Page 1

HOBO® RX Wireless Sensor Network

W

O

RXW Davis® Wind Speed and Direction Sensor (RXW-WCF-xxx) Manual

This sensor measures wind speed and direction and is designed to work with the HOBOnet

Wireless Sensor Network in which data is transmitted wirelessly from the sensor mote across

the network to the RX3000 station and then uploaded to HOBOlink® web-based software. With

HOBOlink, you can monitor sensor readings, view graphs, set up alarms, download data, and

more.

Specifications

Sensor Wind Speed/Gust Wind Direction

Measurement Range 0 to 76 m/sec (0 to 170 mph) 0 to 355 degrees

RXW Davis Wind Speed &

Direction Sensor

Models:

• RXW-WCF-900 (US)

• RXW-WCF-868 (Europe)

• RXW-WCF-922

(Australia/NZ)

Included Items:

• Cable ties

• Screws

Required Items:

• Weather-resistant cable

ties or cable clips

• Electrical tape

• Handheld compass, local

area map, or handheld GPS

If mounting on tripod or mast:

• Adjustable wrench

If mounting on wooden surface:

• Drill with 5 mm (3/16 inch)

drill bit

Accessories:

• Grounding kit (M-GKA)

Accuracy ±1.1 m/sec (±2 mph) or ±5% of

Resolution 0.5 m/sec (1.1 mph) 1.4 degrees (0 to 355 degrees)

Starting Threshold ≤1 m/sec (2.2 mph) 1 m/sec (2.2 mph)

Turning Radius 108 mm (4.25 in.) Approximately 135 mm (5.25 in.)

Measurement Definition Cup revolutions are accumulated

ireless Mote

perating Temperature

Range

Radio Power 12.6 mW (+11 dBm) non-adjustable

Transmission Range Reliable connection to 457.2 m (1,500 ft) line of sight at 1.8 m (6 ft) high

Wireless Data Standard IEEE 802.15.4

Radio Operating

Frequencies

Modulation Employed OQPSK (Offset Quadrature Phase Shift Keying)

Data Rate Up to 250 kbps, non-adjustable

Duty Cycle <1%

Maximum Number of

Motes

Battery Type/

Power Source

Battery Life With NiMH batteries: Typical 3–5 years when operated in the

Memory 16 MB

Dimensions Sensor: 470 x 191 x 121 mm (18.5 x 7.5 x 4.75 in.)

Weight Sensor and cable: 1.332 kg (2 lb, 15 oz)

Materials Sensor: Polycarbonate wind cups, sealed stainless steel bearing, UV-

reading, whichever is greater

every three seconds for the

duration of the logging interval

(see Measurement Operation)

Wind speed: Average speed for

the entire logging interval

Gust speed: The highest threesecond wind recorded during the

logging interval

-25° to 60°C (-13° to 140°F) with rechargeable batteries

-40 to 70°C (-40 to 158°F) with lithium batteries

Reliable connection to 609.6 m (2,000 ft) line of sight at 3 m (10 ft) high

RXW-WCF-900: 904–924 MHz

RXW-WCF-868: 866.5 MHz

RXW-WCF-922: 916–924 MHz

50 motes per one RX Wireless Sensor Network

Two AA 1.2V rechargeable NiMH batteries, powered by built-in solar

panel or two AA 1.5 V lithium batteries for operating conditions of -40 to

70°C (-40 to 158°F)

temperature range -20° to 40°C (-4°F to 104°F) and positioned toward the

sun (see Deployment and Mounting), operation outside this range will

reduce the battery service life

With lithium batteries: 1 year, typical use

Cable length: 3 m (9.8 ft)

Mote: 16.2 x 8.59 x 4.14 cm (6.38 x 3.38 x 1.63 inches)

Mote: 223 g (7.87 oz)

resistant ABS wind vane and black-anodized aluminum anemometer arm

Mote: PCPBT, silicone rubber seal

±7 degrees

Unit vector averaging used; vector

components for each wind

measurement are calculated

every three seconds for duration

of logging interval (see

Measurement Operation)

22245-A

Page 2

RXW Davis Wind Speed and Direction Sensor (RXW-WCF-xxx) Manual

C

Specifications (continued)

