Page 1

Silicon Pyranometer Smart Sensor (S-LIB-M003) Manual

C

C

The silicon pyranometer smart sensor is designed to work with HOBO® stations. The smart sensor

has a plug-in modular connector that allows it to be added easily to a station. All calibration

parameters are stored inside the smart sensor, which automatically communicates configuration

information to the logger without any programming, calibration, or extensive user setup.

Specifications

Measurement Range 0 to 1280 W/m2

Spectral Range 300 to 1100 nm (see Plot A)

Silicon Pyranometer

Smart Sensor

S-LIB-M003

Accessories:

• Light sensor mounting

bracket (M-LBB)

• Light sensor level (M-LLA)

Accuracy Typically within ±10 W/m2 or ±5%, whichever is greater in sunlight;

Angular Accuracy Cosine corrected 0 to 80 degrees from vertical (see Plot B); Azimuth

Resolution 1.25 W/m2

Drift < ±2% per year

alibration Factory recalibration available

Operating Temperature Range -40° to 75°C (-40° to 167°F)

Environmental Rating Weatherproof

Housing Anodized aluminum housing with acrylic diffuser and O-ring seal

Dimensions 4.1 cm height x 3.2 cm diameter (1 5/8 in. x 1 1/4 in.)

Weight 120 g (4 oz)

Bits per Sample 10

Number of Data Channels* 1

Measurement Averaging Option Yes

able Length Available

Length of Smart Sensor

Network Cable*

* A single HOBO station can accommodate 15 data channels and up to 100 m (328 ft) of smart sensor cable (the digital

communications portion of the sensor cables).

Additional temperature induced error ±0.38 W/m

(0.21 W/m

2

/°F from 77°F)

Error < ±2% error at 45 degrees from vertical, 360 degree rotation

3.0 m (9.8 ft)

3.0 m (9.8 ft)

The CE Marking identifies this product as complying with all relevant

directives in the European Union (EU).

