Onuyo HT-R495 User Manual

Ref.No. : 4862

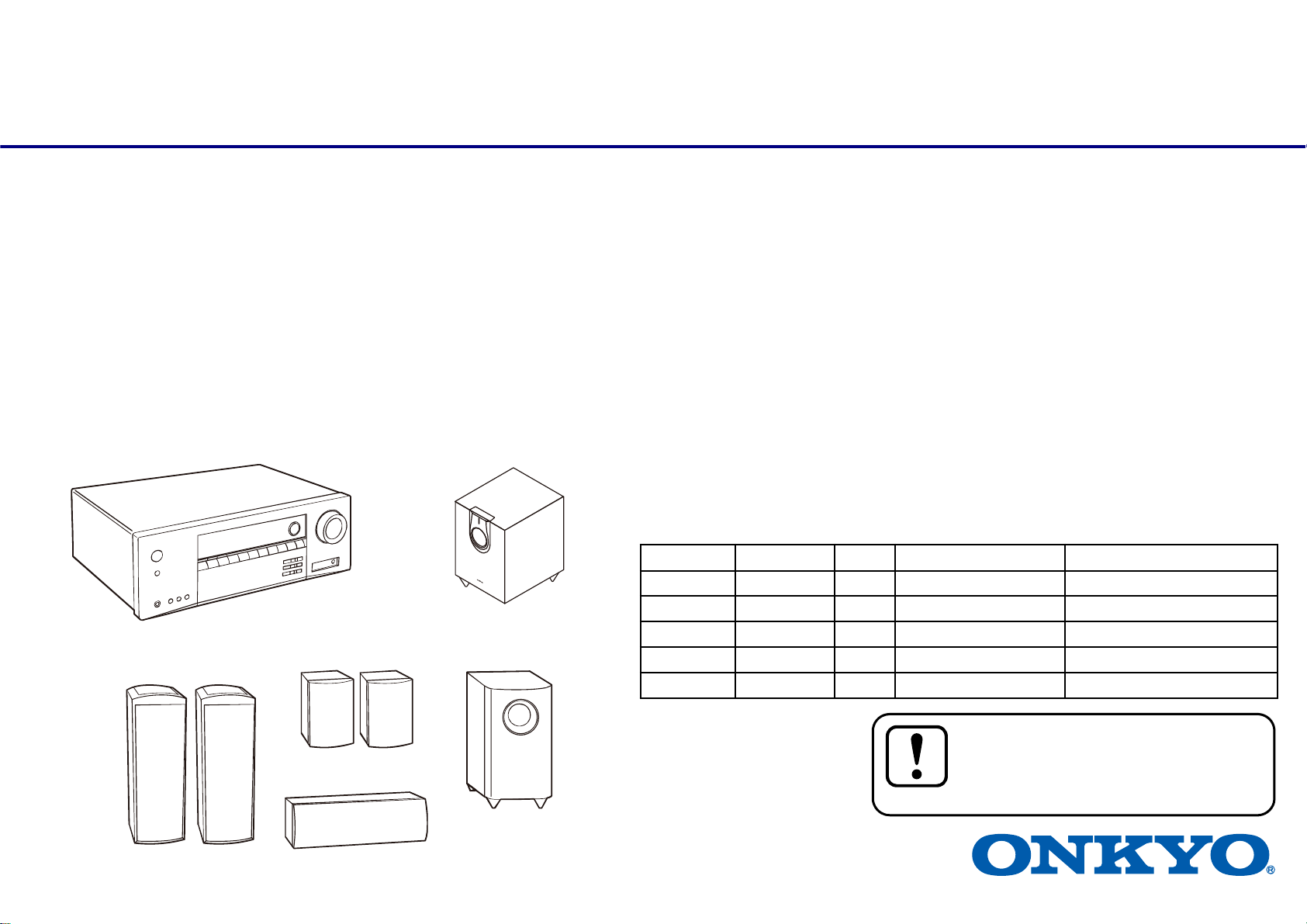

AV Receiver

Service Manual

HT-R495

Final Issue

HT-S5910(B) = HT-R495(B) + HTP-596(B)(SKF-596(B)+SKC-594(B)+SKR-594(B)+SKW-593(B))

HT-S5915(B) = HT-R495(B) + HTP-598(K)(SKF-596(K)+SKC-594(K)+SKR-594(K)+SKW-658(B))

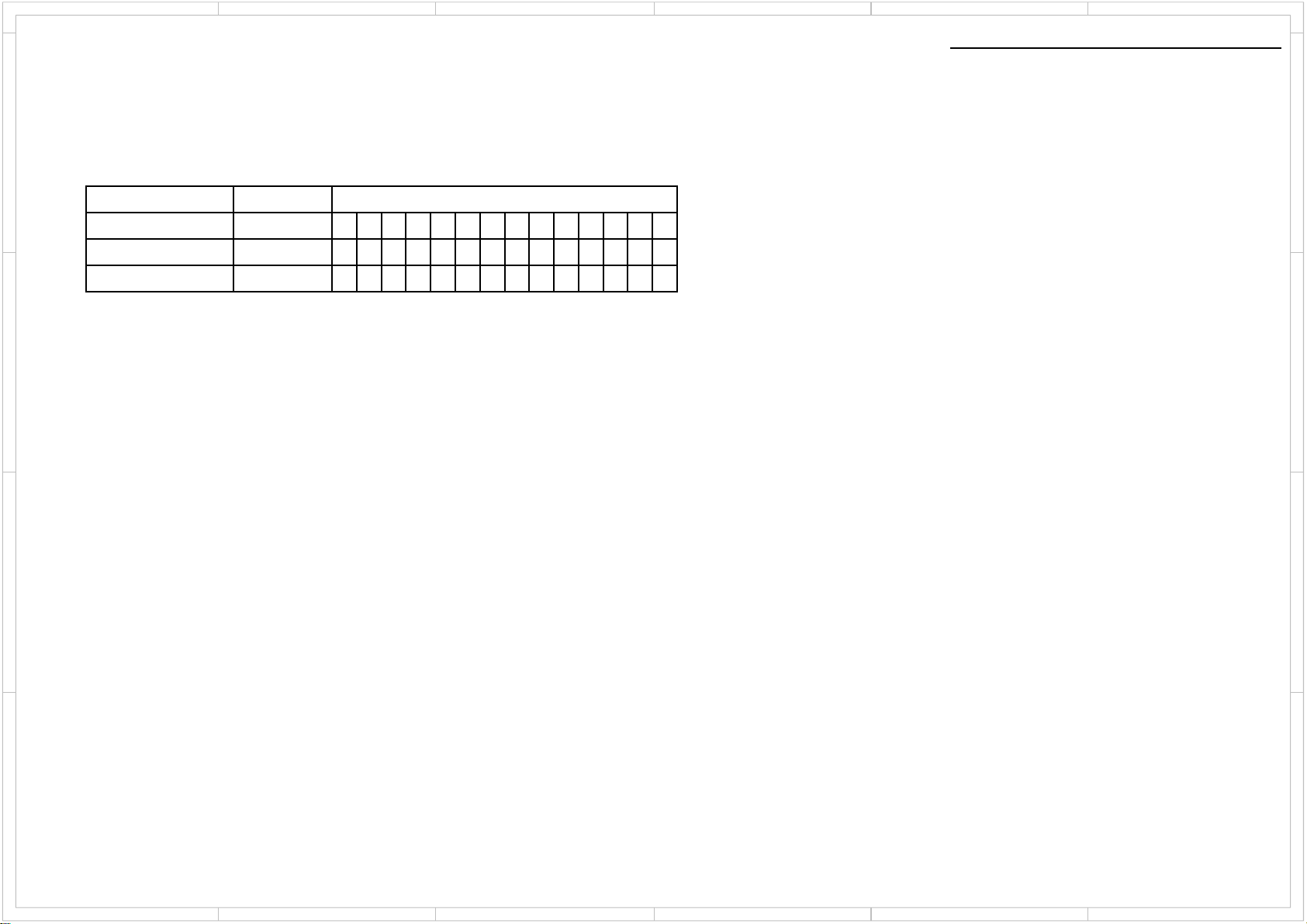

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Color Type Power Requirement Remarks

HT-R495 (B) – Black MDC AC 120 V Canada/USA

HT-R495

SKW-593

(For HT-S5910)

HT-R495 (B) – Black MMP AC 220 V to 240 V Europe

HT-R495 (B) – Black MMB AC 220 V to 240 V UK

HT-R495 (B) – Black MMT AC 220 V to 240 V Thailand

HT-R495 (B) – Black MMA AC 220 V to 240 V Australia/New Zealand

SKF-596

SKR-594

SKC-594

For details, refer to "Important Check Points for good servicing".

SKW-658

(For HT-S5915)

Published by Onkyo & Pioneer Corporation Global CS Department 2019

1

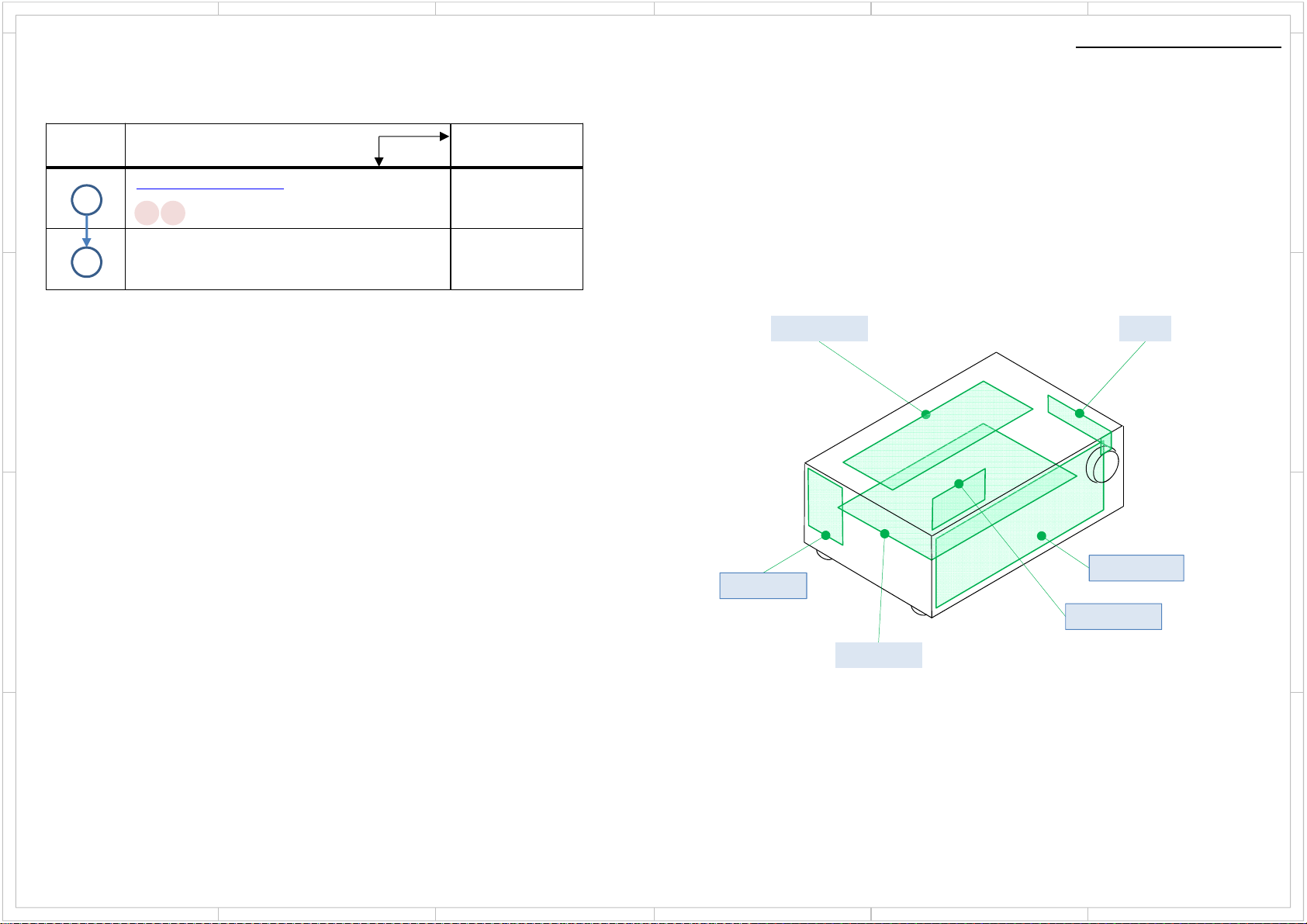

Important Check Points for Good Servicing

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by following the safety instructions described in this manual.

D

C

B

2. Adjustments

3. Lubricants, Glues, and Replacement parts

A

4. Cleaning

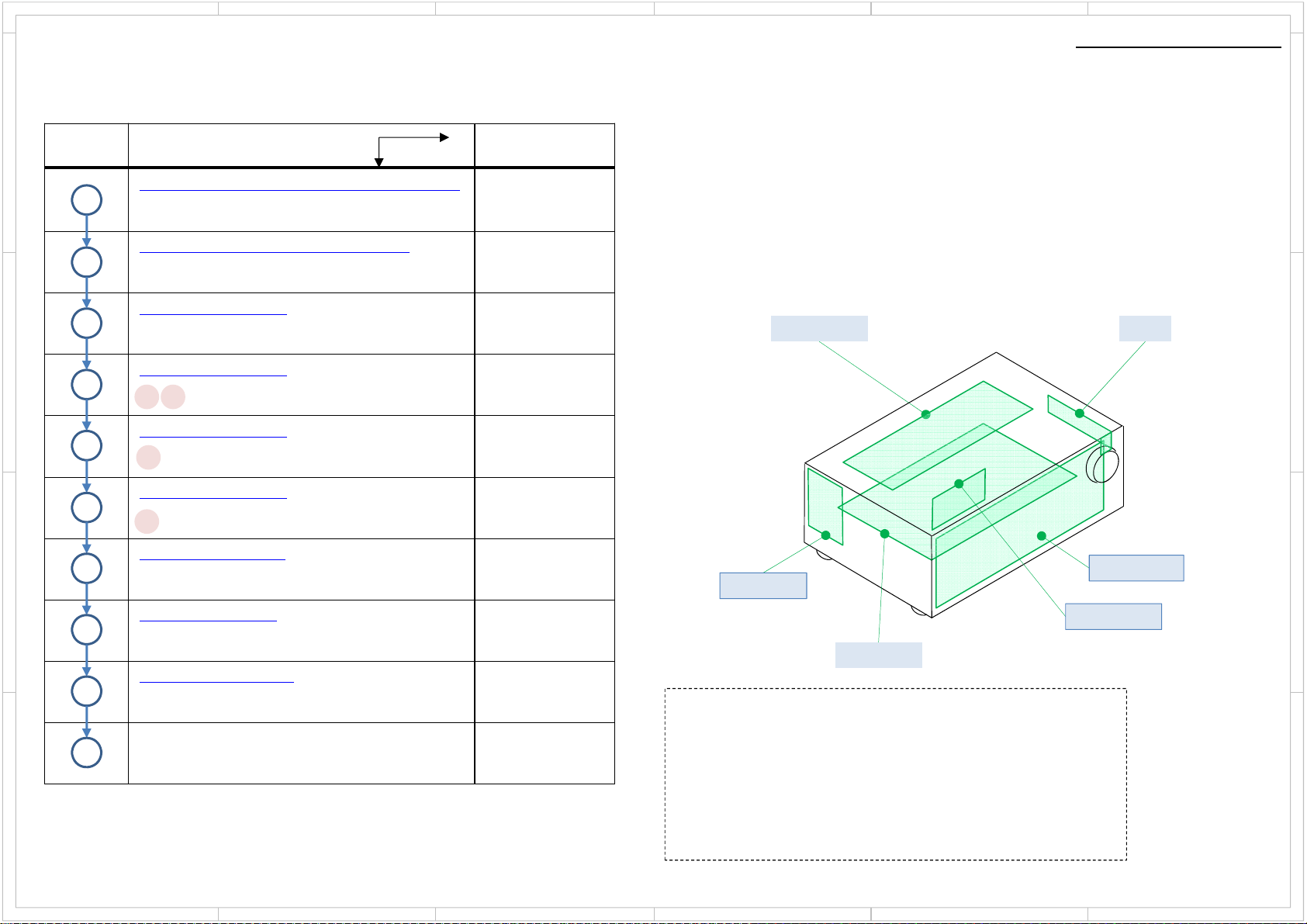

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity.

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure connections and suitable usage.

Please exchange the power cord if necessary.

10 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

Also, No Adjustments should be performed in accordance without the procedures/instructions described in this manual, such as the tuner pack.

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper cleaning should be performed to restore their performances.

5432

6

Service Notes

D

C

B

A

Common

1

5432

6

1

Service Notes

1. Safety-related component warning!!

5432

6

Service Notes

D

Components identified by mark on the schematic diagram and by mark “!” in the parts list are critical for risk of fire and electrical

D

shock. Replace these components with ONKYO parts whose part numbers appear as shown in this manual.

2. Safety check after servicing

(1) To ensure safety, check that the covered insulating sheet or tube are removed, all parts and wires which are removed or

disconnected while servicing have been put back to their original positions after servicing.

(2) To insure structural integrity, check that all the screws or mechanical parts have been put back in their original positions after

servicing.

(3) Check that in the process of servicing or replacing parts that the surrounding area has not been contaminated or adversely affected.

(4) After servicing an insulation check on the external metal connectors and between the blades of the power plug must be performed.

C

Method of checking insulation resistance

C

Unplug the power cord and short the both ends of the plug with a jumper wire.

Using a 500V insulation resistance tester, check that the insulation resistance value between the plug of the power cord

and externally exposed metal parts is 1MΩ or greater.

