Page 1

DO NOT DISCARD – GIVE TO USER

WARNING

PLEASE DO NOT RETURN ANY PRODUCT WITHOUT CALLING

1-800-221-9705 FOR INSTRUCTIONS

BEFORE USE

Study, understand and follow all instructions

provided with this product. Read these instructions

carefully before installing, operating, servicing or

repairing this tool. Keep these instructions in a safe

accessible place.

INTENDED USE OF THE TOOL

Model: Product Type:

PRODUCT INFORMATION:

This pneumatic tool is designed to set aluminum,

steel and stainless rivet nuts in the sizes M10,

M12, 3/8" and 1/2". Do not use this tool outside of

the designed intent. Never modify the tool for any

other purpose or use.

WARNING

Caution: To help prevent personal injury.

• Normal use of this product is likely to expose the

user to dust and/or microscopic particles containing

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm. Always

wear appropriate safety equipment and clothing when

using this product. Study, understand and follow all

instructions provided with this product. Failure to read

and follow all warnings and operating instructions may

result in damages and serious injury or death.

• Always wear ANSI approved goggles when using this

product. (Users and Bystanders).

• Never use this tool for any application other than for

which it was designed.

• Only use accessories designed for this tool.

• Never alter or modify this tool in any way.

• Improper operation and/or maintenance of the tool,

modification of the tool or use of the tool with

accessories not designed for it could result in serious

injury or death.

• Always select the correct accessories of the correct

size and design for the job that you are attempting to

perform.

• Always work in a clean, safe, well-lit, organized and

adequately equipped area.

• Do not begin repairs without assurance that vehicle is

in secure position and will not move during repair.

1 YEAR LIMITED WARRANTY

• Astro Pneumatic Tool Co. warrants our products to the original

user against defective material or workmanship for a period of

1 year (except where noted on our price schedule) from the

date of 1st use. Astro reserves the right to determine whether

the product failed because of defective material, workmanship

or other causes and to charge back for missing parts.

Astro Pneumatic Tool Co., at its discretion, will repair products

covered under this warranty free of charge. The distributor

should direct the original user to return the product (with the

exceptions listed below) with the distributor’s name, address,

adequate proof of date of purchase or a copy of warranty card,

and a short note explaining the problem.

Failures caused by accident, alteration, or misuse are not

covered by this warranty.

• Astro Pneumatic Tool Co. or its authorized service

representatives must perform all warranty repairs. Any repair

to the product by unauthorized service representatives voids

this warranty. The rights under this warranty are limited to the

original user and may not be transferred to subsequent owners.

• This warranty is in lieu of all other warranties, expressed or

implied, including warranties of merchantability and fitness for

a particular purpose. Some states do not allow the exclusion

of limitations of incidental or consequential damages so the

above limitations may not apply to you.

Before use, check the parts diagram and part

number listing on page 4-6 to make sure all parts

are included. If any parts are missing or damaged,

please call your distributor.

Page 1

ONYX PNEUMATIC

RIVET NUT SETTING GUN

• Two different mandrel sizes provided with each tool

• 400 RPM

• 1/2" (12mm) capacity

• Forward and reverse actions for quick operation

• Adjustable power, dial in regulator setting for

specific rivet nut sizes and compositions

SPECIFICATIONS:

PRN12 PRN12M

Free Speed:

Capacity:

Air Inlet:

Optimal pressure:

Net Weight:

400 RPM

1/2" 12 mm

1/4" (6mm)

Adjust at regulator based on rivet

nut size and material composition

3.489 lbs. (1.58 kgs)

PRN12 - SAE 3/8" & 1/2"

PRN12M - Metric M10 & M12

Page 2

Page 2

Model: Product Type:

ONYX PNEUMATIC

RIVET NUT SETTING GUN

MAINTENANCE INSTRUCTION:

1.) LUBRICATION:

Before connection of the hose, apply 4 to 5 drops of a

good quality air tool oil at the air inlet. After 3 to 4 hours

of operation, oiling may be necessary again.

2.) TIGHTNESS OF PARTS:

Regularly check whether all connection parts are

fastened securely. Follow this procedure daily

before beginning work.

3.) STORAGE:

Avoid storing the tool in a location subject to high

humidity. If the tool is left unused, the residual moisture

inside the tool can cause rust. Before storing and after

operation, oil the tool at the air inlet with a good quality

air tool oil and run it for a short period.

