Page 1

NCV891234, NCV891334

NCV891234, NCV891334

Evaluation Board

User'sManual

Description

The NCV891x34 is a Dual Mode regulator intended for

Automotive, battery−connected applications. The output is

fixed to either 3.3 V or 5.0 V, capable of delivering 2.0 A

(NCV891234) or 3.0 A (NCV891334). At low output

currents (≤ 50 mA), the device will operate in LDO mode,

switching to PWM mode as current increases beyond

50 mA. The device is equipped with SYNCI and SYNCO

pins to synchronize to an external clock and/or another

NCV891x34. A reset (with fixed delay) and a fault pin

(flagging low input voltage and high temperature warnings)

simplify interfacing with a microcontroller.

www.onsemi.com

EVAL BOARD USER’S MANUAL

This document will help the user to set up the hardware

and to make demonstration kit running. All evaluation kit

components will be described (evaluation board,

connections, jumper’s configuration). A quick test

procedure will be also described to guide the user.

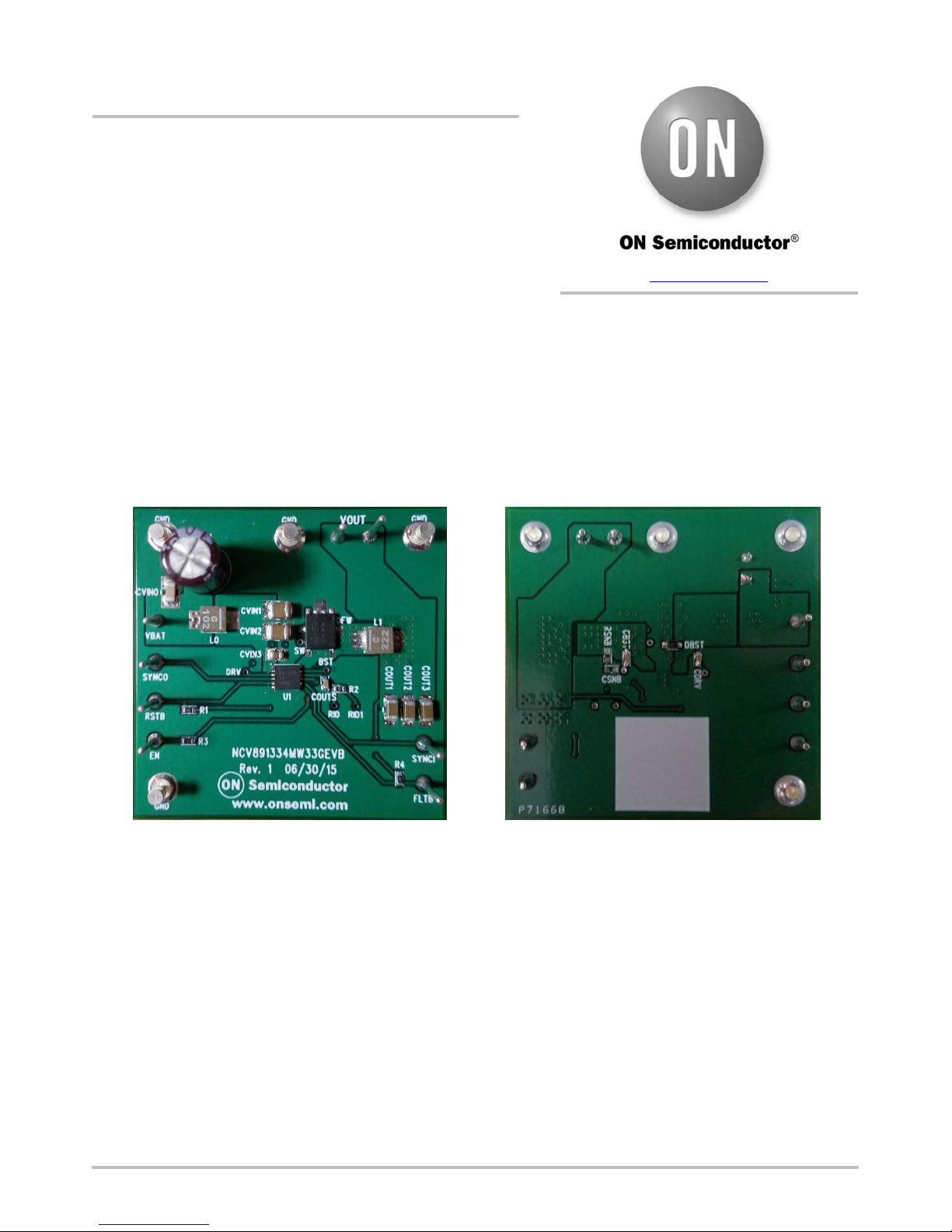

Top Side Bottom Side

Features and Benefits

• 40 mA Iq in Light Load Condition

• 2.0 A Maximum Output Current in PWM Mode in

NCV891234

• 3.0 A Maximum Output Current in PWM Mode in

NCV891334

• Internal N−channel Power Switch

• V

Operating Range 3.7 V to 36 V, Withstands Load

IN

Dump to 45 V

• Logic Level Enable Pin can be Tied to Battery

© Semiconductor Components Industries, LLC, 2016

November, 2016 − Rev. 0

Figure 1. Evaluation Board Photo

• Fixed Output Voltage of 5.0 V or 3.3 V with ±2%

Accuracy

• 2 MHz Free−running Switching Frequency

• Input and Output Synchronization Pins

Typical Applications

• Safety – Vision Systems

• Audio, Infotainment

• Instrumentation

• Telematics

1 Publication Order Number:

EVBUM2492/D

Page 2

NCV891234, NCV891334

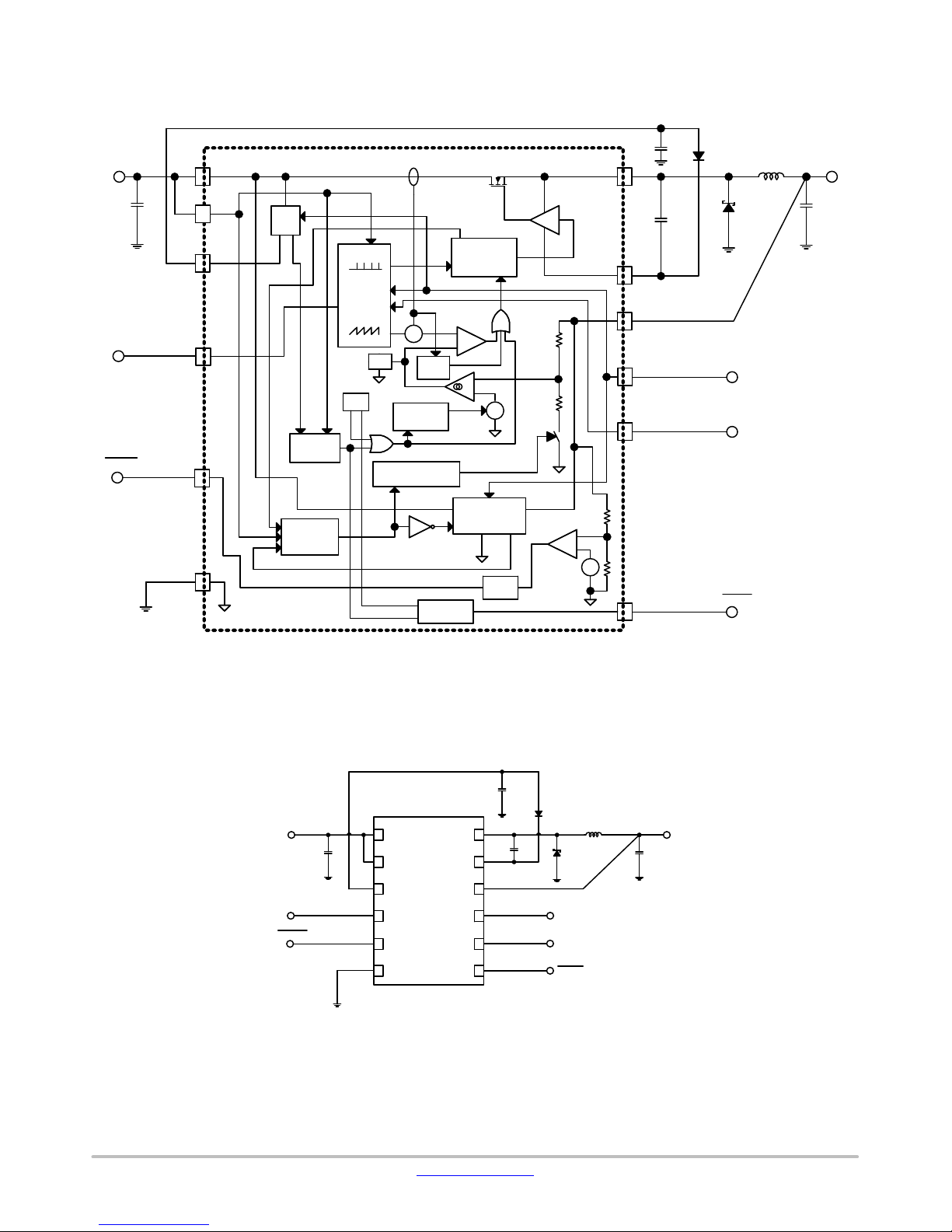

BLOCK DIAGRAM

CDRV

VIN VOUT

CIN

SYNCO

RESET

VIN

VIN2

DRV

SYNCO

RSTB

3.3 V

Reg

VOLTAGES

MONITORS

MODE

SELECTION

Oscillator

Enable

Sync

Sync

Out