2

/°C from 25°C

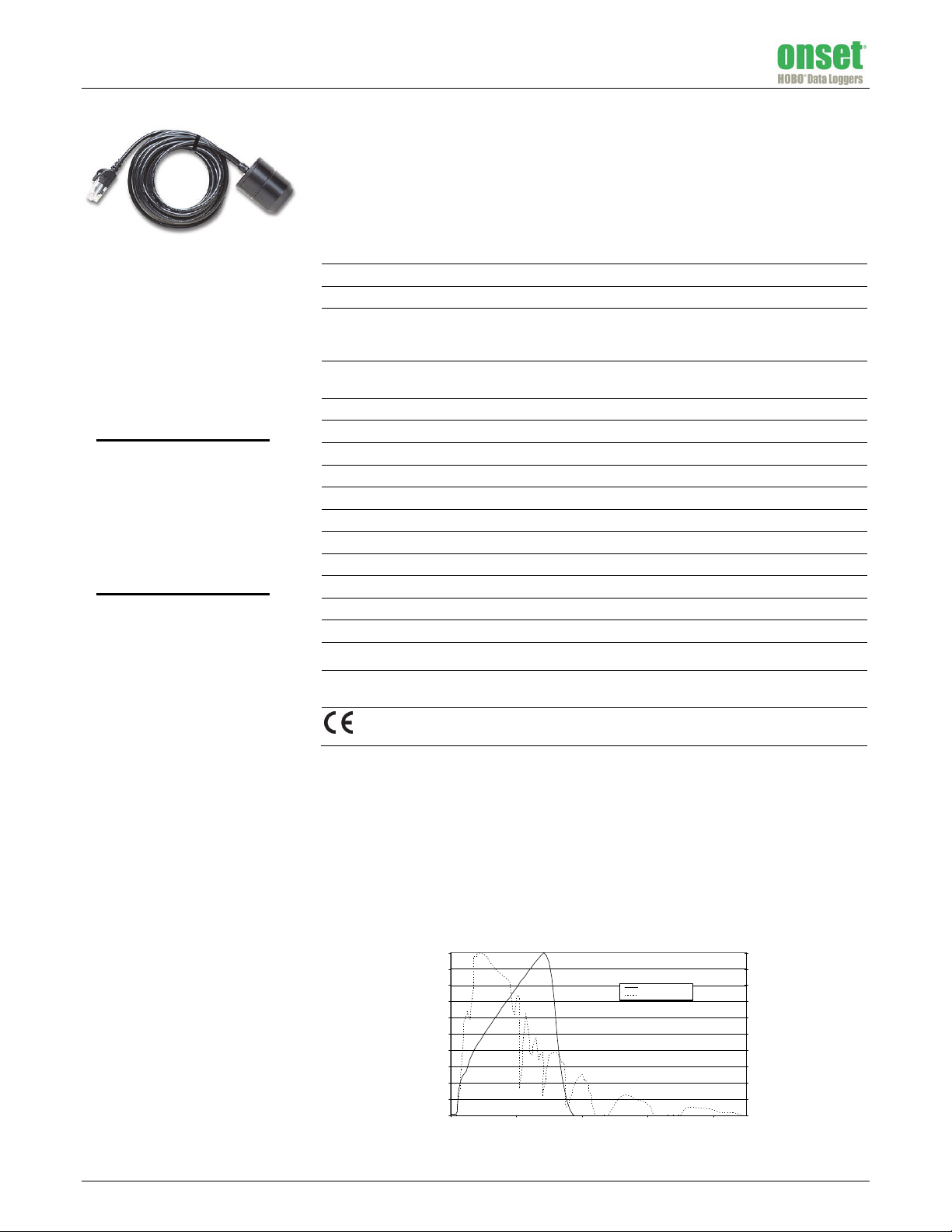

Spectral Characteristics

This sensor uses a silicon photodiode to measure solar power per unit area (watts per square

meter). Silicon photodiodes are not ideal for use as solar radiation sensors and the photodiode

in this silicon pyranometer is no exception (see Plot A). An ideal pyranometer has equal spectral

response from 280 to 2800 nm. However, when calibrated properly and used correctly, the

silicon pyranometer smart sensor should perform well in most situations.

Sun's Relative Intensity and the Typical Relative Response of

the Silicon Pyranometer versus Wavelength

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

Sun's Relative Intensity

0.2

0.1

0.0

250 750 1250 1750 2250

Wavelength (nm)

Silicon Pyranometer

Sunlight

Plot A: S-LIB-M003 Silicon Pyranometer Response Curve

6708-E MAN-S-LIB

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

Photodetector Relative R esponse

0.1

0.0

Page 2

Silicon Pyranometer Smart Sensor (S-LIB-M003) Manual

The sensor is calibrated for use in sunlight (an Eppley Precision

Spectral Pyranometer is used as reference standard).

Accordingly, if the sensor is used under natural sunlight, the

measurement errors will be small. Note that significant errors

may result from using the sensor under artificial light, within

plant canopies, in greenhouses, or any other conditions where

the spectral content differs from sunlight.

