Page 1

HOBO® 4-Channel Pulse Input

Data Logger (UX120-017x) Manual

The HOBO 4-Channel Pulse Input data logger records electronic pulses and mechanical or

electrical contact closures from external sensing devices. Using HOBOware®, you can easily

configure each of its four channels to monitor and record pulse, event, state, or runtime data in

a wide variety of applications, including tracking building energy consumption, monitoring

mechanical equipment, and recording water and gas flow rates. Plus, when combined with the

E50B2 Energy & Power Meter (T-VER-E50B2), this logger provides extensive power and energy

monitoring capabilities. There are two models of the HOBO 4-Channel Pulse Input data logger:

the UX120-017 stores more than 500,000 measurements while the UX120-017M holds more

than 4,000,000 measurements.

Specifications

Inputs

External Contact Input Electronic solid state switch closure or logic driven digital signals to

Maximum Pulse Frequency 120 Hz

Maximum State, Event,

Runtime Frequency

Bits 4–32 bits depending on pulse rate and logging interval

HOBO 4-Channel Pulse

Input Data Logger

Models: UX120-017

UX120-017M

Included Items:

• 4 Mounting screws

• 2 Magnets

• Hook & loop tape

• 4 Terminal block connectors

Required Items:

• HOBOware Pro 3.2 or later

• USB cable (included with

software)

Accessories:

• Additional terminal blocks

(A-UX120-TERM-BLOCK)

• Lithium batteries (HWSB-LI)

Additional sensors and accessories

available at www.onsetcomp.com.

Maximum Pulses Per

Interval

Driven Logic Signal Input Low: ≤ 0.4 V; Input High: 3 to 24 V

Absolute Maximum Rating Maximum Voltage: 25 V DC

Solid State Switch Closure Input Low: < 10 KΩ; Input High: > 500 KΩ

Internal Weak Pull-Up 100 KΩ

Input Impedance Solid state switch closure: 100 KΩ pull up; Driven signal: 4.5 KΩ

Minimum Pulse Width Contact closure duration: 500 uS; Driven logic signal: 100 uS

