Page 1

Pre-configured DSP System

for Hearing Aids

RHYTHM SB3231

Description

ON Semiconductor’s RHYTHM t SB3231 hybrid is

a trimmer−configurable DSP system based on a four−channel

compression circuit featuring Adaptive Feedback Cancellation,

Adaptive Noise Reduction, and directional processing.

Based on a phase cancellation method, Rhythm SB3231’s Adaptive

Feedback Reduction algorithm provides added stable gain to enable

extra gain and user comfort. It features rapid adjustment for dynamic

feedback situations and resistance to tonal inputs.

Rhythm SB3231’s Adaptive Noise Reduction monitors noise levels

independently in 64 individual bands and employs advanced

psychoacoustic models to provide user comfort.

The directional processing system utilizes a pair of microphones to

create a fully customizable static polar pattern, such as bidirectional,

cardiod, hyper−cardiod and super−cardiod.

In addition to these adaptive algorithms, Rhythm SB3231 also

supports the following features: up to four channel WDRC,

low−distortion compression limiting, cross fading between audio

paths for click−free memory changes, eight−band graphic equalizer,

eight configurable generic biquad filters, programming speed

enhancements, in−channel squelch to attenuate microphone and

circuit noise in quiet environments, optional peak clipping, flexible

compression adjustments, volume control, rocker switch, noise

generation for Tinnitus treatment, and industry−leading security

features to avoid cloning and software piracy.

A trimmer interface supports manual circuit configuration. It

continuously monitors trimmer positions and translates them into the

hearing−aid parameters of choice. A Serial Data or I

provides full programmability at the factory and in the field.

The Rhythm SB3231 hybrid contains a 256 kbit EEPROM intended

for programmable and trimmer based devices.

Features

• Directional Processing

• Adaptive Noise Reduction

• Adaptive Feedback Cancellation

• WDRC Compression with Choice of 1, 2 or 4 Channels of

Compression

• Auto Telecoil with Programmable Delay

• EVOKE Acoustic Indicators

• Noise Generator for Tinnitus Treatment or In−situ Audiometry

• Frequency Response Shaping with Graphic EQ

• Trimmer Compatibility – Four Three−Terminal

Trimmers with Configurable Assignments of Control

Parameters

2

C Interface

www.onsemi.com

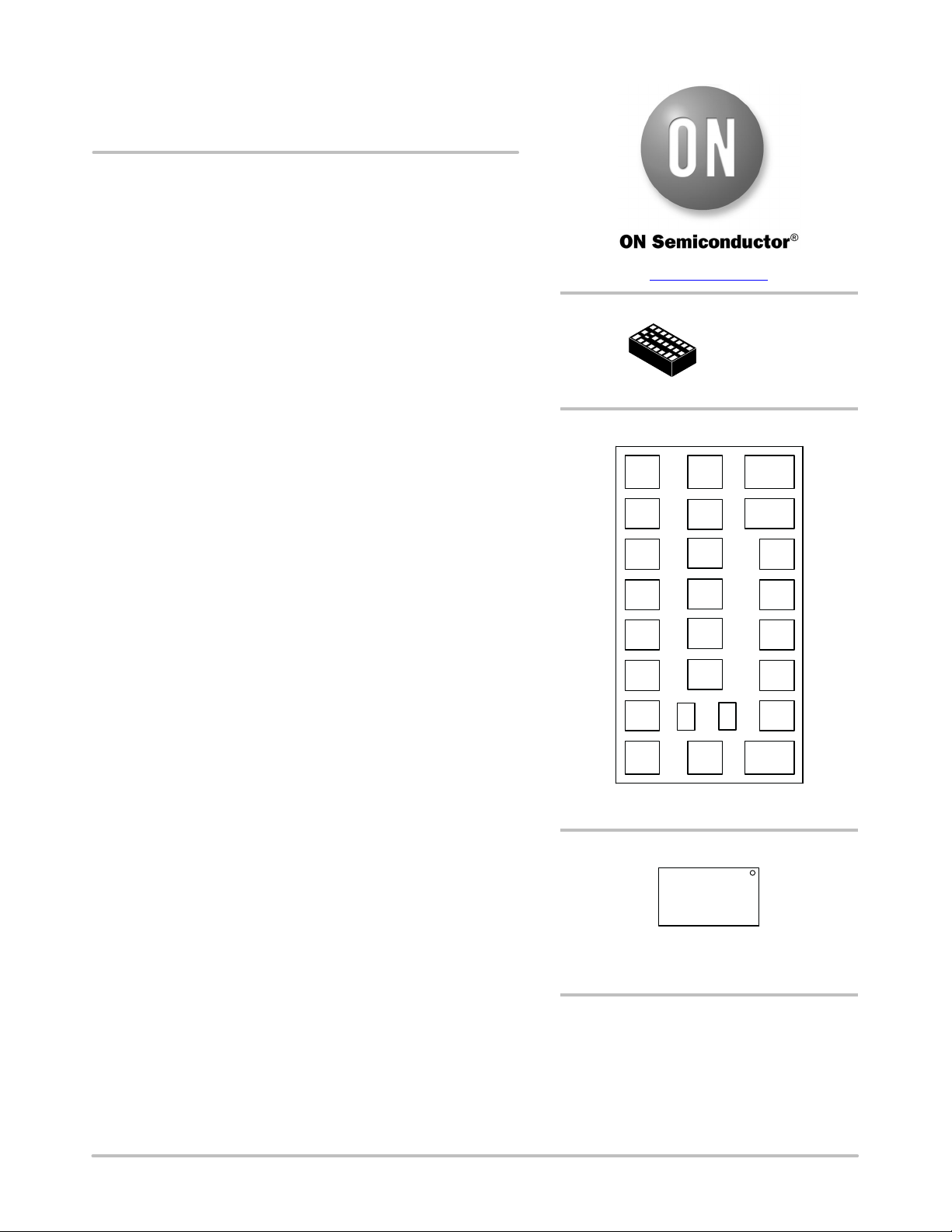

25 PAD

HYBRID

CASE 127DN

PAD CONNECTION

VIN2

D_VC

SDA

CLK

MS1

See detailed ordering and shipping information on page 14 of

this data sheet.

17

16

TIN

DAI

15

VC

14

13

12

11

MARKING DIAGRAM

SB3231 = Specific Device Code

E1 = RoHS Compliant Hybrid

XXXXXX = Work Order Number

ORDERING INFORMATION

18

VIN1

19

TR4

20

TR3

21

TR2

22

TR1

23

N/C

25 24

N/C

MS2

(Bottom View)

