Page 1

查询NCV8141供应商

NCV8141

5.0 V, 500 mA Linear

Regulator with ENABLE,

RESET

, and Watchdog

The NCV8141 is a linear regulator suited for microprocessor

applications in automotive environments.

This ON Semiconductor part provides the power for the

microprocessors along with many of the control functions needed in

today’s computer based systems. Incorporating all of these features

saves both cost, and board space.

The NCV8141 provides a low sleep mode current as compared to

the CS8141. Consult your local sales representative for a low sleep

mode current version of the CS8140.

Features

• 5.0 V ±4.0%, 500 mA Output Voltage

• Lower Quiescent Current

• Improved Filtering for /RESET Functionality

• P Compatible Control Functions

♦ Watchdog

♦ RESET

♦ ENABLE

• Low Dropout Voltage (1.25 V @ 500 mA)

• Low Quiescent Current (7.0 mA @ 500 mA)

• Low Noise, Low Drift

• Low Current SLEEP Mode 50 A (max)

• Fault Protection

♦ Thermal Shutdown

♦ Short Circuit

♦ 60 V Peak Transient Voltage

• NCV Prefix for Automotive and Other Applications Requiring Site

and Control Changes

• Pb−Free Package is Available*

http://onsemi.com

D2PAK−7

DPS SUFFIX

1

7

1

ORDERING INFORMATION

Device Package Shipping

CASE 936AB

A = Assembly Location

WL = Wafer Lot

Y = Year

WW = Work Week

PIN CONNECTIONS

Tab = GND

Pin 1. V

2. ENABLE

3. RESET

4. GND

5. Delay

6. WDI

7. V

MARKING

DIAGRAM

NCV8141

AWLYWW

1

IN

OUT

†

*For additional information on our Pb−Free strategy and soldering details, please

download the ON Semiconductor Soldering and Mounting Techniques

Reference Manual, SOLDERRM/D.

Semiconductor Components Industries, LLC, 2004

August, 2004 − Rev. 5

1 Publication Order Number:

NCV8141D2T D2PAK 50 Units/Rail

NCV8141D2TG D2PAK

(Pb−Free)

