Page 1

NIS54xxGEVB

NIS54xx Evaluation

Board User’s Manual

eFuse test board with multiple

subcircuits for evaluation of

overvoltage protection,

overcurrent protection,

controlled slew rate, and

thermal shutdown features

EVAL BOARD USER’S MANUAL

Introduction

Engineers developing a varied array of systems

utilize sophisticated integrated eFuses to serve a

variety of purposes. They may be found connected to

3.3, 5, and 12 V power rails and have many

interesting features.

The primary features of eFuses are:

Overvoltage clamping

Adjustable current limiting

Enable/Fault control

Thermal shutdown

Controllable slew rate

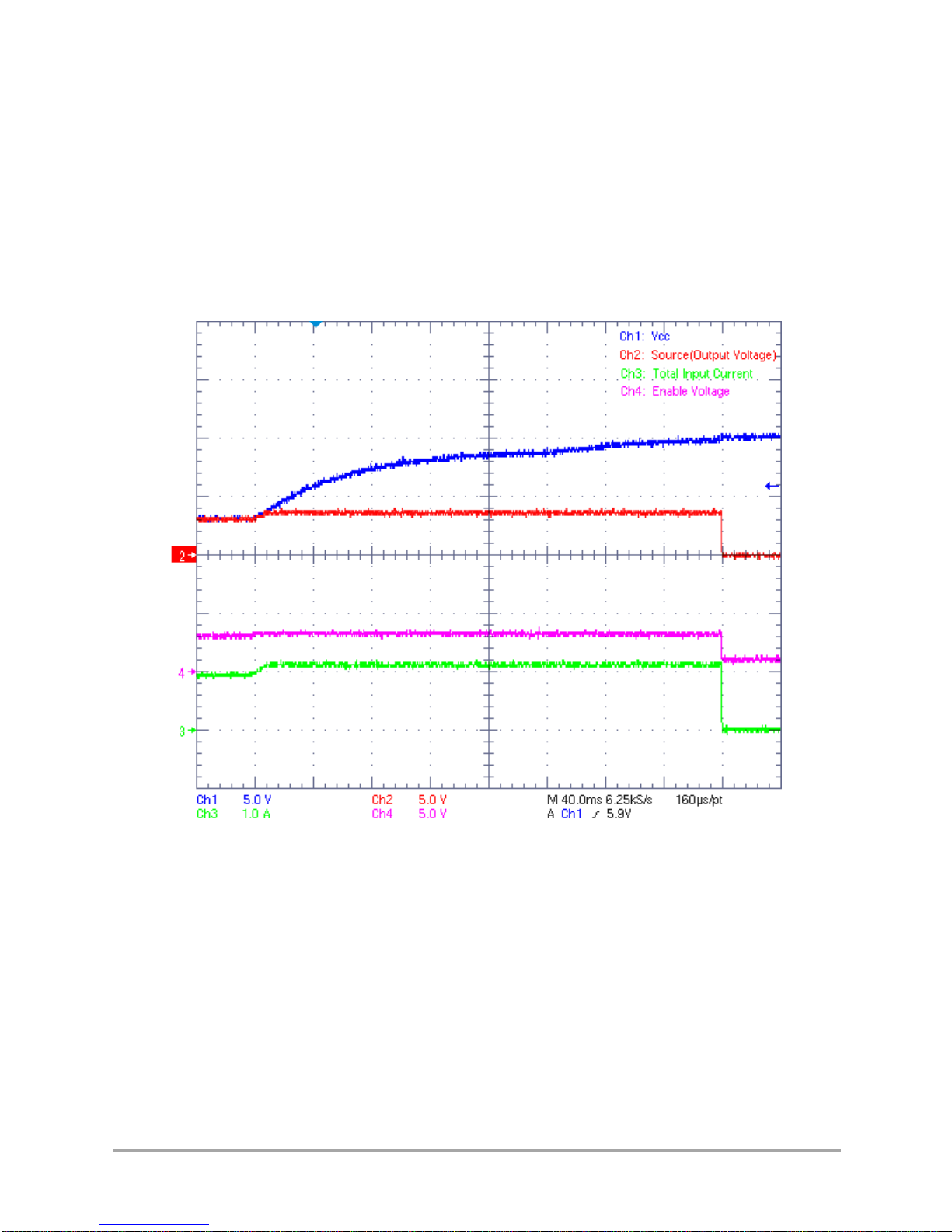

Figure 1: The NIS545xGEVB evaluation

board

This evaluation board has many features which

make it simple to observe the functionality and

performance of the new NIS54xx line of eFuses:

Multiple connectors available for all eFuse

pins (VCC, GND, enable, ILIM, dv/dt)

Input and output capacitors

A pushbutton switch and a MOSFET

connect the enable pin to GND or float it as

needed

Green and yellow LEDs to indicate whether

the eFuse enable pin voltage is high (device

enabled) or low (device disabled)

Three current limit resistor options available

directly on the board (10, 18, 50 Ω)

Two load resistor options (5 and 10 Ω) on

the board

A pushbutton switch to short circuit the

load, featuring an indicator LED which is on

when the output voltage is high during

normal operation

An easy means of connecting an external

copper heat sink for thermal evaluation

Kelvin or direct sensing options via the

jumper between pin 1 and 2 for the NIS54xx

© Semiconductor Components Industries, LLC, 2015

April, 2015 − Rev. 2

Page 2

NIS54xxGEVB

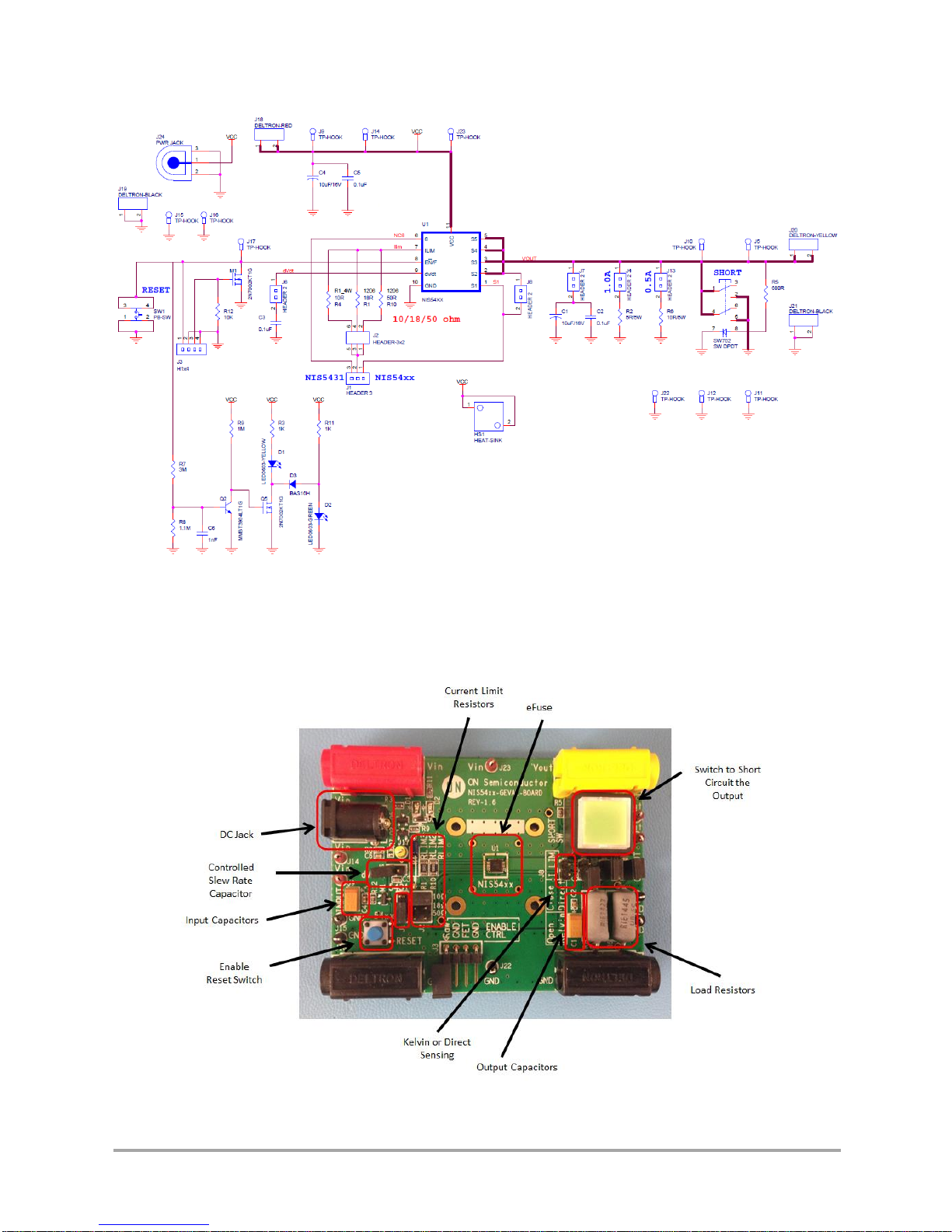

Figure 2: Schematic for the evaluation board.

The user’s manual is divided into two sections. The first section is for the NIS5431 3.3 V series of devices.

The second section covers the NIS545x 5 V series of devices. For these devices ensure that J1 is in the “54xx”

position.

Figure 3: Features of the evaluation board.