※The mechanical power switch should be turned on if it is available.

3. Caution on replacing the battery

Danger of explosion if rechargeable batteries is incorrectly replaced. Replace only with the same or equivalent type recommended by the

manufacturer. When disposing of used batteries, please comply with governmental regulations or environmental public institution’s rules

that apply in your country / area.

B

4. Other Cautions

B

・When AC plug is non-polarized and if Main or Primary fuse enters in the Neutral line of AC Mains supply or if there is possibility of Main

or Primary Fuse entering in the Neutral line of AC Mains supply, then AC Mains supply must be disconnected to de-energize the circuit.

・Be sure to use only lead free solder.

・When soldering, please be careful not to use too much solder and affect adjacent components.

・When you repair the CD Player, Please do not stare into the beam in Optical Instruments and do not view directly since there is visible

and invisible laser radiation when open the unit.

A

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer. Qualified technicians have the necessary test

equipment and tools, and have been trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty. If you are not qualified to perform the

repair of this product properly and safely, you should not risk trying to do so and refer the repair to a qualified service technician.

1

5432

A

Common

6

1

File Name of Parts List File (EXCEL File)

When parts list is EXCEL file, please refer to the following explanation about file name.

5432

6

Note for Parts List

D

D

P L _ T X – S R 3 4 3 ( B ) M J J . x l s x

ModelNo. Color

C

Color

(X) Not related to color

(B) Black (M) Wood

(BR) Brown (O) Orange

(C) Cream (P) Pink

(G) Gold (R) Red

B

A

(GR) Green (S) Silver

(H) Gray (T) Titan

(K) Black (V) Violet

(L) Blue (W) White

(LB) Light Blue (Y) Yellow

Voltage Destination

D AC 120 V

G AC 220 V to 230 V

H AC 220 V to 230 V / 240 V

J AC 100 V

L AC 100 V to 120 V

M AC 220 V to 240 V

P AC 230 V

U AC 100 V to 240 V

V AC 110 V to 240 V

W AC 120 V / 220 V to 240 V

Z ※1

Speaker System (without AMP.) :

0 Passive Subwoofer

F Front Speaker

C Center Speaker

R Rear Speaker

B Back Speaker

A Australia

B United Kingdom

C North America

DUSA

FTaiwan

J Japan

K Korea

L Russia

P Europe

Q Hong Kong

R China

S Brazil

T Thai

U Worldwide

Destination

Look at the rear panel serial number 6 digit.

○○○○○ J ○○○○○○○○○○

Voltage

Look at the rear panel serial number 5 digit.

○○○○ J ○○○○○○○○○○○

C

Speaker System (without AMP.) :

L Left channel

R Right channel

0 Center channel

B

A

※1 There is a charge function and a power supply (adapter) is needed, but an adapter isn't bundled.

1

Common

5432

6

1

5432

6

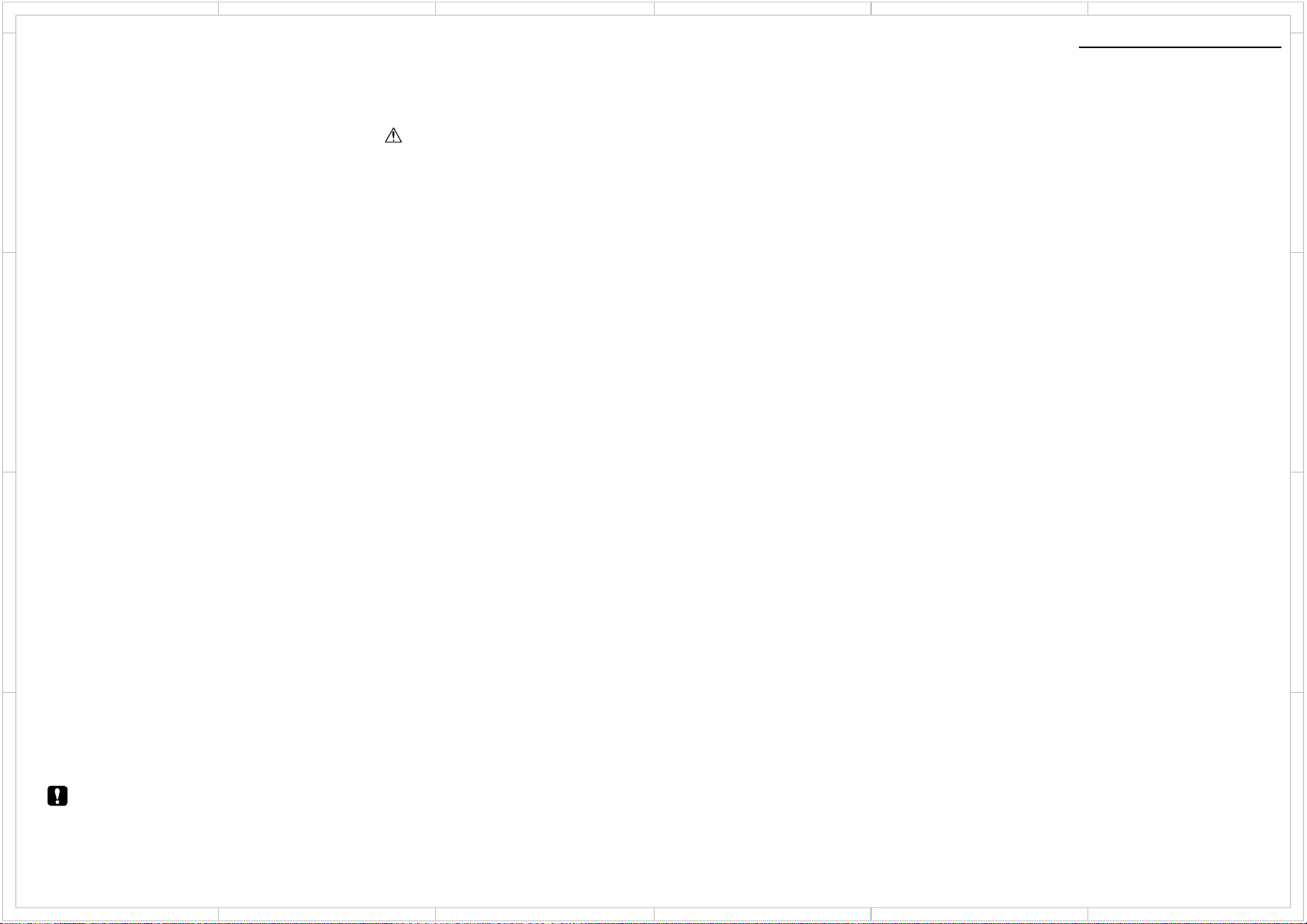

Reset

【STORE】

D

【RESET】

C

【RECALL】

Reset

D

[SETUP]+[ENTER]x2

1.[CBL/SAT]+[ON/STANDBY]

2.UnplugthepowercordfromAVRafterthedisappeared"Clear“ofFLtubeandAVRgoesstandby.

C

[SETUP]+[RETURN]x2

DetailKeyOperationishere.

