Page 1

Note: Before replacing the back plate, check that the logger seals (O-ring, screw, jack

cap) are not contaminated by dust, dirt or other materials. All components must be

cleaned of any contaminants to ensure a weathertight seal. Make sure the back plate

O-ring has a light film of lubricant (Dow Corning DC 111 or Nye Lubricants

NYOGEL). Insert the O-ring in the groove and replace the back plate using the screw

with O-ring. The screw should be tightened until it is snug, be careful not to

overtighten. The screw will go in smoothly and suddenly tighten; rotate the screw no

more than 1mm more. Do not use lubricant on jack cap.

Intrinsically Safe

Factory Mutual Research has certified the H08-032-IS is safe for use in certain

hazardous areas. The National Electrical Code has classified many types of

hazardous locations. The H08-032-IS has been approved as intrinsically safe in

Class I and II locations which are areas where ignitable concentrations of gas

(Class I) and/or dust (Class II) exist. The NEC further classifies hazardous location

by Division (1 or 2). The division designation refers to the likelihood that the area

will contain ignitable concentrations of gas or dust. Division 1 locations will have

ignitable concentrations of gas or dust continuously or under normal operation

conditions. Division 2 locations will have ignitable concentrations of gas or dust

only during infrequent or abnormal operations (which may include areas located

near Division 1 locations). The H08-032-IS has been approved for use in both

Division 1 and 2 locations. The hazardous area classification scheme is further

defined by listing the types of ignitable gases and dusts that may be present in a

hazardous location. Ignitable gases and dusts are sorted into groups with similar

ignition characteristics. The H08-032-IS is certified for all possible groups: A-G for

gas and A-D, F and G for dust. Finally every Intrinsically Safe Device is given a

temperature rating. The H08-032-IS has a T4 rating, which means that no part of

the device will become warmer than +275oF (+135oC) in a worst-case fault. For more

information on Hazardous (Classified) Locations visit the Underwriters Laboratory

web site at w

ww.ul.com/hazloc/define.htm.

Non-Volatile Memory

The HOBO Pro uses a high-capacity Flash EEPROM to store data. This storage is

non-volatile and will retain the data even if the battery is removed. To save power

and maximize the life of the flash memory device, 32 bytes of data are buffered in

RAM prior to writing to the flash memory. In the case of a dead battery, or the

unlikely event that power is interrupted during logging, the data in this RAM buffer

will be lost. For example, if the sample interval was set to one half hour and one

channel with low resolution, then up to 16 hours of data could be lost.

NOTE: The logger software's absolute humidity calculation does not use an actual

pressure measurement but assumes an ambient pressure of 1 atmosphere (14.7 PSI.)

Service and Support

HOBO® products are easy to use and

reliable. In the unlikely event that you have

a problem with the hardware or software,

please read the following.

Who do I contact?

Contact the company that you bought the

loggers from: Onset Computer Corporation

or an Onset Authorized Dealer.

Before calling, you can evaluate and often

solve your problem if you try the following:

1. Read this manual and the ReadMe file on

the software disk. It may only take a few

moments to get the answers you need.

2. Write down the events that led to the

problem. Have you changed anything in

your computer recently? Are you doing

anything differently?

When contacting Onset Computer

Corporation, please indicate that you need

Technical Support for HOBO® products.

Be prepared to:

1. Provide the product number which is

found on the side of the logger, the software

version and serial number if present on the

disk.

2. Provide details on the hardware and

software configuration of your computer

including: manufacturer, model number,

peripherals, and version of operating

system.

3. Completely describe the problem or

question. The more information you provide,

the faster and more accurately we will be

able to respond.

NOTE: Onset provides technical support to

one person for each software license.

Onset Technical Support

Onset Computer Corporation

470 MacArthur Blvd.

Bourne, MA 02532

Mailing: PO Box 3450

Pocasset, MA 02559-3450

1-800-LOGGERS (1-800-564-4377)

Phone: (508) 759-9500

Fax: (508) 759-9100

E-mail: loggerhelp@onsetcomp.com

www.onsetcomp.com

Warranty

Onset Computer Corporation (“Onset”)

warrants to the original end-user purchaser for

a period of one year from the date of original

purchase that the HOBO® product(s)

purchased will be free from defect in material

and workmanship. During the warranty period

Onset will, at its option, either repair or

replace products that prove to be defective in

material or workmanship. This warranty shall

terminate and be of no further effect at the

time the product is (1) damaged by extraneous

cause such as fire, water, lightning, etc. or not

maintained in accordance with the

accompanying documentation; (2) modified; (3)

improperly installed; (4) repaired by someone

other than Onset; or (5) used in a manner or

purpose for which the product was not

intended.