Environmental Rating Sensor: Weatherproof

ompliance Marks RXW-WCF-900: See last page

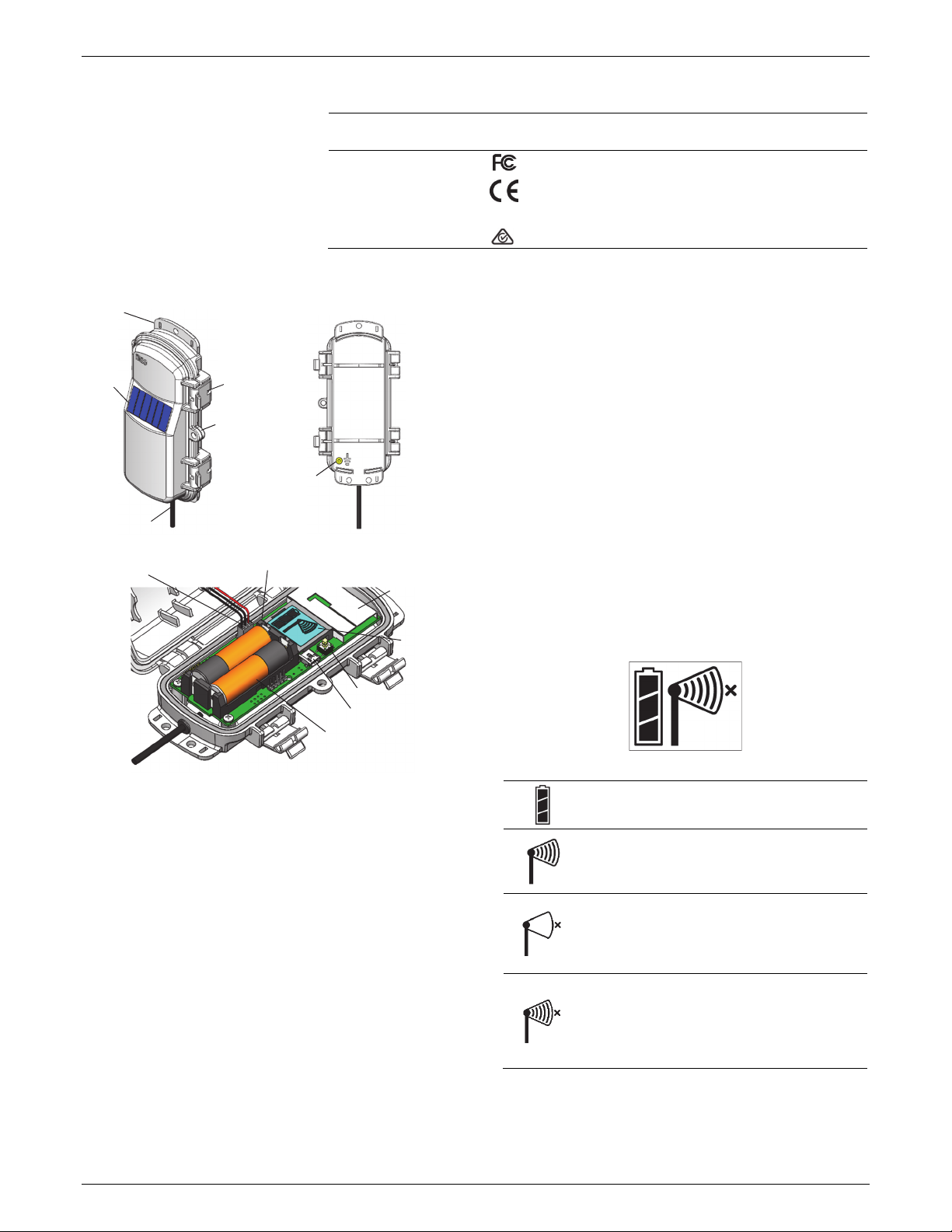

Mote Components and Operation

Mounting

Tab

Solar Panel

Sensor Cable

Sensor Mote Closed, Front Sensor Mote Closed, Back

Solar Panel Cable

Latch

Eyelet

Ground Wire

Port

LEDs

Antenna

LCD Screen

Mote: IP67, NEMA 6

RXW-WCF-868: The CE Marking identifies this product as

complying with all relevant directives in the European Union

(EU).

RXW-WCF-922: See last page

blinking quickly while the mote searches for a network and

then slowly as the mote registers with the network. Once the

network registration process is complete, the blue LED blinks at

4 seconds to indicate normal operation. If the mote is not

currently part of a network, the blue LED will be off. If the blue

LED is on and not blinking, there is a problem with the mote.

Contact Onset Technical Support.

Battery Holder: The location where the batteries are installed

as shown (see Battery Information).

USB Port: Use this port to connect to the mote to a computer

via USB cable if you need to update the firmware (see Updating

Mote Firmware).