NCV8141D2TR4 D2PAK 750 Tape & Reel

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

50 Units/Rail

NCV8141/D

Page 2

NCV8141

V

IN

Overvoltage

Reference & Bias

Overtemperature

Regulation

ENABLE

WDI

Control Logic

ENABLE

RESET

Delay

GND

Watchdog

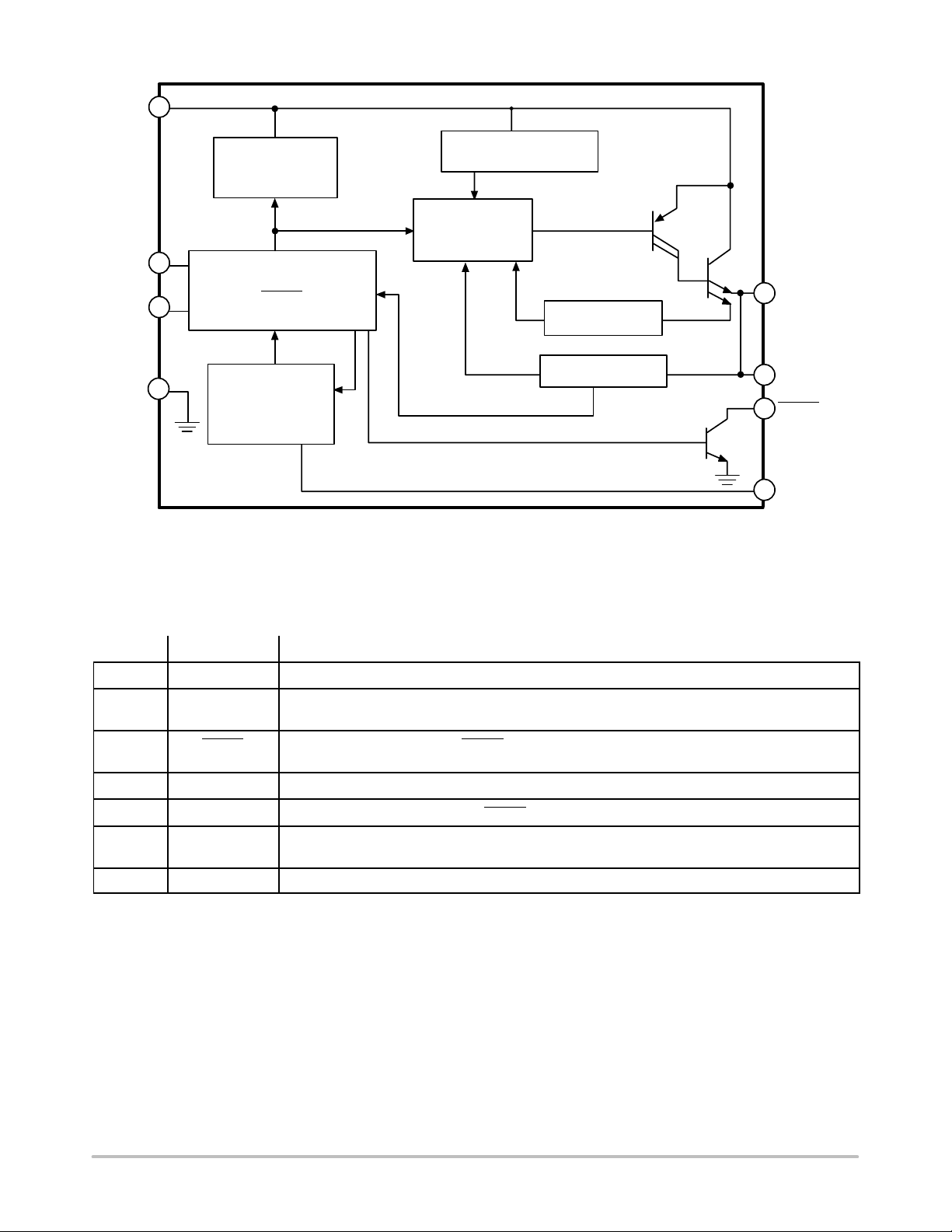

Figure 1. Block Diagram

PIN FUNCTION DESCRIPTION

Pin Symbol Function

1 V

IN

2 ENABLE CMOS compatible logical input. V

Supply voltage to IC, usually direct from the battery.

is disabled when ENABLE is LOW and WDI is beyond its

preset limits.

OUT

Short Circuit

Undervoltage

V

OUT

Sense

RESET

Delay

3 RESET CMOS compatible output lead. RESET goes low whenever V

value for more than 2.0 s or WDI signal falls outside it’s window limits.

drops below 4.5% of it’s typical

OUT

4 GND Ground Connection.

5 Delay Timing capacitor for Watchdog and RESET functions.

6 WDI CMOS compatible input lead. The Watchdog function monitors the falling edge of the incoming digital

pulse train. The signal is usually generated by the system microprocessor.

7 V

OUT

Regulated output voltage, 5.0 V (typ).

http://onsemi.com

2

Page 3

NCV8141

MAXIMUM RATINGS

Rating Value Unit

Input Operating Range −0.5 to 26 V

Peak Transient Voltage (46 V Load Dump @ 14 V V

Electrostatic Discharge (Human Body Model) 4.0 kV

WDI Input Signal Range −0.3 to 7.0 V

Internal Power Dissipation Internally Limited −

Junction Temperature Range (TJ) −40 to +150 °C

Storage Temperature Range −65 to +150 °C

) 60 V

BAT

ENABLE −0.3 to V

IN

V

Package Thermal Resistance, D2PAK 7−Pin

Junction−to−Case, R

Junction−to−Ambient, R

JC

JA

1.5

10−50†

°C/W

°C/W

Lead Temperature Soldering: Reflow (SMD styles only) (Note 1) 225 peak (Note 2) °C

Maximum ratings are those values beyond which device damage can occur. Maximum ratings applied to the device are individual stress limit

values (not normal operating conditions) and are not valid simultaneously . If these limits are exceeded, device functional operation is not implied,

damage may occur and reliability may be affected.

= R

+ R

†Depending on thermal properties of substrate R

1. 60 seconds max above 183°C.

JA

JC

.

CA

2. −5.0°C/+0°C allowable conditions.

ELECTRICAL CHARACTERISTICS (7.0 ≤ V

≤26 V , 5 .0 m A ≤ I

IN

≤500 mA, −40°C ≤ TJ ≤150°C, −40°C ≤ TA ≤125°C, u nle ss o the rwise

OUT

noted.) (Note 3)

Characteristic

Output Stage (V

Output Voltage, V

Dropout Voltage (VIN − V

OUT

OUT

)