Lockout Time 0 to 1 second in 100 ms steps

Edge Detection Falling edge, Schmitt Trigger buffer

Preferred Switch State Normally open or Logic “1” state

Logging

Resolution Pulse: 1 pulse, Runtime: 1 second, State and Event: 1 State or Event

Logging Rate 1 second to 18 hours, 12 minutes, 15 seconds

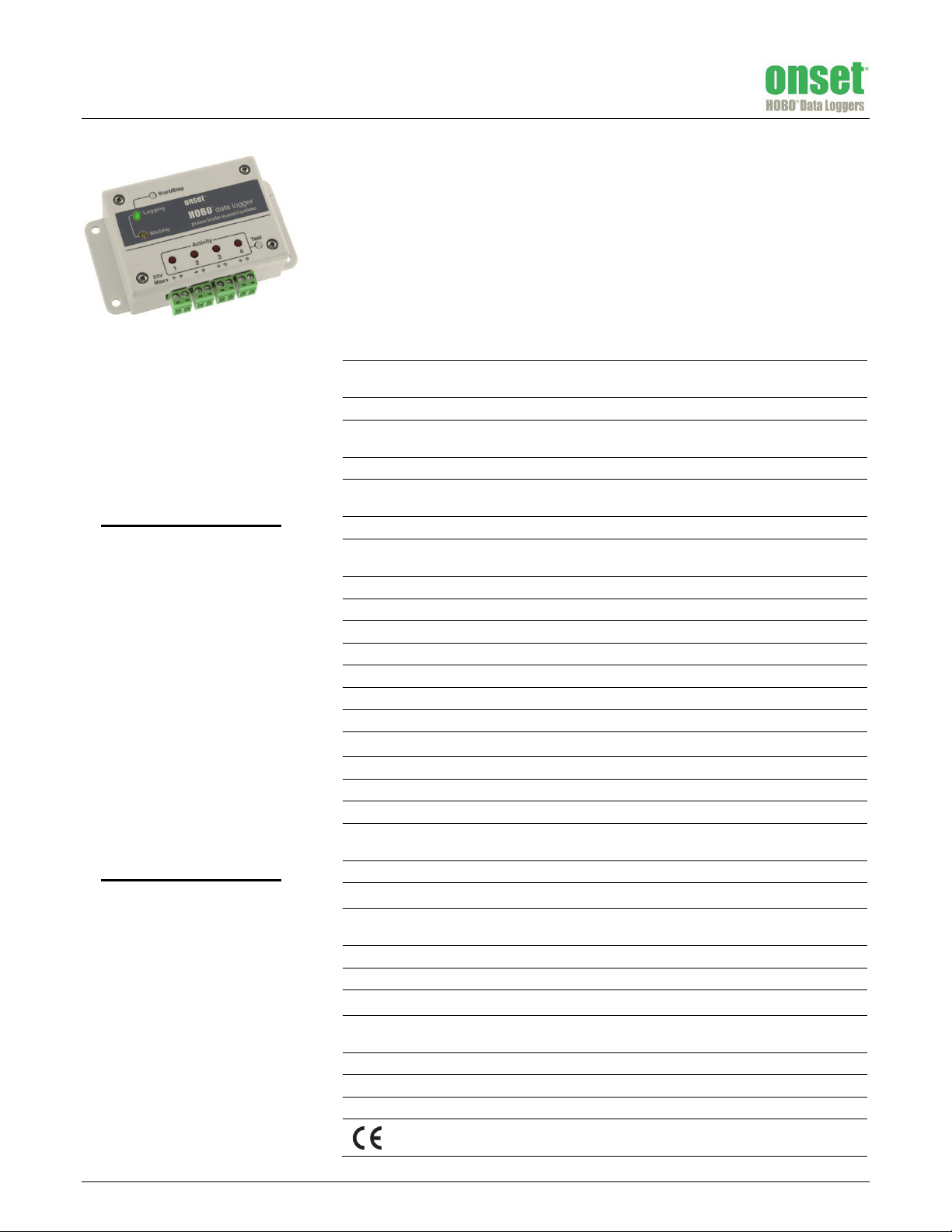

Time Accuracy ±1 minute per month at 25°C (77°F) (see Plot A on next page)

Battery Life 1 year, typical with logging intervals greater than 1 minute and

Battery Type Two AA alkaline or lithium batteries

Memory

Memory UX120-017: 520,192 measurements (assumes 8-bit)

Download Type USB 2.0 interface

Download Time 30 seconds for UX120-017, 1.5 minutes for UX120-017M

Physical

Operating Range Logging: -40° to 70°C (-40° to 158°F); 0 to 95% RH (non-condensing)

Weight 149 g (5.26 oz)

Size 11.4 x 6.3 x 3.3 cm (4.5 x 2.5 x 1.3 inches)

Environmental Rating IP50

24 V

1 Hz

7,863,960 (using maximum logging rate)

Minimum Voltage: -0.3 V DC

normally open contacts

UX120-017M: 4,124,672 measurements (assumes 8-bit)

Launch/Readout: 0° to 50°C (32° to 122°F) per USB specification

The CE Marking identifies this product as complying with all relevant

directives in the European Union (EU).

14638-F

Page 2

Specifications (continued)

