Page 1

NCV8775C

f

Ultra Low Iq 350 mA LDO

Regulator with Reset

The NCV8775C is 350 mA LDO regulator with integrated reset

functions dedicated for microprocessor applications. Its robustness allows

NCV8775C to be used in severe automotive environments. Ultra low

quiescent current as low as 19 mA typical makes it suitable for

applications permanently connected to battery requiring ultra low

quiescent current with or without load. This feature is especially critical

when modules remain in active mode when ignition is off. The

NCV8775C contains protection functions as current limit, thermal

shutdown.

www.onsemi.com

MARKING

DIAGRAMS

Features

• Output Voltage Options: 3.3 V and 5 V

• Output Voltage Accuracy: ±2%

• Output Current up to 350 mA

• Ultra Low Quiescent Current: typ 19 mA (max 28 mA)

• Very Wide Range of C

and ESR Values for Stability

out

• Microprocessor Compatible Control Functions:

− Reset with Adjustable Delay

• Wide Input Voltage Operation Range: up to 40 V

• Protection Features

− Current Limitation

− Thermal Shutdown

• NCV Prefix for Automotive and Other Applications Requiring

Unique Site and Control Change Requirements; AEC−Q100 Grade 1

Qualified and PPAP Capable

• EMC Compliant

• These are Pb−Free Devices

Typical Applications

• Body Control Module

• Instruments and Clusters

• Occupant Protection and Comfort

• Powertrain

DPAK−5

DT SUFFIX

CASE 175AA

D2PAK−5

D5S SUFFIX

CASE 936A

xx = 50 (5.0 V Version)

= 33 (3.3 V Version)

A = Assembly Location

WL, L = Wafer Lot

Y = Year

WW = Work Week

G or G = Pb−Free Package

ORDERING INFORMATION

See detailed ordering and shipping information on page 12 o

this data sheet.

775CxxG

ALYWW

NC

V8775Cxx

AWLYWWG

V

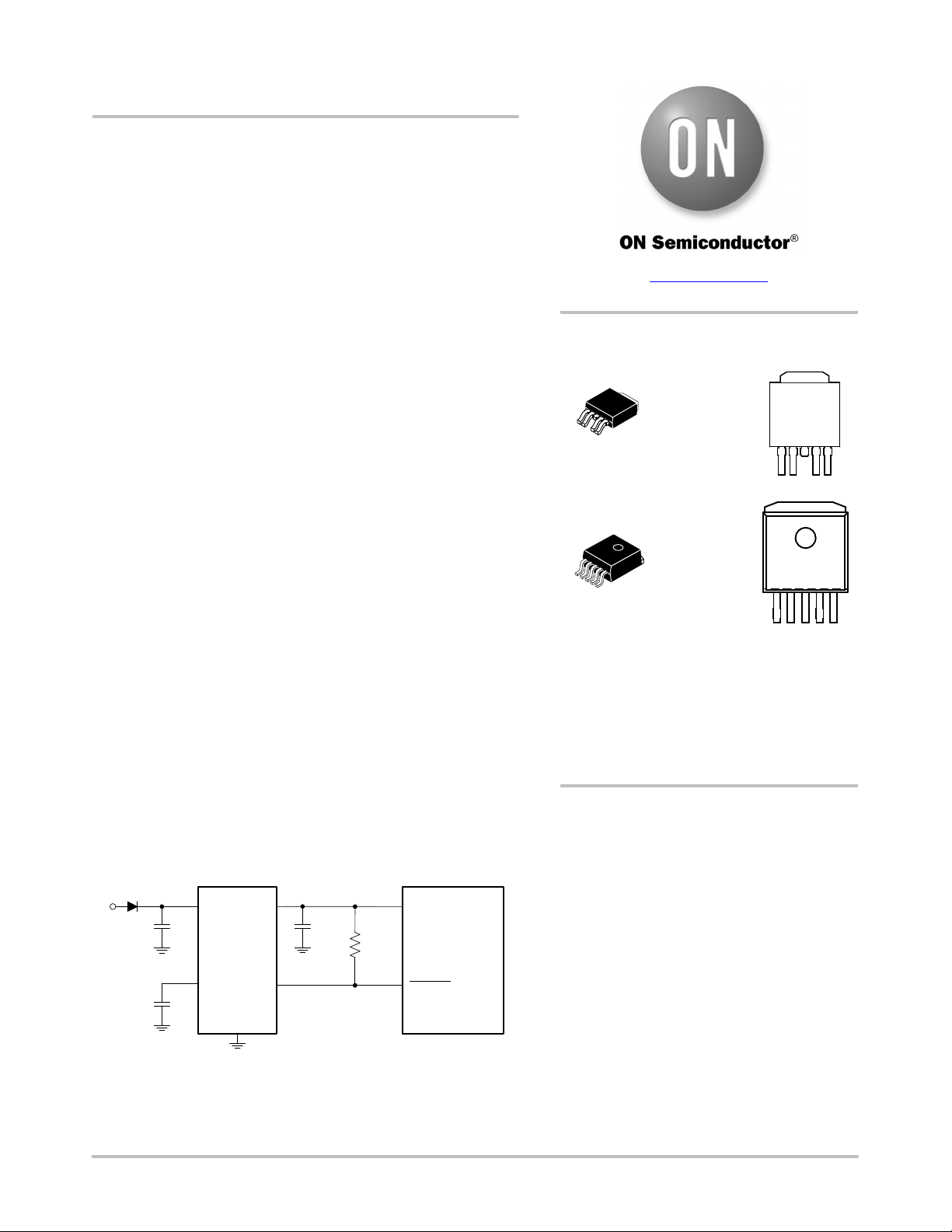

BAT

0.1 mF

C

D

47 nF

Figure 1. Typical Application Schematic

© Semiconductor Components Industries, LLC, 2017

December, 2019 − Rev. 1

C

in

V

in

NCV8775C

D

GND

V

out

RO

V

out

C

out

10 mF

R

RO

5 kW

V

DD

Microprocessor

RESET

1 Publication Order Number:

NCV8775C/D

Page 2

NCV8775C

PIN FUNCTION DESCRIPTION

Pin No.

Pin Name

Description

1

V

Positive Power Supply Input. Connect 0.1 mF capacitor to ground.

2ROReset (Open Collector) Output. External Pull−up resistor connected to V

.

3, TAB

GND

Power Supply Ground. Pin 3 internally connected to tab.

4DReset Delay. Timing capacitor to GND for Reset Delay function.

5

V

Regulated Output Voltage. Connect 10 mF capacitor with ESR < 5 W to ground.