Button: Push this button for 1 second to illuminate the LCD or 3

seconds for the mote to search for an RX Wireless Sensor

Network to join (see Adding the Mote to the RX Wireless Sensor

Network).

LCD Screen: The mote is equipped with an LCD screen that

displays details about the current status. This example shows all

symbols illuminated on the LCD screen followed by definitions

of each symbol in the table.

Button

USB Port

Battery Holder

Sensor Mote Opened

Mounting Tab: Use the tabs at the top and bottom of the mote

to mount it (see Deploying and Mounting).

Solar Panel: Position the solar panel towards the sun to charge

the mote batteries (see Deploying and Mounting).

Sensor Cable: This is the cable that connects the mote to the

sensor.

Eyelet: Use this eyelet to attach a 3/16 inch padlock to the

mote for security.

Latch: Use the two latches to open and close the mote door.

Ground Wire Port: Use this port to connect a ground wire (see

Deploying and Mounting).

Antenna: This is the built-in antenna for the radio

communications across the RX Wireless Sensor Network.

Solar Panel Cable: This cable connects the built-in solar panel

to the mote circuitry.

LEDs: There are two LEDs to the left of the LCD screen. The

green LED blinks during the process of joining a network,

LCD Symbol Description

The battery indicator shows the approximate battery

charge remaining.

This is a signal strength indicator. The more bars, the

stronger the signal between motes. If there is no x

icon next to the signal strength indicator, then the

mote is part of an RX Wireless Sensor Network.

An empty signal strength icon plus the x icon

indicates that the mote is not currently part of a

network. See Adding the Mote to the RX Wireless

Sensor Network for details on how to add a mote to

the network.

When the mote is in the process of joining a

network, the signal strength icon will blink and then

the bars in the icon will cycle from left to right. The x

icon will blink during the last step in the network

registration process (see Adding the Mote to the RX

Wireless Sensor Network for details).

