Page 1

Part #: MAN-CSV-A8, Doc #: 7951-C

r

Installation Instructions

• This product is not intended for life or safety

applications. This product is not intended for

installation in hazardous or classified

locations.

• Potential electrocution hazard exists.

Installing sensors in an energized motor

control center or on any energized conductor

can be hazardous.

• Read instructions thoroughly prior to

installation.

Severe injury or death can result from electrical shock

during contact with high voltage conductors or related

equipment. Disconnect and lock-out all power sources

during installation and service. Applications shown are

suggested means of installing sensors, but it is the

responsibility of the installer to ensure that the

installation is in compliance with all national and local

codes. Installation should be attempted only by

individuals who are familiar with codes, standards, and

proper safety procedures for high-voltage installations.

CSV-A8

Split-Core Adjustable

Current Switch

Onset Computer Corporation

470 MacArthur Blvd.

Bourne, MA 02532

Mailing Address:

P.O. Box 3450

Pocasset, MA 02559-3450

Phone: 1-800-LOGGERS (1-800-564-4377) or 508-759-9500

Fax: 508-759-9100

Email: loggerhelp@onsetcomp.com

www.onsetcomp.com

INSTALLATION

1. Ensure power conductor to be monitored is

disconnected and locked out from the power source!

2. Install the removable mounting bracket to the back

of the electrical enclosure.

3. Snap the split core around the conductor being

monitored and close until the core snaps shut.

4. Connect current switch output to DDC controller or

switched load.

NOTE:

• Contacts are solid state and work just like dry

contacts. When the switch is closed, 1 Ohm is

present. When the switch is open, more than 1

Meg Ohm is present.

