Page 1

9 to 24 Volt Electronic Fuse

NIS4461 Series

The NIS4461 eFuse is a cost effective, resettable fuse which can

greatly enhance the reliability of a hard drive or other circuit from both

catastrophic and shutdown failures.

It is designed to protect the downstream circuitry against an

overcurrent event by limiting the current while protecting against high

inrush current, as well as monitoring the load current in real time.

Features

• Integrated Power Device

• Power Device Thermally Protected

• No External Current Shunt Required

• 9 V to 24 V Input Range

• 39 mW Typical

• Internal Charge Pump

• Internal Undervoltage Lockout Circuit

• ESD Ratings:

Human Body Model (HBM); 2000 V

Charged Device Model (CDM); 2000 V

Latch−Up; Class 1

• These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

Typical Applications

• Hard Drives

• Mother Board Power Management

• Fan Drives

• Industrial

• Handheld Devices

• Portable Instruments

www.onsemi.com

4.2 AMP, 9 to 24 VOLT

ELECTRONIC FUSE

MARKING

DIAGRAM

WDFN10

CASE 522AA

XXX = Specific Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

PIN CONNECTIONS

GND

dV/dt

NC/I

En/Flt

I

LIM

SENSE

V

CC

XXXXX

XXXXX

ALYWG

Src

Src

Src

Src

Src

G

© Semiconductor Components Industries, LLC, 2020

March, 2021 − Rev. 2

WDFN10

(Top View)

See detailed ordering, marking and shipping information in the

ordering information section on page 11 of this data sheet.