SB3231−E1

XXXXXX

N/C

1

VREG

2

MGND

GND

3

PGND

4

OUT+

5

OUT−

6

VBP

7

VB

8910

© Semiconductor Components Industries, LLC, 2014

March, 2021 − Rev. 6

1 Publication Order Number:

SB3231/D

Page 2

RHYTHM SB3231

2

• I

C and SDA Programming

• Rocker Switch Support for Memory Change and/or

Volume Control Adjustment

• Support for Active Hi or Active Lo Switching

• Analog or Digital Volume Control with Programmable

Range

• High Quality 20−bit Audio Processing

• High Power/High Gain Capability

• SOUNDFIT Fitting Software

• Configurable Low Battery Indicator

• Eight Biquadratic Filters

• 16 kHz or 8 kHz Bandwidth

• Four Fully Configurable Memories with Audible

Memory Change Indicator

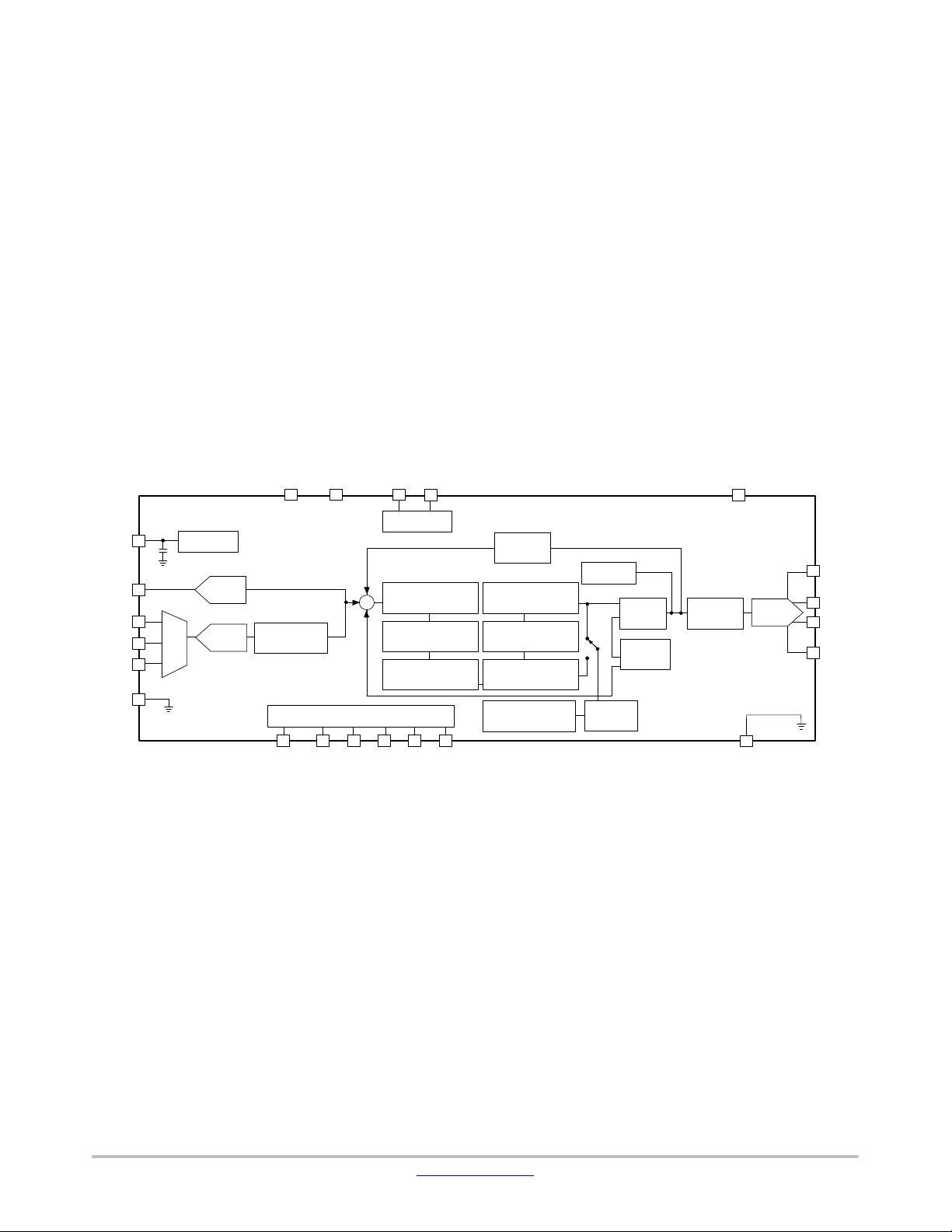

BLOCK DIAGRAM

• 96 dB Input Dynamic Range with Headroom Extension

• 128−bit Fingerprint Security System and Other Security

Features to Protect against Device Cloning and

Software Piracy

• High Fidelity Audio CODEC

• Soft Acoustic Fade between Memory Changes

• Drives Zero−Bias Two−Terminal Receivers

• E1 RoHS−compliant Hybrid

• Hybrid Typical Dimensions:

0.220 x 0.125 x 0.060 in

(5.59 x 3.18 x 1.52 mm)

• These Devices are Pb−Free and are RoHS Compliant

VREG

MIC1

MIC2

TIN

DAI

MGND

1

18

17

16

15

2

SB3231

REGULATOR

A/D

A/D

MS2

9

MIC / TELECOIL

COMPENSATION

13

D_VC

MS1

10

TRIMMER/VC INTERFACE

14

VC

SDA CLK

12

PROGRAMMING

INTERFACE

PRE BIQUAD FILTERS

+

1, 2 or 4 CHANNEL

WDRC, EQ, ANR

POST BIQUAD FILTERS

22 20 19

21

Figure 1. Hybrid Block Diagram

1−4

1 & 2

PEAK

CLIPPING

VB

8

GND

D/A

HBRIDGE

3

7

5

6

4

VBP

OUT+

OUT −

PGND

11

FEEDBACK

CANCELLER

TONE

POST BIQUAD FILTERS

3 & 4

AGC−O

VC GAIN

WIDEBAND GAIN

NOISE GENERATOR

TR4TR3TR2TR1

GENERATOR

BIQUAD 1−4

CROSS

FADER

EVOKE

www.onsemi.com

2

Page 3

RHYTHM SB3231

SPECIFICATIONS

Table 1. ABSOLUTE MAXIMUM RATINGS

Parameter Value Units

Operating Temperature Range 0 to 40 °C

Storage Temperature Range −20 to +70 °C

Absolute Maximum Power Dissipation 25 mW

Maximum Operating Supply Voltage 1.65 VDC

Absolute Maximum Supply Voltage 1.8 VDC

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

WARNING: Electrostatic Sensitive Device − Do not open packages or handle except at a static−free workstation.

WARNING: Moisture Sensitive Device − RoHS Compliant; Level 3 MSL. Do not open packages except under controlled conditions.

Table 2. ELECTRICAL CHARACTERISTICS (Supply Voltage V

Parameter

Hybrid Current I

Symbol Conditions Min Typ Max Units

AMP

All functions, 32 kHz sampling rate − 770 −

= 1.25 V; Temperature = 25°C)

B

mA

All functions, 16 kHz sampling rate − 600 −

Minimum Operating Supply Voltage V

BOFF

Ramp down, audio path 0.93 0.95 0.97

V

Ramp down, control logic 0.77 0.80 0.83

Supply Voltage Turn On Threshold V

BON

Ramp up 1.06 1.10 1.16 V

EEPROM Burn Cycles − − 100 k − − cycles

Low Frequency System Limit − − − 125 − Hz

High Frequency System Limit − − − 16 − kHz

Total Harmonic Distortion THD VIN = −40 dBV − − 1 %

THD at Maximum Input THD

Clock Frequency f

CLK

Audio Path Latency

− 8 kHz bandwidth − 4.2 −

VIN = −15 dBV, Headroom Extension

M

− ON

− 3.973 4.096 4.218 MHz

− − 3 %

ms

− 16 kHz bandwidth − 4.0 −

System Power On Time (Note 1) − SB3231 − 1600 − ms

REGULATOR

Regulator Voltage

V

REG

System PSRR PSRR

SYS

1 kHz, Input referred, Headroom

Extension enabled

− 0.87 0.90 0.93 V

− 70 − dB

INPUT

Input Referred Noise

IRN Bandwidth 100 Hz − 8 kHz,

− −108 −106 dBV

Headroom Extension on

Input Impedance Z

IN

Anti−aliasing Filter Rejection − f = f

CLK/2

1 kHz − 3 −

MW

− 8 kHz, VIN = −40 dBV − 80 − dB

Crosstalk − Between both A/D and Mux − 60 − dB

Maximum Input Level − − −15 −13 − dBV

Analogue Input Voltage Range

V

AN_IN

V

AN_TIN

Input Dynamic Range − Headroom Extension − ON

V

, V

, Al 0 − 800

IN1

IN2

T

IN

−100 − 800

mV

− 95 96 dB

Bandwidth

100 Hz − 8 kHz

1. Times do not include additional programmable startup delay.

www.onsemi.com

3

Page 4

RHYTHM SB3231

Table 2. ELECTRICAL CHARACTERISTICS (Supply Voltage V

= 1.25 V; Temperature = 25°C)

