Page 1

Voltage-Level Translator,

2

Dual Bidirectional I

C-bus

and SMBus

NLA9306

The NLA9306 is a dual bidirectional I2C−bus and SMBus

voltage−level translator with an enable (EN) input.

www.onsemi.com

Features

• 2−bit Bidirectional Translator for SDA and SCL Lines in

2

Mixed−Mode I

• Standard−Mode, Fast−Mode, and Fast−Mode Plus I

C−Bus Applications

2

C−Bus and

SMBus Compatible

• Less Than 1.5 ns Maximum Propagation Delay to Accommodate

2

Standard−Mode and Fast−Mode I

C−Bus Devices and Multiple

Masters

• Allows Voltage Level Translation Between:

♦ 1.0 V V

1.2 V V

♦

♦

1.8 V V

2.5 V V

♦

3.3 V V

♦

and 1.8 V, 2.5 V, 3.3 V or 5 V V

ref(1)

and 1.8 V, 2.5 V, 3.3 V or 5 V V

ref(1)

and 3.3 V or 5 V V

ref(1)

ref(1)

ref(1)

and 5 V V

and 5 V V

bias(ref)(2)

bias(ref)(2)

bias(ref)(2)

bias(ref)(2)

bias(ref)(2)

• Provides Bidirectional Voltage Translation With No Direction Pin

• Low 3.5 W ON−State Connection Between Input and Output Ports

Provides Less Signal Distortion

• Open−Drain I

• 5 V Tolerant I

2

C−Bus I/O Ports (SCL1, SDA1, SCL2 and SDA2)

2

C−Bus I/O Ports to Support Mixed−Mode Signal

Operation

• High−Impedance SCL1, SDA1, SCL2 and SDA2 Pins for

EN = LOW

• Lock−Up Free Operation

• Flow Through Pinout for Ease of Printed−Circuit Board Trace

Routing

• Packages Offered:

♦ US8, UQFN8, UDFN8

• ESD Performance: 2000 V Human Body Model

• NLV Prefix for Automotive and Other Applications Requiring

Unique Site and Control Change Requirements; AEC−Q100

Qualified and PPAP Capable

• These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

MARKING

DIAGRAMS

8

US8

US SUFFIX

CASE 493

UQFN8

8

1

XXXX = Specific Device Code

A = Assembly Location

L = Lot Code

Y = Year

W = Work Week

M = Date Code

G = Pb−Free Package

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 9 of this data sheet.

MU SUFFIX

CASE 523AN

UDFN8

1.45 x 1.0

CASE 517BZ

XXXX

ALYW

1

1

XX MG

X M

1

© Semiconductor Components Industries, LLC, 2018

March, 2021 − Rev. 2

1 Publication Order Number:

NLA9306/D

Page 2

NLA9306

Function Description

The NLA9306 is a dual bidirectional I2C−bus and SMBus

voltage−level translator with an enable (EN) input, and is

operational from 1.0 V to 3.6 V (V

(V

bias(ref)(2)

).

) and 1.8 V to 5.5 V

ref(1)

The NLA9306 allows bidirectional voltage translations

between 1.0 V and 5 V without the use of a direction pin. The

low ON−state resistance (R

) of the switch allows

on

connections to be made with minimal propagation delay.

When EN is HIGH, the translator switch is on, and the SCL1

and SDA1 I/O are connected to the SCL2 and SDA2 I/O,

respectively, allowing bidirectional data flow between

ports. When EN is LOW, the translator switch is off, and a

high−impedance state exists between ports.

The NLA9306 is not a bus buffer that provides both level

translation and physical capacitance isolation to either side

of the bus when both sides are connected. The NLA9306

only isolates both sides when the device is disabled and

provides voltage level translation when active.

The NLA9306 can be used to run two buses, one at

400 kHz operating frequency and the other at 100 kHz

operating frequency. If the two buses are operating at

different frequencies, the 100 kHz bus must be isolated

when the 400 kHz operation of the other bus is required. If

the master is running at 400 kHz, the maximum system

operating frequency may be less than 400 kHz because of

the delays added by the translator.

As with the standard I

2

C−bus system, pull−up resistors are

required to provide the logic HIGH levels on the translator’s

bus. The NLA9306 has a standard open−collector

configuration of the I

2

C−bus. The size of these pull−up

resistors depends on the system, but each side of the

translator must have a pull−up resistor. The device is

designed to work with Standard−mode, Fast−mode and Fast

mode Plus I

2

C−bus devices in addition to SMBus devices.

The maximum frequency is dependent on the RC time

constant, but generally supports > 2 MHz.

When the SDA1 or SDA2 port is LOW, the clamp is in the

ON−state and a low resistance connection exists between the

SDA1 and SDA2 ports. Assuming the higher voltage is on

the SDA2 port, when the SDA2 port is HIGH, the voltage on

the SDA1 port is limited to the voltage set by VREF1. When

the SDA1 port is HIGH, the SDA2 port is pulled to the drain

pull−up supply voltage (V

) by the pull−up resistors.

pu(D)

This functionality allows a seamless translation between

higher and lower voltages selected by the user without the

need for directional control. The SCL1/SCL2 channel also

functions as the SDA1/SDA2 channel.

