Page 1

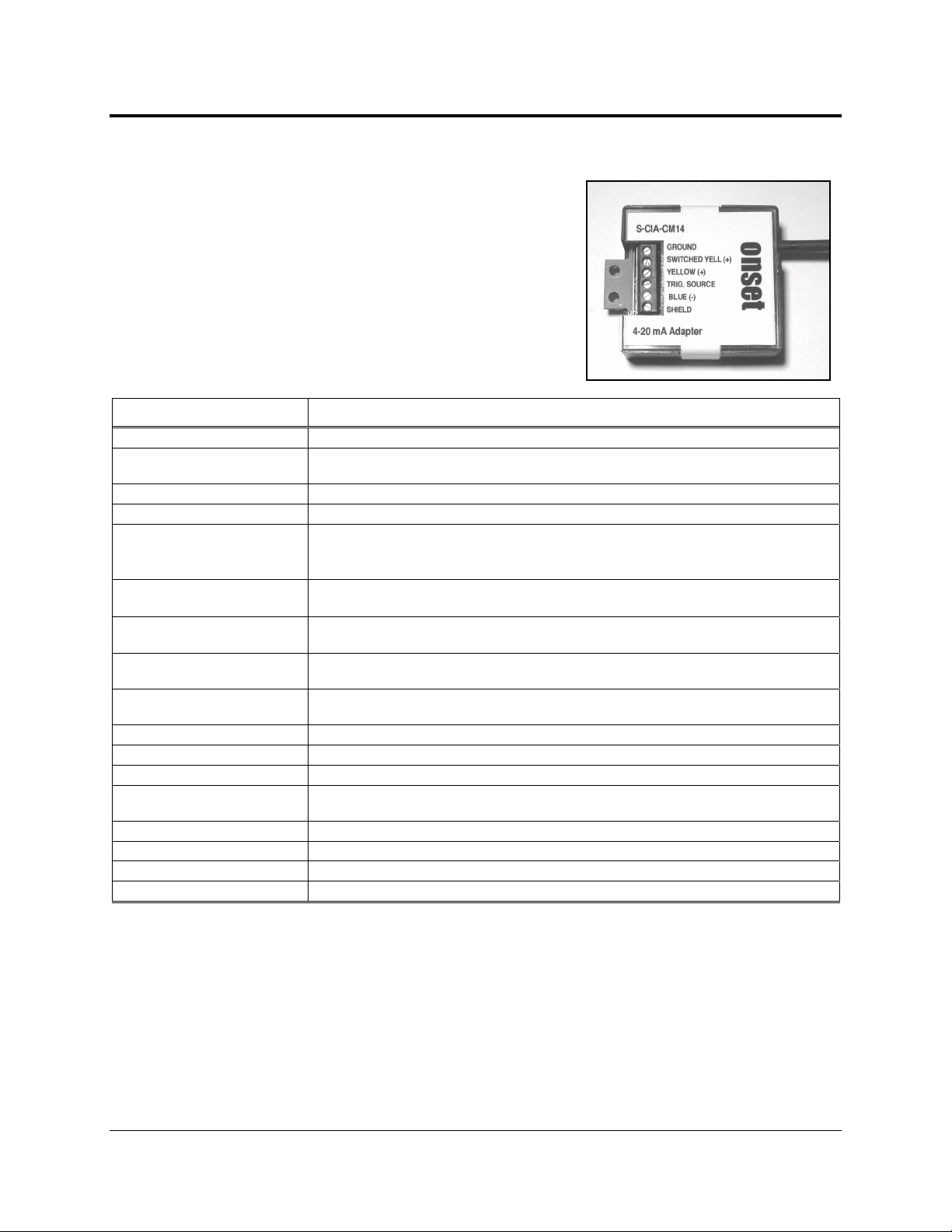

12-Bit 4-20 mA Input Adapter (Part # S-CIA-CM14)

The 12-Bit 4-20 mA Input Adapter is used for sensors with

4-20 mA current loop outputs and is designed to work with the

HOBO

input adapter features both a battery-saving switched input and a

non-switched input. It also provides a trigger source voltage for

controlling power to external sensors. The input adapter has a

plug-in modular connector that allows it to be added easily to the

HOBO Weather Station or HOBO Micro Station.

* The input adapter can provide readings as low as 0 mA. This can be helpful when diagnosing sensor issues such

†

®

Weather Station and Micro Station data loggers. The

Specification 12-Bit 4-20 mA Input Adapter

Measurement Range* 4-20 mA

Accuracy

Resolution ± 4.93 µA

Input Impedance 124Ω

Switched Input Maximum switch voltage above ground (Pin 2 to Pin 1): 20 V

Sensor Trigger: Source Voltage: 2.5 V ± 2.4%; maximum source current: 1 mA

Operating Temperature

Range

Housing

User Connection

Dimensions 4.5 x 4.8 x 1.6 cm (1.8 x 1.9 x 0.6 in.)

