Page 1

N-Channel Logic Level

Enhancement Mode Field

Effect Transistor

NDS331N

General Description

These N−Channel logic level enhancement mode power field effect

transistors are produced using ON Semiconductor’s proprietary, high

cell density, DMOS technology. This very high density process is

especially tailored to minimize on−state resistance. These devices are

particularly suited for low voltage applications in notebook

computers, portable phones, PCMCIA cards, and other battery

powered circuits where fast switching, and low in−line power loss are

needed in a very small outline surface mount package.

Features

• 1.3 A, 20 V

♦ R

♦ R

= 0.21 @ VGS = 2.7 V

DS(on)

= 0.16 @ VGS = 4.5 V

DS(on)

• Industry Standard Outline SOT−23 Surface Mount Package Using

Poprietary SUPERSOTt−3 Design for Superior Thermal and

Electrical Capabilities

• High Density Cell Design for Extremely Low R

DS(on)

• Exceptional On−Resistance and Maximum DC Current Capability

• This is a Pb−Free Device

www.onsemi.com

D

G

S

SOT−23/SUPERSOT−23, 3 LEAD, 1.4x2.9

CASE 527AG

MARKING DIAGRAM

&Y

331 &G

&Y = Binary Calendar Year Coding Scheme

331 = Specific Device Code

&G = Date Code

D

© Semiconductor Components Industries, LLC, 2017

April, 2021 − Rev. 6

G

ORDERING INFORMATION

Device Package Shipping

NDS331N SOT−23−3/

SUPERSOT−23

(Pb−Free)