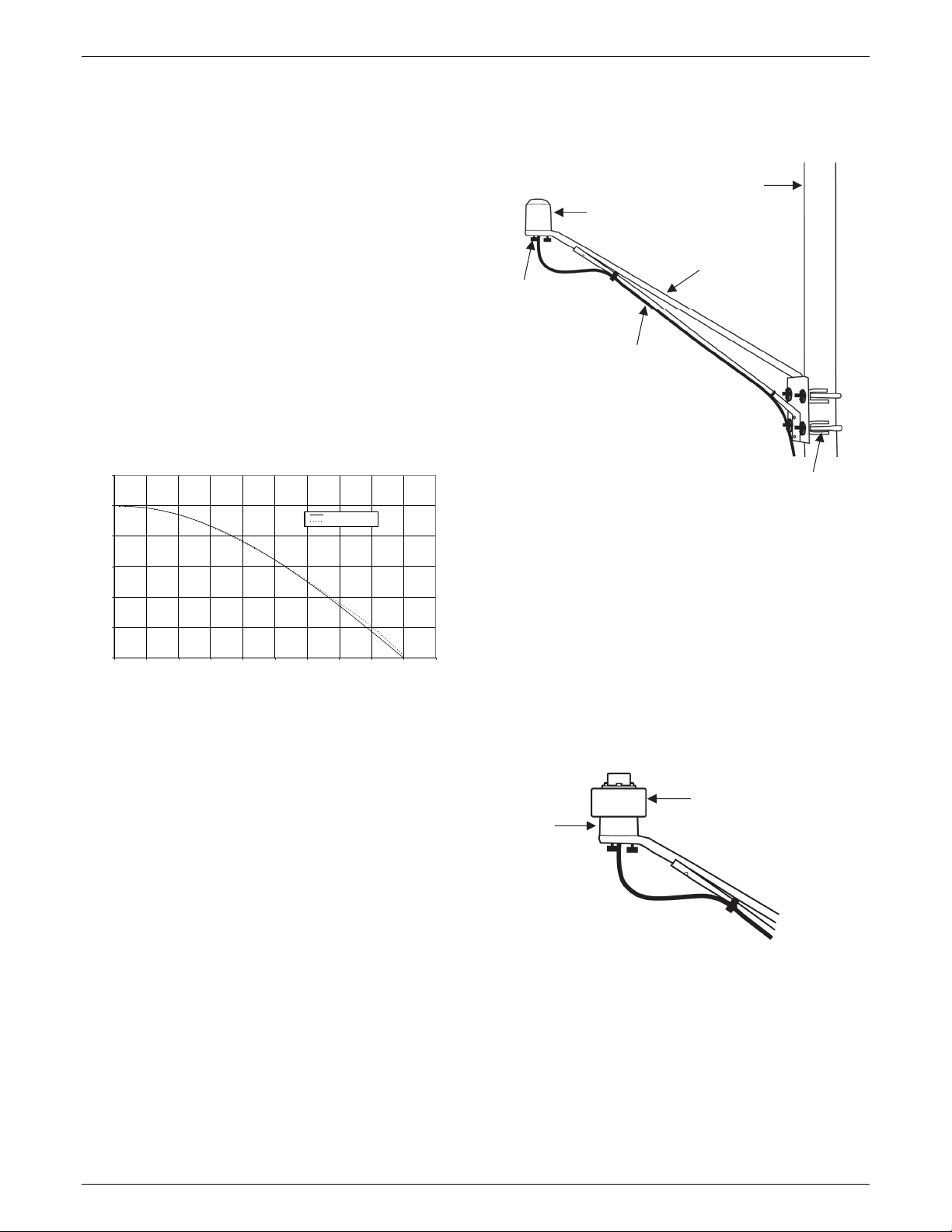

Cosine Correction

The silicon pyranometer smart sensor housing is designed to

give an accurate cosine response. Plot B shows a plot of relative

intensity versus angle of incidence for a typical sensor and for

the theoretical ideal response. Deviation from ideal response is

less than 5% from 0 to 70 degrees and less than 10% from 70 to

80 degrees.

Note that as the angle approaches 90 degrees, the ideal cosine

response approaches zero. As a result, small errors in measured

intensity will result in very large percentage errors compared to

the ideal response from 80 to 90 degrees.

Typical Cosine Response of Silicon Pyranometer

120

100

80

60

40

Percent Relative Response

20

0

0 102030405060708090100

Plot B: S-LIB-M003 Typical Cosine Response Curve

Angle from Vertical (Degrees)

Ideal Response

Silicon Pyranometer

Mounting

Bracket Mounting

It is recommended that you mount the silicon pyranometer

smart sensor with the light sensor bracket (M-LBB) on a pole or

tripod. To mount the sensor using the bracket:

5

1. Attach the light sensor bracket to a 1¼ inch - 1

with the provided U-bolts.

Note: The bracket can also be mounted on a flat, vertical

surface using four screws.

2. Position the silicon pyranometer sensor on top of the

bracket with its cable running through the slot in the

bracket.

3. Using the two screws supplied, attach the sensor to the

bracket through the two holes on either side of the slot.

Note: Do not completely tighten the screws until you level

the sensor.

4. Position the bracket so it faces toward the equator,

minimizing the chance of shading.

5. Mount the bracket on the mast with the two U-bolt

assemblies, mounting it high enough on the mast to avoid

the possibility of shading the sensor.

/8 inch pole

Note: If you mount the sensor above eye level, it is

recommended that you use a step ladder or other secure

platform when leveling the sensor so that you can clearly

view the light sensor level (M-LLA).

Mast

Silicon pyranometer

smart sensor

Light sensor

Thumbscrew

Silicon pyranometer

sensor cable

bracket

U-bolt assembly

Silicon Pyranometer Sensor Bracket Mounting

6. Make sure the screws holding the sensor to the mounting

bracket are loose.