B

A

1

B

A

Common

5432

6

1

2

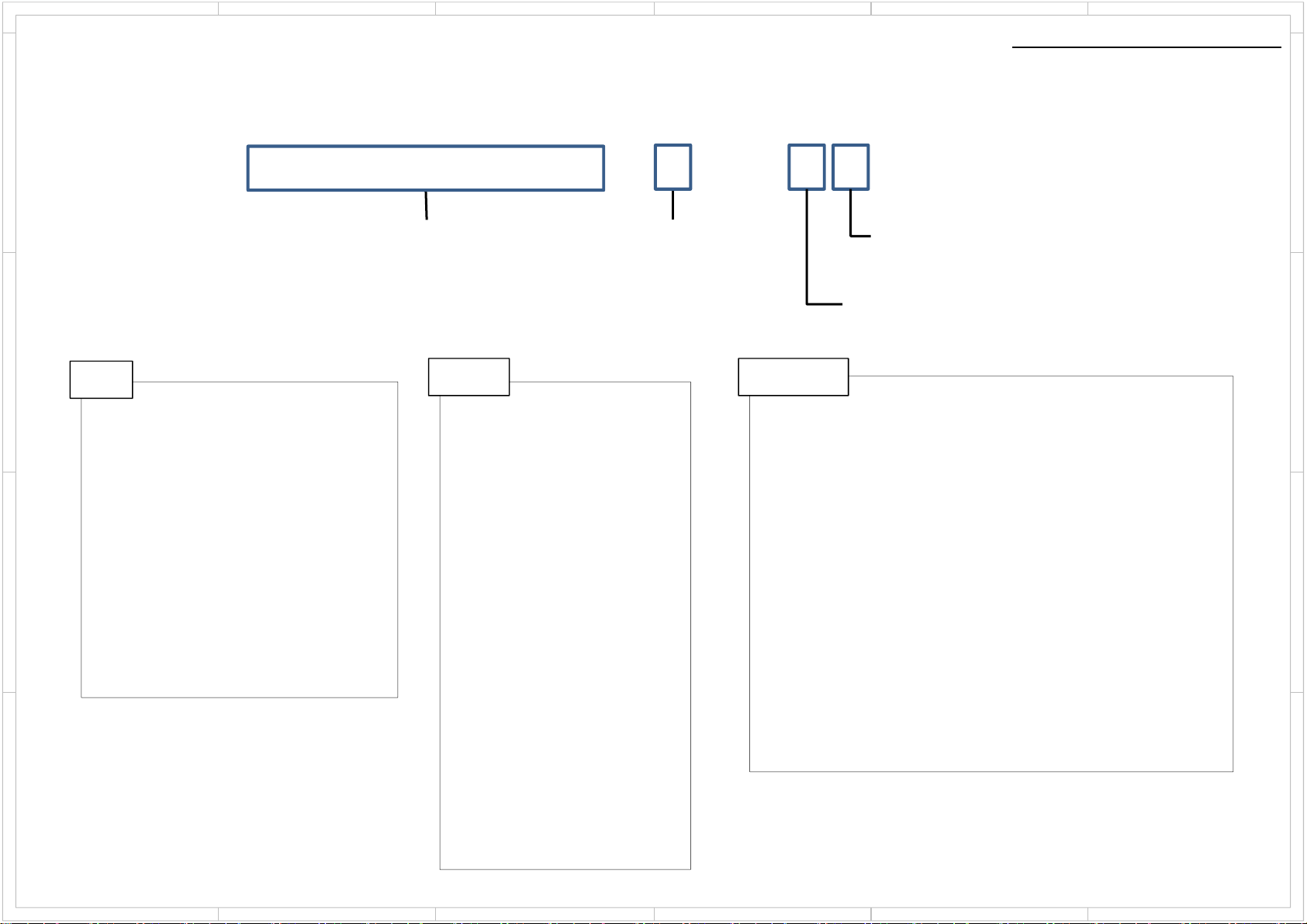

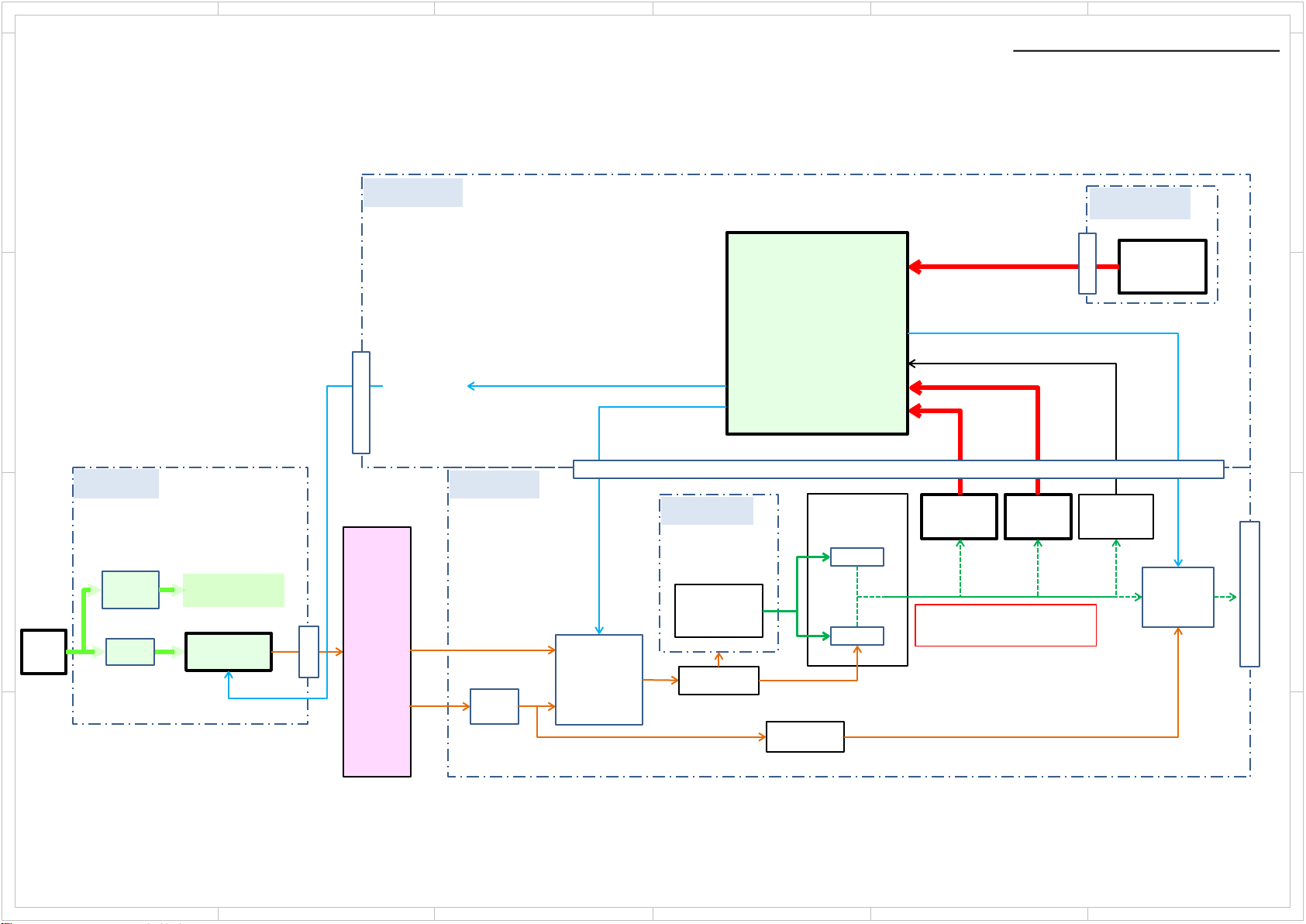

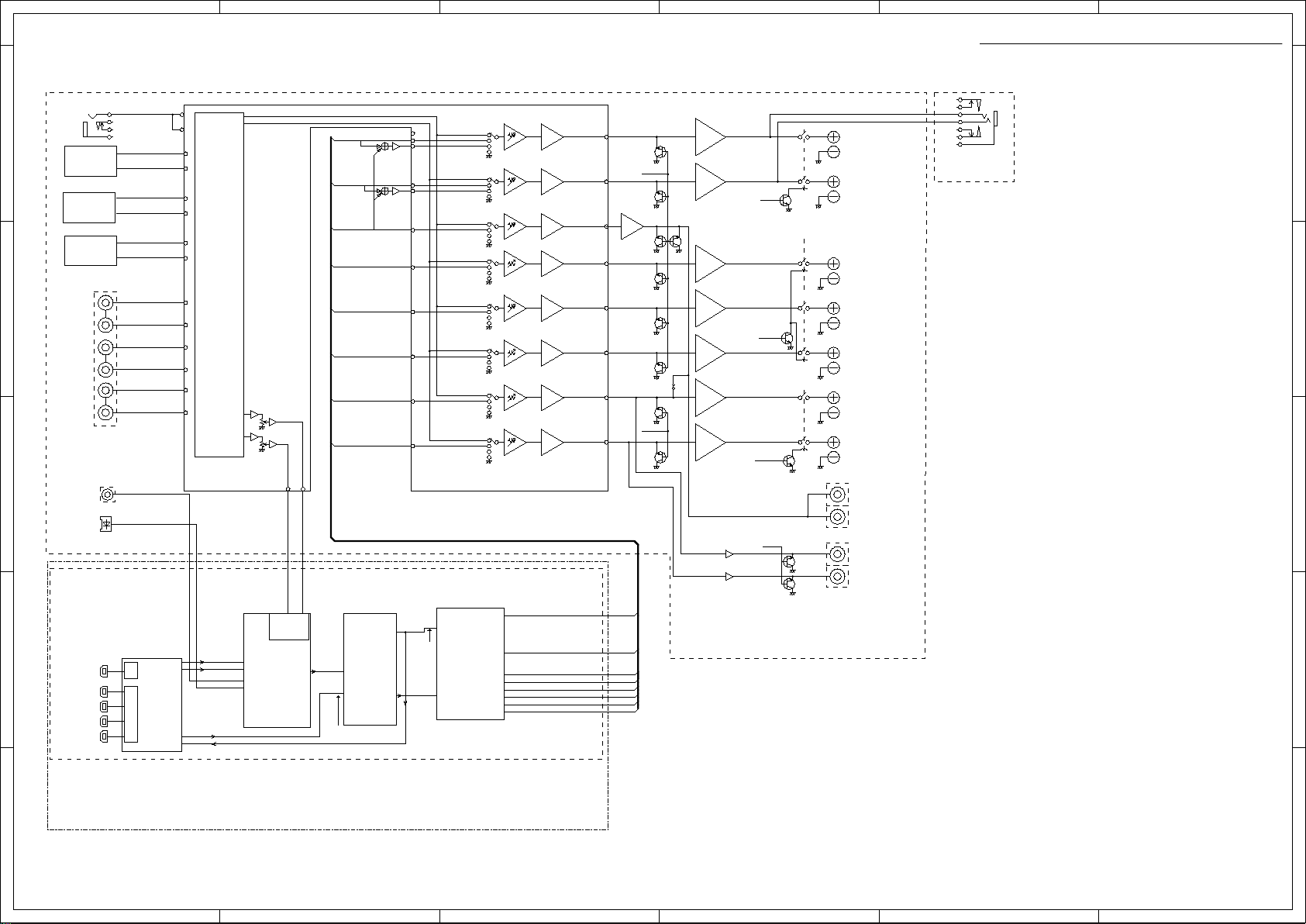

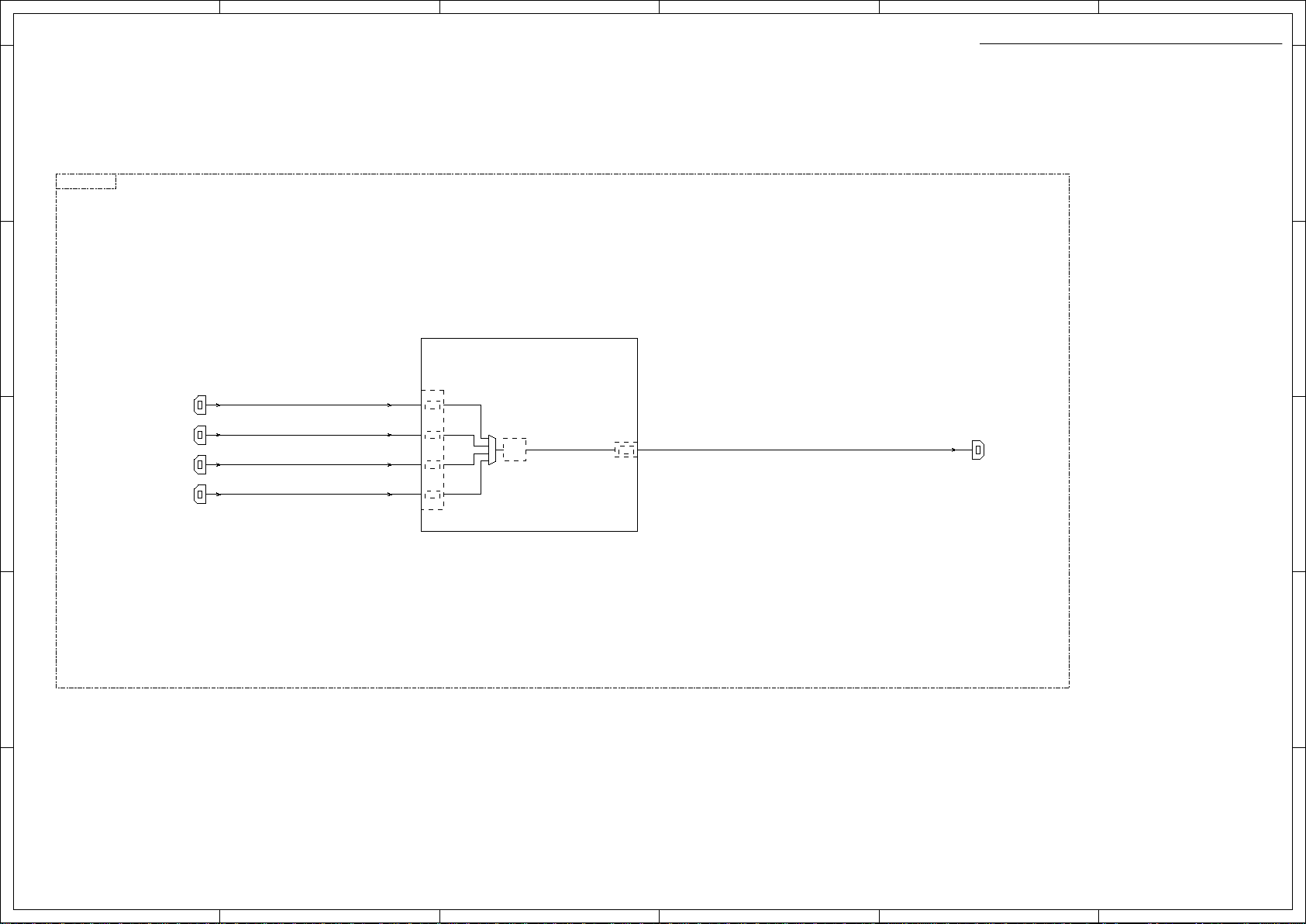

Protect Mode

The unit goes into standby automatically when detect the abnormal condition of thermal detection,

DC voltage detection or current detection. (e.g. TX-SR393 block diagram below)

D

5 4 3

6

Diagnostic Function

D

C

B

AC IN

BAPS-2674

SUB

TRANS.

FUSE

F9002

Power Supply

for STANDBY

Relay

RL9001

P9002

BAPRC-2695

PON_MAIN

P2800B

POWER

TRANS.

T901

SEC-1

(HIGH)

SEC-1

(LOW)

BAAF-2690

FUSE

F6901

F6902

(H)

RELAY

RL6911

RL6912

(L)

BACLA-2673

VOLTAGE

DRIVE

Power

(H)

or

(L)

Supply

PON_MAIN

SEC1H

Power

Supply

THERMAL

MPU

Q7009

VPROTECT

IPROTECT

Power amp.

(Front L)

Q6001

Q6021

SPRLF

VOLH

P8002

CURRENT

DETECT

IPRO

VPRO: DC voltage detection

IPRO: Current detection

DC

DETECT

VPRO

BAETC-2691

THERMAL

DETECT

P6800A

VOLTAGE

DETECT

Q6800

VOLH

RELAY

RL6501

(FL/FR)

C

B

SPEAKER - OUT

A

A

TX-SR393/TX-SR494

HT-R398 / HT-R495

1

2

5 4 3

6

1

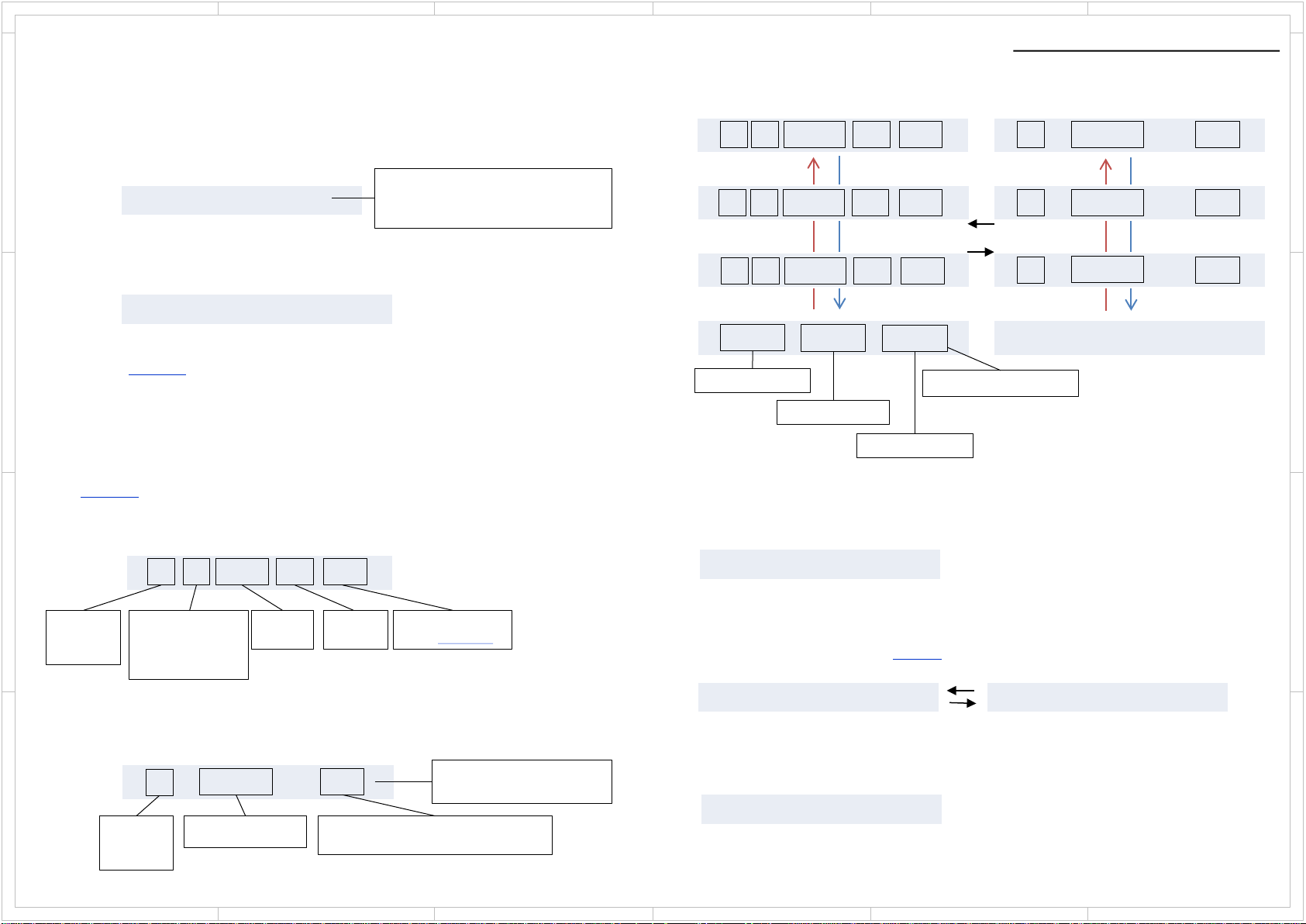

Self-diagnostics

2

5 4 3

6

Diagnostic Function

This function is for avoiding the rupture of electrolytic capacitors with amplifier circuit failure during

power-ON.

Operation of Self-diagnostic

D

Self-diagnostic will start at the timing of next power on, after goes to the protect mode by Current

detection or DC voltage detection.

Only On/Standby key could work in this mode. Also remote control does not work. However, the

CLEAR operation is enabled.

During Self-diagnostic, the power supply for amplifier circuit become low voltage state(SEC1LOW), and the speaker relay will be turned off. Then, MPU will check each amplifier circuits

Internally by entering the test signal (20 kHz,-20 dBFS sine wave) to each channel from DSP.

MPU will judge the amplifier circuit is good or not from VOLH value. The

C

normal range of VOLH value is 0.04 V < VOLH < 0.20 V.

If VOLH value is in the out of this range, it will be judged as NG (No good).

No problem found

When protected by current detection, and no problem found, "CHECK SP WIRE“ will be displayed.

In this State, Only the On/Standby key is effective. And if do not anything for 3 minutes, unit goes

into standby automatically.

When protected by a DC voltage detection, and no problem found, unit goes into normal

operation.

B

Problem found

When judged as there is a problem on any channel, the information of channel that has a problem

will be displayed as in the right figure.

In this State, Only the On/Standby key is effective. Also remote control does not work. If do not

anything for 3 minutes, unit goes into standby automatically. This state will keep also after unit

turn on/off, or AC unplugged.

the power supply for amplifier circuit become low voltage state(SEC1-LOW), and the speaker

relay will be turned off.

A

1

2

Display of during Self-diagnostics

2 Line FL tube type

A M P D i a g M o d e

1 Line FL tube type

A M P D i a g M o d e

“Mode” This part display the channel which is currently checked. (E.g. "[FL]", etc.)

Display of when problem found

2 Line FL tube type

1 Line FL tube type

N G C H :

L C R S L S R B L B R

N G : L C R S L S R B L B R

Front L channel

L

Center channel

C

Front R channel

R

S L

S R

B L

B R

Surround L channel

Surround R channel

Surround back L channel

Surround back R channel

TX-SR393/TX-SR494

HT-R398 / HT-R495

5 4 3

6

D

C

B

A

1

2

Repair Process and How to Confirm

Confirmation of the protect cause

While NG channel is displayed, You can confirm the protect cause by following the step below.

1. Press th

D

2. The protect cause are displayed for 5 seconds.

Please check the around of those amplifier circuit and repair it.

e Enter button

5 4 3

Diagnostic Function

Protected by current detection

D E T . P R O T E C T : I

Protected by DC Voltage detection

6

D

Clear of NG CH information

After repair, you can clear NG CH information by following the steps below.

1. Press th

e On/Standby key while pressing the Enter key.

2. Display as in the right figure appears.

3. Unit goes i

nto Standby automatically after 5 seconds.

Self-diagnostic will start again at the timing of next power on. By this, You can

C

verify whether repair was properly or not.

If problem found after repair, please re-check the around of its circuit.

Cancel of Self-diagnostic

You can cancel this mode by clear operation (press Standby key while pressing CBL/SAT key).

After cancel this mode, receiver will be started as normal operation.

Manual Execution of Self-diagnostic

1. [DIMMER] + [ON/STANDBY] x 2

irmware Version will appear on the main unit’s display.

Main F

B

2. [SETUP] or [HOME]

Service Menu will appear on the main unit’s display

3. Setup & select channel for self-diagnostic by enter service mode to “AMPChDiag” Display as in

the right figure appears. Select channel by cursor Left & Right.

D E T . P R O T E C T : V

Clear of NG CH information

N G C H C L E A R

C

B

Manual Execution of Self-diagnostic

A m p C h D i a g : O f f

4. [STANDBY/ON]

Unit will go into standby.

5. [STANDBY/ON]

Unit will turn on. Then self-diagnostic will start automatically

A

1

A

TX-SR393/TX-SR494

HT-R398 / HT-R495

2

5 4 3

6

1

2

5 4 3

6

Enter Servic e mo de, Serv ice Information

How to enter to service mode.

Step1 :

D

C

B

A

[DIMMER] + [ON/STANDBY] x 2

Step2 :

[SETUP] or [HOME]

Step3:

Follow this Tree operation for each service mode.

M1.xx / xxxxxAEx

1. Service

The version of main

microprocessor. (displayed only for

3 seconds)

Displaying Service information

This service information display system is helpful in analyze the status when the unit goes into

Protect mode and is powered off. Pay attention that the status will change if a button is pushed.

Follow this Tree for “ProtectData” section at the “1-1 Tech Sprt”

Step1 :

When the [ENTER] button is pressed, It will show error history

History No.

: 1 ~ 3

(1 is latest.)

Step2:

When the [ENTER] button during display error history,

the additional information of error history will be appeared.

History No.

: 1 ~ 3

(1 is latest.)

1

1 I 80F 30 DD

PROTECT

I: Current Protect

V: Voltage Protect

T: Thermal Protect

Tempe-

rature

1 01:23 10h

Time after Power on

xx : xx

Cumulative operation time after Reset

: xx h

2

Volume

Value

Listening Mode

See This value

Information Displayed

(Record this Information)

Diagnostic Function

How to change History No. 1 ~ 3.

[CURSOR LEFT] or [CURSOR RIGHT]

1 I 8 0 F 3 0 D D

[CURSOR LEFT] [CURSOR RIGHT]

2 I 9 1 F 2 7 D D

3 - 0 0 F 0 0 A

T : 0 I : 2 V : 0 No Use

T : Thermal Protect

I : Current Protect

V : Voltage Protect

How to exit the service mode.

Please press the [ANY INPUT SELECTOR]

Normal display

How to clear Protect Data

Step1:

Select “ProtectDataCLR” from this tree

Step2:

Press [ENTER] button

After display “DATA Cleared!”, It will be data reset and go to normal mode.

Protect Data CLR Clear:[ENTER]

DataCleared!

