Page 1

NSS35200MR6T1G

35 V, 5 A, Low V

CE(sat)

PNP Transistor

ON Semiconductor’s e2PowerEdge family of low V

transistors are miniature surface mount devices featuring ultra low

saturation voltage (V

) and high current gain capability. These

CE(sat)

are designed for use in low voltage, high speed switching applications

where affordable efficient energy control is important.

Typical application are DC−DC converters and power management

in portable and battery powered products such as cellular and cordless

phones, PDAs, computers, printers, digital cameras and MP3 players.

Other applications are low voltage motor controls in mass storage

products such as disc drives and tape drives. In the automotive

industry they can be used in air bag deployment and in the instrument

cluster. The high current gain allows e

2

PowerEdge devices to be

driven directly from PMU’s control outputs, and the Linear Gain

(Beta) makes them ideal components in analog amplifiers.

Features

• S Prefix for Automotive and Other Applications Requiring Unique

Site and Control Change Requirements; AEC−Q101 Qualified and

PPAP Capable

• These Devices are Pb−Free and are RoHS Compliant*

CE(sat)

http://onsemi.com

35 VOLTS

5.0 AMPS

PNP LOW V

CE(sat)

EQUIVALENT R

6

CASE 318G

3

BASE

TRANSISTOR

DS(on)

4

5

3

2

1

TSOP−6

STYLE 6

COLLECTOR

1, 2, 5, 6

100 mW

MAXIMUM RATINGS (T

Rating Symbol Max Unit

Collector-Emitter Voltage V

Collector-Base Voltage V

Emitter-Base Voltage V

Collector Current − Continuous I

Collector Current − Peak I

Electrostatic Discharge ESD HBM Class 3

Stresses exceeding Maximum Ratings may damage the device. Maximum

Ratings are stress ratings only. Functional operation above the Recommended

Operating Conditions is not implied. Extended exposure to stresses above the

Recommended Operating Conditions may affect device reliability.

*For additional information on our Pb−Free strategy and soldering details, please

download the ON Semiconductor Soldering and Mounting Techniques

Reference Manual, SOLDERRM/D.

= 25°C)

A

CEO

CBO

EBO

C

CM

−35 Vdc

−55 Vdc

−5.0 Vdc

−2.0 Adc

−5.0 A

MM Class C

4

EMITTER

MARKING DIAGRAM

M G

VS8

G

VS8 = Device Code

M = Date Code*

G = Pb−Free Package

(*Note: Microdot may be in either location)

*Date Code orientation may vary depending

upon manufacturing location.

ORDERING INFORMATION

Device

NSS35200MR6T1G TSOP−6

SNSS35200MR6T1G TSOP−6

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

Package Shipping

3,000 /

(Pb−Free)

(Pb−Free)