B

Parameter UnitsMaxTypMinConditionsSymbol

OUTPUT

D/A Dynamic Range

Output Impedance Z

− 100 Hz − 8 kHz − 88 − dB

OUT

− − 10 13

CONTROL A/D

Resolution (monotonic)

− − 7 − − bits

Zero Scale Level − − − 0 − V

Full Scale Level − − − V

REG

− V

VOLUME CONTROL

Volume Control Resistance

R

VC

Three−terminal connection 100 − 360

Volume Control Range − − − − 42 dB

PC_SDA INPUT

Logic 0 Voltage

− − 0 − 0.3 V

Logic 1 Voltage − − 1 − 1.25 V

PC_SDA OUTPUT

Stand−by Pull Up Current

− Creftrim = 6 3 5 6.5

Sync Pull Up Current − Creftrim = 6 748 880 1020

Max Sync Pull Up Current − Creftrim = 15 − 1380 −

Min Sync Pull Up Current − Creftrim = 0 − 550 −

Logic 0 Current (Pull Down) − Creftrim = 6 374 440 506

Logic 1 Current (Pull Up) − Creftrim = 6 374 440 506

Synchronization Time

(Synchronization Pulse Width)

T

SYNC

Baud = 0 237 250 263 ms

Baud = 1 118 125 132

Baud = 2 59 62.5 66

Baud = 3 29.76 31.25 32.81

Baud = 4 14.88 15.63 16.41

Baud = 5 7.44 7.81 8.20

Baud = 6 3.72 3.91 4.10

Baud = 7 1.86 1.95 2.05

1. Times do not include additional programmable startup delay.

W

kW

mA

mA

mA

mA

mA

mA

www.onsemi.com

4

Page 5

RHYTHM SB3231

T

Table 3. I2C TIMING

Standard Mode Fast Mode

Parameter Symbol

Clock Frequency f

Hold time (repeated) START condition. After this

period, the first clock pulse is generated.

LOW Period of the PC_CLK Clock t

HIGH Period of the PC_CLK Clock t

Set−up time for a repeated START condition t

Data Hold Time:

for CBUS Compatible Masters

PC_CLK

t

HD;STA

LOW

HIGH

SU;STA

t

HD;DAT

for I2C−bus Devices

Data set−up time t

Rise time of both PC_SDA and PC_CLK signals t

Fall time of both PC_SDA and PC_CLK signals t

Set−up time for STOP condition t

Bus free time between a STOP and START condition t

Output fall time from V

capacitance from 10 pF to 400 pF

IHmin

to V

ILmax

with a bus

Pulse width of spikes which must be suppressed by

the input filter

Capacitive load for each bus line C

SU;DAT

r

f

SU;STO

BUF

t

of

t

SP

b

1. A device must internally provide a hold time of at least 300 ns for the PC_SDA signal to bridge the undefined region of the falling edge of PC_CLK.

2. The maximum t

3. A Fast−mode I

has only to be met if the device does not stretch the LOW period (t

HD;DAT

2

C−bus device can be used in a Standard−mode I2C−bus system, but the requirement t

This will automatically be the case if the device does not stretch the LOW period of the PC_CLK signal. If such a device does stretch the

LOW period of the PC_CLK signal, it must output the next data bit to the PC_SDA line t

to the Standard−mode I

= total capacitance of one bus line in pF.

4. C

b

2

C−bus specification) before the PC_CLK line is released.

Min Max Min Max

0 100 0 400 kHz

4.0 − 0.6 −

4.7 − − −

4.0 − − −

4.7 − − −

5.0

0

(Note 1)

−

3.45

(Note 2)

−

0

(Note 1)

−

0.9

(Note 2)

250 − 100 − nsec

− 1000 20 + 0.1 C

(Note 4)

− 300 20 + 0.1 C

(Note 4)

b

b

300 nsec

300 nsec

4.0 − 0.6 − nsec

4.7 − 1.3 −

− 250 20 + 0.1 C

(Note 4)

b

250 nsec

n/a n/a 0 50 nsec

− 400 − 400 pF

) of the PC_CLK signal.

LOW

max + t

r

SU;DAT

P250ns must then be met.