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

1 Publication Order Number:

S

†

3000 /

Tape & Reel

NDS331N/D

Page 2

NDS331N

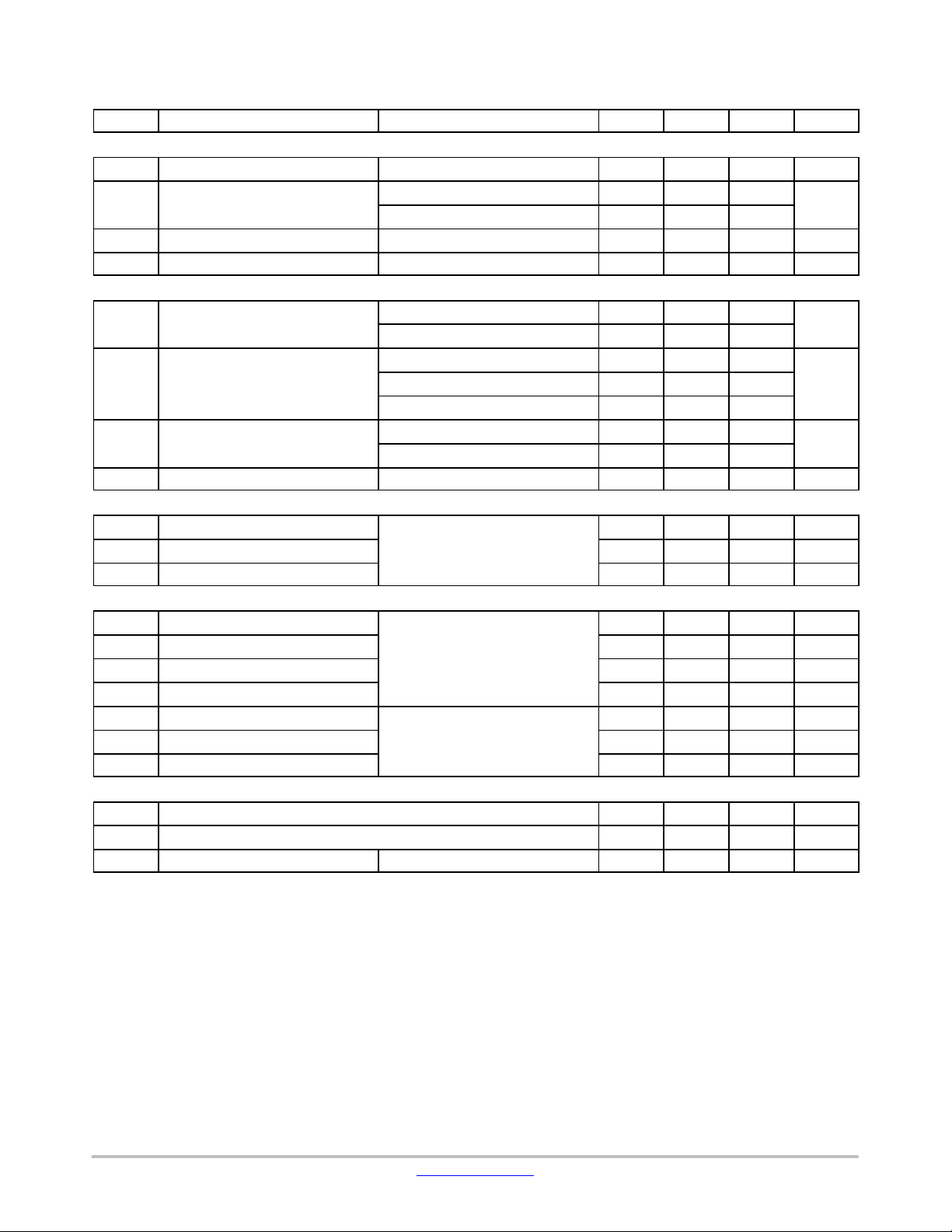

ABSOLUTE MAXIMUM RATINGS T

Symbol

V

V

DSS

GSS

I

D

Drain−Source Voltage 20 V

Gate−Source Voltage − Continuous ±8 V

Maximum Drain Current – Continuous (Note 1a) 1.3

= 25°C unless otherwise noted.

A

Parameter Ratings Unit

A

Maximum Drain Current – Pulsed 10

P

Maximum Power Dissipation (Note 1a) 0.5

D

W

Maximum Power Dissipation (Note 1b) 0.46

TJ, T

Operating and Storage Temperature Range −55 to +150 °C

STG

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

THERMAL CHARACTERISTICS

Symbol Parameter Ratings Unit

R

R

1. R

JA

mounting surface of the drain pins. R

(t) +

P

D

Typical R

Thermal Resistance, Junction−to−Ambient (Note 1a) 250 °C/W

JA

Thermal Resistance, Junction−to−Case (Note 1) 75 °C/W

JC

is the sum of the junction−to−case and case−to−ambient thermal resistance where the case thermal reference is defined as the solder

is guaranteed by design while R

JC

T

* T

J

R

(t)

JA

using the board layouts shown below on 4.5″x5″ FR−4 PCB in a still air environment:

JA

a) 250°C/W when mounted on a 0.02 in

T

A

+

* T

J

A

R

) R

JC

CA

2

+ I

(t) R

DS(on)@T

D

(t)

2

pad

J

of 2oz copper.

is determined by the user’s board design.

CA

b) 270°C/W when mounted on a 0.001 in2 pad

of 2oz copper.

Scale 1:1 on letter size paper

www.onsemi.com

2

Page 3

NDS331N

ELECTRICAL CHARACTERISTICS T

Symbol

Parameter Test Conditions Min Typ Max Unit

= 25°C unless otherwise noted.

A

OFF CHARACTERISTICS

BV

I

DSS

Drain–Source Breakdown Voltage

DSS

Zero Gate Voltage Drain Current

VGS = 0 V, ID = 250 A

VDS = 16 V, VGS = 0 V − − 1 A

20 − − V

VDS = 16 V, VGS = 0 V, TJ = 125°C − − 10

I

GSSF

I

GSSR

Gate–Body Leakage, Forward VGS = 8 V, VDS = 0 V − − 100 nA

Gate–Body Leakage, Reverse VGS = −8 V, VDS = 0 V − − −100 nA

ON CHARACTERISTICS (Note 2)

V

GS(th)

R

DS(on)

Gate Threshold Voltage

Static Drain–Source On–Resistance

VDS = VGS, ID = 250 A

VDS = VGS, ID = 250 A, TJ = 125°C

0.5 0.7 1

0.3 0.53 0.8

VGS = 2.7 V, ID = 1.3 A − 0.15 0.21

V

VGS = 2.7 V, ID = 1.3 A, TJ = 125°C − 0.24 0.4

VGS = 4.5 V, ID = 1.5 A − 0.11 0.16

I

D(on)