) I

OUT

7.0 V ≤ VIN ≤ 26 V, 5.0 mA < I

Line Regulation I

Load Regulation VIN = 14 V, 50 mA ≤ I

Output Impedance, R

OUT

Test Conditions Min Typ Max Unit

< 500 mA 4.8 5.0 5.2 V

OUT

= 500 mA − 1.25 1.50 V

OUT

= 50 mA, 7.0 V ≤ VIN ≤ 26 V, − 5.0 25 mV

OUT

≤ 500 mA − 5.0 80 mV

OUT

500 mA DC and 10 mA AC,

− 200 − m

100 Hz ≤ f ≤ 10 kHz

Quiescent Current, (IQ)

Active Mode

Sleep Mode

Ripple Rejection 7 .0 V ≤ VIN ≤ 17 V, I

Current Limit VIN = 7.0 V, V

0 ≤ I

≤ 500 mA, 7.0 V ≤ VIN ≤ 26 V

OUT

= 0 mA, VIN = 13 V, ENABLE = 0 V

I

OUT

= 250 mA,

OUT

f = 120 Hz

= 4.5 V 600 1200 2000 mA

OUT

−

−

7.0

25

15

50

60 75 − dB

Thermal Shutdown Guaranteed by Design 150 180 − °C

Overvoltage Shutdown V

< 1.0 V 30 34 38 V

OUT

ENABLE

Threshold

HIGH

LOW

V

V

OUT

OUT

≥ 0.5 V, (V

< 0.5 V, (V

OUT(ON)

OUT(OFF)

)

)

3.5

−

4.05

3.95

4.50

−

Input Current

HIGH

LOW

ENABLE = 5.0 V

ENABLE = 0 V

−

−1.0

35

0

1.0

75

Threshold Hysteresis (HIGH − LOW) − 80 − mV

3. To observe safe operating junction temperatures, low duty cycle pulse testing is used in tests where applicable.

http://onsemi.com

3

mA

A

V

V

A

A

Page 4

NCV8141

ELECTRICAL CHARACTERISTICS (continued) (7.0 ≤ V

≤ 26 V, 5.0 mA ≤ I

IN

≤ 500 mA, −40°C ≤ TJ ≤ 150°C, −40°C ≤ TA ≤

OUT

125°C, unless otherwise noted.) (Note 4)

Characteristic

Test Conditions Min Typ Max Unit

RESET

Threshold HIGH V

Threshold LOW V

R(HI)

R(LOW)

V

Increasing 4.65 4.90 V

OUT

V

Decreasing 4.50 4.70 4.90 V

OUT

OUT

− 0.05 V

Threshold Hysteresis (VRH) (HIGH − LOW) 150 200 250 mV

RESET Output Leakage

RESET = HIGH

Output Voltage Low (V

Output Voltage Low (V

Delay Times t

Delay Times t

POR

WDI(RESET)

) 1.0 V ≤ V

L(LOW)

) V

Rpeak

V

≥ V

OUT

R(HI)

≤ V

OUT

, Power up, Power down − 0.6 1.0 V

OUT

C

C

, RP = 2.7 k (Note 5) − 0.1 0.4 V

R(LOW)

= 0.1 F 30 47.5 65 ms

DELAY

= 0.1 F 0.5 1.0 1.5 ms

DELAY

− − 25 A

Watchdog

Input Voltage High

− 2.0 − − V

Input Voltage Low − − − 0.8 V

Input Current WDI ≤ V

Threshold Frequency f

WDI

C

= 0.1 F 64 77 96 Hz

DELAY

OUT

− 0 10 A

4. To observe safe operating junction temperatures, low duty cycle pulse testing is used in tests where applicable.

is connected to RESET and V

5. R

P

OUT.

1000

100

10

ESR ()