comp

TSD

In

+

+

S

2A, 3A

detector

Soft−Start

RESET

Switcher Supply

ON

Low

PWM

LOGIC

ON

+

−

−

+

LINEAR

REGULATOR

ON

OFF

+

OVLD

−

+

GND

Logic

Fault

NCV891234, NCV891334

Detection

SW

BST

VOUT

EN

SYNCI

+

FLTB

CBST

DBST

DFW

EN

SYNCI

FAULT

L1

COUT

Figure 2. NCV891x34 Simplified Block Diagram

TYPICAL APPLICATION

CDRV

DBST

VIN VOUT

CIN

SYNCO

RESET

Figure 3. NCV891x34 Typical Application Diagram

VIN

VIN 2

DRV

SYNCO

GND

NCV891x34

VOUT

SYNCIRSTB

FLTB

SW

BST

L1

CBST

EN

DFW

ENABLE

SYNCI

FAULT

COUT

www.onsemi.com

2

Page 3

NCV891234, NCV891334

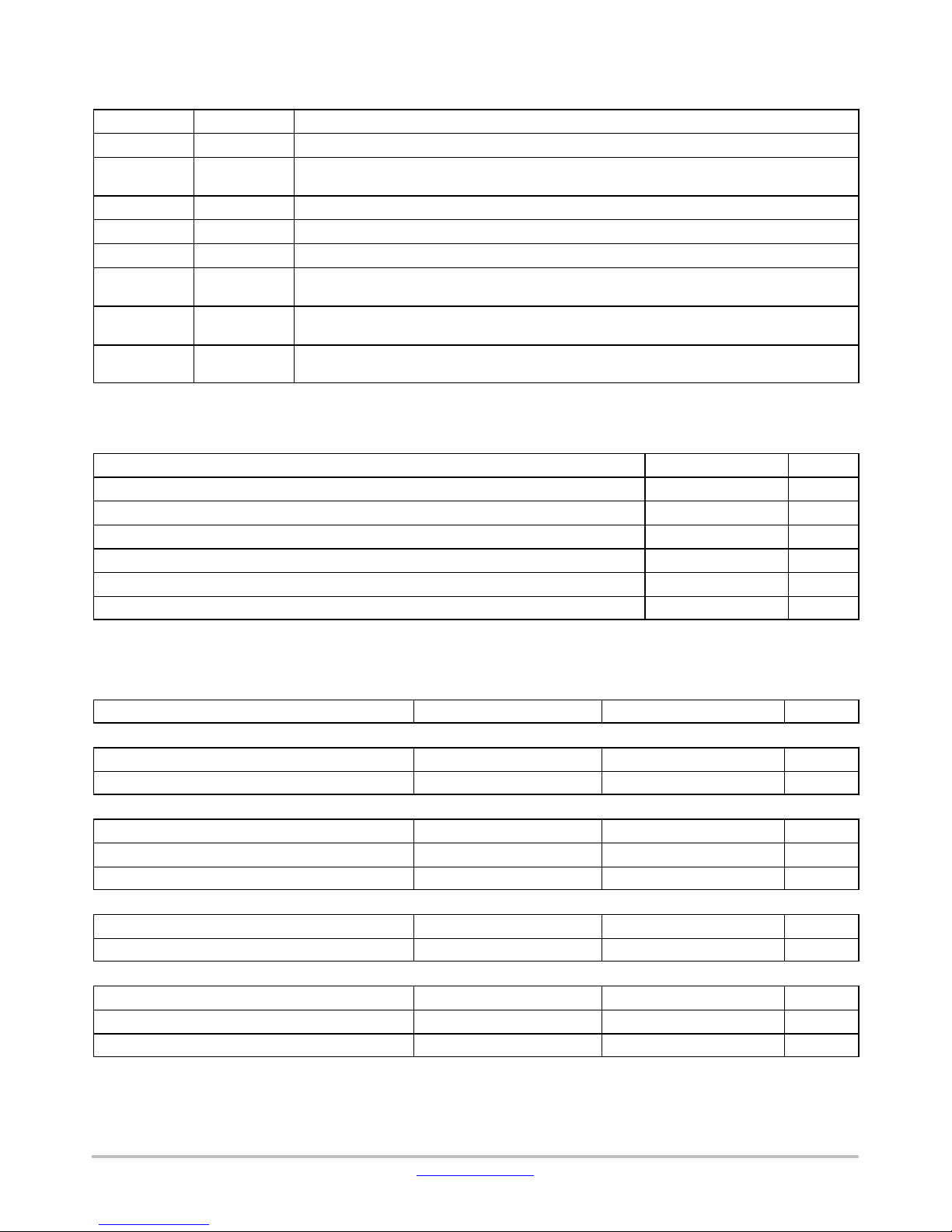

Table 1. EVALUATION BOARD TERMINALS

Pin Number Pin Name Function

1 VBAT Input voltage from battery. Place an input filter capacitor in close proximity to this pin.

4 SYNCO Out−of−phase synchronization output. Turn−on of the Power Switch causes the SYNCO signal to

5 RSTB Reset function. Open drain output, pulling down to ground when output voltage is out of regulation.

6 GND Battery return and output voltage ground reference.

7 FLTB Fault flag indicating various fault conditions for the part.

8 SYNCI Synchronization input. Connecting an external clock to this pin synchronizes switching to the rising

9 EN This TTL compatible Enable input allows the direct connection of Battery as the enable signal.

10 VOUT Output voltage feedback and LDO output. Feedback of output voltage used for regulation, as well

Table 2. ABSOLUTE MAXIMUM RATINGS

(Voltages are with respect to GND)

DC supply voltage (VBAT) −0.3 to 45 V

DC supply voltage (EN) −0.3 to 40 V

DC supply voltage (VOUT) −0.3 to 18 V

DC supply voltage (SYNCI, RSTB, and FLTB) −0.3 to 6 V

DC supply voltage (SYNCO) −0.3 to 3.6 V

Storage Temperature Range −55 to +150 °C

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

fall (and rise half a switching period later).

edge of the SYNCI signal.

Grounding this signal stops switching and reduces quiescent current draw to a minimum.

as LDO output in LDO mode.

