Page 1

TCP-5012UB

s

1.2 pF Passive Tunable

Integrated Circuits (PTIC)

Introduction

ON Semiconductor’s PTICs have excellent RF performance and

power consumption, making them suitable for any mobile handset or

radio application. The fundamental building block of our PTIC

product line is a tunable material called ParaScant, based on Barium

Strontium Titanate (BST). PTICs have the ability to change their

capacitance from a supplied bias voltage generated by the Control IC.

The 1.2 pF ultra−high tuning PTICs are available as wafer-level chip

scale packages (WLCSP).

Key Features

• Ultra−High Tuning Range(5:1) and Operation up to 24 V

• Usable Frequency Range: from 700 MHz to 2.7 GHz

• High Quality Factor (Q) for Low Loss

• High Power Handling Capability

• Compatible with PTIC Control ICs from ON Semiconductor

• These devices are Pb−Free and RoHS Compliant

onsemi.com

www.

WLCSP6

1.097x0.622

CASE 567NZ

MARKING DIAGRAM

AYW

A = Specific Device Code

Y = Year

W = Work Week

Typical Applications

• Multi-band, Multi-standard, Advanced and Simple Mobile Phones

• Tunable Antenna Matching Networks

• Tunable RF Filters

• Active Antennas

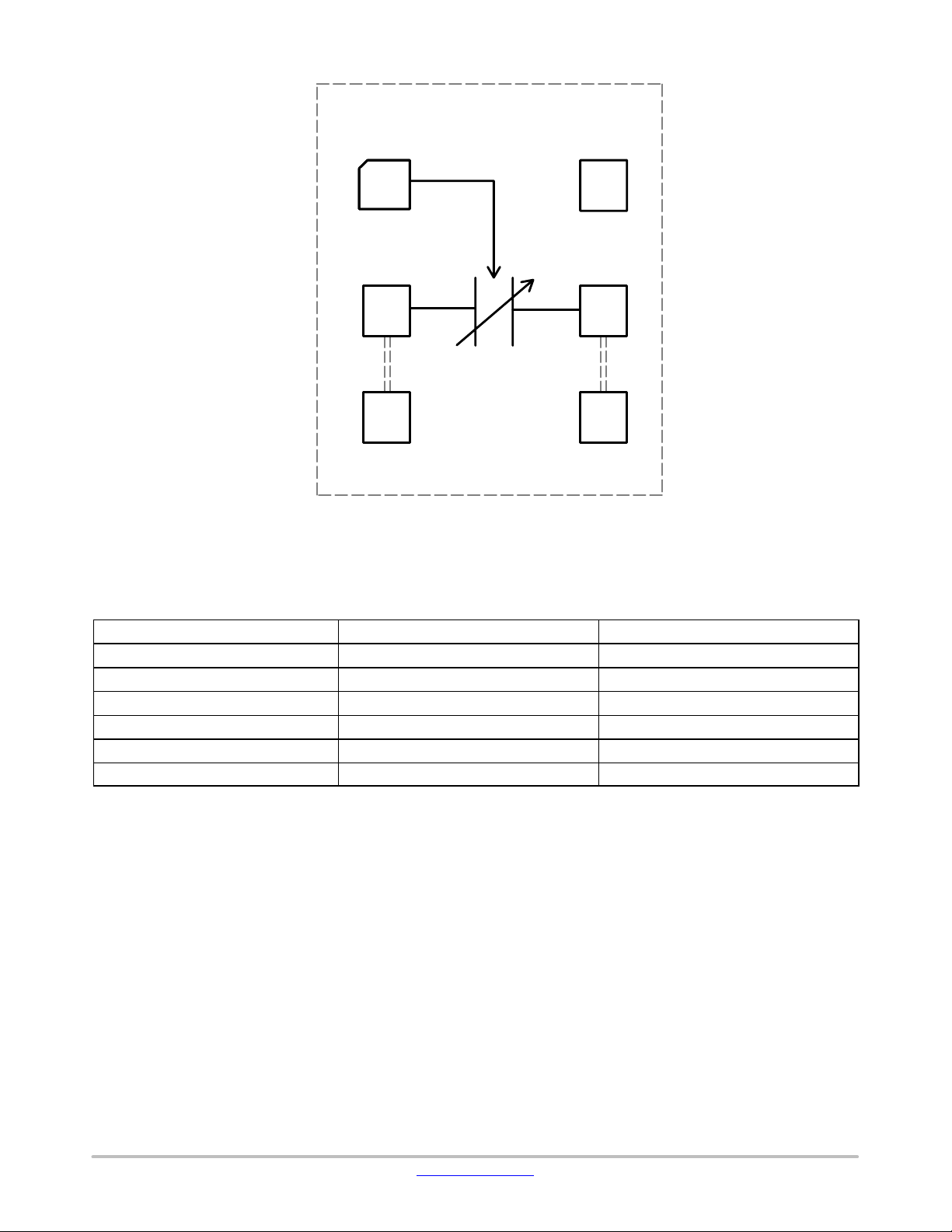

FUNCTIONAL BLOCK DIAGRAM

PTIC

RF1 RF2

Bias

PTIC Functional Block Diagram

ORDERING INFORMATION

Device Package Shipping

TCP−5012UB−DT WLCSP6

(Pb−Free)

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specification

Brochure, BRD801 1/D.

4000 Units /

7” Tape & Reel

†

© Semiconductor Components Industries, LLC, 2016

November, 2016 − Rev. 0

1 Publication Order Number:

TCP−5012UB/D

Page 2

TCP−5012UB

DC Bias 1

RF2

RF2

Table 1. SIGNAL DESCRIPTIONS

Ball / Pad Number Pin Name Description

A1 DC Bias 1 DC Bias Voltage

B1 RF2 RF Output

C1 RF2 RF Output

A2 NC Not Connected

B2 RF1 RF Input

C2 RF1 RF Input

A1

B1

C1

A2

B2

C2

Figure 1. PTIC Functional Block Diagram

(Top View)