4.) DISPOSAL:

Follow national legislation of waste disposal.

5.) ORDERING SERVICE PART:

For further operational and handling information or

for replacement of parts and components, contact the

sales agent from where you purchased the tool, or the

service division of our company, phone number

800-221-9705.

* When ordering parts and components, give each part

number, name, and quantities.

Users of this tool should review the chemical composition of

the work surface and any products used in conjunction with

this tool for any such chemicals prior to engaging in any

activity that creates dust and/or microscopic particles.

Users should obtain the Material Safety Data Sheets for all

identified chemicals, either from the manufacturer or their

employer, and proceed to study, understand, and follow all

instructions and warnings for exposure to such chemicals.

Some examples of these chemicals are: lead from lead

based paints; crystalline silica from bricks, cement and other

masonry products; and arsenic and chromium from chemically

treated lumber. A listing of the chemicals can be obtained at

www.oehha.ca.gov under Propoisition 65.

In order to reduce their exposure to such chemicals

users should always:

- work in well-ventilated areas.

- wear appropriate safety equipment and clothes that are

specifically designed to filter out microscopic particles.

WARNING

1. The tool shall not be used in potentially explosive

atmospheres.

2. Disconnect the air hose before changing or adjusting

any inserted tools.

3. Before using tool, please confirm all couplings and

plugs are fixed securely. An air hose that is under

pressure may lash out when disconnected and could

lead to serious injuries.

4. Prevent loose clothes, long hair or any other personal

accessories from coming close to moving parts to

reduce the risk of being caught, trapped or drawn into

the rotating spindle.

5. Excessive high air pressure that exceeds the

maximum pressure may cause injuries to user.

6. Exposure to strong vibration for extended time may

cause harm to operator.

7. Be aware of the rotation direction before starting the

tool to reduce hazardous situations due to unexpected

rotation direction.

8. WATCH YOUR STEP! Leaving excess hose

unattended near working area or walk path could

result in injury or death.

9. Wearing eye/face protection could reduce the danger

to person from high speed splinters being emitted from

the tool or work surface.

10. Wearing correct breathing protection will help avoid

inhaliing dust or debries from work process that can be

harmful to your health.

11. High sound levels can cause permanent hearing loss.

Use hearing protection while operating tool.

12. Due to the material being processed, there may be a

risk of explosion or fire. Be aware of work surface

dangers prior to beginning work.

13. There is a risk of being cut due to high speed rotation.

Do not touch high speed rotating disc.

14. This power tool is not insulated. If contact is made with

an electric current, injury may occur.

15. Dust created by sanding, sawing, grinding, drilling and

other related activities may expose the user to dust

and/or microscopic particles that may contain

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

PRN12 - SAE 3/8" & 1/2"

PRN12M - Metric M10 & M12

Page 3

Page 3

Model: Product Type:

ONYX PNEUMATIC

RIVET NUT SETTING GUN

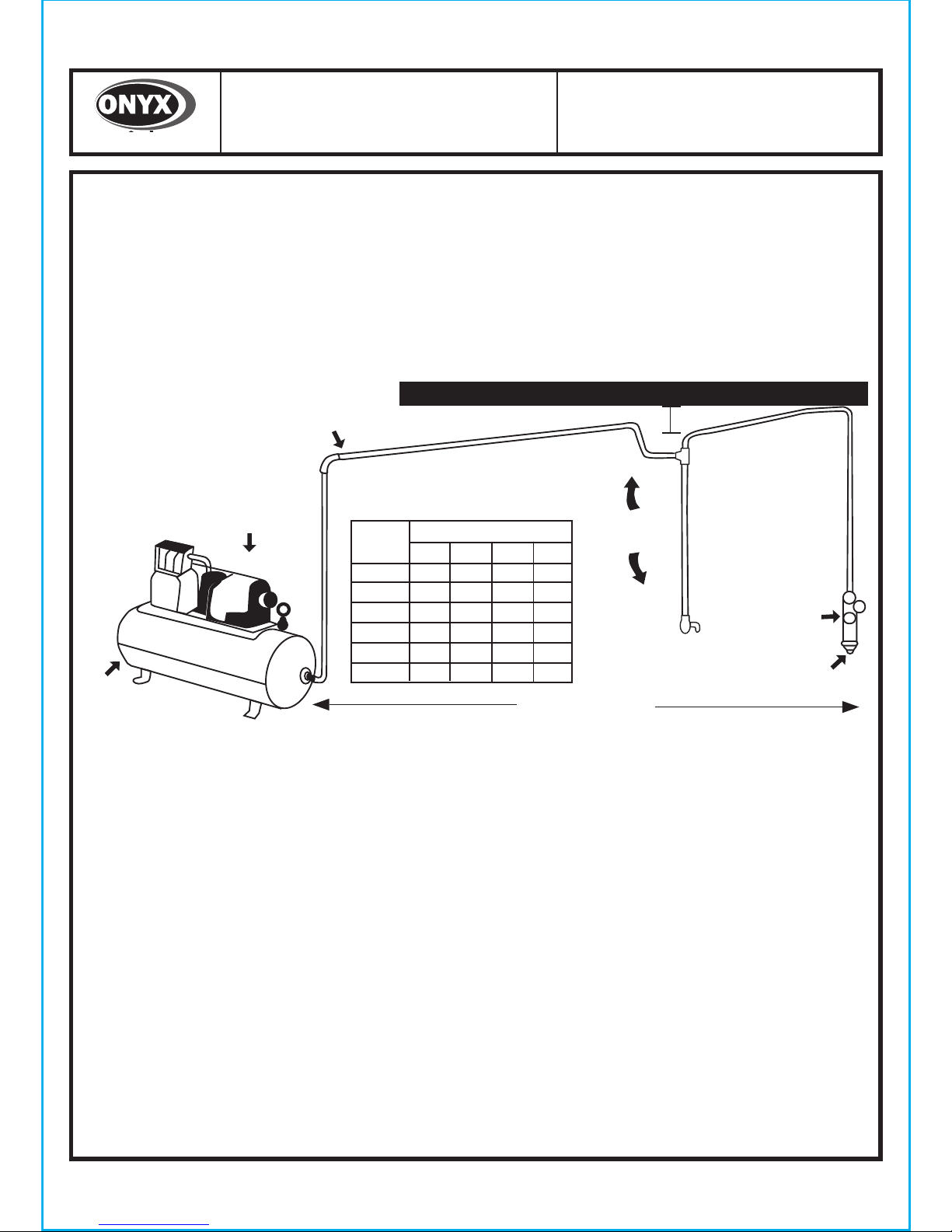

SUGGESTED AIR LINE CONNECTION

Pitch pipe back toward air receiver

Compressor unit

Drain

Daily

25 FEET OR MORE

Oil and Water Extractor should be at least 25 ft. from the compressor. Further if possible.

Drain Daily

Drain

Daily

Oil and Water

Extractor

Install drain at

each low point

PIPE SIZE, I.D. (Inches)

Air Flow

CFM

Length of Pipe (feet)

10

20

30

40

50

70

50

1/2"

3/4"

3/4"

1"

1"

1"

100

3/4"

3/4"

3/4"

1"

1"

1"

150

3/4"

3/4"

1"

1"

1"

1-1/4"

200

3/4"

1"

1"

1"

1-1/4"

The oil and water extractor should not be mounted on or

near the air compressor.

The temperature of air is greatly increased during

compression. As the air cools down to room temperature,

in the air line, on its way to the Air Power Tool, the moisture

contained in it condenses. Thus, for maximum effectiveness,

the oil and water extractor should be mounted at some point

in the air supply system where the temperature of the

compressed air in the line is likely to be lowest. Air lines must

be properly drained daily. Each low point in an air line acts as

a water trap. Such points should be fitted with an easily

accessible drain. See diagram below. Pitch all air lines back

towards the compressor so that condensed moisture will flow

back into the air receiver where it can be drained off.

Drain daily.