http://onsemi.com

Page 3

NIS54xxGEVB

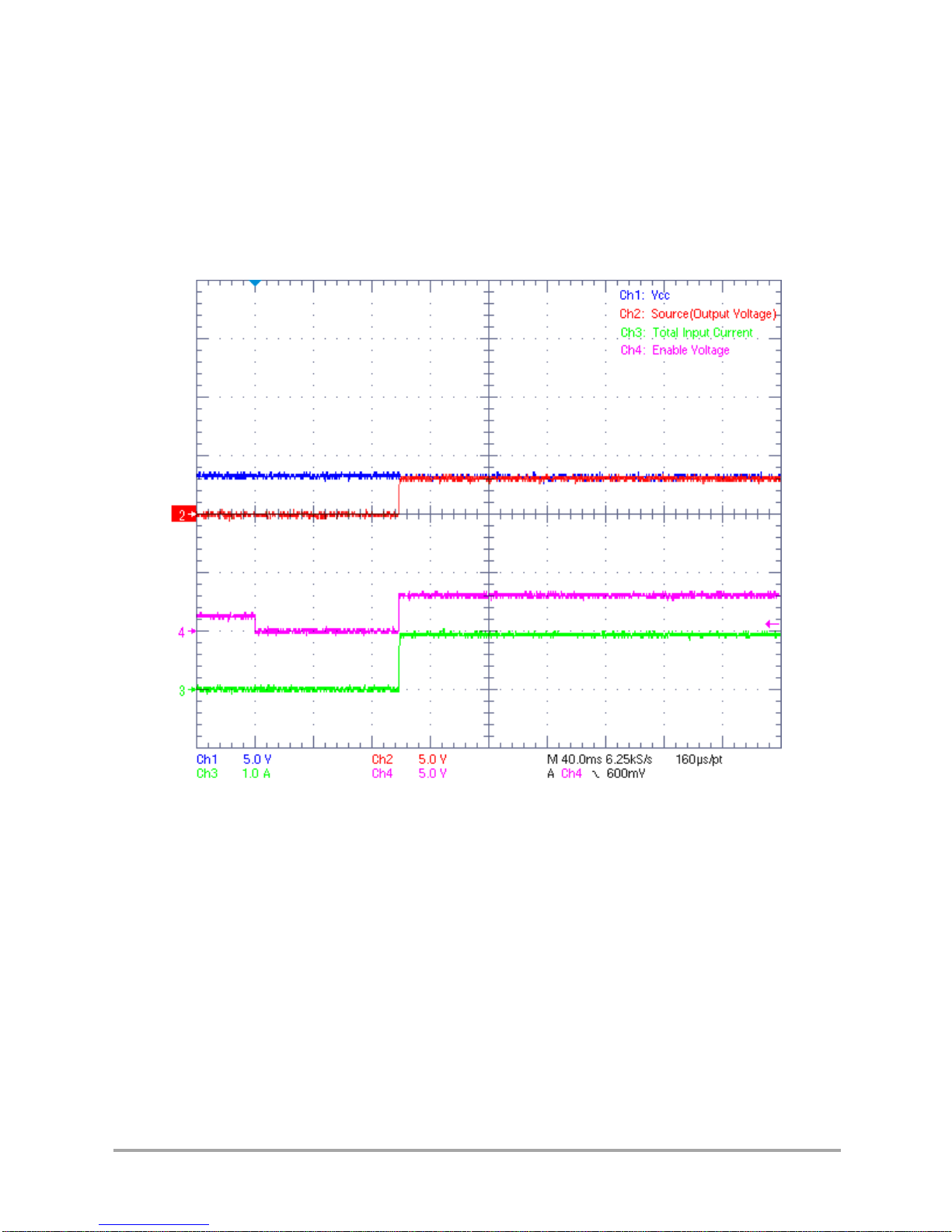

NIS5431 Overvoltage Protection

Connect the eFuse to a variable DC power supply. Place jumpers J2 (10 Ω), J1 (5431), J4, J8, and J13.

Turn the power supply from 3.3 to 10 V to observe the overvoltage protection circuit in operation. The input

voltage will rise, but the output voltage will be maintained at the Vclamp level of about 3.8 V. After conducting 1.1

A with a voltage drop of 6.2 V, the device will reach its thermal shutdown point and latch off. The green indicator

LEDs will turn off and the yellow “fault” indicator LED will be on. An auto-retry eFuse (MT2 part number suffix)

does not latch and automatically cycles the enable pin. For auto-retry eFuses the demo board’s green and yellow

indicator enable pin indicator LEDs will flash as the enable pin cycles between states.

Figure 4: In this test, the input voltage (blue trace) is brought to 10 V. The output voltage (red

trace) is clamped at 3.8 V. After some time the device enters thermal shutdown.