0.1

0.01

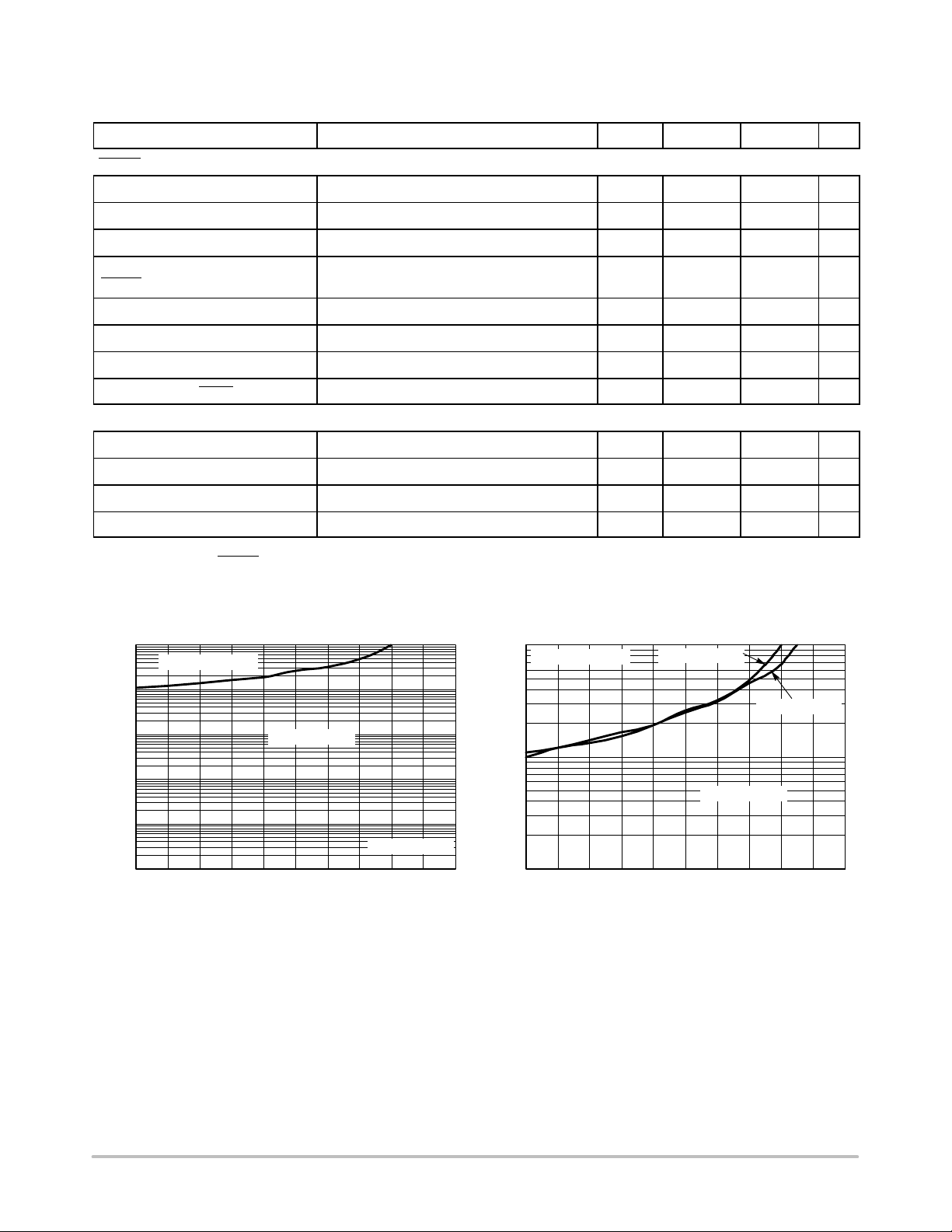

TYPICAL PERFORMANCE CHARACTERISTICS

1000

ESR ()

100

10

0

Unstable Region

550

10 20 30 4015

Output Current (mA)

Unstable Region

Stable Region

1

C

= 10 F

vout

0

10 20 30 4015

550

25 35 45

Output Current (mA)

Figure 2. Output Stability Figure 3. Output Stability with Capacitor Change

C

= 10 F

vout

C

vout

Stable Region

25 35 45

= 0.1 F

http://onsemi.com

4

Page 5

NCV8141

DEFINITION OF TERMS

Dropout Voltage: The input−output voltage differential

at which the circuit ceases to regulate against further

reduction in input voltage. Measured when the output

voltage has dropped 100 mV from the nominal value

obtained at 14 V input, dropout voltage is dependent upon

load current and junction temperature.

Input Voltage:

The DC voltage applied to the input

terminals with respect to ground.

Line Regulation:

The change in output voltage for a

change in the input voltage. The measurement is made under

conditions of low dissipation or by using pulse techniques

CIRCUIT DESCRIPTION

The NCV8141 is a 5.0 V Watchdog Regulator with

protection circuitry and three logic control functions that

allow a microprocessor to control its o wn p ower s upply. The

NCV8141 is designed for use in automotive, switch mode

power supply post regulator, and battery powered systems.

Basic regulator performance characteristics include a low

noise, low drift, 5.0 V ±4.0% precision output voltage with

low dropout voltage (1.25 V @ I

quiescent current (7.0 mA @ I

= 500 mA) and low

OUT

= 500 mA). On board

OUT

short circuit, thermal, and overvoltage protection make it

possible to use this regulator in particularly harsh operating

environments.

The Watchdog logic function monitors an input signal

(WDI) from the microprocessor or other signal source.