All channels have the same electrical characteristics and

there is minimal deviation from one output to another in

voltage or propagation delay. This is a benefit over discrete

transistor voltage translation solutions, since the fabrication

of the switch is symmetrical. The translator provides

excellent ESD protection to lower voltage devices, and at the

same time protects less ESD−resistant devices.

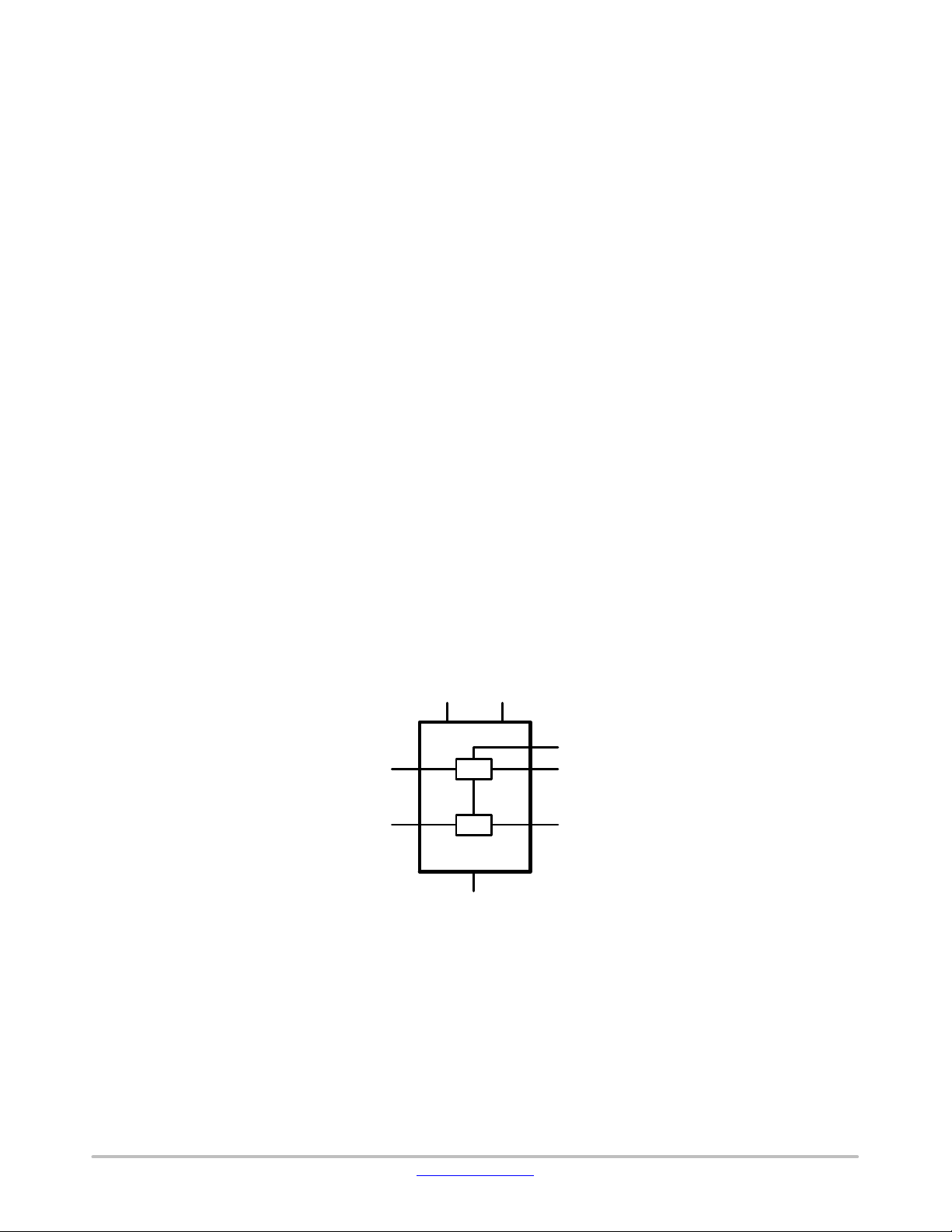

FUNCTIONAL DIAGRAM

VREF1

SCL1

3

4

Figure 1. Logic Diagram

VREF2

2

NLA9306

SW

SW

1

GND

7

8

EN

6

SCL2

5

SDA2SDA1

www.onsemi.com

2

Page 3

NLA9306

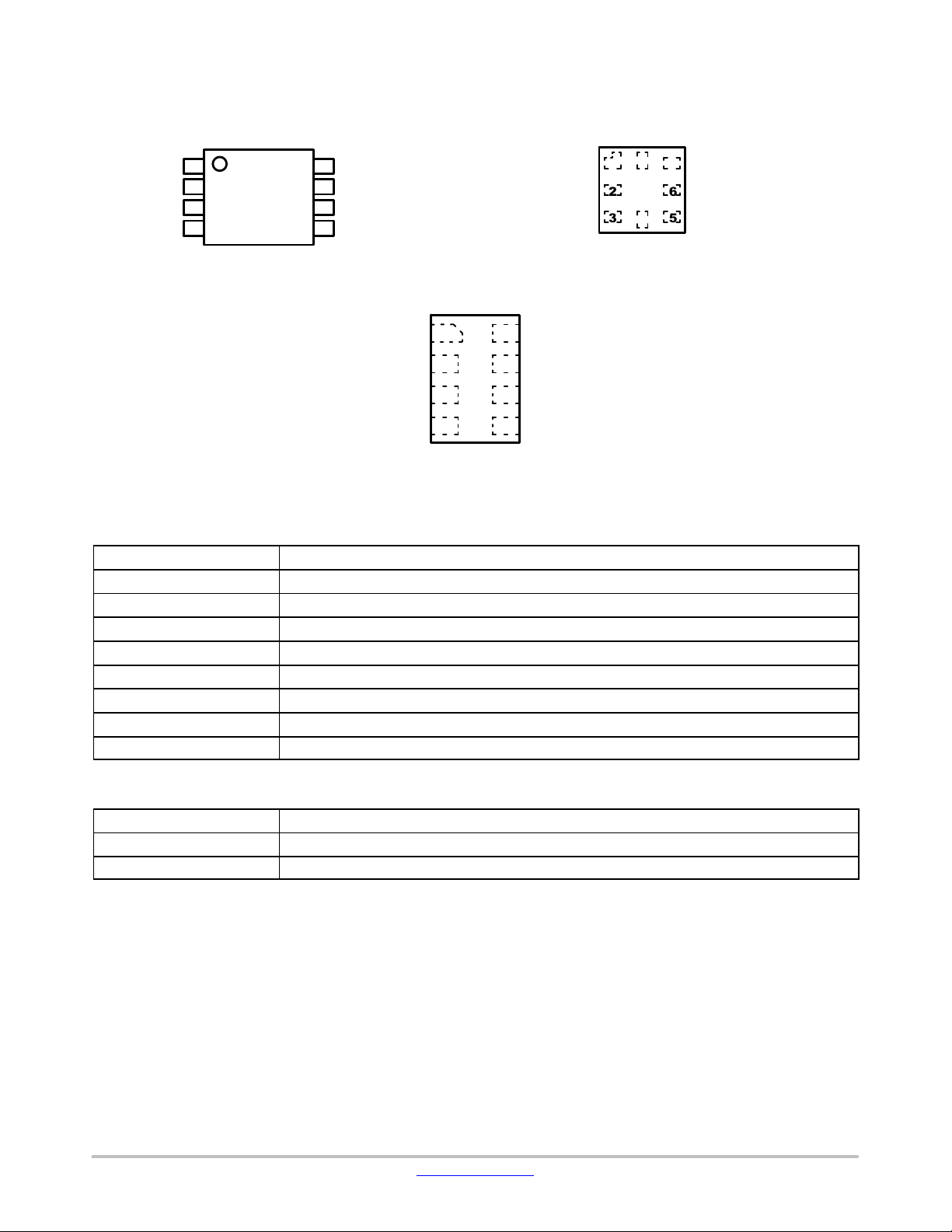

PIN ASSIGNMENTS

EN

GND

VREF1

SCL1

SDA1

1

2

3

4

NLA9306

8

7

6

5

EN

VREF2

SCL2

SDA2

GND

VREF1

SCL1

Figure 2. US8 Pinouts Figure 3. UQFN8 Pinout (Top Thru View)

8

1

NLA9306

2

3

4

SDA1

7

6

5

VREF2

SCL2

SDA2

Table 1. PIN DESCRIPTION

Pin Description

GND Ground

VREF1 Low−voltage side reference supply voltage for SCL1 and SDA1

SCL1 Serial clock, low−voltage side; connect to VREF1 through a pull−up resistor

SDA1 Serial data, low−voltage side; connect to VREF1 through a pull−up resistor

SDA2 Serial data, high−voltage side; connect to VREF2 through a pull−up resistor

SCL2 Serial clock, high−voltage side; connect to VREF2 through a pull−up resistor

VREF2 High−voltage side reference supply voltage for SCL2 and SDA2

EN Switch enable input; connect to VREF2 and pull−up through a high resistor

GND

VREF1

SCL1

1

2

3

4

8

7

6

5

EN

VREF2

SCL2

SDA2SDA1

Figure 4. UDFN8 Pinout (Top Thru View)

Table 2. FUNCTION TABLE

Input EN (Note 1) Function

Low Disconnect

High SCL1 = SCL2; SDA1 = SDA2

1. EN is controlled by the V

bias(ref)(2)

logic levels and should be at least 1 V higher than V

www.onsemi.com

3

for best translator operation.

ref(1)