1 Publication Order Number:

ORDERING INFORMATION

NIS4461/D

Page 2

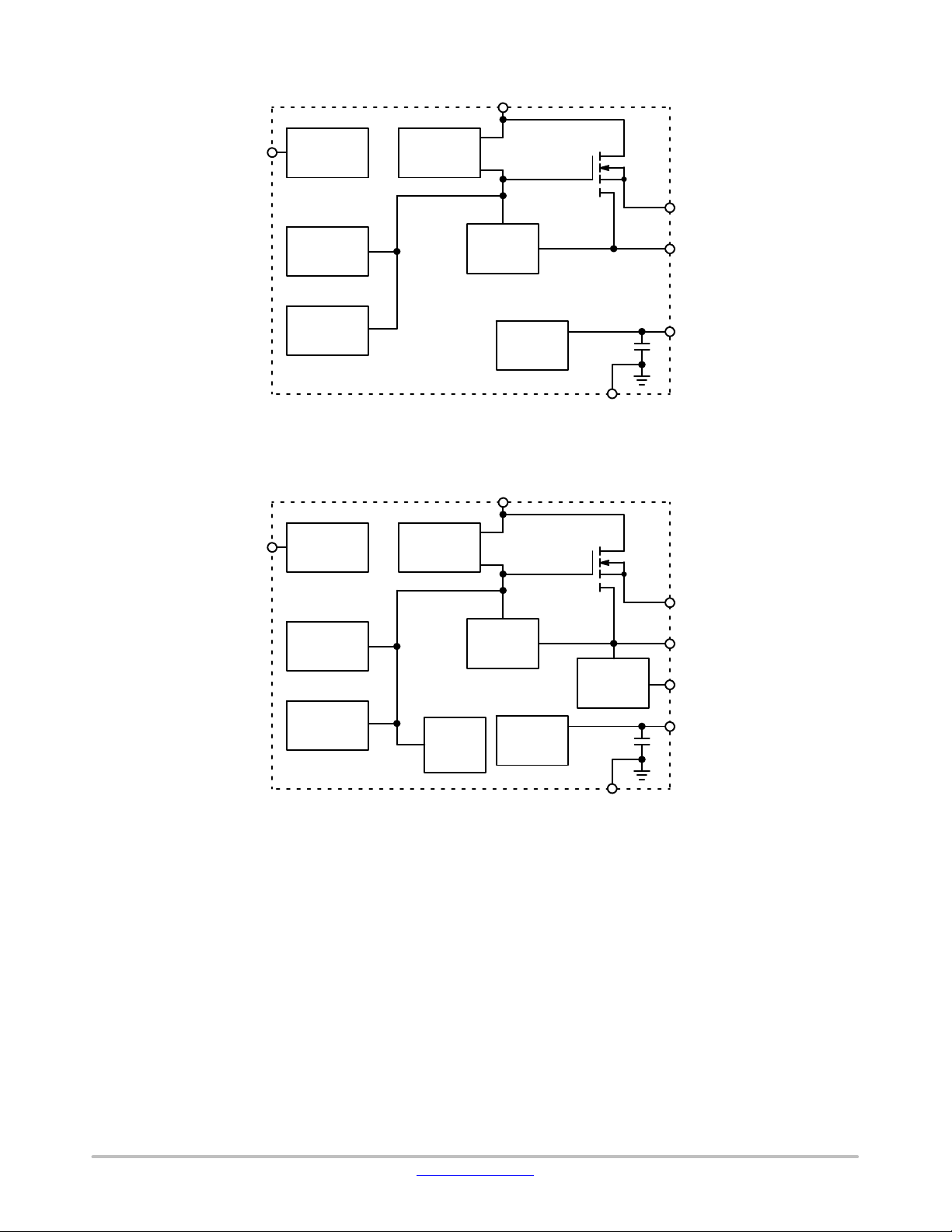

NIS4461 Series

VCC

ENABLE/

FAULT

ENABLE/

FAULT

Enable

Thermal

Shutdown

UVLO

Enable

Charge

Pump

Current

Limit

dv/dt

Control

Figure 1. Block Diagram

(NIS4461MT2TXG, NIS4461MT4TXG)