Rating

Value Units

Table 3. ELECTRICAL CHARACTERISTICS

Characteristics Conditions Typical Value Units

Regulation

Output Voltage (NCV891x34MW33GEVB)

Output Voltage (NCV891x34MW50GEVB) 5.0 V

Switching

Switching Frequency

Soft−start Time 1.4 ms

Synchronization Frequency Range 1.8 to 2.5 MHz

Current Limit

Peak Current Limit (NCV891234MWxxGEVB)

Peak Current Limit (NCV891334MWxxGEVB) 4.4 A

Protections

V

Input Undervoltage Lockout (UVLO)

Input Overvoltage Protection V

Thermal Shutdown TJ rising 170 °C

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

decreasing 3.1 V

BAT

increasing 37.7 V

BAT

3.3 V

2.0 MHz

3.25 A

www.onsemi.com

3

Page 4

NCV891234, NCV891334

Quick−Start Guide

The following steps will get you familiar with the setup of

inputs and outputs of the NCV891x34.

Required Equipment

1 DC Source – ≥ 40 V, ≥ 2 A capable VBAT

1 Oscilloscope – 2 Channel minimum VOUT and SW

1 Multi−meter VOUT

1 DC Electronic Load – 4 A capable ILOAD

1 Clip to Clip Lead or equivalent

1. Connect DC source set to 13.2 V DC between the

VBAT and GND terminals in the upper left of the

evaluation board.

2. Connect a multi−meter or oscilloscope probe

between the VOUT and GND terminals located in

the upper right of the evaluation board.

3. Connect an oscilloscope probe between the SW

and GND terminals located in the center of the

evaluation board.

4. Connect a jumper wire between VBAT to the EN

input.

Verify that VOUT is:

a.) 3.3 V for NCV891x34MW33GEVB

b.) 5.0 V for NCV891x34MW50GEVB

5. Apply a 40 mA load to VOUT.

Verify that VOUT is at the necessary regulated

voltage and the SW signal shows that DC level

(LDO mode).

6. Increase the load on VOUT to 1.5 A.

Verify that VOUT is at the necessary regulated

voltage and the SW signal shows a stable 2 MHz

pulsed waveform with amplitude approximately

between VBAT and GND (PWM mode).

7. While at load, increase VBAT to 21 V.

Verify that the SW signal now shows a stable

1 MHz pulsed waveform with amplitude

approximately between VBAT and GND.

8. Increase VBAT to 39.5 V.

Verify the switching regulator turns off and there is

0 V at VOUT.

9. Reduce VBAT to 13.2 V.

Verify that VOUT is restored to its previous value

and that the SW signal returns to a 2 MHz pulsed

waveform with amplitude approximately between

VBAT and GND.

10. Remove the load on VOUT.

Verify that VOUT is at the necessary regulated

voltage and the SW signal shows that DC level

(LDO mode).

11. Remove the jumper between VBAT the EN input.

Verify the switching regulator turns off and there is

0 V at VOUT.

12. Disconnect VBAT from the board.

Soft Start

The NCV891x34 contains a battery−connectable EN pin

for the primary buck regulator. A common setup includes the

following connections:

EN → VIN

When the EN connection on the board are as shown above,

the following startup profile can be seen on an oscilloscope:

Figure 4. Typical NCV891x34 Startup Profile

www.onsemi.com

4

Page 5

NCV891234, NCV891334

EMI Filter

In a typical application, an LC filter is used on the input

line of a buck regulator to filter EMI from the device. On this

evaluation board, an LC filter is pre−populated to allow you

to perform EMI testing directly with this evaluation board.

Figure 5. LC Filter on VIN Line

L0: 1.0 mH

CVIN0: 4.7 mF

CB1: 100 mF

An input filter can drastically reduce the emissions from

a switching regulator.