1-800-LOGGERS 2 www.onsetcomp.com

Page 3

RXW Davis Wind Speed and Direction Sensor (RXW-WCF-xxx) Manual

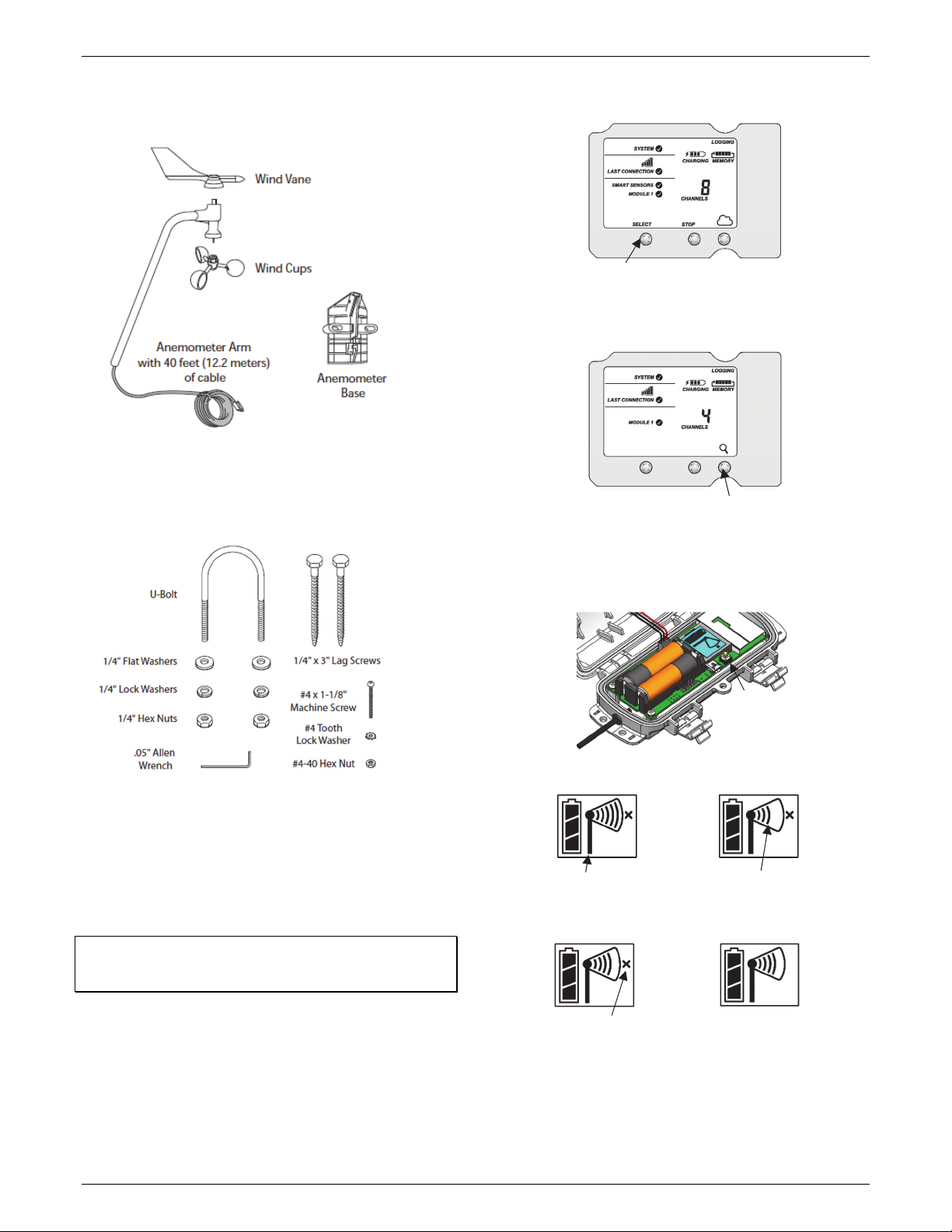

Sensor Components

The sensor includes the components shown below.

The sensor also includes a hardware kit with the items most

commonly needed for installation as shown below. The items

you use from the kit depend on where you install the sensor.

You may need to adapt or purchase additional hardware to fit

your individual requirements.

HOBO RXW Manager is installed in the left slot (module 1)

or twice if it is installed on the right slot (module 2).

Press this button to view the module

where the RXW Manager is installed

3. Press the Search button (the magnifying glass). The

magnifying glass icon will blink while the RX3000 is in search

mode.

Press this button so the station is ready

to have motes join the network

4. Open the mote door and install the batteries if you have not

already done so.

5. Press the button on the mote for 3 seconds. The signal

strength icon will flash and then cycle.

Adding the Mote to the RX Wireless Sensor

Network

The mote must join an RX Wireless Sensor Network before it

can begin measuring wind speed and direction and transmitting

data. This requires accessing the RX3000 station and the mote

at the same time so it is recommended that you complete

these steps before deploying the mote.

Important: If you have not configured the RX3000 station with

the RXW Manager, follow the instructions in the RX3000 Quick

Start before continuing.

To add a mote to the RX Wireless Sensor Network:

1. If the LCD is blank on the RX3000 station, press any button

to wake it up.

2. Press the Select button once (which shows the number of

smart sensors installed) and then press it again once if the

Press this button for 3

seconds for the mote to

join the network

6. Watch the LCD on the mote.

a.

This signal strength icon

blinks while searching for

a network.

c.

This network connection

“x” icon blinks while the

mote completes the

registration process,

which may take up to

five minutes.

b.

Once a network is found,

the icon will stop flashing

and the bars will cycle from

left to right.

d.

Once the mote has finished joining

the network, the “x” icon is

removed and the channel count on

the station LCD increases by three

(two for wind speed/direction and

one for the mote battery).

This process may take up to five minutes. The green LED

blinks quickly while the mote searches for a network to join

1-800-LOGGERS 3 www.onsetcomp.com

Page 4

RXW Davis Wind Speed and Direction Sensor (RXW-WCF-xxx) Manual

and then blinks slowly while it completes the network

registration. Once the mote has finished joining the

network, the green LED turns off and the blue LED then

blinks indefinitely while the mote is part of the network.

Note: If the mote cannot find the network or has trouble

remaining connected during this process, make sure the

mote is in a vertical, upright position and within range of

the station.

7. Press the Search button (the magnifying glass) on the

RX3000 station to stop searching for motes.

Press this button again to

stop searching for motes

If you added more than one more mote to the network, then

the total channel count on the RX3000 station LCD for the RXW

Manager module will represent all measurement channels plus

a battery channel for each mote in the RX Wireless Sensor

Network.

Sensor measurements will be recorded at the logging interval

specified in HOBOlink, transmitted to the RX3000 station, and

uploaded to HOBOlink at the next connection interval

(readout). Use HOBOlink to monitor mote status and health. If a

mote is temporarily offline, any logged data is saved until it is

back online. In addition, if a mote is offline for 30 minutes, the

RX3000 station will automatically connect to HOBOlink and

report the mote as missing. Once the mote is back online, any

logged data will be uploaded the next time the RX3000 station

connects to HOBOlink.

See the HOBOlink Help for details on how to change the logging

and connection intervals, view data, check mote status, add the

mote to a map, and more.