VCC

Charge

Pump

GND

SOURCE

I

LIMIT

dv/dt

Thermal

Shutdown

UVLO

Current

Limit

Voltage

Clamp

dv/dt

Control

Figure 2. Block Diagram

(NIS4461MT1TXG, NIS4461MT3TXG

Current

Monitor

GND

SOURCE

I

LIMIT

I

SENSE

dv/dt

www.onsemi.com

2

Page 3

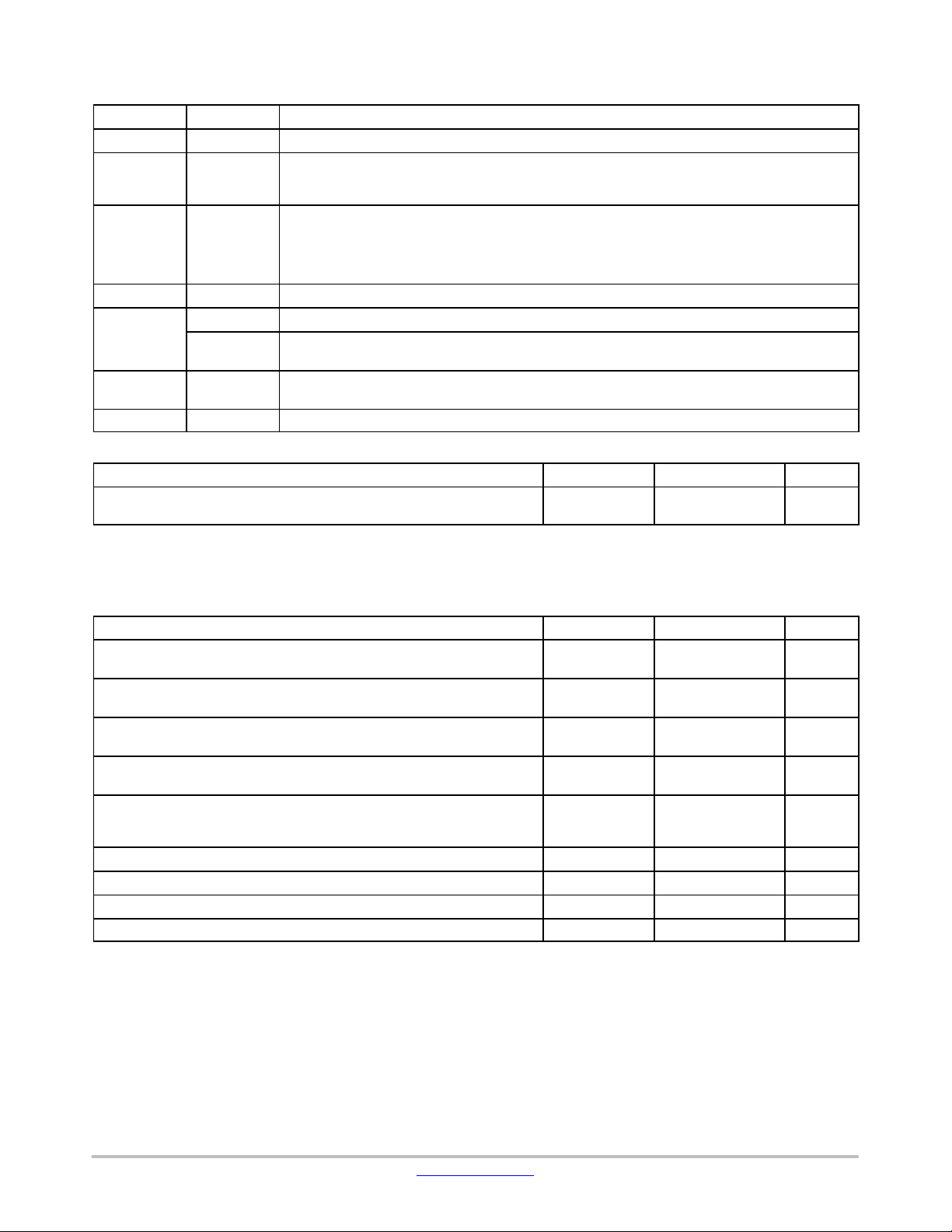

NIS4461 Series

Table 1. FUNCTIONAL PIN DESCRIPTION

Pin Function Description

1 Ground Negative input voltage to the device. This is used as the internal reference for the IC.

2 dv/dt The internal dv/dt circuit controls the slew rate of the output voltage at turn on. It has an internal

3 Enable/Fault The enable/fault pin is a tri−state, bidirectional interface. It can be pulled to ground with external

4 I

5

Limit

NC For NIS4461MT2TXG and NIS4461MT4TXG

I

SENSE

6−10 Source This pin is the source of the internal power FET and the output terminal of the fuse. Connect an

11 (belly pad) V

CC

MAXIMUM RATINGS

Input Voltage, operating, steady−state (VCC to GND, Note 1)

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. Negative voltage will not damage device provided that the power dissipation is limited to the rated allowable power for the package.

Transient (100 ms)

capacitor that allows it to ramp up over a period of 2 ms. An external capacitor can be added to this

pin to increase the ramp time. If an additional time delay is not required, this pin should be left open.

open−drain or open collector device to shutdown the eFuse. It can also be used as a status indicator;

if the voltage level is intermediate around 1.4 V − the eFuse is in the thermal shutdown, if the voltage

level is high around 3 V − the eFuse is operating normally. Do not actively drive this pin to any

voltage. Do not connect a capacitor to this pin.

A resistor between this pin and the source pin sets the overload and short circuit current limit levels.

For NIS4461MT1TXG and NIS4461MT3TXG load current monitor allows the system to monitor the

load current in real time. Connect R

SENSE

to GND.

electrolytic capacitor or Schottky diode for 27 V or higher.

Positive input voltage to the device.

