Page 1

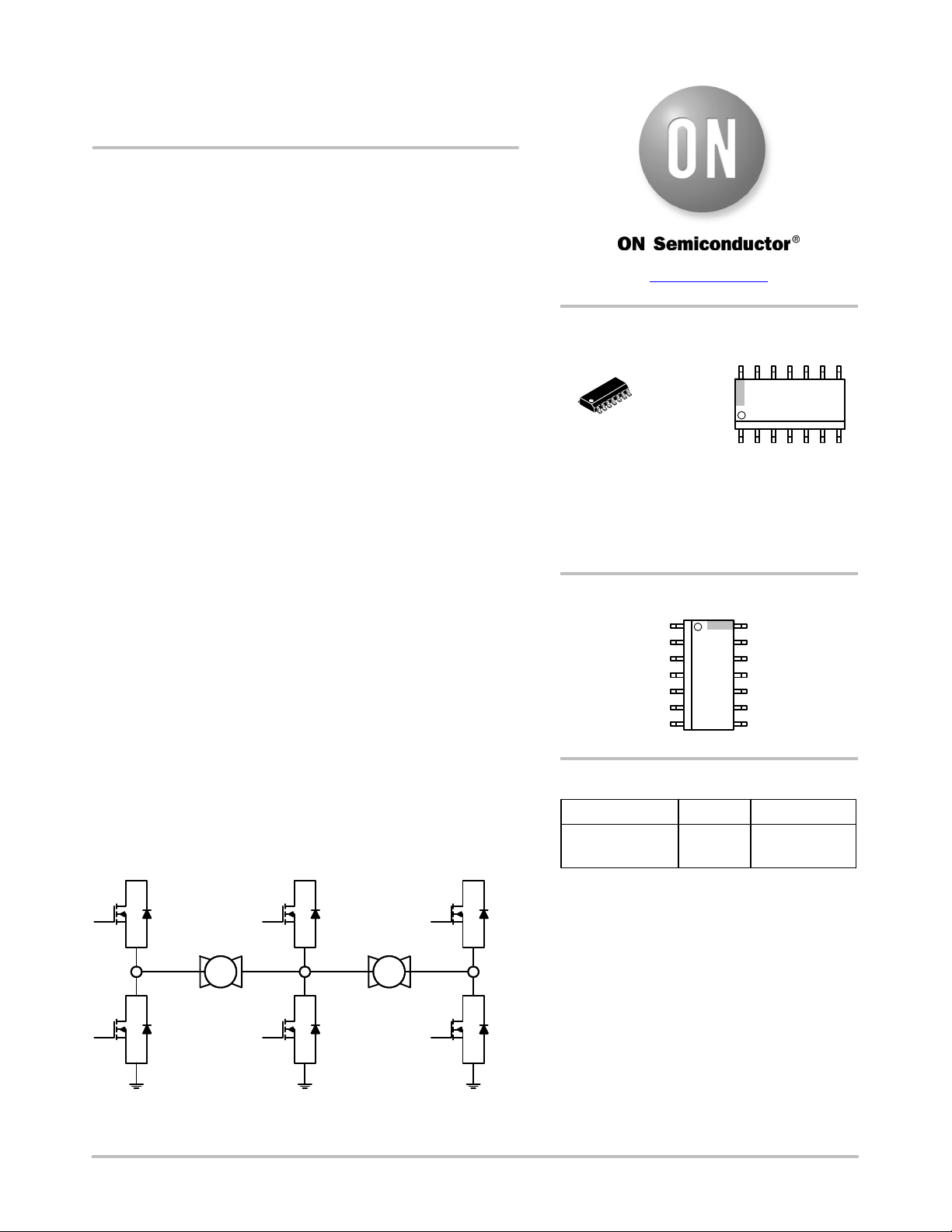

Triple Half-Bridge Driver

with SPI Control

NCV7703C

The NCV7703C is a fully protected Triple Half−Bridge Driver

designed specifically for automotive and industrial motion control

applications. The three half−bridge drivers have independent control.

This allows for high side, low side, and H−Bridge control. H−Bridge

control provides forward, reverse, brake, and high impedance states

(with EN = 0). The drivers are controlled via a standard Serial

Peripheral Interface (SPI).

Features

• Ultra Low Quiescent Current in Sleep Mode, 1 mA for V

• 3 High−Side and 3 Low−Side Drivers Connected as Half−Bridges

• Internal Free−Wheeling Diodes

• Configurable as H−Bridge Drivers

• 500 mA (typ), 1.1 A (max) Drivers

• R

= 0.8 W (typ), 1.7 W (max)

DS(on)

• 5 MHz SPI Control with Daisy Chain Capability

• Compliance with 5 V and 3.3 V Systems

• Overvoltage and Undervoltage Lockout

• Fault Reporting

• 1.45 A Overcurrent Threshold Detection

• 3 A Current Limit

• Shoot−Through Attempt Detection

• Overtemperature Warning and Protection Levels

• Internally Fused Leads in SOIC−14 for Better Thermal Performance

• ESD Protection up to 6 kV

• These are Pb−Free Devices

and V

S

CC

14

www.onsemi.com

MARKING

DIAGRAM

14

SOIC−14

D2 SUFFIX

1

CASE 751A

NCV7703C = Specific Device Code

A = Assembly Location

WL = Wafer Lot

Y = Year

WW = Work Week

G = Pb−Free Package

PIN CONNECTIONS

GND

OUT3

V

S

CSB

SI

SCLK

GND

NCV7703CG

AWLYWW

1

GND

OUT1

OUT2

V

CC

EN

SO

GND

Typical Applications

• Automotive

• Industrial

• DC Motor Management

V

S

OUT1 OUT2

© Semiconductor Components Industries, LLC, 2016

March, 2021 − Rev. 5

M M

Figure 1. Cascaded Application

V

ORDERING INFORMATION

Device Package Shipping†

NCV7703CD2R2G SOIC−14

S

V

S

OUT3

1 Publication Order Number:

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

(Pb−Free)