NC

RF1

RF1

www.onsemi.com

2

Page 3

TCP−5012UB

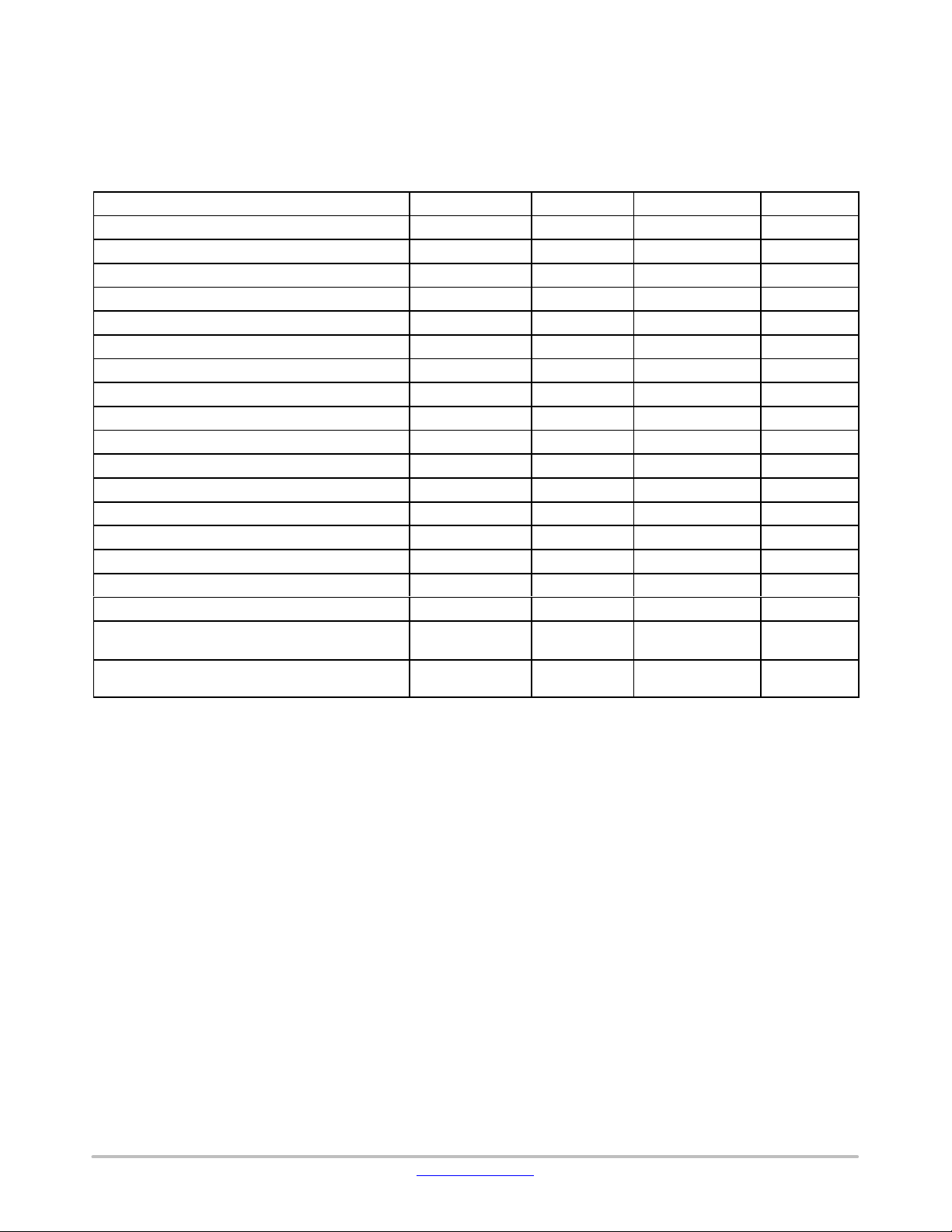

TYPICAL SPECIFICATIONS

Representative Performance Data at 255C

Table 2. PERFORMANCE DATA

Parameter Min Typ Max Unit

Operating Bias Voltage 1.0 24 V

Capacitance (V

Capacitance (V

Tuning Range (1 V - 24 V) 4.80 5.25 6.00

Tuning Range (2 V - 24 V) 4.20 4.65 5.30

Leakage Current (V

Operating Frequency 700 2700 MHz

Quality Factor @ 700 MHz, 2 V (Note 5) 55

Quality Factor @ 700 MHz, 24 V (Note 5) 75

Quality Factor @ 2.4 GHz, 2 V (Note 5) 35

Quality Factor @ 2.4 GHz, 24 V (Note 5) 35

IP3 (V

IP3 (V

= 2 V) (Notes 1, 3 and 5) 70 dBm

bias

= 24 V) (Notes 1, 3 and 5) 80 dBm

bias

2nd Harmonic (V

2nd Harmonic (V

3rd Harmonic (V

3rd Harmonic (V

Average Transition Time (Cmin ³ Cmax) (Note 4

and 5)

Average Transition Time (Cmax ³ Cmin) (Note 4

and 5)

1. f1 = 850 MHz, f2 = 860 MHz, Pin 25 dBm/Tone

2. 850 MHz, Pin +34 dBm

3. IP3 and Harmonics are measured in the shunt configuration in a 50 W environment

4. RF

and RF

IN

5. Sample testing only. Average Transition Time for all start and stop voltage combinations between 2 V and 24 V is 50 ms.

= 2 V) 1.092 1.20 1.308 pF

bias

= 24 V) 0.235 0.258 0.281 pF

bias

= 24 V) 0.1

bias

= 2 V) (Notes 2, 3 and 5) -65 dBm

bias

= 24 V) (Notes 2, 3 and 5) -75 dBm

bias

= 2 V) (Notes 2, 3 and 5) -45 dBm

bias

= 24 V) (Notes 2, 3 and 5) -75 dBm