http://onsemi.com

Page 4

NIS54xxGEVB

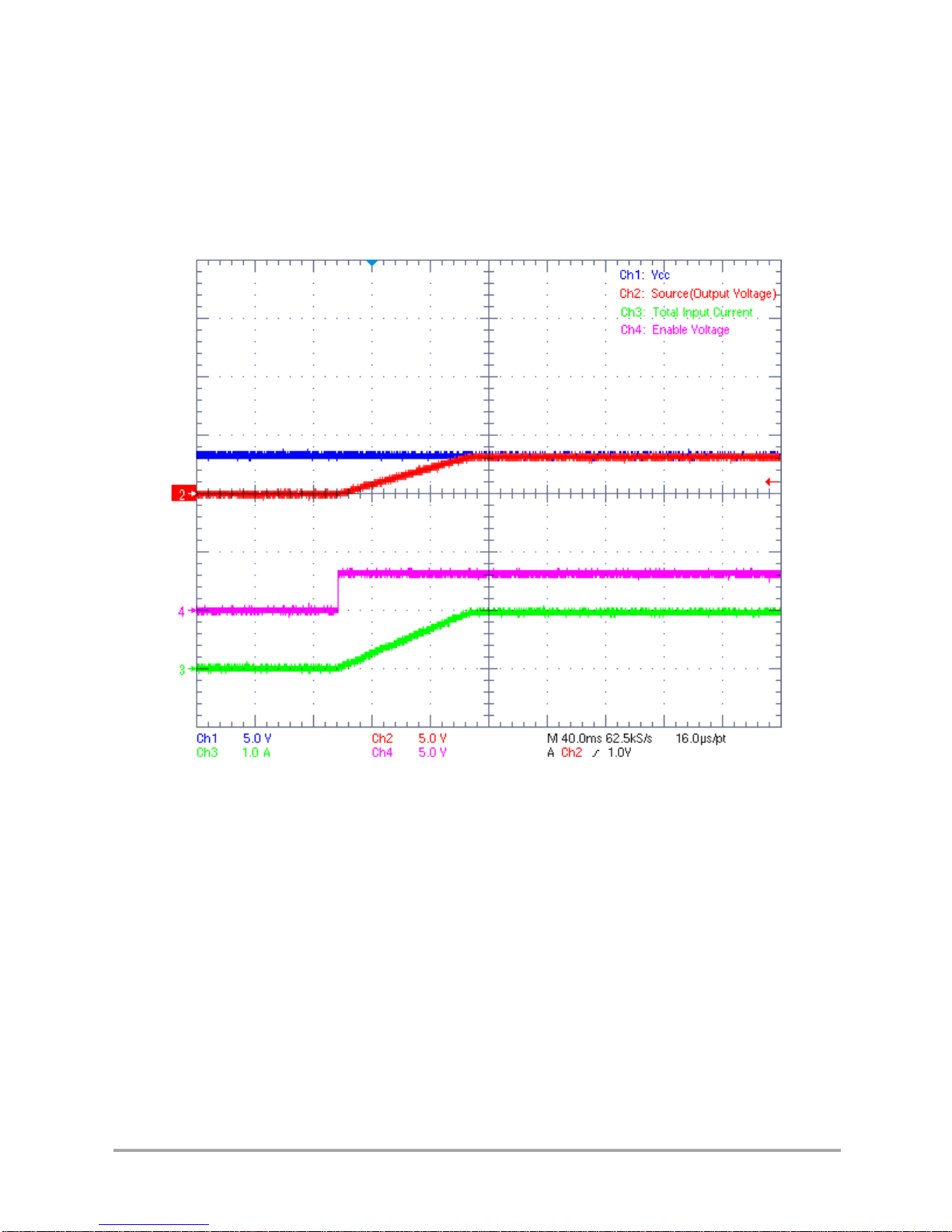

NIS5431 Reset from Thermal Shutdown

Continue with jumpers J2 (10 Ω), J1 (5431), J4, J8, and J13. Once the eFuse reaches thermal shutdown the

enable pin will fall to 1.4 V. Return the power supply to 3.3 V and press the blue button to reset the eFuse. An

auto-retry eFuse (MT2 part number suffix) does not latch and automatically cycles the enable pin. For auto-retry

eFuses the demo board’s green and yellow indicator enable pin indicator LEDs will flash as the enable pin cycles

between states.

Figure 5: This test shows how the enable pin is used to reset the device after a thermal shutdown

event. After pressing the blue button the enable pin falls to 0 V and then comes to about 3.3 V

after releasing the blue button. At that point the eFuse turns on. An auto-retry device will reset

automatically from thermal shutdown and pressing the blue button is not necessary.

http://onsemi.com

Page 5

NIS54xxGEVB

NIS5431 Overcurrent Protection

Continue with jumpers J2 (10 Ω), J1 (5431), J4, J8, and J13. With VCC set to 3.3 V, press the large green

button to short circuit the output. A power supply capable of supplying more than 3 A is recommended. The

mechanical switch will bounce, but the eFuse will have no issue responding to this disturbance. It will respond to

the fault within 10 μs and the current will be limited to the short circuit current limit level. After some time the

device will enter thermal shutdown due to the high current and voltage between VCC and source (output voltage)

pins. An auto-retry eFuse (MT2 part number suffix) does not latch and automatically cycles the enable pin. For

auto-retry eFuses the demo board’s green and yellow indicator enable pin indicator LEDs will flash as the enable pin

cycles between states.