7. Place the light sensor level on the silicon pyranometer

smart sensor.

8. Adjust the height of the thumbscrews to level the sensor

(start with the thumbscrews protruding about 1/16

inch

from the bracket).

9. Once the sensor is near level, tighten the Phillips head

screws.

10. Check the level and repeat above steps if necessary.

11. IMPORTANT: Don’t forget to remove the level when you

are done with it.

Light sensor level

Silicon

pyranometer

sensor

(remove for operation)

Leveling the Sensor on

the Light Sensor Bracket

Specialized Application Mounting

To mount the silicon pyranometer sensor using a mounting

plate of your own design:

1. Drill a 0.56 (9/16) inch hole in the middle of the plate, then

drill two #25 holes 1.063 (1-1/16) inches apart on either

side of the center hole. Cut a 0.31 (5/16) inch-wide slot in

the mounting plate. See diagram on next page. The plate

should be a thickness of 1/8 inch or less.

2. Slide the sensor through the 0.31 (5/16) inch-wide slot.

1-800-LOGGERS 2 www.onsetcomp.com

Page 3

Silicon Pyranometer Smart Sensor (S-LIB-M003) Manual

3. Attach the sensor using two 6-32 x 3/8 inch screws and lock

washers (not included).

4. Shim the sensor as necessary to level it.

Recommended Mounting Plate Dimensions

Mounting Considerations

• Small errors in alignment can produce significant errors.

Be certain that the sensor is mounted level.

• Mount the sensor where it will not be in a shadow. Any

obstruction should be below the plane of the sensor head.

If that is not possible, try to limit obstructions to below 5

degrees, where the effect will be minimal.

• If possible, avoid locating the sensors in dusty locations.

Dust, pollen, and salt residue that collect on the top of the

sensor can significantly degrade accuracy.

• Refer to the station manual and Tripod Setup Guide for

more information regarding setting up stations.

Maintenance

Dust on the sensor will degrade sensor accuracy. Periodically

inspect the sensor, and if necessary, gently clean the diffuser

with a damp sponge. Do not open the sensor as there are no

user serviceable parts inside.

Warning: DO NOT use alcohol, organic solvents, abrasives,

or strong detergents to clean the diffuser element on the

silicon pyranometer smart sensor. The acrylic material used in

the sensors can be crazed by exposure to alcohol or organic

solvents. Clean the sensor only with water and/or a mild

detergent such as dishwashing soap if necessary. It is

recommended that you use vinegar to remove hard water

deposits from the diffuser element. Under no circumstances

should the smart sensor be immersed in any liquid.

Verifying Sensor Accuracy

It is recommended that you test the silicon pyranometer smart

sensor annually for accuracy. If the sensor is not providing

accurate data, it may be damaged or out of calibration. If you

are unsure of accuracy, send the smart sensor back to Onset for

testing and possible re-calibration. Only Onset can complete

calibration. Contact Onset or your dealer for a Return

Merchandise Authorization (RMA) number before sending the

sensor.

Connecting the Smart Sensor to a Station

To connect the sensor to a station, stop the station from

logging and insert the smart sensor’s modular jack into an

available smart sensor port on the station. See the station

manual for details on operating stations with smart sensors.

Operation

The silicon pyranometer smart sensor supports measurement

averaging. When measurement averaging is enabled, data is

sampled more frequently than it is logged. The multiple

samples are then averaged together and the average value is

stored as the data for the interval. For example, if the logging

interval is set at 10 minutes and the sampling interval is set at 1

minute, each recorded data point will be the average of 10

measurements.

Measurement averaging is useful for reducing noise in the data.

It is recommended that you use measurement averaging

whenever the silicon pyranometer smart sensor is placed in an

area where the light level can vary quickly with respect to the

logging interval (for example, during partly cloudy conditions).

Note that fast sampling intervals less than 1 minute may

significantly reduce battery life. See the station manual for

more details about battery life.

© 2001–2015 Onset Computer Corporation. All rights reserved. Onset and HOBO are trademarks or

1-800-LOGGERS (564-4377) • 508-759-9500

www.onsetcomp.com • loggerhelp@onsetcomp.com

registered trademarks of Onset Computer Corporation. All other trademarks are the property of

their respective companies.

6708-E MAN-S-LIB

Loading...

Loading...