Rating Symbol Value Unit

V

IN

−0.6 to 30

−0.6 to 30

V

Table 2. THERMAL RATINGS

Rating Symbol Value Unit

Thermal Resistance, Junction−to−Air

(4 layer High−K JEDEC JESD51−7 PCB, 100 mm

Thermal Characterization Parameter, Junction−to−Lead

(4 layer High−K JEDEC JESD51−7 PCB, 100 mm

Thermal Characterization Parameter, Junction−to−Board

(4 layer High−K JEDEC JESD51−7 PCB, 100 mm

Thermal Characterization Parameter, Junction−to−Case Top

(4 layer High−K JEDEC JESD51−7 PCB, 100 mm

Total Power Dissipation @ TA = 25°C

(4 layer High−K JEDEC JESD51−7 PCB, 100 mm

Derate above 25°C

Operating Ambient Temperature Range T

Operating Junction Temperature Range T

Non−operating Temperature Range T

Lead Temperature, Soldering (10 Sec) T

2

, 2 oz. Cu)

2

, 2 oz. Cu)

2

, 2 oz. Cu)

2

, 2 oz. Cu)

2

, 2 oz. Cu)

Y

Y

Y

P

q

max

STG

JA

J−L

J−B

J−T

A

J

L

90 °C/W

27.5 °C/W

27.5 °C/W

7.6 °C/W

1.39

11.1

W

mW/°C

−40 to 125 °C

−40 to 150 °C

−55 to 155 °C

260 °C

www.onsemi.com

3

Page 4

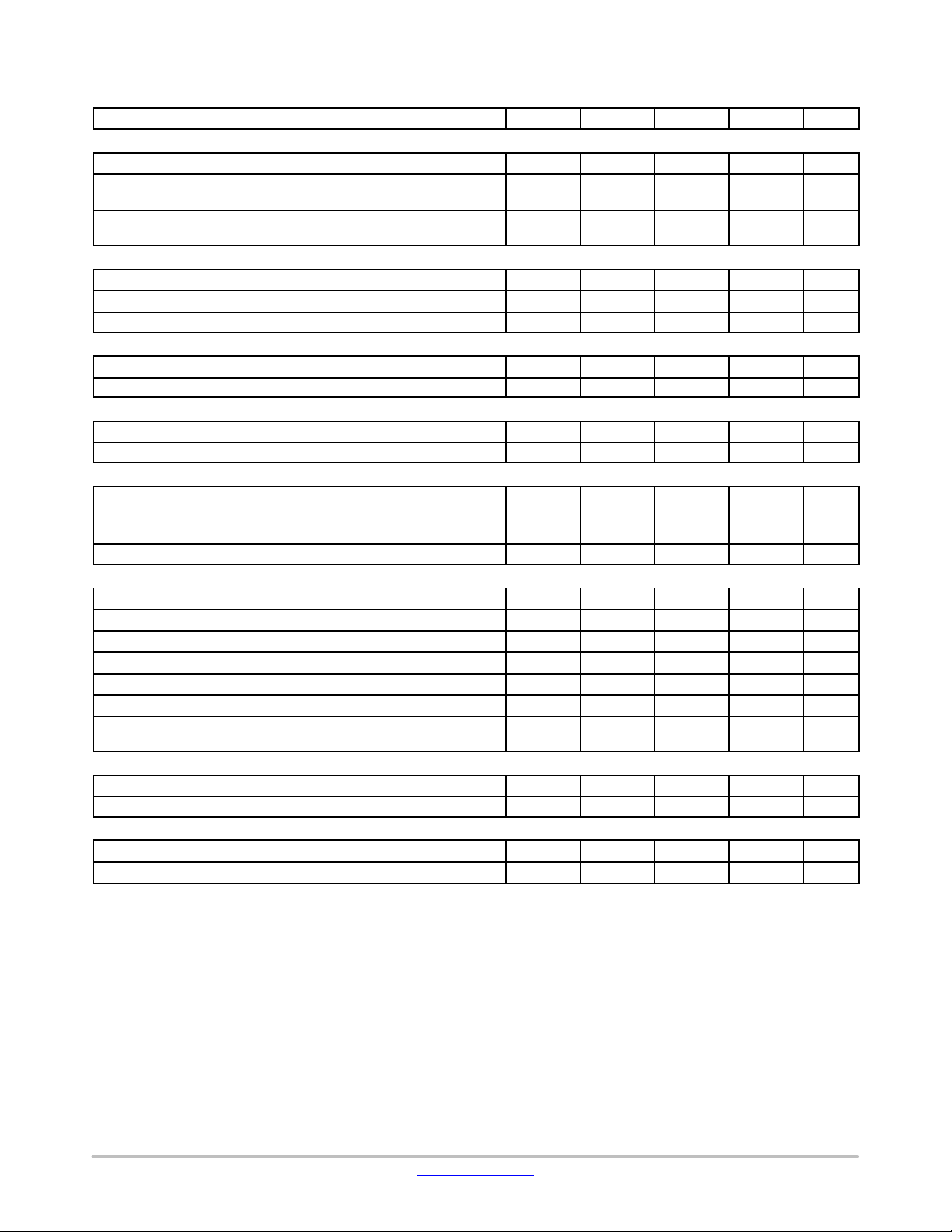

NIS4461 Series

ELECTRICAL CHARACTERISTICS (V

Characteristics

= 24 V, CL = 100 mF, dv/dt pin open, R

CC

Symbol Min Typ Max Unit

= 20 W, Tj = 25°C unless otherwise noted.)

LIMIT

POWER FET

Delay Time (enabling of chip to ID = 100 mA with 1 A resistive load) T

Kelvin ON Resistance (Note 2)

T

= 140°C (Note 3)

J

R

Continuous Current (TA = 25°C, 0.5 in2 copper) (Note 3)

(T

= 80°C, minimum copper)

A

dly

DSon

I

D

I

D

− 220 −