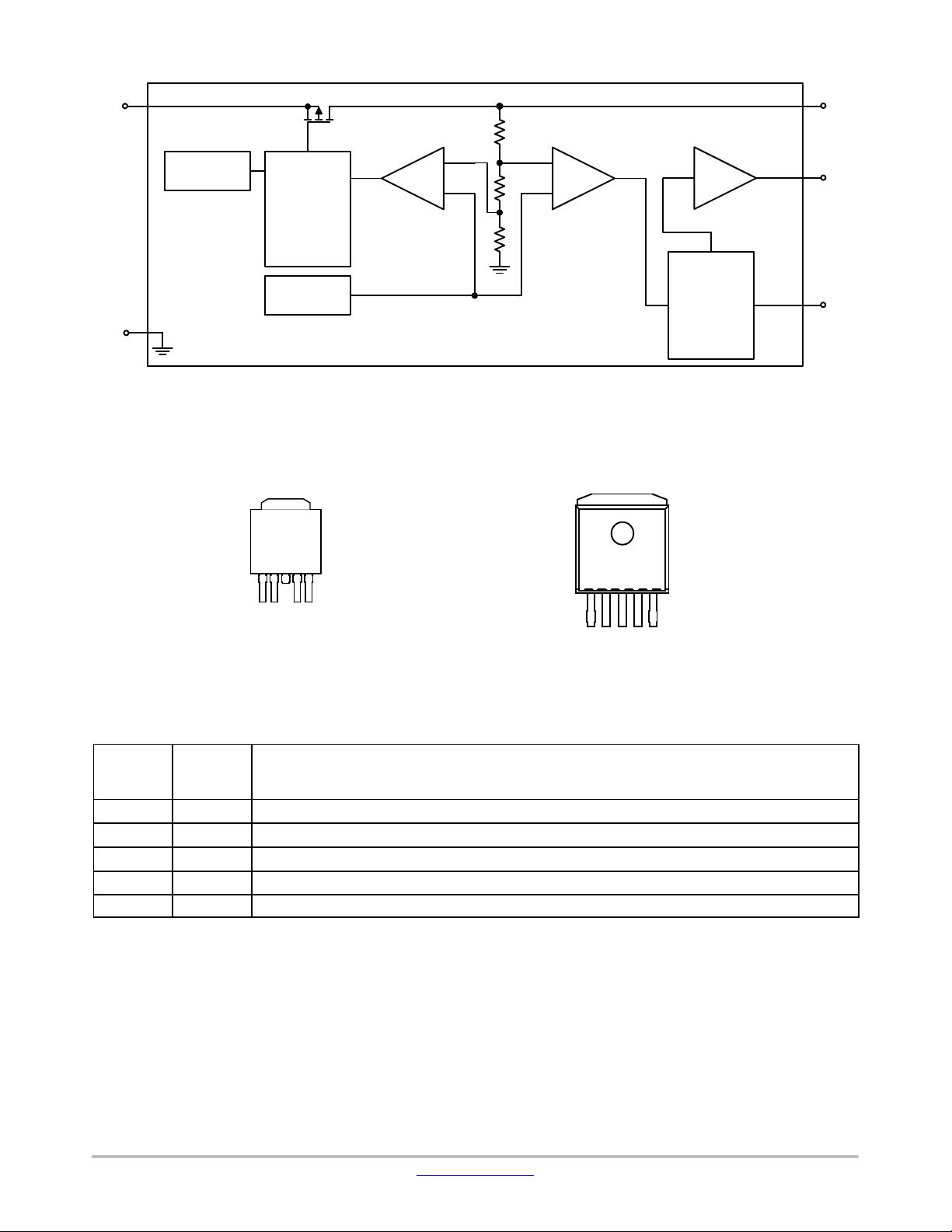

V

GND

in

Thermal

Shutdown

V

RO

out

Driver

With

Current

Error Amplifier

Reset Comparator

Reset Driver

Limit

Reference

Delay

D

Timer

Figure 2. Simplified Block Diagram

PIN CONNECTIONS

PIN 1.V

in

2.RO

Tab, 3.GND

4.D

5.V

out

PIN 1.V

in

2.RO

Tab, 3.GND

4.D

5.V

out

DPAK−5

D2PAK−5

out

1

1

DPAK−5

D2PAK−5

Figure 3. Pin Connections

in

out

www.onsemi.com

2

Page 3

NCV8775C

ABSOLUTE MAXIMUM RATINGS

Rating

Symbol

Min

Max

Unit

Input Voltage (Note 1) DC

Vin−0.3

40

V

Input Voltage (Note 2) Load Dump − Suppressed

Us*−45

V

Output Voltage

V

−0.3

7

V

Reset Delay Voltage

VD−0.3

7

V

Reset Output Voltage

VRO−0.3

7

V

Junction Temperature

TJ−40

150

C

Storage Temperature

T

−55

150

C

ESD CAPABILITY (Note 3)

Rating

Symbol

Min

Max

Unit

ESD Capability, Human Body Model

ESD

−4

4

kV

ESD Capability, Charged Device Model

ESD

−1

1

kV

LEAD SOLDERING TEMPERATURE AND MSL (Note 4)

Rating

Symbol

Min

Max

Unit

Moisture Sensitivity Level DPAK−5

MSL

1

−

THERMAL CHARACTERISTICS (Note 5)

Rating

Symbol

Value

Unit

Thermal Characteristics, DPAK−5

C/W

Thermal Characteristics, D2PAK−5

C/W

RECOMMENDED OPERATING RANGE (Note 8)

Rating

Symbol

Min

Max

Unit

Input Voltage (Note 9)

Vin4.5

40

V

Junction Temperature

TJ−40

150

C

out

°

STG

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. Refer to ELECTRICAL CHARACTERISTICS and APPLICATION INFORMATION for Safe Operating Area.

2. Load Dump Test B (with centralized load dump suppression) according to ISO16750−2 standard. Guaranteed by design. Not tested in

production. Passed Class A according to ISO16750−1.

HBM

CDM

3. This device series incorporates ESD protection and is tested by the following methods:

ESD HBM tested per AEC−Q100−002 (JS−001−2017)

Field Induced Charge Device Model ESD characterization is not performed on plastic molded packages with body sizes 2 x 2 mm due to

the inability of a small package body to acquire and retain enough charge to meet the minimum CDM discharge current waveform

characteristic defined in JEDEC JS−002−2018.