Page 4

NLA9306

Table 3. MAXIMUM RATINGS

Symbol Parameter Value Unit

V

ref(1)

V

bias(ref)(2)

V

IN

V

I/O

I

CH

I

IK

T

STG

T

L

T

J

q

JA

P

D

MSL Moisture Sensitivity Level 1

F

R

V

ESD

I

LATCHUP

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

2. Measured with minimum pad spacing on an FR4 board, using 10 mm−by−1 inch, 2 ounce copper trace no air flow.

3. Tested to ANSI / ESDA / JEDEC JS−001−2017.

4. JEDEC recommends that ESD qualification to EIA / JESD22−A115−A (Machine Model) be discontinued per JEDEC / JEP172A.

5. Tested to EIA / JESD22−C101−F.

6. Tested to EIA / JESD78 Class II.

Reference Voltage (Note 2) −0.5 to +7.0 V

Reference Bias Voltage (Note 3) −0.5 to +7.0 V

Input Voltage −0.5 to +7.0 V

Input / Output Pin Voltage −0.5 to +7.0 V

DC Channel Current 128 mA

DC Input Diode Current VIN < GND −50 mA

Storage Temperature Range −65 to +150 °C

Lead Temperature, 1 mm from Case for 10 Seconds TL = 260 °C

Junction Temperature Under Bias TJ = 150 °C

Thermal Resistance (Note 2)

qJA = 150

°C/W

Power Dissipation in Still Air at 85°C PD = 833 mW

Flammability Rating Oxygen Index: 28 to 34 UL 94 V−0 @ 0.125 in

ESD Withstand Voltage Human Body Mode (Note 3)

Machine Model (Note 4)

Charged Device Model (Note 5)

> 2000

N/A

> 1000

V

Latchup Performance Above VCC and Below GND at 125°C (Note 6) ±100 mA

Table 4. RECOMMENDED OPERATING CONDITIONS

Symbol Parameter Min Max Unit

V

ref(1)

V

bias(ref)(2)

V

I/O

V

I(EN)

I

sw(pass)

T

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

7. V

(ref)(1)

Reference Voltage (1) (Note 7) VREF1 0 5.5 V

Reference Bias Voltage (2) (Note 7) VREF2 0 5.5 V

Input / Output Pin Voltage SCL1, SDA1, SCL2, SDA2 0 5.5 V

Control Pin Input Voltage EN 0 5.5 V

Pass Switch Current 0 64 mA

Operating Free−Air Temperature −55 +125 °C

A

≤ V

bias(ref)(2)

−1 V for best results in level shifting applications.

www.onsemi.com

4

Page 5

NLA9306

Table 5. DC ELECTRICAL CHARACTERISTICS

Symbol Parameter Conditions

C

C

V

IK

I

IH

i(EN)

i/O(off)

Input Clamping Voltage I

High−Level Input Current V

EN Pin Input Capacitance V

OFF−State I/O Pin Capacitance

SCLn, SDAn

= −18 mA; V

I

= 5 V; V

I

= 3 V or 0 V 7.1 pF

I

V

= 3 V or 0 V; V

O

I(EN)

= 0 V 5

I(EN)

TA = −555C to +1255C

Typ

Min

= 0 V −1.2 V

= 0 V 4 6 pF

I(EN)

(Note 8)

Max

Unit

mA

C

R

i/O(on)

ON

ON−State I/O Pin Capacitance

SCLn, SDAn

ON−State Resistance

(2)(3)

SCLn, SDAn VI = 0 V; IO = 64 mA

V

= 3 V or 0 V;

O

V

= 3 V 9.3 13.1

I(EN)

V

= 4.5 V

I(EN)

V

= 3 V

I(EN)

= 2.3 V

V

I(EN)

V

= 1.5 V

I(EN)

V

= 2.4 V; IO = 15 mA

I

V

= 4.5 V

I(EN)

= 3 V

V

I(EN)

V

= 1.7 V; IO = 15 mA

I

V

= 2.3 V 40 80

I(EN)

2.4

3.0

3.8

9.0

4.8

46

pF

W

5.0

6.0

8.0

20

7.5

80

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

8. All typical values are at T

9. Measured by the voltage drop between the SCL1 and SCL2, or SDA1 and SDA2 terminals at the indicated current through the switch.

= 25°C.

A

ON−state resistance is determined by the lowest voltage of the two terminals.

10.Guaranteed by design.