SU;DAT

= 1000 + 250 = 1250 ns (according

Units

msec

msec

msec

msec

msec

msec

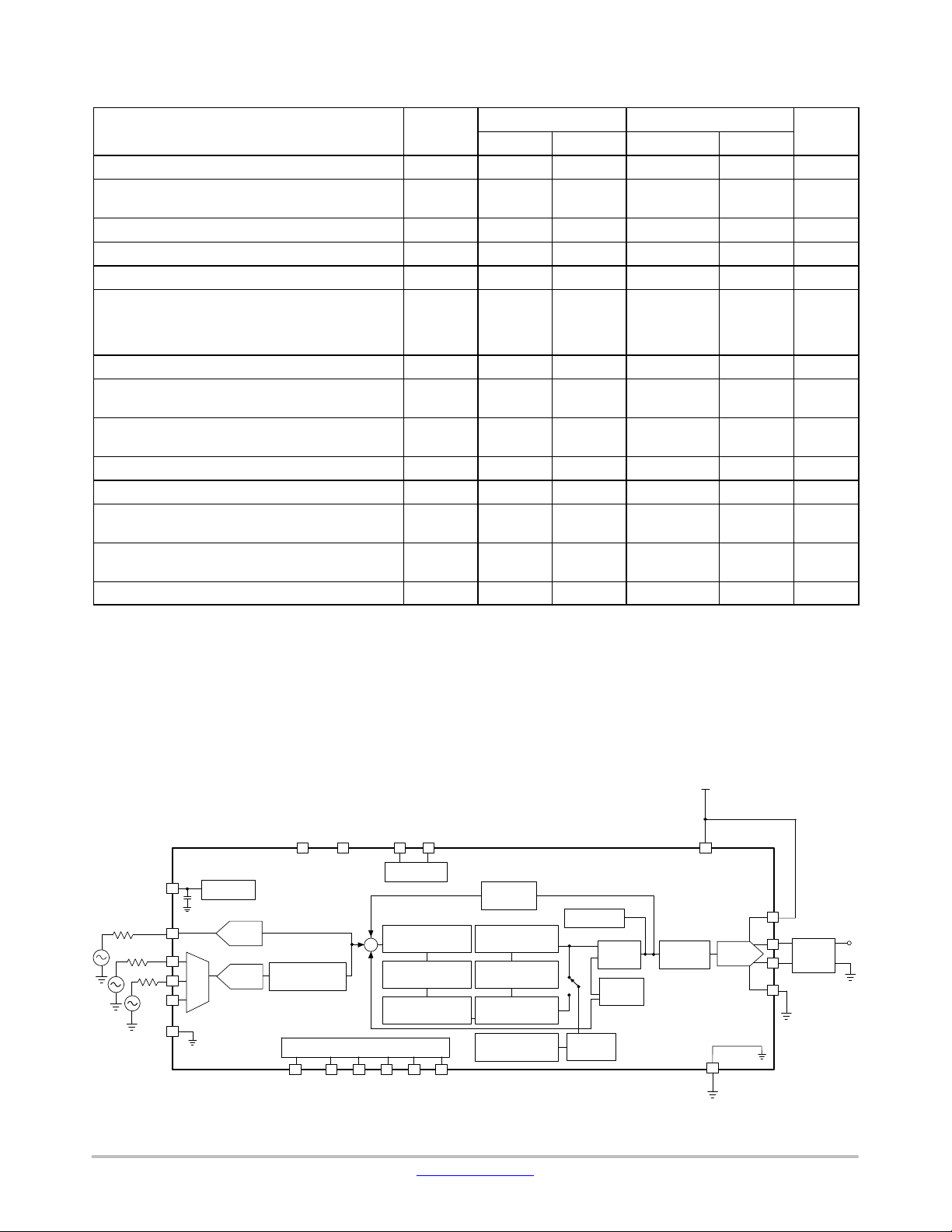

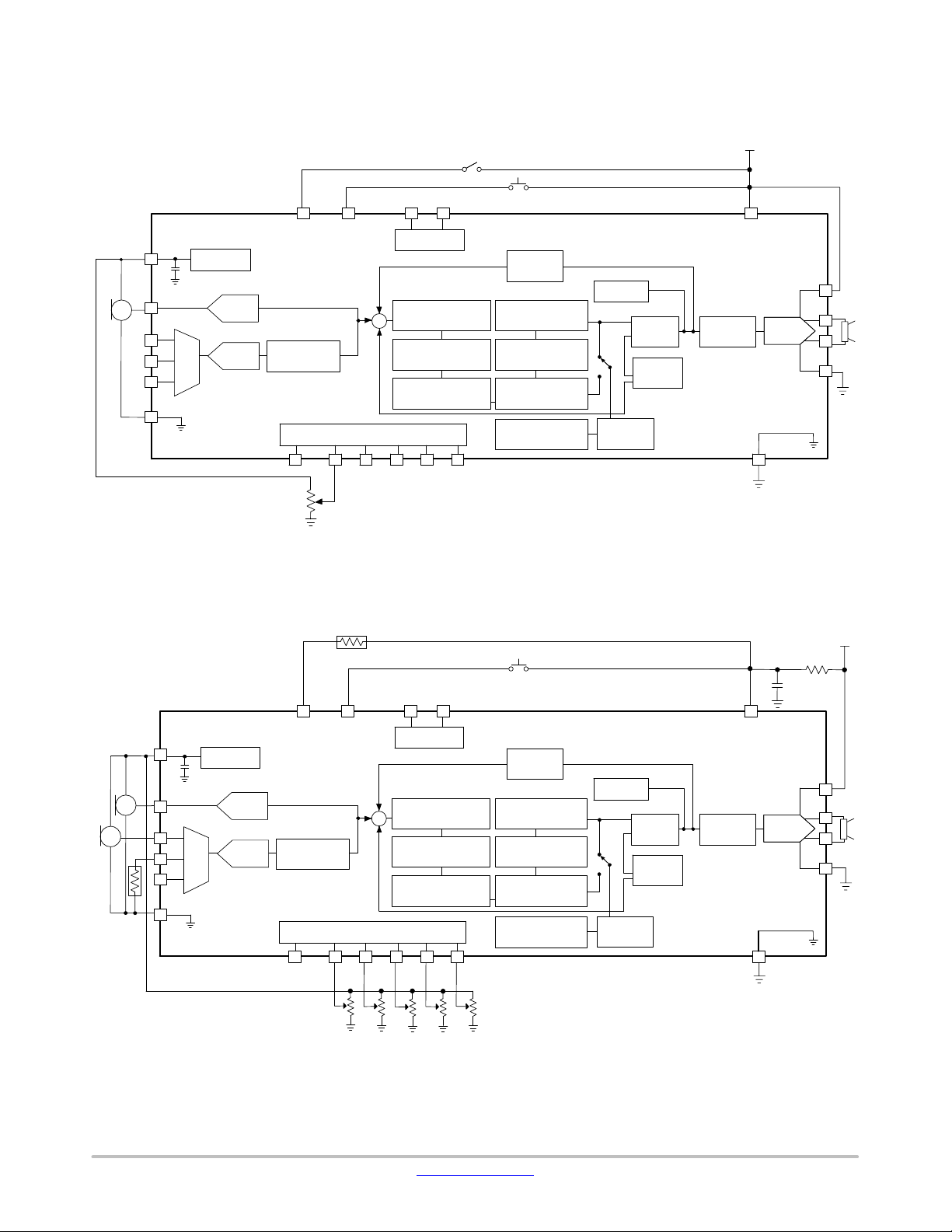

TYPICAL APPLICATIONS

V

B

910

REGULATOR

1

3k9

18

3k9

17

16

1k

15

2

SB3231

A/D

A/D

MIC / TELECOIL

COMPENSATION

TRIMMER/VC INTERFACE

13

Note: All resistors in ohms and all capacitors in farads, unless otherwise stated.

12 11 8

PROGRAMMING

+

POST BIQUAD FILTERS

22 20 1914

21

INTERFACE

PRE BIQUAD FILTERS

1−4

1, 2 or 4 CHANNEL

WDRC, EQ, ANR

1 & 2

FEEDBACK

CANCELLER

POST BIQUAD FILTERS

3 & 4

AGC−O

VC GAIN

WIDEBAND GAIN

NOISE GENERATOR

TONE

GENERATOR

BIQUAD 1−4

CROSS

FADER

EVOKE

Figure 2. Test Circuit

www.onsemi.com

5

PEAK

CLIPPING

3

D/A

HBRIDGE

7

5

6

4

OU

LP FILTER

Page 6

RHYTHM SB3231

TYPICAL APPLICATIONS (continued)

MS2

V

B

MS1

FEEDBACK

CANCELLER

POST BIQUAD FILTERS

3 & 4

AGC−O

VC GAIN

WIDEBAND GAIN

NOISE GENERATOR

1

18

17

16

15

2

SB3231

REGULATOR

A/D

A/D

910

MIC / TELECOIL

COMPENSATION

13

VC

200 k

To Programming box

12 11 8

PROGRAMMING

INTERFACE

PRE BIQUAD FILTERS

+

1, 2 or 4 CHANNEL

WDRC, EQ, ANR

POST BIQUAD FILTERS

TRIMMER/VC INTERFACE

14

21

22 20 19

1−4

1 & 2

Note: All resistors in ohms and all capacitors in farads, unless otherwise stated.

Figure 3. Typical Programmable Application Circuit

Reed Switch

For Autotcoil

MS1

12 11 8

PROGRAMMING

INTERFACE

FEEDBACK

CANCELLER

PRE BIQUAD FILTERS

+

1, 2 or 4 CHANNEL

WDRC, EQ, ANR

POST BIQUAD FILTERS

21

22 20 1914

TR1 TR2 TR3

1−4

1 & 2

POST BIQUAD FILTERS

NOISE GENERATOR

TR4

3 & 4

AGC−O

VC GAIN

WIDEBAND GAIN

1

18

17

16

15

2

SB3231

REGULATOR

A/D

A/D

910

MIC / TELECOIL

COMPENSATION

TRIMMER/VC INTERFACE

13

VC

TONE

GENERATOR

BIQUAD 1−4

TONE

GENERATOR

BIQUAD 1−4

CROSS

FADER

EVOKE

CROSS

FADER

EVOKE

PEAK

CLIPPING

PEAK

CLIPPING

3

3

D/A

HBRIDGE

47μ

D/A

HBRIDGE

7

5

6

4

V

B

22

7

5

6

4

Note: All resistors in ohms and all capacitors in farads, unless otherwise stated.

Figure 4. Typical Trimmer Application Circuit

www.onsemi.com

6

Page 7

RHYTHM SB3231

RHYTHM SB3231 OVERVIEW

Rhythm SB3231 is a DSP system implemented on

ON Semiconductor’s Wolverine hardware platform.

Wolverine is the hearing industry’s first 90 nm

Silicon−on−Chip platform enabling design of

highly−efficient and flexible hearing aid solutions. The

device is packaged for easy integration into a wide range of

applications from CIC to BTE. Rhythm SB3231 can be used

as a programmable or trimmer adjustable device. It may be

configured as one, two or four channels with linear or

WDRC processing. Configuration data stored in

non−volatile memory defines hearing−aid parameters.

Rhythm SB3231 can be programmed via the SDA or I

2

programming interfaces.