PRN12 - SAE 3/8" & 1/2"

PRN12M - Metric M10 & M12

Page 4

Page 4

Model: Product Type:

ONYX PNEUMATIC

RIVET NUT SETTING GUN

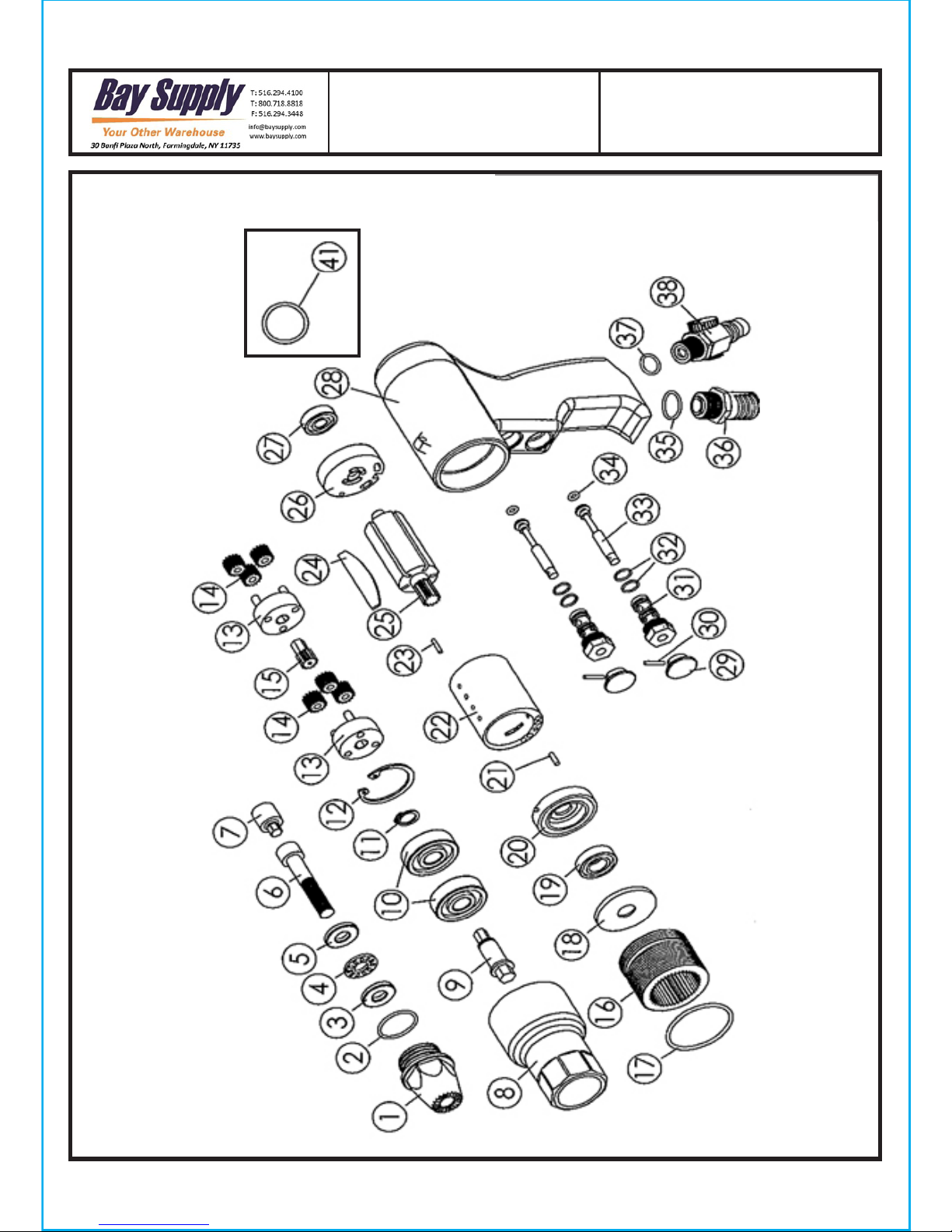

PARTS BREAKDOWN

705

PRN12 - SAE 3/8" & 1/2"

PRN12M - Metric M10 & M12

Page 5

Page 5

Model: Product Type:

ONYX PNEUMATIC

RIVET NUT SETTING GUN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Index Part No.

Qty

PRN12-01A

PRN12-01B

PRN-GUNXL-02

PRN12-03A

PRN12-03B

PRN12-04A

PRN12-04B

PRN12-05A

PRN12-05B

PRN12-06A

PRN12-06B

PRN12-07A

PRN12-07B

PRN-GUNXL-08

PRN-GUNXL-09

PRN-GUNXL-10

PRN-GUNXL-11

PRN-GUNXL-12

PRN-GUNXL-13

PRN-GUNXL-14

PRN-GUNXL-15

PRN-GUNXL-16

PRN-GUNXL-17

PRN-GUNXL-18

Hexagonal Head

10m/m (3/8")

Hexagonal Heag 1/2"