2500 /

Tape & Reel

NCV7703C/D

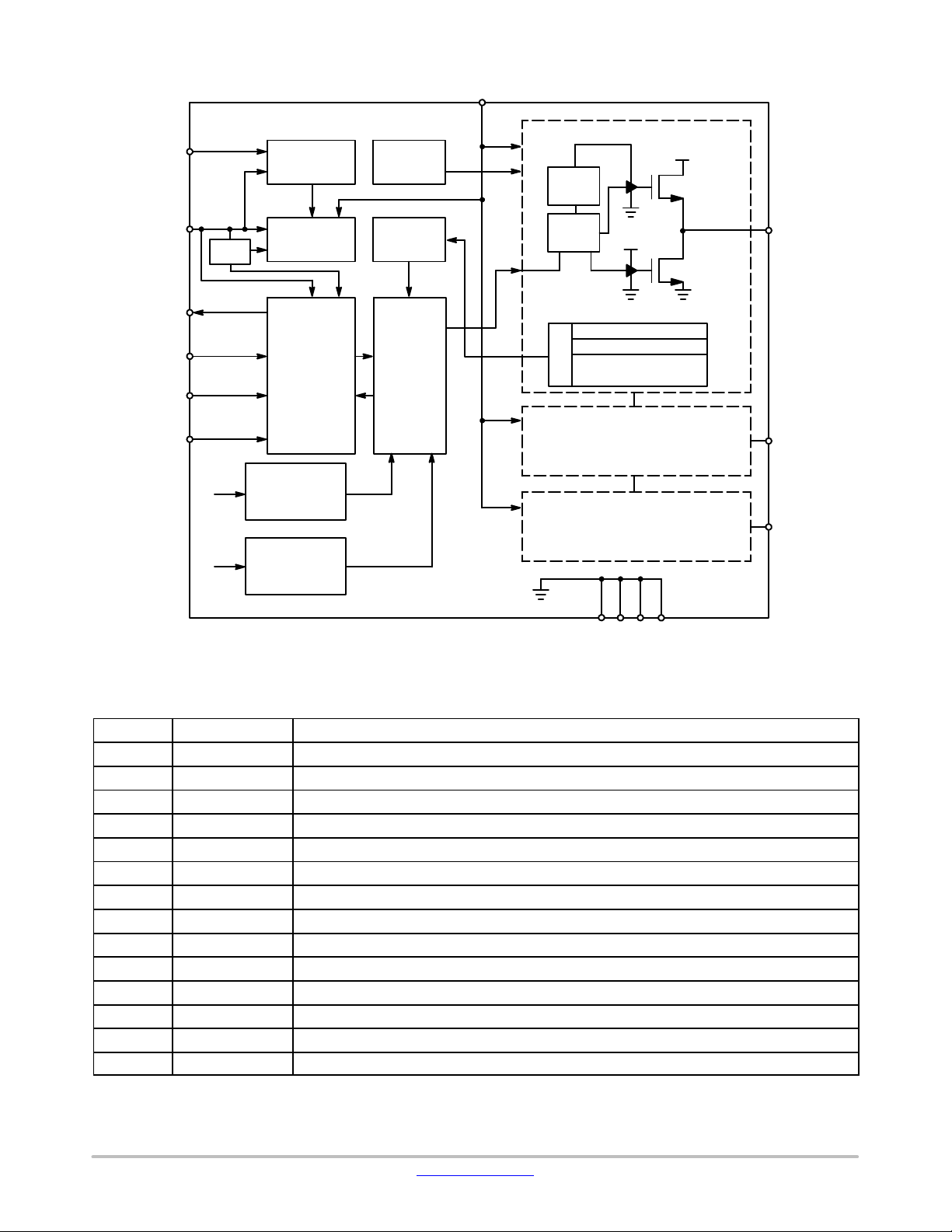

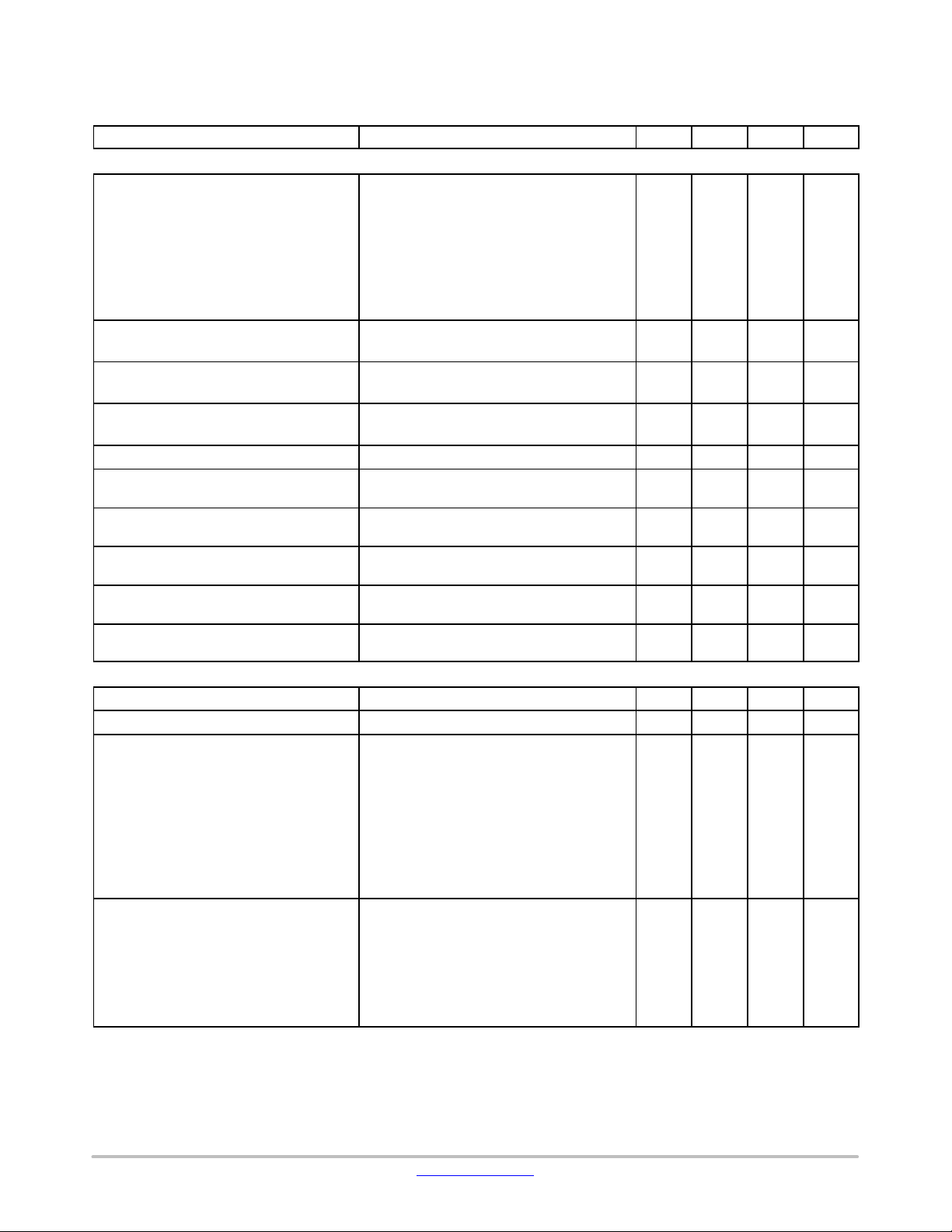

Page 2

NCV7703C

V

S

EN

V

CC

SO

SCLK

CSB

V

POR

ENABLE OSC

Reference

& Bias

Fault

Detect

clk

S

clk

Charge

Pump

Control

Logic

Channel Enable

Waveshaping

V

V

S

High−Side

Driver

S

OUT1

Low−Side

Driver

Waveshaping

Under−Load

DRIVE 1

SI

SPI

16 Bit

Logic

and

Overcurrent

Fault

Thermal

Warning/Shutdown

Latch

V

S

clk

Channel Enable

DRIVE 2

OUT2

Fault

V

V

S

S

Undervoltage

Lockout

Overvoltage

V

S

clk

Channel Enable

Fault

DRIVE 3

OUT3

Lockout

Figure 2. Block Diagram

GND

PACKAGE PIN DESCRIPTION

Pin #

1 GND* Ground. Connect all grounds together.

2 OUT3 Half Bridge Output 3.

3 V

4 CSB Chip Select Bar. Active low serial port operation.

5 SI Serial Input

6 SCLK Serial Clock

7 GND* Ground. Connect all grounds together.

8 GND* Ground. Connect all grounds together.

9 SO Serial Output

10 EN Enable. Logic high wakes the IC up from a sleep mode.

11 V

12 OUT2 Half Bridge Output 2.

13 OUT1 Half Bridge Output 1.

14 GND* Ground. Connect all grounds together.

*Pins 1, 7, 8, and 14 are internally shorted together. It is recommended to also short these pins externally.

Symbol Description

S

CC

Power Supply input for the output drivers and internal supply voltage.

Power supply input for internal logic.