The DSP core implements Adaptive Feedback

Cancellation, Adaptive Noise Reduction, directional

FUNCTIONAL BLOCK DESCRIPTION

A/D and D/A Converter

The system’s A/D converter is a 2nd−order sigma−delta

modulator operating at a 2.048 MHz sample rate.

The system’s input is pre−conditioned with anti−alias

filtering and a programmable gain pre−amplifier. The

analog output is oversampled and modulated to produce

a1−bit pulse density modulated (PDM) data stream. The

digital PDM data is then decimated down to pulse−code

modulated (PCM) digital words at the system’s sampling

rate of 32 kHz.

The D/A is comprised of a digital 3rd−order sigma−delta

modulator and an H−bridge. The modulator accepts PCM

audio data from the DSP path and converts it into a 64−times

oversampled, 1−bit PDM data stream, which is then

supplied to the H−bridge. The H−bridge is a specialized

CMOS output driver used to convert the 1−bit data stream

into a low−impedance, differential output voltage

waveform suitable for driving zero−biased hearing aid

receivers.

Analog Inputs

Rhythm SB3231 provides for up to four analog inputs,

Microphone 1 (MIC1), Microphone 2 (MIC2), Telecoil

(TCOIL) and Direct Audio Input (DAI) with the following

configurable front end modes:

• 1 Mic Omni

• 1 Mic Omni (Rear channel only)

• Directional Processing

• 2 Mic Omni (MIC1 + MIC2)

• DAI

• TCOIL

• 1 Mic Omni + TCOIL

• 1 Mic Omni + DAI

Attenuation can be applied to the input when mixing with

either TCOIL or DAI inputs.

processing, compression, wideband gain, and volume

control. The Adaptive Feedback Canceller reduces acoustic

feedback while offering robust performance against pure

tones.

The Rhythm SB3231 contains a 256 kbit EEPROM and

can be used for both programmable and trimmer based

applications. It is compatible with ON Semiconductor’s

ARK tools and SOUNDFIT fitting software.

During trimmer mode operation, a low−speed A/D circuit

monitors the positions of up to four manual trimmers and

a VC potentiometer. Trimmer position changes are

C

immediately interpreted and translated into new circuit

parameter values, which are then used to update the signal

path.

Analog input signals should be ground referenced to

MGND. (Microphones, telecoils, DAI). MGND is

internally connected to GND to minimize noise, and should

not be connected to any external ground point.

Channel Processing

Figure 5 represents the I/O characteristic of independent

AGC channel processing. The I/O curve can be divided into

four main regions:

• Low input level expansion (squelch) region

• Low input level linear region

• Compression region

• High input level linear region (return to linear)

0

−10

−20

−30

Low Level

Gain

−40

−50

−60

−70

OUTPUT LEVEL (dBV)

−80

−90

−100

−120 −110 −100 −90 −80 −70 −60 −50 −40 −30 −20

Figure 5. Independent Channel I/O Curve Flexibility

Compression

Ratio

Lower

Threshold

Squelch

Threshold

INPUT LEVEL (dBV)

Channel I/O processing is specified by the Squelch

threshold (SQUELCHTH) and any four of the following

five parameters (only four of the five properties are

independent):

High Level

Gain

Upper

Threshold

• Low level gain (LLGAIN)

• Lower threshold (LTH)

www.onsemi.com

7

Page 8

RHYTHM SB3231

• High level gain (HLGAIN)

• Upper threshold (UTH)

• Compression ratio (CR)

During the Parameter Map creation, constraints are

applied to the compression parameters to ensure that the I/O

characteristics are continuous. Parameter adjustments

support two popular styles of compression ratio adjustment:

• The compression region of the I/O curve pivots about

the upper threshold. As the compression ratio trimmer

is adjusted, high−level gain remains constant while the

low−level gain changes.

• The compression region of the I/O curve pivots about

the lower threshold. Low−level gain remains constant

as the compression ratio trimmer is adjusted.

The squelch region within each channel implements a low

level noise reduction scheme (1:3 expansion) for listener

comfort. This scheme operates in quiet listening

environments (programmable threshold) to reduce the gain

at very low levels.

Automatic Telecoil

The automatic telecoil feature in Rhythm SB3231 is to be

used with memory D programmed with the telecoil or

MIC + TCOIL front end configuration. The feature enables

the part to transition to memory D upon the closing of

a switch connected to MS2. With the feature enabled and

a reed switch connected to MS2, the static magnetic field of

a telephone handset will close the switch whenever the

handset is brought close to the device, causing the hybrid to

change to memory D. The part will transition back to the

initial memory once the switch is deemed opened after

proper debouncing.

A debounce algorithm with a programmable debounce

period is used to prevent needless switching in and out of

memory D due to physical switch bounces when MS2 is

configured for automatic telecoil. Upon detecting a close to

open switch transition, the debounce algorithm monitors the

switch status. The debounce algorithm switches the device

out of memory D only once the switch signal has been

continuously sampled open over the specified debounce

period.

Adaptive Feedback Canceller

The Adaptive Feedback Canceller (AFC) reduces

acoustic feedback by forming an estimate of the hearing aid

feedback signal and then subtracting this estimate from the

hearing aid input. The forward path of the hearing aid is not

affected. Unlike adaptive notch filter approaches, Rhythm

SB3231’s AFC does not reduce the hearing aid’s gain. The

AFC is based on a time−domain model of the feedback path.

The third−generation AFC (see Figure 6) allows for an

increase in the stable gain

minimizing artefacts for music and tonal input signals. As

with previous products, the feedback canceller provides

completely automatic operation.

1

of the hearing instrument while

1. Added stable gain will vary based on hearing aid style and

acoustic setup. Please refer to the Adaptive Feedback

Cancellation Information note for more details.

Feedback path

+

Σ

−

Estimated feedback

Figure 6. Adaptive Feedback Canceller (AFC)

Block Diagram

Feedback Path Measurement Tool

H

G

H’

The Feedback Path Measurement Tool uses the onboard

feedback cancellation algorithm and noise generator to

measure the acoustic feedback path of the device. The noise

generator is used to create an acoustic output signal from the

hearing aid, some of which leaks back to the microphone via

the feedback path. The feedback canceller algorithm

automatically calculates the feedback path impulse response

by analyzing the input and output signals. Following

a suitable adaptation period, the feedback canceller

coefficients can be read out of the device and used as an

estimate of the feedback−path impulse response.

Adaptive Noise Reduction

The noise reduction algorithm is built upon a high

resolution 64−band filter bank (32 bands at 16 kHz

sampling) enabling precise removal of noise. The algorithm

monitors the signal and noise activities in these bands, and

imposes a carefully calculated attenuation gain

independently in each of the 64 bands.

The noise reduction gain applied to a given band is

determined by a combination of three factors:

• Signal−to−Noise Ratio (SNR)

• Masking threshold

• Dynamics of the SNR per band

The SNR in each band determines the maximum amount

of attenuation to be applied to the band − the poorer the SNR,

the greater the amount of attenuation. Simultaneously, in

each band, the masking threshold variations resulting from

the energy in other adjacent bands is taken into account.

Finally, the noise reduction gain is also adjusted to take

advantage of the natural masking of ‘noisy’ bands by speech

bands over time.

Based on this approach, only enough attenuation is

applied to bring the energy in each ‘noisy’ band to just below

the masking threshold. This prevents excessive amounts of

attenuation from being applied and thereby reduces

unwanted artifacts and audio distortion. The Noise

www.onsemi.com

8

Page 9

RHYTHM SB3231

Reduction algorithm efficiently removes a wide variety of

types of noise, while retaining natural speech quality and

level. The level of noise reduction (aggressiveness) is

configurable to 3, 6, 9 and 12 dB of reduction.