Efficiency

Figure 6. NCV891x34 Efficiency Curves

www.onsemi.com

5

Page 6

NCV891234, NCV891334

SCHEMATIC

Figure 7. NCV891x34MWxxGEVB Evaluation Board Schematic − Rev.1

www.onsemi.com

6

Page 7

NCV891234, NCV891334

PCB LAYOUT

Figure 8. NCV891334MW50GEVB PCB Layout − Top

Figure 9. NCV891334MW50GEVB PCB Layout − Bottom

All evaluation board PCB layouts are identical with the

exception of TOP Silkscreen and device mounted upon

them.

www.onsemi.com

7

Page 8

NCV891234, NCV891334

BILL OF MATERIALS

Table 4. BILL OF MATERIALS

Reference

Designator(s)

CVIN0 1 CAP CER 0.1UF 250V

CVIN1, CVIN2 2 CAP CER 4.7UF 50V 10%

CVIN3 1 CAP CER 1.0UF 50V X7R

CB1 1 CAP ALUM 100UF 63V

CBST, CDRV,

COUTS

COUT1,

COUT2, COUT3

CSNB 1 CAP CER 100pF 50V 5%

R1, R3, R4 3 RES 10.0K OHM 1/10W

R2 1 RES 0.0 OHM 1/10W

RSNB 1 RES 10.0 OHM 1/10W

DFW 1 DIODE SCHOTTKY 4.0A

DBST 1 DIODE SWITCH 200MA

L0 1 High Current Shielded

L1 1 High Current Shielded

GND1, GND2,

GND3, GND4

EN, FAULTB,

RSTB, SYNCI,

SYNCO, VBAT,

VOUT1, VOUT2

BST, DRV,

RID1, RID2, SW

U1 * 1 Automotive Buck

Qty Description Value

10% X7R 1210

X7R 1210

0805

20% RADIAL

3 CAP .10UF 16V

3 CAP CER 10UF 10V X7R

CERAMIC X7R 0603

1206

NP0 603

1% 0603 SMD

0603 SMD

0603 SMD

40V SMB

100V SOD323

Inductor 1.0uH, 8.7A SAT

Inductor 2.2uH, 5.6A SAT

4 TERM SOLDER TURRET

8 PIN INBOARD .042”

5 CIRCUIT PIN PRNTD

.219”, .109”L

HOLE 1000/PKG

.020”D .425”L

Switching Regulator

0.1 mF

4.7 mF

1.0 mF

100 mF

0.1 mF

10 mF

Do Not

Populate

10.0 K 1% 603 Vishay/Dale CRCW060310K0FKEA

0.0 N/A 603 Vishay/Dale CRCW06030000Z0EA

Do Not

Populate

40 V /

4.0 A

100 V /

0.2 A

1.0 mH

2.2 mH

N/A N/A TURRET Mill−Max

N/A N/A TP Vector Electronics K24C/M

Do Not

Populate

*The Bills of Materials for all four evaluation boards covered in this user’s manual are identical with the exception of the mounted device.

This can be either NCV891234MW33R2G, NCV891234MW50R2G, NCV891334MW33R2G, or NCV891334MW50R2G.

Toler-

ance

Foot-

print

10% 1210 TDK Corporation CGA6M3X7R2E104K200AA

10% 1210 Murata Electronics

10% 805 Murata Electronics

20% CAP_RAD

_8X11P5

10% 603 Murata Electronics

10% 1206 Murata Electronics

5% 603 Murata Electronics

1% 603 Vishay/Dale CRCW060310R0FKEA

N/A MBR340MFSON Semiconductor NRVB440MFST1G

N/A SOD_323 ON Semiconductor BAS16HT1G

20% XAL4020−

20% XAL4020−

102ME

222ME

N/A SMALLTP Mill−Max

* N/A 12PINDF

N4X4P65

Manufacturer’s Part

Manufacturer

North America

North America

Chemi−Con ELXZ630ELL101MH15D

North America

North America

North America

Coilcraft XAL4020−102ME

Coilcraft XAL4020−222ME

Manufacturing Corp.

Manufacturing Corp.

ON Semiconductor NCV891x34MWxxR2G

Number

GCM32ER71H475KA55L

GCM21BR71H105KA03L

GCM188R71C104KA37D

GCM31CR71A106KA64L

GCM1885C1H101JA16D

2501−2−00−44−00−00−07−0

3128−2−00−15−00−00−08−0

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. ON Semiconductor reserves the right to make changes without further notice to any products herein.

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

19521 E. 32nd Pkwy, Aurora, Colorado 80011 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

◊

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

www.onsemi.com

8

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

EVBUM2492/D

Loading...

Loading...