Page 1

Part number: 849215

Unrivalled Detection. www.ionscience.com

TVOC

Instrument User Manual V4.5

Page 2

Part number: 849215

Register your instrument online for extended warranty

Thank you for purchasing your Ion Science instrument.

The standard warranty of your instrument can be extended to up to five years

on PhoCheck Tiger and two years on other Ion Science instruments.

To receive your extended warranty, you must register your instrument online

within one month of purchase (terms and conditions apply.)

Visit www.ionscience.com/instrument-registration

Page 3

TVOC MANUAL Ion Science Ltd

Page 3 of 32

Unrivalled Detection. www.ionscience.com

Declaration of conformity

Manufacturer: Ion Science Ltd, The Way, Fowlmere, Cambridge, SG8 7UJ, UK

Product: TVOC

Product Description: An intrinsically safe fixed continuous monitor comprising of a photo-ionisation

detector for detecting and measuring volatile organic compounds with a 4-20mA

output

Directive 94/9/EC ATEX

Identification: II 2G EEx ia IIC T4 (-20oC ≤ Ta ≤ +50oC)

Notified Body: Baseefa Ltd, 1180, Buxton, UK

Identification: II 3G Ex nA IIC T4 (-40oC < Ta < +50oC)

Ion Science Ltd Self certified EC Type Examination Certificate(s)

Baseefa05ATEX0277 latest supplement Baseefa05ATEX0277/2 issued 24

th

November 2008

Ionscience09849 Examination certificate issued 4th September 2009

Ref Ion Science Cert Report 849237, 849242

International Standards

IECEx BAS 06.0057 latest revision no.1 issued 20th November 2008

Ref Baseefa Cert Report 05(c)0423, 06(c)0614, 08(c)0578

Ex ia IIC T4 (-20oC Ta + +50oC)

Standards

BS EN 60079-0:2006 Electrical Apparatus for Potentially Explosive Atmospheres – General Requirement

BS EN 60079-11:2007 Explosive Atmospheres - Equipment Protection by Intrinsic Safety ‘i’

BS EN 60079-15:2007 Explosive Atmospheres - Equipment Protection by other means ‘n’

BS EN 61010-1:2010 Safety requirements for electrical equipment for measurement, control and

laboratory use – General requirements

Directive 2004/108EC Electrical Equipment – Electromagnetic Compatibility (EMC)

EN61000-6-3:2007 Class 1 (light industrial and domestic) Electromagnetic Compatibility (EMC) Generic

standards. Emission standard for residential, commercial and light industrial

environments

EN50270:2006 Electromagnetic compatibility. Electrical apparatus for the detection and

measurement of combustible gases, toxic gases or oxygen.

Other Standards

BS EN ISO 9001:2008 Quality Management Systems – Requirements

BS EN 13980:2002 Potentially Explosive Atmospheres – Application of Quality Systems

On behalf of Ion Science Ltd, I declare that, on the date this product accompanied by this declaration is

placed on the market, the product conforms to all technical and regulatory requirements of the above listed

directives.

Name: Mark Stockdale Position: Technical Director

Signature: Date: 20th November 2009

Page 4

TVOC MANUAL Ion Science Ltd

Page 4 of 32

Unrivalled Detection. www.ionscience.com

Contents

Declaration of conformity .............................................................................................................................. 3!

Statements ...................................................................................................................................................... 5!

Responsibility for use .................................................................................................................................... 5!

Quality assurance ......................................................................................................................................... 5!

Disposal ........................................................................................................................................................ 5!

Legal Notice .................................................................................................................................................. 5!

Introduction to TVOC ...................................................................................................................................... 6!

Packing list ...................................................................................................................................................... 8!

Standard TVOC instrument ........................................................................................................................... 8!

TVOC Calibration Tool Kit ............................................................................................................................. 8!

TVOC setup ..................................................................................................................................................... 9!

Selector Pins ................................................................................................................................................. 9!

Duty Cycle ................................................................................................................................................... 10!

Installation ..................................................................................................................................................... 11!

Location ....................................................................................................................................................... 11!

Cable and gland requirements .................................................................................................................... 11!

Dimensions for mounting ............................................................................................................................ 12!

Power requirements .................................................................................................................................... 13!

Initial calibration .......................................................................................................................................... 15!

Operation ....................................................................................................................................................... 16!

Start Up ....................................................................................................................................................... 16!

Adjusting the Duty Cycle ............................................................................................................................. 16!

LED’s ........................................................................................................................................................... 17!

Selector pins ............................................................................................................................................... 17!

Calibration mode ......................................................................................................................................... 17!

Calibration gases ........................................................................................................................................ 17!

Calibration routine ....................................................................................................................................... 18!

Setting the ZERO ........................................................................................................................................ 18!

Setting the gas concentration (The actual value that the calibration has been supplied at) ....................... 19!

Setting the SPAN ........................................................................................................................................ 19!

Maintenance .................................................................................................................................................. 21!

Cleaning / replacing the lamp ...................................................................................................................... 21!

Fuse rupture and replacement .................................................................................................................... 23!

Lamp Warranty Statement .......................................................................................................................... 23!

System recommendations ........................................................................................................................... 24!

Remote area monitoring .............................................................................................................................. 24!

Gas sample systems ................................................................................................................................... 24!

Instrument warranty and service ................................................................................................................ 26!

Warranty ...................................................................................................................................................... 26!

Service ........................................................................................................................................................ 26!

Contact details ............................................................................................................................................ 26!

Diagnostics .................................................................................................................................................... 27!

F4 errors ...................................................................................................................................................... 28!

Technical specifications .............................................................................................................................. 30!

Manual log ..................................................................................................................................................... 31!

Page 5

TVOC MANUAL Ion Science Ltd

Page 5 of 32

Unrivalled Detection. www.ionscience.com

Statements

Responsibility for use

TVOC detects a large range of gases, which are potentially dangerous from both a poisoning and/or an

explosive perspective. TVOC has a number of selectable features allowing the detector to be used in a

variety of applications. Ion Science Ltd can accept no responsibility for the incorrect adjustment of features

that cause harm or damage to persons or property. It is the users’ responsibility to respond appropriately to

the readings delivered.

Inadequate performance of the gas detection equipment described in this manual may not necessarily be

self-evident and consequently equipment must be regularly inspected and maintained. Ion Science

recommends that personnel responsible for equipment use institute a regime of regular checks to ensure it

performs within calibration limits, and that a record be maintained which logs calibration check data. The

equipment should be used in accordance with this manual, and in compliance with local safety standards.

Warning

1. Substitution of components may impair intrinsic safety and result in unsafe conditions.

2. For reasons of safety, TVOC must only be operated and serviced by qualified personnel.

3. Please read and understand this user manual fully before installing, operating or servicing TVOC.

Quality assurance

TVOC has been manufactured in compliance with ISO9001:2008, which ensures that the equipment

supplied to our customers has been designed and assembled reproducibly, from traceable components, and

leaves Ion Science calibrated to stated standards.

Disposal

Dispose of TVOC and its components in accordance with all local and national safety and environmental

requirements. This includes the European WEEE (Waste Electrical and Electronic Equipment) directive. Ion

Science Ltd offers a take back service. Please contact us for more information.

Legal Notice

Whilst every attempt is made to ensure the accuracy of the information contained in this manual, Ion Science

accepts no liability for errors or omissions, or any consequences deriving from the use of information

contained herein. It is provided "as is" and without any representation, term, condition or warranty of any

kind, either express or implied. To the extent permitted by law, Ion Science shall not be liable to any person

or entity for any loss or damage which may arise from the use of this manual. We reserve the right at any

time and without any notice to remove, amend or vary any of the content which appears herein.

Page 6

TVOC MANUAL Ion Science Ltd

Page 6 of 32

Unrivalled Detection. www.ionscience.com

Introduction to TVOC

TVOC is a fixed continuous monitor for the detection and measurement of total volatile organic compounds,

which can be dangerous from both a poisoning and explosive perspective. Total VOC’s are detected using

PID (Photo ionisation detection) technology.

TVOC has a number of user selectable features which define its operation and will be application dependent.

The user can define the detection ranges or 0.01 - 10ppm, 0.1 – 100 ppm or 1 – 1,000 ppm (Default);

detection units, either ppm or mg/m3; and the duty cycle time i.e. the frequency that the instrument takes a

measurement. Duty cycles are explained in more detail under TVOC set up, and Operation.