bias

66

48

are both connected to DC ground

OUT

mA

ms

ms

www.onsemi.com

3

Page 4

TCP−5012UB

Representative performance data at 255C for 1.2 pF WLCSP Package

Figure 2. Capacitance

Figure 3. Harmonic Power*

Figure 4. IP3*

Figure 5. Q*

*Data shown is representative only.

Table 3. ABSOLUTE MAXIMUM RATINGS

Parameter Rating Units

Input Power +40 dBm

Bias Voltage +30 (Note 6) V

Operating Temperature Range −30 to +85 °C

Storage Temperature Range −55 to +125 °C

ESD − Human Body Model Class 1B JEDEC HBM Standard (Note 7)

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

6. WLCSP: Recommended Bias Voltage not to exceed 24 V.

7. Class 1B defined as passing 500 V, but may fail after exposure to 1000 V ESD pulse.

www.onsemi.com

4

Page 5

TCP−5012UB

ASSEMBLY CONSIDERATIONS AND REFLOW PROFILE

The following assembly considerations should be observed:

Cleanliness

These chips should be handled in a clean environment.

Electro-static Sensitivity

ON Semiconductor’s PTICs are ESD Class 1B sensitive.

The proper ESD handling procedures should be used.

Mounting

The WLCSP PTIC is fabricated for Flip Chip solder

mounting. Connectivity to the RF and Bias terminations on

the PTIC die is established through SAC305 solder balls

with 90 mm nominal height (65 mm to 115 mm height

variation). The PTIC die is RoHS-compliant and compatible

with lead-free soldering profile.