30

−

−

−

39

60

4.2

2.5

50

ms

mW

−

−

A

−

THERMAL LATCH

Shutdown Temperature (Note 3) T

Thermal Hysteresis (Auto−retry part only) T

Thermal Shutdown Response Time T

Hyst

SD

SD

Res

150 175 200 °C

− 45 − °C

10 15 20

ms

UNDERVOLTAGE PROTECTION

Undervoltage Lockout V

UVLO Hysteresis V

UVLO

Hyst

6 6.5 7 V

− 0.80 − V

CURRENT LIMIT

Kelvin Short Circuit Current Limit (R

Kelvin Overload Current Limit (R

Limit

= 20 W, Note 4)

Limit

= 20 W, Note 4)

I

Lim−SS

I

Lim−OL

1.76 2.1 2.64 A

− 4.6 − A

dv/dt CIRCUIT

Output Voltage Ramp Time (Enable to V

Output Voltage Ramp Time

(10% to 90% − V

= 2.4 V to 21.6 V with 24W Load)

OUT

Maximum Capacitor Voltage V

= 23.7 V) t

OUT

slew

t

slew

max

− 2.0 − ms

− 1.2 − ms

− − V

CC

V

ENABLE/FAULT

Logic Level Low (Output Disabled)

Logic Level Mid (Thermal Fault, Output Disabled) V

Logic Level High (Output Enabled) V

High State Maximum Voltage V

Logic Low Sink Current (V

Logic High Leakage Current for External Switch (V

= 0 V) I

enable

= 3.3 V) I

enable

Maximum Fanout for Fault Signal (Total number of chips that can be

V

in−low

in−mid

in−high

in−max

in−low

in−leak

0.35 0.58 0.81 V

0.82 1.4 1.95 V

1.96 2.6 3.0 V

2.51 4.6 5 V

− −15 −25

− − 1.0

Fan − − 3.0 Units

mA

mA

connected to this pin for simultaneous shutdown)

TOTAL DEVICE

Bias Current (Operational)

Bias Current (Shutdown) I

I

Bias

Bias

− − 450

− − 220

mA

mA

LOAD CURRENT MONITOR

Current Monitor Sense (R

SENSE

= 1 kW)