[ENTER]

Count of each protect

5 4 3

1 01: 23 10h

[CURSOR LEFT] [CURSOR RIGHT]

2 01: 47 8h

3 00: 00 00h

TX-SR393/TX-SR494

HT-R398 / HT-R495

D

C

B

A

6

1

THX_CINEMA_LMD_BEGIN

THX_20_PLII_MOVIE

THX_20_PLIIX_MOVIE

THX_20_PLIIZ_CINEMA

THX_20_NEO6_MOVIE

THX_20_NEURAL_CINEMA

THX_51_OFF_CINEMA

THX_51_MTR_CINEMA

THX_51_DSC_CINEMA

THX_51_NEO6_CINEMA

THX_51_PLIIX_MOVIE

THX_51_PLIIZ_CINEMA

THX_51_NEURAL_CINEMA

THX_51_EX

THX_20_NEOX_CINEMA

THX_51_NEOX_CINEMA

THX_20_DOLBY_SURR_CINEMA

THX_51_DOLBY_SURR_CINEMA

THX_CINEMA_LMD_END

THX_U2GAME_LMD_BEGIN

THX_20_PLII_SLCT2_GAME

THX_20_PLIIZ_SLCT2_GAME

THX_51_SLCT2_GAM

THX_51_PLIIZ_SLCT2_GAME

THX_U2GAME_LMD_END

THX_U2MUSIC_LMD_BEGIN

THX_51_SLCT2_MUS

THX_51_PLIIZ_SLCT2_MUSIC

THX_U2MUSIC_LMD_END

D0 AUDYSSEY_LMD_BEGIN

D1 AUDYSSEY_20_PLII_MUSIC

D2 AUDYSSEY_20_PLIIX_MUSIC

D3 AUDYSSEY_20_NEO6_MUSIC

D4 AUDYSSEY_20_NEURAL_CINEMA

D5 AUDYSSEY_20_NEURAL_MUSIC

D6 AUDYSSEY_20_PLII_MOVIE

D7 AUDYSSEY_20_PLIIX_MOVIE

D8 AUDYSSEY_20_NEO6_MOVIE

D9 AUDYSSEY_20_PLII_GAME

DA AUDYSSEY_20_PLIIX_GAME

DB AUDYSSEY_51_OFF

DC AUDYSSEY_51_PLIIX_MUSIC

DD AUDYSSEY_51_PLIIX_MOVIE

DE AUDYSSEY_51_NEO6

DF AUDYSSEY_51_NEURAL_CINEMA

E0 // AUDYSSEY_51_NEURAL_MUSIC

E1 AUDYSSEY_51_EX

E2 AUDYSSEY_LMD_END

F0 SPECIAL_LMD_BEGIN

F1 TESTTONE

F2 TESTTHR

F3 TESTAUTO

F4 ASC

F5 FLASH

F6 DEBUGMODE

F7 FLASH2

F8 FLASH3

F9 FLASH4

FA FLASH_CHECK

FB SPECIAL_LMD_END

2

5 4 3

6

Service Information

Listening Mode Code List

D

00 NORMAL_LMD_BEGIN

01 LAST

02 PURE

03 DIRECT

04 STEREO

05 MONO

06 ORCHESTRA

07 UNPLUGGED

08 STUDIOMIX

09 TVLOGIC

0A ALLCHST

0B FULLMONO

0C TD

C

0D RPG

0E ACTION

0F ROCKBAND

10 SPORTS

11 WHOLEHOUSE

12 RPG_GENRE

13 ACTION_GENRE

14 ROCKBAND_GENRE

15 SPORTS_GENRE

12 NORMAL_LMD_END

B

20 SURR_LMD_BEGIN

21 SURR_20_PLII_MOVIE

22 SURR_20_PLII_MUSIC

23 SURR_20_PLII_GAME

24 SURR_20_PLIIX_MOVIE

25 SURR_20_PLIIX_MUSIC

26 SURR_20_PLIIX_GAME

27 SURR_20_PLIIZ

28 SURR_20_NEO6_MOVIE

29 SURR_20_NEO6_MUSIC

2A SURR_20_NEURAL_MUSIC

2B SURR_20_NEURAL_CINEMA

2C SURR_51_OFF

2D SURR_51_MTR

2E SURR_51_DSC

2F SURR_51_NEO6

30 SURR_51_EX

31 SURR_51_PLIIX_MOVIE

32 SURR_51_PLIIX_MUSIC

33 SURR_51_PLIIZ

34 SURR_51_NEURAL_CINEMA

35 SURR_20_NEOX_CINEMA

36 SURR_20_NEOX_MUSIC

37 SURR_20_NEOX_GAME

38 SURR_51_NEOX_CINEMA

39 SURR_51_NEOX_MUSIC

40 SURR_51_NEOX_GAME

41 SURR_20_DOLBY_SURR

42 SURR_51_DOLBY_SURR

43 SURR_LMD_END

48 DTSSS_LMD_BEGIN

49 DTSSS_20_NEO6_MUSIC

4A DTSSS_20_NEO6_CINEMA

4B DTSSS_51

4C DTSSS_LMD_END

50 THX_MUSIC_LMD_BEGIN

51 THX_20_PLII_MUSIC

52 THX_20_PLIIX_MUSIC

53 THX_20_PLIIZ_MUSIC

54 THX_20_NEO6_MUSIC

55 THX_20_NEURAL_MUSIC

56 THX_51_OFF_MUSIC

57 THX_51_MTR_MUSIC

58 THX_51_DSC_MUSIC

5A THX_51_PLIIX_MUSIC

5B THX_51_PLIIZ_MUSIC

5C THX_51_NEO6_MUSIC

5D THX_51_NEURAL_MUSIC

5E THX_20_NEOX_MUSIC

5F THX_51_NEOX_MUSIC

60 THX_20_DOLBY_SURR_MUSIC

61 THX_51_DOLBY_SURR_MUSIC

62 THX_MUSIC_LMD_END

70 THX_GAME_LMD_BEGIN

71 THX_20_PLII_GAME

72 THX_20_PLIIX_GAME

73 THX_20_PLIIZ_GAME

74 THX_20_NEURAL_GAMES

75 THX_51_OFF_GAMES

76 THX_51_MTR_GAMES

77 THX_51_DSC_GAMES

78 THX_51_PLIIX_GAME

79 THX_51_PLIIZ_GAMES

7A THX_51_NEO6_GAMES

7B THX_51_NEURAL_GAMES

7C THX_20_NEOX_GAMES

7D THX_51_NEOX_GAMES

7E THX_20_DOLBY_SURR_GAME

7F THX_51_DOLBY_SURR_GAME

80 THX_GAME_LMD_END

90

91

92

93

94

95

96

97

98

99

9A

9B

9C

9D

9E

9F

A0

A1

A2

B0

B1

B2

B3

B4

B5

B6

B7

B8

B9

BA THX_U2CINEMA_LMD_BEGIN

BB THX_51_SLCT2_CIN

BC THX_51_PLIIZ_SLCT2_CINEMA

BD THX_U2CINEMA_LMD_END

Diagnostic Function

D

C

B

A

1

A

TX-SR393/TX-SR494

HT-R398 / HT-R495

2

5 4 3

6

1

2

5 4 3

6

How to check Firmware Version & Preparation of Update

Step1 : [INFO] + [ON/STANDBY] x 2

D

Main Firmware Version will appear on the main unit’s display.

Step2 : [Cursor UP +1]

DSP Firmware Version will appear on the main unit’s display.

Step3 : [Cursor UP +2]

Video Firmware Version will appear on the main unit’s display.

C

Step4 : [Cursor UP +3 ]

OSD Firmware Version will appear on the main unit’s display.

Step7 : [TONE +3 over]

Return to Display Main Firmware Version ( Return Step1)

When It is pushed Cursor Down, It is appeared before step.

B

A

1

2

Firmware Update

[Preparation of Update]

1. Connect the USB storage device to your PC . If there is any data in the USB storage

device, remove it.

2. Download the firmware file (package file) from the OPSIS-server.

However European serv ice partner s should download the firmware file (package file)

from the ExtraNet.

ID and Password are those we informed when changed.

Filename is as follows: ONKAVR002B_Rxxx_xxx.zip for TX-SR393, HT-R398

Filename is as follows: ONKAVR002C_Rxxx_xxx.zip for TX-SR494, HT-R495

Filename is as follows: ONKAVR002B_Rxxx.zip for TX-SR292BT

Unzip the downloaded file. A following file is created.

AVR002B**************.of1 for TX-SR393, HT-R398

AVR002C**************.of1 for TX-SR494

AVR002B**************.of1 for TX-SR292BT

There is one file for update.

3. Copy it to the USB storage device. Be careful not to copy the zip file.

4. Remove the USB storage device from your PC.

TX-SR393/TX-SR494

HT-R398 / TX-SR292BT

HT-R495

5 4 3

6

D

C

B

A

1

2

5 4 3

6

How to Update (service mode) 1/2

Overwriting is also possible.

D

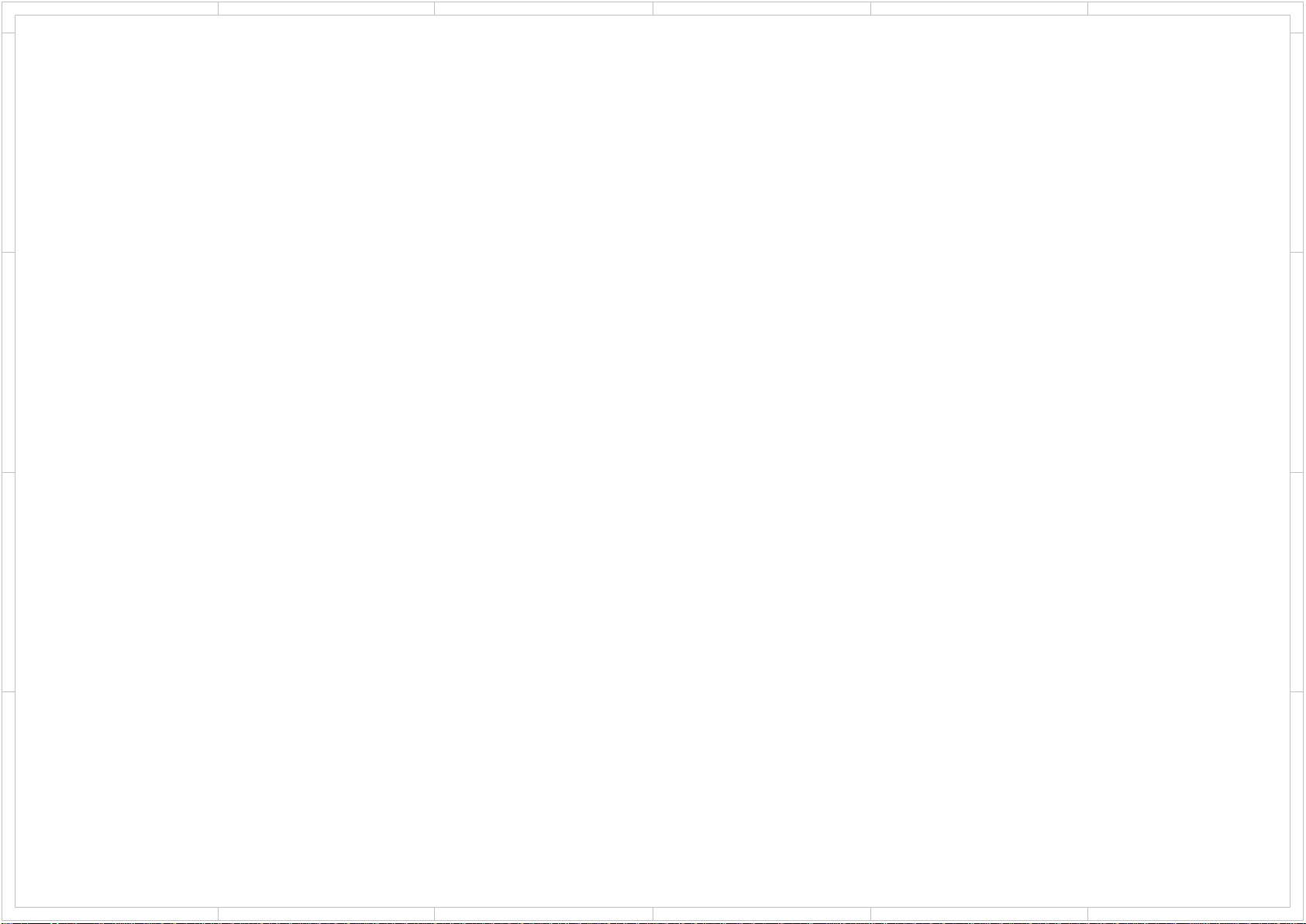

1. Connect the USB storage to the USB port on the unit.

C

B

A

2. Turn on the unit. It takes some time to start after you switch on the unit.

Press: [DIMMER] + [ON/STANDBY] x 2

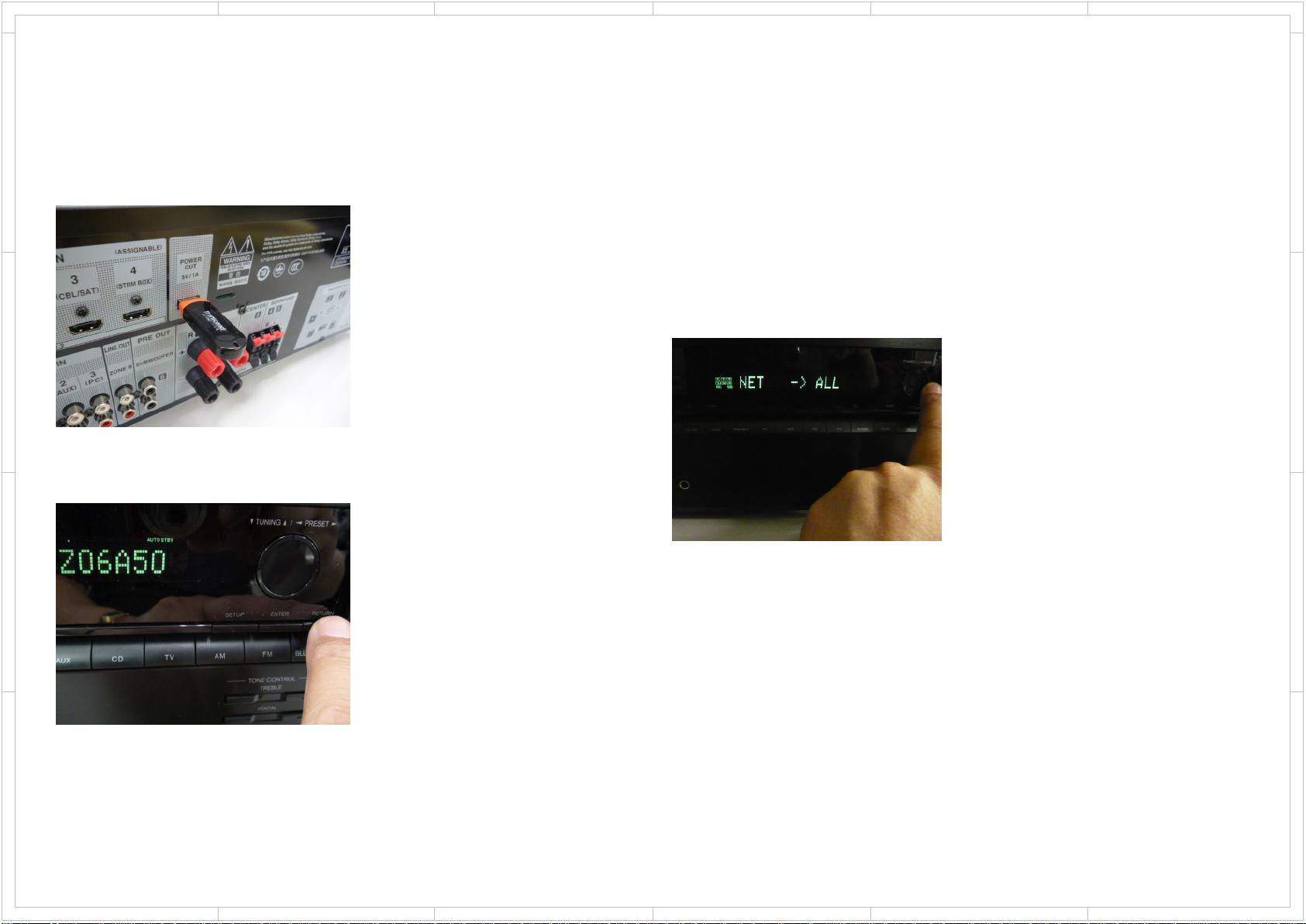

3. Press [RETURN] button, Then it is displayed as below

If you need each module of the firmware update, you can select the module by pressing

PRESET < and > button.

It should be updated firmware by selecting USB -> ALL normally.

1

2

Firmware Update

USB -> ALL: ALL firmware update ( default )

USB -> DSP1: DSP firmware update

USB -> OSD: OSD firmware update

USB -> VMPU: VMPU firmware update

USB -> MMPU: Main MPU firmware update

USB -> WORK: Compare between AVR and USB, Only update new version firmware

The default setting is “ ALL”

CAUTION: When you will update each module firmware,

you have to keep combination of firmware.

TX-SR393/TX-SR494

HT-R398 / TX-SR292BT

HT-R495

5 4 3

6

D

C

B

A

1

2

5 4 3

6

How to Update (service mode) 2/2

4. Press [ENTER] button. Start update firmware.

D

C

B

A

5. Wait until update is completed. When the update ends, “Completed!” is displayed. When

“ Completed!” message appeared, you can power off by pressing “ ON/STANDBY” button.

(If you leave it, it automatically turns standby mode. )

1

2

Firmware Update

6. Press [ON/STANDBY] button, and the unit turns on.

7. Check the new FW version number.

<Note>

If the procedure might not be successful, please select “USB -> ALL”.