3. Use the Allen wrench provided to tighten the set screw on

the side of the wind cups. The wind cups should drop

slightly when you let go.

4. Ensure the set screw is screwed in fully and very tight.

Failure to do so will cause the anemometer to function

improperly.

5. Spin the wind cups; they should spin freely. If they do not

spin freely, take them off and repeat these steps

Attaching the Anemometer Arm to the Base

1. Insert the anemometer arm into the base, sliding the cable

through the notch in the base as shown below. Be sure to

line up the small hole in the arm with the holes in the base.

Assembling the Sensor

Attaching the Wind Vane

The wind direction has been calibrated in the factory so that

the wind direction will be correct when the arm is installed

pointing north and the vane is installed correctly.

1. Slide the wind vane onto the wind vane shaft. The shaft’s

cross-section is D-shaped to ensure that the anemometer is

installed correctly.

2. Tighten the set screw in the wind vane with the Allen wrench.

Attaching the Wind Cups

1. Push the wind cups onto the anemometer’s stainless steel

wind cup shaft.

2. Slide the wind cups up the shaft as far as possible.

1-800-LOGGERS 4 www.onsetcomp.com

2. Insert the machine screw through the holes in the base and

arm.

3. Slide the tooth-lock washer and hex nut onto the machine

screw. Tighten the hex nut while holding the screw with a

Phillips head screwdriver to prevent it from turning.

4. Press the sensor cable firmly and completely into the zig-

zagging channel in the base, starting from the arm and

progressing downward to the bottom of the base.

Deployment and Mounting

Mounting and Positioning the Mote

• Mount the mote to a mast or pipe using cable ties or affix

the mote to a wooden post or flat surface with screws.

Page 5

RXW Davis Wind Speed and Direction Sensor (RXW-WCF-xxx) Manual

Insert the cable ties or screws through the holes on the

mounting tabs.

• Consider using plastic poles such as PVC to mount the

mote as certain types of metal could decrease signal

strength.

• Make sure the mote remains in a vertical position once it

is placed in its deployment location for optimal network

communications.

• Make sure the mote door is closed, with both latches fully

locked to ensure a watertight seal.

• Consider using a 3/16 inch padlock to restrict access to the

mote. With the mote door closed, hook a padlock through

the eyelet on the right side of the door and lock it.

• Position the mote towards the sun, making sure the solar

panel is oriented so that it receives optimal sunlight

throughout each season. I It may be necessary to

periodically adjust the mote position as the path of the

sunlight changes throughout the year or if tree and leaf

growth alters the amount of sunlight reaching the solar

panel.

• Make sure the mote is mounted a minimum of 1.8 m (6 ft)

from the ground or vegetation to help maximize distance

and signal strength.

• Place the mote so there is full line of sight with the next

mote. If there is an obstruction between two sensor

motes or between the sensor mote and the RXW

Manager, then use an RXW Repeater (RXW-RPTR-xxx). For

example, if there is a hill between the sensor mote and

the RXW Manager, place a repeater at the top of the hill

between the sensor mote and the RXW Manager.

• There should not be more than five motes in any direction

at their maximum transmission range from the RXW

Manager. Data logged by a wireless sensor must travel or

“hop” across the wireless network from one mote to the

next until it ultimately reaches the RXW Manager at the

RX3000 station. To make sure the data can successfully

travel across the network, the mote should not be more

than five hops away from the manager.

• The RX Wireless Sensor Network can support a maximum

of 50 motes.

• Use a #4-40 screw to attach a ground wire to the port on

the back of the mote if you are deploying the mote in a

location where lightning is a concern.

mast, or a metal pipe. You may mount the sensor on a

wooden post if it has a side facing due north for mounting.

• The tripod or mounting mast must be properly grounded.

For field installations, you can use Onset’s Grounding Kit

(M-GKA).

• If you live in an area subject to frequent thunderstorms,

installing a lightning rod nearby can reduce the risk of

damage.

• Be sure to secure the sensor cable with cable ties to

protect it from damage.

• Secure the mast the wind sensor is mounted on so that it

does not vibrate. If you are using Onset masts or tripods,

secure them with guy wires.

• The sensor can be damaged with improper handling. Store

the sensor in its shipping box until you are ready to install it.

• To minimize measurement errors due to ambient RF, use

the shortest possible probe cable length and keep the

probe cable as far as possible from other cables carrying

high frequency or high current signals.