Returning Products to Onset

Direct all warranty claims to place of

purchase. Before returning a failed unit, you

must obtain a Return Merchandise

Authorization (RMA) number from Onset. You

must provide proof that you purchased

the Onset product(s) directly from Onset

(purchase order number or Onset invoice

number). Onset will issue an RMA

number that is valid for 30 days. You

must ship the product(s), properly

packaged against further damage, to

Onset (at your expense) with the RMA

number marked clearly on the outside of

the package. Onset is not responsible for

any package that is returned without a

valid RMA number or for the loss of the

package by any shipping company. Loggers

must be clean and free of any toxins before

they are sent back to Onset or they may be

returned to you.

Repair Policy

Products that are returned after the warranty

period or that are damaged by the customer as

specified in the warranty provisions can be

returned to Onset with a valid RMA number

for evaluation.

Please contact Onset for more information and

prices on:

ASAP Repair Policy

Onset will expedite the repair of a returned

product.

Data-back™ Service

HOBO® data loggers store data in nonvolatile

EEPROM memory. Onset will, if possible,

recover your data to a disk.

Tune Up™ Service

Onset will examine and retest any HOBO

data logger.

®

Thank you for buying a HOBO H8 Pro Temp/RH IS data logger. With proper care

it will give you years of accurate and reliable measurements.

This manual covers the HOBO H8 Pro Temp/RH IS product. This logger stores up

to 65,291 time-stamped measurements.

Unlike most other HOBOs, the HOBO Pro does not have the wrap-around-whenfull option for storing data; its large memory capacity eliminates the need for this

function in most cases.

Safety Information - Read First

WARNING: The H08-032-IS logger is rated as Intrinsically Safe, however,

available communication accessories are not. Do not attempt to download or

relaunch the logger using the HOBO Shuttle, handheld PDA or any host computer

in a hazardous environment, as these devices do not carry the Intrinsically Safe

rating and are not intrinsically compatible with HOBO-IS Loggers. See the “Logger

Specifications” for the complete Intrinsically Safe listing and see the section of this

manual entitled “Intrinsically Safe” for more information about hazardous location

and the H08-032-IS.

WARNING: Fire, Explosion, and Severe Burn Hazard. The logger contains a

lithium battery. The battery may explode if the logger is exposed to extreme heat or

conditions that could damage or destroy the battery case. Do not attempt to

recharge or heat the logger or battery above +185oF (+85oC). Do not dispose of the

logger or battery in fire. Do not expose the contents of the battery to water. Dispose

of the battery according to local regulations for lithium batteries.

WARNING: Only qualified personnel should install and service equipment

located in Hazardous (Classified) Areas.

Common Specifications

Operating range (logger): -30°C to +50°C (-22°F to +122°F),

0 - 100% RH, HOBO Pro RH/Temp IS should be mounted

so that water does not impact or collect in the RH sensor.

RH Sensor operating environment: 0°C to +50°C (+32°F to

+122°F) in intermittent condensing environments up to

+30°C; and above +30°C in non-condensing environments.

Sensor requires protection from rain, splashing, mist,

dust, and airborne chemicals such as salt and ammonia.

Time accuracy: approx. ±1 minute per week (±100 ppm at

+20°C or +68°F), full dependence shown in Plot A.

Measurement capacity: 65,291 standard-resolution (8-bit) measurements, 32,645

high-resolution (12-bit) measurements or 21,763 measurements if one channel

uses standard-resolution and the other channel uses high-resolution. RH

measurements use standard resolution only. All measurements are stored in

nonvolatile memory, with seven levels of data archiving (See Non-Volatile

Memory).

Data offload time: 1 minute typical

Size: 4.0" H x 3.2" W x 2.0" D

Weight: approx. 3.7 oz.