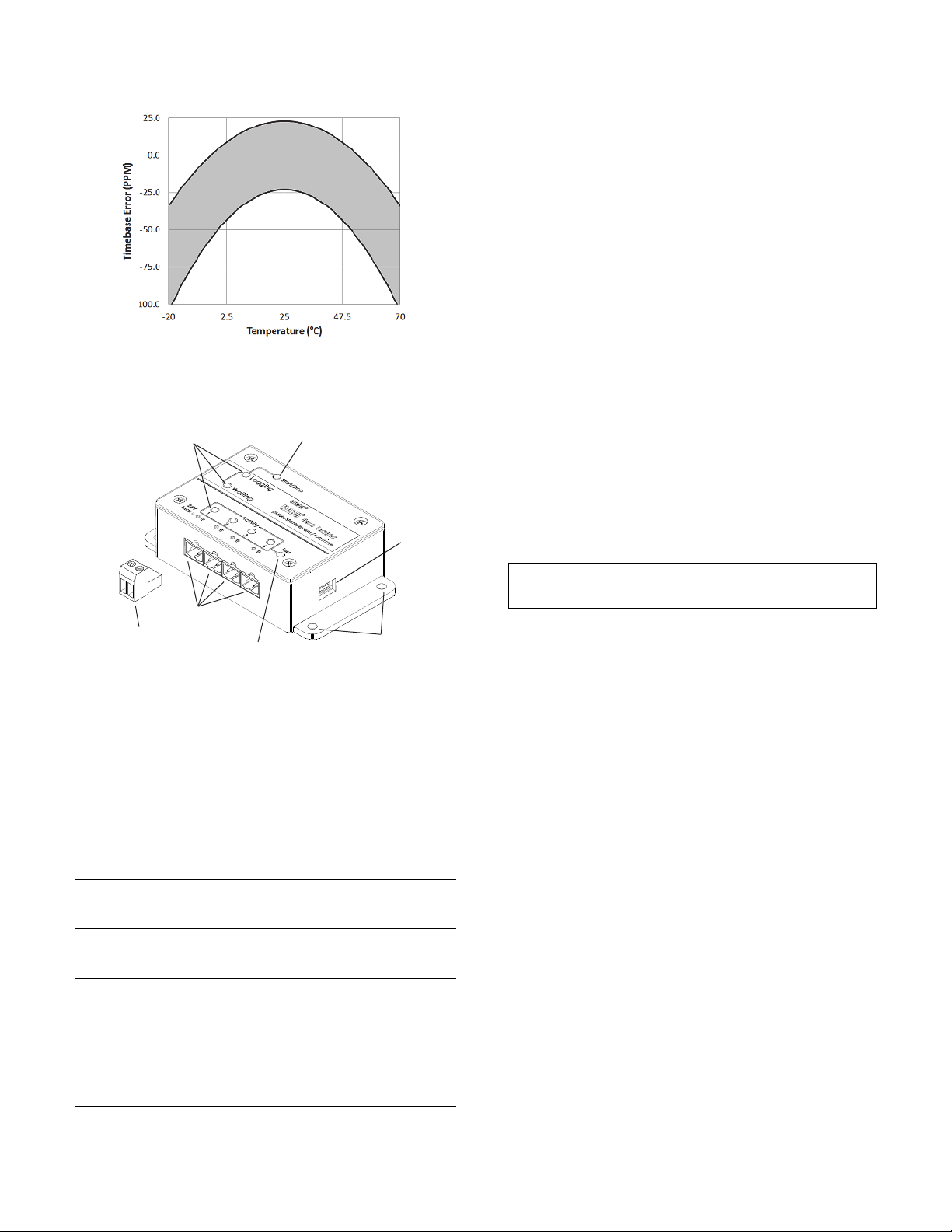

Terminal Blocks: There are 4 terminal blocks included with the

logger to plug into the inputs for connecting devices.

Test Button: Press this button to activate the Activity Lights for

10 minutes to test for contact resistance or voltage signal in any

of the four input channels (see the LED table).

Mounting Holes: There are four mounting holes, two on each

side, that you can use to mount the logger to a surface (see

Mounting the Logger).

USB Port: This is the port used to connect the logger to the

computer or the HOBO U-Shuttle via USB cable (see Setting up

the Logger and Reading Out the Logger).

Plot A: Time Accuracy

Logger Components and Operation

LEDs

Inputs

One of Four

Terminal Blocks

Test Button

Start/Stop Button: Press this button for 3 seconds to start or

stop logging data. This requires configuring the logger in

HOBOware with a Button Start and/or a Button Stop (see

Setting up the Logger). You can also press this button for

1 second to record an internal event (see Recording Internal

Logger Events).

LEDs: There are three types of LEDs on the logger to indicate

logger operation: Logging, Waiting, and Activity. Note that all

LEDs will blink when the logger is initially powered (i.e. when

the batteries are installed).

LED Description

Logging

(green)

Waiting

(orange)

Activity

(red)

Blinks every 2 seconds when the logger is recording data.

Disable this LED by selecting the Turn Off LEDs option in

HOBOware.

Blinks every 2 seconds when awaiting a start because the

logger was configured with Start At Interval, Delayed

Start, or Button Start settings in HOBOware.

There is one Activity LED per input channel. Press the

Test button to activate all four Activity LEDs for 10

minutes to determine the state of the four input

channels. When the logger is recording data, the Activity

LED for the corresponding channel will blink at every

pulse signal. Note: If you press the Test button during

logging, then the Activity LED will remain illuminated for

any channel that has not been configured to record data.

Inputs: There are 4 input channels to connect the logger to

external sensors/devices.

Start/Stop Button

USB Port

Mounting Holes

Setting Up the Logger

Use HOBOware Pro to set up the logger, including selecting the

start and stop logging options, configuring the input channels

for specific sensor types, and entering scaling factors. It may be

helpful to set up the logger with a Delayed Start or a Button

Start first and then bring it to the location where you will

mount it to connect the external sensors/devices and test the

connections before logging begins.

1. Connect the logger and open the Launch window. To

connect the logger to a computer, plug the small end of the

USB cable into the side of the logger and the large end into a

USB port on the computer. Click the Launch icon on the

HOBOware toolbar or select Launch from the Device menu.

Important: USB specifications do not guarantee operation

outside this range of 0°C (32°F) to 50°C (122°F).