IMPORTANT: TVOC can be calibrated on alternative gases to Isobutylene however to ensure TVOC

remains within specification, the correct concentration for the alternative gas must be chosen.

Example: Benzene gas has a response factor of 0.5 which means only half as much concentration is

required to produce the equivalent to Isobutylene.

The ideal gas / concentrations used to set the calibration SPAN are shown below:-

Lower limit Upper limit

10 ppm range 8 ppm 12 ppm Isobutylene equivalent

100 ppm range 90 ppm 110 ppm Isobutylene equivalent

1,000 ppm range 90 ppm 110 ppm Isobutylene equivalent

How to calculate alternative concentration of gases for gases other than Isobutylene:-

Calibration Ideal response Response factor Ideal calibration gas

Gas for Isobutylene concentration

Benzene 100 x 0.5 = 50 ppm

Isoprene 100 x 0.7 = 70 ppm

Isobutylene 100 x 1.0 = 100 ppm

Carbon disulfide 100 x 1.4 = 140 ppm

Ethyl acrylate 100 x 2.0 = 200 ppm

For other gas response factors please refer to the Ion Science web site or contact Ion Science Ltd.

http://www.ionscience.com/GasSearch/tabid/87/Default.aspx

WARNING: Ignoring these guide lines may result in calibration failure, loss of resolution or loss of range.

The default settings of TVOC are:

Detection range – 1 – 1000 ppm

Units - ppm

Signal update - 60 seconds

TVOC gives a continuous 4-20 mA output which can be integrated into a DCS control system to give an

indication of VOC levels in the operating environment. Note the 4-20 mA output must be externally powered

with 8-35 V.

In addition to the 4-20 mA output TVOC has an LCD display showing gas concentration and 4 colour LED’s.

LED functions are as follows:

Green - is an indicator of TVOC’s working status

Red - is the fault indicator

Yellow x 2 - are calibration status indicators

Please see Calibration for more information on LED status.

Page 7

TVOC MANUAL Ion Science Ltd

Page 7 of 32

Unrivalled Detection. www.ionscience.com

Introduction to TVOC

For installation requirements please refer to Installation and Technical Specification of this manual. Before

attempting an installation, please fully read and understand this user manual, and for hazardous area (IS)

installations please also refer to the TVOC Intrinsically safe certificate for further details.

The TVOC safety rating permits its deployment in all hazardous areas of the quoted (or less demanding)

rating. For detail please refer to the marking on your instrument (found on the front main label). As of 1st of

October units will be manufactured with two protection concepts applied by separate certifications. Intrinsic

safety (ia) and Non sparking (nA). All units manufactured up to that date will only have intrinsic safety.

a) Intrinsic Safety (ia) permits the deployment in areas where explosive gases (of group IIA, IIB and IIC) are

intermittently present (zone 1) with an ambient temperature range of -20 to 50°C. Intrinsically safe

installations will require the use of safety barriers and appropriate wiring.

b) Non sparking (nA) permits deployment in areas where explosive gases (of group IIA, IIB, IIC) are unlikely

but possible (Zone 2) with ambient temp range of -20°C to 50°C. Non sparking installations do not require

safety barriers however the maximum working voltage should be strictly adhered to as a matter of safety. As

no safety barriers are required there is complete flexibility on the implementation of a three wire system.

TVOC does require regular calibration onsite please see the Calibration section for more information. TVOC

calibration mode is accessed via a magnetic on site switch system.

Page 8

TVOC MANUAL Ion Science Ltd

Page 8 of 32

Unrivalled Detection. www.ionscience.com

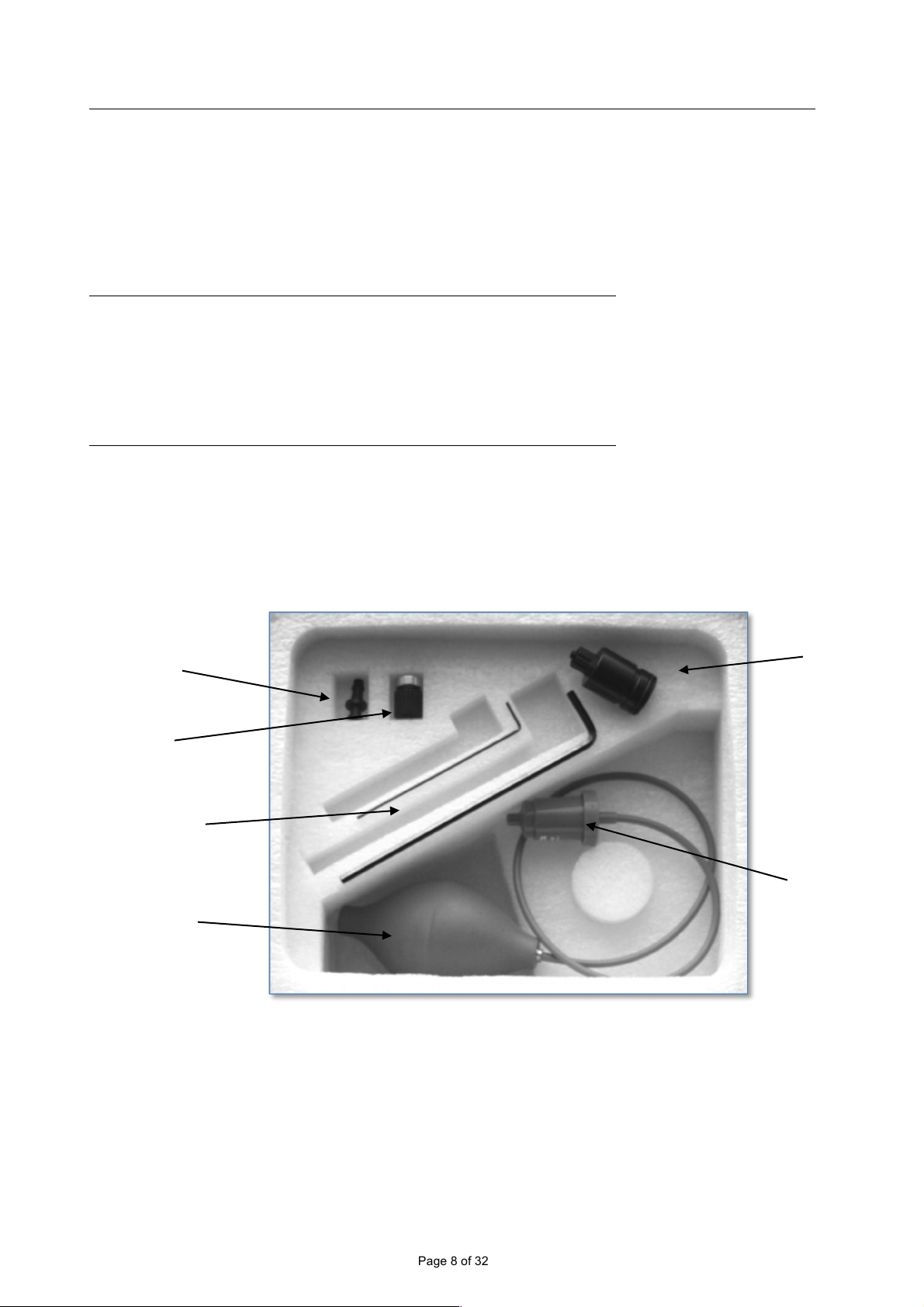

Packing list

All items of equipment shipped by Ion Science Ltd are packed in suitable containers and enclosed in a shock

absorbing filling which affords a considerable degree of protection against physical damage.

Contents should be carefully removed and checked against the packing list. Any discrepancies between the

contents and the packing list must be reported to Ion Science Ltd within ten days of receipt of shipment. Ion

Science cannot be held responsible for shortages not reported with in the period.