www.onsemi.com

2

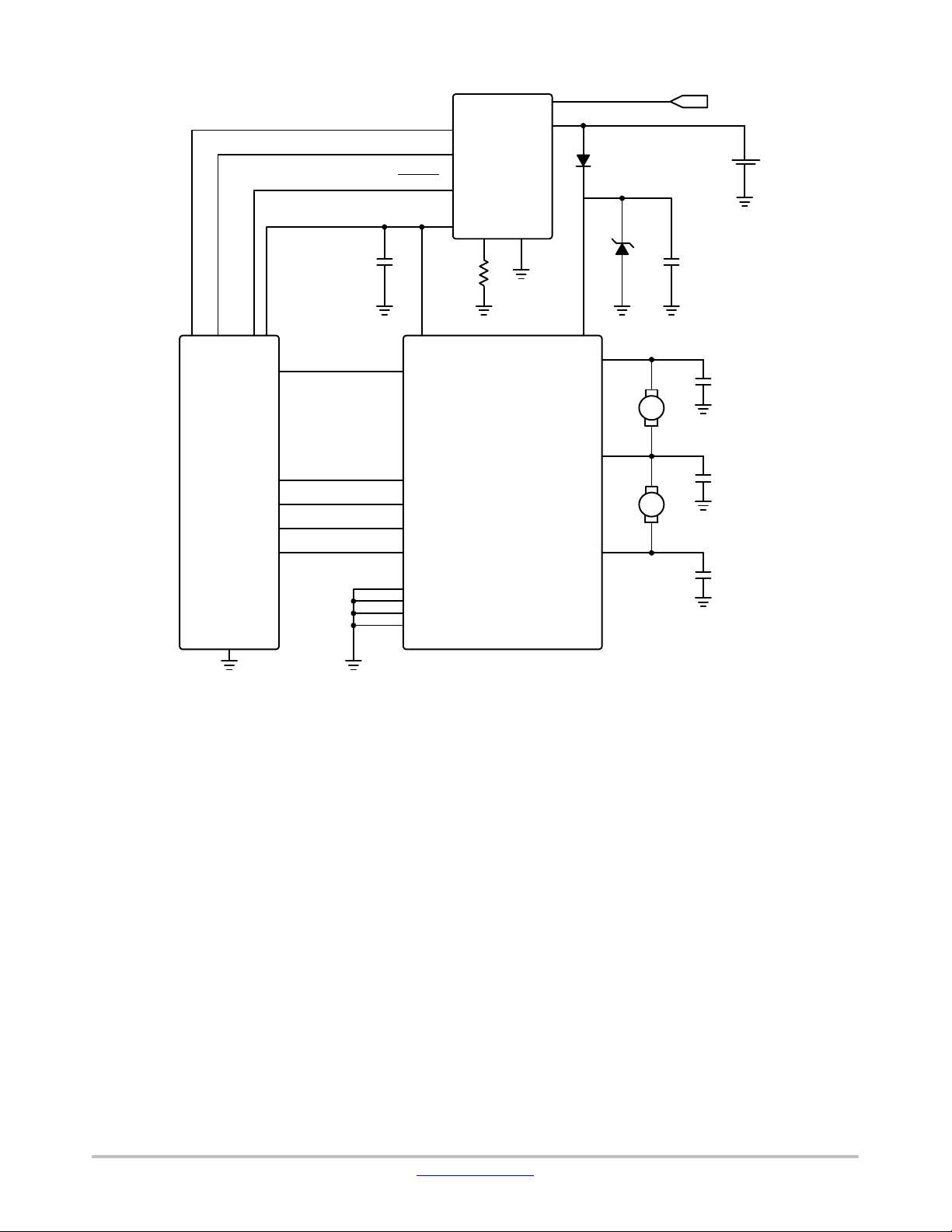

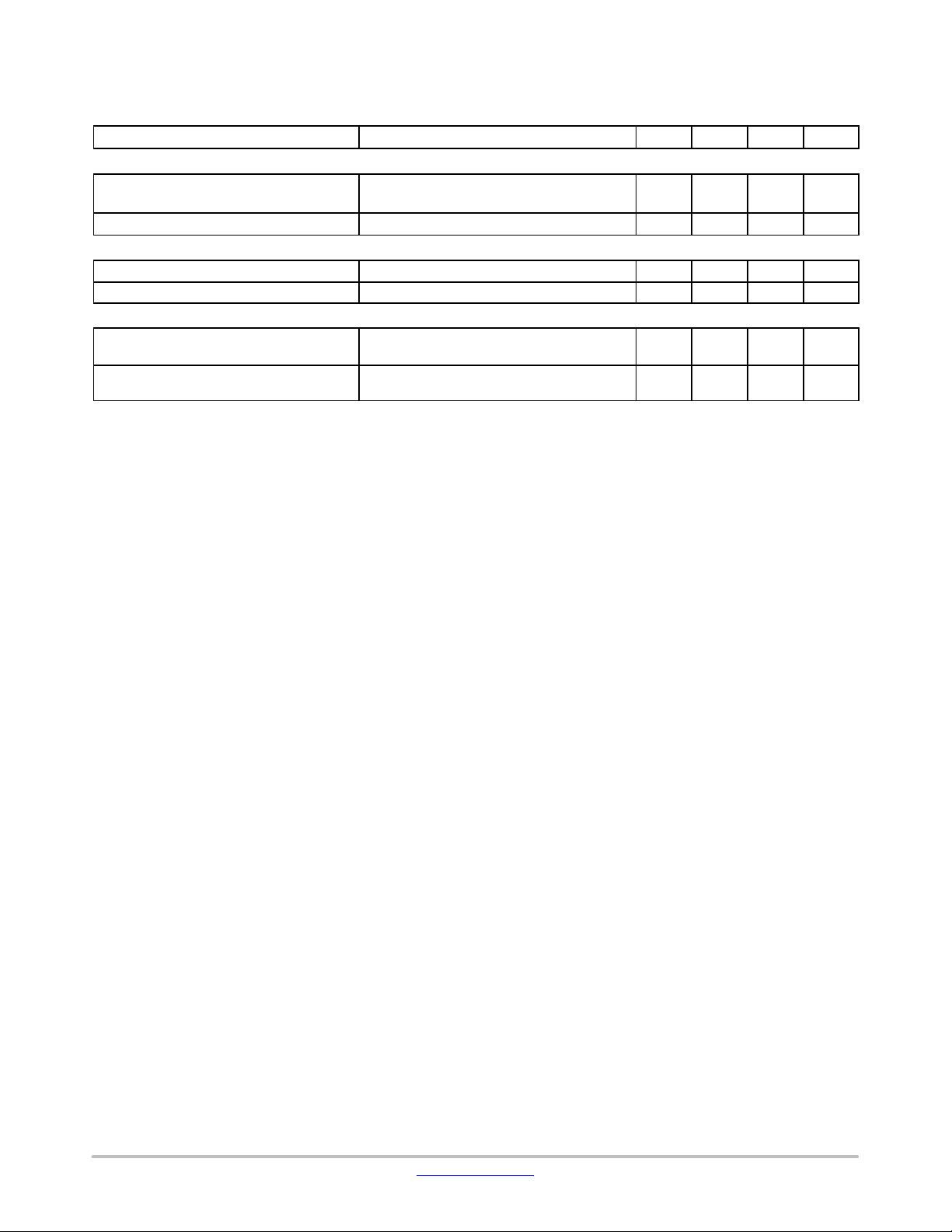

Page 3

22 mF

C1

WDI

Wake Up

RESET

Vout

NCV7703C

NCV8518

Delay

120k

GND

D1*

1N4001

D2**

ENABLE

VBAT

10 mF

+

−

V

CC

EN

CSB

microprocessor

GND

SI

SCLK

SO

GND

GND

GND

GND

NCV7703C

* D1 optional. For use where reverse battery protection is required.

** D2 optional. For use where load dump exceeds 40V.

*** C2−C4, Recommended for EMC performance.

Figure 3. Application Circuit

V

S

OUT1

C2***

M

OUT2

M

OUT3

10 nF

C3***

10 nF

C4***

10 nF

www.onsemi.com

3

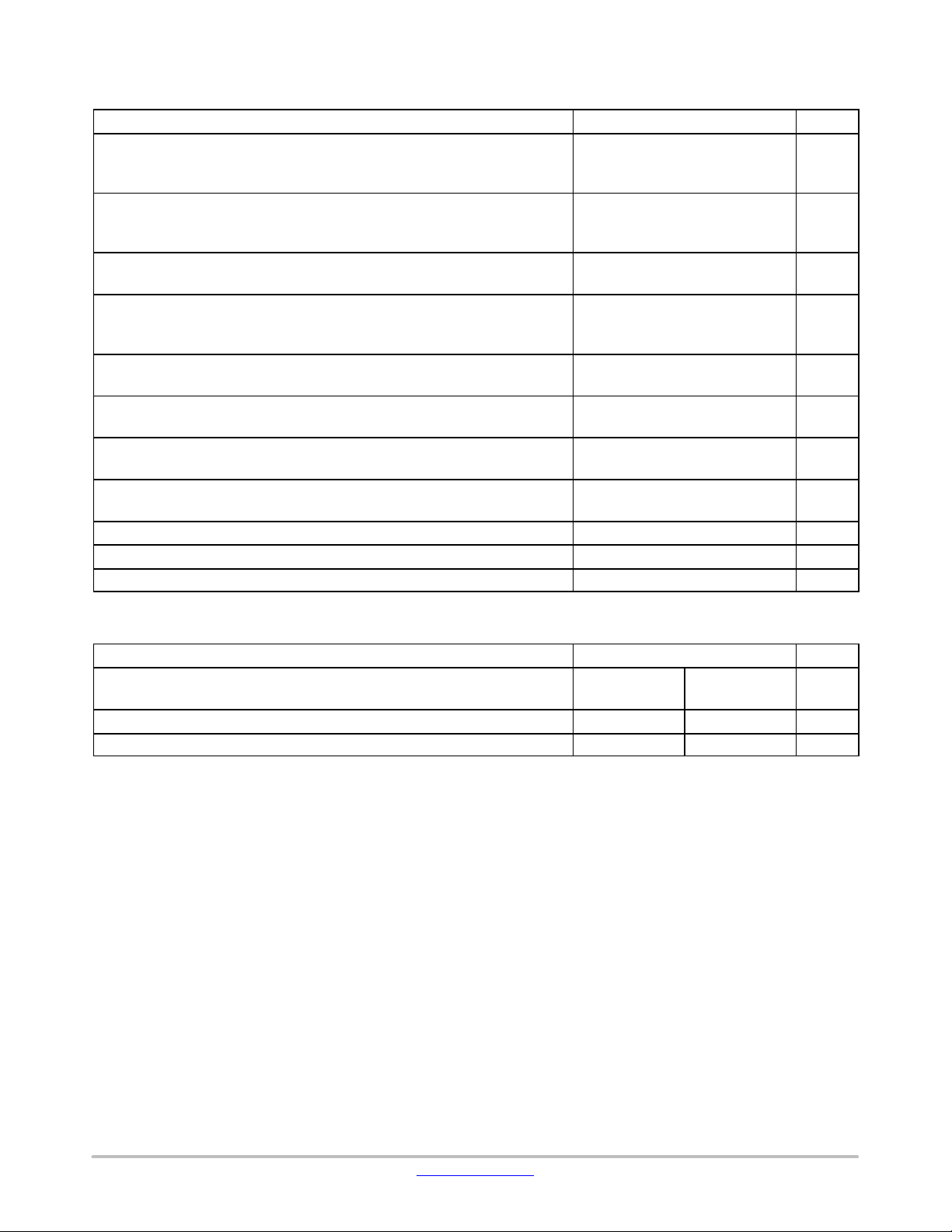

Page 4

NCV7703C

MAXIMUM RATINGS

Rating Value Unit

Power Supply Voltage (VS)

