Page 1

ESD Protection Diode

Dual Line Automotive Bus Protector

NUP2125, SZNUP2125

The SZ/NUP2125 has been designed to protect both CAN and LIN

transceivers from ESD and other harmful transient voltage events.

This device provides bidirectional protection for each data line with a

single compact SC−70 (SOT−323) package, giving the system

designer a low cost option for improving system reliability and

meeting stringent EMI requirements.

Features

• 200 W Peak Power Dissipation per Line (8/20 ms Waveform)

• Diode Capacitance Matching

• Low Reverse Leakage Current (< 100 nA)

• IEC Compatibility: − IEC 61000−4−2 (ESD): Level 4

− IEC 61000−4−4 (EFT): 50 A – 5/50 ns

− IEC 61000−4−5 (Lighting) 3.0 A (8/20 ms)

• ISO 7637−1, Nonrepetitive EMI Surge Pulse 2, 8.0 A (1/50 ms)

• ISO 7637−3, Repetitive Electrical Fast Transient (EFT)

EMI Surge Pulses, 50 A (5/50 ns)

• Flammability Rating UL 94 V−0

• SZ Prefix for Automotive and Other Applications Requiring Unique

Site and Control Change Requirements; AEC−Q101 Qualified and

PPAP Capable

• These are Pb−Free Devices

Applications

• Automotive Networks

♦ CAN / CAN−FD

♦ Low and High−Speed CAN

♦ Fault Tolerant CAN

♦ LIN

www.onsemi.com

MARKING

DIAGRAM

SC−70

CASE 419

1

25 = Specific Device Code

M = Date Code

G = Pb−Free Package

(Note: Microdot may be in either location)

PIN 1

PIN 2

CAN_H / Single Wire LIN

CAN

Transceiver

CAN_L

CAN Bus

25MG

G

PIN 3

NUP2125

© Semiconductor Components Industries, LLC, 2015

December, 2020 − Rev. 7

ORDERING INFORMATION

See detailed ordering and shipping information on page 2 of

this data sheet.

1 Publication Order Number:

NUP2125/D

Page 2

NUP2125, SZNUP2125

MAXIMUM RATINGS (T

Symbol

PPK

ESD Human Body Model (HBM)

Peak Power Dissipation, 8/20 ms Double Exponential Waveform (Note 1)

T

Operating Junction Temperature Range −55 to 150 °C

J

T

Storage Temperature Range −55 to 150 °C

J

T

Lead Solder Temperature (10 s) 260 °C

L

Machine Model (MM)

IEC 61000−4−2 Contact

IEC 61000−4−2 Air

ISO 10605 150 pF / 2 kW Contact

ISO 10605 330 pF / 2 kW Contact

= 25°C, unless otherwise specified)

J

Rating Value Unit

200 W

±8.0

±1.6

±30

±30

±30

±30

kV

kV

kV

kV

kV

kV

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. Non−repetitive current pulse per Figure 1.

ELECTRICAL CHARACTERISTICS (T

Symbol

V

RWM

V

BR

I

R

V

C

V

C

I

PP

C

J

Reverse Working Voltage (Note 2) 24 − − V

Breakdown Voltage IT = 1 mA (Note 3) 27 28.5 32 V

Reverse Leakage Current V

Clamping Voltage

Clamping Voltage

Maximum Peak Pulse Current

Capacitance

Parameter Test Conditions Min Typ Max Unit

= 25°C, unless otherwise specified)

J

= 24 V − 15 100 nA

RWM

IPP = 1 A (8/20 ms Waveform)

− 33.4 36.6 V

(Note 4)

IPP = 3 A (8/20 ms Waveform)

− 44 50 V

(Note 4)

8/20 ms Waveform (Note 4)

− − 3.0 A

VR = 0 V, f = 1 MHz (Line to GND) − 7.0 10 pF

VR = 5 V, f = 1 MHz (Line to GND) − 4.5 6.0 pF

DC

VR = 5 V, f = 1 MHz (Line to GND),

T

= +150°C

A

Diode Capacitance Matching VR = 0 V, 5 MHz (Note 5) − 0.26 2 %

− 5.0 − pF

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

2. Surge protection devices are normally selected according to the working peak reverse voltage (V

than the DC or continuous peak operating voltage level.

is measured at pulse test current IT.