Battery: Tadiran TL-5902, lithium, (3.6V 1.2Ah), user-replaceable (Use only Onset

part # HP-B)

Battery life (continuous use): 3 years

Storage temperature: -30°C to +75°C (-22°F to +167°F)

Intrinsically Safe Rating: IS, Class I, II, Division 1, Groups A-G, Temperature

Code T4 (<135oC); NI, Class I, Division 2, Groups A-D, Temperature Code T4

(<135oC); S, Class II, Division 2, Groups F and G

5896-D MAN-HO8-032-IS 4/21/04, 8:01 AM2

Page 2

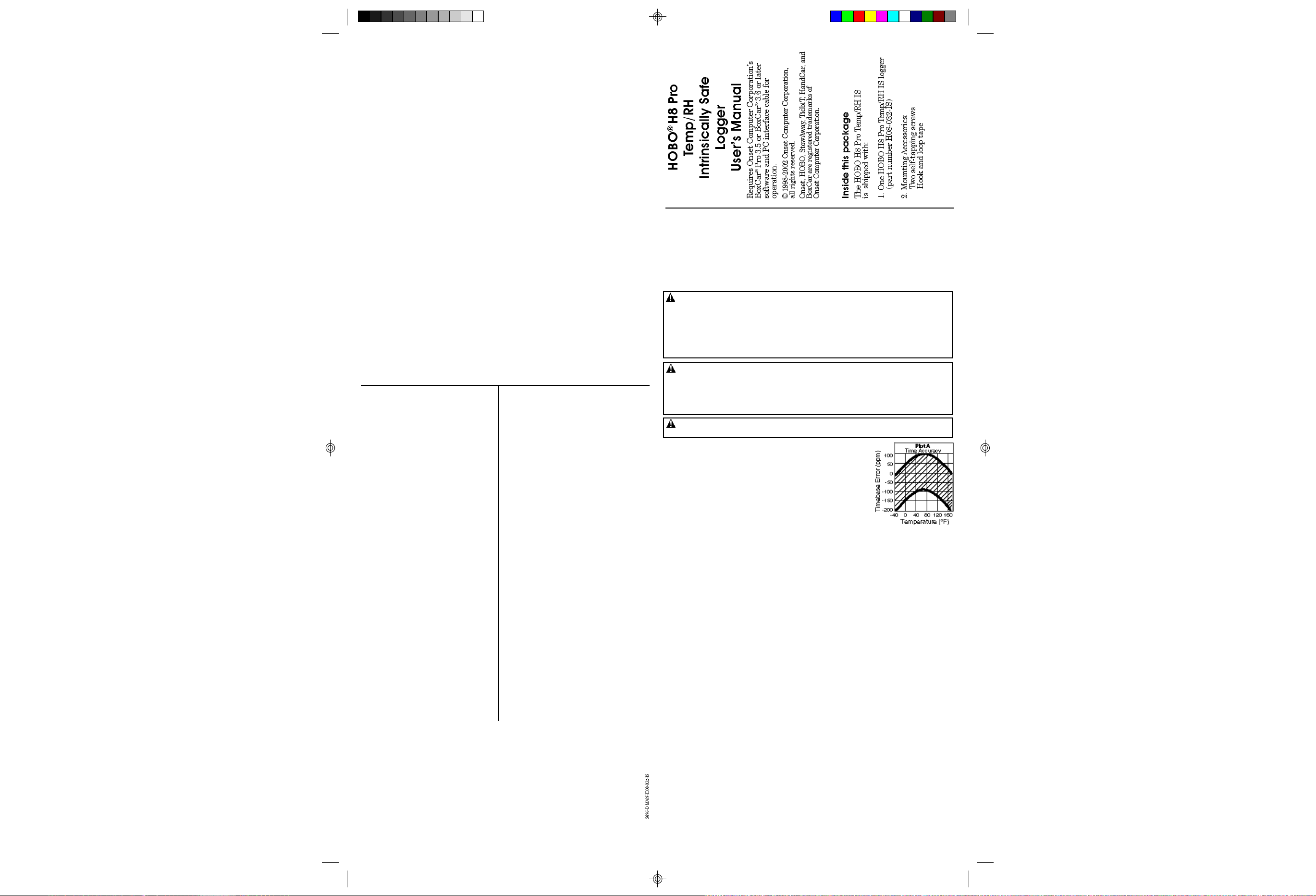

Measurement Specifications

Temperature - Each HOBO Pro Temp/RH IS logger

Plot B

Temperature Accuracy and Resolution

Standard Resolution Mode

has an internal temperature sensor mounted inside the

front of the logger's case (Diagram A). The sensor

measures ambient air temperature over the operating

range of the logger; -30°C to +50°C (-22°F to +122°F)

with a response time of less than thirty-five minutes

(typical to 90%) in still air. The HOBO Pro Temp/RH IS

logger has a standard and a high-resolution mode

which is selectable in the logger's software. For

temperature accuracy and resolution specifications,

please refer to Plot B for standard-resolution mode

and Plot C for high-resolution mode. See “Selecting

Channels and Resolutions” for more information.