(DC)

(AC), t < 500 ms, Ivs > −2 A

−0.3 to 40

−1

Output Pin OUTx

(DC)

(AC), t < 500 ms, IOUTx > −2 A

Pin Voltage

(Logic Input pins, SI, SCLK, CSB, SO, EN, V

CC

)

−0.3 to 40

−1

−0.3 to 5.5 V

Output Current (OUTx)

(DC)

(AC) (50 ms pulse, 1 s period)

Electrostatic Discharge, Human Body Model,

, OUT1, OUT2, OUT3 (Note 3)

V

S

Electrostatic Discharge, Human Body Model,

−2.0 to 2.0

−5.0 to 5.0

6 kV

2 kV

all other pins (Note 3)

Electrostatic Discharge, Machine Model,

, OUT1, OUT2, OUT3 (Note 3)

V

S

Electrostatic Discharge, Machine Model,

300 V

200 V

all other pins (Note 3)

Operating Junction Temperature −40 to 150 °C

Storage Temperature Range −55 to 150 °C

Moisture Sensitivity Level (MAX 260°C Processing) MSL3 −

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

V

V

A

Thermal Parameters

Test Conditions (Typical Value) Unit

14 Pin Fused SOIC Package min−pad board

(Note 1)

Junction−to−Lead (psi−JL8, Y

Junction−to−Ambient (R

1. 1−oz copper, 67 mm2 copper area, 0.062″ thick FR4.

2. 1−oz copper, 645 mm

q

2

) or Pins 1, 7, 8, 14

JL8

, qJA)

JA

copper area, 0.062″ thick FR4.

23 22

122 83

3. This device series incorporates ESD protection and is characterized by the following methods:

ESD HBM according to AEC−Q100−002 (EIA/JESD22−A114)

ESD MM according to AEC−Q100−003 (EIA/JESD22−A115)

1″ pad board

(Note 2)

°C/W

°C/W

www.onsemi.com

4

Page 5

NCV7703C

ELECTRICAL CHARACTERISTICS

(−40°C ≤ TJ ≤ 150°C, 5.5 V ≤ VS ≤ 40 V, 3.15 V ≤ VCC ≤ 5.25 V, EN = VCC, unless otherwise specified)

Characteristic Conditions Min Typ Max Unit

GENERAL

Supply Current (V

Sleep Mode (Note 5)

)

S

VS = 13.2 V, OUTx = 0 V

EN = SI = SCLK = 0 V, CSB = V

0 V < VCC < 5.25 V

(T

= −40°C to 85°C)

J

CC

−

1.0

5.0

mA

= 13.2 V, OUTx = 0 V

V

S

EN = SI = SCLK = 0 V, CSB = V

CC

−

−

2.0

0 V < VCC < 5.25 V, TJ = 25°C

Supply Current (VS)

Active Mode

Supply Current (VCC)

Sleep Mode (Note 6)

Supply Current (VCC)

EN = VCC, 5.5 V < VS < 35 V

No Load

VCC = CSB, EN = SI = SCLK = 0 V

= −40°C to 85°C)

(T

J

EN = V

CC

− 2.0 4.0 mA

− 0.1 2.5

− 1.5 3.0 mA

Active Mode

VCC Power−On−Reset Threshold − 2.55 2.90 V

VS Undervoltage Detection Threshold

Hysteresis

VS Overvoltage Detection Threshold

Hysteresis

Thermal Warning (Note 4) Threshold

Hysteresis

Thermal Shutdown (Note 4) Threshold

Hysteresis

Ratio of Thermal Shutdown to Thermal

VS decreasing 3.7

100

VS increasing 33.0

1.0

120

−

155

−

1.05 1.20 − °C/°C

4.1

365

36.5

2.5

140

20

175

30

4.5

450

40.0

4.0

170

−

195

−

Warning temperature (Note 4)

OUTPUTS

Output R

Output R

(Source) I

DS(on)

(Sink) I

DS(on)

Source Leakage Current

Sum of I(OUTx) x = 1, 2, 3

= −500 mA − − 1.7

out

= 500 mA − − 1.7

out

OUTx = 0 V, VS = 40 V, EN = 0 V

CSB = V

CC

−5.0

−

−

0 V < VCC < 5.25 V

Sum(I(OUTx)

mA

mA

V

mV

V

°C

°C

W

W

mA

OUTx = 0 V, V

CSB = V

= 40 V, EN = 0 V

S

CC

−1.0

−

−

0 V < VCC < 5.25 V, TJ = 25°C

Sum(I(OUTx)

Sink Leakage Current OUTx = VS = 40 V, EN = 0 V

CSB = V

CC

−

−

300

mA

0 V < VCC < 5.25 V

OUTx = V

CSB = V

= 13.2 V, EN = 0 V

S

CC

−

−

10

0 V < VCC < 5.25 V, TJ = 25°C

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

4. Thermal characteristics are not subject to production test

5. For temperatures above 85°C, refer to Figure 6.

6. For temperatures above 85°C, refer to Figure 7.

7. Current limit is active with and without overcurrent detection.

www.onsemi.com

5

Page 6

NCV7703C

ELECTRICAL CHARACTERISTICS

(−40°C ≤ TJ ≤ 150°C, 5.5 V ≤ VS ≤ 40 V, 3.15 V ≤ VCC ≤ 5.25 V, EN = VCC, unless otherwise specified)

Characteristic UnitMaxTypMinConditions

OUTPUTS

Under Load Detection Threshold Source

Power Transistor Body Diode Forward Voltage If = 500 mA − 0.9 1.3 V

OVERCURRENT

Overcurrent Shutdown Threshold (OUTHx)

Overcurrent Shutdown Threshold (OUTLx) VCC = 5 V, Vs = 13.2 V 1.1 1.45 2.0 A

CURRENT LIMIT (Note 7)

Current Limit (OUTHx)

Current Limit (OUTLx) VCC = 5 V, Vs = 13.2 V,

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

4. Thermal characteristics are not subject to production test

5. For temperatures above 85°C, refer to Figure 6.

6. For temperatures above 85°C, refer to Figure 7.

7. Current limit is active with and without overcurrent detection.

Sink

VCC = 5 V, Vs = 13.2 V −2.0 −1.45 −1.1 A

VCC = 5 V, Vs = 13.2 V

−17

2.0

−5.0 −3.0 −2.0

2.0 3.0 5.0

−7.0

7.0

−2.0

17

mA

A

A

www.onsemi.com

6

Page 7

NCV7703C

ELECTRICAL CHARACTERISTICS

(−40°C ≤ TJ ≤ 150°C, 5.5 V ≤ VS ≤ 40 V, 3.15 V ≤ VCC ≤ 5.25 V, EN = VCC, unless otherwise specified)

Characteristic Symbol Conditions Min Typ Max Unit

LOGIC INPUTS (EN, SI, SCLK, CSB)

Input Threshold

High

Low

2.0

−

−

−

−

0.8

Input Hysteresis (EN, SI, SCLK, CSB) 100 400 800 mV

Pulldown Resistance (EN, SI, SCLK) EN = SI = SCLK = V

CC

50 125 250

Pullup Resistance (CSB) CSB = 0 V 50 125 250

Input Capacitance (Note 8) − 10 15 pF

LOGIC OUTPUT (SO)