°

D2PAK−5

1

4. For more information, please refer to our Soldering and Mounting Techniques Reference Manual, SOLDERRM/D.

°

Thermal Resistance, Junction−to−Air (Note 6)

Thermal Reference, Junction−to−Lead (Note 6)

Thermal Resistance, Junction−to−Air (Note 7)

Thermal Reference, Junction−to−Lead (Note 7)

R

R

R

R

θJA

ψJL1

θJA

ψJL1

53.5

8.2

23.9

7.4

°

Thermal Resistance, Junction−to−Air (Note 6)

Thermal Reference, Junction−to−Lead (Note 6)

Thermal Resistance, Junction−to−Air (Note 7)

Thermal Reference, Junction−to−Lead (Note 7)

R

R

R

R

θJA

ψJL1

θJA

ψJL1

53.3

7.6

23.7

6.9

5. Refer to ELECTRICAL CHARACTERISTICS and APPLICATION INFORMATION for Safe Operating Area.

6. Values based on 1s0p board with copper area of 645 mm2 (or 1 in2) of 1 oz copper thickness and FR4 PCB substrate. Single layer − according

to JEDEC51.3.

7. Values based on 2s2p board with copper area of 645 mm2 (or 1 in2) of 1 oz copper thickness for inner layers, 2 oz copper thickness for signal

layers and FR4 PCB substrate. 4 layers − according to JEDEC51.7.

°

8. Refer to ELECTRICAL CHARACTERISTICS and APPLICATION INFORMATION for Safe Operating Area.

9. Minimum Vin = 4.5 V or (V

+ VDO), whichever is higher.

out

www.onsemi.com

3

Page 4

NCV8775C

ELECTRICAL CHARACTERISTICS V

= 13.5 V, Cin = 0.1 mF, C

= 10 mF, Min and Max values are valid for temperature range

Parameter

Test Conditions

Symbol

Min

Typ

Max

Unit

REGULATOR OUTPUT

Output Voltage (Accuracy %)

V

V

A

V

V

Line Regulation

V

V

Reg

−20020

mV

Load Regulation

I

= 0.1 mA to 350 mA

Reg

−351035

mV

Dropout Voltage (Note 12)

V

mV

QUIESCENT CURRENT

Quiescent Current (Iq = Iin − I

)

I

A

CURRENT LIMIT PROTECTION

Current Limit

V

= 0.96 x V

I

500−1100

mA

Short Circuit Current Limit

V

= 0 V

ISC500−1100

mA

PSRR

Power Supply Ripple Rejection (Note 13)

f = 100 Hz, 0.5 V

PSRR−80−dB

D (RESET DELAY)

Reset Charging Current

VD = 1.0 V

ID2.0

4.0

6.5

A

Upper Timing Threshold

VDU1.2

1.3

1.4

V

Reset Delay Time

CD = 47 nF

tRD101622

ms

Reset Reaction Time

tRR6.0

s

RESET OUTPUT RO

Input Voltage Reset Threshold

V

Vin decreasing, V

> V

V

V

Output Voltage Reset Threshold

V

decreasing

VRT909396

%V

Reset Hysteresis

VRH−

2.0−%V

Reset Output Low Voltage

V

> 1 V, RRO > 5 k

V

−

0.2

0.4

V

Reset High Level Leakage Current

I

−−5

A

THERMAL SHUTDOWN

Thermal Shutdown Temperature

TSD150

175

195°C

Thermal Shutdown Hysteresis

TSH−10−°C

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product per-

ty

in

out

−40°C ≤ TJ ≤ 150°C unless noted otherwise and are guaranteed by test, design or statistical correlation. Typical values are referenced to

T

= 25°C (Notes 10 and 11)

J

out

DO

LIM

line

load

q

3.234

3.234

4.9

4.9

−

−

−

−

3.3

3.3

5.0

5.0

200

350

19

−

3.366

3.366

5.1

5.1

350

600

m

27

28

out

3.3

Vin = 4.5 V to 40 V, I

= 4.5 V to 16 V, I

V

in

V

5.0

3.3

5.0

5.0 VI

= 5.6 V to 40 V, I

in

V

= 5.975 V to 16 V, I

in

Vin = 4.5 V to 28 V, I

Vin = 6 V to 28 V, I

out

= 200 mA

out

I

= 350 mA

out

I

= 0.1 mA, TJ = 25°C

out

I

= 0.1 mA, TJ ≤ 125°C

out

out

out

= 0.1 mA to 200 mA

out

= 0.1 mA to 350 mA

out

= 0.1 mA to 200 mA

out

out

= 5 mA

out

= 5 mA

out

out_nom

= 0.1 mA to 350 m

pp

out

3.3

out

out

RT

W

in_RT

ROL

ROLK

− 3.8 4.2

(Note 13)

(Note 13)

formance may not be indicated by the Electrical Characteristics if operated under different conditions.

10.Refer to ABSOLUTE MAXIMUM RATINGS and APPLICATION INFORMATION for Safe Operating Area.

11.Performance guaranteed over the indicated operating temperature range by design and/or characterization tested at T

cycle pulse techniques are used during testing to maintain the junction temperature as close to ambient as possible.

12.Measured when output voltage falls 100 mV below the regulated voltage at V

13.Values based on design and/or characterization.

= 13.5 V.