2. Select Sensor Type. Each of the input channels can be

configured to log the following:

• Pulse. This records the number of pulse signals per logging

interval (the logger records a pulse signal when the input

transitions to the logic low). There are built-in scaling

factors you can select for supported devices and sensors,

or you can set your own scaling when you select raw pulse

counts. You can also adjust the maximum pulse frequency

and lockout time as necessary.

• State. This records how long an event lasts by storing the

date and time when the state of the signal or switch

changes (logic state high to low or low to high). The logger

checks every second for a state change, but will only

record a time-stamped value when the state change

occurs. One state change to the next represents the event

duration.

• Event. This records the date and time when a connected

relay switch or logic low transition occurs (the logger

records an event when the input transitions to the logic

low). This is useful if you need to know when an event

occurred, but do not need to know the duration of the

event. You can also adjust the lockout time to debounce

switches.

• Runtime.

This records the number of state changes that

happen over a period of time. The logger checks the state

of the line once a second. At the end of each logging

interval, the logger records how many seconds the line

was in the logic low state.

1-800-LOGGERS 2 www.onsetcomp.com

Page 3

3. Choose the logging interval, from 1 second to a maximum

of 18 hours, 12 minutes, and 15 seconds (available for Pulse

or Runtime logging only).

4. Choose when to start logging:

• Now. Logging begins immediately.

• At Interval. Logging will begin at the next even interval.

• Push Button. Logging will begin once you press the

Start/Stop logging button for 3 seconds.

• On Date/Time. Logging will begin at a date and time you

specify.

5. Choose when to stop logging:

• When Memory Fills. Logging will end once the logger

memory is full.

• Never (Wrap When Full). The logger will record data

indefinitely, with newest data overwriting the oldest.

• Push Button. Logging will end once you press the

Start/Stop logging button for 3 seconds. Note: If you also

configured a Push Button start, then you must wait 5

minutes after logging begins before you can use the

button to stop logging.

• Specific Stop Date. Logging will end at a date and time you

specify.

6. Select any other logging options as desired and finish the

launch configuration. Depending on the start type, verify

that the logging or waiting LED is blinking.

Connecting Sensors, Transducers, or

Instruments to the Logger

You can connect the logger to an external sensing device using

the four input channels. To connect a device to the logger:

1. Follow the instructions and wiring diagrams in the user

manual for the device.

2. Connect the device to the terminal block as directed in the

device instructions.

3. Plug in the terminal block into one of the four inputs (labeled

1 through 4).

4. Press the Test button as needed to activate the Activity LEDs

and check whether the logger reads the pulse signal.

5. Configure logger launch settings if you have not already.

Notes:

• Be sure that all devices are connected before logging

begins. Any sensors/devices attached after logging begins

will not record accurate data.

• If connecting an E50B2 Energy & Power Meter

(T-VER-E50B2), you have the option to use the default

meter settings or your own custom settings.

• If any channels have been configured to record raw pulse

counts or events in HOBOware, there is also an option to

specify lockout time. This can prevent false readings from

mechanical contact/closure bouncing. For more

information on setting lockout time, see the HOBOware

Help.

Determining Logging Duration for

Event/State Data

The logger’s storage capacity and logging duration varies

depending on several factors, including logging interval, number

of channels configured, and the type of data being recorded. This

table estimates the logging duration based on recording event or

state changes on one input channel with logging set to stop when

the memory is full. To estimate logging duration for multiple

event or state channels, divide the logging duration by the

number of active channels. If you want to know exactly how long

the logger will run, use pulse or runtime modes.

Time

Between

Events

1 to 15

seconds

16 seconds

to

4.2 minutes

4.3 to 68.2

minutes

68.3

minutes to

18.2 hours

Approximate

Total Data

Points

346,795 4 to 60 days UX120-017

2,749,781 32 days to 1.3 years UX120-017M

260,096 48 days to 2.1 years UX120-017

2,062,336 1 to 16.6 years UX120-017M

208,077 1.6 to 27 years UX120-017

1,649,869 13 to 214 years UX120-017M

173,397 22.5 to 360 years UX120-017

1,374,891 17.8 to 285 decades UX120-017M

Approximate

Logging Duration

(1 Year Battery Life)

Logger Part

Number

Notes:

• Typical battery life is 1 year.

• The logger can record battery voltage data in an additional

channel. This is disabled by default. Recording battery

voltage reduces storage capacity and is generally not used

except for troubleshooting.

Setting Maximum Pulse Frequency

When recording raw pulse counts, the logger dynamically

adjusts its memory usage from 4 to 32 bits instead of a typical

fixed width. This results in the ability to store more data using

less space, which in turn extends logging duration. The default

pulse rate is 120 Hz, which is also the maximum. You can adjust

this rate in HOBOware (see the HOBOware Help for details).