Standard TVOC instrument

Item Description Qty

1. TVOC instrument 1

2. Cable gland M20 (Intrinsically Safe Certified) 2

3. Blanking plug M20 intrinsically (Intrinsically Safe Certified) 1

4. TVOC Manual 1

TVOC Calibration Tool Kit

Item Description Qty

1. Calibration magnet 1

2. Calibration adaptor 1

3. Calibration connector 1

4. Aspirator 1

5. Carbon filter 1

6. Allen keys 1

3. Calibration

connector

1. Calibration

magnet

6. Allen keys X 2

4. Aspirator

2. Calibration

adaptor

5. Carbon

filter

Diagram 1

Page 9

TVOC MANUAL Ion Science Ltd

Page 9 of 32

Unrivalled Detection. www.ionscience.com

Diagram 3

TVOC setup

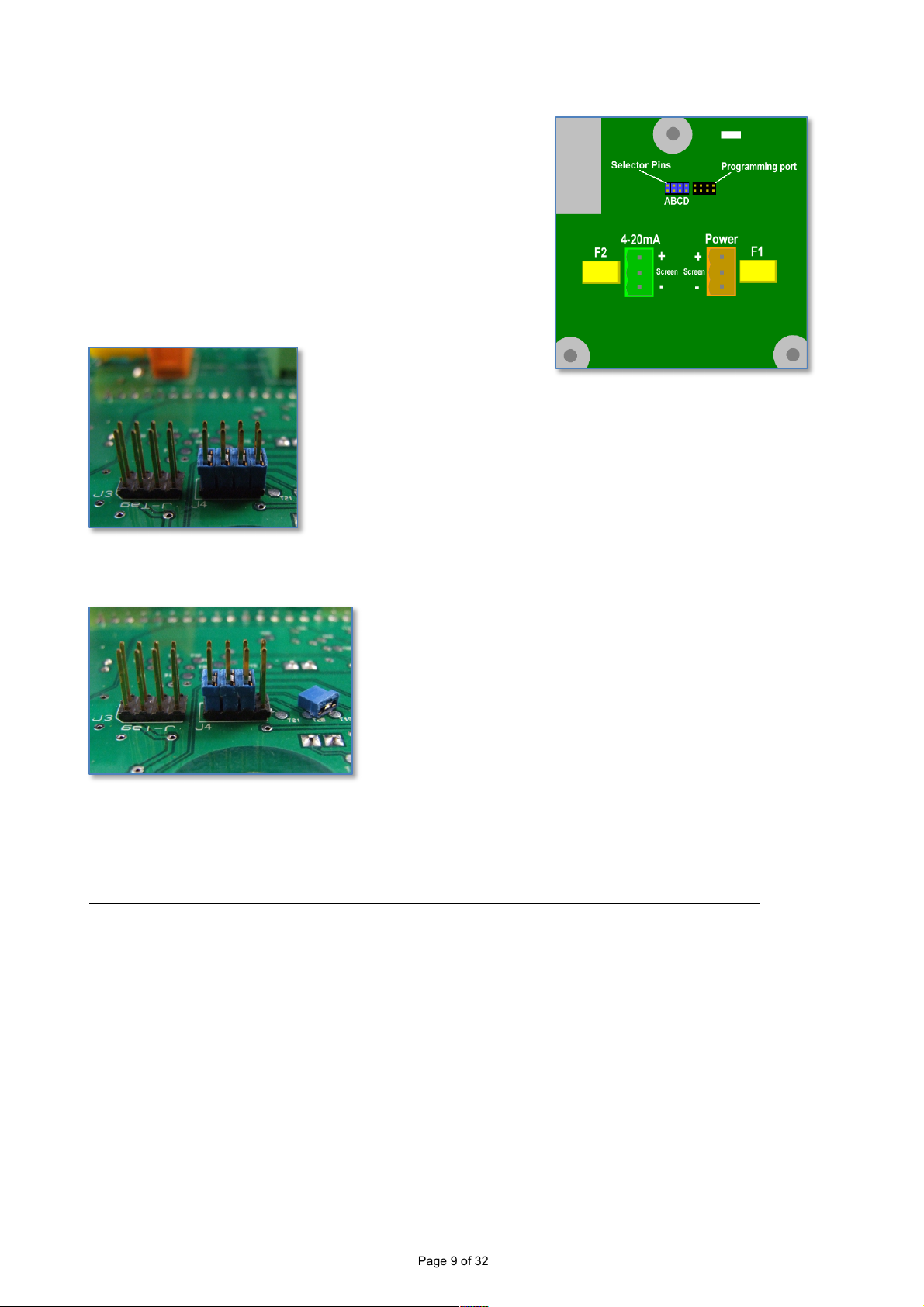

Selector Pins

TVOC has a number of settings that can be selected by the

user via a row of four selector pins mounted on the reverse side

of the main PCB. Diagram 2 shows the location of the functional

selector pins labelled - A, B, C & D.

The selector pins absence or presence determines the chosen

setting.

TVOC is shipped with all four selector pins fitted as shown in

diagram 3.

Diagram 4 shows the removal of 1 selector pin.

The following table shows the selector pin combinations and the corresponding function.

!= Selector pin fitted " = Selector pin removed

Selector pin

A B C D Range Displayed units

! ! ! ! 1000 ppm (Default)

! ! x ! 100 ppm

! x ! ! 10 ppm

! ! ! x 2280 mg/m

3

! ! x x 228 mg/m3

! x ! x 22.8 mg/m3

Selector pin ‘B’ and ‘C’ selects the ranges - 10 ppm, 100 ppm or 1000 ppm

Selector pin ‘D’ selects the units - ppm’ or ‘mg/m3

Selector pin ‘A’ - Fault output range

NOTE: During an Alarm condition (F1 or F2) the output will drop to either 3.5 mA or 2.0 mA.

Jumper ‘A’ fitted: 3.5 mA during an alarm condition

Jumper ‘A’ removed: 2.0 mA during an alarm condition.

As default, the TVOC has a 100 ppm factory calibration

Diagram 2

Diagram 4

Page 10

TVOC MANUAL Ion Science Ltd

Page 10 of 32

Unrivalled Detection. www.ionscience.com

TVOC setup

NOTE: * TVOC is shipped with ALL selector pins fitted as standard

* TVOC only reads the selector pin settings when power is connected.

Always ensure power is disconnected from TVOC before changing

setting or carrying out maintenance.

* Never place selector pins on the programming port connector.

* Ensure static build up is discharged before touching components.

* If the jumper selection is not a recognised option then error F4 will occur. To recover switch

the instrument off perform the correct jumper selection and switch the instrument back on.