When the signal frequency moves outside externally

programmable window limits, a RESET

(RESET

). An external capacitor (C

signal is generated

) programs the

DELAY

watchdog window frequency limits as well as the power on

reset (POR) and RESET delay.

The RESET function is activated by any of three

conditions: the watchdog signal moves outside of its preset

limits; the output voltage drops out of regulation by more

than 4.5%; or the IC is in its power up sequence. The RESET

signal is independent of VIN and reliable down to V

OUT

=

1.0 V.

In conjunction with the Watchdog, the ENABLE

function controls the regulator’s power consumption. The

NCV8141’s output stage and its attendant circuitry are

enabled by setting the ENABLE lead high. The regulator

goes into sleep mode when the ENABLE lead goes low and

the watchdog signal moves outside its preset window limits.

This unique combination of control functions in the

NCV8141 gives the microprocessor control over its own

power down sequence: i.e. it gives the microprocessor the

flexibility to perform housekeeping functions before it

powers down.

such that the average chip temperature is not significantly

affected.

Load Regulation: The change in output voltage for a

change in load current at constant chip temperature.

Quiescent Current:

The part of the positive input current

that does not contribute to the positive load current. The

regulator ground lead current.

Ripple Rejection: The ratio of the peak−to−peak input

ripple voltage to the peak−to−peak output ripple voltage.

Current Limit:

Peak current that can be delivered to the

output.

VOLTAGE REFERENCE AND OUTPUT CIRCUITRY

Precision Voltage Reference

The regulated output voltage depends on the precision band

gap voltage reference in the IC. By adding an error amplifier

into the feedback loop, t he o utput v o ltage i s maintained w ithin

±4.0% over temperature and supply variation.

Output Stage

The composite PNP−NPN output structure (Figure 4)

provides 500 mA (min) of output current while maintaining

a low drop out voltage (1.25 V) and drawing little quiescent

current (7.0 mA).

V

IN

V

OUT

Figure 4. Composite Output Stage of the NCV8141

The NPN pass device prevents deep saturation of the

output stage which in turn improves the IC’s efficiency by

preventing excess current from being used and dissipated by

the IC.

Output Stage Protection

The output stage is protected against overvoltage, short

circuit and thermal runaway conditions (Figure 5).

If the input voltage rises above 30 V (e.g. load dump), the

output shuts down. This response protects the internal

circuitry and enables the IC to survive unexpected voltage

transients.

http://onsemi.com

5

Page 6

NCV8141

Using an emitter sense scheme, the amount of current

through the NPN pass transistor is monitored. Feedback

circuitry insures that the output current never exceeds a

preset limit.

> 30 V

V

IN

V

OUT

I

O

Load

Dump

Figure 5. Typical Circuit Waveforms for Output

Short

Circuit

Stage Protection

Thermal

Shutdown

Should the junction temperature of the power device

exceed 180°C (typ), the power transistor is turned off.

Thermal shutdown is an effective means to prevent die

overheating since the power transistor is the principle heat

source in the IC.

REGULATOR CONTROL FUNCTIONS

The NCV8141 differs from all other linear regulators in its

unique combination of control features.

Watchdog and ENABLE Function

V

is controlled by the logic functions ENABLE and

OUT

Watchdog (Table 1).

Table 1. V

ENABLE

H 5 5 5 5 5

L 0 5 0 0 0

as a Function of ENABLE and Watchdog

OUT

V

(V)

OUT

WDI

Slow Normal Fast High Low

As long as ENABLE is high or ENABLE is low and the

Watchdog signal is normal, V

will be at 5.0 V (typ). If

OUT

ENABLE is low and the Watchdog signal moves outside

programmable limits, the output transistor turns off and the

IC goes into SLEEP mode. Only the ENABLE circuitry in

the IC remains powered up, drawing a quiescent current of

less than 50 A.

The Watchdog monitors the frequency of an incoming

WDI signal. If the signal falls outside of the WDI window,

a frequency programmable pulse train is generated at the

RESET

lead (Figure 6) until the correct Watchdog input

signal reappears at the lead (ENABLE = HIGH).

The lower and upper window threshold limits of the

watchdog function are set by the value of C

DELAY

. The limits

are determined according to the following equations for the

NCV8141:

t

WDI

f

WDI

The capacitor C

(1.3 105)C

(7.69 10−6)C

also determines the frequency of

DELAY

DELAY

or

DELAY

−1

the RESET signal and the POWER−ON−RESET (POR)

delay period.