TX-SR393/TX-SR494

HT-R398 / TX-SR292BT

5 4 3

D

C

B

A

HT-R495

6

1

5432

6

Model and Destination

1.[ TV ] + [ ON/STANDBY ] → [ ENTER ] → [ TUNER UP/DOWN ] x 4

D

Model Name Destination FL Display

HT-R495 DC R495 DC 0101

HT-R495 xx R495 xx 0111

HT-R495 xA R495 xA 0141

C

Model and Destination

D

C

B

A

B

A

HT-R495

1

5432

6

1

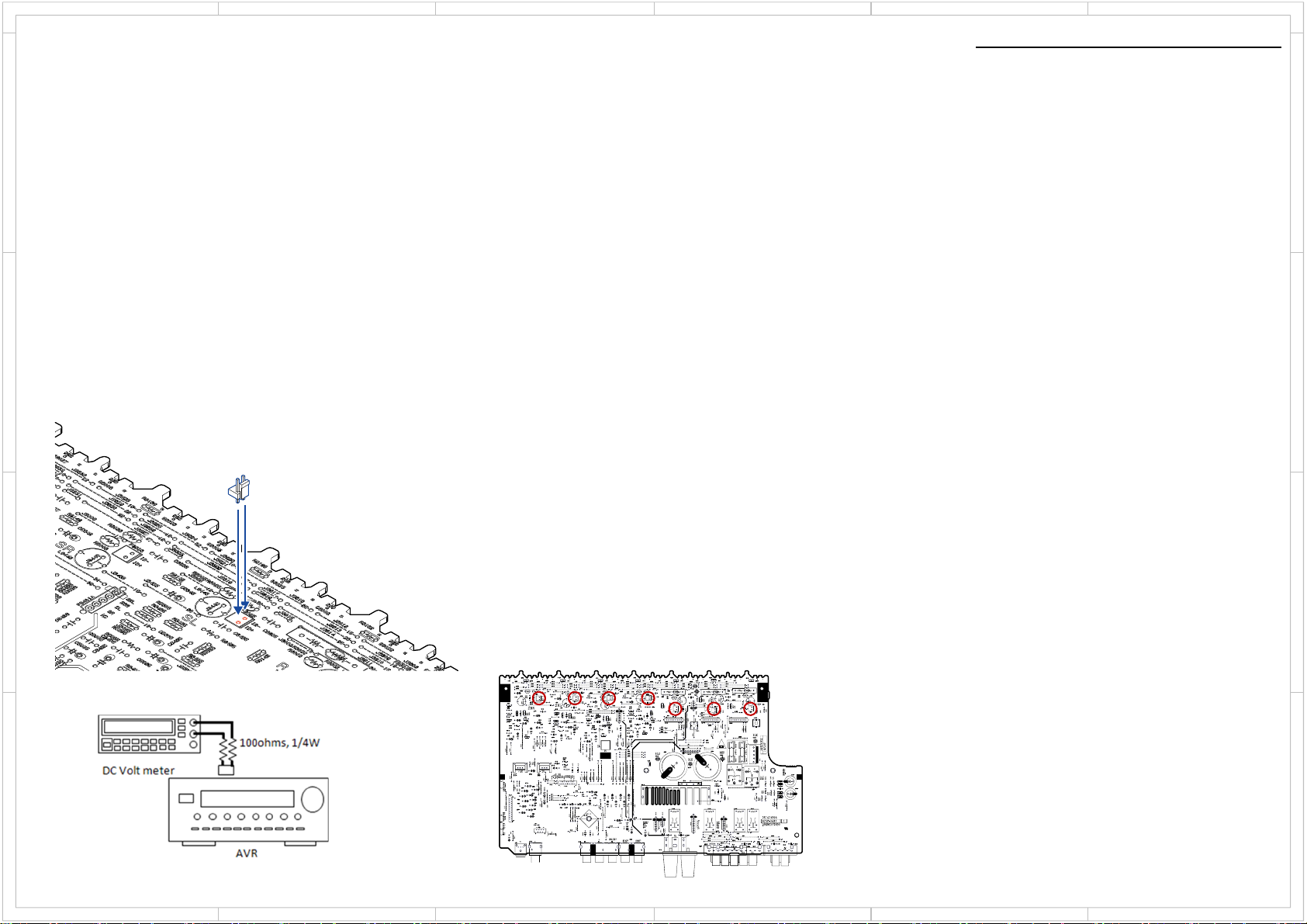

How to Check Idling Current

a. Aging

D

The AVR is turned on about 6 minutes for aging.

b. Idling After-check

Channel FL,FR,C,SL,SR,SBL,SBR

Terminals P6021,P6022,P6023,P6025,P6026,P6027,P6028

*Connect 1/4W 100 ohms resisters in each probe of multi mater .

C

*If the measured value are under 1 mV or over 10 mV, you have to make sure repair.

When there is no measured connector on the board:

1. Measure by inserting a like thin pin into the hole of the connector for measurement.

2. Measure via connector as shown.

5432

6

Check Idling Current

D

C

B

A

BAAF-2690

1

2

543

HT-R495

6

B

A

1

No Sound

■ No sound from connected player

D

C

□ Chose input selector which is assigned to connected input terminal ?

□ Isn’t muting on ?

■ No sound from connected TV

□ Chose wrong input selector ?

□ Connect to this model’s HDMI OUT terminal from TV by HDMI cable ?

□ When TV supports ARC function, connect to his model’s HDMI OUT terminal from

TV’s HDMI input terminal for ARC function ?

□ When TV doesn’t support ARC function, connect TV to this model with optical cable

etc. ?

□ Isn’t muting on ?

■ No sound from some connected loudspeaker(s)

□ No sound loudspeaker(s) config is enabled ?

5432

6

Hookup and Setting

D

C

■ No sound from all connected TV or Blu-ray player etc.

□ After chose loudspeaker volume level setting, test tone is OK ?

B

■ No problem about above items

□ Unplug power cord

After 10 seconds, connect power cord again

□ Reset this model

A

1

B

A

Common

5432

6

1

No Picture

■ In general

D

C

□ Connection cable is bent , twisted or damaged ?

□ Input is switched on TV ?

■ No picture from connected player by HDMI input terminal

□ Chose input selector which is connected to player ?

□ Listening mode is not Pure Audio ?

□ Don’t use HDMI-DVI adaptor. From personal computer ?

■ No picture from connected player by component video terminal

□ Output to TV connected to component video out terminal from player's picture

connected to the composite video input terminals ?

■ No problem about above items

□ Unplug power cord

After 10 seconds, connect power cord again

□ Reset this model

5432

6

Hookup and Setting

D

C

B

A

B

A

Common

1

5432

6

1

No Power

■ In general

D

C

□ Check if the connection cable is bent or twisted, damaged.

■ There is time when indication on the front panel doesn't just light up.

□ Please check the connecting cord of a DISPLAY PCB.

■ No problem about above items

□ Unplug power cord

After 10 seconds, connect power cord again

□ Reset this model

5432

6

Hookup and Setting

D

C

B

A

B

A

Common

1

5432

6

1

5432

6

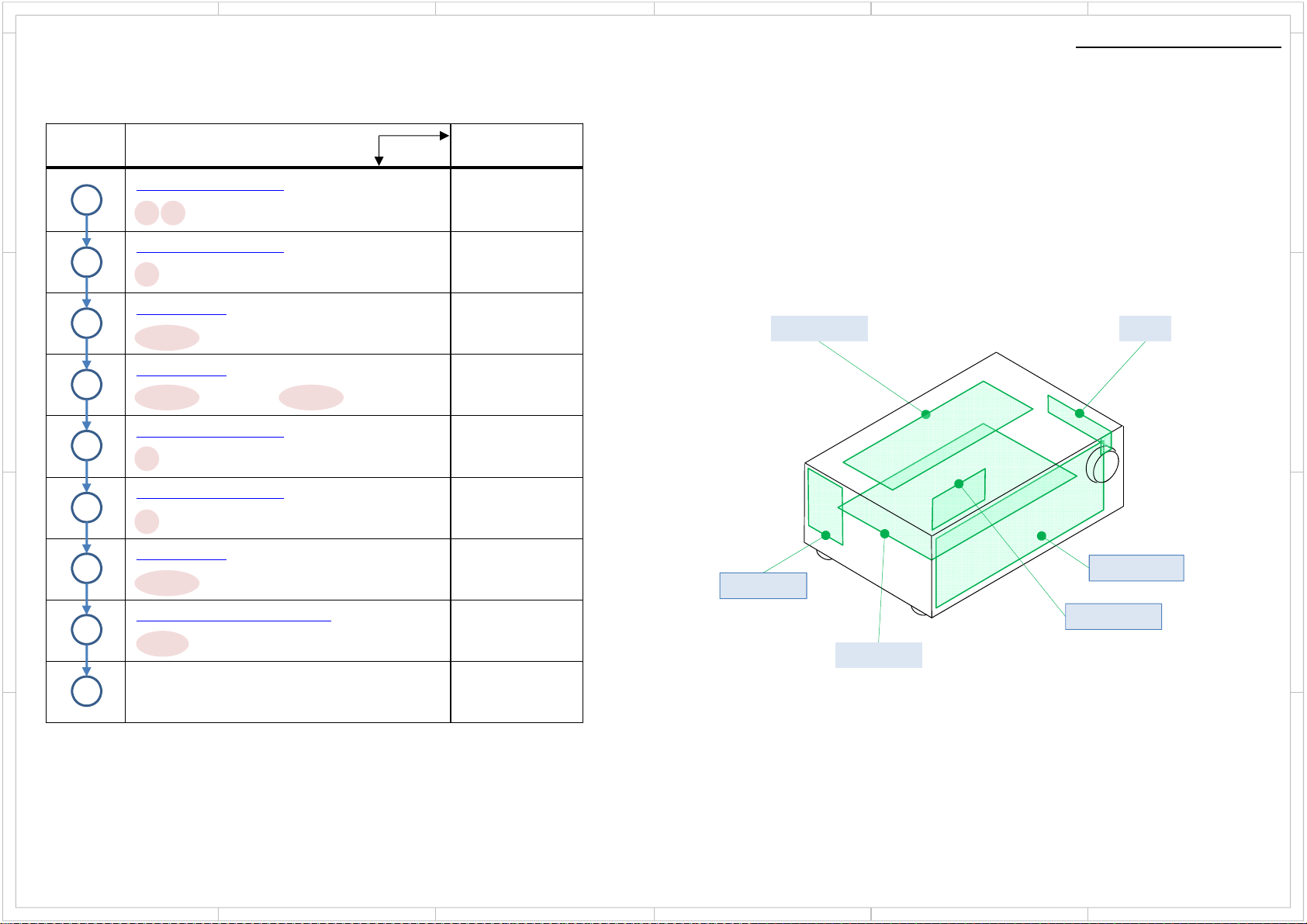

No Sound (HDMI in)

Here the trouble shoot which focuses on the hardware troubles regarding PCB assembly is explained.

Of course, with actual repair there are also troubles due to damaged Power Transformer, Wiring, soldering etc. in addition to PCB assembly.

D

Process Check Point Damaged PCB

P2802 (BAPRC-2695)

1

1

3 ca. +18V (+12VDG)

P7002 (BAPRC-2695)

2

3 ca. +3.3V (+3.3VDG)

(BAAF-2690)

3

J4251 ca. +24V

C

(BAAF-2690)

4

J4187 ca. -15V J4188 ca. +15V

P7002 (BAPRC-2695)

5

12 ca. +3V (SPRLF)

No Good

OK

BAPS-2674

BAPRC-2695

BAAF-2690

BAAF-2690

BAAF-2690

BAPRC-2695

Trouble Shoot

D

P7001

C

P7003 (BAPRC-2695)

6

BAPRC-2695

19 Audio Signal (DAC OUT)

(BAAF-2690)

B

J4101 Audio Signal (FL OUT, CLA-IN)

7

BAAF-2690

BAPS-2674

Q6001, Q6021 (BAAF-2690)

8

Base Audio Signal (FL OUT, CLA-OUT)

BACLA-2673

BAAF-2690

BADIS-2672

B

BACLA-2673

9 BAAF-2690

A

A

TX-SR292BT/SR393/SR494, HT-R398/R495

1

5432

6

1

5432

6

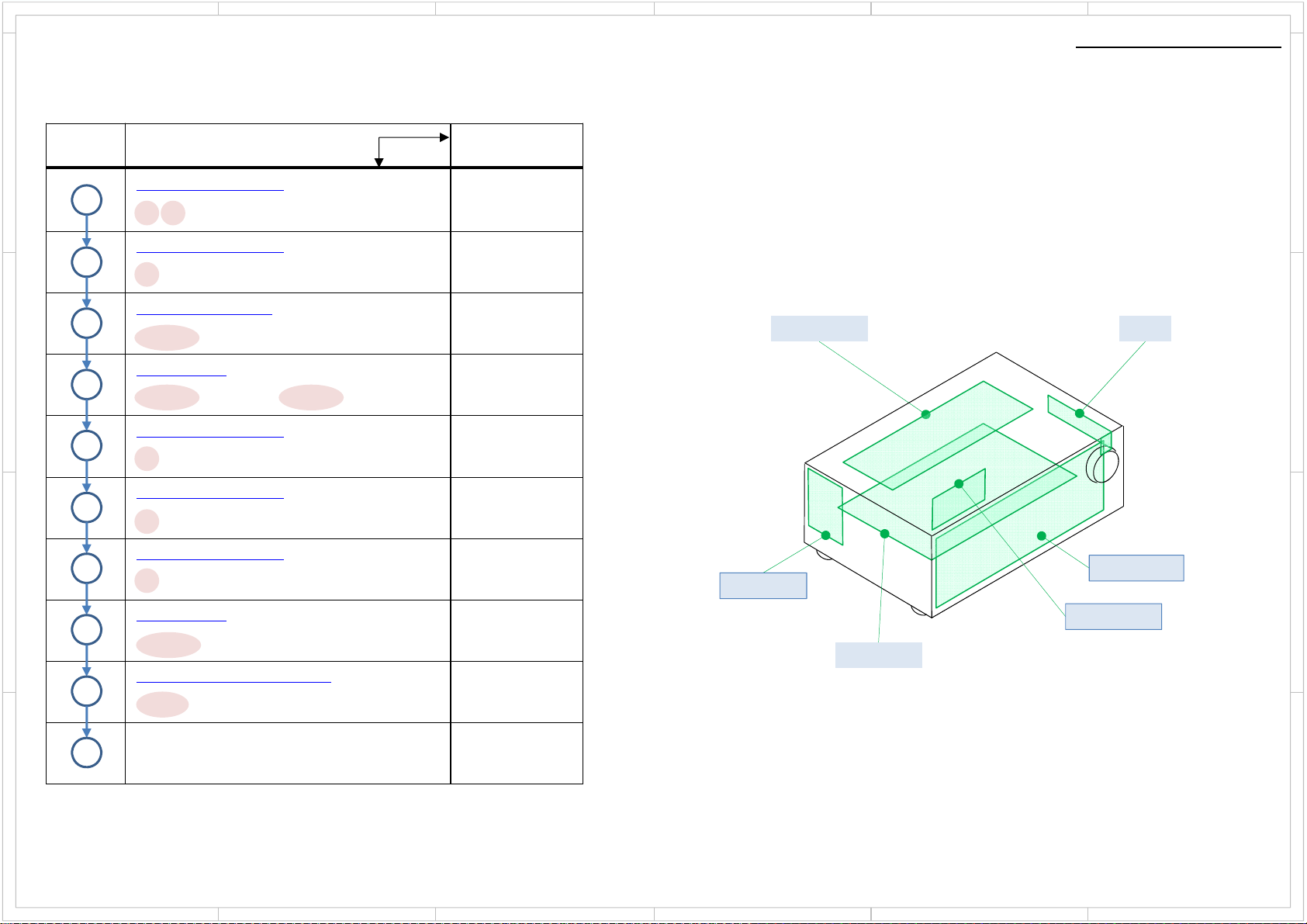

No Sound (Opt in)

Here the trouble shoot which focuses on the hardware troubles regarding PCB assembly is explained.

Of course, with actual repair there are also troubles due to damaged Power Transformer, Wiring, soldering etc. in addition to PCB assembly.

D

Process Check Point Damaged PCB

P2802 (BAPRC-2695)

1

1 3 ca. +18V (+12VDG)

P7002 (BAPRC-2695)

2

3 ca. +3.3V (+3.3VDG)

J4251 (BAAF-2690)

3

J4251 ca. +24V

C

(BAAF-2690)

4

J4187 ca. -15V J4188 ca. +15V

P7002 (BAPRC-2695)

5

12 ca. +3V (SPRLF)

No Good

OK

BAPS-2674

BAPRC-2695

BAAF-2690

BAAF-2690

BAAF-2690

BAPRC-2695

Trouble Shoot

D

P7001

C

P7003 (BAPRC-2695)

6

BAPRC-2695

25 Audio Signal (OPT IN)

P7003 (BAPRC-2695)

B

7

19 Audio Signal (DAC OUT)

BAPRC-2695

BAPS-2674

(BAAF-2690)

8

J4101 Audio Signal (FL OUT, CLA IN)

BAAF-2690

BAAF-2690

BADIS-2672

B

BACLA-2673

Q6001, Q6021 (BAAF-2690)

9

BACLA-2673

Base Audio Signal (FL OUT, CLA OUT)

10 BAAF-2690

A

A

TX-SR292BT/SR393/SR494, HT-R398/R495

1

5432

6

1

5432

6

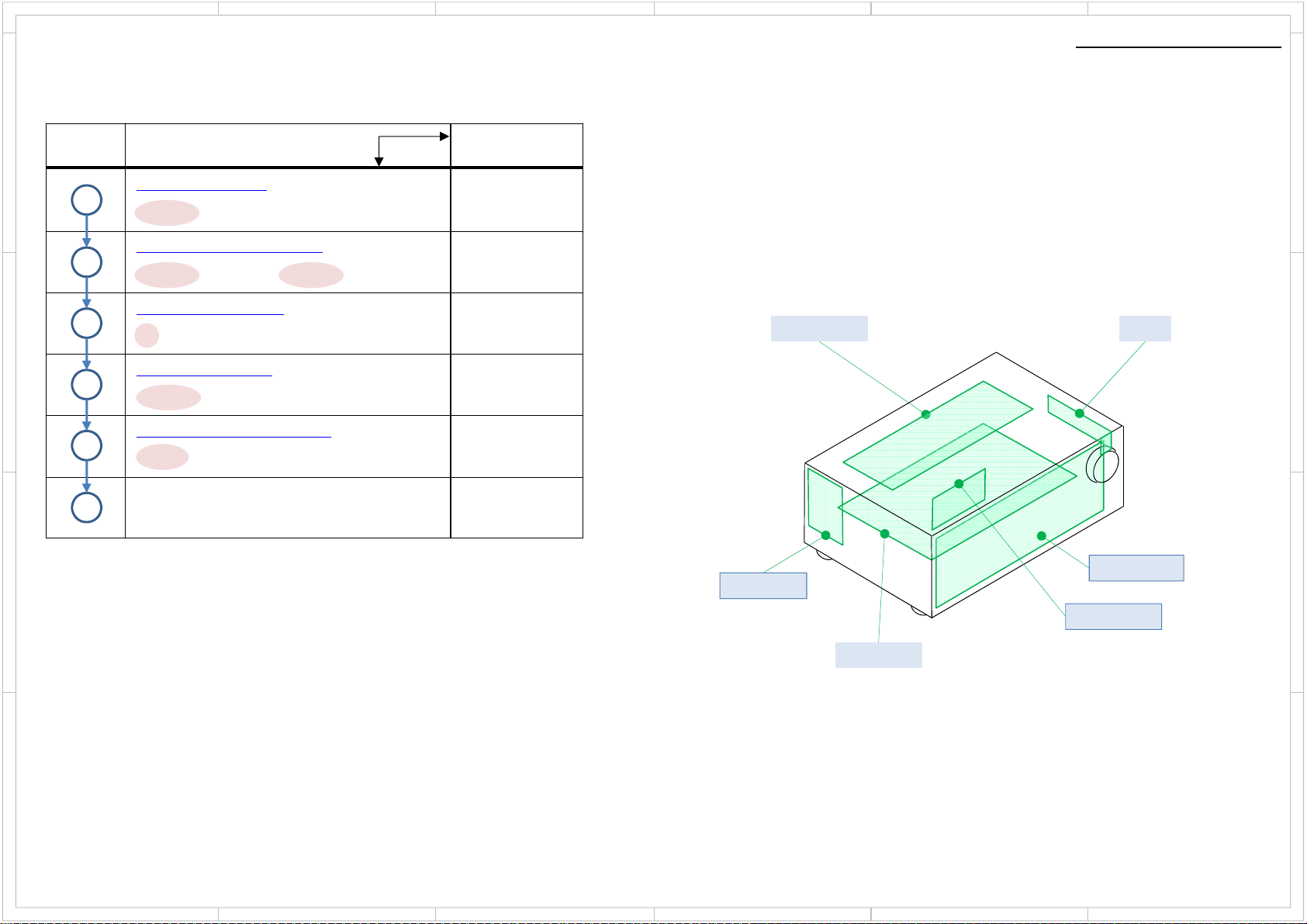

No Sound (Analog in)

Here the trouble shoot which focuses on the hardware troubles regarding PCB assembly is explained.