in

[ TJ. Low du

A

m

m

out

out

m

www.onsemi.com

4

Page 5

NCV8775C

TYPICAL CHARACTERISTICS

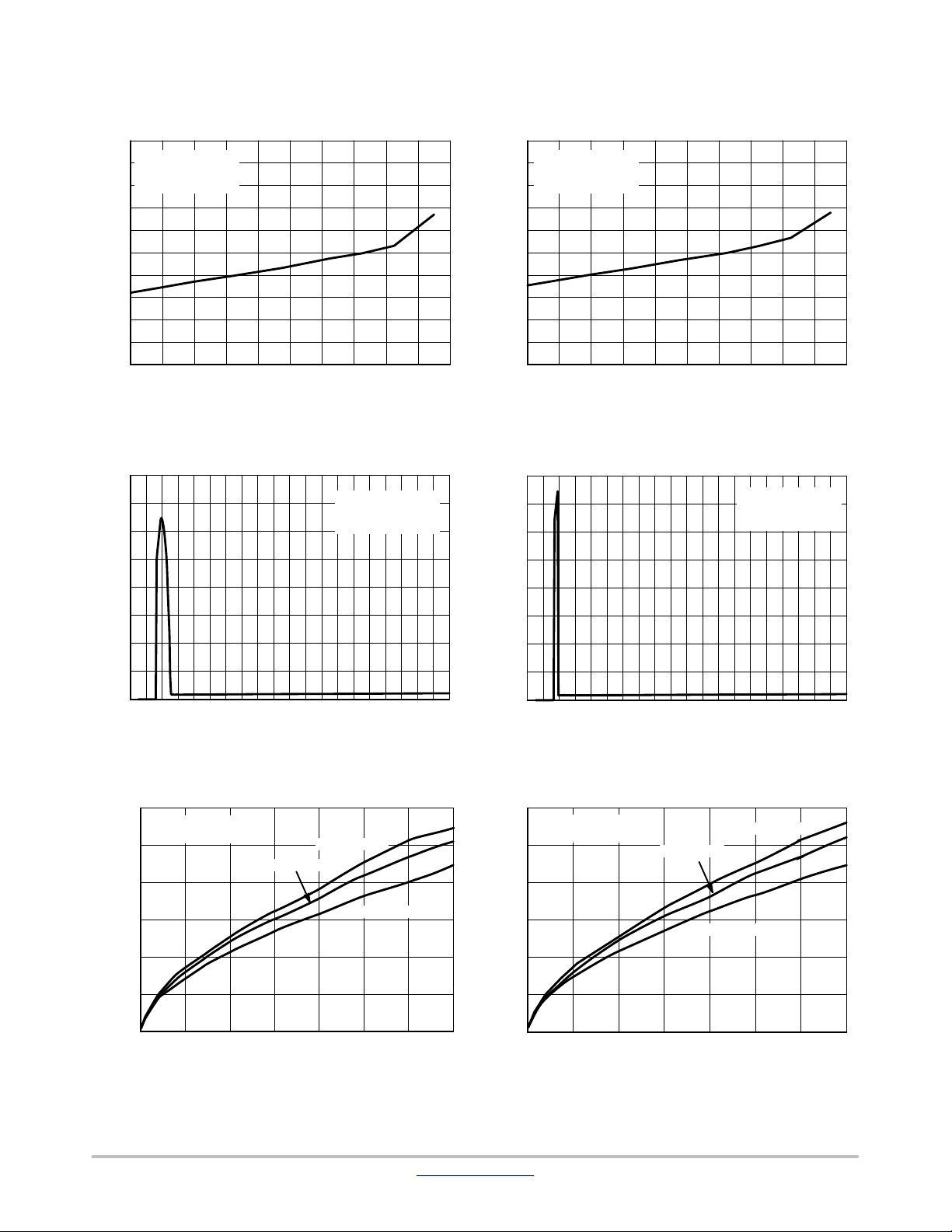

30

Vin = 13.5 V

28

I

= 100 mA

out

26

V

out(nom)

= 5.0 V

24

22

20

18

16

14

, QUIESCENT CURRENT (mA)

q

I

12

10

−40 −20 0 20 40 60 80 100 120 140 160

TJ, JUNCTION TEMPERATURE (°C)

Figure 4. Quiescent Current vs. Junction

Temperature

800

I

= 100 mA

700

600

500

400

out

= 25°C

T

J

V

out(nom)

= 5.0 V

30

Vin = 13.5 V

28

I

= 100 mA

out

26

V

out(nom)

= 3.3 V

24

22

20

18

16

14

, QUIESCENT CURRENT (mA)

q

I

12

10

−40 −20 0 20 40 60 80 100 120 140 160

TJ, JUNCTION TEMPERATURE (°C)

Figure 5. Quiescent Current vs. Junction

Temperature

800

I

= 100 mA

700

600

500

400

out

= 25°C

T

J

V

out(nom)

= 3.3 V

, QUIESCENT CURRENT (mA)

q

I

300

200

100

0

300

200

, QUIESCENT CURRENT (mA)

100

q

I

0

0 4 8 12 16 20 24 28 32 36 40 0 4 8 12 16 20 24 28 32 36 40

Vin, INPUT VOLTAGE (V)

Figure 6. Quiescent Current vs. Input Voltage

1200

1000

Vin = 13.5 V

out(nom)

= 5.0 V

V

TJ = −40°C

Figure 7. Quiescent Current vs. Input Voltage

1200

1000

Vin = 13.5 V

V

out(nom)

Vin, INPUT VOLTAGE (V)

= 3.3 V

TJ = 25°C

TJ = −40°C

TJ = 25°C

800

600

TJ = 150°C

800

600

TJ = 150°C

400

200

, QUIESCENT CURRENT (mA)

q

I

0

0 50 100 150 200 250 300 350

I

, OUTPUT CURRENT (mA)

OUT

Figure 8. Quiescent Current vs. Output Current

400

200

, QUIESCENT CURRENT (mA)

q

I

0

0 50 100 150 200 250 300 350

I

, OUTPUT CURRENT (mA)

out

Figure 9. Quiescent Current vs. Output Current

www.onsemi.com

5

Page 6

NCV8775C

TYPICAL CHARACTERISTICS

5.10

Vin = 13.5 V

5.08

I

= 100 mA

out

5.06

V

out(nom)

= 5.0 V

5.04

5.02

5.00

4.98

4.96

, OUTPUT VOLTAGE (V)

4.94

out

V

4.92

4.90

−40 −20 0 20 40 60 80 100 120 140 160

TJ, JUNCTION TEMPERATURE (°C)

Figure 10. Output Voltage vs. Junction

Temperature

6

I

= 100 mA

out

out(nom)

= 5.0 V

V

5

4

3.38

Vin = 13.5 V

3.36

I

= 100 mA

out

3.34

V

out(nom)

= 3.3 V

3.32

3.30

3.28

3.26

, OUTPUT VOLTAGE (V)

out

V

3.24

3.22

−40 −20 0 20 40 60 80 100 120 140 160

TJ, JUNCTION TEMPERATURE (°C)

Figure 11. Output Voltage vs. Junction

Temperature

4

I

= 100 mA

out

out(nom)

= 3.3 V

3.5

2.5

V

3

3

2

, OUTPUT VOLTAGE (V)

out

1

V

0

012345678

TJ = 25°C

TJ = −40°C

TJ = 150°C

Vin, INPUT VOLTAGE (V)

Figure 12. Output Voltage vs. Input Voltage

700

Vin = 13.5 V

out(nom)

= 5.0 V

600

V

500

400

TJ = 25°C

300

TJ = 150°C

200

, DROPOUT VOLTAGE (mV)

100

DO

V

TJ = −40°C

0

0 50 100 150 200 250 300 350

I

, OUTPUT CURRENT (mA)

out

Figure 14. Dropout Voltage vs. Output Current

2

1.5

1

, OUTPUT VOLTAGE (V)

out

V

0.5

TJ = 25°C

TJ = −40°C

TJ = 150°C

0

012345678

Vin, INPUT VOLTAGE (V)