Molding

The PTIC die is compatible for over-molding or

under-fill.

ORIENTATION OF THE PTIC FOR OPTIMUM LOSSES

Figure 6. Reflow Profile

When configuring the PTIC in your specific circuit

design, at least one of the RF terminals must be connected

to DC ground. If minimum transition times are required, DC

ground on both RF terminals is recommended. To minimize

losses, the PTIC should be oriented such that RF2

is at the

lower RF impedance of the two RF nodes. A shunt PTIC, for

example, should have RF2

connected to RF ground.

RF ANT

RF1

(PTIC Pad)

RF2

(PTIC Pad)

Bias

Figure 7. PTIC Orientation Functional Block

Diagram

www.onsemi.com

5

Page 6

TCP−5012UB

PART NUMBER DEFINITION

Table 4. PART NUMBERS

Capacitance

Part Number

TCP−5012UB−DT 1.20 0.258 A YW** 6−bump WLCSP

*See PTIC package dimensions on following page.

**Refer to table below (Table 5) for YW trace code.

2 V 24 V

Device ID Trace Code

For information on device numbering and ordering codes, please download the Device Nomenclature technical note

(TND310/D) from www.onsemi.com

Table 5. Two Digits Year and Work Week Date coding (YW) − In Process Product / Traceability Date Code Marking

Code

YW Year and

Term Definition

Work Week

.

Two−character Alpha Code. Example: 2005, workweek 10 = GJ

Marking

Package*

YEAR WORK

WEEK

2003 1

26

27

52

2006 1

26

27

52

2009 1

26

27

52

2012 1

26

27

52

2015 1

26

27

52

CODE YEAR WORK

CA

CZ

DA

DZ

IA

IZ

JA

JZ

PA

PZ

RA

RZ

WA

WZ

XA

XZ

CA

CZ

DA

DZ

2004 1

2007 1

2010 1

2013 1

2016 1

WEEK

26

27

52

26

27

52

26

27

52

26

27

52

26

27

52

CODE YEAR WORK

EA

EZ

FA

FZ

KA

KZ

LA

LZ

SA

SZ

TA

TZ

YA

YZ

ZA

ZZ

EA

EZ

FA

FZ

2005 1

2008 1

2011 1

2014 1

2017 1

WEEK

26

27

52

26

27

52

26

27

52

26

27

52

26

27

52

CODE

GA

GZ

HA

HZ

MA

MZ

NA

NZ

UA

UZ

VA

VZ

AA

AZ

BA

BZ

GA

GZ

HA

HZ

For dates outside of the table: the first character of the code is incremented at the start of workweek 01 and workweek 27

each year . The second character begins with “A” in workweek 01 of each year and increments weekly. “A” follows “Z” to make

the code continuous.

ParaScan is a trademark of Paratek Microwave, Inc.

www.onsemi.com

6

Page 7

È

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 4:1

WLCSP6, 1.097x0.622

CASE 567NZ

ISSUE A

DATE 27 SEP 2016

REFERENCE

2X

2X

NOTE 3

DETAIL A

PIN A1

0.05 C

0.05

0.06 C

0.05 C

E

C

TOP VIEW

DETAIL C

A1

SIDE VIEW

e

C

B

A

12

BOTTOM VIEW

e/2

A B

D

A

C

e

6X

b1

6X

DETAIL A

NOTE 4

TAPE

DETAIL C

SEATING

PLANE

RECOMMENDED

SOLDERING FOOTPRINT*

0.40

PACKAGE

OUTLINE

A1

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

b

A0.05 BC

0.03

C

A3

2. CONTROLLING DIMENSION: MILLIMETERS.

3. COPLANARITY APPLIES TO SPHERICAL

CROWNS OF SOLDER BALLS.

4. BACKSIDE TAPE APPLIED TO IMPROVE

PIN 1 MARKING.

MILLIMETERS

DIMAMIN NOM

0.295

A1

0.065 0.090

A3 0.025 REF

b 0.125 0.150

b1 0.075 0.100

D 1.047 1.097

E 0.572 0.622

e 0.40 BSC

0.335

MAX

0.375

0.115

0.175

0.125

1.147

0.672

GENERIC

MARKING DIAGRAM*

XYW

X = Specific Device Code

Y = Year

W = Work Week

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

0.40

PITCH

6X

DIMENSIONS: MILLIMETERS

0.20

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

98AON11898G

WLCSP6, 1.097X0.622

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

Page 8

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...