Tape & Reel

3,000 /

Tape & Reel

†

© Semiconductor Components Industries, LLC, 2013

September, 2013 − Rev. 5

1 Publication Order Number:

NSS35200MR6/D

Page 2

NSS35200MR6T1G

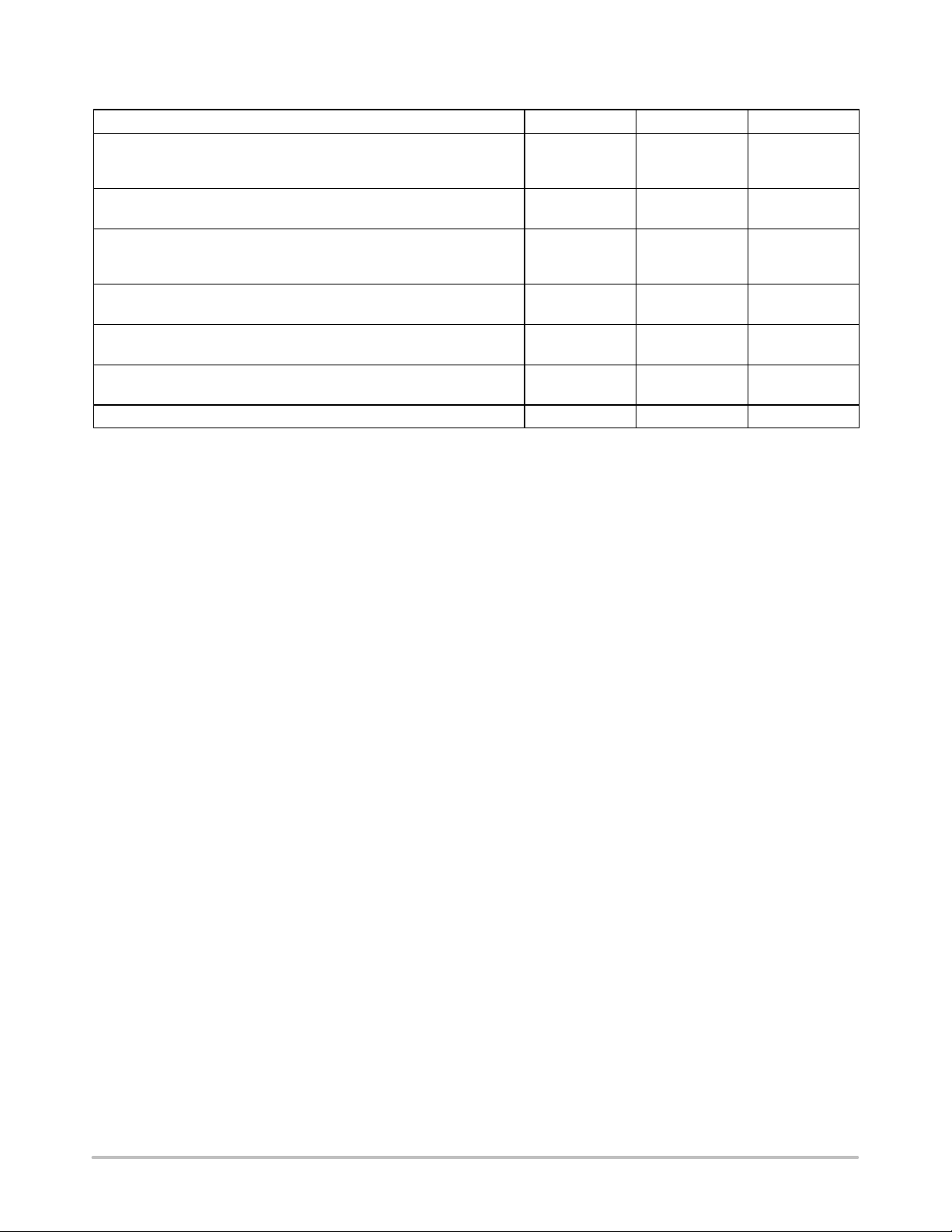

THERMAL CHARACTERISTICS

Characteristic Symbol Max Unit

Total Device Dissipation

T

= 25°C

A

Derate above 25°C

Thermal Resistance,

Junction−to−Ambient

Total Device Dissipation

T

= 25°C

A

Derate above 25°C

Thermal Resistance,

Junction−to−Ambient

Thermal Resistance,

Junction−to−Lead #1

Total Device Dissipation

(Single Pulse < 10 sec.)

Junction and Storage Temperature Range TJ, T

1. FR− 4 @ Minimum Pad.

2. FR− 4 @ 1.0 X 1.0 inch Pad.

3. Refer to Figure 8.

PD (Note 1)

R

q

JA

PD (Note 2)

R

q

JA

P

(Notes 2 & 3) 1.75

(Note 1)

(Note 2)

R

q

JL

Dsingle

stg

625

5.0

mW

mW/°C

°C/W

200

1.0

8.0

W

mW/°C

°C/W

120

°C/W

80

W

−55 to +150 °C

http://onsemi.com

2

Page 3

NSS35200MR6T1G

ELECTRICAL CHARACTERISTICS (T

Characteristic

= 25°C unless otherwise noted)

A

Symbol Min Typical Max Unit

OFF CHARACTERISTICS

Collector−Emitter Breakdown Voltage

(I

= −10 mAdc, IB = 0)

C

Collector−Base Breakdown Voltage

(I

= −0.1 mAdc, IE = 0)

C

Emitter−Base Breakdown Voltage

(I

= −0.1 mAdc, IC = 0)

E

Collector Cutoff Current

(VCB = −35 Vdc, IE = 0)

Collector−Emitter Cutoff Current

(V

= −35 Vdc)

CES

Emitter Cutoff Current

(V

= −4.0 Vdc)

EB

V

(BR)CEO

V

(BR)CBO

V

(BR)EBO

I

CBO

I

CES

I

EBO

−35 −45 −

−55 −65 −

−5.0 −7.0 −

− −0.03 −0.1

− −0.03 −0.1

− −0.01 −0.1

ON CHARACTERISTICS

DC Current Gain (Note 4)

(I

= −1.0 A, VCE = −1.5 V)

C

(IC = −1.5 A, VCE = −1.5 V)

(IC = −2.0 A, VCE = −3.0 V)

Collector−Emitter Saturation Voltage (Note 4)

(I

= −0.8 A, IB = −0.008 A)

C

(IC = −1.2 A, IB = −0.012 A)