Directional Processing Directional Microphones

The directional processing feature is implemented in two

front−end modes on Rhythm SB3231: static directional and

two−microphone omnidirectional. Both these front−end

modes are designed to operate using two closely spaced

omnidirectional microphones connected to the VIN1 and

VIN2 inputs.

In static directional mode, directional processing

synthesizes a directional response pattern by delaying the

rear−microphone signal and subtracting it from the front

microphone signal. Various microphone response patterns

can be obtained by adjusting the rear−microphone time

delay.

In two−microphone omnidirectional mode, directional

processing synthesizes a secondary omnidirectional

response pattern by delaying the front microphone signal

and adding it to the rear microphone signal. The resulting

omnidirectional microphone signal possesses a noise floor

that is approximately 3 dB lower than that provided by a

single microphone (assuming both microphones have

similar noise floors).

The directional processing feature includes three

parameters that can be set via external software: time delay,

rear−microphone compensation filter and a low−frequency

boost filter intended for static directional mode. Time delay

can be configured using IDS software. It determines the

polar patter in static directional mode and accounts for

microphone spacing in two−microphone omnidirectional

mode. The rear−microphone compensation filter provides

a means to adjust the rear−microphone sensitivity so that it

can better match the front microphone. It is controlled

automatically through Cal/Config software. The

low−frequency boost filter compensates for the 6 dB/octave

roll−off in frequency response that occurs in directional

mode. The amount of low frequency equalization is

programmable through IDS.

NOTE: For optimum directional processing operation,

ON Semiconductor recommends using matched

microphone pairs.

The time delay implemented using directional processing

is not explicitly limited within the system. Optimum

accuracy is obtained, however, for smaller time delays. For

example, in 32 kHz operation, a time delay of 81.5

microseconds can be achieved with a maximum deviation of

5% over a bandwidth of 0 to 4 kHz. This allows a

microphone port spacing of approximately 28 mm. For

16 kHz operation, a similar accuracy is observed for a time

delay of 78.1 microseconds, corresponding to a port spacing

of approximately 26.8 mm. Smaller time delays can be

implemented with improved accuracy.

Volume Control, Trimmers and Switches

External Volume Control

The volume of the device can either be set statically via

software or controlled externally via a physical interface.

Rhythm SB3231 supports both analog and digital volume

control functionality, although only one can be enabled at

a time. Digital control is supported with either a momentary

switch or a rocker switch. In the latter case, the rocker switch

can also be used to control memory selects.

Analog Volume Control

Both the external (analog) volume control and trimmers

work with a three−terminal 100 kW − 360 kW variable

resistor. The volume control can have either a log or linear

taper, which is selectable via IDS. It is possible to use a VC

with up to 1 MW of resistance, but this could result in a slight

decrease in the resolution of the taper.

Trimmers

The trimmer interface provides the ability to control up to

19 hearing aid parameters through up to four trimmers.

A single trimmer parameter can have up to 16 values and

a single trimmer can control multiple parameters (e.g.,

Trimmer 1 can control compression ratio in all four channels

simultaneously). The trimmer must be three−terminal

100 kW to 360 kW variable resistors and have a linear taper.

Parameters that can be assigned to trimmers include Noise

Reduction, Low Cut, High Cut, Compression Ratio,

Wideband Gain, Tinnitus Noise Level, Crossover

Frequency, Lower Threshold, Upper Threshold, EQ Gain,

Squelch Threshold, High Level Gain, Low Level Gain,

AGC−O Threshold, Static Volume Control and Peak Clipper

Threshold.

NOTE: There may be limitations to which parameters

can be used together.

Digital Volume Control

The digital volume control makes use of two pins for

volume control adjustment, VC and D_VC, with

momentary switches connected to each. Closure of the

switch to the VC pin indicates a gain increase while closure

to the D_VC pin indicates a gain decrease. Figure 7 shows

how to wire the digital volume control to Rhythm SB3231.

GND

VC

D_VC

Figure 7. Wiring for Digital Volume Control

www.onsemi.com

9

Page 10

RHYTHM SB3231

Memory Select Switches

One or two, two−pole Memory Select (MS) switches can

be used with Rhythm SB3231. This enables user’s

tremendous flexibility in switching between configurations.

Up to four memories can be configured and selected by the

MS switches on Rhythm SB3231. Memory A must always

be valid. The MS switches are either momentary or static

and are fully configurable through IDS in the IDS setting

The behavior of the MS switches is controlled by two

main parameters in IDS:

MSSmode: this mode determines whether a

connected switch is momentary or static.

Donly: this parameter determines whether the MS2

switch is dedicated to the last memory position

There are four basic MS switch modes of operation as

shown in Table 4 below.

tab.

Table 4. MS SWITCH MODES

Max # of Valid

MS Switch Mode MS1 Switch MS2 Switch

Mode 1 Momentary None 4 Off Momentary Simplest configuration

Mode 2 Momentary Static 4 On Momentary Jump to last memory

Mode 3 Static Static 4 Off Static Binary selection of memory

Mode 4 Static Static 3 On Static Jump to last memory

The flexibility of the MS switches is further increased by

allowing the MS switches to be wired to GND or VBAT,

corresponding to an active low or active high logic level on

Table 5. MS SWITCH LOGIC LEVELS VS. IDS PULLUPDOWN SETTINGS

“PullUpDown” Setting in IDS MS Switch State MS Input Logic Level Switch Connection

Pulldown CLOSED HI To VBAT

Pulldown OPEN LOW To VBAT

Pullup CLOSED LOW To GND

Pullup OPEN HI To GND

Memories

Donly MSSMode Use

the MS pins. This option is configured with the

MSPullUpDown/MS2PullUpDown setting in the IDS

settings tab as shown in Table 5 below.

In the following mode descriptions, it is assumed that the

PullUpDown setting has been properly configured for the

MS switch wiring so that a CLOSED switch state is at the

correct input logic level.

Mode 1: Momentary Switch on MS1

This mode uses a single momentary switch on MS1 input

to change memories. Using this mode causes the part to start

in memory A, and whenever the button is pressed, the next

valid memory is loaded. When the user is in the last valid

memory, a button press causes memory A to be loaded.

Thus, the possible selection sequences are:

• If 4 valid memories: ABCDABCDA…

• If 3 valid memories: ABCABCA…

• If 2 valid memories: ABABA…

• If 1 valid memory: AAA…

Mode 2: Momentary Switch on MS1, Static Switch on

MS2 (D−only, Jump to Last Memory)

This mode uses a static switch on MS2 and a momentary

switch on MS1 to change memories. It can be used to support

the Automatic Telecoil feature, see section Automatic

Telecoil.

If the static switch on MS2 is OPEN, the part starts in

memory A and is controlled by the momentary switch on

MS1 as described in section Momentary Switch on MS1,

with the exception that memory D is not used. If the static

switch on MS2 is set to CLOSED, the part automatically

jumps to memory D (occurs on startup or during normal

operation). In this setup, the state of the momentary switch

on MS1 is ignored. When MS2 is set to OPEN, the part loads

in the memory that was active prior to jumping to memory

D.

The possible memory selection sequences are:

If MS2 = OPEN and there are four valid memories, MS1

selects: ABCABCA…

If MS2 = OPEN and there are three valid memories, MS1

selects: ABABA…

If MS2 = OPEN and there is one valid memory: A

If MS2 = CLOSED: D

Mode 3: Static Switch on MS1 and MS2

This mode uses two static switches to change memories.

In this mode, it is possible to jump from any memory to any

other memory by changing the state of both switches. If the

two switches are changed one after the other, the part

www.onsemi.com

10

Page 11

RHYTHM SB3231

transitions to an intermediate memory before reaching the

final memory. The part starts in whatever memory the

switches are selecting. If a memory is invalid, the part

defaults to memory A.