Figure 13. Output Voltage vs. Input Voltage

700

Vin = 13.5 V

out(nom)

= 5.0 V

I

= 350 mA

out

600

500

V

400

300

I

= 200 mA

out

200

, DROPOUT VOLTAGE (mV)

100

DO

V

0

−40 160140−20 0 20406080 120100

TJ, JUNCTION TEMPERATURE (°C)

Figure 15. Dropout Voltage vs. Junction

Temperature

www.onsemi.com

6

Page 7

NCV8775C

TYPICAL CHARACTERISTICS

1000

800

600

ISC @ V

I

LIM

out

@ V

= 0 V

out

= 4.8 V

400

, CURRENT LIMIT (mA)

SC

I

200

LIM

I

0

0 5 10 15 20 25 30 35 40

TJ = 25°C

V

out(nom)

= 5.0 V

Vin, INPUT VOLTAGE (V)

Figure 16. Output Current Limit vs. Input

Voltage

1100

1000

900

800

700

Vin = 13.5 V

V

out(nom)

= 5.0 V

ISC @ V

I

@ V

LIM

out

out

= 0 V

= 4.8 V

1000

ISC @ V

out

= 0 V

800

I

@ V

LIM

= 3.168 V

out

600

400

, CURRENT LIMIT (mA)

SC

I

200

LIM

I

0

0 5 10 15 20 25 30 35 40

TJ = 25°C

V

out(nom)

Vin, INPUT VOLTAGE (V)

Figure 17. Output Current Limit vs. Input

Voltage

1100

1000

900

800

700

Vin = 13.5 V

out(nom)

= 3.3 V

V

ISC @ V

I

@ V

LIM

= 0 V

out

= 3.168 V

out

= 3.3 V

, CURRENT LIMIT (mA)

600

SC

I

500

LIM

I

400

−40 −20 0 20 40 60 80 100 120 140 160

TJ, JUNCTION TEMPERATURE (°C)

Figure 18. Output Current Limit vs. Junction

Temperature

100

10

Unstable Region

Stable Region

1

ESR (W)

0.1

Vin = 13.5 V

out(nom)

= 5.0 V

0.01

V

Cout = 1.0 mF − 100 mF

0 50 100 150 200 250 300 350

I

, OUTPUT CURRENT (mA)

out

Figure 20. Output Stability with Output

Capacitor ESR

, CURRENT LIMIT (mA)

600

SC

I

500

LIM

I

400

−40 −20 0 20 40 60 80 100 120 140 160

TJ, JUNCTION TEMPERATURE (°C)

Figure 19. Output Current Limit vs. Junction

Temperature

100

10

Unstable Region

Stable Region

1

ESR (W)

0.1

0.01

Vin = 13.5 V

out(nom)

= 3.3 V

V

Cout = 1.0 mF − 100 mF

0 50 100 150 200 250 300 350

I

, OUTPUT CURRENT (mA)

out

Figure 21. Output Stability with Output

Capacitor ESR

www.onsemi.com

7

Page 8

NCV8775C

TYPICAL CHARACTERISTICS

4.8

4.75

Vin = 13.5 V

out(nom)

= 5.0 V

V

4.7

4.65

4.6

, RESET THRESHOLD (V)

4.55

RT

V

4.5

−40 −20 0 20 40 60 80 100 120 140 160

TJ, JUNCTION TEMPERATURE (°C)

Figure 22. Reset Threshold vs. Junction

Temperature

4.2

4.1

4.0

3.9

Vin = 13.5 V

V

out(nom)

= 3.3 V

3.17

Vin = 13.5 V

V

out(nom)

3.13

3.09

3.05

, RESET THRESHOLD (V)

3.01

RT

V

2.97

−40 −20 0 20 40 60 80 100 120 140 160

TJ, JUNCTION TEMPERATURE (°C)

Figure 23. Reset Threshold vs. Junction

Temperature

= 3.3 V

3.8

3.7

THRESHOLD (V)

, INPUT VOLTAGE RESET

3.6

RT

_

in

3.5

V

3.4

−40 −20 0 20 40 60 80 100 120 140 160

TJ, JUNCTION TEMPERATURE (°C)

Figure 24. Input Voltage Reset Threshold vs.

Junction Temperature

22

20

18

16

14

, RESET DELAY TIME (ms)

12

RD

t

10

−40 −20 0 20 40 60 80 100 120 140 160

TJ, JUNCTION TEMPERATURE (°C)

Vin = 13.5 V

= 47 nF

C

D

V

out(nom)

= 5.0 V

Figure 25. Reset Delay Time vs. Junction

Temperature

22

Vin = 13.5 V

= 47 nF

C

20

D

V

out(nom)

= 3.3 V

18

16

14

, RESET DELAY TIME (ms)

12

RD

t

10

−40 −20 0 20 40 60 80 100 120 140 160

TJ, JUNCTION TEMPERATURE (°C)

Figure 26. Reset Delay Time vs. Junction

Temperature

www.onsemi.com

8

Page 9

TYPICAL CHARACTERISTICS

PSRR (dB)

120

0

100

I

= 100 mA

80

60

40

Vin = 13.5 V ± 0.5 V

20

0

C

out

V

out(nom)

= 1 mF

= 5.0 V

PP

10 100 1000 10000 100000 1000000

f, FREQUENCY (Hz)

Figure 27. PSRR vs. Frequency

out

I

= 100 mA

out

NCV8775C

6000

5500

5000

4500

4000

3500

3000

2500

2000

1500

NOISE DENSITY (nV/√Hz)

1000

500

0

f = 10 Hz − 100 kHz

V

= 268 mV

n

Vin = 13.5 V

C

= 1 mF

out

I

= 100 mA

out

V

out(nom)

= 5.0 V

10 100 1000 10000 10000

f, FREQUENCY (Hz)

Figure 28. Noise vs. Frequency

V

in

(10 V/div)

V

out

(20 mV/div)

V

in

(5 V/div)

V

out

(5 V/div)

V

RO

(5 V/div)

0 V

28 V

6 V

TJ = 25°C

I

= 100 mA

out

C

= 10 mF

out

t

= 1 ms (Vin)

rise/fall

I

out

(200 mA/div)

350 mA

5.17 V

5.012 V

out

(200 mV/div)

5 V

V

4.78 V

5 V

TIME (400 ms/div)

4.995 V

TIME (100 ms/div)

Figure 29. Line Transients Figure 30. Load Transients

TJ = 25°C

= 100 mA

I

13.5 V

0 V

0 V

out

C

out

C

= 47 nF

D

t

rise/fall

= 10 mF

= 1 s (Vin)

