Page 1

onset

®

Choosing a Water Level Logger:

5 Things You Should Know

Page 2

onset

®

onset

®

Introduction

As the demand for water resources continues to grow in the United States and

abroad, the ability to assess the impact of urban development and agriculture on

water resources is more important than ever. To meet this growing demand, water

resource managers, engineers, and hydrologists have a greater need to monitor

groundwater and surface water levels with water level data loggers in order to

document baseline and changing water levels over time.

Water level loggers typically incorporate built-in micro-processors, pressure

sensors, and battery power in a rugged enclosure designed for long-term

underwater deployment. They can be deployed and left unattended for months at

a time, collecting water level data at user-dened intervals and storing it digitally

into logger memory. By operating in a continuous 24/7 monitoring mode, water

level loggers eliminate many of the hassles of manual data collection, and facilitate

monitoring of multiple locations at the same time.

Water level loggers also automate the process of archiving and reporting data.

Hydrologists can simply ofoad the logger data to a mobile device or computer

and easily create detailed graphs or data les. The charts can be easily printed

for documentation purposes, while the electronic data can be shared with other

programs or archived.

While water level loggers have become the data collection instrument of choice

for an increasing number of hydrologists, the myriad of product choices available

today can make it difcult to determine which product is right for your application.

Whether you have previous experience with water level logging, or are just getting

started, this report can help you choose the right products for your needs. It points

out the ve most important considerations to keep in mind, and offers tips on

specic features.