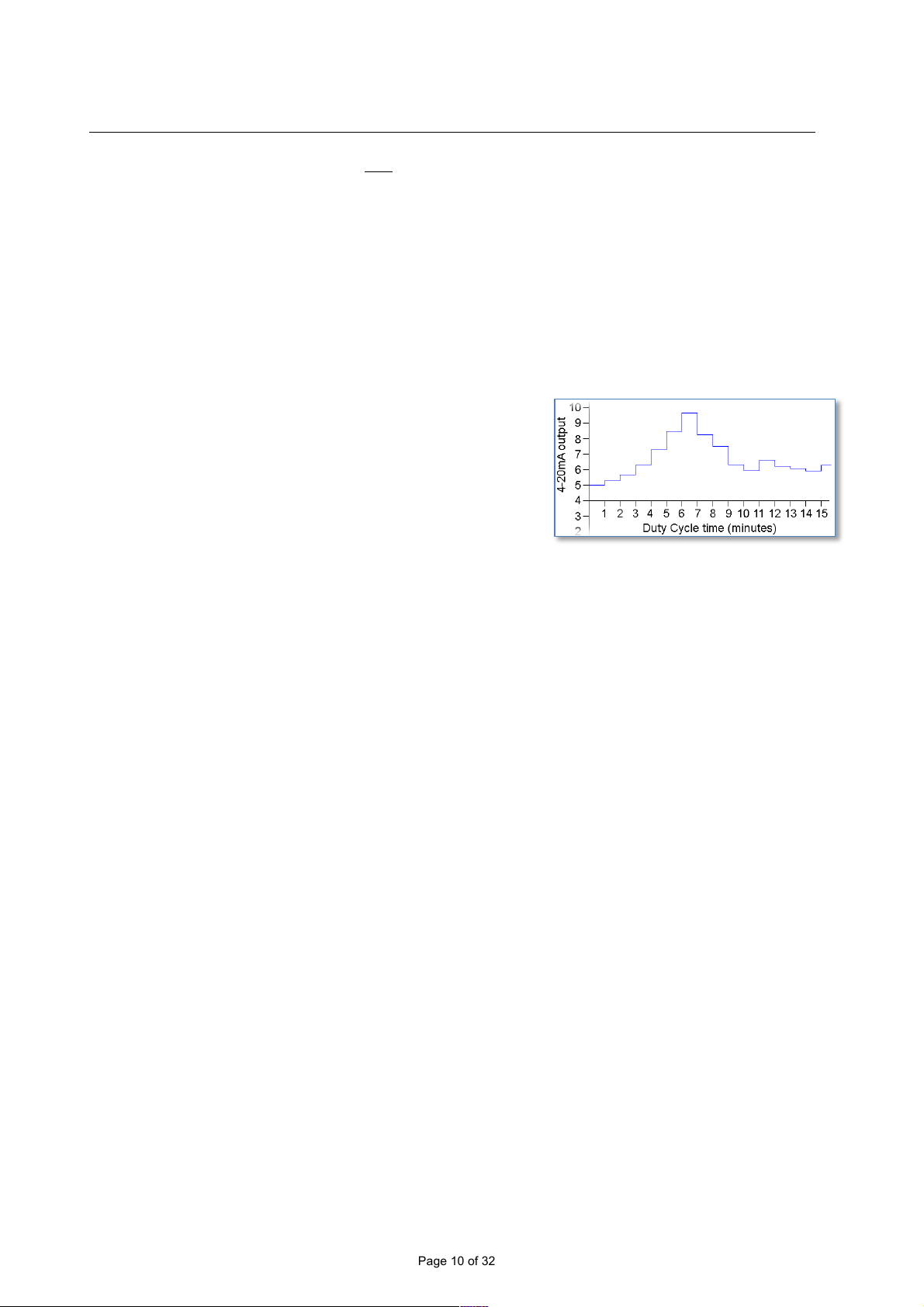

Duty Cycle

The life of a photoionization lamp is used up when the lamp is illuminated, the lamp window can also

contaminate resulting in a reduced level of detection. The TVOC pulses the lamp on and off which extends

lamp life and reduces lamp contamination. This in turn can increase the time between servicing.

The TVOC switches on the lamp, takes a reading and then

updates the 4-20 mA output and display screen. The default Duty

Cycle is the frequency between test cycles, the factory default is

set to 1 minute however this time can be adjusted from 0 to 5

minutes.

Please note: When bump testing after a calibration the response

may be delayed depending on when in the gas is applied during

the test cycle.

Fast response mode

The TVOC can be set to Fast Response Mode, when selected the TVOC will update the output every one

second. Fast response mode can be selected by setting both the seconds and minutes to zero.

Please note: The warrantee of Ion Science PID lamps is based upon a duty cycle of 1 minute. Lamps used

with Duty Cycle below one minute will not be covered under the standard warrantee terms.

Page 11

TVOC MANUAL Ion Science Ltd

Page 11 of 32

Unrivalled Detection. www.ionscience.com

Installation

Location

There are many variables involved in defining the optimum location for a gas detector. Obvious though it

may sound, the most important rule is:

• A detector will not detect gas unless gas actually reaches the detector.

• TVOC should be mounted in the location most likely to detect gas.

• TVOC must be mounted vertically with the sensor underneath the case. This avoids dust and debris

blocking the access to the detector cell.

• If possible, mount TVOC near the ceiling to target VOC gases that are lighter than air or just above

floor level to detect VOC gases that are heavier than air.

• Mount TVOC in an area that has good air circulation. Restricting natural air current may result in

delayed detection.

• Never mount TVOC in direct sunlight or over a heat source such as a radiator. This may cause TVOC

to exceed its certified working temperature range.

• Do not mount TVOC in areas likely to flood.

• Mount TVOC’s in areas that are easily accessible for servicing.

• Percentage variations in the composition of air (78% Nitrogen, 21% Oxygen and 1% Argon) may affect

the detected signal.

Please refer to the technical specifications of the instrument under Technical Specifications of this

manual before beginning a TVOC installation.

Cable and gland requirements

The Screw terminal sockets for connecting wires in the TVOC accept wires of 0.5mm2 to 2.5mm

2

C.S.A.

Screened cables for both power and signal out are necessary to achieve EMC compliance. Cable

screens must be terminated at both ends for them to be effective in achieving electromagnetic

compatibility (EMC). The screens should be terminated to the TVOC enclosure using EMC

compatible cable glands. It is important for an EMC compatible gland to make electrical contact to the

enclosure. This is usually done using a serrated washer or EMC lock nut that bites through the paint

making electrical contact. EMC lock nuts have been provided. These locknuts are orientation specific

the points should be facing against the case in order to cut through the paint during tightening.

Two M20 cable glands and one blanking plug have been supplied as standard to ease installation in

most circumstances. These parts will not be appropriate for all applications so they should be used at

the discretion of the installation engineer. It is recommended that the manufacturer’s instructions are

followed for the gland and blanking plug installation. The M20 blanking plug has been included to

enable installations using a single entry cable (for example a three wire system) to be implemented.

While Ion Science can not recommend the cable gland suitable for every application the following

information may be useful to the installation engineer for the selection of the appropriate cable gland.

• For intrinsically safe operation using safety barriers, the only requirements on the cable

glands are that they are better than IP20 rated. This may seem extraordinary however

where the power is safely limited to the TVOC it is intrinsically safe so does not rely on the

prevention of dirt or moisture into the enclosure.

• For intrinsically safe operation in Zone 2 without safety barriers, cable glands must be ATEX

or IECX rated (Ex e, Ex n or Ex d) and at least IP54.

Installation of the TVOC depends on preferences of the installer, intrinsically safe operating legislation and

the application.

Ion Science suggests connecting the screens from cables via a gland as shown on the diagrams and under

Installation Section of this manual. There may however be technical circumstances where connection to the

PCB is necessary.

Page 12

TVOC MANUAL Ion Science Ltd

Page 12 of 32

Unrivalled Detection. www.ionscience.com

Installation

Dimensions for mounting

Diagram 5

Page 13

TVOC MANUAL Ion Science Ltd

Page 13 of 32

Unrivalled Detection. www.ionscience.com

Installation

NOTE: The TVOC case can be used as a template when marking out fixing holes but do not drill

through the fixing holes.

Power requirements

Non Intrinsically Safe Operation applications:

Input power 5-28 Vdc. 80 mA max. (0.5 to 2.5 mm2 C.S.A.)

Output power (4-20mA) 8-35 Vdc. 80 mA max. (0.5 to 2.5 mm2 C.S.A.)

Note: 4-20mA loop must be externally powered.

4 Wire System

(Non IS)

3 Wire System

(Non IS)

Diagram 6

Diagram 7

Page 14

TVOC MANUAL Ion Science Ltd

Page 14 of 32

Unrivalled Detection. www.ionscience.com

Installation – Hazardous location

Warning!

The label on the enclosure details the IS and nA certifications. The appropriate section of the Intrinsically

Safe label should be covered up or blocked out to reflect the type of installation. For Non-intrinsically Safe

applications the label should be covered completely. For Intrinsically Safe (IS) Zone 2 applications with out

safety barriers the ia certification details should be blanked out. For Zone 1 or Zone 2 IS applications with

safety barriers the nA certification details should be covered. This will prevent safety discrepancies and or

mis-use in the future should the equipment be moved or the site be re-defined as a hazardous area.

Entry parameters for intrinsically safe Zone 2, nA (non-sparking) areas only:

Input power 5-24 Vdc, 80 mA max

Output power (4-20 mA) 8-35 Vdc, 22 mA

For information only: please see Intrinsically Safe operation certificate before installation.

The wiring of Intrinsically Safe systems is identical to the wiring showing for non Intrinsically Safe

applications. The only difference is the requirements to ensure that the power supplied used provides 24 V

or less in normal operation.

Intrinsically Safe (IS) applications: Entry parameters

Input power Ui = 18V Ii = 800mA Pi = 1.2W Ci = 0µF Li = 0mH

Output power(4-20mA) Ui = 30V Ii = 200mA Pi = 1.2W Ci = 0µF Li = 0mH

For information only please see Intrinsically Safe certificate before installation

Ion Science Ltd suggest using the following zener barriers for IS approved applications. Use competent

installation engineers and ask them for installation and application advice.

Note

• All cable lengths are estimated for Zone 1 IIC installation of the equipment

• Using 1 mm2 C.S.A conductor S.T.P cables with capacitance per meter of 250 pF/m, L/R ratio of 25

muH/Ω conductor resistance at 20°C of 18.4 Ω/km.