Decreasing the rate will increase logging duration. The

following table shows examples of how pulse rate and logging

interval affect logging duration.

Logging

Interval

1 minute 4 8 520,192 361 days

1 minute 50 12 346,795 240 days

1 minute 120 16 260,096 180 days

Pulse

Rate

(Hz)

Number

of Bits

Required

Approximate

Total Data

Points

Approximate

Logging

Duration

Reading Out the Logger

There are two options for reading out the logger: connect it to

the computer with a USB cable and read out it with HOBOware,

or connect it to a HOBO U-Shuttle (U-DT-1, firmware version

1.14m030 or higher) and then offload the datafiles from the

1-800-LOGGERS 3 www.onsetcomp.com

Page 4

HOBO 4-Channel Pulse Input Data Logger Manual

U-Shuttle to HOBOware. Refer to the HOBOware Help for more

details.

Recording Internal Logger Events

The logger records several internal events to help track logger

operation and status. These events, which are unrelated to

state and event logging, include the following:

Internal Event Name Definition

Host Connected The logger was connected to the computer.

Started The Start/Stop button was pressed to begin

Stopped The logger received a command to stop

Button Up/Button

Down

Safe Shutdown The battery level is 1.8 V; the logger shut

logging.

recording data (from HOBOware or by

pushing the Start/Stop button).

The Start/Stop button was pressed for

second.

1

down.

Mounting the Logger

There are three ways to mount the logger using the materials

included:

• Screw the logger to a surface with a Phillips-head

screwdriver and the four mounting screws, using the

following dimensions.

10.16 cm (4 inches)

discharge by grounding yourself to protect the logger. For more

information, search for “static discharge” in the FAQ section on

onsetcomp.com.

Battery Information

The logger is shipped with two AA alkaline batteries. You can

also use 1.5 V AA lithium batteries when deploying the logger in

cold environments. Expected battery life varies based on the

temperature where the logger is deployed and the frequency

(the logging interval and the rate of state changes and/or

events) at which the logger is recording data. A new battery

typically lasts one year with logging intervals greater than one

minute and when the input signals are normally open or in the

high logic state. Deployments in extremely cold or hot

temperatures, logging intervals faster than one minute, or

continuously closed contacts may reduce battery life.

The logger can also be powered through the USB cable

connected to the computer. This allows you to read out the

logger when the remaining battery voltage is too low for it to

continue logging. Connect the logger to the computer, click the

Readout button on the toolbar, and save the data as prompted.

Replace the batteries before launching the logger again.

To replace the batteries:

1. Disconnect the logger from the computer.

2. Unscrew the logger case using a Philips-head screwdriver.

3. Carefully remove the two batteries.

4. Insert two new AA batteries (alkaline or lithium) observing

polarity. When batteries are inserted correctly, all LEDs blink

briefly.

5. Carefully realign the logger case and re-fasten the screws.

4.57 cm

(1.8 inches)

• Attach the two magnets to the back of the logger and

then place the logger on a magnetic surface.

• Use the hook-and-loop tape to affix the logger to a

surface.

Protecting the Logger

The logger is designed for indoor use and can be permanently

damaged by corrosion if it gets wet. Protect it from

condensation. If it gets wet, remove the battery immediately

and dry the circuit board. It is possible to dry the logger with a

hair dryer before reinstalling the battery. Do not let the board

get too hot. You should be able to comfortably hold the board

in your hand while drying it.

Note: Static electricity may cause the logger to stop logging.

The logger has been tested to 4 KV, but avoid electrostatic

WARNING: Do not cut open, incinerate, heat above 85°C

(185°F), or recharge the lithium batteries. The batteries may

explode if the logger is exposed to extreme heat or conditions

that could damage or destroy the battery cases. Do not dispose

of the logger or batteries in fire. Do not expose the contents of

the batteries to water. Dispose of the batteries according to

local regulations for lithium batteries.

HOBOware provides the option of recording the current battery

voltage at each logging interval, which is disabled by default.

Recording battery life at each logging interval takes up memory

and therefore reduces logging duration. It is recommended you

only record battery voltage for diagnostic purposes.

1-800-LOGGERS (564-4377) • 508-759-9500

www.onsetcomp.com • loggerhelp@onsetcomp.com

© 2011–2015 Onset Computer Corporation. All rights reserved. Onset, HOBO, and HOBOware are

trademarks or registered trademarks of Onset Computer Corporation. All other trademarks are the

property of their respective companies.

14638-F

Loading...

Loading...