Table 6. STATIC SWITCH TRUTH TABLE:

D−ONLY DISABLED

State (MS1/MS2) Selected Memory

OPEN OPEN Memory A

CLOSED OPEN Memory B

OPEN CLOSED Memory C

CLOSED CLOSED Memory D

Mode 4: Static Switch on MS1, Static Switch on MS2

(D−Only, Jump to Last Memory)

This mode uses two static switches to change memories.

Similar to the behaviour described in the Static Switch on

MS1 and MS2 section, this mode will switch to memory D

if the static switch on MS2 is HIGH (the state of the switch

on MS1 is ignored). The mode, however, supports

a maximum of three memories (even if four valid memories

are programmed). This mode can be used to support the

Automatic Telecoil feature (see the Automatic Telecoil

section).

In this mode, it is possible to jump from any memory to

any other memory by changing the state of both switches. If

the two switches are changed one after the other, the part

transitions to an intermediate memory before reaching the

final memory.

The part starts in whatever memory the switches are

selecting. If a memory is invalid, the part defaults to

memory A.

Table 7. STATIC SWITCH TRUTH TABLE:

D−ONLY ENABLED; (EXAMPLE WITH THREE VALID

MEMORIES)

State (MS1/MS2) Selected Memory

OPEN OPEN Memory A

CLOSED OPEN Memory B

X CLOSED Memory D

Rocker Switch Support

The device supports connection of a rocker switch to the

digital volume control interface that can perform volume

control (VC) adjustments and/or memory selection (MS).

There are three modes of operation:

• Digital Volume Control Mode

• Momentary Memory Select Mode

• Mixed Mode (VC and MS)

In Digital VC mode, the rocker switch provides the digital

volume control functionality described in this section.

In Momentary Memory Select mode, the rocker switch

allows cycling through the memory profiles in both

directions. An “up” switch closure indicates a program

advance to the next higher numbered memory and “down”

switch closures indicates a program retreat to the next lower

numbered memory. In this mode, volume control is only

available through software control.

In Mixed Mode, operation of the switch as a volume

control or memory select is governed by the time duration

of the switch closure: either short or long. The

discrimination of short and long pulses is set by

a programmable, time−threshold value, from 1 s to 5 s in 1 s

increments. An additional programmable parameter

determines whether the short pulses refer to volume−control

operation or memory−select operation.

If long pulses control memory select operation, the

memory change is initiated once the switch is held for the

long pulse period without requiring the switch to be

released. In Digital VC mode or Momentary Memory Select

mode, the action takes place after the switch is released.

AGC−O

The AGC−O module is an output limiting circuit with

a fixed compression ratio of ∞ : 1. The limiting level is

programmable as a level measured in dB from full scale. The

maximum output of the device is 0 dBFS.

The AGC−O module has its own level detector, with

programmable attack and release time constants.

Graphic Equalizer

Rhythm SB3231 has a 8−band graphic equalizer. Each

band provides up to 31 dB of gain adjustment in 1 dB

increments.

Biquadratic Filters

Additional frequency shaping can be achieved by

configuring generic biquad filters. The transfer function for

each of the biquad filters is as follows:

H(z) +

b0 ) b1 z

*1

) b2 z

1 ) a1 z*1) a2 z

*2

*2

NOTE: The a0 coefficient is hard−wired to always be

‘1’. The coefficients are each 16 bits in length

and formatted as one sign bit, one integer bit and

14 fractional bits. This maps onto a decimal

range of −2.0 to 2.0 before quantization (−32767

to 32767 after quantization).

Thus, before quantization, the floating−point coefficients

must be in the range −2.0 ≤ x < 2.0 and quantized with the

function:

round(x 2

14

)

After designing a filter, the quantized coefficients can be

entered into the PreBiquads or PostBiquads tab in the

Interactive Data Sheet. The coefficients b0, b1, b2, a1, and

a2 are as defined in the transfer function above. The

parameters meta0 and meta1 do not have any effect on the

signal processing, but can be used to store additional

information related to the associated biquad.

www.onsemi.com

11

Page 12

RHYTHM SB3231

The underlying code in the product components

automatically checks all of the filters in the system for

stability (i.e., the poles have to be within the unit circle)

before updating the graphs on the screen or programming

the coefficients into the hybrid. If the Interactive Data Sheet

receives an exception from the underlying stability checking

code, it automatically disables the biquad being modified

and displays a warning message. When the filter is made

stable again, it can be re−enabled.

Also note that in some configurations, some of these

filters may be used by the product component for

microphone/telecoil compensation, low−frequency EQ, etc.

If this is the case, the coefficients entered by the user into

IDS are ignored and the filter designed by the software is

programmed instead. For more information on filter design

refer to the Biquad Filters In PARAGON

®

Digital Hybrid

information note.

Tinnitus Treatment Noise

The Tinnitus Treatment noise is generated using white

noise generator hardware and shaping the generated noise

using four 2

nd

order biquadratic filters. The filter parameters

are the same coefficients as those presented in the

Biquadratic Filters section.

The Tinnitus Treatment noise can be added into the signal

path at two possible locations: before the VC (before the

AGC−O, but compensated for the Wideband Gain) or after

the VC (between the last generic biquad and the Cross

Fader).

If the noise is injected before the VC and the audio path

is also enabled, the device can be set up to either have both

the audio path and noise adjust via the VC, or to have only

the noise adjust via the VC (see Table 8). If the noise in

injected after the VC, it is not affected by VC changes.

Table 8. NOISE INSERTION MODES

Noise Insertion Modes VC Controls Noise Injected

Off Audio Off

Pre VC Audio + Noise Pre VC

Post VC Audio Post VC

Noise only Pre VC Noise Pre VC

Noise only Post VC − Post VC

Pre VC with Noise Noise Pre VC

EVOKE Acoustic Indicators

Ten Acoustic Indicators are available for indicating

events. Each indicator is fixed to a particular event. Any

event can have its assigned indicator enabled or disabled

although not always independently. Individual

enable/disable control is provided for the following event or

group of events:

• Power on reset (POR)

• Four memory selects

• Volume Up and Volume Down

• Volume Max and Volume Min

• Low Battery

Each Acoustic Indicator is made up of up to four faded

tones. A faded tone exhibits a nominal 32 ms fade−in and

fade−out transition time. The duration of an Acoustic

Indicator is configurable, with a maximum value of 6.35

seconds.

EVOKE Acoustic Indicators can be programmed as

output referred or input referred (prior to the filter bank).

Power Management

Rhythm SB3231 has three user−selectable power

management schemes to ensure the hearing aid turns off

gracefully at the end of battery life. Shallow reset, Deep reset

and Advanced Reset mode. It also contains a programmable

power on reset delay function.

Power On Reset Delay

The programmable POR delay controls the amount of

time between power being connected to the hybrid and the

audio output being enabled. This gives the user time to

properly insert the hearing aid before the audio starts,

avoiding the temporary feedback that can occur while the

device is being inserted. During the delay period,

momentary button presses are ignored.

Power Management Functionality

As the voltage on the hearing aid battery decreases, an

audible warning is given to the user indicating the battery

life is low. In addition to this audible warning, the hearing

aid takes other steps to ensure proper operation given the

weak supply. The exact hearing aid behaviour in low supply

conditions depends on the selected POR mode. The hearing

aid has three POR modes:

• Shallow Reset Mode

• Deep Reset Mode

• Advanced Mode

Shallow Reset Mode

In Shallow Reset mode, the hearing aid will operate

normally when the battery is above 0.95 V. Once the supply

voltage drops below 0.95 V the audio will be muted and

remain in that state until the supply voltage rises above

1.1 V. Once the supply voltage drops below the control logic

ramp down voltage, the device will undergo a hardware

reset. At this point, the device will remain off until the supply

voltage returns to 1.1 V. When the supply voltage is below

the control logic voltage, but above 0.6 V and rises above the

1.1 V turn on threshold, the device will activate its output

and operate from the memory that was active prior to reset.