On–State Drain Current

VGS = 2.7 V, VDS = 5 V 3 − −

A

VGS = 4.5 V, VDS = 5 V 4 − −

g

Forward Transconductance VDS = 5 V, ID = 1.3 A − 3.5 − S

FS

DYNAMIC CHARACTERISTICS

C

C

C

Input Capacitance

iss

Output Capacitance − 85 − pF

oss

Reverse Transfer Capacitance − 28 − pF

rss

VDS = 10 V, VGS = 0 V, f = 1.0 MHz

− 162 − pF

SWITCHING CHARACTERISTICS (Note 2)

t

D(on)

t

t

D(off)

t

Q

Q

Q

Turn–On Delay Time

Turn–On Rise Time − 25 40 ns

r

Turn–Off Delay Time − 10 20 ns

Turn–Off Fall Time − 5 20 ns

f

Total Gate Charge

g

Gate–Source Charge − 0.3 − nC

gs

Gate–Drain Charge − 1 − nC

gd

VDD = 5 V, ID = 1 A, VGS = 5 V,

= 6

R

GEN

VDS = 5 V, ID = 1.3 A, VGS = 4.5 V

− 5 20 ns

− 3.5 5 nC

DRAIN−SOURCE DIODE CHARACTERISTICS AND MAXIMUM RATINGS

Maximum Continuous Drain–Source Diode Forward Current − − 0.42 A

I

S

I

SM

V

Maximum Pulsed Drain−Source Diode Forward Current − − 10 A

Drain–Source Diode Forward Voltage VGS = 0 V, IS = 0.42 A (Note 2) − 0.8 1.2 V

SD

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

2. Pulse Test: Pulse Width ≤ 300 s, Duty Cycle ≤ 2.0%.

www.onsemi.com

3

Page 4

NDS331N

TYPICAL ELECTRICAL CHARACTERISTICS

4

3

2

1

, Drain−Source Current (A)

D

I

0

0

Figure 1. On−Region Characteristics Figure 2. On−Resistance Variation with

1.8

ID = 1.3 A

V

GS

1.6

1.4

1.2

, Normalized

1

DS(on)

R

0.8

Drain−Source On−Resistance

VGS = 4.5 V

3.0

2.7

2.5

123

VDS, Drain−Source Voltage (V)

= 2.7 V

2.0

1.5

1.75

1.5

VGS = 2.0 V

1.25

, Normalized

1

DS(on)

R

0.75

Drain−Source On−Resistance

2.5

2.7 3.0

0.5

021 1.5 2.5 3

0.5

I

, Drain Current (A)

D

Drain Current and Gate Voltage

1.75

1.25

, Normalized

DS(on)

R

0.75

Drain−Source On−Resistance

1.5

1

VGS = 2.7 V

TJ = 125°C

25°C

−55°C

3.5

4.5

0.6

−50 −25 0 25 50 75 100 125 150

Figure 3. On−Resistance Variation with

Temperature

4

VDS = 5.0 V

3

2

, Drain Current (A)

D

I

1

0

0 0.5 1 1.5 2

VGS, Gate To Source Voltage (V)

TJ = −55°C

25°C

125°C

2.5 3

Figure 5. Transfer Characteristics Figure 6. Gate Threshold Variation with

0.5

0 0.5 1 1.5 2

I

, Drain Current (A)TJ, Junction Temperature (°C)

D

Figure 4. On−Resistance Variation with

Drain Current and Temperature

1.3

1.2

VDS = V

ID = 250 A

1.1

1

0.9

0.8

Threshold Voltage

0.7

, Normalized Gate−Source

th

V

0.6

0.5

−50 −25 0 25 50 75 100 125 150

T

, Junction Temperature (°C)

J

Temperature

2.5 3

GS

www.onsemi.com

4

Page 5

NDS331N

2

TYPICAL ELECTRICAL CHARACTERISTICS (continued)

1.12

ID = 250 A

1.08

1.04

1

Breakdown Voltage

, Normalized Drain−Source

0.96

DSS

BV

0.92

−50 −25 0 25 50 75 100 125 150

TJ, Junction Temperature (°C)

Figure 7. Breakdown Voltage Variation with

Temperature

600

400

200

100

1

VGS = 0 V

0.1

0.01

TJ = 125°C

0.001

, Reverse Drain Current (A)

S

I

25°C

−55°C

0.0001

0 0.2 0.4 0.6 0.8

1

1.