RESET Function

The RESET function is activated when the Watchdog

signal is outside of its preset window (Figure 6), when the

regulator is in its power up state (Figure 7) or when V

drops below V

−4.5% for more than 2.0 s (Figure 8)

OUT

OUT

If the Watchdog signal falls outside of the preset voltage

and frequency window, a frequency programmable pulse

train is generated at the RESET

lead (Figure 6) until the

correct Watchdog input signal reappears at the lead. The

duration of the RESET pulse is determined by C

DELAY

according to the following equation:

t

WDI(RESET

RESET

CIRCUIT WAVEFORMS WITH DELAYS

(1.0 104)C

)

INDICATED

DELAY

If an undervoltage condition exists, the voltage on the

RESET lead goes low and the delay capacitor, C

discharged. RESET

regulation, the voltage on C

remains low until output is in

exceeds the upper

DELAY

DELAY

, is

switching threshold and the Watchdog input signal is within

its set window limits (Figures 7 and 8). The delay after the

output is in regulation is:

t

POR(typ)

(4.75 105)C

DELAY

The RESET delay circuit is also programmed with the

external cap C

DELAY

.

The output of the reset circuit is an open collector NPN.

RESET is operational down to V

= 1.0 V. Both RESET

OUT

and its delay are governed by comparators with hysteresis to

avoid undesirable oscillations.

http://onsemi.com

6

Page 7

V

V

When Watchdog is Held

OUT

High and ENABLE = HIGH

V

When Watchdog is Held Low

OUT

and ENABLE = HIGH

V

When Watchdog is too Slow

OUT

and ENABLE = HIGH

V

ENABLE

WDI

RESET

V

OUT

V

ENABLE

WDI

RESET

V

OUT

V

ENABLE

WDI

RESET

V

OUT

IN

0 V

0 V

0 V

IN

0 V

0 V

0 V

IN

0 V

0 V

0 V

NCV8141

Batt

Batt

POR Normal Operation WDI held High

Batt

Batt

Normal Operation

POR

Batt

Batt

POR Normal Operation Slow WDI signal

WDI held Low

Batt

Batt

POR Normal Operation Sleep Mode

Batt

Batt

POR

Normal

Operation

WDI

high

WDI

low

Sleep Mode

POR Normal Operation

POR Normal Operation

WDI Held High After a Normal Period

of Operation; ENABLE = LOW

WDI Held Low or is too Slow after

a Normal Period of Operation;

ENABLE = LOW

V

ENABLE

WDI

RESET

V

OUT

V

ENABLE

WDI

RESET

V

OUT

IN

0 V

0 V

0 V

IN

0 V

0 V

0 V

Figure 6. Timing Diagrams for Watchdog and ENABLE Functions

V

OUT

V

R(HI)

V

R(LO)

RESET

V

R(LO)

V

R(PEAK)

Figure 7. Power RESET

t

POR

and Power Down

V

OUT

−4.5%

OUT

RESET

5.0 V

< 6.0 s

≥ 6.0 s

Figure 8. Undervoltage Triggered RESET

t

POR

http://onsemi.com

7

Page 8

NCV8141

APPLICATION NOTES

NCV8141 DESIGN EXAMPLE

The NCV8141 with its unique integration of linear

regulator and control features: RESET, ENABLE and

WATCHDOG, provides a single IC solution for a

microprocessor power supply. The reset delay, reset

duration and watchdog frequency limit are all determined by

a single capacitor. For a particular microprocessor the

overriding requirement is usually the reset delay (also

known as power on reset). The capacitor is chosen to meet

this requirement and the reset duration and watchdog

frequency follow.

The reset delay is given by:

t

POR(typ)

(4.75 105)C

DELAY

Assume that the reset delay must be 200 ms minimum.

From the NCV8141 data sheet the reset delay has a 37%

tolerance due to the regulator.

Assume the capacitor tolerance is 10%.

t

(min) (4.75 105 0.63) C

POR

C

DELAY

C

(min)

(min) 0.743 F

DELAY

t

(min)

POR

2.69 10

DELAY

5

0.9

Closest standard value is 0.82 F.

Minimum and maximum delays using 0.82 F are 220 ms

and 586 ms.

The duration of the reset pulse is given by:

T

WDI(RESET

(typ) (1.0 104) C

)

DELAY

This has a tolerance of ±50% due to the IC, and ±10% due

to the capacitor.

The duration of the reset pulse ranges from 3.69 ms to

13.5 ms.

The watchdog signal can be expressed as a frequency or

time. From a programmers point of view, time is more useful

since they must ensure that a watchdog signal is issued

consistently several times per second.

The watchdog time is given by:

t

(1.3 105)C

WDI

DELAY

There is a tolerance of ±20% due to the NCV8141.