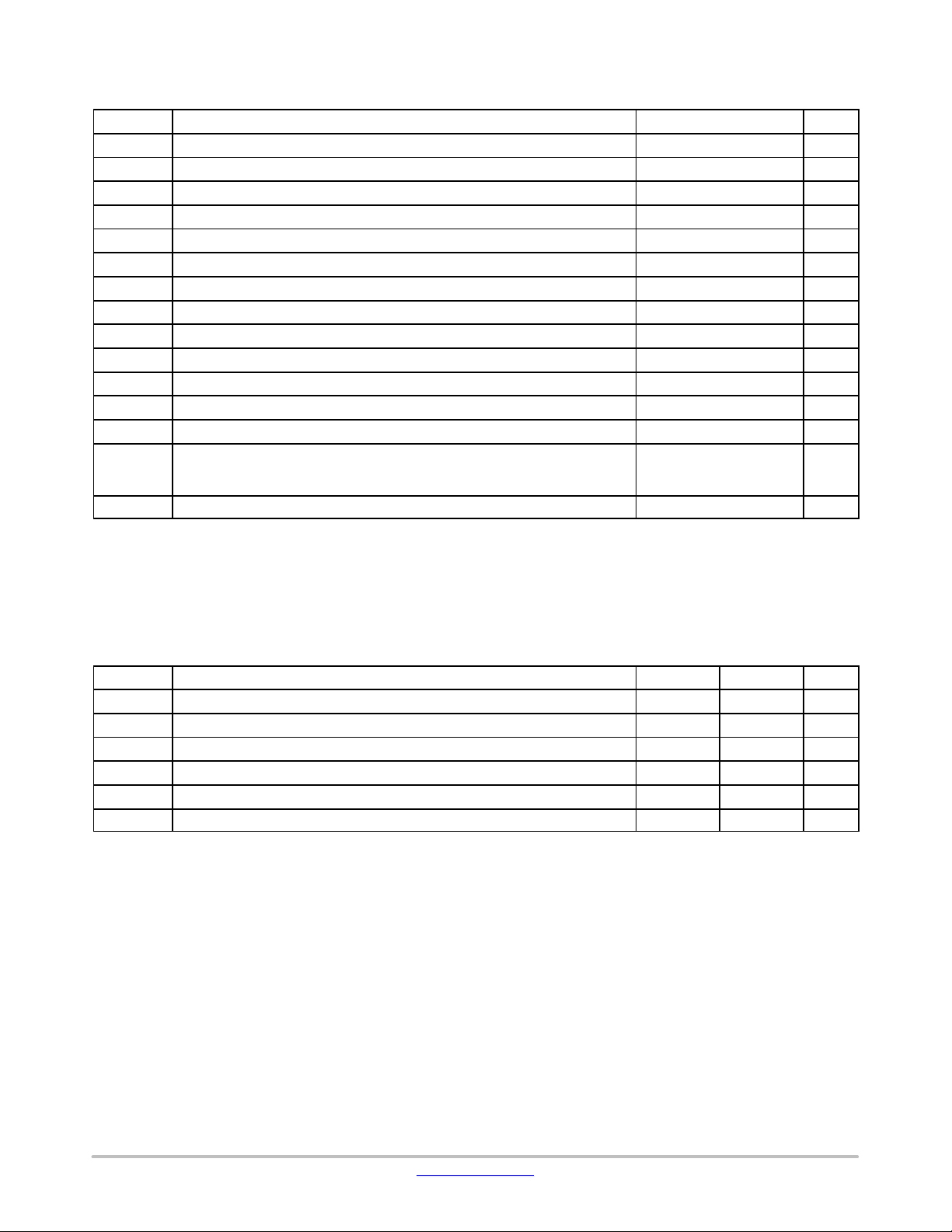

Table 6. AC ELECTRICAL CHARACTERISTICS (Translating Down) − Values Guaranteed by Design

TA = −555C to +1255C

Min Max

Unit

ns

ns

Symbol

Parameter Test Condition

SEE FIGURE 4 LOAD SWITCH AT S2 POSITION

t

PLH

Low−to−High Propagation Delay, from (input) SCL2 or

SDA2 to (output) SCL1 or

SDA1

t

PHL

High−to−Low Propagation Delay, from (input) SCL2 or

SDA2 to (output) SCL1 or

SDA1

t

PLH

Low−to−High Propagation Delay, from (input) SCL2 or

SDA2 to (output) SCL1 or

SDA1

t

PHL

High−to−Low Propagation Delay, from (input) SCL2 or

SDA2 to (output) SCL1 or

SDA1

V

= 3.3 V; V

I(EN)

VIL = 0 V; V

V

I(EN)

V

= 0 V; VM = 0.75 V

IL

= 1.15 V

M

= 2.5 V; VIH = 2.5 V;

= 3.3 V;

IH

Load

Condition

CL = 15 pF 0 0.6

CL = 30 pF 0 1.2

CL = 50 pF 0 2.0

CL = 15 pF 0 0.75

CL = 30 pF 0 1.5

CL = 50 pF 0 2.0

CL = 15 pF 0 0.6

CL = 30 pF 0 1.2

CL = 50 pF 0 2.0

CL = 15 pF 0 0.75

CL = 30 pF 0 1.5

CL = 50 pF 0 2.5

www.onsemi.com

5

Page 6

NLA9306

Table 7. AC ELECTRICAL CHARACTERISTICS (Translating Up) − Values Guaranteed by Design