O-Ring

Washer 10m/m (3/8")

Washer 12m/m (1/2")

Bearing 10m/m (3/8")

Bearing 12m/m (1/2")

Washer 10m/m (3/8")

Washer 12m/m (1/2")

Screw 3/8"

Screw 1/2"

Hexagonal Guiding Rod

10m/m (3/8")

Hexagonal Guiding Rod

12m/m (1/2")

Front Housing

Bearing Rod

Bearing

C-buckle

C-buckle

Gear Housing & Pin

Gear

Transmission Gear

Internal Gear

O-Ring

Washer

Description Qty

PRN-GUNXL-19

PRN-GUNXL-20

PRN-GUNXL-21

PRN-GUNXL-22

PRN-GUNXL-23

PRN-GUNXL-24

PRN-GUNXL-25

PRN-GUNXL-26

PRN-GUNXL-27

PRN-GUNXL-28

PRN-GUNXL-29

PRN-GUNXL-30

PRN-GUNXL-31

PRN-GUNXL-32

PRN-GUNXL-33

PRN-GUNXL-34

PRN-GUNXL-35

PRN-GUNXL-36

PRN-GUNXL-37

PRN-GUNXL-38

PRN-GUNXL-39

PRN12-40A

PRN12-40B

PRN-GUNXL-41

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Bearing

Front End Plate & Pin

Pin

Cylinder

Pin

Rotor Blade

Rotor

Rear End Plate

Bearing

Housing

Push Button

Pin

Valve Bushing

O-Ring

Switch Axis

O-Ring

O-Ring

Silencer Part

O-Ring

Adjuster Part

Switch Part(#27~#32)

Hexagonal Head Part

3/8"(#1~#7)

Hexagonal Head Part

1/2"(#1~#7)