(IC = −2.0 A, IB = −0.02 A)

Base −Emitter Saturation Voltage (Note 4)

(I

= −1.2 A, IB = −0.012 A)

C

Base −Emitter Turn−on Voltage (Note 4)

(I

= −2.0 A, VCE = −3.0 V)

C

Cutoff Frequency

(I

= −100 mA, VCE = −5.0 V, f = 100 MHz)

C

Input Capacitance (VEB = −0.5 V, f = 1.0 MHz) Cibo − 600 650 pF

Output Capacitance (VCB = −3.0 V, f = 1.0 MHz) Cobo − 85 100 pF

Turn−on Time (VCC = −10 V, IB1 = −100 mA, IC = −1 A, RL = 3 W)

Turn−off Time (VCC = −10 V, IB1 = IB2 = −100 mA, IC = 1 A, RL = 3 W)

4. Pulsed Condition: Pulse Width = 300 msec, Duty Cycle ≤ 2%.

h

V

CE(sat)

V

BE(sat)

V

BE(on)

FE

100

100

100

−

−

−

200

200

200

−0.125

−0.175

−0.260

−

400

−

−0.15

−0.20

−0.31

− −0.68 −0.85

− −0.81 −0.875

f

T

t

on

t

off

100 − −

− 35 − nS

− 225 − nS

Vdc

Vdc

Vdc

mAdc

mAdc

mAdc

V

V

V

MHz

http://onsemi.com

3

Page 4

NSS35200MR6T1G

1

IC/IB = 100

0.1

, COLLECTOR−EMITTER

SATURATION VOLTAGE (V)

CE(sat)

V

0.01

0.001 0.01 0.1 1 10

TA = −55°C

TA = 25°C

IC, COLLECTOR CURRENT (A) IC, COLLECTOR CURRENT (AMPS)

TA = 150°C

Figure 1. Collector Emitter Saturation Voltage

versus Collector Current

1000

TA = 150°C

TA = 25°C

TA = −55°C

100

, DC CURRENT GAIN

FE

h

10

0.001 0.01 0.1 1 10

IC, COLLECTOR CURRENT (A)

VCE = 1.5 V

Figure 3. DC Current Gain versus

Collector Current

0.25

IC/IB = 50

0.20

0.15

0.10

, COLLECTOR−EMITTER

0.05

SATURATION VOLTAGE (V)

CE(sat)

V

0

0.01

0.1 1.00.001

Figure 2. Collector Emitter Saturation Voltage

versus Collector Current

1.1

1

0.9

0.8

0.7

0.6

0.5

, BASE−EMITTER

0.4

0.3

BE(sat)

V

0.2

SATURATION VOLTAGE (V)

0.1

TA = −55°C

TA = 25°C

TA = 150°C

0

0.001 0.01 0.1 1 10

I

, COLLECTOR CURRENT (A)

C

Figure 4. Base Emitter Saturation Voltage

versus Collector Current

100°C

25°C

−55°C

IC/IB = 100

1.2

VCE = 3 V

1.1

1

0.9

TA = −55°C

0.8

0.7

TA = 25°C

0.6

0.5

0.4

, BASE−EMITTER ON VOLTAGE (V)

BE(ON)

V

TA = 150°C

0.3

0.2

0.001 0.01 0.1 1 10

IC, COLLECTOR CURRENT (A) VR, REVERSE VOLTAGE (V)

Figure 5. Base Emitter Turn−On Voltage

versus Collector Current

1000

100

C, CAPACITANCE (pF)

10

0.1 1 10

http://onsemi.com

4

C

ibo

C

obo

Figure 6. Capacitance

Page 5

NSS35200MR6T1G

1.0

0.1

RESISTANCE

0.01

D = 0.5

0.2

0.1

0.05

0.02

0.01

10

1.0

0.1

, COLLECTOR CURRENT (AMPS)

C

I

SINGLE PULSE AT T

0.01

0.1 1.0

1 ms10 ms100 ms1 s

DC

= 25°C

amb

10 100

V

, COLLECTOR-EMITTER VOLTAGE (VOLTS)

CE

Figure 7. Safe Operating Area

100 ms

r(t), NORMALIZED TRANSIENT THERMAL

0.001

SINGLE PULSE

0.00001 0.01 0.1 1.0

0.0001 0.001

t, TIME (sec)

Figure 8. Normalized Thermal Response

10

100 1000

http://onsemi.com

5

Page 6

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

1

SCALE 2:1

D

456

E1

NOTE 5

0.05

A1

23

1

e

E

b

A

DETAIL Z

c

CASE 318G−02

H

L

M

DETAIL Z

TSOP−6

ISSUE V

L2

GAUGE

PLANE

SEATING

C

PLANE

DATE 12 JUN 2012

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. MAXIMUM LEAD THICKNESS INCLUDES LEAD FINISH. MINIMUM

LEAD THICKNESS IS THE MINIMUM THICKNESS OF BASE MATERIAL.