Of course, with actual repair there are also troubles due to damaged Power Transformer, Wiring, soldering etc. in addition to PCB assembly.

D

Process Check Point Damaged PCB

J4251(BAAF-2690)

1

J4251 ca. +24V

J4187, J4188 (BAAF-2690)

2

J4187 ca. -15V J4188 ca. +15V

P7002 (BAPRC-2695)

3

C

12 ca. +3V (SPRLF)

J4101 (BAAF-2690)

4

J4101 Audio Signal (FL OUT, CLA IN)

Q6001, Q6021 (BAAF-2690)

5

Base Audio Signal (FL OUT, CLA OUT)

No Good

OK

BAAF-2690

BAAF-2690

BAAF-2690

BAAF-2690

BACLA-2673

BAPRC-2695

Trouble Shoot

D

P7001

C

6 BAAF-2690

BADIS-2672

B

BAPS-2674

B

BACLA-2673

BAAF-2690

A

A

TX-SR292BT/SR393/SR494, HT-R398/R495

1

5432

6

1

5432

6

No Picture (HDMI in/ out)

Here the trouble shoot which focuses on the hardware troubles regarding PCB assembly is explained.

Of course, with actual repair there are also troubles due to damaged Power Transformer, Wiring, soldering etc. in addition to PCB assembly.

D

Process Check Point Damaged PCB

P2802 (BAPRC-2695)

1

1 3 ca. +18V (+12VDG)

2 BAPRC-2695

C

No Good

OK

BAPS-2674

BAPRC-2695

Trouble Shoot

D

P7001

C

BADIS-2672

B

BAPS-2674

B

BACLA-2673

BAAF-2690

A

A

TX-SR292BT/SR393/SR494, HT-R398/R495

1

5432

6

1

5432

6

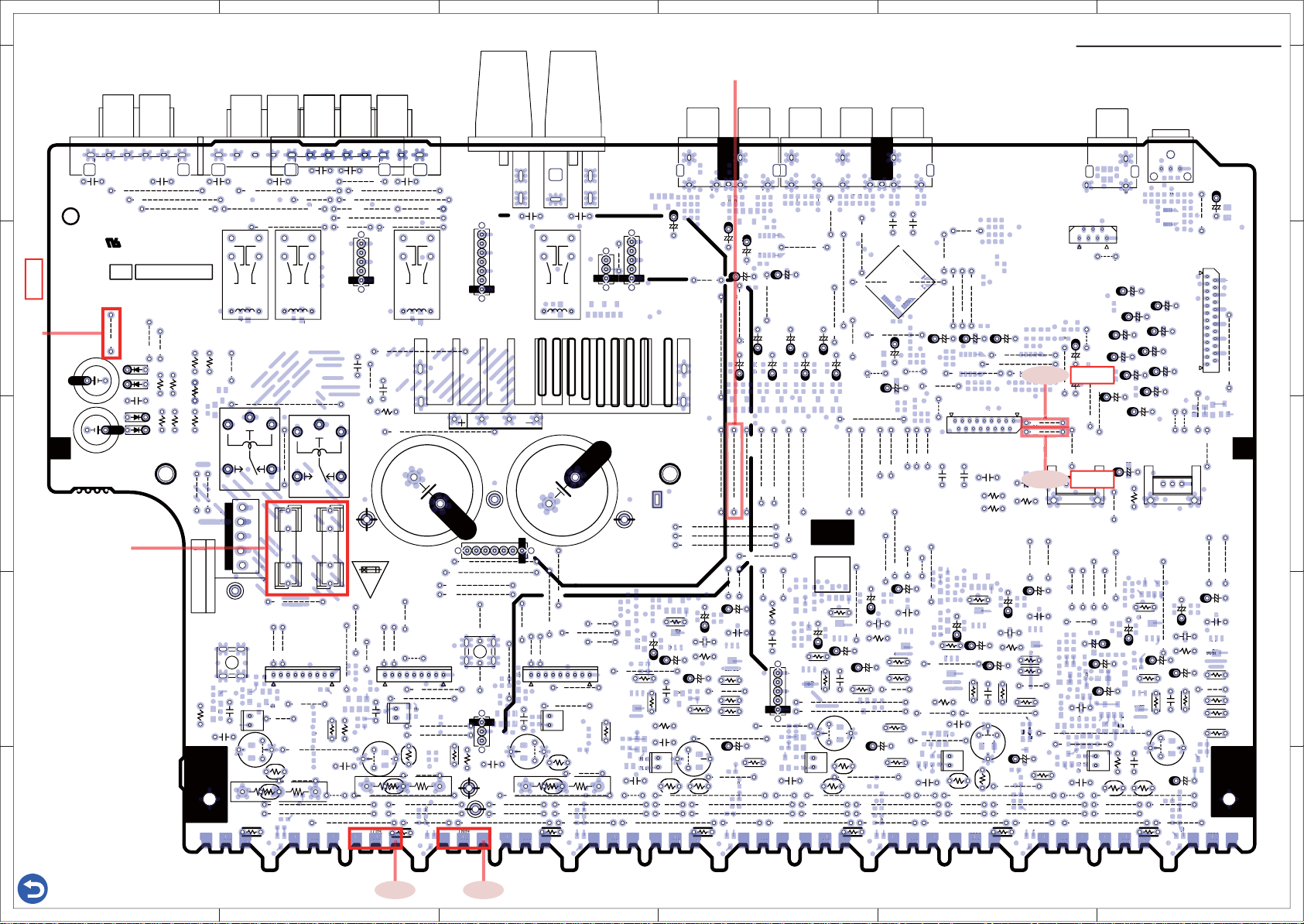

No Power

Here the trouble shoot which focuses on the hardware troubles regarding PCB assembly is explained.

Of course, with actual repair there are also troubles due to damaged Power Transformer, Wiring, soldering etc. in addition to PCB assembly.

D

Process Check Point Damaged PCB

F9001,F6901,F6902 (BAPS-2674/ BAAF-2690)

1

ANY PARTS (BAAF-2674/ BACLA-2673)

2

P7001 (BAPRC-2695)

3

C

4

P2802 (BAPRC-2695)

1 3 ca. +10V → +18V (+12VDG)

P2802 (BAPRC-2695)

5

7 ca. +5.8V(POFF)

No Good

OK

BAAF-2690

and

BACLA-2673

BAAF-2690

and

BACLA-2673

P7001(FFC)

BAPS-2674

BAPS-2674

BAPRC-2695

Trouble Shoot

D

P7001

C

P2802 (BAPRC-2695)

6

6 ca. 0 → +2.5V (M_PON)

RL9001 (BAPS-2674)

7

B

P9002 (BAPS-2674)

8

AC 100 V to 240 V

P7001B (BADIS-2672)

9

10 BADIS-2672

A

1. When being not turned on with remote control unit only, BADIS-2672 is abnormal.

2. When being

not turned on with button on the main unit only, BADIS-2672 is abnormal.

1

BAPRC-2695

BAPS-2674

BAPS-2674

P7001(FFC)

BAPS-2674

BAAF-2690

ANY PARTS on BAAF-2690

Check damage parts

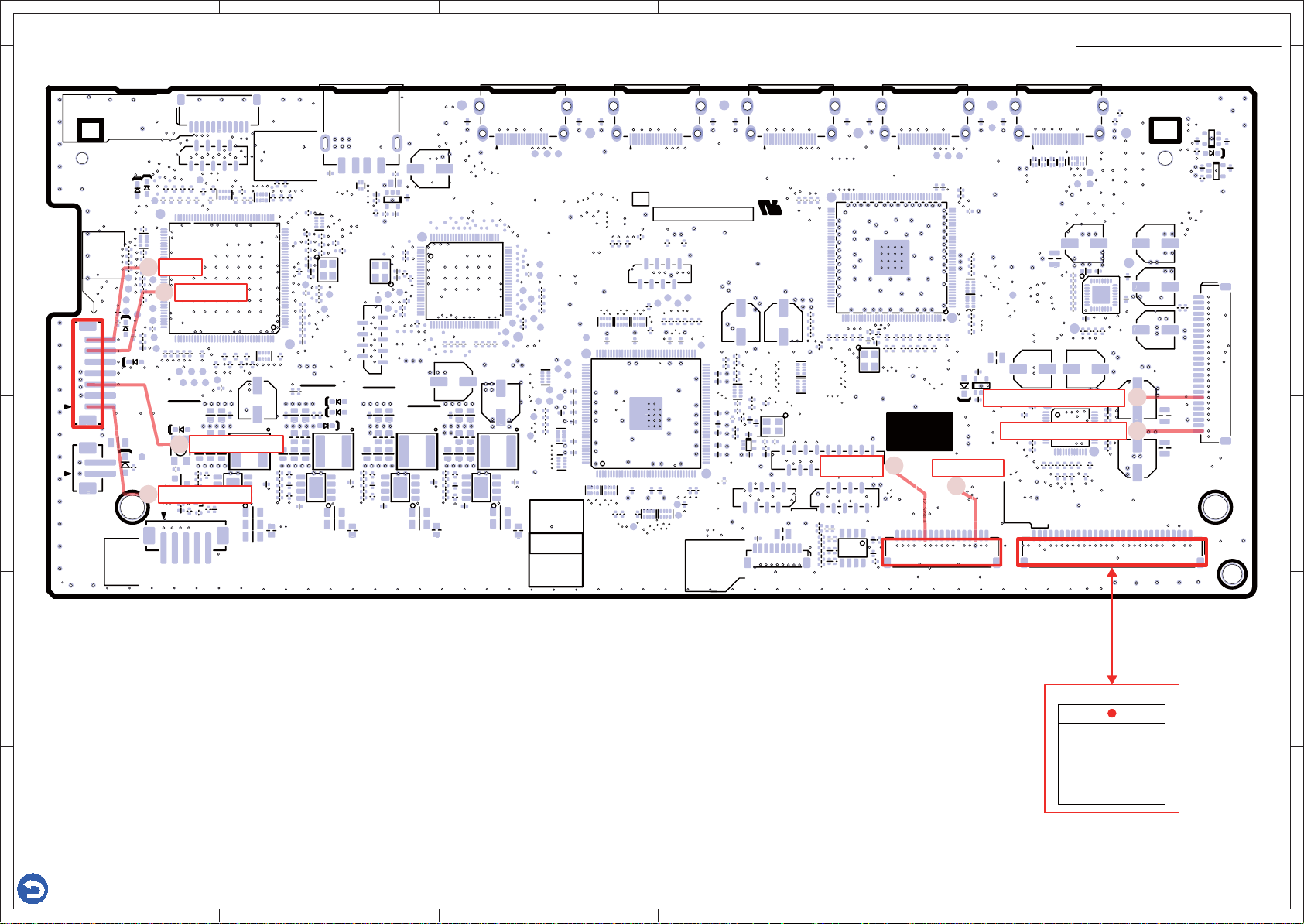

Normal(OK) or Damage (No good)

Check the damage in the red framework part as shown with visual

inspection.

e.g. Broken, Burnout, Discoloration, etc.

TX-SR292BT/SR393/SR494, HT-R398/R495

5432

BADIS-2672

B

BACLA-2673

A

6

123456

J6903

902D

901

F69

F69

O

NC

10

02

0

10

C6

86

R5385

J5465

R5386

48

52

C5

R5

C

R5388

S

7

R

28

0

B

S

S

64JJ

07

6

C

J

1D+06

0

LI

D+

6064428

1

07

J6

901

J6

6

4B

L

J

J

J

J

J

J6

J

J

J

J

J

J

J

C

J

J

C

JJC

J

B

P5

55

J

C

01100

003

0

14

61

J

7

C

7J5J

J

J

SB

63

J4

42

4180J

2

02

40

002

02

S

Z

08

38

SW

6001

B

2SD

2SD

C

6001E6002

B

2SD

2SD

C

6002E6003

B

2SD

2SD

C

6003E6005

B

2SD

2SD

C

6005E6006

B

2SD

2SD

C

6006E6007

B

2SD

2SD

C

6007

E

6008

B

2SD

2SDC6008

E

Q6021

B

B

2SB

2SB

C

Q6021E6022

B

2SB

2SB

C

6022

E

6023

B

B

2SB

2SB

C

E

6025

B

2SB

2SB

C

6025E6026

B

2SB

2SB

C

6026

E

6027

B

2SB

2SBC6027E6028

B

2SB

2SB

C

E

05

813

IN

IN

IN

2915

C6

40

00

07

6407

5067

50

00CR5

8

64

AT

AT

1

1

PC

/S

/S

RL6

5

L65

C

J5

C60074R5

R5

20

J4

00

R

R

C67

741

D-

D+

D+

C

C

0

05

BL

BL

BSS

1

C

R

23

1

R

2

26

6

06C40

5507

7

R5

C5

8

R

R5

256602

02

02

0202C6526405C55

6

6406

5

6407

C

406

4

05

813

53

22

9

29

C

J55

428

C6

00

00

00

84

C5

485

486R556

BSS

C

85

50

50

C

+

C66

6667

7

C6

6

P6

27

7

I

D+

D+

I

D+

P

60

660

3

465

45

C4

10

I

D-

I

D-

C

C

I

D+

L

R6

J6

2

J64

J6J7

1

J

J164

662

9

77

T

52528

76

JJ550

6

J

41

066814

1

3

30

7

00

0

503

07

40

C

VOVC

C

C

V

V

V

VOVOO

TU

Z

00

00

BO

4

4

TV

C4

28

190

18

AUTTVX

V

LI

02

2

R

84

78

78

46

45

55

R6

J64

5

C6

6

068

R5

902

8

R

RCC

C

8

C5

5

R61

R61

R6

R6

616

4444RLR6

64

L

P

00

TV

1

1

64

ID

ID

D-

7

SW

652

UT

DA

GN

J60

17

R

L

T

B

10

J4187

L

J4103

10

J4188

1

B

B

F

P4

P4

P4

F

88

88

1.+15VA

CheckPoint(BAAF-2690)

E

PowerSupplyforSPRelay

+24V

D

J4251

C

CheckDamage

B

A

10

C4251

C4252

F6901

F6902

SW

25

1

J4251

P6506

D4252

D4251

C4250

D4253

D4254

C

C6528 C6529

J6043

25

J6033

J6042

20

C6527

QPWBCAF2690

BCAF-2690

25142690A

J4252

J4253

10

7

R4251

R4252

R4254

R6914

J6914

R6913

RL6911

J4250

R4253

J6901

J6902

10

10

10A/125V

F6901/F6902

R6463

C6463

R4255

R4256

J6908

7

RL6912

NO

P6901

P5506B

C6603

Q6023

CE

2SB2SB2SB2SB2SB2SB2SB2SD 2SD 2SD 2SD 2SD 2SD 2SD

SBR SBL

P6502

P6505

C6526

27

J6911

30

COM

P6902A

BLK

J6443

L6443

R6083

B

10

J6032J6031

15

NC

NO

F6901C F6901D

F6901

15

J6903

J5023

J5003

10

10

9

ID+

10

P6023

ID-

7

J6023

C

20

R6003

R6023

10

30

30

R6163

J4101

10

R

7

7

J5502

J6022

R6142

R6002

R6022

J6814

J6813

J6812

C6521

J6561

1.C

2.FL

3.FR

P6400B

C6902

P6002B

J6002

P6501

SWOUT

C4104

5.FL

7

J6665

J6465

J5515

P7880B

P6904A

BLU

17

C6605

25

4.GNDFR

3.FR

2./HPDET

1.GNDDG_HP

7

J4193

27

J4002

C4107

D6901A

C

J4103

221522

P5510

C5085

J5505

R5405

R5525

R6465

C6465

ID+ID+

ID-

P6025

30

J6815

7

J6816

22

27

27

27

J5025

7

C6425

R6405

C5525

C5485

10

C5505

R5485

20

J6445

L6445

1217

R6025

J6819

27

J6818

27

J6817

Q6025Q6026

CE

10

B

R6165

P4007

C4109

C4110

C4117

15

J4196

C4108

C4105

FLFR

J4101

J4102

20720

J6366

J6368

J6367

15

J5005

7

7

C5025

C5005

C6405

R5065

R5385

J5465

NC

SR

SL

R5465

R5505

C5645C5646

J6005J6006

R6005

J6822

J6821

J6820

SRSL

C6525

J6041

J6040

2730

30

J6039

10 20

P6401B

C6903

COM

NC

F6902C F6902D

F6902

J6461

P6003B

17

1

J5503

R6143

R6461

J6453

J6003

J6803

22

Q6003Q6005

C

C6524

12

J6034

25

30

J6037

17

J6038

J6013

5.NC

4.SR

3.SL

2.SBR

1.SBL

25

J6907

C6904

J6904

10

R6901

J6905

30

P6903A

RED

7.SBL

6.SL

J6660

12

C6461

R6081

J6802

J6801

J6800

J6011

7

J5021

J5001

J6661

10

10

7

9

17

C6601

P6021

L6441

J6441

27

20

20

Q6021Q6022

CE

B

P6504

C6523

J6036

J6035

12

J6030

7.SBL

6.SL

5.L

4.C

3.R

2.SR

1.SBR

C6901

5.L

4.C

3.R

2.SR

1.SBR

22

25

J5326

20

J5327

20

10

P5509A

J6721

P6001B

J6462

11

15

ID+

ID17

17

R6001

10

J6807

12

R6161R6162

7

J5501

P6400A

J6021

L

J6433

J6451

R6462

R6141

R6021

J6001

P6903B

J6806

J6805

25

J6804

Q6001Q6002

FR FL

C6522

P6402B

RL6501 RL6503 RL6505 RL6507

D6901

P6902B

BLK

P6402A

J6357

J5365

J6452

J6662

15

C6602

C

FL

FR

C6462

RED

30

BLU

15

15

P6904B

J6808

BCEBCE BCEBCEBCEBCEBCE

J6365

J6012

17

10

J5022

J5002

7

7

9

12

J6442

L6442

R6082

J6811

J6810

J6809

CE

B

15

J6352

12

P6022

25

25

15

ID+

ID-

AudioSignal(FLOUT,CLA-IN)