Sensor Mounting on a Mast

Follow these instructions for mounting the sensor on a tripod

or mast. The U-bolts included can be used for mounting the

sensor on a mast or tripod with an outside diameter ranging

from 32–44 mm (1.25–1.75 inches). Larger U-bolts (not

supplied) can be used to mount on a mast or tripod with a

maximum outside diameter of 64 mm (2.5 inches). To mount

the sensor on a mast or tripod smaller than 32 mm (1.25

inches), use a U-Bolt that fits the anemometer base openings,

but has a shorter threaded section.

1. Place the U-bolt around the pole so that its two ends

extend through the holes in the mounting base. Loosely

secure with the flat washers, lock washers, and hex nuts.

Sensor Mounting Guidelines

Use the following guidelines to determine the best location for

installing the sensor.

• To ensure correct orientation of the wind vane, the sensor

must be mounted so that the anemometer arm points

north. See North Alignment for steps on finding true north.

• For the most accurate readings, the sensor should be

mounted 2 m (7 ft) or more above the ground and

consistent with meteorological standards for the

application. The sensor should be mounted at least 2.1 m

(7 ft) above the roof line if mounted on a roof and

mounted at a distance of at least five times the height of

the nearest tree, building, or other obstruction. You may

do this by mounting the sensor on an Onset tripod or

1-800-LOGGERS 5 www.onsetcomp.com

2. Raise the anemometer to the desired height on the pole

and swivel it so the anemometer arm is pointing north.

3. Using an adjustable wrench or 7/16 inch wrench, tighten

the hex nuts until the anemometer is firmly fastened on the

pole.

Page 6

RXW Davis Wind Speed and Direction Sensor (RXW-WCF-xxx) Manual

Sensor Mounting on a Wooden Post or Surface

Follow these instructions for mounting the sensor on a wooden

post or surface. The sensor must be mounted on the side that is

facing due north (the mounting arm must point north for

proper wind direction measurements).

1. Hold the anemometer base against the wood surface and

use a pencil to mark the location of the two holes on the

base.

2. Use a drill with a 5 mm (3/16 inch) drill bit to make pilot

holes in these locations.

3. Drive the 3-inch lag screws through the holes in the

anemometer base and into the wood.

Securing the Sensor Cables

To prevent fraying or cutting the anemometer cables where it is

exposed to weather, secure it so it does not whip about in the

wind. Use cable clips or weather resistant cable ties to secure

the cable. Place clips or cable ties approximately every 1 to 1.6

m (3 to 5 ft). Do not use metal staples to secure cables as they

can cut the cables.

Measurement Operation

Wind speed measurements are averaged automatically every 3

seconds within each logging interval. Wind speed is reported as

the average speed for the entire logging interval. For example,

if the logging interval is set to 1 minute, then 20 measurements

(1 measurement every 3 seconds for 60 seconds) are averaged

together and the result is logged each minute. The gust speed is

the highest 3-second wind recorded during the logging interval.

Unit vector averaging is used to determine wind direction

because traditional averaging would produce inaccurate

results. For example, three measurements of 350, 11, and 12

degrees—which are all winds from the north—averaged

together would result in 126 degrees, which incorrectly

indicates a southeasterly wind. Instead, the vector components

(North/South and East/West) for each wind measurement are

calculated every three seconds for the duration of the logging

interval. At the conclusion of the logging interval, the

North/South and East/West components are averaged and

then re-combined to calculate the average wind direction for

the logging interval.

North Alignment

The sensor must be oriented to true north to obtain meaningful

data. There are two methods to align the sensor:

• Compass Alignment

• Global Positioning Satellite (GPS) alignment

Note: The magnetic declination must be known to align the

direction sensor to true north using a magnetic compass.

Worldwide declination information is available from the

National Space Science Data Center at:

http://nssdc.gsfc.nasa.gov/space/cgm/cgm.html.

Compass Alignment

Tools required:

• Compass

• Binoculars

• Tape (such as electrical, packing, or duct tape)

Two people are required to complete this procedure.

1. Position the wind vane so that it points in the same

direction as the mounting arm. Secure the vane on the arm

with a piece of tape so that the vane cannot rotate.

2. While standing 150 to 200 feet south of the sensor, use the

compass to determine magnetic north. If true north is the

same as magnetic north, align yourself so the compass

points north and directly at the sensor. If you are in area

with an east variation, align yourself so that the station is

that number of degrees to the east of magnetic north. If

you are in an area with a west variation, align yourself so

that the station is that number of degrees to the west of

magnetic north.

3. While viewing the sensor through binoculars, instruct

another person to rotate the arm to point the vane north.

The vane should seem to disappear from sight when

properly aligned.