• Calculation assumes cables are at 50°C.

Warning! Intrinsically Safe (IS) applications

• Units should not be powered using non IS power supplies prior to installation in an IS application.

• If non IS power is supplied the unit will require inspection by Ion Science Ltd or an Ion Science Approved

Service Centre prior to installation in an IS application.

• TVOC fuses may not be replaced in the field.

• If a fuse is blown TVOC will require inspection by Ion Science Ltd or and Ion Science Approved Service

Centre before it is used in an IS application.

Page 15

TVOC MANUAL Ion Science Ltd

Page 15 of 32

Unrivalled Detection. www.ionscience.com

Installation – Hazardous location

4-wire Control equipment sensing 4 – 20 mA on return line

Notes:

! For intrinsically safe installations, the enclosure may be opened while the system is live,

provided the work is undertaken by competent personal and suitable safety precautions are

taken. This overrides the warning on the enclosure label.

Initial calibration

TVOC is calibrated at Ion Science before dispatch using 100 ppm Isobutylene. However, if you wish to

calibrate your TVOC after installation, Ion Science recommends that the TVOC is left to run on its chosen

settings (see ‘TVOC Setup Section’) for 24 hours before an initial calibration is carried out, to allow the

instrument to stabilise.

Diagram 8

Page 16

TVOC MANUAL Ion Science Ltd

Page 16 of 32

Unrivalled Detection. www.ionscience.com

Operation

Start Up

After electrical power is connected, TVOC runs through a ‘Start up’ routine, which lasts for approximately 1

minute. During this ‘Start up’ routine TVOC demonstrates the following characteristics:

* The LCD screen displays the software version number

* The GREEN LED flashes

* The 4-20 mA output is set to 4 mA (0.0 ppm)

NOTE: If the 0-10 ppm range is selected the TVOC will require calibration using 10ppm Isobutylene before

use (See the calibration section of this manual)

During this ‘Start-up’ time the user can adjust the Duty Cycle time as referred to in ‘TVOC Setup’ under the

Duty Cycle section. This time can be adjusted from 0 to 5 minutes in 10 second increments.

Adjusting the Duty Cycle

NOTE: Please read this entire procedure before attempting to adjust the lamp OFF time.

There are two stages to adjusting the Duty Cycle time. The first stage adjusts the seconds 0 to 59 seconds,

the second stage adjusts from 0 to 5 minutes. Please see the description of the Duty Cycle on page 10.

1. During the 1 minute ‘Start up’ time place the calibration magnet over the top

right hand corner of the Ion Science logo. (See diagram 9) Two numbers on the

right of the LCD screen will flash.

Diagram 9

2. While the magnet is held in this position the number on screen will roll over from 00

through to 50 in 10 second steps. Quickly remove the magnet when the desired time

appears.

3. After 5 seconds the TVOC will move on to the next stage. (Reapply the magnet

within 5 seconds if further adjustment is necessary)

4. The TVOC will move to the next stage indicated by a digit appearing on the left of

the screen. Holding the magnet in place will cause this number to roll over from 0 to 5

minutes. Quickly remove the magnet when the desired time appears.

5. After 5 seconds the TVOC will display both the minutes and seconds selected.

(Reapply the magnet within 5 seconds if further adjustment is necessary)

6. TVOC will restart the start-up sequence and then enter running mode. The Duty

cycle is then saved to memory. The duty cycle will be remembered through a power

cycle.

Fast response mode

If the Duty Cycle time is adjusted lower than 0:10 (10 seconds) the instrument will update the output every

one second. In this mode of operation the F2 fault condition is disabled. This means that removal of the

sensor may go undetected.

Page 17

TVOC MANUAL Ion Science Ltd

Page 17 of 32

Unrivalled Detection. www.ionscience.com

Operation

LED’s

see Diagram 12

The green indicates TVOC’s working status:

ON Indicates the PID lamp is OFF

Flashing Indicates the PID lamp is ON

A red indicates fault status:

ON Indicates TVOC cannot function correctly. The 4-20mA output drops

to 3.5mA.

URGENT attention is required.

Flashing Indicates the TVOC cannot function but a reading is being

attempted

A yellow Zero LED indicates during normal operation

ON Last calibration zero level was outside expected limits

(The instrument will operate normally with the previous calibration)

A yellow Span LED indicates during normal operation

ON Last calibration Span level was outside expected limits

(The instrument will operate normally with the previous calibration)

Please see Section 7 Calibration for YELLOW LED status.

Selector pins

TVOC has a range of options that are selected via the selector pins on the back of the main PCB (please see

the ‘TVOC Set up’ Section).

The options are shown below with the defaults highlighted in bold:

1-1000 ppm or 0.01 – 10 ppm or 0.1 – 100 ppm

ppm units or mg/m3 units

Calibration mode

TVOC calibration mode can be accessed using the calibration

magnet supplied in the TVOC calibration tool kit (Part number: A-

845214).

To enter calibration place the magnet over the top right of the Ion

Science Logo until the state changes (i.e. an LED illuminates and/or

the display changes).

Ensure the magnet is withdrawn away from the magnetic switch by

at least 1 cm once a change has occurred.

Calibration gases

TVOC has three (3) ranges that can be selected however the 010ppm range requires the instrument is calibrated by the user before

use. The 0-100ppm and the 0-1000 ppm ranges can initially run

using the Factory calibration carried out during the instruments

manufacture, however because the 0-10 ppm range is more

sensitive and more susceptible to environmental and system

tolerances the instrument must be calibrated before use.

If the 0-10 ppm range is selected TVOC will display the following

screen to indicate that a calibration is required before it can be used.

Follow the calibration instructions before use.

Diagram 10

Diagram 11

Page 18

TVOC MANUAL Ion Science Ltd

Page 18 of 32

Unrivalled Detection. www.ionscience.com

Hand aspirator

Calibration

Calibration routine

Ion Science recommends calibrating TVOC after any maintenance or lamp cleaning is carried out and on a 3

monthly basis to ensure TVOC is working to specification.

NOTE: Please read this entire calibration procedure before attempting a calibration.

TVOC calibration is undertaken in four steps:

1. Setting the ZERO (Using clean gas via carbon filter)

2. Setting the gas tolerance (1 – 200 ppm Isobutylene on 0-100 ppm and 0-1000 ppm ranges)

(0.1 – 20.0 ppm Isobutylene on the 0-10ppm range)

3. Setting the SPAN (Using the SPAN gas)

Setting the ZERO

1 – Place the calibration magnet over the top right hand corner of the Ion Science logo to enter

calibration mode. The ‘ZERO LED’ will illuminate and the ‘STATUS LED’ will extinguish.

2 – Remove the calibration magnet

3 – Insert the calibration adaptor into the sensor cap, attach the carbon filter to the calibration adaptor.

The carbon filter should be attached to the hand aspirator.

4 – Again place the calibration magnet over the logo. The ‘ZERO LED’ will flash, during this stage

TVOC displays a direct millivolt (mV) output from the PID sensor.

STATUS LED

ZERO LED

SPAN LED

FAULT LED

Calibration adaptor

Carbon filter

Diagram 12: LE D’s

STATUS, ZERO, SPAN, FAULT

Diagram 13

Page 19

TVOC MANUAL Ion Science Ltd

Page 19 of 32

Unrivalled Detection. www.ionscience.com

Calibration

5 - Slowly and repeatedly squeeze the hand aspirator to push clean air through the carbon filter and past

the PID sensor. The ‘ZERO LED’ will stop flashing after approximately 2 minutes.

6 – Now remove the equipment except for the calibration adaptor.

NB During the above process the 'mV' reading on the display must fall below 30 mV to pass the Calibration

stage.

An acceptable ZERO calibration level will result in the illumination of the ‘STATUS LED’.

An unacceptable ZERO calibration level will result in the illumination of the ‘FAULT LE’D. Should this occur

the TVOC will not proceed to the gas tolerance setting and return to normal operation the previous

calibration levels will be used. The Yellow ‘ZERO LED’ will be illuminated to indicate the failure to set a zero

calibration level.

Setting the gas concentration (The actual value that the calibration has been supplied at)

1 Now, again place the calibration magnet over the corner of the logo –

The GREEN or FAULT LED will be extinguished and the numeric

display will start to flash.