I

Output High

Output Low I

Tri−state Leakage CSB = VCC, 0 V v SO v V

Tri−state Input Capacitance (Note 8) CSB = V

= 1 mA VCC – 1.0 VCC – 0.7 − V

out

= −1.6 mA − 0.2 0.4 V

out

CC

CC

−10 − 10

− 10 15 pF

TIMING SPECIFICATIONS

Under Load Detection Delay Time

200 350 600

Overcurrent Shutdown Delay Time VCC = 5 V, Vs = 13.2 V,

High Side Turn On Time ThsOn

High Side Turn Off Time ThsOff

Low Side Turn On Time TlsOn

Low Side Turn Off Time TlsOff

High Side Rise Time ThsTr

High Side Fall Time ThsTf

Low Side Rise Time TlsTr

Low Side Fall Time TlsTf

Bit13 = 0

Bit13 = 1

VS = 13.2 V, R

VS = 13.2 V, R

VS = 13.2 V, R

VS = 13.2 V, R

VS = 13.2 V, R

VS = 13.2 V, R

VS = 13.2 V, R

VS = 13.2 V, R

load

load

load

load

load

load

load

load

= 25 W

= 25 W

= 25 W

= 25 W

= 25 W

= 25 W

= 25 W

= 25 W

80

10

200

25

400

− 7.5 15

− 3.0 6.0

− 6.5 15

− 3.0 6.0

− 5.0 10

− 2.0 5.0

− 1.0 3.0

− 1.0 3.0

50

NonOverlap Time ThsOffLsOn High Side Turn Off to Low Side Turn On 1.0 − −

NonOverlap Time TlsOffHsOn Low Side Turn Off to High Side Turn On 1.0 − −

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

8. Not production tested.

V

kW

kW

mA

ms

ms

ms

ms

ms

ms

ms

ms

ms

ms

ms

ms

ms

www.onsemi.com

7

Page 8

NCV7703C

ELECTRICAL CHARACTERISTICS

(−40°C ≤ TJ ≤ 150°C, 5.5 V ≤ VS ≤ 40 V, 3.15 V ≤ VCC ≤ 5.25 V, EN = VCC, unless otherwise specified)

Characteristic Conditions Symbol Min Typ Max Unit

SERIAL PERIPHERAL INTERFACE (VCC = 5 V)

SCLK Frequency

SCLK Clock Period VCC = 5 V

SCLK High Time TCLKH 85 − − ns

SCLK Low Time TCLKL 85 − − ns

SCLK Setup Time TCLKSU1

SI Setup Time TISU 50 − − ns

SI Hold Time TIHT 50 − − ns

CSB Setup Time TCSBSU1

CSB High Time (Note 10) TCSBHT 5.0 − −

SO enable after CSB falling edge TSOCSBF − − 50 ns

SO disable after CSB rising edge TSOCSBR − − 50 ns

SO Rise Time (10% to 90%) C

SO Fall Time (90% to 10%) C

SO Valid Time (Note 9) SCLK High to SO 50% TSOV − 50 100 ns

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

9. Not tested in production

10.This is the minimum time the user must wait between SPI commands.

V

= 3.3 V

CC

= 40 pF − − 10 25 ns

load

= 40 pF − − 10 25 ns

load

− − − 5.0 MHz

− 200

TCLKSU2

TSSBSU2

500

85

85

100

100

−

−

−

−

−

−

−

−

−

−

−

−

ns

ns

ns

ms

www.onsemi.com

8

Page 9

NCV7703C

CHARACTERISTIC TIMING DIAGRAMS

TlsTr

TlsOff

90%

50%

LS Turn OFF

HS Turn ON

CSB

LS Turn On

HS Turn Off

50%

10%

TlsOffHsOn

ThsOn

TlsOn

90%

90%

50%

10%

ThsTr

TlsTf

90%

50%

10%

ThsOffLsOn

CSB

50%

10%

ThsTf

50%

ThsOff

Figure 4. Detailed Driver Timing

www.onsemi.com

9

Page 10

NCV7703C

CSB

SCLK

50%

TCSBSU1

TCLKSU1

CSB

TCLKSU2

50% 50% 50%50% 50% 50%

TCLKH TCLKL

50% 50%

TCSBHT

50%50%

TCSBSU2

SI

SCLK

SO

SO

50% 50%

50%

50% 50%

TSOCSBF

50% 50%

TSOV

TISU

Figure 5. SPI Timing Diagram

TSOCSBR

TIHT

www.onsemi.com

10

Page 11

NCV7703C

7.0

6.0

5.0

4.0

3.0

2.0

SLEEP CURRENT (mA)

S

V

1.0

0

VS = 13.2 V

VCC = 0 V to 5.25 V

100806040200−20−40

TJ, TEMPERATURE (°C)

120

Figure 6. VS Sleep Supply Current vs. Temperature

140 160

4.0

3.5

3.0

2.5

2.0

1.5

SLEEP CURRENT (mA)

1.0

CC

V

0.5

0

VS = 5.25 V

100806040200−20−40

TJ, TEMPERATURE (°C)

120

140 160

Figure 7. VCC Sleep Supply Current vs. Temperature

www.onsemi.com

11

Page 12

140

120

100

NCV7703C

TYPICAL CHARACTERISTICS

1 oz Cu

1000

100

R(t) (°C/W)

0.1

10

(°C/W)

JA

q

80

60

40

20

0

2 oz Cu

7006005004003002001000

COPPER HEAT SPREADING AREA (mm2)

800

Figure 8. qJA vs. Copper Spreader Area,

14 Lead SON (fused leads)

Cu Area = 100 mm2 1.0 oz

200 mm2 1.0 oz

300 mm2 1.0 oz

1

400 mm2 1.0 oz

500 mm2 1.0 oz

0.01

140

120

100

R(t) (°C/W)

80

60

40

20

0.00010.00001

TIME (sec)

10001001010.10.010.0010.000001

Figure 9. Transient Thermal Response to a

Single Pulse 1 oz Copper (Log−Log)

Cu Area = 100 mm2 1.0 oz

200 mm2 1.0 oz

300 mm2 1.0 oz

400 mm2 1.0 oz

500 mm2 1.0 oz

0

0.00010.00001

TIME (sec)

10001001010.10.010.0010.000001

Figure 10. Transient Thermal Response to a

Single Pulse 1 oz Copper (Semi−Log)

www.onsemi.com

12

Page 13

NCV7703C

SPI Communication

Standard 16−bit communication has been implemented to

this IC to turn drivers on/off, and to report faults. (See

Figure 12). The LSB (Least Significant Bit) is clocked in

first.

Communication is Implemented as Follows:

1. CSB goes low to allow serial data transfer.

2. A 16 bit word is clocked (SCLK) into the SI

(Serial Input) pin.

3. CSB goes high to transfer the clocked in

information to the data registers.

NOTE: SO is tristate when CSB is high.

Frame detection starts

after the CSB falling edge

and the SCLK rising edge.

CSB

SCLK

SI

nternal Counter

SRR OUTL1 XOUTH1 OUTL2 OUTH2 OUTL3 OUTH3

12345 678

Figure 11. Frame Detection

Frame Detection

Input word integrity (SI) is evaluated by the use of a frame

consistency check. The word frame length is compared to an

h x 16 bit acceptable word length before the data is latched

into the input register. This guarantees the proper word

length has been imported and allows for daisy chain

operation applications.

The frame length detector is enabled with the CSB falling

edge and the SCLK rising edge.

SCLK must be low during the CSB rising edge. The fault

register is cleared with a valid frame detection. Existing

faults are re−latched after the fault filter time.

Frame detection mode ends with

CSB rising edge.

ULDSDXXXX OCDX OVLO

9 1011 12 1314 1516

Valid 16 bits shown

CSB

SI

SCLK

SO

SRR OUTL1 OUTH1 OUTL2 OUTH2 OUTL3 OUTH3 X X X X X X OCD ULDSD OVLO

TW OUTL1 OUTH1 OUTL2 OUTH2 OUTL3 OUTH3 X X X X X STA OCDR ULDR PSF

Figure 12. SPI Communication Frame Format

Table 1 defines the programming bits and diagnostic bits.

Figure 12 displays the timing diagram associated with

Table 1. Fault information is sequentially clocked out the

SO pin of the NCV7703C as programming information is

clocked into the SI pin of the device. Daisy chain

communication between SPI compatible IC’s is possible by

connection of the Serial Output pin (SO) to the input of the

sequential IC (SI) (Reference the Daisy Chain Section).

www.onsemi.com

13

Page 14

NCV7703C

Table 1. SPI BIT DESCRIPTION

Input Data Output Data

Bit Number Bit Description Bit Status Bit Number Bit Description Bit Status

15 Over Voltage Lock Out

Control (OVLO)

14 Under Load Detection Shut

Down Control (ULDSD)

13 Over Current Detection Shut

Down Control (OCD)

12 Not Used 12 Shoot−Through Attempt

11 Not Used 11 Not Used

10 Not Used 10 Not Used

9 Not Used 9 Not Used

8 Not Used 8 Not Used

7 Not Used 7 Not Used

6 OUTH3

5 OUTL3

4 OUTH2

3 OUTL2

2 OUTH1

1 OUTL1

0 Status Register Reset (SRR)

0 = Disable

1 = Enable 1 = Fault

0 = Disable

1 = Enable 1 = Fault

0 = 200 msec

1 = 25 msec

0 = Off

1 = On 1 = On

0 = Off

1 = On 1 = On

0 = Off

1 = On 1 = On

0 = Off

1 = On 1 = On

0 = Off

1 = On 1 = On

0 = Off

1 = On 1 = On

0 = No Reset

1 = Reset 1 = In TW

15 VS Power Supply Fail Signal

(PSF for OVLO or UVLO)

14 Under Load Detection Reporting

Signal (ULDR)

13 Over Current Detection

Reporting Signal (OCDR)

(STA)

6 OUTH3

5 OUTL3

4 OUTH2

3 OUTL2

2 OUTH1

1 OUTL1

0 Thermal Warning (TW)

0 = No Fault

0 = No Fault

0 = No Fault

1 = Fault

0 = No Attempt

1 = Attempt

0 = Off

0 = Off

0 = Off

0 = Off

0 = Off

0 = Off

0 = Not in TW

DETAILED OPERATING DESCRIPTION

General

The NCV7703C Triple Half Bridge Driver provides drive

capability for 3 Half−Bridge configurations. Each output

drive is characterized for a 500 mA load and has a typical

1.4 A surge capability. Strict adherence to integrated circuit

die temperature is necessary, with a maximum die

temperature of 150°C. This may limit the number of drivers

enabled at one time. Output drive control and fault reporting

are handled via the SPI (Serial Peripheral Interface) port.