Figure 6: This is a demonstration of the current limiting circuit. The eFuse responds quickly to

the short circuit event and begins conducting at the short circuit current limit.

http://onsemi.com

Page 6

NIS54xxGEVB

NIS5431 Controlled slew rate

Continue with jumpers J2 (10 Ω), J1 (5431), J4, J8, and J13. Perform this test with and without the J6

jumper in place to observe how the duration of the controlled slew rate changes. When J6 is in place, the slew rate

will be longer because a capacitor is connected between the dv/dt pin and GND. With VCC set to 3.3 V, press and

release the blue button to see the eFuse turn on with a controlled output voltage slew rate.

Figure 7. This is a demonstration of the controlled slew rate circuit with J6 in place. Without J6 in

place, the slew rate will be lower.

http://onsemi.com

Page 7

NIS54xxGEVB

NIS5431 Hot Plug Power On

Use jumpers J2 (10 Ω), J1 (5431), J4, J6, J8, and J13. Manually take the 3.3 V power cable and plug it into

the demo board. Observe that the eFuse turns on with no issue and the output voltage rises in a controlled fashion.

Figure 8. This shows a standard hot plug test. The input cable is manually plugged into the board

and the output voltage rises slowly to minimize inrush current.

http://onsemi.com

Page 8

NIS54xxGEVB

NIS5431 Hot Plug Power On into a Short Circuit

Use jumpers J2 (10 Ω), J1 (5431), J4, J6, J8, and J13. Short circuit the output and manually take the 3.3 V

power cable and plug it into the demo board. The eFuse briefly turns on and conducts at the short circuit current

limit level. After some time the devices reaches the thermal shutdown level and latches off. An auto-retry eFuse

(MT2 part number suffix) does not latch and automatically cycles the enable pin. For auto-retry eFuses the demo

board’s green and yellow indicator enable pin indicator LEDs will flash as the enable pin cycles between states.