VSD, Body Diode Forward Voltage (V)

Figure 8. Body Diode Forward Voltage Variation

with Source Current and Temperature

5

ID = 1.3 A

C

iss

C

oss

4

3

VDS = 5 V

10 V

15 V

50

Capacitance (pF)

20

f = 1 MHz

= 0 V

V

GS

10

0.1 0.5

2 5 10 20

VDS, Drain−Source Voltage (V)

C

rss

2

, Gate−Source Voltage (V)

1

GS

V

0

0123 410.2

Q

, Gate Charge (nC)

g

Figure 9. Capacitance Characteristics Figure 10. Gate Charge Characteristics

V

DD

t

V

IN

V

GS

R

GEN

G

R

L

D

V

OUT

DUT

S

d(on)

V

V

OUT

IN

10%

t

on

10%

50%

t

r

90%

Pulse Width

t

d(off)

Figure 11. Switching Test Circuit Figure 12. Switching Waveforms

50%

90%

t

off

90%

10%

t

f

Inverted

5

www.onsemi.com

5

Page 6

NDS331N

TYPICAL ELECTRICAL CHARACTERISTICS (continued)

8

V

= 5.0 V

DS

6

TJ = −55°C

4

125°C

2

, Transconductance (Siemens)

FS

g

0

02

ID, Drain Current (A)

Figure 13. Transconductance Variation with Drain

Current and Temperature

1

0.8

0.6

1a

1b

0.4

0.2

Steady−State Power Dissipation (W)

0

0 0.2

2oz Copper Mounting Pad Area (in2)

4.5″x5″ FR−4 Board

= 25°C

T

A

Still Air

25°C

0.4

50

This Area is Limited by r

DS(on)

10

100 s

1 ms

1

10 ms

, Drain Current (A)

D

I

0.1

0.01

Single Pulse

= Max Rated

T

J

R

= 270°C/W

JA

T

= 25°C

A

Curve Bent to

Measured Date

4 0.1 1 1031

, Drain to Source Voltage (V)

V

DS

100 ms

60

Figure 14. Maximum Safe Operating Area

1.8

1.6

1.4

1a

1.2

1b

, Steady−State Drain Current (A)

D

I

1

0 0.1 0.2 0.30.30.1

2oz Copper Mounting Pad Area (in

4.5″x5″ FR−4 Board

= 25°C

T

A

Still Air

V

= 2.7 V

GS

2

)

0.4

Figure 15. SUPERSOT−3 Maximum Steady−State

Power Dissipation versus Copper Mounting Pad Area

2

1

0.1

0.01

, Normalized Thermal Impedance

JA

Z

0.001

10

Duty Cycle−Descending Order

D = 0.5

0.2

0.1

0.05

0.02

0.01

Single Pulse

−4

10

−3

10

−2

10

−1

t, Rectangular Pulse Duration (s)

Figure 17. Transient Thermal Response Curve

NOTE: Thermal characterization performed using the conditions described in

Note 1b. Response will change depending on the circuit board design.

www.onsemi.com

Figure 16. Maximum Steady−State Drain

Current versus Copper Mounting Pad Area

P

DM

t

1

t

NOTES:

Z

(t)= r(t) x R

JA

R

= 270°C/W

JA

Peak T

= PDM x Z

J

Duty Cycle, D = t1 / t

1 10 100

6

2

JA

(t) + T

A

JA

2

1000

Page 7

NDS331N

SUPERSOT is a trademark of Semiconductor Components Industries, LLC (SCILLC) or its subsidiaries in the United States and/or other countries.

www.onsemi.com

7

Page 8

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SOT−23/SUPERSOTt−23, 3 LEAD, 1.4x2.9

CASE 527AG

ISSUE A

DATE 09 DEC 2019

GENERIC

MARKING DIAGRAM*

XXXMG

G

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98AON34319E

SOT−23/SUPERSOT−23, 3 LEAD, 1.4X2.9

XXX = Specific Device Code

M = Month Code

G = Pb−Free Package

(Note: Microdot may be in either location)

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

not follow the Generic Marking.

PAGE 1 OF 1

www.onsemi.com

Page 9

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...