Symbol

SEE FIGURE 4 LOAD SWITCH AT S1 POSITION

t

PLH

Low−to−High Propagation Delay, from (input) SCL1 or

SDA1 to (output) SCL2 or

SDA2

t

PHL

High−to−Low Propagation Delay, from (input) SCL1 or

SDA1 to (output) SCL2 or

SDA2

t

PLH

Low−to−High Propagation Delay, from (input) SCL1 or

SDA1 to (output) SCL2 or

SDA2

t

PHL

High−to−Low Propagation Delay, from (input) SCL1 or

SDA1 to (output) SCL2 or

SDA2

Parameter Test Condition Load Condition

V

I(EN)

V

= 0 V; V

IL

V

= 1.15 V

M

= 3.3 V; V

= 3.3 V;

TT

= 2.3 V;

IH

RL = 300 W, CL = 15 pF

RL = 300 W, CL = 30 pF

RL = 300 W, CL = 50 pF

RL = 300 W, CL = 15 pF

RL = 300 W, CL = 30 pF

RL = 300 W, CL = 50 pF

V

= 2.5 V; VIH = 1.5 V;

I(EN)

V

= 0 V; V

IL

= 0.75 V

V

M

TT

= 2.5 V;

RL = 300 W, CL = 15 pF

RL = 300 W, CL = 30 pF

RL = 300 W, CL = 50 pF

RL = 300 W, CL = 15 pF

RL = 300 W, CL = 30 pF

RL = 300 W, CL = 50 pF

TA =

−555C to +1255C

Min Max

0 0.5

0 1.0

0 1.75

0 0.8

0 1.65

0 2.75

0 0.5

0 1.0

0 1.75

0 1.0

0 2.0

0 3.3

Unit

ns

ns

V

from output under test

TT

R

L

S1

S2 (open)

C

L

input

output

V

M

V

M

A. Load Circuit B. Timing Diagram

S1 = translating up; S2 = translating down.

includes probe and jig capacitance.

C

L

All input pulses are supplied by generators having the following characteristics: PRR ≤ 10 MHz; Z

The outputs are measured one at a time, with one transition per measurement.

Figure 5. Load Circuit for Outputs

V

V

= 50 W; t

o

M

M

≤ 2 ns; t

r

V

IH

V

IL

V

OH

V

OL

≤ 2 ns.

f

www.onsemi.com

6

Page 7

V

CC

2

C−Bus

I

MASTER

SCL

SDA

V

REF(1)

= 1.8 V

(Note 1)

R

PURPU

NLA9306

APPLICATION INFORMATION

200 kW

VREF1

SCL1

SDA1

2

3

4

NLA9306

SW

SW

EN

8

VREF2

7

65SCL2

SDA2

V

PU(D)

= 3.3 V

(Note 1)

R

PURPU

SCL

I2C−Bus

DEVICE

SDA

V

CC

GND

1. The applied voltages at V

operation.

V

CC

2

C−Bus

I

MASTER

GND

ref(1)

and V

should be such that V

pu(D)

Figure 6. Typical Application (Switch Always Enabled)

3.3 V Enable Signal (Note 2)

V

= 1.8 V

REF(1)

(Note 2)

SCL

SDA

RPUR

VREF1

PU

SCL1

SDA1

2

3

4

1

GND

bias(ref)(2)

ONOFF

NLA9306

SW

SW

1

GND

is at least 1 V higher than V

200 kW

EN

8

VREF2

7

65SCL2

SDA2

2. In the Enabled mode, the applied enable voltage and the applied voltage at V

higher than V

for best translator operation.

ref(1)

Figure 7. Typical Application (Switch Enable Control)

V

= 3.3 V

PU(D)

R

PURPU

should be such that V

ref(1)

SCL

2

I

DEVICE

SDA

GND

for best translator

ref(1)

V

CC

C−Bus

GND

bias(ref)(2)

is at least 1 V

Bidirectional Translation

For the bidirectional clamping configuration (higher

voltage to lower voltage or lower voltage to higher voltage),

the EN input must be connected to VREF2 and both pins

pulled to HIGH side V

through a pull−up resistor

pu(D)

(typically 200 kW). This allows VREF2 to regulate the EN

input. A filter capacitor on VREF2 is recommended. The

2

I

C−bus master output can be totem−pole or open−drain

(pull−up resistors may be required) and the I

2

C−bus device

output can be totem−pole or open−drain (pull−up resistors

are required to pull the SCL2 and SDA2 outputs to V

pu(D)).

However, if either output is totem−pole, data must be

www.onsemi.com

unidirectional or the outputs must be 3−stateable and be

controlled by some direction−control mechanism to prevent

HIGH−to−LOW contentions in either direction. If both

outputs are open−drain, no direction control is needed.

The reference supply voltage (V

) is connected to the

ref(1)

processor core power supply voltage. When VREF2 is

connected through a 200 kW resistor to a 3.3 V to 5.5 V

power supply, and V

V

pu(D)

(V

− 1 V), the output of each SCL1 and SDA1 has a

pu(D)

is set between 1.0 V and

ref(1)

maximum output voltage equal to VREF1, and the output of

each SCL2 and SDA2 has a maximum output voltage equal

to V

7

pu(D)

.