Figure 9. This shows a hot plug test into a short circuit. The input cable is manually plugged into

the board. The eFuse limits the current, enters thermal shutdown, and latches off. Auto-retry

devices such as the NIS5450MT2 will not latch off.

http://onsemi.com

Page 9

NIS54xxGEVB

NIS545x Overvoltage Protection

Connect the eFuse to a variable DC power supply. Place jumpers J2 (10 Ω), J1 (545x), J4, and J13. Turn

the power supply from 5 to 10 V to observe the overvoltage protection circuit in operation. The input voltage will

rise, but the output voltage will be maintained at the Vclamp level of about 6 V. After conducting 1.5 A with a

voltage drop of 4 V, the eFuse will reach its thermal shutdown point and latch off. The green indicator LEDs will

turn off and the yellow “fault” indicator LED will be on. An auto-retry eFuse (MT2 part number suffix) does not

latch and automatically cycles the enable pin. For auto-retry eFuses the demo board’s green and yellow indicator

enable pin indicator LEDs will flash as the enable pin cycles between states.

Figure 10: In this test, the input voltage (blue trace) is brought to 10 V. The output voltage (red

trace) is clamped at about 6 V. After some time the device enters thermal shutdown.

http://onsemi.com

Page 10

NIS54xxGEVB

NIS545x Reset from Thermal Shutdown

Continue with jumpers J2 (10 Ω), J1 (545x), J4, and J13. Once the eFuse reaches thermal shutdown the

enable pin falls to 1.4 V. Return the power supply to 5 V and press the blue button to reset the eFuse. An auto-retry

eFuse (MT2 part number suffix) does not latch and automatically cycles the enable pin. For auto-retry eFuses the

demo board’s green and yellow indicator enable pin indicator LEDs will flash as the enable pin cycles between

states.

Figure 11: This test shows how the enable pin is used to reset the device after a thermal

shutdown event. After pressing the blue button the enable pin falls to 0 V and then comes to

about 3.3 V after releasing the blue button. At that point the efuse turns on. An auto-retry device

such as the NIS5450MT2 will reset automatically from thermal shutdown and pressing the blue

button is not necessary.

http://onsemi.com

Page 11

NIS54xxGEVB

NIS545x Overcurrent Protection

Continue with jumpers J2 (10 Ω), J1 (545x), J4, and J13. With VCC set to 5 V, press the large green

button to short circuit the output. A power supply capable of supplying more than 3 A is recommended. The

mechanical switch will bounce, but the eFuse will have no issue responding to this disturbance. It will respond to

the fault within 10 μs and the current will be limited to the short circuit current limit level. After some time the

device will enter thermal shutdown due to the high current and voltage between VCC and source (output voltage)

pins. An auto-retry eFuse (MT2 part number suffix) does not latch and automatically cycles the enable pin. For

auto-retry eFuses the demo board’s green and yellow indicator enable pin indicator LEDs will flash as the enable pin

cycles between states.

Figure 12: This is a demonstration of the current limiting circuit. The eFuse responds quickly to

the short circuit event and begins conducting at the short circuit current limit.