Plot C

Temperature Accuracy and Resolution

High Resolution Mode

Relative Humidity - The HOBO’s relative humidity

sensor has an accuracy of ±3% over the range of 0 to

50°C (32 to 122°F). The relative humidity sensor

range is 0 to 100% RH. It can read up to 104.1% in a

condensing environment. While the sensor is

saturated, you will not get accurate readings. In

general, the RH response time is less than 5 minutes

typical to a 90% change (independent of temp). Drift

is less than 1% per year in normal operating

conditions (non-corrosive, non-condensing). An

additional temporary drift of up to 3% can occur when the average humidity is above

70%. Factory verification and tune-up service available. White RH sensor case may

yellow with exposure to light. This is not a problem.

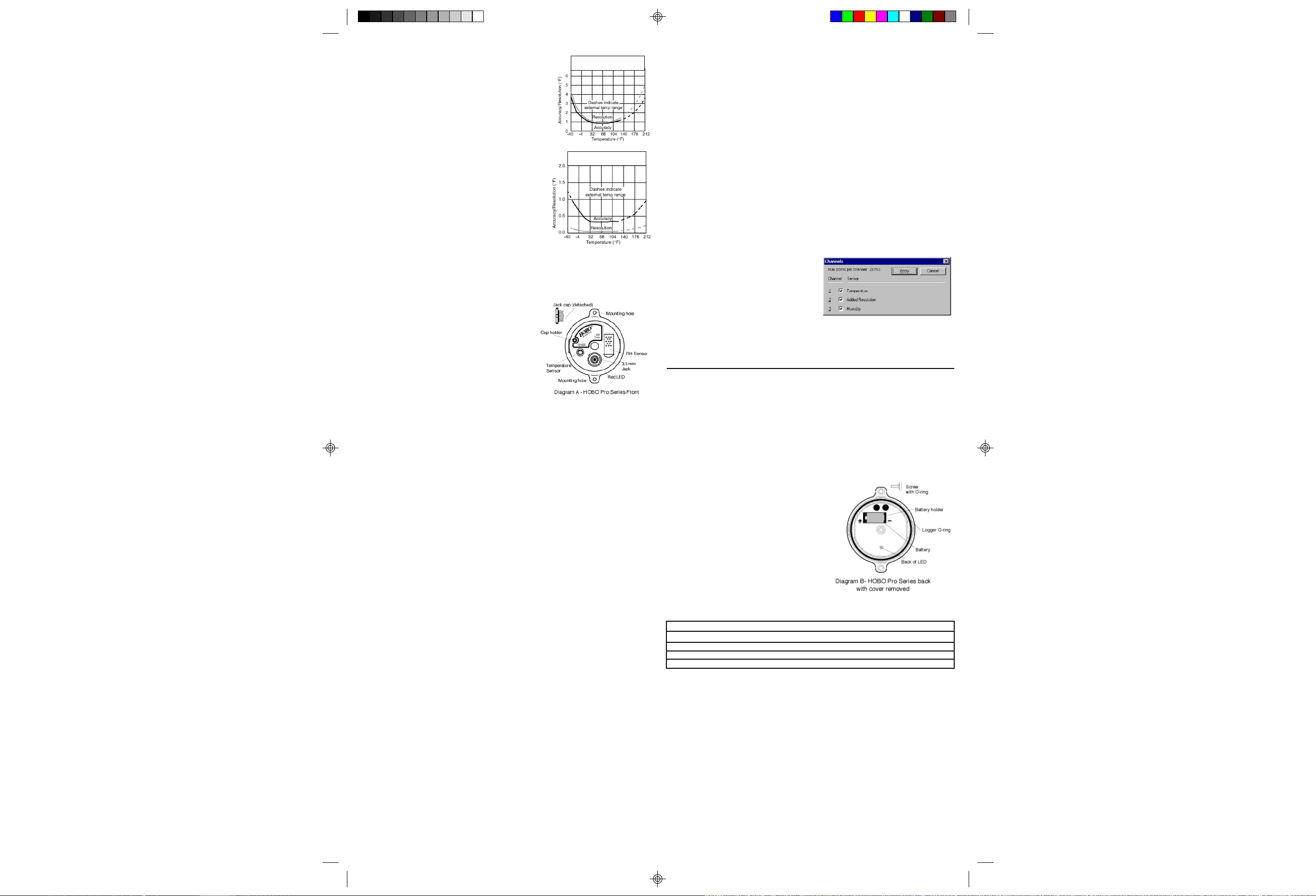

Connecting the Communications Cable and Launching

A Starter Kit, which includes the appropriate PC

interface cable and software, is required to operate

your logger. The HOBO logger must be launched

before it is deployed in a hazardous location.