4. DIMENSIONS D AND E1 DO NOT INCLUDE MOLD FLASH,

PROTRUSIONS, OR GATE BURRS. MOLD FLASH, PROTRUSIONS, OR

GATE BURRS SHALL NOT EXCEED 0.15 PER SIDE. DIMENSIONS D

AND E1 ARE DETERMINED AT DATUM H.

5. PIN ONE INDICATOR MUST BE LOCATED IN THE INDICATED ZONE.

DIMAMIN NOM MAX

A1 0.01 0.06 0.10

b 0.25 0.38 0.50

c 0.10 0.18 0.26

D 2.90 3.00 3.10

E 2.50 2.75 3.00

E1

e 0.85 0.95 1.05

L 0.20 0.40 0.60

L2

M

MILLIMETERS

0.90 1.00 1.10

1.30 1.50 1.70

0.25 BSC

0° 10°

−

STYLE 1:

PIN 1. DRAIN

2. DRAIN

3. GATE

4. SOURCE

5. DRAIN

6. DRAIN

STYLE 7:

PIN 1. COLLECTOR

2. COLLECTOR

3. BASE

4. N/C

5. COLLECTOR

6. EMITTER

STYLE 13:

PIN 1. GATE 1

2. SOURCE 2

3. GATE 2

4. DRAIN 2

5. SOURCE 1

6. DRAIN 1

STYLE 2:

PIN 1. EMITTER 2

2. BASE 1

3. COLLECTOR 1

4. EMITTER 1

5. BASE 2

6. COLLECTOR 2

STYLE 8:

PIN 1. Vbus

2. D(in)

3. D(in)+

4. D(out)+

5. D(out)

6. GND

STYLE 14:

PIN 1. ANODE

2. SOURCE

3. GATE

4. CATHODE/DRAIN

5. CATHODE/DRAIN

6. CATHODE/DRAIN

STYLE 3:

PIN 1. ENABLE

2. N/C

3. R BOOST

4. Vz

5. V in

6. V out

STYLE 9:

PIN 1. LOW VOLTAGE GATE

2. DRAIN

3. SOURCE

4. DRAIN

5. DRAIN

6. HIGH VOLTAGE GATE

STYLE 15:

PIN 1. ANODE

2. SOURCE

3. GATE

4. DRAIN

5. N/C

6. CATHODE

RECOMMENDED

SOLDERING FOOTPRINT*

6X

0.60

3.20

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

98ASB14888C

TSOP−6

6X

0.95

0.95

PITCH

STYLE 4:

PIN 1. N/C

2. V in

3. NOT USED

4. GROUND

5. ENABLE

6. LOAD

STYLE 10:

PIN 1. D(OUT)+

2. GND

3. D(OUT)−

4. D(IN)−

5. VBUS

6. D(IN)+

STYLE 16:

PIN 1. ANODE/CATHODE

2. BASE

3. EMITTER

4. COLLECTOR

5. ANODE

6. CATHODE

STYLE 5:

PIN 1. EMITTER 2

2. BASE 2

3. COLLECTOR 1

4. EMITTER 1

5. BASE 1

6. COLLECTOR 2

STYLE 11:

PIN 1. SOURCE 1

2. DRAIN 2

3. DRAIN 2

4. SOURCE 2

5. GATE 1

6. DRAIN 1/GATE 2

STYLE 17:

PIN 1. EMITTER

2. BASE

3. ANODE/CATHODE

4. ANODE

5. CATHODE

6. COLLECTOR

STYLE 6:

PIN 1. COLLECTOR

2. COLLECTOR

3. BASE

4. EMITTER

5. COLLECTOR

6. COLLECTOR

STYLE 12:

PIN 1. I/O

2. GROUND

3. I/O

4. I/O

5. VCC

6. I/O

GENERIC

MARKING DIAGRAM*

XXXAYWG

G

1

XXX = Specific Device Code

A =Assembly Location

Y = Year

XXX = Specific Device Code

M = Date Code

G = Pb−Free Package

W = Work Week

G = Pb−Free Package

*This information is generic. Please refer to device data sheet

for actual part marking. Pb−Free indicator, “G” or microdot “

G”, may or may not be present.

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

XXX MG

G

1

STANDARDIC

PAGE 1 OF 1

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

Page 7

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...