http://onsemi.com

Page 12

NIS54xxGEVB

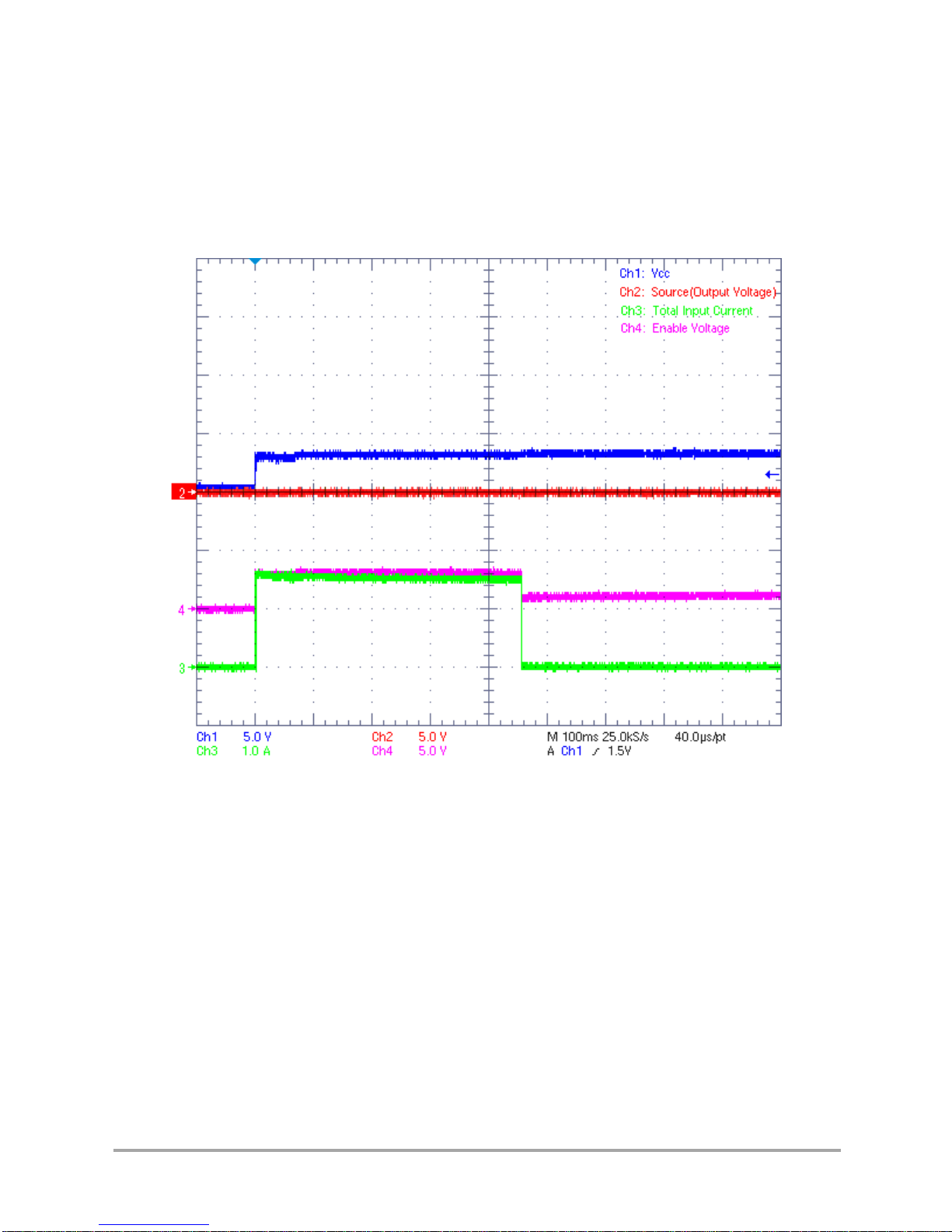

NIS545x Controlled slew rate

Continue with jumpers J2 (10 Ω), J1 (545x), J4, and J13. Perform this test with and without the J6 jumper

in place to observe how the duration of the controlled slew rate changes. When J6 is in place, the slew rate will be

longer because a capacitor is connected between the dv/dt pin and GND. With VCC set to 5 V, press and release the

blue button to see the eFuse turn on with a controlled output voltage slew rate.

Figure 13. This is a demonstration of the controlled slew rate circuit with J6 in place. Without J6

in place, the slew rate will be lower.