Weight 25 g (0.88 oz)

Number of Data Channels† 1

Measurement Averaging

Option

Digital Filtering Automatic digital filtering with 32 readings/sample in 16.6 ms

Bits per Sample 12

Length of Network Cable† 14 cm (5.5 in.)

Part Number S-CIA-CM14

as open inputs.

The HOBO Weather Station and HOBO Micro Station have 10 and 4 data ports, respectively. A single HOBO

Weather Station or HOBO Micro Station can theoretically accommodate up to 15 data channels and up to 100 m

(328 ft) of network cable (the digital communications portion of the input adapter and smart sensor cables),

although available space in the enclosure may limit the number of sensors you can attach.

± 0.1 mA (± 0.5% full scale) over full temperature range of -40°C to 75°C

(-40°F to 167°F)

Maximum switch current: 50 mA

On time: 316.6 ms ± 3%

On time: 316.6 ms ± 3%

-40° to 75°C (-40° to 167°F)

Plastic case; must be placed inside logger enclosure to protect from direct

exposure to the weather

Six-position screw terminal strip (16 – 30AWG); shielded cable recommended with

outside diameter of 3.2 mm to 3.8 mm (0.125 in. to 0.150 in.)

Yes

Part # S-CIA-CM14

© 2003 Onset Computer Corporation

Part #: MAN-S-CIA

Doc #: 7583-A

Page 2

12-Bit 4-20 mA Input Adapter

Inside this package

• 12-Bit 4-20 mA Input Adapter

• Hook-and-loop tape

• Three cable ties

Mounting

For the HOBO Weather Station, use the self-adhesive hook-and-loop tape included in the package to

mount the input adapter on top of the battery cover inside the logger enclosure. To mount more than one

adapter, use the back of the logger enclosure door.

For the HOBO Micro Station, you can place the input adapter inside the logger enclosure and allow it to

float freely. It is not necessary to use the hook-and-loop tape.

You can connect up to 10 adapters inside the HOBO Weather Station enclosure, or up to two adapters

inside the HOBO Micro Station, based on available space.

Mounting Considerations

• If sensor cables are left on the ground, use a conduit to protect against animals, lawn mowers,

exposure to chemicals, etc.

• Refer to the HOBO Weather Station User’s Guide or the HOBO Micro Station User’s Guide for

information about setting up complete stations.

Attaching Sensor Cables

For the HOBO Weather Station, bring the cable through the opening at the bottom of the logger

enclosure. Leave some slack in the cable inside the logger housing so that you can open and close the

logger’s door and change the batteries without straining the cable connection. Be sure to provide “drip

loops” underneath the logger to prevent water from trickling up the cable and into the logger. Pack the

opening with duct seal.

For the HOBO Micro Station, bring the cable through the logger’s sensor port. (See the HOBO Micro

Station User’s Guide for details on removing the dome nut and stuffing gland from the sensor port.)

Ensure that the cables to the sensor are the appropriate size for the stuffing gland (0.125”-0.15”). Be sure

to provide “drip loops” underneath the logger to prevent water from trickling up the cable and into the

logger.

Use the included cable tie to provide strain relief to the cable (or individual wires), as shown below.

Figure 1: Cable strain relief

Page 2 of 6

Page 3

12-Bit 4-20 mA Input Adapter

Sensor Input Connections

The

12-Bit 4-20 mA Input Adapter utilizes a 6-position screw-terminal block for sensor connections

with wire sizes ranging from 16 to 30AWG. Pin numbers, names and descriptions are as follows.

Pin # Pin Name Description

1 GROUND Ground. Used as a common connection.

2 SWITCHED YELL (+) Yellow switched. Makes connection to Pin 3 (+ Yellow) once per

sample. This helps to conserve external sensor battery life. Maximum

20 V, 50 mA. See “Operation” below for timing diagrams.

3 YELLOW (+) Positive current input for sampling.

4 TRIG. SOURCE Triggered source. Provides voltage from the logger’s battery to power,

or trigger, the external circuitry. Maximum 2.5 V, 1 mA. See

“Operation” below for timing diagrams.

5 BLUE (–) Negative current input for sampling.

6 SHIELD Connects cable shield for noise suppression and circuit protection.

Typical Setup

A typical remote data logging setup consists of a 12-Bit 4-20 mA Input Adapter, a two-wire 4-20 mA

transducer (i.e. flow, pressure, pH, etc.), and an external battery to provide transducer power.

Figure 2: Switched connection

If battery conservation is not an issue, or if longer transducer warmup time is required, the following

non-switched connection can be made.

Figure 3: Non-switched connection

Page 3 of 6

Page 4

12-Bit 4-20 mA Input Adapter

Connecting the Adapters to the Logger

To use the 12-Bit 4-20 mA Input Adapter, stop the logger and insert the adapter’s modular jack into an

available sensor connection port on the logger. If no port is available, use a 1-to-2 sensor connection

adapter (Onset part # S-ADAPT), which allows you to plug two sensors into one port (HOBO Weather

Station only).