Page 8

NLA9306

Table 8. APPLICATION OPERATING CONDITIONS Refer to Figure 6.

Symbol

V

bias(ref)(2)

V

I(EN)

V

ref(1)

I

sw(pass)

I

ref

T

amb

11.All typical values are at T

Sizing Pull−up Resistor

The pull−up resistor value needs to limit the current

through the pass transistor when it is in the ON state to about

15 mA. This ensures a pass voltage of 260 mV to 350 mV.

If the current through the pass transistor is higher than

15 mA, the pass voltage also is higher in the ON state. To set

the current through each pass transistor at 15 mA, the

pull−up resistor value is calculated as:

Parameter Conditions Min Typ

Reference Bias Voltage (2) V

EN Pin Input Voltage V

Reference Voltage (1) 0 1.5 4.4 V

Pass Switch Current 14 mA

Reference Current Transistor 5

Ambient Temperature Operating in free−air −55 +125 °C

= 25 °C.

amb

voltages and currents at 15 mA, 10 mA, and 3 mA. The

resistor values shown in the +10% column or a larger value

should be used to ensure that the pass voltage of the

transistor would be 350 mV or less. The external driver must

be able to sink the total current from the resistors on both

sides of the NLA9306 device at 0.175 V, although the

15 mA only applies to current flowing through the

NLA9306 device.

RPU+

V

PU(D)

0.015 A

* 0.35 V

(eq. 1)

(1)

+ 0.6 2.1 5 V

ref(1)

+ 0.6 2.1 5 V

ref(1)

Max Unit

mA

The following table summarizes resistor reference

Table 9. PULLUP RESISTOR VALUES Calculated for V

15 mA 10 mA 3 mA

V

pu(D)

5 V 310 341 465 512 1550 1705

3.3 V 197 217 295 325 983 1082

2.5 V 143 158 215 237 717 788

1.8 V 97 106 145 160 483 532

1.5 V 77 85 11 5 127 383 422

1.2 V 57 63 85 94 283 312

12.+10% to compensate for V

Nominal +10% (Note 12) Nominal +10%

range and resistor tolerance.

CC

Maximum Frequency Calculation

The maximum frequency is totally dependent upon the

specifics of the application and the device can operate >

33 MHz. Basically, the NLA9306 behaves like a wire with

the additional characteristics of transistor device physics

and should be capable of performing at higher frequencies

if used correctly.

Here are some guidelines to follow that will help

maximize the performance of the device:

• Keep trace length to a minimum by placing the

NLA9306 close to the processor.

• The trace length should be less than half the time of

flight to reduce ringing and reflections.

• The faster the edge of the signal, the higher the chance

for ringing.

• The higher the drive strength (up to 15 mA), the higher

the frequency the device can use.

In a 3.3 V to 1.8 V direction level shift, if the 3.3 V side

= 0.35 V; assumes output driver VOL = 0.175 V at stated current.

OL

Pullup Resistor Value (W)

(1)

Nominal +10% (Note 12)

resistor is needed on the 3.3 V side. The capacitance and line

length of concern is on the 1.8 V side since it is driven

through the ON resistance of the NLA9306. If the line length

on the 1.8 V side is long enough there can be a reflection at

the chip/terminating end of the wire when the transition time

is shorter than the time of flight of the wire because the

NLA9306 looks like a high−impedance compared to the

wire. If the wire is not too long and the lumped capacitance

is not excessive the signal will only be slightly degraded by

the series resistance added by passing through the

NLA9306. If the lumped capacitance is large the rise time

will deteriorate, the fall time is much less affected and if the

rise time is slowed down too much the duty cycle of the clock

will be degraded and at some point the clock will no longer

be useful. So the principle design consideration is to

minimize the wire length and the capacitance on the 1.8 V

side for the clock path. A pull−up resistor on the 1.8 V side

can also be used to trade a slower fall time for a faster rise

time and can also reduce the overshoot in some cases.

is being driven by a totem pole type driver no pull−up

www.onsemi.com

8

Page 9

NLA9306

ORDERING INFORMATION

Pin 1 Orientation

Device Marking

NLA9306MUQ1TCG AY Q4 UQFN8

NLA9306MU3TAG D Q1 UDFN8

NLA9306MU3TCG D Q4 UDFN8

NLA9306USG

NLVA9306USG*

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

*NLV Prefix for Automotive and Other Applications Requiring Unique Site and Control Change Requirements; AEC−Q100 Qualified and PPAP

Capable.