http://onsemi.com

Page 13

NIS54xxGEVB

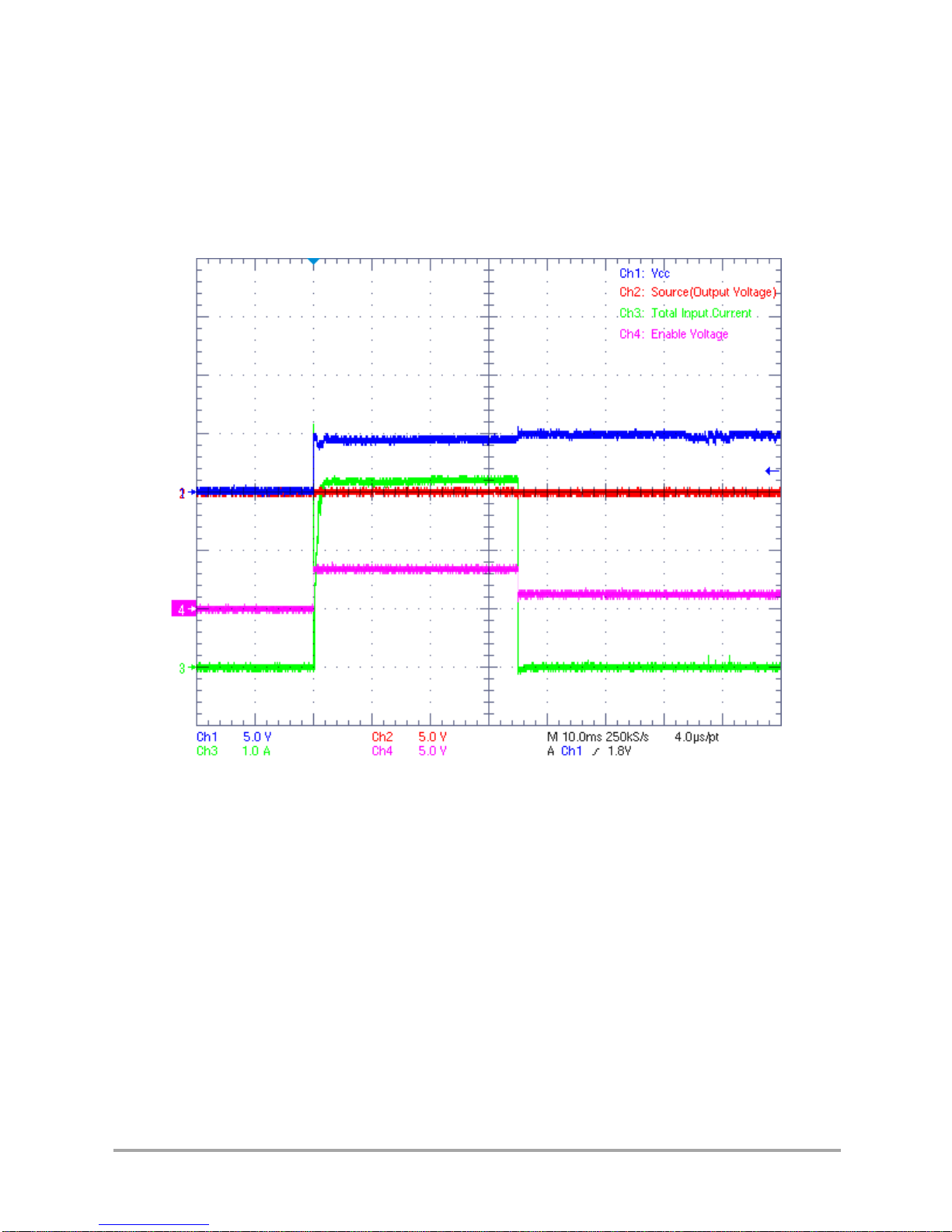

NIS545x Hot Plug Power On

Use jumpers J2 (10 Ω), J1 (545x), J4, J6, and J13. Manually take the 5 V power cable and plug it into the

demo board. Observe that the eFuse turns on with no issue and the output voltage rises in a controlled fashion.

Figure 14. This shows a standard hot plug test. The input cable is manually plugged into the

board and the output voltage rises slowly to minimize inrush current.

http://onsemi.com

Page 14

NIS54xxGEVB

NIS545x Hot Plug Power On into a Short Circuit

Use jumpers J2 (10 Ω), J1 (545x), J4, J6, and J13. Short circuit the output and manually take the 5 V

power cable and plug it into the demo board. The eFuse briefly turns on and conducts at the short circuit current

limit level. After some time the eFuse reaches the thermal shutdown level and latches off. An auto-retry eFuse

(MT2 part number suffix) does not latch and automatically cycles the enable pin. For auto-retry eFuses the demo

board’s green and yellow indicator enable pin indicator LEDs will flash as the enable pin cycles between states.

Figure 15. This shows a hot plug test into a short circuit. The input cable is manually plugged

into the board. The eFuse limits the current, enters thermal shutdown, and latches off. Auto-retry

devices such as the NIS5450MT2 will not latch off.

http://onsemi.com

Loading...

Loading...