1

Page 3

onset

®

1. Barometric Compensation

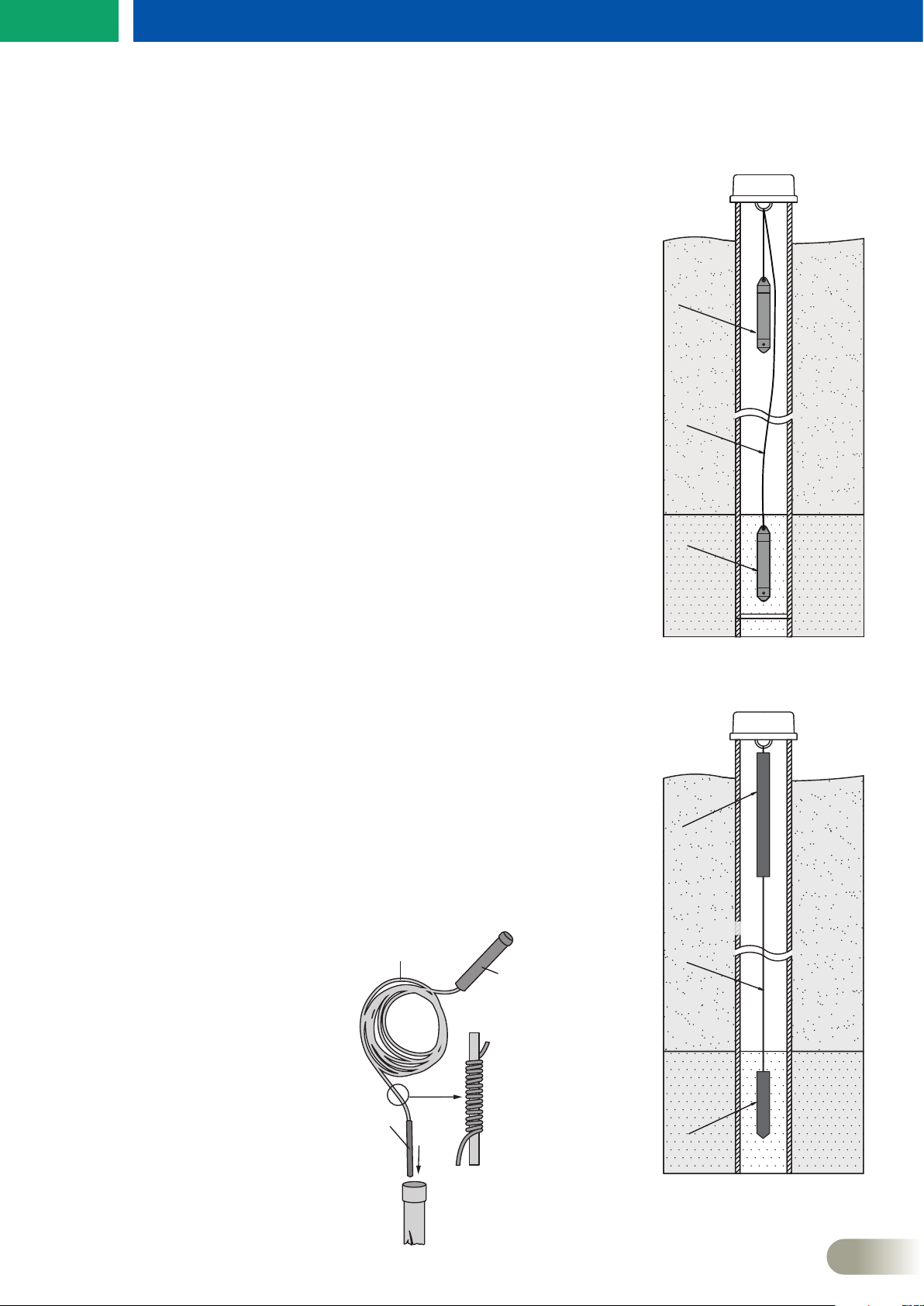

There are two primary types of water level loggers – vented and non-vented.

Vented loggers include a built-in vent tube that enables the loggers to

automatically compensate for atmospheric pressure changes. By equalizing these

changes on both sides of the pressure sensor, a well-designed and maintained

vented water level logger can provide high-accuracy water level data.

Non-vented loggers do not use vent tubes. Instead, these loggers can be

barometrically compensated using a barometric pressure logger and a simple

software function to perform the mathematics. Barometric pressure values can

also be obtained from weather stations within a 10-mile radius.

Now there’s also a type of non-vented logger that incorporates both an in-water

sensor and a barometric pressure sensor.

Keep in mind that while vented loggers have the potential to provide the greatest

accuracy, they also have a number of limitations that can cause problems and

result in bad data and/or data loss. These limitations include:

• Vented loggers are bulkier than non-vented loggers, which makes them

more difcult to transport and deploy.

• Most vented loggers require the use of desiccants for moisture protection,

which increases the amount of maintenance that’s required and therefore

the total cost of ownership of the logger. And condensation buildup can

lead to accuracy problems.

Non-vented with two loggers

GROUND LEVEL

BAROMETRIC

PRESSURE

LOGGER

SUSPENSION

CABLE

WATER LEVEL

WATER LEVEL

LOGGER

onset

®

• When monitoring water containing contaminants, vent tubes with

contaminant-resistant material must be used, which adds to the cost of

the logger, as does the decontamination process that’s required before the

logger can be redeployed.

• Vented loggers lack exibility when it comes to deploying them at various

depths. Cables cannot be lengthened without sending them back to the

supplier, and shortening requires delicately coiling the cable without

creating any kinks.

• If the end of the vented logger cable is inundated by rising water,

all subsequent data are compromised due to unknown pressure

compensation dynamics during the ood event.

These limitations highlight the

Vented

advantages of non-vented loggers,

which are more compact, require

minimal maintenance, can be easily

Vented cable

Logger

deployed in wells of varying depths,

and are not affected by ood water.

The new non-vented logger that

incorporates two sensors offers the

additional advantage of providing

water level data directly, with no

need for post-processing.

Sensor

Excess vent cable

has to be looped

around a 1/2” pipe

Non-vented with integrated

barometric sensor

GROUND LEVEL

LOGGER WITH

BAROMETRIC

PRESSURE

SENSOR

COMMUNICATION

SUSPENSION

CABLE

WATER LEVEL

WATER LEVEL

SENSOR

Protective

well pipe

2

Page 4

onset

®

onset

®

A water level logger’s sensor

and analog-to-digital (ADC)

converter both contribute to

error. The error from the ADC

can be just as signicant as

sensor error.

Accuracy for typical loggers over temperature

2. Understanding Accuracy

When evaluating water level accuracy, you’ll want answers to the following

questions:

• What is the system level accuracy? For non-vented loggers, the system

accuracy is the sum of the water level logger’s error plus the barometric

pressure logger’s error. The barometric pressure error is often overlooked, but

needs to be included. On the other hand, vented water level loggers or sensors

are measuring the differential pressure directly, so there is just the one sensor

measurement error to include.

• Does the accuracy specied relate only to the logger’s sensor,

or to the entire logger? A water level logger’s sensor and

analog-to-digital (ADC) converter both contribute to error. The

error from the ADC can be just as signicant as sensor error.

For this reason, you’ll want to conrm with the manufacturer

that the specied accuracy refers to the entire measurement

rather than just the sensor. To realize a 0.01-foot water level

resolution requires at least a 12-bit ADC with a 30 psi water level

sensor. Likewise, you should make sure the barometric logger’s

accuracy specication includes all sources of error.

• Does the accuracy specication apply across the full-calibrated measurement

range of the logger? The accuracy a water level logger can achieve at the

high or low end of a given range may be far different from the accuracy at the

middle of the range. For this reason, it’s important to nd out if the logger’s

accuracy specication refers to a single point or the entire measurement range.