Current Monitor Sense Accuracy I

I

SENSE

ACC

− 1 − mA/A

−10 − 10 %

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

2. Pulse test: Pulse width 300 ms, duty cycle 2%.

3. Verified by design.

4. Refer to explanation of short circuit and overload conditions in application note AND9441.

5. Device will shut down prior to reaching this level based on actual UVLO trip point.

6. For output slew rate calculation with external capacitor, please refer to ”Output Slew Rate (dv/dt)” in the ”Application Information ” section

www.onsemi.com

4

Page 5

100

10

TIME (ms)

NIS4461 Series

−40_C

25_C

85_C

+12 V

ENABLE

GND

1

01020 405060 80

30 70

POWER (W)

Figure 3. Thermal Trip Time vs. Power Dissipation

I

LIMIT

dv/dtGND

10

9

8

7

6

4

11

V

CC

SOURCE

NIS4461MT2/4

3

ENABLE/

FAULT

12

Figure 4. Application Circuit with Direct Current Sensing

R

S

LOAD

+12 V

ENABLE

GND

11

V

CC

SOURCE

10

9

8

7

3

ENABLE

NIS4461MT1/3

I

SENSE

I

LIMIT

dv/dtGND

6

4

R

SENSE

12

Figure 5. Application Circuit with Direct Current Sensing

www.onsemi.com

5

R

S

LOAD

Page 6

NIS4461 Series

LOAD

SOURCE

I

LIMIT

dv/dt

V

CC

V

CC

NIS5420 NIS4461

ENABLE/

FAULT

GND

ENABLE/

FAULT

GND

ENABLE

Figure 6. Common Thermal Shutdown

SOURCE

I

LIMIT

dv/dt

R

S

LOAD

www.onsemi.com

6

Page 7

NIS4461 Series

TYPICAL CHARACTERISTICS

2.0

1.95

1.9

1.85

1.8

(V)

1.75

SENSE

1.7

VI

1.65

1.6

1.55

1.5

−40 −20 0 20 40 60 80 100

TEMPERATURE (°C)

Figure 7. VI

vs. Temperature

SENSE

50

48

46

44

42

(mW)

40

38

DS(ON)

R

36

34

32

30

0 5 10 15 20 25 30

(V)

V

CC

Figure 9. R

DS(ON)

vs. V

CC

4.5

4

3.5

3

(V)

2.5

2

SENSE

VI

1.5

1

0.5

0

0 0.5 1 1.5 2 2.5 3 3.5 4

LOAD CURRENT (A)

Figure 8. VI

vs. Load Current

SENSE

100

90

80

70

60

(mW)

50

40

DS(ON)

R

30

20

10

0

−40 −20 0 20 40 60 100

TEMPERATURE (°C)

Figure 10. R

vs. Temperature

DS(ON)

4.5 5

80

10

9

IOL, R

LIM

= 10 W

8

(A)

SC

/I

OL

I

7

6

5

4

IOL, R

LIM

= 40 W

ISC, R

IOL, R

LIM

LIM

= 10 W

= 20 W

3

2

1

0

ISC, R

LIM

= 40 W

ISC, R

LIM

= 20 W

−40 −20 0 20 40 60 100

TEMPERATURE (°C)

Figure 11. IOL and ISC vs. Temperature

(A)

SC

/I

OL

I

80

www.onsemi.com

7

8

7

6

5

4

I

OL

3

2

I

SC

1

0

010 30 50 70

20 40 60

R

(W)

LIM

Figure 12. IOL and ISC vs. R

LIM

Page 8

NIS4461 Series

TYPICAL CHARACTERISTICS

30

VCC = 24 V

I

LOAD

25

20

(ms)

15

SLEW

T

10

5

= 1 A

Figure 13. Slew Rate Control Screenshot

1.4

1.2

1

0.8

(ms)

0.6

SLEW

T

0.4

0.2

0

−40 0 20 60 100

TEMPERATURE (°C)

Figure 15. T

SLEW

40−20 80

vs. Temperature

0

0 100 600

Figure 14. T

7.0

6.8

6.6

6.4

6.2

6.0

5.8

5.6

UVLO TURN ON (V)

5.4

5.2

5.0

−40 −20 0 20 40 60 100

200 300 400 500

Capacitance from dV/dt Pin to GND (pF)

vs. dV/dt Capacitance

SLEW

TEMPERATURE (°C)

Figure 16. UVLO TURN ON vs. Temperature

80

www.onsemi.com

8

Page 9

NIS4461 Series

APPLICATION INFORMATION

Basic Operation

This device is a self−protected, resettable, electronic fuse.