TJ = 25°C

= 13.5 V

V

in

C

= 10 mF

out

t

= 1 ms (I

rise/fall

0.1 mA

out

)

TIME (400 ms/div)

Figure 31. Power Up/Down Response

www.onsemi.com

9

Page 10

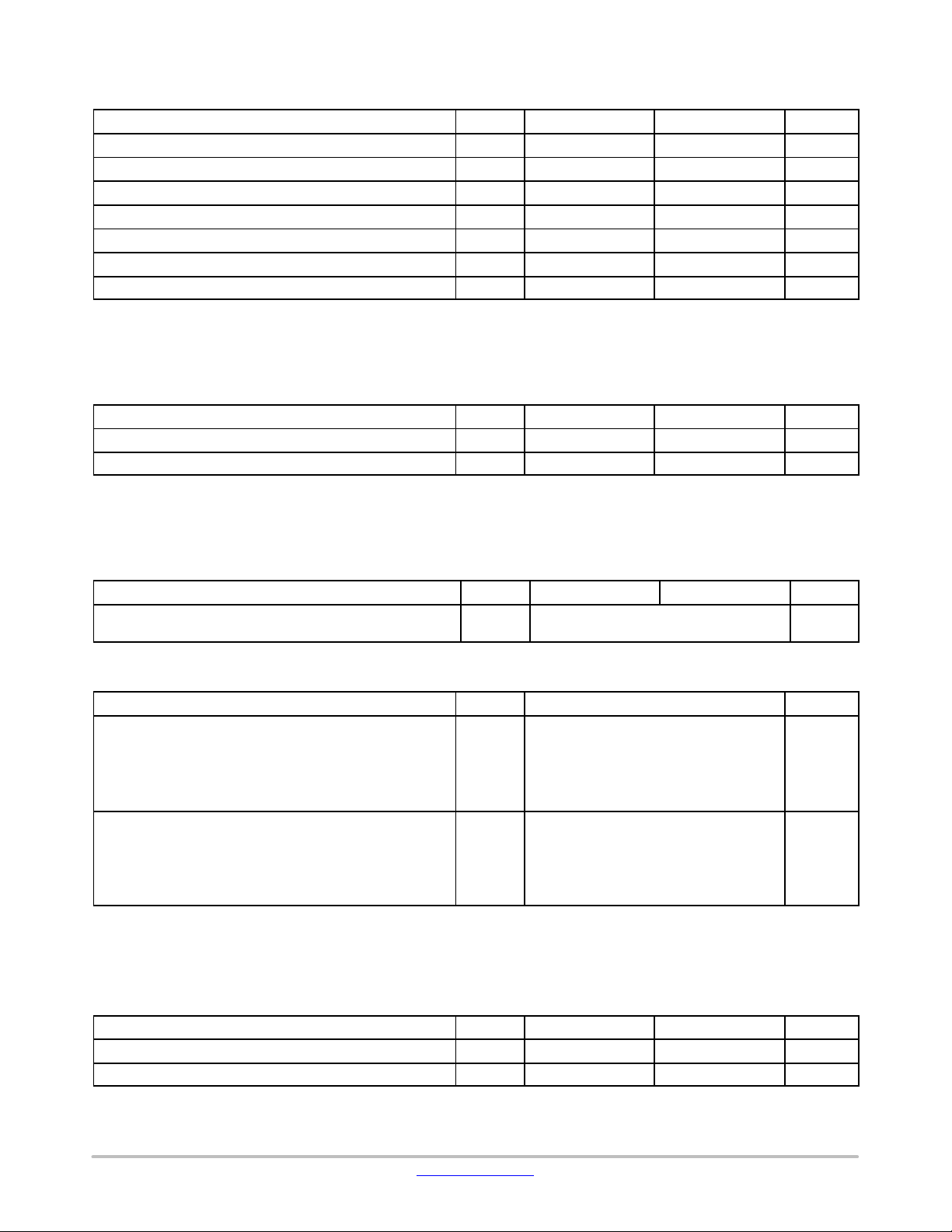

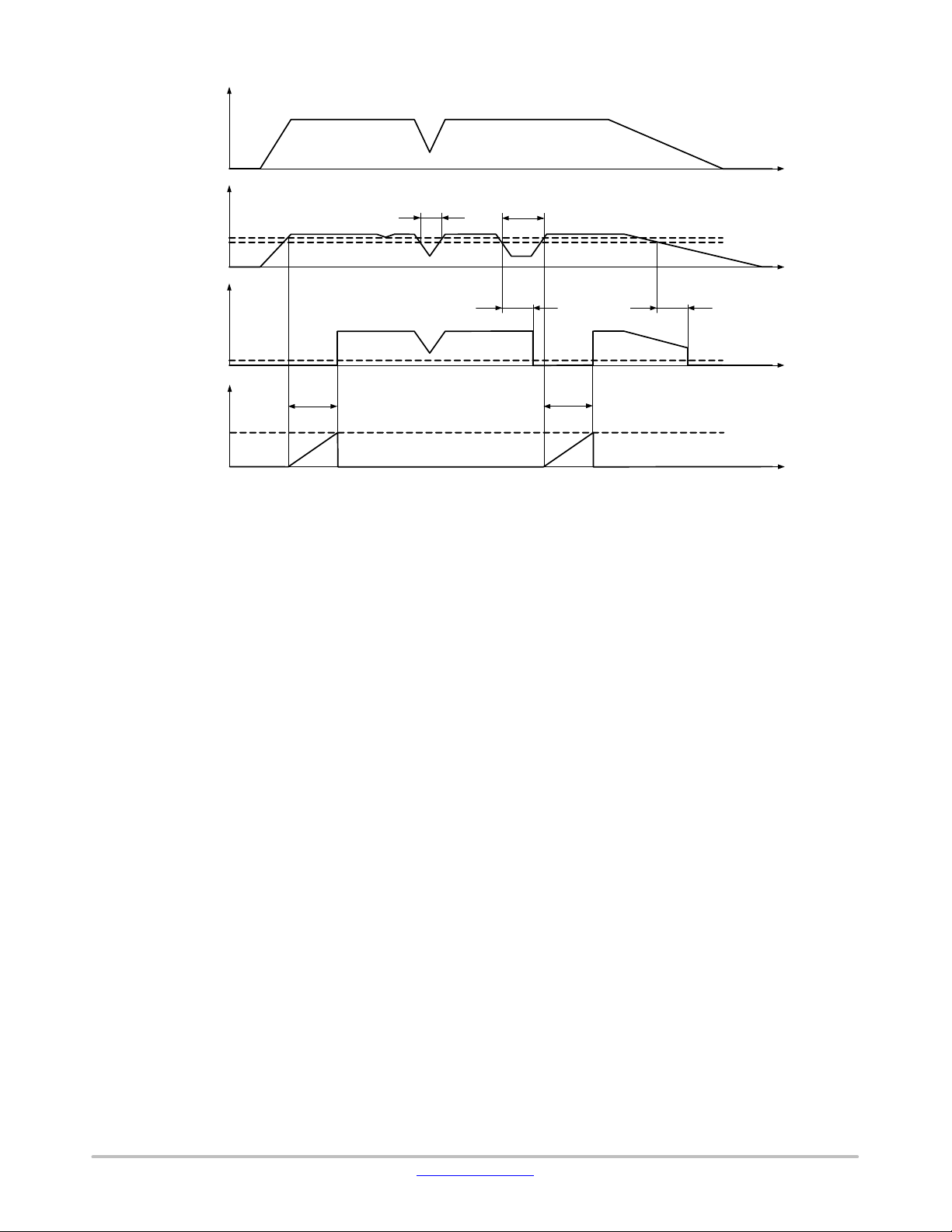

NCV8775C

V

in

V

out

VRT+ V

RH

V

RT

V

RO

V

ROL

V

D

V

DU

t

RD

Figure 32. Reset Function and Timing Diagram

DEFINITIONS

General

All measurements are performed using short pulse low

duty cycle techniques to maintain junction temperature as

close as possible to ambient temperature.

Output voltage

The output voltage parameter is defined for specific

temperature, input voltage and output current values or

specified over Line, Load and Temperature ranges.

Line Regulation

The change in output voltage for a change in input voltage

measured for specific output current over operating ambient

temperature range.

Load Regulation

The change in output voltage for a change in output

current measured for specific input voltage over operating

ambient temperature range.

Dropout Voltage

The input to output differential at which the regulator

output no longer maintains regulation against further

reductions in input voltage. It is measured when the output

drops 100 mV below its nominal value. The junction

temperature, load current, and minimum input supply

requirements affect the dropout level.

Quiescent Current

Quiescent Current (Iq) is the difference between the input

current (measured through the LDO input pin) and the

output load current.

t

>t

RR

RR

t

RR

t

RD

< t

RR

Current Limit and Short Circuit Current Limit

Current Limit is value of output current by which output

voltage drops below 96% of its nominal value. Short Circuit

Current Limit is output current value measured with output

of the regulator shorted to ground.

PSRR

Power Supply Rejection Ratio is defined as ratio of output

voltage and input voltage ripple. It is measured in decibels

(dB).

Line Transient Response

Typical output voltage overshoot and undershoot

response when the input voltage is excited with a given

slope.

Load Transient Response

Typical output voltage overshoot and undershoot

response when the output current is excited with a given

slope between low−load and high−load conditions.

Thermal Protection

Internal thermal shutdown circuitry is provided to protect

the integrated circuit in the event that the maximum junction

temperature is exceeded. When activated at typically 175°C,

the regulator turns off. This feature is provided to prevent

failures from accidental overheating.

Maximum Package Power Dissipation

The power dissipation level is maximum allowed power

dissipation for particular package or power dissipation at

which the junction temperature reaches its maximum

operating value, whichever is lower.

t

t

t

t

www.onsemi.com

10

Page 11

NCV8775C

APPLICATIONS INFORMATION

The NCV8775C regulator is self−protected with internal

thermal shutdown and internal current limit. Typical

characteristics are shown in Figure 4 to Figure 34.

Input Decoupling (Cin)

A ceramic or tantalum 0.1 mF capacitor is recommended

and should be connected close to the NCV8775C package.

Higher capacitance and lower ESR will improve the overall

line and load transient response.

