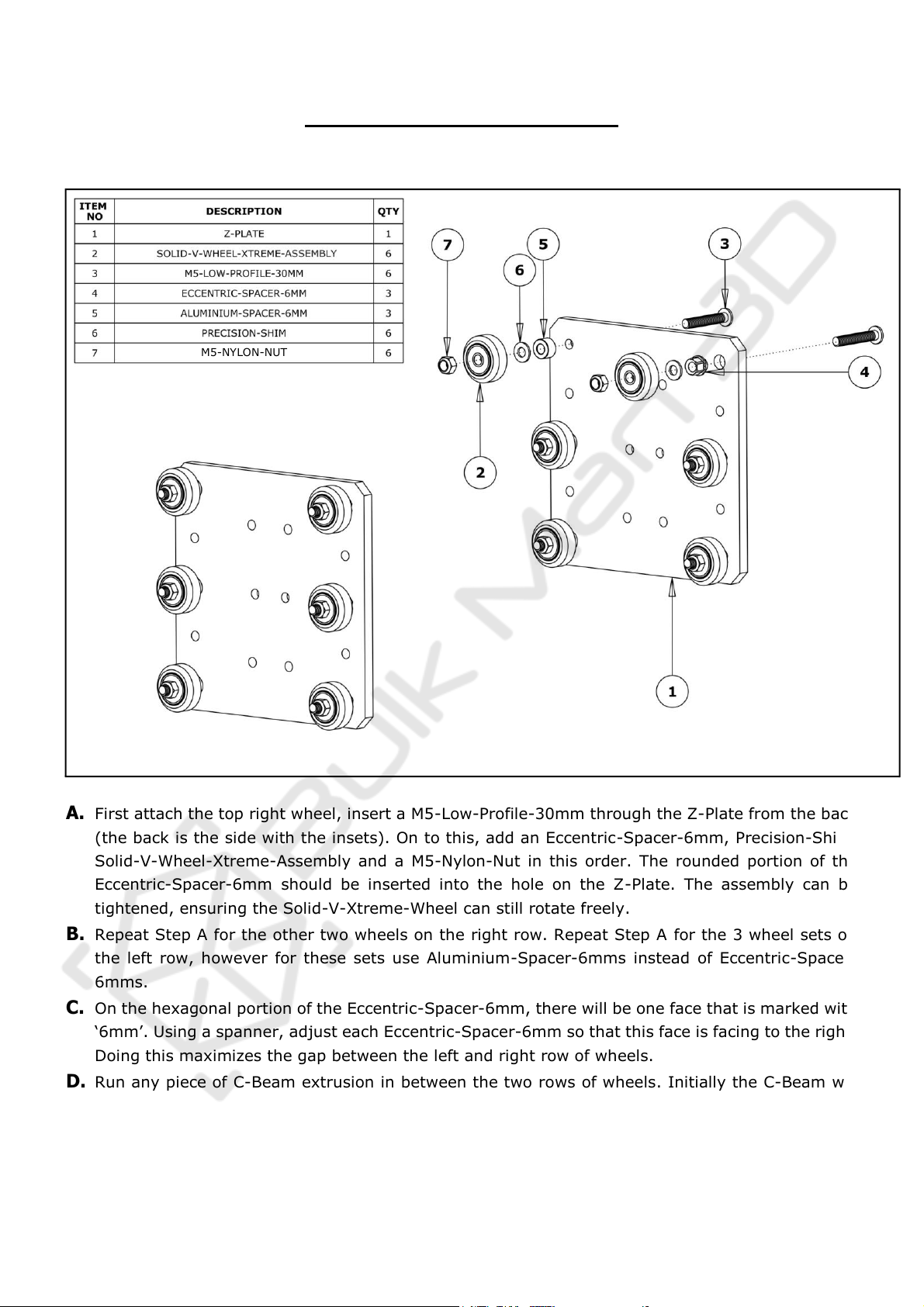

2.3 X-Carriage Assembly

A. First attach the top right wheel, insert a M5-Low-Profile-30mm through the Z-Plate from the back

(the back is the side with the insets). On to this, add an Eccentric-Spacer-6mm, Precision-Shim,

Solid-V-Wheel-Xtreme-Assembly and a M5-Nylon-Nut in this order. The rounded portion of the

Eccentric-Spacer-6mm should be inserted into the hole on the Z-Plate. The assembly can be

tightened, ensuring the Solid-V-Xtreme-Wheel can still rotate freely.

B. Repeat Step A for the other two wheels on the right row. Repeat Step A for the 3 wheel sets on

the left row, however for these sets use Aluminium-Spacer-6mms instead of Eccentric-Spacer-

6mms.

C. On the hexagonal portion of the Eccentric-Spacer-6mm, there will be one face that is marked with

‘6mm’. Using a spanner, adjust each Eccentric-Spacer-6mm so that this face is facing to the right.

Doing this maximizes the gap between the left and right row of wheels.

D. Run any piece of C-Beam extrusion in between the two rows of wheels. Initially the C-Beam will

wobble between the wheels. Turn the assembly so the C-Beam is sitting on the row of wheels with

the Aluminium-Spacer-6mms. Starting with an outside wheel, adjust the Eccentric-Spacer-6mm

down onto the C-Beam Extrusion until there is a small amount of friction between the wheel and

the C-Beam Extrusion. Repeat this for the other outside wheel, and then for the middle wheel.

M5-NYLON-NUT

WorkBee CNC 11

E. Slide the C-Beam extrusion back and forth through the wheels. This should require a small amount

of force, and all wheels should spin as it rolls. Also check there is no wobbling of the extrusion.

Once happy, double check the tightness of the M5-Nylon-Nuts.

Loading...

Loading...