4. Once you’ve obtained the correct position, secure the

sensor base and remove the tape.

GPS Alignment

Tools required:

• Handheld GPS with WAAS-enabled receiver or any

similar high accuracy GPS device

• Flag, orange cone, or other temporary marker

• Access to your HOBOlink account

This procedure requires only one person, but is easier to

complete with two people. In this procedure, you will be using

the GPS receiver first to create an arbitrary waypoint and then

to determine the bearing from the sensor to that waypoint. You

will then align the sensor so that when the vane is pointed at

the waypoint, the direction reported by HOBOlink matches the

GPS receiver’s bearing to the waypoint.

1. In HOBOlink, temporarily set the logging interval to 1 minute

or the fastest logging interval supported by the device

communication plan (if applicable). Refer to the online help

for details on operating HOBOlink.

1-800-LOGGERS 6 www.onsetcomp.com

Page 7

RXW Davis Wind Speed and Direction Sensor (RXW-WCF-xxx) Manual

2. Pick a visible location that is at least 100 meters (110 yards)

away from the sensor and walk to it. Establish a waypoint

with the handheld GPS receiver. You may want to use

averaging to minimize the waypoint position error if your

GPS receiver is so equipped. (For best results, the estimated

position error of the waypoint should be less than 10 feet if

the distance to the sensor is 100 meters, and less than 20

feet for a distance of 200 meters. Mark the waypoint with a

flag, orange cone, or other suitable marker. Walk back to

the sensor and determine the bearing to the waypoint you

just created with the GPS receiver. Again you may need to

determine the average value of the bearing to keep the

errors to a minimum.

3. Check the latest reading in HOBOlink keeping in mind that

the data is only updated when the station connects to

HOBOlink. It may take a couple of connections before the

latest reading from the mote is transmitted to the station

and then uploaded to HOBOlink. The value should match

the angle obtained with the GPS receiver. If it does not,

reposition the sensor vane so that it is pointed directly at

the waypoint flag or marker and then rotate the sensor

mounting arm as needed and wait for the next HOBOlink

reading. Repeat this until the wind direction sensor value in

HOBOlink matches the angle obtained with the GPS

receiver.

4. Once the vane is in position, secure the mounting base and

then double-check that the reported angle is correct.

Maintenance

The sensor does not normally require any maintenance other

than an occasional cleaning. If the vane becomes dirty, rinse it

with mild soap and fresh water. Do not immerse the sensor in

water or use any organic solvents to clean the unit. Do not

attempt to lubricate the wind cup shaft or bearings or the wind

vane shaft. Natural or synthetic lubricants will inhibit the

normal operation of the anemometer.

The mote is designed for outdoor use, but should be inspected

periodically. When inspecting the mote, do the following:

• Verify the mote is free of visible damage or cracks.

• Make sure the mote is clean. Wipe off any dust or grime

with a damp cloth.

• Wipe off any water before opening the mote.

• Make sure the interior seal is intact and the latches are

fully locked when the mote door is closed.

Verifying Sensor Accuracy

It is recommended that you check the accuracy of the sensor

annually. The sensor cannot be calibrated. If the sensor is not

providing accurate data, then it is damaged or possibly worn

out if it has been in use for several years.

Updating Mote Firmware

If a new firmware version is available for the mote, use

HOBOlink to download the file to your computer.

1. In HOBOlink, go to Devices > List and click your station

name.

2. On the station page, click Overview and scroll down to

Device Information.

3. Click the Wireless tab. This icon appears next to the

mote if there is a new version of firmware available.

4. Click the firmware upgrade link. Click Download and

save the firmware .bin file to your computer.

5. Connect the mote to the computer with a USB cable (open

the mote door and use the USB port to the right of the

LCD). The blue LED is illuminated while connected.

6. The mote appears as a new storage device in the

computer’s file storage manager. Copy the downloaded

firmware file to the new storage device (the mote). The

blue LED will blink slowly while the file is copying.

7. After the file is copied to the mote, the LED will stop

blinking and remain a steady blue. Eject the storage device

from the computer and disconnect the cable from the

mote. The firmware installation process will begin

automatically on the mote. The blue LED will blink rapidly

while the firmware is installed. Once the firmware

installation is complete, the LCD symbols return and the

mote will automatically rejoin the network.

Notes:

• Mac® users: A message may appear indicating the disk

has not ejected properly when disconnecting the mote

from the computer. The mote is operational and you can

ignore the message.

• If the blue LED turns off abruptly while copying the file or

installing the firmware, a problem has occurred. Contact

Onset Technical Support for help.