Input Capacitor is required if regulator is located far from

power supply filter . If extremely fast input voltage transients

are expected with slew rate in excess of 4 V/ms then

appropriate input filter must be used. The filter can be

composed of several capacitors in parallel.

Output Decoupling (C

out

)

The NCV8775C is a stable component and does not

require a minimum Equivalent Series Resistance (ESR) for

the output capacitor. Stability region of ESR vs Output

Current is shown in Figures 20 and 21. The minimum output

decoupling value is 1 mF and can be augmented to fulfill

stringent load transient requirements. The regulator works

with ceramic chip capacitors as well as tantalum devices.

Larger values improve noise rejection and load regulation

transient response.

Reset Operation

A reset signal is provided on the Reset Output (RO) pin to

provide feedback to the microprocessor of an out of

regulation condition. The timing diagram of reset function

is shown in Figure 32. This is in the form of a logic signal on

RO. Output voltage conditions below the Reset threshold

cause RO to go low. RO is pulled up to V

by an external

out

resistor, typically 5.0 kW in value. Output voltage regulation

must be maintained for the delay time before the reset output

signals a valid condition. The delay for the reset output is

defined as the amount of time it takes the timing capacitor

on the delay pin to charge from a residual voltage of 0 V to

the upper timing threshold voltage V

charging current for this is I

of 4 mA and D pin voltage in

D

of 1.3 V. The

DU

steady state is typically 0 V. By using typical IC parameters

with a 47 n F capacitor on the D Pin, the following time delay

is derived:

V

tRD+ C

tRD+ 47 nF

DU

D

I

D

1.3 V

4 mA

+ 15.3 ms

(eq. 1)

Other time delays can be obtained by changing the C

capacitor value. The Delay Time can be reduced by

decreasing the ca p acitance of C

. Using the formula above,

D

Delay can be reduced as desired. For minimum reset delay

time Delay pin must be left open with no PCB trace

connected to the pin.

Thermal Considerations

As power in the NCV8775C increases, it might become

necessary to provide some thermal relief. The maximum

power dissipation supported by the device is dependent

upon board design and layout. Mounting pad configuration

on the PCB, the board material, and the ambient temperature

affect the rate of junction temperature rise for the part. When

the NCV8775C has good thermal conductivity through the

PCB, the junction temperature will be relatively low with

high power applications. The maximum dissipation the

NCV8775C can handle is given by:

P

D(max

ƪ

T

J(max)

+

)

R

qJA

* T

ƫ

A

(eq. 2)

Since TJ is not recommended to exceed 150°C, then the

NCV8775C soldered on 645 mm

2

, 1 oz copper area, FR4

can dissipate up to 2.35 W (for D2PAK−5) when the ambient

temperature (T

) is 25°C. See Figures 33 and 34 for R

A

JA

q

versus PCB area. The power dissipated by the NCV8775C

can be calculated from the following equations:

PD+ V

in

ǒ

Iq@I

out

Ǔ

) I

out

ǒ

Vin* V

out

Ǔ

(eq. 3)

or

V

NOTE: Items containing I

in(max)

+

P

D(max)

can be neglected if I

q

ǒ

)

V

out

I

) I

out

Ǔ

I

out

q

out

(eq. 4)

>> Iq.