The logger automatically detects the new input adapter the next time you launch it. Launch the logger and

verify that the input adapter is functioning correctly. Measurements are recorded in milliamps (mA). See

the HOBO Weather Station User’s Guide or the HOBO Micro Station User’s Guide for details.

Operation

The 12-Bit 4-20 mA Input Adapter uses digital filtering and optional measurement averaging to reduce

the effect of noise and improve accuracy.

Regardless of whether measurement averaging is used or not, each sample is comprised of a 300 ms

(± 3%) warmup period and a 16.6 ms (± 3%) sample period. During the sample period, digital filtering is

accomplished by taking 32 readings. These readings are then averaged to produce a single measurement,

as shown in the following diagram:

Figure 4: Measurement averaging (not to scale)

Optional measurement averaging can be selected at launch. Use measurement averaging if measurements

may fluctuate significantly within the logging interval. Measurement averaging helps to prevent the

sampling error known as aliasing.

To use measurement averaging, set the Sampling Interval to a rate that is faster than the logging interval.

When measurement averaging is selected in this way, the adapter takes several measurements during the

logging interval and averages them to produce a single logged data point. For example, if the logging

interval is 10 minutes and the sampling interval is 1 minute, each recorded data point is the average of 10

measurements.

Note that fast sampling intervals (less than one minute) significantly reduce battery life.

For more information about sampling intervals, refer to the HOBO Weather Station User’s Guide or the

HOBO Micro Station User’s Guide.

Page 4 of 6

Page 5

12-Bit 4-20 mA Input Adapter

Using the Switched Input

The 12-Bit 4-20 mA Input Adapter can be used with continuously powered 4-20 mA transducers as well

as remote applications with external battery-powered 4-20 mA transducers. (See Figures 2 and 3.)

To take advantage of the switched input, the 4-20 mA transducer must meet the following criteria:

• The sensor must be able to be powered from the 4-20 mA loop.

• The sensor must have a warmup time of less than 300 ms.

Using the switched input can significantly reduce external battery consumption because the transducer is

powered only during warmup and sampling, as shown in the following diagram, instead of being powered

continuously.

Figure 5: Logging with switched input

Note

• Using an external battery to drive the 4-20 mA transducer does not increase the battery life of the

logger (HOBO Weather Station or HOBO Micro Station).

Compared with continuously powering the 4-20 mA transducer, the average current drain is significantly

reduced. For an example of the power savings with and without using the switched input:

• If the logger’s sampling interval is 60 seconds and the worst case current drain for the transducer

is 20 mA, then the average current drain will be:

transducer current × sample duration ÷ sampling interval

20 mA × 0.327 s ÷ 60 s = 0.109 mA

• If we assume that the transducer battery used has a useful capacity of 2000 mAh, the battery life

is:

battery capacity ÷ average current

2000 mAh ÷ 0.109 mA ÷ 24 hr/day = 764 days

• Without switched input, the battery life would be:

2000 mAh ÷ 20 mA ÷ 24 hr/day = 4.1 days

Therefore, using the switched input allows the device to run approximately 186 times longer!

Page 5 of 6

Page 6

12-Bit 4-20 mA Input Adapter

Maintenance

With normal usage, if the adapter is installed correctly, the adapter’s circuitry is protected against

excessive moisture and does not require any maintenance or cleaning. However, in an unusually wet

environment, excessive moisture can collect in the logger enclosure and adversely affect measurement

accuracy and communications in the adapter module.

The circuit board is conformal coated to provide limited protection against moisture, but if you observe

heavy condensation, consider the following options:

• Verify that the logger is installed properly and sealed according to the instructions given in the

HOBO Weather Station User’s Guide or the HOBO Micro Station User’s Guide.

• Consider moving the logger to a location that is better protected from moisture, is better

ventilated, or receives some sunlight to help keep the logger dry.

• Apply WD-40, LPS 1, or 711 to the six-position terminal block and the modular connectors to

displace moisture and help prevent corrosion. (Other spray lubricants may be appropriate; check

product labeling to ensure that it is safe to use on plastics and electronics.)

Verifying Accuracy

You should check the accuracy of the 12-Bit 4-20 mA Input Adapter annually. Verify the accuracy of the

input adapter against a known standard, such as a calibrated current source. If it is not providing accurate

data, it may have been damaged. If you are unsure of the input adapter accuracy, you can send it back to

Onset for re-certification. Contact Onset or your place of purchase for a Return Merchandise

Authorization (RMA) number and associated costs prior to sending it.

Warranty

This product is warranted to be free from defects in material and workmanship for a period of one year

from the date of original purchase. During the warranty period, Onset will, at its option, either repair or

replace products that prove to be defective. This warranty is void if the Onset products have been

damaged by customer error or negligence, or if there has been an unauthorized modification.

Tune-up Service

Onset will examine and re-test this input adapter. A tune up fee may be charged.

© 2003 Onset Computer Corporation. All rights reserved.

Onset and HOBO are registered trademarks of Onset Computer Corporation.

Part #: MAN-C-CIA

Document #: 7583-A

Page 6 of 6

Loading...

Loading...