Battery Information

The mote uses two 1.2 V rechargeable NiMH batteries, charged

by the built-in solar panel. The quality and quantity of solar

light can affect whether the battery is sufficiently charged to

last through the night and cloudy periods. Make sure the mote

is placed in a location that will receive several hours of sunlight

each day. If the mote does not receive enough sunlight to

recharge the batteries, the battery life is estimated at 3–4

months. When batteries are regularly recharged, expected

battery life is estimated at 3–5 years. Battery life varies based

on the ambient temperature where the mote is deployed, the

logging interval, the number of tripped alarms, and other

factors. Deployments in extremely cold or hot temperatures

can impact battery life. Estimates are not guaranteed due to

uncertainties in initial battery conditions and operating

environment.

Mote operation will stop when battery voltage drops to 1.8 V.

Mote operation will return if the battery recharges to 2.3 V. If

the batteries are unable to be recharged, replace them with

fresh rechargeable batteries. Note: if you install used

rechargeable batteries that together are less than 2.3 V, the

mote will not resume operation.

To replace rechargeable batteries:

1. Open the mote door.

2. Remove the old batteries and install fresh ones observing

polarity.

1-800-LOGGERS 7 www.onsetcomp.com

Page 8

RXW Davis Wind Speed and Direction Sensor (RXW-WCF-xxx) Manual

3. Make sure the solar panel cable is plugged in.

3. Push in the side tab of the solar panel cable connector and

pull the connector out of the cable port.

Make sure

solar panel

cable is

installed

when using

rechargeable

batteries

4. Place the connector in the slot on the inside of the mote

door. Make sure the solar panel cables are tucked inside the

door so that they do not interfere with the interior seal

when the mote is closed.

The mote contacts the network once the new batteries are

installed. The green LED blinks quickly while the mote searches

for a network to join and then blinks slowly while it completes

Store the solar

panel connector

here when using

lithium batteries

the network registration. Once the mote has finished joining

the network, the green LED turns off and the blue LED then

blinks indefinitely while the mote is part of the network.

The mote contacts the network once the new batteries are

Lithium Batteries

You can use two 1.5 V lithium batteries (HWSB-LI) for operation

at the extreme ends of the mote operating range. Lithium

battery life is an estimated at 1 year, but varies based on the

ambient temperature where the mote is deployed, the logging

interval, the number of tripped alarms, and other factors.

Estimates are not guaranteed due to uncertainties in initial

battery conditions and operating environment. When using

lithium batteries, you must disconnect the solar panel cable

because the batteries will not be recharged.

To install lithium batteries:

1. Open the mote door.

2. Remove any old batteries and install the new ones

installed. The green LED blinks quickly while the mote searches

for a network to join and then blinks slowly while it completes

the network registration. Once the mote has finished joining

the network, the green LED turns off and the blue LED then

blinks indefinitely while the mote is part of the network.

WARNING: Do not cut open, incinerate, heat above 85°C

(185°F), or recharge the lithium batteries. The batteries may

explode if the mote is exposed to extreme heat or conditions

that could damage or destroy the battery cases. Do not mix

battery types, either by chemistry or age; batteries may rupture

or explode. Do not dispose of the logger or batteries in fire. Do

not expose the contents of the batteries to water. Dispose of

the batteries according to local regulations for lithium

batteries.

observing polarity.

Federal Communication Commission Interference Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment generates uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

• Consult the dealer or an experienced radio/TV technician for help

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired operation.

FCC Caution: Any changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate this equipment.

Industry Canada Statements

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause undesired operation of the device.

Avis de conformité pour l’Industrie Canada

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence. L'exploitation est autorisée aux deux conditions suivantes : (1)

l'appareil ne doit pas produire de brouillage, et (2) l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d'en compromettre le

fonctionnement.

To comply with FCC and Industry Canada RF radiation exposure limits for general population, the logger must be installed to provide a separation distance of at least 20cm from

all persons and must not be co-located or operating in conjunction with any other antenna or transmitter.

© 2018 Onset Computer Corporation. All rights reserved. Onset, HOBO, and HOBOlink are registered

1-800-LOGGERS (564-4377) • 508-759-9500

www.onsetcomp.com/support/contact

trademarks of Onset Computer Corporation. Some material reprinted with permission from Davis

Instruments Corporation. Davis is a registered trademark of Dav is Instrumen ts Corporat ion. Mac is a

registered trademark of Apple Inc. All other trademarks are the property of their respective companies.

22245-A

Loading...

Loading...