Knowing the full-range accuracy of a water level logger will give you assurance

that the logger will meet your accuracy requirements.

• Do temperature variations cause additional error outside of the accuracy

spec? Some water level loggers are not able to effectively compensate for

temperature changes, which cause incorrect pressure readings. For this

reason, it’s important to nd out if error that results from temperature changes

is included in the accuracy specication, or if there is a separate error term that

must be added. Data loggers with reduced overall mass will equilibrate more

quickly to changing temperature conditions to increase dynamic response

during changing conditions. The response-time specications will indicate how

quickly the logger will equilibrate.

• Is drift important? The pressure sensors in water level loggers will drift over

time. Whether or not you need to be concerned about drift depends on your

application. Drift is important in cases when absolute pressure values are

needed, or if there are no recent reference level or depth measurements

available. This may be the case if a water level logger is deployed for

more than one year and no reference-level readings are taken during that

deployment. Otherwise, drift is not a signicant factor since it will be offset by

regular (i.e. monthly) manual reference-level readings. Regardless of whether

drift will affect your data, it is a good idea to ask the logger manufacturer for

drift specications.

In addition to these questions, be sure to ask the manufacturer if the logger’s

accuracy has been veried or measured against NIST-traceable standards.

Some companies offer NIST-traceable calibration certicates as verication of the

accuracy of each logger.

3

Page 5

onset

®

3. Software features that really matter

Just as water level loggers can vary considerably from model to model, so

too can the graphing & analysis software or app that accompanies them.

From a general standpoint, it’s a good idea to look for something that’s

highly intuitive, so the learning curve is minimal. You’ll also want to be

able to quickly and easily perform tasks such as conguring loggers, and

ofoading, graphing, and sharing data.

The software features you’ll want to consider depend on where the

software is being used. For software being used in the eld, look for

capabilities related to deploying loggers and ofoading data. For software

being used to analyze data in your ofce, look for more powerful analysis

capabilities.

In terms of specic features, here are some you’ll want to consider,

depending on where you will be using it:

• Time-saving launch features – If you will be launching many loggers

at once, look for software that allows you to congure the logging

parameters once, and then use those settings to congure all of the

loggers for the deployment. Not only does this save time, it also helps to

ensure that all loggers are congured the same. For example, you may

want to congure a group of loggers to all start at the same time and

with the same logging rate.

onset

The software should enable

you to quickly and easily

perform tasks such as

conguring loggers, and

ofoading, graphing, and

sharing data.

®

• Barometric compensation (for loggers that don’t include integrated

barometric pressure compensation) – To convert a non-vented logger’s

pressure readings to barometrically-corrected water level values, make

sure the logger software has a barometric compensation utility. These

tools typically allow you to enter reference level, water density, and other

values into a dialogue box, and then automatically perform the pressureto-water level conversion.

• Multi-logger graphing – When monitoring water levels at multiple sites,

it is often advantageous to be able to view and analyze data from each

water level logger on a single graph. Be sure to ask the manufacturer

about this capability.

• Easy data export – Because water level

data often needs to be incorporated

into other software programs, such as

spreadsheets or modeling programs,

make sure you’re able to quickly and

easily export data in a range of data

formats.

• Project save and recall – While the

ability to save and recall projects may

seem like a basic feature of any logger

software package, the reality is that

many do not support this capability.

Since data analysis typically involves

a number of steps, including merging

multiple data les together, converting

pressure readings to water level units,

and formatting charts, you’ll want to be

sure that the logger’s software allows you

to save your work so you can easily recall

it and add to it in the future.

HOBOware graph showing U20 temperature in red, and water

level at two points along a stream in blue and green.

HOBOware’s Barametric Compensation

Assistant

HOBO U20-001-01

water level logger

4

Page 6

onset

4. Buying vs. renting

In the past, the relatively high price of water level loggers has prevented many

hydrologists from purchasing their own supply of loggers. Many have chosen

to rent loggers instead. While renting can be a convenient option for short-term

deployments, it is important to be aware that the price of water level loggers

has decreased to the point where purchasing is more cost-effective for many

applications.

If you provide hydrology or groundwater services, owning an inventory of water

level loggers may give you a competitive edge, since you’ll be able to waive

additional equipment rental fees for your customers.

5. Connecting to the Logger

Data loggers with wireless connection to a mobile device offer the convenience

of not having to take a laptop into the eld, while still being able to view data

and change conguration settings in the eld, if needed. Wireless loggers

with Bluetooth Low Energy (BLE) technology provide the additional benet

of not having to physically access the logger to push a button to activate

communication, as earlier versions of Bluetooth require.