It contains circuits to monitor the input voltage, output

voltage, output current and die temperature.

On application of the input voltage, the device will apply

the input voltage to the load based on the restrictions of the

controlling circuits. The dv/dt of the output voltage will be

controlled by the internal dv/dt circuit. The output voltage

will slew from 0 V to the rated output voltage in 1 ms, unless

additional capacitance is added to the dv/dt pin.

The device will remain on as long as the temperature does

not exceed the 175°C limit that is programmed into the chip.

The current limit circuit does not shut down the part but will

reduce the conductivity of the FET to maintain a constant

current at the internally set current limit level.

An internal charge pump provides bias for the gate voltage

of the internal n−channel power FET and also for the current

limit circuit. The remainder of the control circuitry operates

between the input voltage (V

Current Limit

) and ground.

CC

The current limit circuit uses a SENSEFET along with a

reference and amplifier to control the peak current in the

device. The SENSEFET allows for a small fraction of the

load current to be measured, which has the advantage of

reducing the losses in the sense resistor as well as increasing

the value and decreasing the power rating of the sense

resistor. Sense resistors are typically in the tens of ohms

range with power ratings of several milliwatts making them

very inexpensive chip resistors.

The current limit circuit has two limiting values, one for

short circuit events which are defined as the mode of

operation in which the gate is high and the FET is fully

enhanced. The overload mode of operation occurs when the

device is actively limiting the current and the gate is at an

intermediate level. For a more detailed description of this

circuit please refer to application note AND9441.

There are two methods of biasing the current limit circuit

for this device. They are shown in the two application

figures. Direct current sensing connects the sense resistor

between the current limit pin and the load. This method

includes the bond wire resistance in the current limit circuit.

This resistance has an impact on the current limit levels for

a given resistor and may vary slightly depending on the

impedance between the sense resistor and the source pins.

The on resistance of the device will be slightly lower in this

configuration since all five source pins are connected in

parallel and therefore, the effective bond wire resistance is

one fifth of the resistance for any given pin.

The other method is Kelvin sensing. This method uses one

of the source pins as the connection for the current sense

resistor. This connection senses the voltage on the die and

therefore any bond wire resistance and external impedance

on the board have no effect on the current limit levels. In this

configuration the on resistance is slightly increased relative

to the direct sense method since only four of the source pins

are used for power.

Undervoltage Lockout

The undervoltage lockout circuit uses a comparator with

hysteresis to monitor the input voltage. If the input voltage

drops below the specified level, the output switch will be

switched to a high impedance state.

Output Slew Rate dv/dt

The dv/dt circuit brings the output voltage up under a

linear, controlled rate regardless of the load impedance

characteristics. An internal ramp generator creates a linear

ramp, and a control circuit forces the output voltage to

follow that ramp, scaled by a factor.

The default ramp time is approximately 1 ms. This can be

modified by adding an external capacitor at the dv/dt pin.

This pin includes an internal current source of

approximately 85 nA. Since the current level is very low, it

is important to use a ceramic cap or other low leakage

capacitor. Aluminum electrolytic capacitors are not

recommended for this circuit.

The ramp time from 0 to the nominal output voltage can

be determined by the following equation, where t is in

seconds:

t

2.4*21.6

C

+ 3.8e7 @ǒ28 pF ) C

ǒ

ext

t

+

2.4−21.6

* 0.00127

3.8e7

Ǔ

) 0.00127

ext

Ǔ

* 28 pF

Where:

C is in Farads

t is in seconds

Any time that the unit shuts down due to a fault, enable

shut−down, or recycling of input power, the timing capacitor

will be discharged and the output voltage will ramp from 0

at turn on.