ZBOUT

12

J4110

C4106

SBLSBR

J4107

J4108

J6666

SBR

SBL

15

J6455

R6145

C6606

C4118

C4103

30

J4115

J6466

7

R6466

C6466

P6401A

22

SLSR

J4105

22

C5086

ID-

J6823

J6824

PC

CBL/SAT

10

J4185

12

J4109

C4101

15

C4102

J4106

R5406

C5486

R5526

30

30

J6446

J6456

P6026

27

12

12

CE

J4014

J4013

25

22

QR

R6406

J6827

J6826

J6825

B

TV

J4015

10

J4017

22

J5506

20

C5526

R6006

AUX

15

J4173

25

J4016

L6446

R6026

22

22

C4011

15

C4262

J4180

C4261

12

C5506

R5486

SR SL

15

R6166

J4261

J4262

12

J5026

17

12

C6426

C6406

R5066

7

101710

J5006

J6667

7

J6435

J6436

R5506

R6146

J6830

J6829

J6828

CD

C4012

VOLIC

J4190

J4179

J4195

J4267

J4265

J4257

J4266

10

J5517

15

C5026

C5006

R5386

R5466

J5466

R6467

1020

15

J6457

C6607

Q6006

10

C4181

J6467

15

J6831

22

P4001

1.RDSI

17

20

P7002B

10.SEC1H

VOLH

AMUT

SBMUT

C4254

R4262

R4261

C6427

C5527

J6447

R6027

12

25

25

B

C4063 C4064

12

J4188

1

5.VOLDAT

VPROTECT

IPROTECT

VOLCLKBD

J4187

J5027

10

7

L6447

C5647

R6007

10

R6167

CKDAGNDTU

10

10

+3.3VDD

-15VA

R4260

R5467

SBL

J6007

7

J4182

J4007

10

J4009

151515

J4184

J4192

J4183

C4190

15

J4177

J4178

17

15.SPRLCS

17.SPRLSB

SPRLF

ZBMUT

GNDDG

HPDET

C4253

R6407

C5087

R5407

J5507

C5507

R5527

R5487

C5487

J6437J6438

C6467

P6027

ID+

ID-

30

J6835

10

J6834

10

J6833

J6832

Q6027

CE

TroubleShoot

Q4002

P4002

C4255

C5088

C5488

R5528

J6458

J6741

J6842

J6841

Q6028

C4031

R6408

C5528

R5408

R5488

SBR

C6468

R6468

12

B

C4029

J5508

25

J6448

12

R6168

TV

J4263

J4264

+15V

L6448

R6008

J4181

1

C4021

C4023

C4025

25

C4027

J4258

C5648

J6843

J6008

J6844

10

10

Q4251A

Q4251 Q4252

C6428

7.+3.3VTU

TUR

TUL

J4066

J4176

J4175

J4174

12

J4188

1.+15VA

C4256

J5007

10

C5027

C5007

C6407

R5067

R5387

R5507

J5467

30

R6147

J6838

J6837

J6836

CD

71

P101B

J4194

C4020

C4022

J4065

C4024

C4176

C4026

+15V

C4175

J4255

J4187

10

-15V

J6743

10

7

15

C6608

22

Q6007

12

J6703

10

J6781

C6700

P6028

ID+

ID-

J6839

15

J4191

-15V

J6744

12

C6744

C6780

J4189

Q4252A

10

C4028

C4030

R4259

J4260

7

J6468

J6780

12

C6741

R6028

27

12

12

J6840

CE

C4307

J4186

10

J5028

12

C5508

7

20

P7003B

J5008

12

C5028

C5008

C6408

R5068

R5388

J5468

R5468

R5508

R6148

Q6008

GNDTU

DA

CK

GNDAD

AUXL

GNDAD

AUXR

BTR

MICOUT

DACSBL

DACSBR

ADLSR

DACCT

J4197

DACSW

DACFL

ADRIN

ADLIN

GNDDG

COAX

E

1.3.3VTU

5.GNDAD

10.BTL

15.DACSL

D

20.DACFR

25.OPT

C

B

A

Back

Q6021 Q6001

1

23456

Base

AudioSignal(FLOUT,CLA-OUT)

Base

● Eachvoltageisshownasthereferencevalue.

TX-SR292BT/SR393/SR494, HT-R398/R495

123456

J6903

902D

901

F69

F69

O

NC

10

02

0

10

C6

86

R5385

R5386

48

5

C5

R5

C

R5388

S

7

R

28

0

B

S

64

J

J

07

6

C

J

1D+06

0

LI

D+

6064428

1

07

J6

901

41

74

J6

4B

L

J

J

J

J

J

J6

J

J

J

J

J

J

C

J

J

C

J

J

C

J

B

P5

55

J

C

01000031461J7

C

7

J5

J

J

SB

63

J4

42

4180J

2

02

40

002

02

S

Z

08

38

SW

6001

B

2SD

2SDC6001E6002

B

2SD

2SDC6002E6003

B

2SD

2SDC6003E6005

B

2SD

2SDC6005E6006

B

2SD

2SDC6006E6007

B

2SD

2SDC6007E6008

B

2SD

2SDC6008EQ6021

B

B

2SB

2SBCQ6021E6022B2SB

2SBC6022

E

6023

B

B

2SB

2SB

E

6025

B

2SB

2SBC6025E6026

B

2SB

2SBC6026E6027

B

2SB

2SBC6027

E

6028

B

2SB

2SB

C

E

05

813

N

N

N

2915

C6

40

00076407

5067

50

00CR5

8

64

AT

AT

1

1

PC

/S

/S

RL6

5

L65

C

J5

C60074R5R520J400

R

R

C67

741

D-

D+

D+

C

C

0

05

BL

BL

BSS

1

C

R

23

1

R

2

26

6

06C40

55077R5

C5

8

R

R5

25417

66

02

J402020202C652

6405C556640656407

C

406

4

05

813

53

22

9

29

C

J55

428

C6

00

00

00

84

C5

485

486R556

BSS

C

85

50

50

C

+

C66

6667

7

C6

6

P6

27

7

I

D+

D+

I

D+

P

60

660

3

465

45

C4

10

I

D-

I

D-

C

C

I

D+

L

R6

J6

2

J64

J6J7

1

J

J164

662

9

77

T

52528

76

JJ550

6

J

41

066814

1

3

30

7

00

0

503

07

40

CCVO

Q400

C

CCC

C

Q

Q

Q4

Q

Q40

40V00

V

VVOVO

O

TU

Z

00

00BOP4

P4TVC428190

18

AU

T

T

V

X

V

LI

02

2

R

84

78

78

46

45

55

R6

J64

5

C6

6

068

R5

902

8

R

RCCC8C55

R61

R61

R6

R6

616

4444RLR6

64

L

P

00

TV

1

1

64

ID

ID

D-

7SW652

UT

DA

GN

J60

17

R

L

T

B

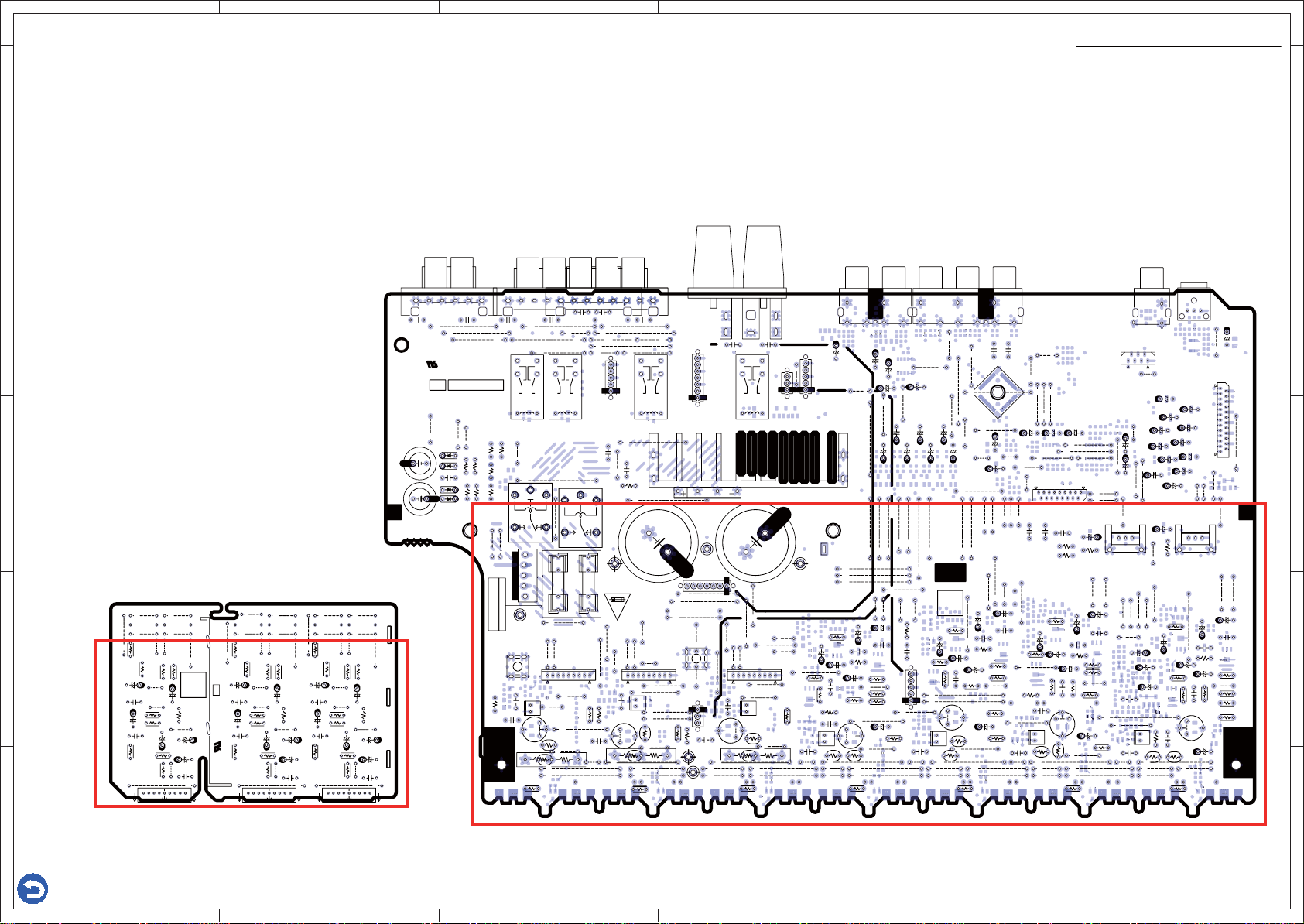

CheckPoint(BAAF-2690/BACLA-2673)

ANYPARTS

Checkdamage

E

Normal(OK)orDamage(Nogood)

Checkthedamageintheredframeworkpartasshownwithvisualinspection.

e.g.Broken,Burnout,Discoloration,etc.