With a capacitor tolerance of ±10%:

t

(1.3 105) 1.2 1.1 C

WDI

t

141 ms (max)

WDI

t

(1.3 105) 0.8 0.9 C

WDI

t

76 ms (min)

WDI

Delay

DELAY

The software must be written so that a watchdog signal

arrives at least every 76 ms.

FAIL

Hz

ms

7

141 76

Figure 9. WDI Signal for C

ENERGY CONSERVATION AND SMART FEATURES

13

NCV8141

PASS

= 0.82 F using

Delay

Energy conservation is another benefit of using a

regulator with integrated microprocessor control features.

Using the NCV8141 as indicated in Figure 10, the

microprocessor can control its own power down sequence.

The momentary contact switch quickly charges C1 through

R1.

When the voltage across C1 reaches 3.95 V ( the enable

threshold), the output switches on and V

After a delay period determined by C

rises to 5.0 V.

OUT

, a frequency

Delay

programmable reset pulse train is generated at the reset

output. The pulse train continues until the correct watchdog

signal appears at the WDI lead. C1 is now left to discharge

through the input impedance of the enable lead

(approximately 150 k) and the enable signal disappears.

The output voltage remains at 5.0 V as long as the NCV8141

continues to receive the correct watchdog signal.

The microprocessor can power itself down by terminating

its watchdog signal. When the microprocessor finishes its

housekeeping or power down software routine, it stops

sending a watchdog signal. In response, the regulator

generates a reset signal and goes into a sleep mode where

V

drops to 0 V, shutting down the microprocessor.

OUT

http://onsemi.com

8

Page 9

9.0 V

V

IN

NCV8141

V

OUT

R

110 K

C

DELAY

NCV8141

C

2

0.1 F

V

CC

RESET

WDI

GND

Switch

1

ENABLE

C

1

0.1 F

10 F

2.7 k

Microprocessor

RESET

WATCHDOG PORT

Figure 10. Application Diagram for NCV8141. The NCV8141 Provides a 5.0 V Tightly Regulated

Supply and Control Function to the Microprocessor. In this Application, the Microprocessor

Controls its own Power Down Sequence (see text).

http://onsemi.com

9

Page 10

Battery

C1*

0.1 F

(optional)

V

IN

NCV8141

NCV8141

V

OUT

C

*

2

10 F*

2.7 k

V

CC

Ignition

0.1 F

*C1 is required if regulator is located far from the power source filter.

**C2 is required for stability.

***R ≤ 80 k.

STABILITY CONSIDERATIONS

ENABLE

DELAY

RESET

WDI

GND

Figure 11. Application Diagram

The output or compensation capacitor C2 in Figure 11

helps determine three main characteristics of a linear

regulator: startup delay, load transient response and loop

stability.

The capacitor value and type should be based on cost,

availability, size and temperature constraints. An aluminum

electrolytic capacitor is the least expensive solution, but, if

the circuit operates at low temperatures (−25°C to −40°C),

both the value and ESR of the capacitor will vary

considerably. The capacitor manufacturers data sheet

usually provides this information.

The value for the output capacitor C

shown in Figure 11

2

should work for most applications, however it is not

necessarily the optimized solution.

To determine an acceptable value for C

for a particular

2

application, start with a tantalum capacitor of the

recommended value and work towards a less expensive

alternative part.

Step 1: Place the completed circuit with a tantalum

capacitor of the recommended value in an environmental

chamber at the lowest specified operating temperature and

monitor the outputs with an oscilloscope. A decade box

connected in series with the capacitor will simulate the

higher ESR of an aluminum capacitor. Leave the decade box

outside the chamber, the small resistance added by the

longer leads is negligible.

Step 2: With the input voltage at its maximum value,

increase the load current slowly from zero to full load while

observing the output for any oscillations. If no oscillations

are observed, the capacitor is large enough to ensure a stable

design under steady state conditions.

Step 3: Increase the ESR of the capacitor from zero using

the decade box and vary the load current until oscillations

appear. Record the values of load current and ESR that cause

the greatest oscillation. This represents the worst case load

conditions for the regulator at low temperature.

RESET

WATCHDOG

PORT

R***

Microprocessor

Step 4: Maintain the worst case load conditions set in

Step 3 and vary the input voltage until the oscillations

increase. This point represents the worst case input voltage

conditions.

Step 5: If the capacitor is adequate, repeat Steps 3 and 4

with the next smaller valued capacitor. A smaller capacitor

will usually cost less and occupy less board space. If the

output oscillates within the range of expected operating

conditions, repeat Steps 3 and 4 with the next larger standard

capacitor value.