Unscrew the jack cap from the logger. You can store

it temporarily by pushing it onto the cap holder

(Diagram A). Connect the interface cable into the

3.5 mm jack on the logger and into a working serial

port on your computer. Install and start the logger's

software. Select Launch... under Logger on the

menu bar and a launch dialog box will be provided.

For a complete explanation on installing the software

and launching your logger, please refer to the logger

software manual.

When launching a logger, the software defaults to the parameters specified the last

time the logger was launched. The factory default is to select all channels with highresolution mode for temperature measurements. See “Selecting Channels and

Resolutions” for details.

Operation Indicator

The HOBO data loggers have a red LED that blinks while they are logging. The

blinking LED is located inside the 3.5 mm jack and is only visible when the PC

interface cable and jack cap are removed (Diagram A). The LED blinks brightly at

every measurement, and weakly every two seconds if the interval between

measurements is longer than two seconds. Once you have verified the operation

of the logger, rescrew the jack cap, making sure there is no dust or dirt on the cap

that might compromise the integrity of the weatherproof seal. Hand tighten lightly.

The cap only needs to be snug. If it is overtightened it may require a pair of pliers

to unscrew.

Operation on Computers Equipped with a Power Conservation

Mode

Many newer computers, especially laptops, have a power conservation feature which

shuts the serial port off after a short period of time. If a HOBO or StowAway logger

is still connected to the serial port when this happens, the logger will shut off. To

resolve power conservation shut off of the serial port, BoxCar Pro 4.0, 4.1, and 4.2.x

customers should download the BoxCar Pro 4.3 or later upgrade patch. Similarly,

BoxCar 3.6 and 3.7.1 customers should download the BoxCar 3.7.3 or later upgrade

patch. Both are available for free on our website under Support and Upgrades,

Software Upgrades and Utilities. If you have an earlier version of BoxCar and you

would like to test to see if you will be affected by the power conservation feature do

the following. Using BoxCar, launch your logger from the computer that you are

testing. If you are using a laptop, it may behave differently when running off battery

versus running off the power plug; please test both. After launch, leave the logger

attached to the PC interface cable and watch the LED to see if it remains blinking.

When a logger is actively logging, the LED will blink faintly every 2 seconds. If the

power conservation is causing a problem, the LED will stop blinking within one

minute. When you are using a HOBO Pro logger, the LED is located under the PC

interface cable, and is not visible when the cable is plugged in. To test a HOBO Pro,

launch the logger to take readings at 10 second intervals. Leave the logger attached

to the interface cable for one minute. You can either remove the interface cable at

this point and check the LED status, or download the datafile to see how many

points were collected. If power conservation is causing the logger to shut off, you will

only see one data point in the file. If your computer has the power conservation

feature, you should download an upgrade patch as noted above.

Mounting Options

The HOBO Pro Temp/RH IS data logger has mounting tabs. Be careful not to stress

the case when using the screws to mount the logger to an uneven surface, as this

may crack the tabs. The supplied hook and loop tape can be stuck on the back of

your HOBO for mounting. Do not use double sided tape on the back of the logger for

mounting, as this could disturb the weatherproof seal when the logger is removed.

HOBO Pro RH Sensor Should not get Saturated

The RH sensor used on the HOBO Pro is among the best in its price range. It is

designed for normal outdoor environments with cyclical high and low humidity

levels. Saturation of the sensor is evident when the logger reads values of 100% RH

or greater. Like all RH sensors, repeated saturation from exposure to condensing

environments will lead to irreversible drift and eventually destroy the RH sensor. If

this happens, the logger will need to be returned to Onset Computer Corp. for

sensor replacement. The rate at which this degradation of the sensor occurs

depends on the harshness of the environment to which the sensor is exposed.

Condensing environments with temperatures above 30°C (86°F), exposure to salt

spray, ammonia vapor, or some other chemicals will accelerate the sensor

degradation.