If the supply voltage drops below 0.6 V, and rises above the

1.1 V turn on threshold, the device will reinitialize, activate

its output and operate from memory A.

www.onsemi.com

12

Page 13

RHYTHM SB3231

Deep Reset Mode

In Deep Reset mode, the hearing aid will operate normally

when the battery is above 0.95 V. Once the supply voltage

drops below 0.95 V the audio will be muted. The device

remains in this state until the supply voltage drops below the

hardware reset voltage of 0.6 V. When this occurs, the

device will load memory A and operate normally after the

supply voltage goes above 1.1 V.

Advanced Reset Mode

Advanced Reset Mode on Rhythm SB3231 is a more

sophisticated power management scheme than shallow and

deep reset modes. This mode attempts to maximize the

device’s usable battery life by reducing the gain to stabilize

the supply based on the instantaneous and average supply

voltage levels. Instantaneous supply fluctuations below

0.95 V can trigger up to two 3 dB, instantaneous gain

reductions. Average supply drops below 0.95 V can trigger

up to eighteen, 1 dB average gain reductions.

While the average supply voltage is above 0.95 V, an

instantaneous supply voltage fluctuation below 0.95 V will

trigger an immediate 3 dB gain reduction. After the 3 dB

gain reduction has been applied, the advanced reset model

holds off checking the instantaneous voltage level for

a monitoring period of 30 second in order to allow the

voltage level to stabilize. If after the stabilization time the

instantaneous voltage drops a second time below 0.95 V

during the next monitoring period, the gain will be reduced

an additional 3 dB for a 6 dB total reduction and a 30 second

stabilization time is activated. The advanced reset mode

continues to monitor the instantaneous voltage levels over

30 second monitoring periods. If the instantaneous voltage

remains above 1.1 V during that monitoring period, the gain

will be restored to the original setting regardless of whether

one or two gain reductions are applied. If two gain

reductions are applied and the instantaneous voltage level

remains above 1.0 V for a monitoring period, the gain will

be restored to a 3 dB reduction.

Should the average supply voltage drop below 0.95 V, the

device will then reduce the gain by 1 dB every 10 seconds

until either the average supply voltage rises above 0.95 V or

a total of 18 average gain reductions have been applied, at

which point the audio path will be muted. If the average

supply voltage returns to a level above 1.1 V, the audio path

will first be un−muted, if required. The gain will then be

increased by 1 dB every 10 seconds until either the average

supply voltage drops below 1.1 V, or all average gain

reductions have been removed. No action is taken while the

average supply voltage resides between 0.95 V and 1.1 V.

NOTE: Instantaneous and average gain reductions are

adjusted independently.

When the instantaneous voltage falls below the hardware

shutdown voltage of 0.6 V, the device will undergo

a hardware reset. When it turns back on because the voltage

has risen above the turn−on threshold, it will behave the

same as it would in shallow reset mode.

Low Battery Notification

Notification of the low battery condition via an acoustic

indicator is optionally performed when the battery voltage

drops below a configurable low battery notification

threshold. The low battery indicator is repeated every five

minutes until the device shuts down.

SDA and I2C Communication

Rhythm SB3231 can be programmed using the SDA or

2

I

C protocol. During parameter changes, the main audio

signal path of the hybrid is temporarily muted using the

memory switch fader to avoid the generation of disturbing

audio transients. Once the changes are complete, the main

audio path is reactivated. Any changes made during

programming are lost at power−off unless they are explicitly

burned to EEPROM memory.

Improvements have been made to the ARK software,

resulting in improved communication speed. Certain

parameters in ARKonline

®

can be selected to reduce the

number of pages that need to be read out. In SDA mode,

Rhythm SB3231 is programmed via the SDA pin using

industry standard programming boxes. I

2

C mode is

a two−wire interface which uses the SDA pin for

bidirectional data and CLK as the interface clock input. I

2

programming support is available on the HiPro (serial or

USB versions) and ON Semiconductor’s DSP

Programmer 3.0.

Input Connection and Layout Considerations

It is recommended to connect unused audio input pins

directly to MGND to minimize the possibility of noise

pickup. Inputs are internally AC coupled, so there is no

additional leakage current when inputs are connected

directly to ground.

In order to further minimize noise at the inputs the following

guidelines are recommended:

• MGND is used as reference ground plane for input

signals. All input components should be grounded to

MGND. This ground plane should be isolated from all

other ground connections in the system.

• Keep the input traces as short as possible and avoid

routing traces near high noise sources such as the

OUT+ and OUT− pins

• Star ground input component grounds to the MGND

connection.

Unused trimmer inputs should also be connected to GND.

C

www.onsemi.com

13

Page 14

RHYTHM SB3231

ORDERING INFORMATION

Device Package Shipping

SB3231−E1 25 Pad Hybrid

Case 127DN

SB3231−E1−T 25 Pad Hybrid

Case 127DN

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

25 Units / Bubble Pack

250 Units / Tape & Reel

Hybrid Jig Ordering Information

To order a Hybrid Jig Evaluation Board for Rhythm SB3231 contact your Sales Account Manager or FAE and use part

number SA3405GEVB.

†

www.onsemi.com

14

Page 15

Table 9. PAD POSITION AND DIMENSIONS

Pad Position Pad Dimensions

Pad No.

1 0 0 20 33

2 −27 0 20 33

3 −54 −5 20 23

4 −81 −5 20 23

5 −108 −5 20 23

6 −135 −5 20 23

7 −162 −5 20 23

8 −189 0 20 33

9 −189 42 20 23

10 −189 85 20 23

11 −162 85 20 23

12 −135 85 20 23

13 −108 85 20 23

14 −81 85 20 23

15 −54 85 20 23

16 −27 85 20 23

17 0 85 20 23

18 0 42 20 23

19 −27 42 20 23

20 −54 42 20 23

21 −81 42 20 23

22 −108 42 20 23

23 −135 42 20 23

24 −162 26.5 18 12

25 −162 53.5 18 12

X Y Xdim (mil) Ydim (mil)

RHYTHM SB3231

PAD LOCATIONS

www.onsemi.com

15

Page 16

Table 9. PAD POSITION AND DIMENSIONS

Pad No. X Y Xdim (mm) Ydim (mm)

1 0 0 0.508 0.838

2 −0.686 0 0.508 0.838

3 −1.372 −0.127 0.508 0.584

4 −2.057 −0.127 0.508 0.584

5 −2.743 −0.127 0.508 0.584

6 −3.429 −0.127 0.508 0.584

7 −4.115 −0.127 0.508 0.584

8 −4.801 0 0.508 0.838

9 −4.801 1.067 0.508 0.584

10 −4.801 2.159 0.508 0.584

11 −4.115 2.159 0.508 0.584

12 −3.429 2.159 0.508 0.584

13 −2.743 2.159 0.508 0.584

14 −2.057 2.159 0.508 0.584

15 −1.372 2.159 0.508 0.584

16 −0.686 2.159 0.508 0.584

17 0 2.159 0.508 0.584

18 0 1.067 0.508 0.584

19 −0.686 1.067 0.508 0.584

20 −1.372 1.067 0.508 0.584

21 −2.057 1.067 0.508 0.584

22 −2.743 1.067 0.508 0.584

23 −3.429 1.067 0.508 0.584

24 −4.115 0.673 0.457 0.305

25 −4.115 1.359 0.457 0.305

RHYTHM SB3231

RHYTHM is a trademarks of Semiconductor Components Industries, LLC.

www.onsemi.com

16

Page 17

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 2:1

SIP25, 5.59x3.18

CASE 127DN

ISSUE A

DATE 21 JUL 2020

GENERIC

MARKING DIAGRAM*

XXXXXXXXXX

ZZZZZZ

XX = Specific Device Code

ZZ = Lot Traceability

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2018

98AON89696F

SIP25, 5.59x3.18

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

not follow the Generic Marking.

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

Page 18

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...