2 If the 0-10ppm range is selected you will be able to adjust between 1.0 ppm and 100ppm, for both

the 100 ppm and 1000 ppm ranges a concentration of between 1 and 200 ppm can be selected.

Leaving the magnet in position will cause the displayed number to cycle through the concentration,

remove the magnet when the displayed value matches that stated on the Calibration gas bottle.

Should you miss the desired reading quickly reapply the magnet to continue scrolling through the

numbers and remove the magnet at the desired figure.

The selected number will be recorded 5 seconds after the removal of the magnet when the display

stops flashing. The display will initially show 90, should this be the desired figure remove the magnet

straight away.

Setting the SPAN

1 Connect the SPAN gas to the calibration connector then the connector to the adaptor. Do not over

tighten the Luer fitting; only a one quarter turn is required.

Switch on the gas supply and then place the magnet over the logo.

The SPAN LED will flash and TVOC will display the direct millivolt (mV) output from the PID sensor.

Now remove the magnet.

Calibration adaptor

SPAN gas

Calibration connector

Diagram 14

Page 20

TVOC MANUAL Ion Science Ltd

Page 20 of 32

Unrivalled Detection. www.ionscience.com

2 The SPAN LED will stop flashing after approximately 2 minutes.

3 Turn off the gas and disconnect the equipment

Calibration

NB during the span measurement process the mV reading of the span must be greater than the zero level to

pass the ZERO calibration stage.

An acceptable SPAN calibration level will result in the illumination of the green STATUS LED.

An unacceptable SPAN calibration level will result in the illumination of the red FAULT LED. Should this

occur the previous calibration levels will be used when the instrument returns to normal operation. The

Yellow span LED will be illuminated to indicate the failure to calibrate the span.

Now place the magnet over the logo corner to return to normal monitoring routine.

The GREEN LED will start flashing as TVOC starts its cycle with a lamp ON cycle.

IMPOTANT: Unacceptable calibration levels will not be adopted; the instrument will default to the

previously stored acceptable calibration factor.

NOTE:

* Always check the accuracy of your calibration by checking readings from TVOC when it is running

normally using the ZERO filter and SPAN gas.

* Accuracy of calibration is the responsibility of the person carrying out the calibration. If in doubt seek

advice.

* TVOC must be calibrated after lamp/cell cleaning or general maintenance.

NOTE: Causes of contamination and error in signal:

* Changes in air pressure when detecting ppm concentration

* Variation in oxygen, argon beyond ambient levels.

* Variation in ambient moisture content.

Page 21

TVOC MANUAL Ion Science Ltd

Page 21 of 32

Unrivalled Detection. www.ionscience.com

Maintenance

Cleaning / replacing the lamp

TVOC has been designed to ensure servicing is quick and easy:

1. Before servicing TVOC,

disconnect the electrical power

supply.

2. Remove the locking screw from

the metal sensor cap using the

Allen key supplied within the

Calibration tool kit. (part number

A-849214)

Warning:

Failing to remove the locking

screw before unscrewing the

sensor cap will damage the

sensor holder.

3. Unscrew the sensor cap to

access the PID sensor.

4. Remove the PID Sensor by

withdrawing it from the sensor

housing. Only light force is

required

Warning:

Do not twist the PID Sensor while

it is within the sensor housing.

Sensor cap

Locking screw

PID sensor

Sensor housing

Diagram 15

Diagram 16

Page 22

TVOC MANUAL Ion Science Ltd

Page 22 of 32

Unrivalled Detection. www.ionscience.com

Maintenance

5. The PID sensor’s metal spring

cover can be pulled off using

moderate force. The electrode stack

and PID lamp can then be removed

by holding the PID sensor upside

down.

Warning:

Ensure the electrode stack and

PID Lamp falls onto a soft surface

such as a piece of tissue. This will

avoid damaging the parts as they

fall out and avoids finger contact

with the PID lamp window.

6. Clean the PID Lamp using

Alumina powder loaded onto a

cotton bud. Rub the cotton bud /

Alumina power on the PID lamp

window using a circular motion

until a light audible squeak can be

heard.

NOTE:

Contamination of the PID Lamp

window can considerably reduce

the detection capability of the PID

cell, even when the contamination

is not visible.

Cleaning of the lamp should be carried out on a regular

basis depending on the duty cycle of the PID lamp

and the environment.

Electrode

stack

PID lamp

Metal spring

cover

Alumina powder

Cotton bud / Alumina

powder

Diagram 17

Diagram 18

Pellet

Page 23

TVOC MANUAL Ion Science Ltd

Page 23 of 32

Unrivalled Detection. www.ionscience.com

Maintenance

The humidity of the air and contaminants may affect the time required between servicing.

Warning:

7. The Electrode Stack should be inspected for visible signs of contamination, if contamination can be

seen the Stack it must be replaced. ( part number 1/EA-02)

Reassembly:

8. Place the clean PID Lamp into the PID Cell avoiding finger contact with the Window.

9. Refit the electrode stack with the electrical pin holes and electrode contacts facing down.

10. Refit the metal spring cover.

11. Ensure the electronic

pins of the PID sensor are

at the 12 o’clock position

before inserting the PID

sensor.

The PID sensor should

insert into the connectors

easily, if significant

resistance is felt, remove

the cell and check

alignment before

reinserting.

Warning:

Irreparable damage will be caused by forcing the PID into the sensor housing if not correctly aligned.

NOTE: Always calibrate TVOC after servicing is carried out.

Fuse rupture and replacement

TVOC has a 125 mA BASEEFA certified fuse to provide intrinsically safe protection when the unit is installed

in hazardous areas.

This fuse may rupture for example due to over voltage or a current surge, if this is the case replacement is

different depending upon the application being intrinsically safe (IS) or not.

For IS applications the unit must be inspected and have the fuse replaced by Ion Science Ltd or an Ion

Science Approved Service Centre. The intrinsically safe rating is not maintained if the fuse is simply

replaced.

For non-IS) applications the fuse may be replaced by an equivalent rated fuse and operation tested by

qualified engineering personnel.

Lamp Warranty Statement

Please note: The standard warranty period for a 10.6 PID lamp is one year, providing that the default duty

cycle for lamp is set to 1 minute of greater.

Electronic pins

Diagram 19

Page 24

TVOC MANUAL Ion Science Ltd

Page 24 of 32

Unrivalled Detection. www.ionscience.com

System recommendations

TVOC is generally used to measure gas concentrations in the ambient atmosphere. The sensor is open to

the atmosphere and any gas that diffuses or moves under convection into the locality of the TVOC sensor

will be detected. Generally, the ambient environment in which TVOC is located is readily accessed, but there

are applications listed below that require special consideration.