An Enable function (EN) provides a low quiescent sleep

current mode when the device is not being utilized. A pull

down is provided on the EN, SI and SCLK inputs to ensure

they default to a low state in the event of a severed input

signal. A pull−up is provided on the CSB input disabling SPI

communication in the event of an open CSB input.

www.onsemi.com

Power Up/Down Control

A feature incorporated in the IC is an under voltage

lockout circuit that prevents the output drivers from turning

on unintentionally. V

and VS are monitored for

CC

undervoltage conditions supporting a smooth turn−on

transition. All drivers are initialized in the off (high

impedance) condition, and will remain off during a V

V

undervoltage condition. This allows power up

S

sequencing of V

, and VS up to the user. Once VCC is above

CC

the Power−On−Reset threshold, SPI communication can

begin regardless of the voltage on V

. The VS supply input

S

does not ever affect the SPI logic. However, drivers will

remain off if V

in both V

is in an undervoltage condition. Hysteresis

S

and VS circuits results in glitch free operation

CC

during power up/down.

14

CC

or

Page 15

NCV7703C

Overvoltage Shutdown (Table 2)

Overvoltage lockout circuitry monitors the voltage on the

V

pin. The response to an overvoltage condition is selected

S

by SPI input bit 15. PSF output bit 15 is set when a V

overvoltage condition exists. If input bit 15 (OVLO) is set

Table 2. INPUT BIT 15, OVERVOLTAGE LOCK OUT (OVLO) SHUT DOWN

OVLO Input

Bit 15

0 0 0 Unchanged

0 1 1 (Need SRR to reset) Unchanged

1 0 0 Unchanged

1 1 1 (Need SRR to reset) All Outputs Shut Off (Remain off until VS is out of OVLO)

H−Bridge Driver Configuration

VS OVLO

Condition

Output Data Bit 15 Power

Supply Fail (PSF) Status

The NCV7703C has the flexibility of controlling each half

bridge driver independently. This allows for high side, low

side and H−bridge control. H−bridge control provides

forward, reverse, brake and high impedance states.

Overvoltage Clamping − Driving Inductive Loads

Each output is internally clamped to ground and VS by

internal freewheeling diodes. The diodes have ratings that

complement the FETs they protect. A flyback event from

driving an inductive load causes the voltage on the output to

rise up. Once the voltage rises higher than VS by a diode

voltage (body diode of the high−side driver), the energy in

the inductor will dissipate through the diode to VS. If a

reverse battery diode is used in the system, care must be

taken to insure the power supply capacitor is sufficient to

dampen any increase in voltage to VS caused by the current

flow through the body diode so that it is below 40 V.

Negative transients will momentarily occur when a

to “1”, all outputs will turn off during this overvoltage

condition. Turn On/Off status is maintained in the logic

circuitry, so that when proper input voltage level is

reestablished, the programmed outputs will turn back on.

S

The PSF output bit is reset with SRR = 1.

OUTx Status

Detection shutdown protects the device during current limit

because the Overcurrent threshold is below the Current

Limit threshold. The Overcurrent Detection Shutdown

Control Timer is initiated at the Overcurrent Shutdown

Threshold which starts before the Current Limit is reached.

Note: High currents will cause a rise in die temperature.

Devices will not be allowed to turn on if the die temperature

exceeds the thermal shutdown temperature.

Shoot−Through Attempt

The NCV7703C provides detection for attempting to turn

on common drivers of the same channel (OUTL1&OUTH1,

OUTL2&OUTH2, OUTL3&OUTH3) simultaneously. An

attempt to turn on common drivers if allowed would result

in a high current event from VS to GND. Any attempt to

create this setup is recorded in bit 12 of the output data and

forces the common high−side and low−side driver to an off

state. The STA output bit is reset with SRR = 1. The STA bit

must be cleared before an affected driver can turn on.

high−side driver driving an inductive load is turned off. This

will be clamped by an internal diode from the output pin

(OUT1 or OUT2) to the IC ground.

Overcurrent Shutdown

Effected outputs will turn off when the Overcurrent

Shutdown Threshold has been breached for the Overcurrent

Current Limit

OUTx current is limited per the Current Limit electrical

parameter for each driver. The magnitude of the current has

a minimum specification of 2 A at V

= 5 V and Vs =

CC

13.2 V. The output is protected for high power conditions

during Current Limit by thermal shutdown and the

Overcurrent Detection shutdown function. Overcurrent

Shutdown Delay Time. The respective OCDR status bit will

be set to a “1” and the driver will latch off. The driver can

only be turned back on via the SPI port with a SPI command

that includes an SRR = 1.

Note: High currents will cause a rise in die temperature.

Devices will not be allowed to turn on if the die temperature

exceeds the thermal shutdown temperature.

Table 3. OVERCURRENT DETECTION SHUT DOWN

OCD Input

Bit 13

0 0 0 Unchanged 3 A

0 1 1 (Need SRR to reset)

1 0 0 Unchanged 3 A

1 1 1 (Need SRR to reset)

OUTx OCD

Condition

Output Data Bit 13 Over

Current Detect (OCDR) Status

www.onsemi.com

OUTx Status

OUTx Latches off after 200 ms

(Need SRR to reset)

OUTx Latches Off After 25 ms

(Need SRR to reset)

15

Current Limit

of all Drivers

3 A

3 A

Page 16

NCV7703C

Overcurrent Detection Shut Down Control Timer

There are two protection mechanisms for output current,

overcurrent and current limit.

1. Current limit − Always active with a typical

threshold of 3 A (typ).

2. Overcurrent Detection − Selectable shutdown time

via Bit 13 with a 1.45 A (typ) threshold.

Figure 13 shows the typical performance of a part which

has exceeded the 1.45 A (typ) Overcurrent Detection

threshold and started the shutdown control timer. When Bit

13 = 1, the shutdown time is 25 msec (typ). When Bit 13 =

0, the shutdown time is 200 msec (typ).

(Current Limit) 3 A

(Overcurrent

Detection)

(Current Limit) 3 A

(Overcurrent

Detection)

1.45 A

OUTx Current

Bit13 = 1

1.45 A

OUTx Current

Bit13 = 0

25 msec (typ)

Once an Overcurrent Shutdown Delay Time event has

been detected by the NCV7703C, the timer setting cannot be

interrupted by an attempted change via a SPI command of

Bit 13.

Table 4.

Input Bit 13 Overcurrent Shutdown Delay Time

0

1

200 msec (typ)

25 msec (typ)

200 msec (typ)

Figure 13. Output Current Shutdown Control

UnderLoad Detection (Table 5)

The underload detection circuit monitors the current from

each output driver. A minimum load current (this is the

maximum open circuit detection threshold) is required when

the drivers are turned on. If the under−load detection

threshold has been detected continuously for more than the

under−load delay time, the ULDR bit (output bit #14) will

be set to a “1”. In addition, the offending driver will be

latched off if input Bit 14 (ULDSD) is set to 1 (true).