Step 6: Test the load transient response by switching in

various loads at several frequencies to simulate its real

working environment. Vary the ESR to reduce ringing.

Step 7: Increase the temperature to the highest specified

operating temperature. Vary the load current as instructed in

Step 5 to test for any oscillations.

Once the minimum capacitor value with the maximum

ESR is found, a safety factor should be added to allow for the

tolerance of the capacitor and any variations in regulator

performance. Most good quality aluminum electrolytic

capacitors have a tolerance of ± 20% so the minimum value

found should be increased by at least 50% to allow for this

tolerance plus the variation which will occur at low

temperatures. The ESR of the capacitor should be less than

50% of the maximum allowable ESR found in Step 3 above.

CALCULATING POWER DISSIPATION IN A SINGLE

OUTPUT LINEAR REGULATOR

The maximum power dissipation for a single output

regulator (Figure 12) is:

P

D(max)

V

IN(max)

V

OUT(min)

I

OUT(max)

V

IN(max)IQ

(1)

where:

V

V

I

OUT(max)

is the maximum input voltage,

IN(max)

OUT(min)

is the minimum output voltage,

is the maximum output current for the

application, and

http://onsemi.com

10

Page 11

NCV8141

IQ is the quiescent current the regulator consumes at

I

OUT(max)

V

IN

Figure 12. Single Output Regulator With Key

Once the value of P

permissible value of R

The value of R

.

I

IN

SMART

REGULATOR

Control

Features

I

Q

Performance Parameters Labeled

is known, the maximum

D(max)

can be calculated:

JA

R

JA

150°C T

JA

P

D

can then be compared with those in the

I

OUT

A

V

OUT

(2)

package section of the data sheet. Those packages with

R

’s less than the calculated value in Equation 2 will keep

JA

the die temperature below 150°C.

In some cases, none of the packages will be sufficient to

dissipate the heat generated by the IC, and an external

heatsink will be required.

HEATSINKS

A heatsink effectively increases the surface area of the

package to improve the flow of heat away from the IC and

into the surrounding air.

Each material in the heat flow path between the IC and the

outside environment will have a thermal resistance. Like

series electrical resistances, these resistances are summed to

determine the value of R

R

R

JA

JC

.

JA

R

CS

R

SA

(3)

where:

R

= the junction−to−case thermal resistance,

JC

R

= the case−to−heatsink thermal resistance, and

CS

R

= the heatsink−to−ambient thermal resistance.

SA

R

appears in the package section of the data sheet. Like

JC

R

, it too is a function of package type. R

JA

CS

and R

are

SA

functions of the package type, heatsink and the interface

between them. These values appear in heatsink data sheets

of heatsink manufacturers.

http://onsemi.com

11

Page 12

NCV8141

PACKAGE DIMENSIONS

D2PAK−7 (SHORT LEAD)

CASE 936AB−01

ISSUE O

NOTES:

1. DIMENSIONS AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

DIM MIN MAX MIN MAX

A 0.396 0.406 10.05 10.31

B 0.326 0.336 8.28 8.53

C 0.170 0.180 4.31 4.57

D 0.026 0.036 0.66 0.91

E 0.045 0.055 1.14 1.40

G 0.050 REF 1.27 REF

H 0.539 0.579 13.69 14.71

K

0.055 0.066 1.40 1.68

L 0.000 0.010 0.00 0.25

M 0.100 0.110 2.54 2.79

N 0.017 0.023 0.43 0.58

P 0.058 0.078 1.47 1.98

R

0 8 °°0 8 °°

S 0.095 0.105 2.41 2.67

U 0.256 REF 6.50 REF

V 0.305 REF 7.75 REF

MILLIMETERSINCHES

E

M

TERMINAL 8

U

V

K

A

S

B

H

L

P

D

G

N

R

C

SMART REGULATOR is a registered trademark of Semiconductor Components Industries, LLC (SCILLC).

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 61312, Phoenix, Arizona 85082−1312 USA

Phone: 480−829−7710 or 800−344−3860 Toll Free USA/Canada

Fax: 480−829−7709 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Japan: ON Semiconductor, Japan Customer Focus Center

2−9−1 Kamimeguro, Meguro−ku, Tokyo, Japan 153−0051

Phone: 81−3−5773−3850

http://onsemi.com

12

ON Semiconductor Website: http://onsemi.com

Order Literature: http://www.onsemi.com/litorder

For additional information, please contact your

local Sales Representative.

NCV8141/D

Loading...

Loading...