Loggers that rely on mechanical plug-in connectors can be damaged by water in

the eld and cause logger failures. Water level loggers with an optical interface

that is completely sealed within the logger’s housing eliminate the possibility of

water-related damage and/or failures.

®

For loggers with an optical interface, you will need an optical base station to

connect the logger to a computer. The best option for connecting to the computer

is a direct USB interface. Some older loggers use serial communications to the

logger, and use a serial-to-USB converter to allow them to be connected to USB.

Because the loggers still are using serial communications internally, their data

ofoad speeds are limited to the slower serial speeds, and they require special

drivers to be installed on the computer.

5

Page 7

Other informational resources available from Onset:

onset

®

Data Logger Basics

In today’s data-driven world of satellite uplinks, wireless

networks, and the Internet, it is common to hear the terms “data

logging” and “data loggers” and not really have a rm grasp of

what they are.

Most people have a vague idea that data logging involves

electronically collecting measurements of key environmental

parameters, such as temperature, relative humidity, or energy

use. They’re right, but that’s just a small view of what data

logging is.

Choosing a Conductivity Logger

Whether you are selecting a conductivity logger for the rst time

or have experience measuring conductivity, this paper can help

you determine the type of logger that best suits your needs. It

highlights the ve most important considerations in selecting

and deploying a conductivity logger: measurement range and

accuracy, other factors that affect accuracy, ease of deployment

and ofoad, software capabilities, and cost of ownership.

Robust, low-cost data loggers for stream

temperature, ow intermittency, and relative

conductivity monitoring

Underwater Temperature Loggers: Considerations

For Selection & Deployment

This paper offers guidance and tips on selecting and deploying

water temperature loggers. Three main phases of operation

are discussed: conguration & launch, deployment, and data

retrieval & analysis.

Deploying Weather Stations: A Best Practices Guide

From the tropics to the poles, climate, agriculture and

other researchers rely on unattended research-grade, data

logging weather stations. For example, the US Department

of Agriculture uses weather stations to study anything from

molecular plant pathology to forest management. Nongovernment groups, such as universities, use weather stations

to study a wide array of subjects including how glacial activity

affects air temperature. Additionally, commercial companies

depend on weather stations to conduct businesses.

Our new best-practices guide, Weather Station Deployment

Techniques, shares eld-proven tips and techniques for

installing research-grade weather stations in the eld. A range

of topics are discussed, including weather station site location,

sensor placement, system conguration, and cable protection.

Water temperature and stream ow intermittency are critical

parameters inuencing aquatic ecosystem health. Low-cost

temperature loggers have made continuous water temperature

monitoring relatively simple but determining stream ow timing

and intermittency using temperature data alone requires

signicant and subjective data interpretation.

Monitoring Wetlands with Data Loggers: A Best

Practices Guide

Wetlands act as a natural lter for polluted water and thus

play an essential role in water quality protection. They serve

as oodwater storage to help minimize erosion, and create a

habitat for many sh and wildlife.

While a variety of factors have decreased the number of

wetlands in the U.S. by half since 1950, many organizations are

restoring wetlands back to their original ourishing ecosystems.

To ensure success, it is necessary to monitor wetland factors

such as water level, temperature, and rainfall.

This guide shares eld-proven best practices for conguring,

launching and deploying portable data loggers in wetland

monitoring applications. A range of data logger types is covered,

and tips are provided on logger installation and maintenance.

Access our full resources library at: www.onsetcomp.com/learning

6

Page 8

About Onset

Onset is a world leader in data loggers. Our HOBO data logger products are used around the world in a broad

range of monitoring applications, from verifying the performance of green buildings and renewable energy

systems to agricultural and coastal research.

Based on Cape Cod, Massachusetts, Onset has been designing and manufacturing its HOBO data loggers on

site since the company’s founding in 1981.

onset

®

Sales (8am to 5pm ET, Monday through Friday)

Email sales@onsetcomp.com

Call 508-759-9500

In US call toll free 800-564-4377

Fax 508-759-9100

Technical Support (8am to 8pm ET, Monday through Friday)

Email loggerhelp@onsetcomp.com

Call 508-759-9500

In US call toll free 877-564-4377

Onset Computer Corporation

470 MacArthur Blvd.

Bourne, MA 02532

Copyright© 2015, Onset Computer Corporation. All information in this document is subject to change without notice. Onset and HOBO are registered trademarks of Onset Computer Corporation.

All other trademarks are the property of their respective owners. All rights reserved. Printed in the USA. Lit. No. MKT1128-1015

Loading...

Loading...