Enable/Fault

The Enable/Fault pin is a multi−function, bidirectional pin

that can control the output of the chip as well as send

information to other devices regarding the state of the chip.

When this pin is low, the output of the fuse will be turned off.

When this pin is high the output of the fuse will be

turned−on. If a thermal fault occurs, this pin will be pulled

low to an intermediate level by an internal circuit.

To use as a simple enable pin, an open drain or open

collector device should be connected to this pin. Due to its

tri−state operation, it should not be connected to any type of

logic with an internal pullup device.

If the chip shuts down due to the die temperature reaching

its thermal limit, this pin will be pulled down to an

intermediate level. This signal can be monitored by an

external circuit to communicate that a thermal shutdown has

occurred. If this pin is tied to another device in this family,

www.onsemi.com

9

Page 10

NIS4461 Series

a thermal shutdown of one device will cause both devices to

disable their outputs. Both devices will turn on once the fault

is removed for the auto−retry devices.

For the latching thermal device, the outputs will be

enabled after the enable pin has been pulled to ground with

an external switch and then allowed to go high or after the

input power has been recycled. For the auto retry devices,

both devices will restart as soon as the die temperature of the

device in shutdown has been reduced to the lower thermal

limit.

Thermal Protection

The NIS4461 includes an internal temperature sensing

circuit that senses the temperature on the die of the power

3.3 V

1.95 V

FET. If the temperature reaches 175°C, the device will shut

down, and remove power from the load. Output power can

be restored by either recycling the input power or toggling

the enable pin for thermally latching devices. Power will

automatically be reapplied to the load for auto−retry devices

once the die temperature has been reduced by 45°C.

The thermal limit has been set high intentionally, to

increase the trip time during high power transient events. It

is not recommended to operate this device above 150°C for

extended periods of time.

Enable/Fault

0.81 V

Gnd

Figure 17. Fault/Enable Signal Levels

12 mA

1.4 V

SD

Startup

Blanking

Thermal

Shutdown

2.64 V

0.58 V

+

−

−

+

Thermal Reset

Thermal SD

Enable SD

Figure 18. Enable/Fault Simplified Circuit

www.onsemi.com

10

Page 11

NIS4461 Series

ORDERING INFORMATION

Device Marking Features ISENSE Package Shipping

NIS4461MT1TXG 61T1 Thermal Latching Ye s

NIS4461MT2TXG 61T2 Thermal Latching No

NIS4461MT3TXG 61T3 Auto−Retry Ye s

NIS4461MT4TXG 61T4 Auto−Retry No

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

WDFN10

(Pb−Free)

3000 / Tape & Reel

†

www.onsemi.com

11

Page 12

NIS4461 Series

PACKAGE DIMENSIONS

WDFN10, 3x3, 0.5P

CASE 522AA

ISSUE A

10X

REFERENCE

2X

2X

PIN ONE

0.15 C

0.10 C

0.08 C

10X

0.15 C

L

D

TOP VIEW

SIDE VIEW

D2

1

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED

TERMINAL AND IS MEASURED BETWEEN

0.15 AND 0.30mm FROM TERMINAL.

4. COPLANARITY APPLIES TO THE EXPOSED

PAD AS WELL AS THE TERMINALS.

DIMAMIN NOM MAX

A1 0.00 0.03 0.05

A3 0.20 REF

b 0.18 0.24 0.30

D 3.00 BSC

D2 2.45 2.50 2.55

E 3.00 BSC

E2

e 0.50 BSC

K

L

MILLIMETERS

0.70 0.75 0.80

1.75 1.80 1.85

0.19 TYP

0.35 0.40 0.45

A3

B

A

E

A

A1

SEATING

C

PLANE

SOLDERING FOOTPRINT*

2.6016

e

5

E2

2.1746

1.8508

3.3048

10X

K 10

BOTTOM VIEW

6

b

10X

0.05 C

A0.10 C

B

NOTE 3

10X

0.5651

10X

0.3008

0.5000 PITCH

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

12

Loading...

Loading...