A5 Q4

A5 Q4

(See below)

Package Shipping

(Pb−Free)

(Pb−Free)

(Pb−Free)

US8

(Pb−Free)

US8

(Pb−Free)

3000 / Tape & Reel

3000 / Tape & Reel

3000 / Tape & Reel

3000 / Tape & Reel

3000 / Tape & Reel

Pin 1 Orientation in Tape and Reel

†

www.onsemi.com

9

Page 10

NLA9306

PACKAGE DIMENSIONS

US8

CASE 493

ISSUE D

SEATING

PLANE

T

A

X Y

58

J

DETAIL E

LB

41

P

G

C

D

K

0.10 (0.004) XY

M

T

R

S

U

H

T0.10 (0.004)

N

R 0.10 TYP

V

F

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION A DOES NOT INCLUDE MOLD

FLASH, PROTRUSION OR GATE BURR. MOLD

FLASH. PROTRUSION AND GATE BURR SHALL

NOT EXCEED 0.14MM (0.0055”) PER SIDE.

4. DIMENSION B DOES NOT INCLUDE INTERLEAD

FLASH OR PROTRUSION. INTERLEAD FLASH

AND PROTRUSION SHALL NOT EXCEED 0.14MM

(0.0055”) PER SIDE.

5. LEAD FINISH IS SOLDER PLATING WITH

THICKNESS OF 0.0076−0.0203MM (0.003−0.008”).

6. ALL TOLERANCE UNLESS OTHERWISE

SPECIFIED ±0.0508MM (0.0002”).

MILLIMETERS

DIMAMIN MAX MIN MAX

1.90 2.10 0.075 0.083

B 2.20 2.40 0.087 0.094

C 0.60 0.90 0.024 0.035

D 0.17 0.25 0.007 0.010

F 0.20 0.35 0.008 0.014

G 0.50 BSC 0.020 BSC

H 0.40 REF 0.016 REF

J 0.10 0.18 0.004 0.007

K 0.00 0.10 0.000 0.004

L 3.00 3.20 0.118 0.128

M 0 6 0 6

____

N 0 10 0 10

M

____

P 0.23 0.34 0.010 0.013

R 0.23 0.33 0.009 0.013

S 0.37 0.47 0.015 0.019

U 0.60 0.80 0.024 0.031

V 0.12 BSC

INCHES

0.005 BSC

DETAIL E

RECOMMENDED

SOLDERING FOOTPRINT*

8X

0.30

8X

0.68

3.40

1

0.50

PITCH

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

www.onsemi.com

10

Page 11

NLA9306

PACKAGE DIMENSIONS

UQFN8, 1.6x1.6, 0.5P

CASE 523AN

ISSUE O

PIN ONE

REFERENCE

2X

0.10 C

2X

0.05 C

0.05 C

DETAIL A

0.10 C

TOP VIEW

SIDE VIEW

8X

L

3

1

BOTTOM VIEW

D

DETAIL B

8

A1

8X

5

7

A

B

E

(A3)

L3

8X

A

C

e

b

0.10 B

0.05ACC

EXPOSED Cu

A1

SEATING

PLANE

NOTE 3

DETAIL B

OPTIONAL

CONSTRUCTION

L1

b

(0.10)

DETAIL A

OPTIONAL

CONSTRUCTION

*For additional information on our Pb−Free strategy and soldering

MOLD CMPD

A3

L3

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED TERMINAL

AND IS MEASURED BETWEEN 0.15 AND

0.30 mm FROM THE TERMINAL TIP.

MILLIMETERS

DIM MIN MAX

A 0.45 0.60

A1 0.00 0.05

A3 0.13 REF

b 0.15 0.25

D 1.60 BSC

E 1.60 BSC

e 0.50 BSC

L 0.35 0.45

L1 −−− 0.15

L3 0.25 0.35

(0.15)

SOLDERING FOOTPRINT*

1.70

1

0.35

7X

0.25

DIMENSIONS: MILLIMETERS

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

0.50

PITCH

1.70

8X

0.538X0.53

www.onsemi.com

11

Page 12

PIN ONE

REFERENCE

2X

2X

0.10 C

0.10

0.05 C

0.05 C

L1

C

e/2

D

TOP VIEW

SIDE VIEW

1

NLA9306

PACKAGE DIMENSIONS

UDFN8, 1.45x1, 0.35P

CASE 517BZ

ISSUE O

A B

E

A3

A

A1

e

4

SEATING

C

PLANE

L7X

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED

TERMINAL AND IS MEASURED BETWEEN

0.15 AND 0.20 MM FROM TERMINAL TIP.

4. PACKAGE DIMENSIONS EXCLUSIVE OF

BURRS AND MOLD FLASH.

MILLIMETERS

DIM MIN MAX

A 0.45 0.55

A1 0.00 0.05

A3 0.13 REF

b 0.15 0.25

D 1.45 BSC

E 1.00 BSC

e 0.35 BSC

L 0.25 0.35

L1 0.30 0.40

RECOMMENDED

SOLDERING FOOTPRINT*

7X

0.48

8X

0.22

1.18

58

BOTTOM VIEW

b

8X

0.10 B

0.05ACC

PKG

OUTLINE

1

DIMENSIONS: MILLIMETERS

0.35

PITCH

M

M

NOTE 3

0.53

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

◊

www.onsemi.com

12

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

Loading...

Loading...