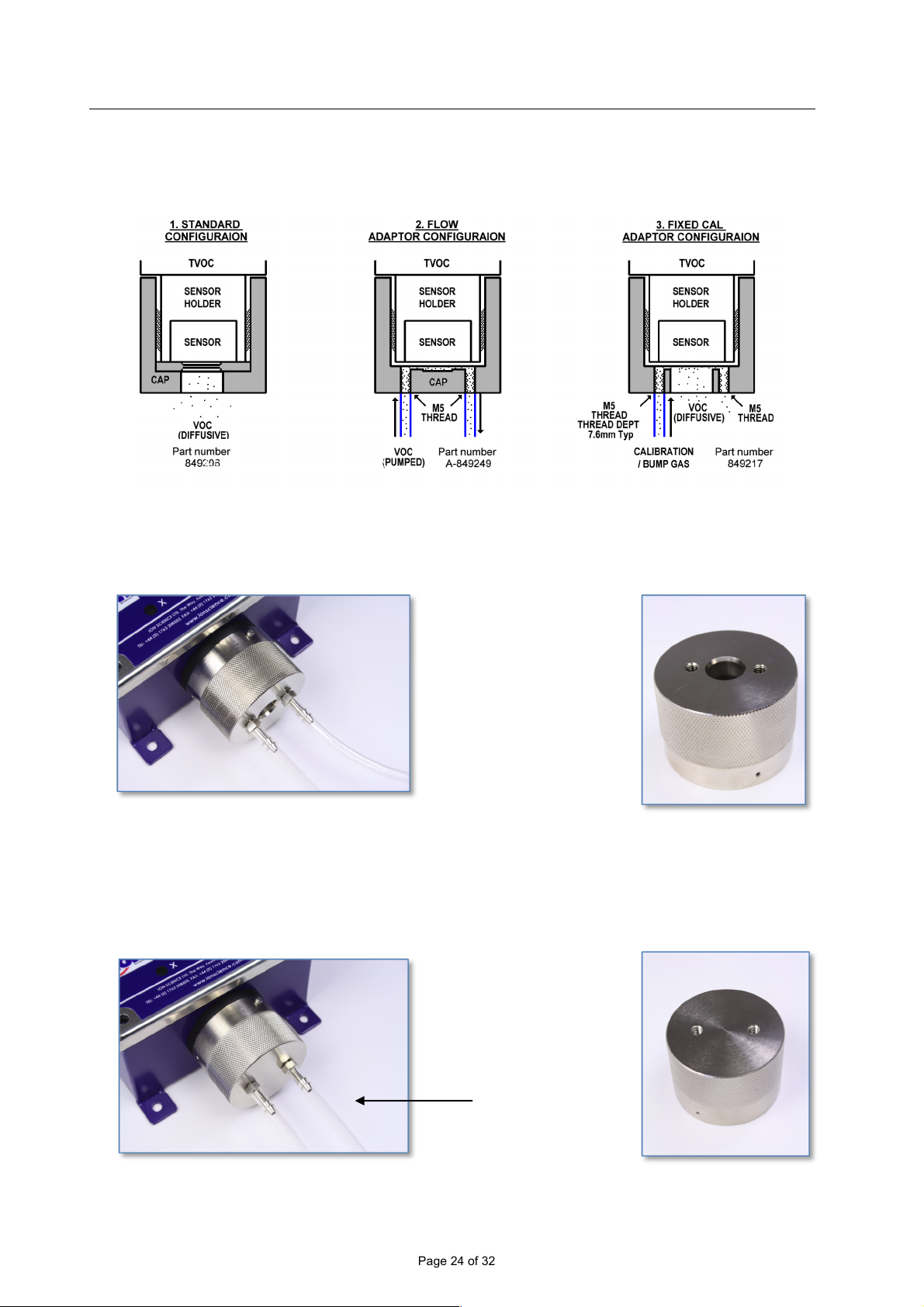

Remote area monitoring

TVOC may be placed in a roof or other space that is hard to access but where the TVOC requires regular

bump tests. In this event, TVOC can be fitted with a Fixed calibration adaptor, Diagram 22. A flow adaptor is

also available for remote testing.

Fixed calibration

adaptor

Gas sample systems

It is sometimes necessary to pump or draw a gas sample past the TVOC. For this a “Flow Adaptor " can be

fitted. The flow adaptor has an inlet and an outlet port so that gas may be pushed or drawn across the

sensor. See diagram 2 above.

TVOC Flow Adaptor

5/JHS-01

Diagram 20

Diagram 21

Diagram 22

Diagram 23

Diagram 24

Page 25

TVOC MANUAL Ion Science Ltd

Page 25 of 32

Unrivalled Detection. www.ionscience.com

System recommendations

For a gas sample system we have the following recommendations:

1. Where possible use the Flow Adaptor (as described above) that is sold by ISL. This has an integral

o-ring to seal the sensor housing and ports for connection of inlet and out let sample tubes. Please refer

to Spare parts section for part number.

2. The pressure difference of a pumped system relative to atmosphere should be minimised to avoid the

effects of gas law.

3. The maximum pressure that can be applied to the TVOC sensor housing is 300 mbar. However this is

not a recommended working pressure. Ideally working pressure should be +/- 30 mBar relative to

ambient pressure.

4. In line flow restrictions must be minimized. Flow restrictions cause differential pressures which can

directly affect the TVOC ready. If flow restrictions are unavoidable the flow rate should be lowered to

minimize the pressure effects, this however will increase the response time.

5. A flow between 250 and 500 ml/min is recommended for calibration. This will ensure a full response to

applied gas in a sensible time.

6. The working flow should be very similar to that use to calibrate the instrument or errors in output will

occur (see point 2).

7. The response time of the system is defined by the sensor response rate and sample flow rate will in

combination with the tube length and diameter as well as any dead volumes.

Page 26

TVOC MANUAL Ion Science Ltd

Page 26 of 32

Unrivalled Detection. www.ionscience.com

Instrument warranty and service

Warranty

Standard Warranty can be extended to up to 2 years on the TVOC when registering your

instrument via our website: www.ionscience.com/instrument-registration

To receive your Extended Warranty, you need to register within one month of purchase (Terms

and Conditions apply). You will then receive a confirmation email that your Extended Warranty

Period has been activated and processed.

Full details, along with a copy of our Warranty Statement can be found by visiting:

www.ionscience.com/instrument-registration

Service

Ion Science is pleased to offer a number of service options on our TVOC product range that

allow you to choose the instrument cover that best suits your needs.

At Ion Science we recommend that all of our gas detection instruments be returned for service

and factory calibration once every 12 months.

Contact Ion Science or your local distributor for service options in your area.

Find your local distributor by visiting: www.ionscience.com

Contact details

USA Office

Ion Science LLC

4153 Bluebonnet Drive

Stafford

TX 77477

USA

Tel: +1 (877) 864 7710

Email: info@ionscienceusa.com

Web: www.ionscienceusa.com

UK Head Office

Ion Science Ltd

The Way, Fowlmere

Cambridge

SG8 7UJ

UK

Tel: +44 (0)1763 207206

Fax: +44 (0) 1763 208814

Email: info@ionscience.com

Web: www.ionscience.com

German Office

Ion Science Messtechnik GMBH

Laubach 30

Metmann-Neandertal

40822

GERMANY

Tel: +49 2104 14480

Fax: +49 2104 144825

Email: info@ism-d.de

Web: www.ism-d.de

Italian Office

Ion Science Italia

Via Emilia 51/c

40011 Anzola Emilia

Bologna

ITALY

Tel: +39 051 0561850

Fax: +39 051 0561851

Email: info@ionscience.it

Web: www.ionscience.it

Page 27

TVOC MANUAL Ion Science Ltd

Page 27 of 32

Unrivalled Detection. www.ionscience.com

Diagnostics

Below are two conditions your TVOC can be in when it is working correctly:

The two conditions shown below are of the instrument in an error state with potential checks/cures

for these faults:

If an F1 error occurs when the instrument is first switched on there may not be an issue. The instrument

needs to be left on for a few cycles to see if the lamp strikes on its own. If an F1 error, as shown below, is

displayed when the instrument is still on screen after 5 minutes then look at the information below

If the F1 error persists for more than 5 minutes, firstly check the red cable between the sensor PCB and the

main PCB is securely connected. The red cable is sufficiently rigid to be gripped inside the case and pushed

into the sensor housing. Instruments wit serial numbers exceeding 10-1790 include an improved

connection and diagnostic fault F3 which indicates if this connection has failed.

Diagram 25

Diagram 26

Diagram 27

Page 28

TVOC MANUAL Ion Science Ltd

Page 28 of 32

Unrivalled Detection. www.ionscience.com

Diagnostics

If the F1 diagnostic persists, replace the sensor electrode stack, part number 1/EA-02, re-power the

instrument and wait 5 minutes. If the F1 error continues, replace the sensor lamp, part number 833229.

Pellet and lamp spares are identified in.

If the instrument continues to exhibit the F1 failure after replacement of parts please contact your Ion

Science distributor.

The F2 error occurs when the lamp appears to be illuminated yet power is removed from the PID sensor,

TVOC checks the PID lamp status using a light sensor. Running TVOC with the sensor or the sensor cap

removed will result in an F2 error.

Please note: The F2 error is disabled when the duty cycle is set below 10 seconds.

A light guard is fitted within the PID sensor housing. This ensures the light sensor is unaffected by ambient

light.

IMPORTANT:

The F3 error occurs when the sensor is disconnected from the power supply. Instruments with serial

numbers earlier than 10-01790 will not indicate an F3 error if the cable. Instead, an F1 error will be

displayed instead and the diagnostics associated with F1 errors, as above, should be performed.

If an F3 error occurs then check the cable is properly connected to the main PCB. If not push it fully home.

F4 errors

The F4 error occurs when an incorrect jumper cable selection is used, see TVOC Set up.