5. Calibrate the sensor (see calibration section)

1

WIRING EXAMPLE

contacto

motor

HOBO UX90-001/M, UX90-004/M,

UX120-017/M

fan or pump

Page 2

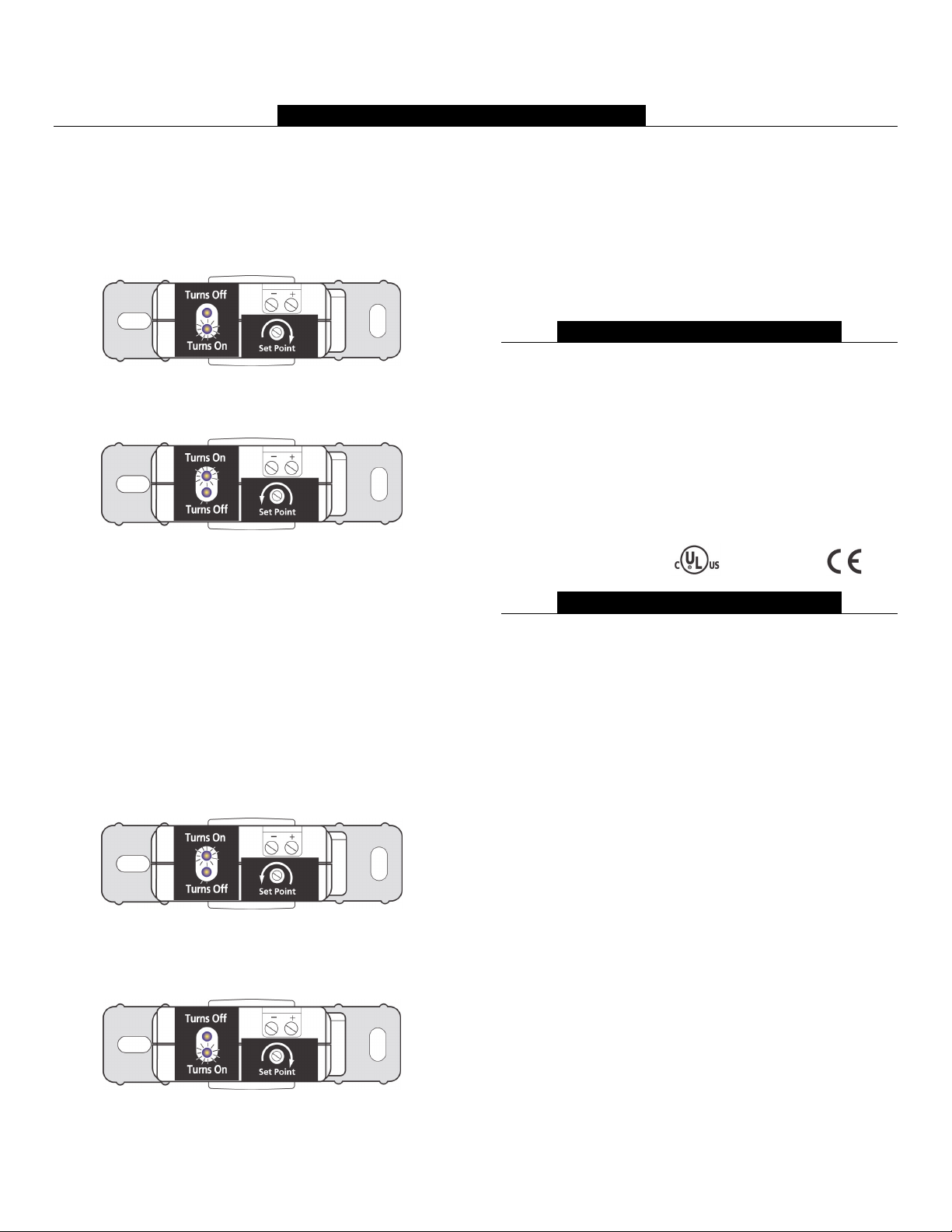

CALIBRATION AFTER INSTALLATION

Orient the current switch so the status output terminal is

facing you and follow method (A) (undercurrent) or (B)

(over-current), below. The monitored motor must be

running normally.

A. For under current status indication: (Belt loss,

coupling shear, fan & pump status)

STEP 1: Turn the setpoint screw clockwise until the

Status Closed LED turns off and the Status Open

LED turns on.

STEP 2: Slowly turn the setpoint screw counterclockwise until the Status Closed LED turns on and

the Status Open LED turns off.

STEP 3: Turn the setpoint screw 1/4 turn more

counter-clockwise to create a grace margin.

STEP 4: The sensor is now calibrated to provide

indication of current flows below normal full load

amps.

Output Status:

Normal: Output Closed

Alarm: Output Open

B. For over current status indication: (Locked rotor,

seized impeller)

Part #: MAN-CSV-A8, Doc #: 7951-C

STEP 3: Turn the setpoint screw 1/4 turn more

clockwise to create a grace margin.

STEP 4: The sensor is now calibrated to provide

indication of current flows above normal full load

amps.

Output Status:

Normal: Output Open

Alarm: Output Closed

SPECIFICATIONS

Amperage Range .............. 0.5-175A Continuous

Sensor Supply Voltage ...... Induced from monitored conductor

Isolation ............................. 600VAC rms. (max. voltage when

monitoring an uninsulated

conductor)

Temperature Range .......... -15º to 60ºC

Humidity Range ................. 0-95% non-condensing

Status Output Ratings ....... N.O. 1.0A@30VAC/DC not polarity

sensitive

Off-state Leakage .............. 0 (open switch represents 1+ MEG

ohms of resistance)

Listings .............................. UL508 E150462

TROUBLESHOOTING

1. The unit will not come on at all.

A. Check to be sure that no more than 30VAC/DC or

1.0A has passed through the contact. Voltages or

currents above these levels will damage the unit.

B. Verify that the conductor you are monitoring is

carrying at least 0.5 Amps.

C. Verify that the setpoint is not above operating

amps by turning screw counter-clockwise (up to

20 full turns) until the contacts close (status

closed LED turns on).

STEP 1: Turn the setpoint screw counter-clockwise

until the Status Open LED turns off and the Status

Closed LED turns on. (Sensor should be in this state

right out of the box.)

STEP 2: Slowly turn the setpoint screw clockwise

until the Status Closed LED turns off and the Status

Open LED turns on.

2

2. Set-point screw has no stops. Keeps turning.

A. The 20 turn set-point screw has a slip clutch

which prevents damage at either end. To start the

calibration process over again turn the screw 20

full turns counter-clockwise. This sets the device

in its original and most sensitive position.

Resume calibration from the beginning.

3. Both LEDs are lit.

A. If the setpoint screw has been turned too far to

the right the user will be notified that the current

switch is out of calibration by seeing both LEDs

lit. To correct this, turn the set-point screw 20 full

turns counterclockwise and resume calibration

from the begi

nning.

Loading...

Loading...