3. V

BR

4. Pulse waveform per Figure 1.

5. DC is the percentage difference between C

table.

of lines 1 and 2 measured according to the test conditions given in the electrical characteristics

J

), which should be equal or greater

RWM

ORDERING INFORMATION

Device Package Shipping

NUP2125WTT1G

SZNUP2125WTT1G*

NUP2125WTT3G

SZNUP2125WTT3G*

SC−70

(Pb−Free)

3000 / Tape & Reel

10000 / Tape & Reel

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

*SZ Prefix for Automotive and Other Applications Requiring Unique Site and Control Change Requirements; AEC−Q101 Qualified and PPAP

Capable.

†

www.onsemi.com

2

Page 3

NUP2125, SZNUP2125

TYPICAL PERFORMANCE CURVES

(TJ = 25°C unless otherwise noted)

110

100

90

80

70

60

50

40

30

20

% OF PEAK PULSE CURRENT

10

0

0 5 15 25

c−t

td = IPP/2

10 20

t, TIME (ms)

Figure 1. Pulse Waveform, 8 × 20 ms

9

8

125°C

7

6

5

4

C, CAPACITANCE (pF)

3

2

05

25°C

10 15 20 25

V

, REVERSE VOLTAGE (V)

R

Figure 3. Typical Junction Capacitance vs

Reverse Voltage

WAVEFORM

PARAMETERS

= 8 ms

t

r

t

= 20 ms

d

3.5

3.0

2.5

2.0

1.5

1.0

, PEAK PULSE CURRENT (A)

PP

I

0.5

30

0.0

30 35 45 50

Figure 2. Clamping Voltage vs Peak Pulse Current

50

45

40

35

30

25

, (mA)

T

I

20

15

10

5

0

20 22 24 26 28 30 32 34

Figure 4. VBR versus IT Characteristics

40

, CLAMPING VOLTAGE (V)

V

C

25°C

TA = −55°C

V

, VOLTAGE (V)

BR

65°C

125°C

25

−55°C

20

15

10

5

, REVERSE BIAS VOLTAGE (V)

R

V

0

012345

+25°C

TA = +150°C

I

, LEAKAGE CURRENT (nA)

L

Figure 5. IR versus Temperature Characteristics

www.onsemi.com

120

100

80

60

40

20

PERCENT DERATING (%)

0

−60 −30 0 30 60 90 120 150 180

TEMPERATURE (°C)