Diagram 28

Diagram 29

Diagram 30

Page 29

TVOC MANUAL Ion Science Ltd

Page 29 of 32

Unrivalled Detection. www.ionscience.com

Spare parts

Part Description Part number

Calibration tool kit Calibration magnet, Calibration adaptor,

Calibration connector, Zero gas aspirator,

Carbon filter, 2 x Allen keys. A-849214

Flow adaptor Replaces the standard Sensor Cap

(Allows an external pump to be fitted as

Shown in diagram below) A-849246

Fixed calibration adaptor Replaces the standard Sensor Cap

(Allows an external pip connection as

Shown in diagram below) 849217

PID Lamp cleaning kit Alumina powder and cotton buds A-31063

Span Gas kit (100 ppm) 100ppm Isobutylene (103Liters) and Flow

Regulator in a carry case A-845213

Span Gas kit (10 ppm) 10ppm Isobutylene (103Liters) and flow

Regulator in a carry case 849230

PID sensor Replacement PID Sensor 1/EO-2

Carbon filter User for ZERO span A-31057

Calibration magnet User to step through calibration A-849219

Electrode stack 1/EA-02

PID lamp A-833227

Sensor light guard Prevents bright light conditions causing 849245

False F2 alarms.

O Ring for Sensor Light Fits to outside of Sensor Light Guard 5/OV-11

Guard

Calibration Adaptor (Part of the Calibration toolkit)

For connecting to the standard cap for calibration. A-849209

Page 30

TVOC MANUAL Ion Science Ltd

Page 30 of 32

Unrivalled Detection. www.ionscience.com

Technical specifications

PID Sensor With fence electrode technology

Lamp type 10.6 eV (Krypton)

TVOC enclosure ingress protection IP65

Sensor ingress protection IP54

Range 0 – 10 ppm / 0 – 22.8 mg/m3 (0.01 resolution)

0 – 100 ppm / 0 – 228 mg/m3 (0.1 resolution)

0- 1,000 ppm / 0 – 2280 mg/m3 (1.0 resolution)

Non IS applications Input power 5 – 28 Vdc. 65 mA (0.5mm2 to 2.5mm2 C.S.A.)

4 – 20 mA power 8 – 35 Vdc. 22 mA (0.5mm2 to 2.5mm2 C.S.A.)

4-20mA loop must be externally powered

ATEX approval II 2G EEx ia IIC T4 (-20°C ≤Ta ≤+50°C)

IECEx approval Ex ia IIC T4 (-20°C Ta +50°C)

Certificate number Baseefa05ATEX0277

IS applications Entry parameters

Input power Ui = 18V Ii = 800mA Pi = 1.2W Ci = 0µF Li = 0mH

4-20mA power Ui = 30V Ii = 200mA Pi = 1.2W Ci = 0µF Li = 0mH

For information only please see ATEX certificate before installation

Zener Barriers: Required Ask your installation engineers for installation/application advice.

(Non sparking) approval II 3G Ex nA IIC T4 (-40oC < Ta < +50oC) (nA for zone 2 only)

Dimensions Weight

Height 188 mm (7.40”) Instrument 1.3kg (2.9 lb)

Width 126 mm (4.96”) Packed 1.47kg (3.2lb)

Depth 78 mm (3.07”)

Display 7 Segment, 4 Digit LCD. 4 Colour LED’s

Response Sensor T90 < 5sec

TVOC output update: Variable 1 second to 10 minutes

Accuracy 0 to 100 ppm: +/- 1 ppm (whichever is greater)

100 to 1000 ppm: +/- 10% or +/- 10 ppm (whichever is greater)

Linearity 0 – 1000 ppm >75%

Calibration Magnetically accessed

ZERO = Carbon canister

SPAN = 100 ppm Isobutylene +/- 10%

Temperature Operation: -20 oC to +50 oC (-4 oF to 122 oF)

Humidity 0 – 95% RH (non-condensing)

EMC Screened cables are required to archive the light industrial immunity

levels.

NB: All specifications are against an isobutylene calibration at 20 °C, 90% RH and up to 100 ppm.

Page 31

TVOC MANUAL Ion Science Ltd

Page 31 of 32

Unrivalled Detection. www.ionscience.com

Manual log

Manual Version

Amendment

Date updated

Instrument

Firmware

PC

Software

TVOC Manual

V2.1

Diagram 5.2.1 updated on

page 11

31/3/08

V3.09

N/A

TVOC Manual

V2.2

Diagram updated on page

15

21/4/08

V3.09

N/A

TVOC Manual

V2.3

Declaration on conformity

change only

27/11/08

V3.09

N/A

TVOC Manual

V2.4

Log added to back of manual

09/01/09

V3.09

N/A

TVOC Manual

V2.5

Diagnostics added and P&F

barrier changed

20/02/09

V3.09

NA

TVOC Manual

V2.6

TVOC firmware modified to

allow customers to calibrate

using an alternative

concentration. Aldo

improved the description of

the F2 fault condition. (P6,

P17, P24)

22/07/09

V3.10

N/A

TVOC Manual

V2.7

TVOC ATEX certification to

allow zone 2 installation

without safety barriers. (P12,

P13, P26)

1.09.09

V3.10

N/A

TVOC Manual

V2.9

Inclusion of Cable gland in

kit, so addition of details

regarding cable gland

selection and use

Change to EMC details as

result of testing

23.3.10

V3.10

N/A

TVOC Manual

V3.0

Warranty Cover updated

Declaration of Conformity

updated

Contents page updated

Instrument Warranty and

Service updated

22/07/10

V3.10

N/A

TVOC Manual

V3.1

Addition of fault output level

on page 9, Calibration fault

LED indication changed on

Page 20, 22 ,23

07/08/10

V3.25

N/A

TVOC Manual

V3.1

Addition of F3 and F4 fault to

diagnostics section pages

27, 28, & 29. Additional

notes in TVOC setup,

selector pin section page 11

08/09/10

V3.25

N/A

TVOC Manual

V3.1

Addition wire C.S.A areas

accepted on pages 14 & 30

Mounting diagram 5.2.1 on

page changed to general

assembly drawing

06/10/10

V3.25

N/A

TVOC Manual

V3.2

Page 9. Text amended to

emphasise when TVOC is

un-calibrated.

06/11/10

V3.25

N/A

TVOC Manual

V3.4

Page 14. Barrier part

numbers removed

20/12/10

V3.25

N/A

Page 32

TVOC MANUAL Ion Science Ltd

Page 32 of 32

Unrivalled Detection. www.ionscience.com

Manual log

TVOC Manual

V3.5

Barrier details removed for

technical specification, notes

added that 4-20mA requires

external power

14/01/2011

V3.25

N/A

TVOC Manual

V3.6

Pages 3&4 updated to

correct Quality Management

System

Page 5 Responsibility of use

updated an legal notice

added

Page 18 Setting the gas

tolerance changed to ‘0.1 –

20.0’ to reflect instrument

function.

Page 24 & 25 System

Recommendations added.

Page 26 contact details

moved here

Page 28 details of Sensor

Light Guard added.

Page 29 Parts notes

updated.

Pages 7,11,13 & 14 ATEX

comments changed.

23/03/11

V3.27

N/A

TVOC Manual

V3.7

Page 30 – Accuracy and

Linearity specifications

updated

15/03/12

V3.27

N/A

TVOC Manual

V3.8

IS wiring diagrams and

photos updated.

24/05/12

V.3.27

N/A

TVOC Manual

V3.9

Slight modification to

installation instructions.

Page 11, Point 7

Page 30, IP clarification

26/05/12

V3.27

N/A

TVOC Manual

V4.0

Page 30, Accuracy

specification only

29/10/2012

V3.27

N/A

TVOC Manual

V4.1

Manual format and layout

updated

07/01/2013

V3.27

N/A

TVOC Manual

V4.2

Change to duty cycle. Pages

9, 10, 16 and 28

28/02/2013

V4.09

N/A

V4.3

Firmware now suitable for

old and new product

09/07/2013

V4.11

N/A

V4.4

Certification updated Page 3

and various minor updates

made through out to text,

capitalisation, italics

etc…

15/05/2014

V4.11

N/A

4.5

Removal of obsolete

comment on red LED status

on page 20.

14/08/2015

V4.11

N/A

Loading...

Loading...