Mounting considerations in wet environments

The HOBO Pro Temp/RH IS version should be mounted so that the RH sensor is

protected from water saturation. To prolong the life of your RH sensor, Onset

strongly recommends mounting the HOBO Pro Temp/RH IS logger (H08-032-IS)

face down in a protective housing such as the Solar Radiation Shield (Onset part #

RS1) or the Rain Shield (Onset part # RS2).

Readout

The HOBO data logger must be removed from the hazardous location for readout.

Reconnect the HOBO data logger to the interface cable, start the logger software,

select Readout under Logger on the menu bar and the data will be displayed in a

graphical or tabular form. For a complete explanation on reading out your logger,

please refer to the logger software manual.

Selecting Channels and Resolutions

The HOBO Pro IS logger offers a choice of

standard-resolution (8-bit) or high-resolution

(12-bit) operation for its temperature

channel. High-resolution mode doubles the

amount of memory required by each

measurement, reducing the deployment time

for each interval setting, but dramatically

improving the temperature resolution and

accuracy. The high-resolution mode is not available for the RH channel. For highresolution mode select the sensor and "Added Resolution" on the channel that

follows it. For standard-resolution select only the temperature channel. “Added

Resolution” should not be enabled unless the corresponding temperature channel is

enabled, otherwise the data will be invalid.

Data Archiving

The HOBO Pro Temp/RH IS logger preserves the data from up to seven

deployments preceding the current deployment. You will be able to retrieve data

from all eight deployments by using the archive reader function in the logger

software. (In some versions of the software it is a separate utility for Windows 95/

98/NT on the installation disk.) The reader will contact your logger, readout the last

eight deployments, display information such as the deployment number, start time,

end time, number of points and the description, and then allow you to select which

file(s) you would like to save. For more information on the archive reader function,

consult your logger software manual or the Archive Reader Utility readme.txt file.

This archiving feature provides backup of your measurements in the logger, giving

you another level of protection from accidental data loss.

Battery Life Specifications and Battery Level Indication

The battery level is displayed on the host computer

during Launch. For the HOBO Pro IS logger this will

display one of two states: 98% or 20%. The lowest

battery level that will be shown is 20%. Thus if the

battery status indicates 20%, the battery is

effectively dead and should be replaced immediately.

Launching the logger when the battery level

reads 20% risks data corruption and/or data

loss.

In normal usage the HOBO Pro’s battery can last

up to three years when used with an interval of 1

minute or greater. Battery life is very dependent

upon the sample interval and service temperature.

See Table 1 for approximate run times at various

intervals and service temperatures.

Table 1. Approximate Operational Battery Life for the HOBO Pro

Logging Interval

Operating Temperature < 10 seconds 10 secs - 1 minute 1 minute – 1 hour

+40 - +50°C+ (104 - +122°F) ~ 3 - 6 months

+25 - +39°C (+77 - +102°F) ~ 3 - 6 months

< +25°C (< +77°F) ~ 3 - 6 months

1

/2 - 11/2 years 11/2 - 2 years

1

/2 - 2 years 2 - 3 years

1

/2- 21/2 years 21/2 - 3+ years

The above times are intended only as guidelines. For critical field

applications of long duration we recommend installing a fresh battery before each

deployment. We recommend replacing the HOBO’s battery and O-rings

simultaneously (Onset battery/service kit part #HP-BK includes battery, O-ring,

stainless steel self-sealing screw with O-ring, O-ring lubricant and jack cap.)

Changing or Accessing the Battery

The HOBO data logger must be removed from the hazardous location for changing

the battery. If you can, offload the logger before changing the battery. This will

ensure that no data will be lost (See Non-Volatile Memory). To change the battery,

open the case by removing the Phillips screw in the center of the back of the logger

and removing the stainless steel back plate. Remove the old battery and install the

new one. Be careful to put the battery in the battery holder with the correct polarity

(Diagram B). In order to maintain the Intrinsically Safe rating, your logger

must use a Tadiran TL-5902 (3.6v 1.2Ah) battery, Onset part number HP-B.

The logger’s red LED will blink three times after the battery has been installed. If

you have difficulty seeing the LED flash, use the battery check in the Launch dialog

box of the logger software to verify the battery status. Warning: Do not cut open,

incinerate, heat above +185°F (+85°C) or recharge the removed lithium

battery. Dispose per local regulations.

5896-D MAN-HO8-032-IS 4/21/04, 8:02 AM3

Loading...

Loading...