Figure 6. Temperature Power Dissipation Derating

3

Page 4

NUP2125, SZNUP2125

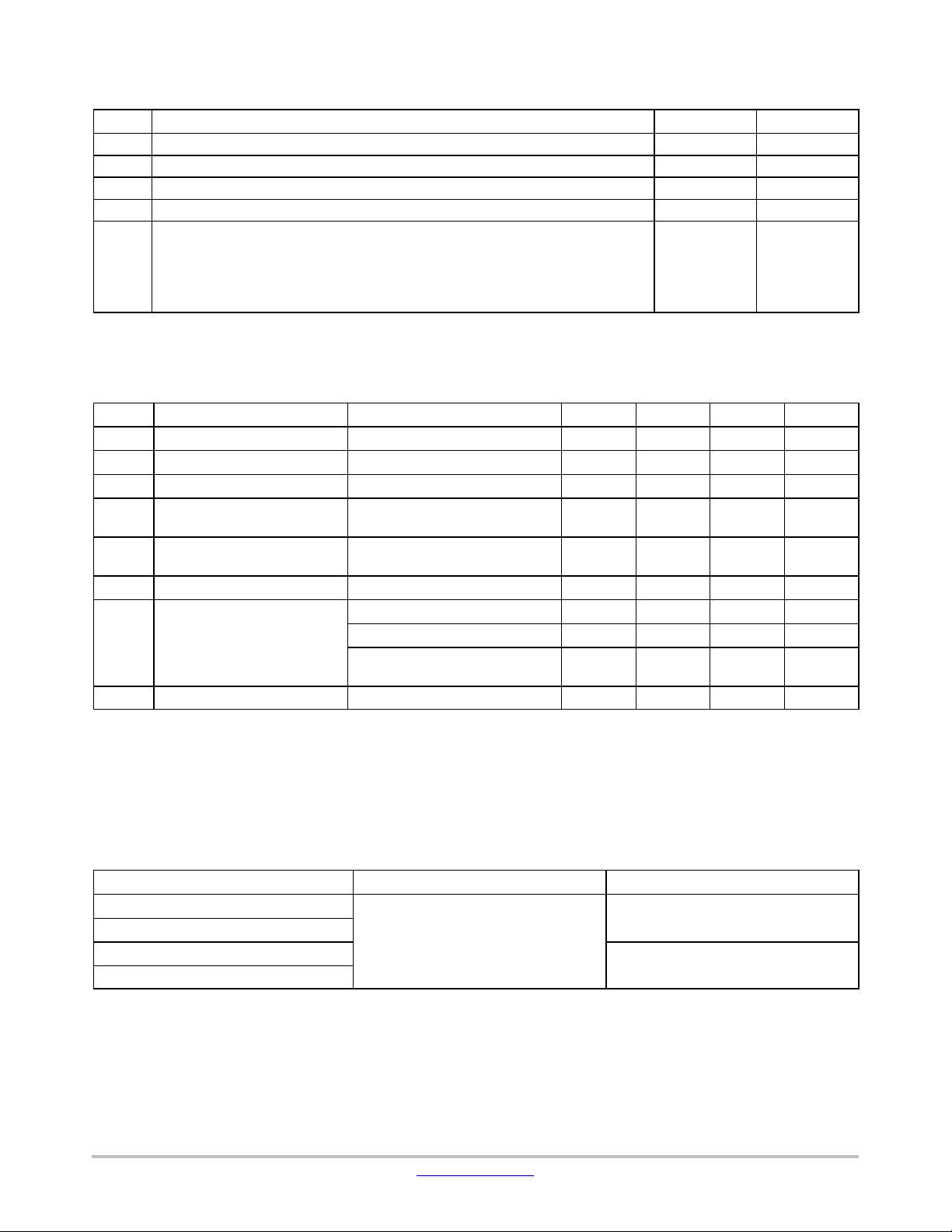

Surge Protection Diode Circuit

Surge protection diodes provide protection to a

transceiver by clamping a surge voltage to a safe level. Surge

protection diodes have high impedance below and low

impedance above their breakdown voltage. A surge

protection Zener diode has its junction optimized to absorb

the high peak energy of a transient event, while a standard

Zener diode is designed and specified to clamp a

steady state voltage.

Figure 7 provides an example of a dual bidirectional surge

protection diode array that can be used for protection with

the high−speed CAN network. The bidirectional array is

created from four identical Zener TVS diodes. The

clamping voltage of the composite device is equal to the

breakdown voltage of the diode that is reversed biased, plus

the diode drop of the second diode that is forwarded biased.

CAN_H

CAN

Transceiver

Figure 7. High−Speed and Fault Tolerant CAN Surge

CAN_L

Protection Circuit

CAN Bus

NUP2125

www.onsemi.com

4

Page 5

0.05 (0.002)

D

e1

3

H

E

12

e

A1

NUP2125, SZNUP2125

PACKAGE DIMENSIONS

SC−70 (SOT−323)

CASE 419−04

ISSUE N

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

DIMAMIN NOM MAX MIN

E

b

A

A2

A1 0.00 0.05 0.10 0.000

A2 0.70 REF

b 0.30 0.35 0.40 0.012

c 0.10 0.18 0.25 0.004

D 1.80 2.10 2.20 0.071

E 1.15 1.24 1.35 0.045

e 1.20 1.30 1.40 0.047

e1

L

H

E

STYLE 11:

c

PIN 1. CATHODE

MILLIMETERS

0.80 0.90 1.00 0.032

0.65 BSC

0.38

0.20 0.56

2.00 2.10 2.40 0.079 0.083 0.095

2. CATHODE

3. CATHODE

L

SOLDERING FOOTPRINT*

0.65

0.65

0.025

0.025

INCHES

NOM MAX

0.035 0.040

0.002 0.004

0.028 REF

0.014 0.016

0.007 0.010

0.083 0.087

0.049 0.053

0.051 0.055

0.026 BSC

0.015

0.008 0.022

1.9

0.075

0.9

0.035

0.7

0.028

SCALE 10:1

mm

ǒ

inches

Ǔ

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

Honeywell and SDS are registered trademarks of Honeywell International Inc.

DeviceNet is a trademark of Rockwell Automation.

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

◊

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

www.onsemi.com

5

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

NUP2125/D

Loading...

Loading...