D

www.onsemi.com

11

Page 12

NCV8775C

ORDERING INFORMATION

Device

Output Voltage

Package

Shipping

†

NCV8775CDT33RKG

3.3 V

DPAK−5

2500 / Tape & Reel

NCV8775CDT50RKG

5.0 V

DPAK−5

2500 / Tape & Reel

NCV8775CDS33R4G

3.3 V

D2PAK−5

800 / Tape & Reel

NCV8775CDS50R4G

5.0 V

D2PAK−5

800 / Tape & Reel

110

100

90

80

70

60

50

(°C/W)

40

30

, THERMAL RESISTANCE

20

JA

q

R

10

1 oz, Single Layer

2 oz, Single Layer

1 oz, 4 Layer

0

0 200 400 600 800 1000

COPPER HEAT SPREADER AREA (mm2)

Figure 33. Thermal Resistance vs. PCB Copper

Area (DPAK−5)

Hints

Vin and GND printed circuit board traces should be as

wide as possible. When the impedance of these traces is

high, there is a chance to pick up noise or cause the regulator

to malfunction. Place external filter components, especially

the output capacitor, as near as possible to the device to

increase EMC performance.

110

100

90

80

70

1 oz, Single Layer

2 oz, Single Layer

1 oz, 4 Layer

(°C/W)

, THERMAL RESISTANCE

JA

q

R

60

50

40

30

20

10

0

0 200 400 600 800 1000

COPPER HEAT SPREADER AREA (mm2)

Figure 34. Thermal Resistance vs. PCB Copper

Area (D2PAK−5)

The NCV8775C is not developed in compliance with

ISO26262 standard. If application is safety critical then the

above application example diagram shown in Figure 35 can

be used.

V

BAT

V

in

C

in

NCV8775C

C

D

D

GND

V

RO

V

out

out

C

out

V

CC

RESET

Voltage

Supervisor

(e.g. NCV30X, NCV809)

GND

V

DD

I/O

Microprocessor

I/O

Figure 35. NCV8775C Application Diagram

(Pb−Free)

(Pb−Free)

(Pb−Free)

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

(Pb−Free)

www.onsemi.com

12

Page 13

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

DPAK−5, CENTER LEAD CROP

SCALE 1:1

B

V

S

R

A

1234 5

K

F

L

D

5 PL

G

0.13 (0.005) T

RECOMMENDED

SOLDERING FOOTPRINT*

C

J

H

M

−T−

CASE 175AA

SEATING

PLANE

E

U

ISSUE B

R1

DATE 15 MAY 2014

NOTES:

1. DIMENSIONING AND TOLERANCING

PER ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

DIM MIN MAX MIN MAX

A 0.235 0.245 5.97 6.22

B 0.250 0.265 6.35 6.73

Z

C 0.086 0.094 2.19 2.38

D 0.020 0.028 0.51 0.71

E 0.018 0.023 0.46 0.58

F 0.024 0.032 0.61 0.81

G 0.180 BSC 4.56 BSC

H 0.034 0.040 0.87 1.01

J 0.018 0.023 0.46 0.58

K 0.102 0.114 2.60 2.89

L 0.045 BSC 1.14 BSC

R 0.170 0.190 4.32 4.83

R1 0.185 0.210 4.70 5.33

S 0.025 0.040 0.63 1.01

U 0.020 −−− 0.51 −−−

V 0.035 0.050 0.89 1.27

Z 0.155 0.170 3.93 4.32

MILLIMETERSINCHES

GENERIC

MARKING DIAGRAMS*

6.4

0.252

5.8

0.228

10.6

0.417

2.2

0.086

0.013

SCALE 4:1

0.34

0.8

0.031

ǒ

inches

5.36

0.217

mm

Ǔ

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

XXXXXXG

ALYWW

AYWW

XXX

XXXXXG

DiscreteIC

XXXXXX = Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

WW = Work Week

G = Pb−Free Package

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98AON12855D

DPAK−5 CENTER LEAD CROP

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

Page 14

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 1:1

G

S

H

OPTIONAL

CHAMFER

N

R

K

B

D

0.010 (0.254) T

M

C

A

123

45

SOLDERING FOOTPRINT

8.38

0.33

D2PAK 5−LEAD

CASE 936A−02

ISSUE D

−T−

E

M

L

1.702

0.067

TERMINAL 6

V

P

DATE 15 SEP 2015

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. TAB CONTOUR OPTIONAL WITHIN DIMENSIONS A

U

AND K.

4. DIMENSIONS U AND V ESTABLISH A MINIMUM

MOUNTING SURFACE FOR TERMINAL 6.

5. DIMENSIONS A AND B DO NOT INCLUDE MOLD

FLASH OR GATE PROTRUSIONS. MOLD FLASH

AND GATE PROTRUSIONS NOT TO EXCEED 0.025

(0.635) MAXIMUM.

_

8

MILLIMETERS

_

0

8

_

DIMAMIN MAX MIN MAX

INCHES

0.386 0.403 9.804 10.236

B 0.356 0.368 9.042 9.347

C 0.170 0.180 4.318 4.572

D 0.026 0.036 0.660 0.914

E 0.045 0.055 1.143 1.397

G 0.067 BSC 1.702 BSC

H 0.539 0.579 13.691 14.707

K 0.050 REF 1.270 REF

L 0.000 0.010 0.000 0.254

M 0.088 0.102 2.235 2.591

N 0.018 0.026 0.457 0.660

P 0.058 0.078 1.473 1.981

_

R

0

S 0.116 REF 2.946 REF

U 0.200 MIN 5.080 MIN

V 0.250 MIN 6.350 MIN

GENERIC

MARKING DIAGRAM*

xx

xxxxxxxxx

AWLYWWG

10.66

0.42

xxxxxx = Device Code

A = Assembly Location

WL = Wafer Lot

Y = Year

WW = Work Week

G = Pb−Free Package

*This information is generic. Please refer to

device data sheet for actual part marking.

16.02

0.63

3.05

0.12

SCALE 3:1

ǒ

inches

1.016

mm

0.04

Ǔ

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

98ASH01006A

D2PAK 5−LEAD

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

Page 15

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...