C

C4251

C4252

10

J4251

SW

25

1

P6506

D4252

D4251

C4250

D4253

D4254

C6528 C6529

J6043

25

J6033

J4252

J4253

10

7

R4254

R4252

R4251

R4253

D

C

LR C

J5131

7

J5162

B

15

C5642

P6002A

R5522

R5402

J5032

R5442

R6402

C5482

J5182

C6422

R5422

R5462

R5502

C5002

J5172

R5382

C5082

7

J5022

J5161

J5181

15

10

J5192

QR

R5062

C5502 C5503

C5022

R5441

R5401

QPWBCCLA2673

0

C5521C5522 C5523

C5481

P5509B

C5641

25142673

BCCLA-2673

C6401C6402 C6403

R6401

R5521

J5031

P6001A

C6421

J5160

15

J5171

10

J5191

R5381

R5421

C5081

R5481R5482 R5483

R5061

R5461

C5643

C5501

R5523

C5021

J5021

R5501

C5001

P6003A

J5130J5132

10 10

J5140J5141J5142

10 10 10

J5150J5151J5152

10 10 10

R5443

R5403

J5030

C5483

R6403

J5180

J5040J5041J5042

J5050J5051J5052

C6423

R5423

R5503

R5463

J5100J5101J5102

10 10 10

J5110J5111J5112

10 10 10

J5120J5121J5122

10 10 10

J5170

J5060J5061J5062

J5020

R5383

C5083

R5063

77

10

J5190

C5023

252525

C5003

P6502

C6527

27

J6042

20

QPWBCAF2690

BCAF-2690

25142690A

R4255

R4256

J6908

7

R6914

J6914

J6911

30

COM

RL6911

RL6912

J4250

R6913

NO

J6901

J6902

10

10

P6901

10A/125V

F6901/F6902

P6902A

BLK

P5506B

C6603

R6463

C6463

J6443

R6083

Q6023

CE

C

2SB2SB2SB2SB2SB2SB2SB2SD 2SD 2SD 2SD 2SD 2SD 2SD

B

SBR SBL

SRSL

P6505

C6526

J6041

10

J6040

2730

J6032J6031

J6039

COM

15

NC

NO

F6902C F6902D

F6901C F6901D

F6901

F6902

15

J6903

J5023

J5003

10

10

9

ID+

10

P6023

J5503

ID-

7

R6143

R6461

J6023

C

20

J6453

R6003

L6443

R6023

J6003

10

30

30

22

Q6003Q6005

R6163

C

C6524

C6525

12

J6034

NC

30

10 20

P6401B

C6903

J6461

P6003B

17

1

J6803

30

J6013

J6660

12

C6461

R6081

J6802

J6801

J6800

25

J6036

J6035

J6030

J6037

17

J6038

5.NC

4.SR

3.SL

2.SBR

1.SBL

25

J6907

C6904

J6904

10

R6901

J6905

30

P6903A

RED

C6901

7.SBL

6.SL

5.L

4.C

3.R

2.SR

J6011

7

J5021

J5001

J6661

J6721

10

10

7

9

15

17

C6601

ID+

ID-

17

P6021

17

L6441

R6001

J6441

10

27

J6807

20

20

12

Q6021Q6022

CE

B

R6161R6162

TroubleShoot

15

FR FL

J6352

12

P6022

25

25

P6501

Q4002

TV

CD

P4002

J4181

C4255

C5088

C5488

SBR

R6468

C5528

R5488

C6468

B

C4031

R6408

R5408

25

12

C4029

J5508

J6448

12

R6168

J4264

L6448

R6008

C4021

C4023

C4025

C4027

J4263

+15V

1

25

J4258

10

C5648

J6843

J6008

J6844

10

Q4251A

Q4251 Q4252

C6428

C5508

C4307

12

7

71

J4194

C4020

C4022

C4024

C4026

C4028

C4030

R4259

J4260

7

J6468

12

R5528

C6741

J6458

J6741

R6028

J6842

J6841

Q6028

CE

C4011

15

C4262

J4180

C4261

J4262

12

J5026

12

12

17

C6426

C6406

R5066

7

J4261

J5006

J6435

J6436

J6830

J6829

J6828

VOLIC

J4267

J4266

101710

J6667

7

R5386

R5466

J5466

R5506

R6146

CD

C4012

Q4001

J4190

J4265

J5517

C5026

C5006

10

15

Q6006

P4001

7

J4182

J4007

10

J4009

151515

J4184

J4192

J4183

C4190

17

20

15

J4179

J4177

10

J4178

J4195

17

P7002B

10.SEC1H

15.SPRLCS

17.SPRLSB

J4257

C4181

J6467

15

15

R6467

1020

J6457

C6607

J6831

22

VOLH

AMUT

SBMUT

SPRLF

ZBMUT

GNDDG

HPDET

C4254

C4253

R4262

R4261

R6407

C6427

C5087

C5527

R5407

J5507

C5507

C5487

R5487

R5527

2

J6437J6438

C6467

J6447

P6027

ID+

ID-

R6007

R6027

12

30

J6835

10

25

J6834

10

25

J6833

J6832

Q6027

CE

B

1.RDSI

CKDAGNDTU

C4063 C4064

12

1

5.VOLDAT

+3.3VDD

VPROTECT

IPROTECT

VOLCLKBD

J5027

10

7

L6447

SBL

C5647

10

R6167

10

10

-15VA

R4260

R5467

J6007

TUR

TUL

J4176

J4175

J4174

J4188

1.+15VA

C4256

J5007

10

C5027

C5007

C6407

R5067

R5387

R5507

J5467

30

R6147

J6838

J6837

J6836

7.+3.3VTU

J4066

12

C4175

J4255

J4187

10

J6703

J6743

10

10

7

15

P6028

ID+

ID-

C6608

J6839

22

Q6007

J4065

C4176

J4191

12

-15V

12

J6781

C6744

C6700

J6744

C6780

P101B

15

J4189

Q4252A

J6780

10

27

12

12

J6840

SWOUT

C4104

C6521

J6561

1.C

2.FL

3.FR

7

P7880B

P6400B

RL6501 RL6503 RL6505 RL6507

P5510

P6904A

BLU

C6902

7

J6665

15

C5085

J6465

7

J5515

P6002B

J5505

17

J5502

J6022

ID+

ID-

R

10

R5405

R5525

R6142

R6465

C6465

ID+ID+

R6002

C6605

R6022

ID-

J6002

P6025

30

J6815

J6814

J6813

J6812

7

25

J6816

P4007

C4109

5.FL

4.GNDFR

3.FR

2./HPDET

1.GNDDG_HP

R6405

C5525

C5485

J6818

J6817

Q6025Q6026

CE

C4117

7

J4193

15

J4196

27

J4002

C4108

C4107

D6901A

C

FLFR

J4101

J4102

J4103

221522

22

27

J6366

27

J6368

27

J6367

15

J5005

J5025

7

7

C5025

C6425

C5005

C6405

R5065

R5385

J5465

10

C5505

R5485

R5465

R5505

20

J6445

C5645C5646

L6445

1217

J6005J6006

R6005

R6025

J6819

27

J6822

27

J6821

10

J6820

B

R6165

C4110

C4105

20720

7

NC

SR

SL

12

J4110

SBLSBR

J4107

J6666

SBR

SBL

15

R6145

C4118

C4106

J4108

R6466

J6455

C6606

J4115

7

C6466

22

C4103

SLSR

J4105

30

J6466

P6401A

J6823

C4101

J4106

22

C5086

J6456

ID-

J6824

R5526

30

30

CBL/SAT

12

J4109

C4102

C5486

27

12

12

TV

10

J4185

15

J4173

25

J4014

J4013

25

J4015

15

10

J4016

J4017

22

22

QR

J5506

R6406

20

C5526

R5406

J6446

R6006

P6026

R6026

J6827

J6826

J6825

CE

B

R5486

L6446

22

22

R6166

C5506

SR SL

15

AUX

PC

ZBOUT

P6504

C6523

12

7.SBL

6.SL

5.L

4.C

3.R

2.SR

1.SBR

C6522

P6402B

D6901

P6902B

BLK

1.SBR

J5326

J5327

L

R6141

R6021

J6806

J6805

J6804

P6402A

22

J6357

25

J5365

20

20

J6452

10

P5509A

P6001B

J6462

11

7

J5501

P6400A

J6021

J6433

J6451

R6462

J6001

P6903B

25

Q6001Q6002

BCEBCE BCEBCEBCEBCEBCE

RED

BLU

C

FL

FR

J6808

J6662

15

C6602

C6462

30

15

15

P6904B

10

J5002

9

J6365

J6012

17

J5022

7

7

12

J6442

L6442

R6082

J6811

J6810

J6809

CE

B

J4186

10

J5028

P7003B

12

C5028

C5008

C6408

R5068

R5388

J5468

R5468

R5508

R6148

Q6008

20

J5008

J4197

1.3.3VTU

GNDTU

DA

CK

5.GNDAD

GNDAD

AUXL

GNDAD

AUXR

BTR

MICOUT

DACSBL

DACSBR

ADLSR

DACCT

DACSW

DACFL

20.DACFR

ADRIN

ADLIN

GNDDG

COAX

25.OPT

E

D

10.BTL

15.DACSL

C

B

A

Back

BACLA-2673 BAAF-2690

●Eachvoltageisshownasthereferencevalue.

1

23456

A

TX-SR292BT/SR393/SR494, HT-R398/R495

123456

10

5

2525252525

2525

10

10

15

15

5

15

12

7

15

15

27

3012301710

7

0

7

7

15

121212

5

TX-SR393/494

ATMOS

2

N

T

DBL/

GAME

OX

V

UXPC

C

AM

uetoot

UP

T

RETU

R

R

o

Movie/TV

N

VOC

P

VOC

N

9007901

900

900

1

636763776387639

1

2

917

217722

J

J7780

J7782

J7906

1

0

1

2

J7850

J7851

4

1

0

01

J7902

J7858

802

1

2

612

611

J

621

610

9097910

B

3

914

1

0

0

7

8

3

27

85

T

17

51

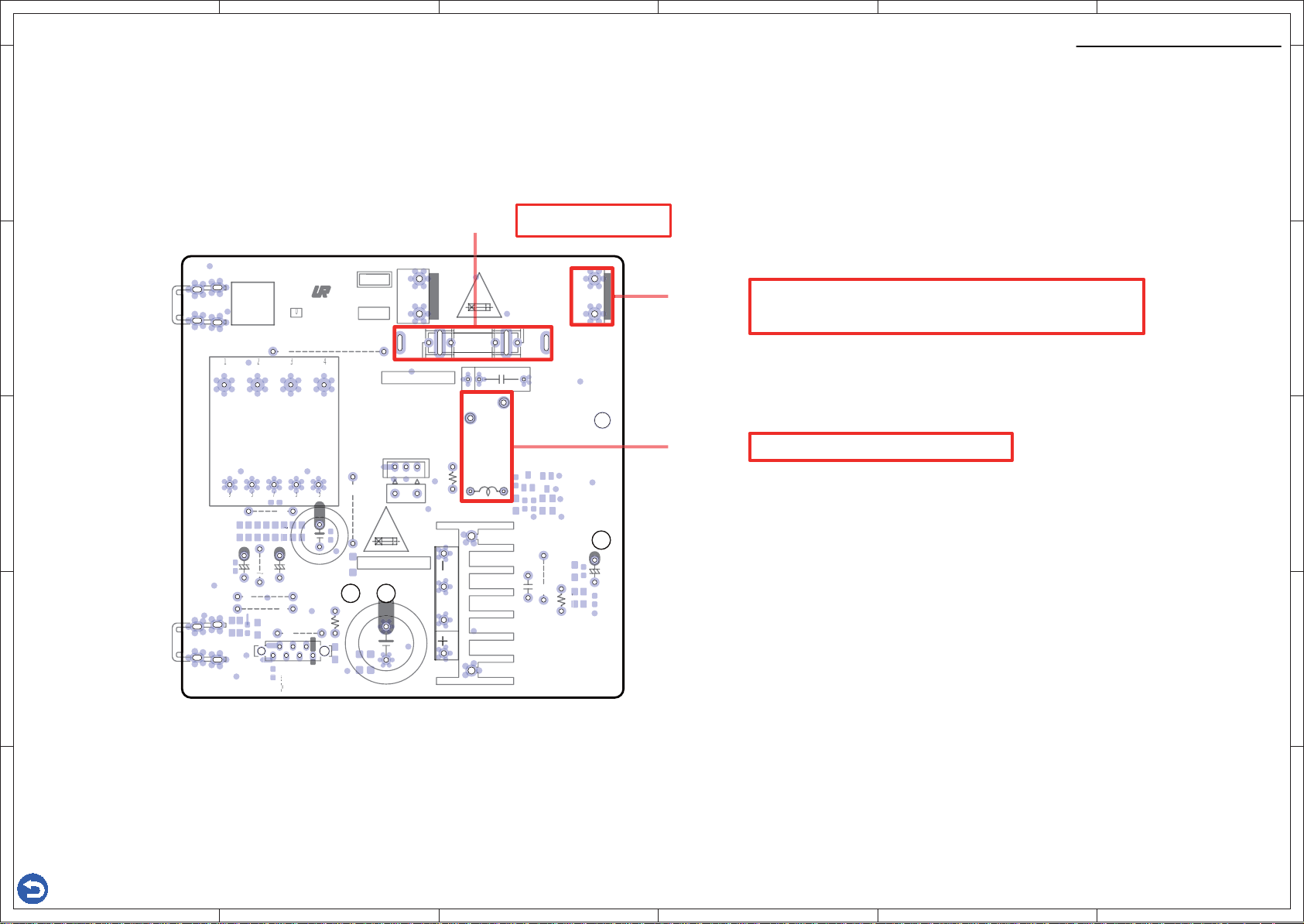

CheckPoint(BADIS-2672)

E

NC

KEY3

7700

NC

LED_ATMOS_4K

KEY2

FLDCLK

/REMIN

FLDSDO

GNDDG

FLDCS

+3.3S

/FLDRST

+3.3VDIS

MICMUT

VOLA

MICDET

VOLB

MICOUT

-15VA

AUXR

+15VA

75

GNDA

LED_BT_FLOFF

HT-R397

AUXL

PON_FL

/KEYINT1

/KEYINT0

KEY1

KEY2

15

7852

750075027503

7

7908

7

7635

TREBLE UP

ASS UP

7

77

777

7803

780

7

780

7

D

C

P7001

P7001B

7773777

5

AL U

TroubleShoot

7905

RIGH

FLAC1

FLAC2

STANDBY/O

MUSIC OP

ENTE

7622

ETUP

7634

TREBLE DOW

7

AL DOW

BASS DOWN

7907

7902

7905

7905A

1

7911

A

760

T

7

D

7903

TRM B

7

7922792

792

7923

DIMME

2

2

SAT

790

7918

7781

7605

2

2

7750775

775

D/DV

7

7

7

7

7924

SEC3_1

NC

SEC3_2

790

790

R7

BCDIS-267

Music

7633

7632

763

tere

7624

RN

l

h

E

D

C

B

A

Back

P7001

● Checkdamageandconnection

FFC

P7001

Howtocheck

1.DisconnecttheFFCfromthesocket.

2.CheckthecontactsoftheFFC.

●Eachvoltageisshownasthereferencevalue.

1

23456

B

A

TX-SR292BT/SR393/SR494, HT-R398/R495

123456

0

1

P863

2299

29

R34

P6800B

RR3

4

30

R34

L1010

L8933

L8934

L8941

7051A

L8943

L8944

L8951

L8953

L895403L8963

L8964

P81

94

R3495R3496R34

P8902

1

Q870

6

6

C8912

C8915

C8916

C8918

C8919

04

Q10

C8921

05

Q1

4

C8922

C8936

C8937

C8938

C8939

C8946

C8947

C8948

C8956

C8957

C8958

C8966

C8967

C8968

Q700

P780

01

R70

D7009

17

R70

Q800

P2802B

P36

Q3404

75

R70

08

R34

334

0

09

R34

C311

7053

7003

2

C

C100

C

0

027

C

8000C8006

3

8917

8157

C8158

8945

7062

3401

3418

C

8050

8632

8061

8062

8641

8101

8105

8109

5

L89

1

L802L803L804L80

1006

1007

8000

8006

R8239

8053

R8060

R8061

R8062

R8063

R8064

R8065

R8066

R3442

R8072

R8085

R8093

R8094

R8095

R8096

R71030R71361R7137

8103

8107

8111

R890

1

R8931

R8936

R10242R1026

1027

1028

R8941

R8946

R103513R1037

R8951

R8956

R8769

R8961

1054

1057

R1060

R7213

R7215

R7028

R7035

R7239

R7049

R7055

R7072

R7273

R7093

8033

8004

2

R

058234

L3

C8C83471

2

0

C1012

9

4

VP

1.

C

M_

_

S

8642

8611

C8001

.H

C8

0

2

Q

R

.G

8

VD

7

4

65Q8

f

T

1

B

14.

40

4.V

.+3.3VDG

02

0

C8902

890

C83

8904

R7228

22

3

1

R7142

14

CheckPoint(BAPRC-2695)

10.RS232TXD

11.GNDDG

9.RS232RXD

8.+3.3VST

5.GNDDG

E

D

C

2.~RESET

1.UB_M_PON

From PS

P2802B

P2802B

forSERVICE

6.USBM_DP

4.DBG_TXD

3.DBG_RXD

7.USBM_DM

11

P7053

2.GNDDG

1.M_PON

8

9

R7210

R7075

R7001

R7133

R7243R7244

Q7009

Q7009

R7017

R7028

R7239

R7055

R7236

R7238

R7240

R7057

7.~POFF

6.M_PON

5.~POFF2

R7201

4.GNDDG

3.+12VDG

R7229

2.GNDDG

R7277

1.+12VDG

R7227

D7009

R8904

R8903

D7009

D7016

R7218

R7034

R7230

R7024

R7228

7

R7074

R7274

R7226

R7142

R7019

C7001

R7009

C7001

R7007

C7003

D7001

D7015

73

D7001

1

MAIN_UPG

P7051A

R7215

R7035

R7049

R7216

R7044

R7046

72

+5.8V

0 → +2.5V

6

108

R7220

109

C7003

R7221R7222

R7103

R7136R7137

2

1

P7051A

R7211

R7213

R7072

R7212

R7020 R7214

R7273

R7030

+5.2V

17

P2802B

C8902

C8902

R8906

D8963

12

P8902

2.GNDDG

1.+12VWR

P8902

5.THERMAL

1.~PTC

2.GNDDG

3.+3.3VDC

4.GNDDG

D7014

S8901

3

S8901

D8963

Q8962

R8905

Q8962

Q8963

+10V → +18V

1

R8969

R8968

C8969

1

C8920

C7073

D7014

+10V → +18V

C8968

R8965

R8966

R8964

C8965

R8963

Q8963

R8970

R8961

R8962

P6800B

C707

C8921

C8922

L8963 L8964

C8966

C8967

L8962

Q8961

C8961

C8964

C8963

C8903

P6800B

5

C8962

1

L8961

L8961

THERMAL

MMPU_WRITE

DEGUG

MMPU/VMPU

P7053

3.RS232TXD

4.FINED_M

5.+3.3VST

7.RS232RXD

6.USBM_DP

8.USBM_DM

9.~RESET

R7132

R7084

R7223

R7209

R7196

37

R7203

36

R7021

R7202

R7199

R7198

R7029

C7195

C7196

R7257

R7258

R7153

R7241

R7146

R7145

R7237

R7208

R7054

R7048

R7121

1

R7094

C7031

144

R7093

C7073

C8050

R8053

C8917

R8958

C8918 C8919

L8953 L8954

C8956 C8957 C8958

R8954

R8956

R8955

R8957

C8955

R8953

R8951

R8952

Q8951

C8964

C8951

C8954

C8963

C8903

C8953

C8968

R7200

R7245

R7197

R8921

C8922

C8967

C3101

P3100

1

L8965

R7003

R8235

X7002

X8702

X7002

forVMCU

P8702

D8907

+3.3V

D8906

D8907

D8906

D8951

L8952

C8952

1

C8954

L8951

C8953

L8951

L8962

C8921

L8963 L8964

C8966

P3100

L8965

C3105

R3238

R8239

P8702

C8911

D8951

R8934

R8936

R8935

R8933

C8935

R8937

R8931 R8932

L3102

C3103

1

Q3121

C3166

R8234

C8988

R8996

C8989

X8702

+1.0V

C8912

C8939

L8933 L8934

C8936 C8937 C8938

Q8931

C8931

C3104

1

R8774

R8759

R8995

R8744

R8748

25

R8749

R8769

L8932

C8934

C8933

Q8951 Q8961

1

C8934

C8933

UPD

F/W

C8710

L3102

Q3121

C3103

100

26

C8932

C8918 C8919

L8953 L8954

C8956 C8957 C8958

C8642

C8710

Q8701

R8735

R8747

R8772

R8771

C3471

C3471

+1.1V

C8914

C8915C8916

R8945

R8946

R8944

R8943

C8945

R8947

R8942

R8941

C8941

L8931

L8931

L8952

Q8701

R8709

R8713

L8943 L8944

C8946 C8947 C8948

Q8941

76

50

R8712

R8750

C3472

C347

L8942

C8944

C8944

C8943

C8943

C8912

P8641

IN4

75

51

R8719

R8718

C3472

C8942

L8941

1

L8941

L8932

C8939

L8933 L8934

C8936 C8937 C8938

Q8931

TroubleShoot

C8001

C8632

C8641

C8641

C8632

P8631

C8622

C8631

C8631

C8622

P8621

IN3

QPWBCPRC2695

1

R8007

R8131

R8007

2

R3494 R3495 R3496

R3485

R3484

Q3404

R3409

L8943 L8944

C8946 C8947 C8948

Q8941

P8104

R3504 R3505

C3437 C3438 C3439

C3403 C3404 C3405

R3408 R3409

L8942

R8155

8

7

R3500

R3501

R3502 R3503

C3440

73

36

Q3404

R3401

R3405

C3401

R3408

7.BT_RST

8.BT_3.3V

9.BT_GND

R8132 R8133R8134

OSD_FLASH

R8706

R8727

R8708

R8716

R8715

P8104

1

108

109

R3497

R3497

C3425

C3423

R3452

C3422

C3424

C3424

R3450

R3448

R3447

R3445

R3445

R3441

QR

C3419

C3415

C3412

144

R3441

QR

1

R3430

R3430

Q3404

R3429

R3429

R3421 R3424 R3425

C8915C8916

25142695

BCPRC-2695

C8000

C8000C8006

C

L3404

72

R3460

R3459

R3467

L3404

R3463

C3429

R3458

C3427

R3457

R3456

L3403

R3454

R3453

C3420

R3443

R3442

C3413

C3418

C3414