Ring

1

1

1

1

1

5

1

1

1

1

2

2

2

4

2

2

1

1

1

1

2

1

1

1

Index Part No. Description

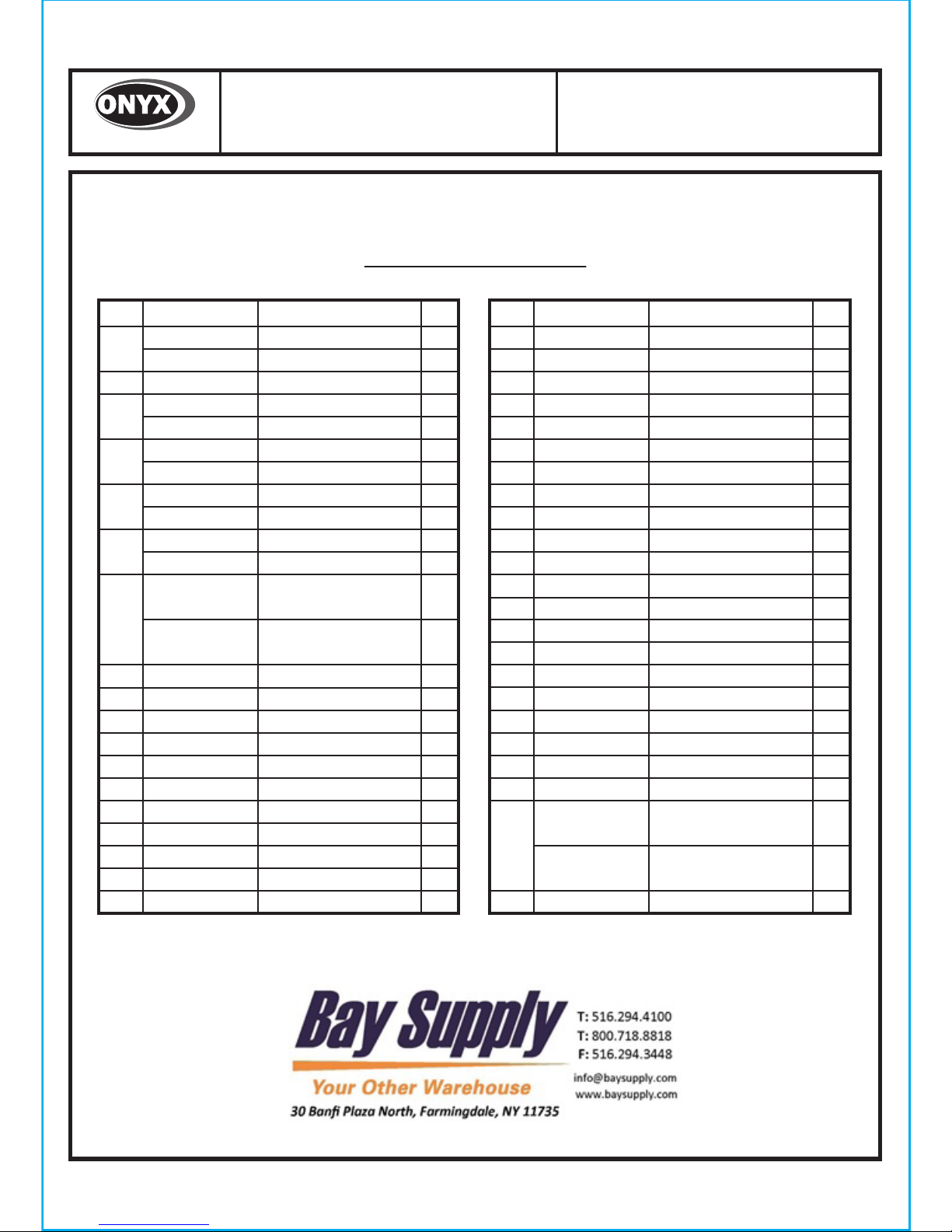

PRN12 Parts List

705

PRN12 - SAE 3/8" & 1/2"

PRN12M - Metric M10 & M12

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

6

1

1

1

1

Page 6

Page 6

Model: Product Type:

ONYX PNEUMATIC

RIVET NUT SETTING GUN

PRN12M Parts List

705

PRN12 - SAE 3/8" & 1/2"

PRN12M - Metric M10 & M12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Index Part No.

Qty

PRN12M-01A

PRN12M-01B

PRN-GUNXL-02

PRN12M-03A

PRN12M-03B

PRN12M-04A

PRN12M-04B

PRN12M-05A

PRN12M-05B

PRN12M-06A

PRN12M-06B

PRN12M-07A

PRN12M-07B

PRN-GUNXL-08

PRN-GUNXL-09

PRN-GUNXL-10

PRN-GUNXL-11

PRN-GUNXL-12

PRN-GUNXL-13

PRN-GUNXL-14

PRN-GUNXL-15

PRN-GUNXL-16

PRN-GUNXL-17

PRN-GUNXL-18

Hexagonal Head 10m/m

Hexagonal Heag 12m/m

O-Ring

Washer 10m/m

Washer 12m/m

Bearing 10m/m

Bearing 12m/m

Washer 10m/m

Washer 12m/m

Screw 10m/m

Screw 12m/m

Hexagonal Guiding Rod

10m/m

Hexagonal Guiding Rod

12m/m

Front Housing

Bearing Rod

Bearing

C-buckle

C-buckle

Gear Housing & Pin

Gear

Transmission Gear

Internal Gear

O-Ring

Washer

Description Qty

PRN-GUNXL-19

PRN-GUNXL-20

PRN-GUNXL-21

PRN-GUNXL-22

PRN-GUNXL-23

PRN-GUNXL-24

PRN-GUNXL-25

PRN-GUNXL-26

PRN-GUNXL-27

PRN-GUNXL-28

PRN-GUNXL-29

PRN-GUNXL-30

PRN-GUNXL-31

PRN-GUNXL-32

PRN-GUNXL-33

PRN-GUNXL-34

PRN-GUNXL-35

PRN-GUNXL-36

PRN-GUNXL-37

PRN-GUNXL-38

PRN-GUNXL-39

PRN12M-40A

PRN12M-40B

PRN-GUNXL-41

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Bearing

Front End Plate & Pin

Pin

Cylinder

Pin

Rotor Blade

Rotor

Rear End Plate

Bearing

Housing

Push Button

Pin

Valve Bushing

O-Ring

Switch Axis

O-Ring

O-Ring

Silencer Part

O-Ring

Adjuster Part

Switch Part(#27~#32)

Hexagonal Head Part

10m/m(#1~#7)

Hexagonal Head Part

12m/m(#1~#7)

Ring

1

1

1

1

1

5

1

1

1

1

2

2

2

4

2

2

1

1

1

1

2

1

1

1

Index Part No. Description

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

6

1

1

1

1

Loading...

Loading...