The NCV7703C uses a global under load timer. An under

under load occurs in another channel after the global timer

has been started, the delay for any subsequent under load

will be the remainder of the initially started timer. The timer

runs continuously with any persistent under load condition

and will impact multi−underload situations. The under load

detect bit is reset by setting input data bit 0, SRR = 1. Figures

14 and 15 highlight the timing conditions for an underload

state where the global timer is reset (discontinuous time) and

the conditions where the global timer is not reset

(continuous time).

load condition starts the global under load delay timer. If

Table 5. OUTPUT BIT 14, UNDER LOAD DETECTION SHUT DOWN

ULDSD Input

Bit 14

0 0 0 Unchanged

0 1 1 (Need SRR to reset) Unchanged

1 0 0 Unchanged

1 1 1 (Need SRR to reset) OUTx Latches Off (Need SRR to reset)

OUTx ULD

Condition

Output Data Bit 14, Under

Load Detect (ULDR) Status

OUTx Status

www.onsemi.com

16

Page 17

load[mA]

NCV7703C

load[mA]

OUTx

OUTx

Global Timer

<350[us](typ)

resets

here

OUTy

Bit 14 − Underload Detection Reporting Signal (ULDR) is set

>350[us](typ)

Figure 14. Underload Discontinuous Time

If the 1stunderload condition is <350 us,

the global timer resets and starts again

with the 2ndunderload condition.

7[mA](typ)

Underload Detection Threshold

OUTy

Time

7[mA](typ)

Underload Detection Threshold

Bit 14 − Underload Detection Reporting Signal (ULDR) is set

350[us](typ)

Figure 15. Underload Continuous Time

After a total continuous period is more than 350[us] (typ)

(underload detection time), Bit 14 in the output register is set

Time

www.onsemi.com

17

Page 18

NCV7703C

Thermal Shutdown

Three independent thermal shutdown circuits are featured

(one common sensor for each HS and LS transistor pair).

Each sensor has two temperature levels; Level 1, Thermal

Warning sets the “TW” status bit to a 1 and would have to

be reset with a command that includes the SRR after the IC

cools to a temperature below Level 1. The output will remain

on in this condition.

If the IC temperature reaches Level 2, Over Temperature

Shutdown, all drivers are latched off. It can be reset only

after the part cools below the shutdown temperature,

(including thermal hysteresis) with a turn−on command that

includes the SRR set bit.

The output data bit 0, Thermal Warning, will latch and

remain set, even after cooling, and is reset by sending a SPI

command to reset the status register (SRR, input 0 set to

“1”). Since thermal warning precedes a thermal shutdown,

software polling of this bit will allow for load control and

possible prevention of thermal shutdown conditions.

Thermal warning information can be retrieved

immediately without performing a complete SPI access

cycle. Figure 16 below displays how this is accomplished.

Bringing the CSB pin from high to low with SI = 0

immediately displays the information on Output Data Bit 0,

thermal warning. As the temperature of the NCV7703C

changes from a condition from below the thermal warning

threshold to above the thermal warning threshold, the state

of the SO pin changes and this level is available immediately

when the CSB goes low. A low on SO indicates there is no

thermal warning, while a high indicates the IC is above the

thermal warning threshold. This warning bit is reset by

setting SRR to “1”.

CSB

SCLK*

SO

Tristate Level

*SCLK can be high or low in order to maintain the thermal information on SO. Toggling SCLK will cause other output bits to shift out.

TWH = Thermal Warning High

NTW = No Thermal Warning

Figure 16. Access to Temperature Warning Information

TWH

CSB

SCLK*

Tristate Level

SO

NTW

No Thermal WarningThermal Warning High

Applications Drawing

Daisy Chain

The NCV7703C is capable of being setup in a daisy chain

configuration with other similar devices which include

additional NCV7703C devices as well as the NCV7708

Double Hex Driver. Particular attention should be focused

on the fact that the first 16 bits which are clocked out of the

will be the Diagnostic Output Data. These are the bits

representing the status of the IC and are detailed in the SPI

Bit Description Table. Additional programming bits should

be clocked in which follow the Diagnostic Output bits. Word

length must be h x 16 due to the use of frame detection.

SO pin when the CSB pin transitions from a high to a low

www.onsemi.com

18

Page 19

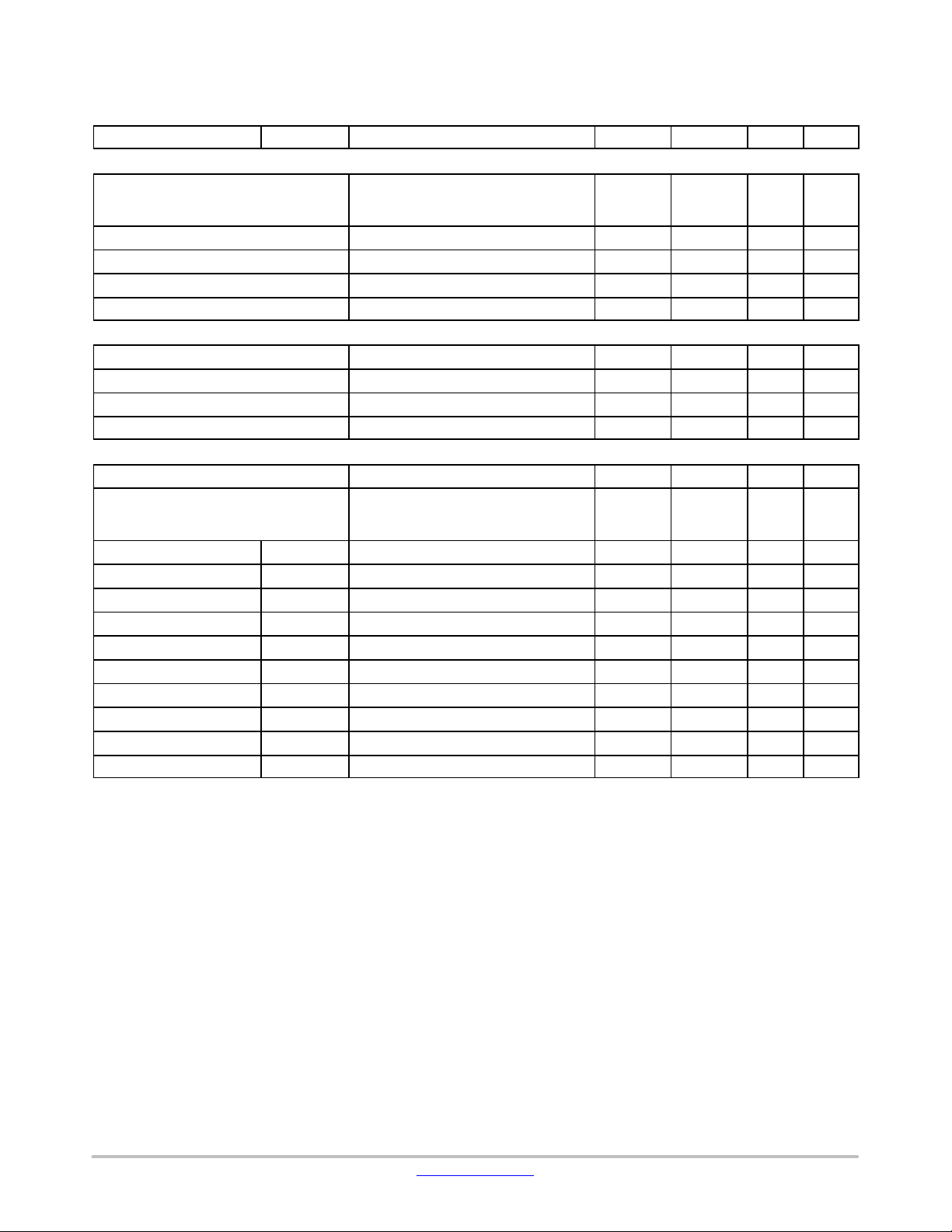

NCV7703C

CSB SCLK

NCV7703C

microprocessor

SI SO

CSB SCLK

NCV7703C

SI SO

Figure 17. Daisy Chain Operation

Parallel Control

A more efficient way to control multiple SPI compatible

devices is to connect them in a parallel fashion and allow

each device to be controlled in a multiplex mode. The

diagram below shows a typical connection between the

microprocessor or microcontroller and multiple SPI

compatible devices. In a daisy chain configuration, the

programming information for the last device in the serial

string must first pass through all the previous devices. The

parallel control setup eliminates that requirement, but at the

cost of additional control pins from the microprocessor for

each individual CSB pin for each controllable device. Serial

data is only recognized by the device that is activated

through its respective CSB pin.

CSB SCLK

NCV7708C

SI SO

CSB SCLK

NCV7708C

SI SO

V

S

OUTx

NCV7703C

SI

SCLK

SO

CSB

chip1

CSB

microprocessor

chip2

CSB

chip3

Figure 18. Parallel Control

SI

SCLK

CSB

OUT1

SO

OUT2

OUT3

NCV7703C

SI

SCLK

CSB

OUT1

SO

OUT2

OUT3

NCV7703C

SI

SCLK

CSB

OUT1

SO

OUT2

OUT3

Additional Application Setup

In addition to the cascaded H−Bridge application shown

in Figure 1, the NCV7703C can also be used as a high−side

driver or low−side driver (Figure 19).

OUTx

GND

Figure 19. High−Side / Low−Side Application Drawing

Any combination of H−bridge and high or low−side

drivers can be designed in. This allows for flexibility in

many systems.

www.onsemi.com

19

Page 20

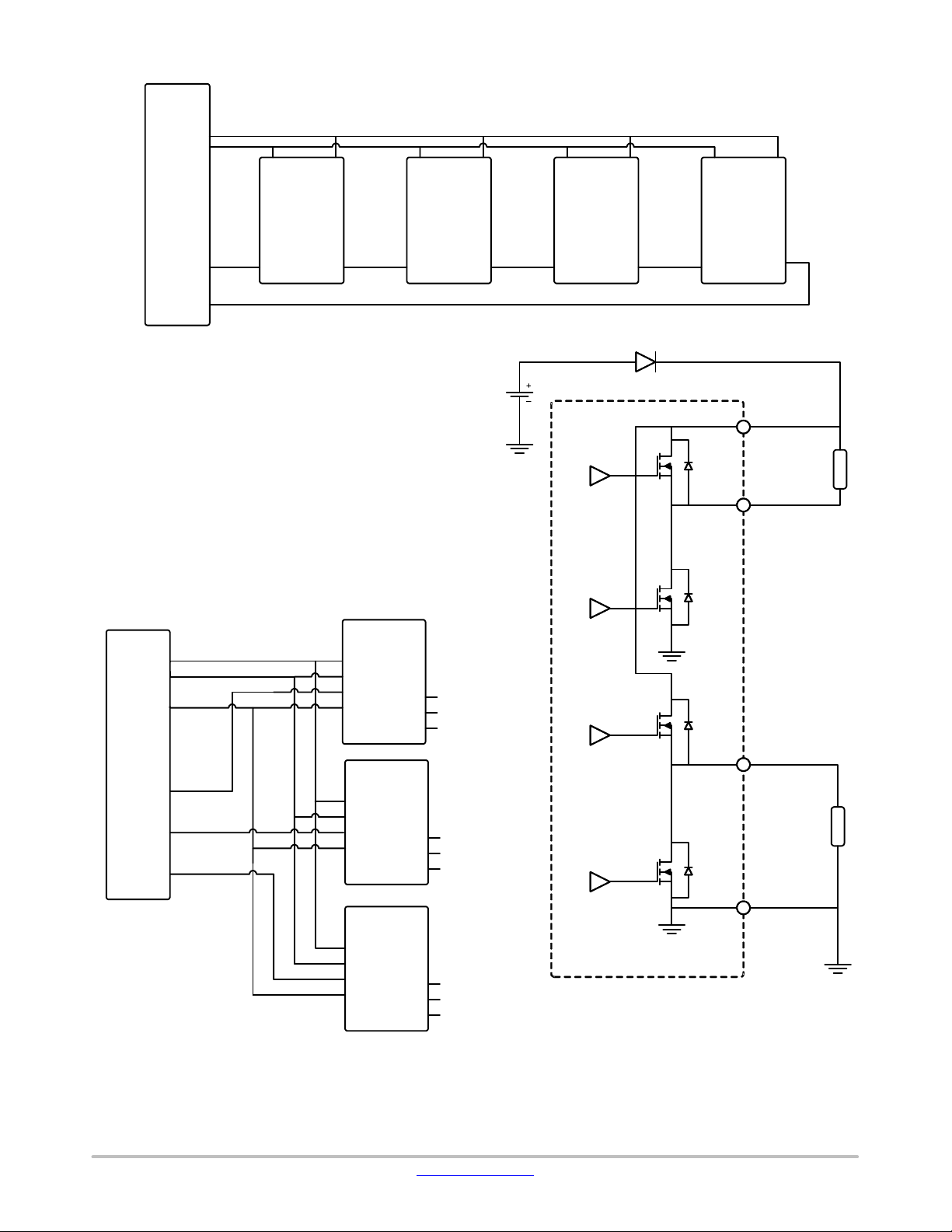

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

14

1

SCALE 1:1

SOIC−14 NB

CASE 751A−03

ISSUE L

DATE 03 FEB 2016

14

H

M

0.25 B

0.10

14X

0.58

D

M

13X

e

SOLDERING FOOTPRINT*

6.50

1

A

B

8

E

71

b

S

M

0.25 B

A

C

A

A1

SEATING

C

PLANE

14X

1.18

S

1.27

PITCH

DETAIL A

h

X 45

_

M

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b DOES NOT INCLUDE DAMBAR

A3

L

DETAIL A

PROTRUSION. ALLOWABLE PROTRUSION

SHALL BE 0.13 TOTAL IN EXCESS OF AT

MAXIMUM MATERIAL CONDITION.

4. DIMENSIONS D AND E DO NOT INCLUDE

MOLD PROTRUSIONS.

5. MAXIMUM MOLD PROTRUSION 0.15 PER

SIDE.

DIM MIN MAX MIN MAX

A 1.35 1.75 0.054 0.068

A1 0.10 0.25 0.004 0.010

A3 0.19 0.25 0.008 0.010

b 0.35 0.49 0.014 0.019

D 8.55 8.75 0.337 0.344

E 3.80 4.00 0.150 0.157

e 1.27 BSC 0.050 BSC

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.019

L 0.40 1.25 0.016 0.049

M 0 7 0 7

__ __

INCHESMILLIMETERS

GENERIC

MARKING DIAGRAM*

14

XXXXXXXXXG

AWLYWW

1

XXXXX = Specific Device Code

A = Assembly Location

WL = Wafer Lot

Y = Year

WW = Work Week

G = Pb−Free Package

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

STYLES ON PAGE 2

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB42565B

SOIC−14 NB

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 2

www.onsemi.com

Page 21

SOIC−14

CASE 751A−03

ISSUE L

DATE 03 FEB 2016

STYLE 1:

PIN 1. COMMON CATHODE

2. ANODE/CATHODE

3. ANODE/CATHODE

4. NO CONNECTION

5. ANODE/CATHODE

6. NO CONNECTION

7. ANODE/CATHODE

8. ANODE/CATHODE

9. ANODE/CATHODE

10. NO CONNECTION

11. ANODE/CATHODE

12. ANODE/CATHODE

13. NO CONNECTION

14. COMMON ANODE

STYLE 5:

PIN 1. COMMON CATHODE

2. ANODE/CATHODE

3. ANODE/CATHODE

4. ANODE/CATHODE

5. ANODE/CATHODE

6. NO CONNECTION

7. COMMON ANODE

8. COMMON CATHODE

9. ANODE/CATHODE

10. ANODE/CATHODE

11. ANODE/CATHODE

12. ANODE/CATHODE

13. NO CONNECTION

14. COMMON ANODE

STYLE 2:

CANCELLED

STYLE 6:

PIN 1. CATHODE

2. CATHODE

3. CATHODE

4. CATHODE

5. CATHODE

6. CATHODE

7. CATHODE

8. ANODE

9. ANODE

10. ANODE

11. ANODE

12. ANODE

13. ANODE

14. ANODE

STYLE 3:

PIN 1. NO CONNECTION

2. ANODE

3. ANODE

4. NO CONNECTION

5. ANODE

6. NO CONNECTION

7. ANODE

8. ANODE

9. ANODE

10. NO CONNECTION

11. ANODE

12. ANODE

13. NO CONNECTION

14. COMMON CATHODE

STYLE 7:

PIN 1. ANODE/CATHODE

2. COMMON ANODE

3. COMMON CATHODE

4. ANODE/CATHODE

5. ANODE/CATHODE

6. ANODE/CATHODE

7. ANODE/CATHODE

8. ANODE/CATHODE

9. ANODE/CATHODE

10. ANODE/CATHODE

11. COMMON CATHODE

12. COMMON ANODE

13. ANODE/CATHODE

14. ANODE/CATHODE

STYLE 4:

PIN 1. NO CONNECTION

2. CATHODE

3. CATHODE

4. NO CONNECTION

5. CATHODE

6. NO CONNECTION

7. CATHODE

8. CATHODE

9. CATHODE

10. NO CONNECTION

11. CATHODE

12. CATHODE

13. NO CONNECTION

14. COMMON ANODE

STYLE 8:

PIN 1. COMMON CATHODE

2. ANODE/CATHODE

3. ANODE/CATHODE

4. NO CONNECTION

5. ANODE/CATHODE

6. ANODE/CATHODE

7. COMMON ANODE

8. COMMON ANODE

9. ANODE/CATHODE

10. ANODE/CATHODE

11. NO CONNECTION

12. ANODE/CATHODE

13. ANODE/CATHODE

14. COMMON CATHODE

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB42565B

SOIC−14 NB

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 2 OF 2

www.onsemi.com

Page 22

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...