Page 1

12 Channels 60 mA LED

Linear Current Driver I

2

C

Controllable for Automotive

Applications

NCV7685

The NCV7685 consists of twelve linear programmable constant

current sources with common reference. The part is designed for use in

the regulation and control of LED for automotive applications. The

NCV7685 allows 128 different duty cycle levels adjustable using

pulse width modulation (PWM) independently for each output

channel programmable via I

be chosen in four different configurations up to 1200 Hz. The device

can be used with micro−controller applications using the I

stand−alone applications where a choice could be done in between 2

different static configuration settings. The IC also provides 3.3 V

voltage reference to the application for loads up to 1 mA.

LED brightness level is easily programmed using an external

resistor. Each channel has an internal circuitry to detect open−load

conditions with an optional auto−recovery mode. If one driver is in

open−load condition, all other channels could be turned off according

to the programmable bit setting.

The device is available in small body size SSOP24−EP package.

Features

• 12 Common Current Programmable Sources up to 60 mA

• Independent PWM Duty Cycle Control for each Channel via PC

• Common PWM Duty Cycle Control via I

• On−Chip 150, 300, 600 and 1200 Hz PWM

• Open LED String Diagnostics

• Low Dropout Operation for Pre−Regulator Applications

• Single Resistor for Current Set Point

• Voltage Reference 3.3 V/1 mA

• 8 Bits I

2

C Interface with CRC8 Error Detection

• OTP Bank for Stand−Alone Operation (2 Configurations)

• Output Enable Pin

• Detection and Protection Against Open Load and Under−Voltage

• Over Temperature Detection and Protection

• Low Emission with Spread Spectrum Oscillator

• NCV Prefix for Automotive and Other Applications Requiring

Unique Site and Control Change Requirements; AEC−Q100

Qualified and PPAP Capable

• SSOP24−EP Packaging

2

C serial interface. PWM frequency can

2

C bus or in

2

C

www.onsemi.com

SSOP24−NB EP

CASE 940AQ

MARKING DIAGRAM

NCV7685

AWLYYWW

G

NCV7685 = Specific Device Code

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

ORDERING INFORMATION

Device Package Shipping†

NCV7685DQR2G SSOP24−EP

(Pb−Free)

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specification

Brochure, BRD8011/D.

2500/

Tape & Reel

Applications

• Dashboard Applications

• Rear Combination Lamps (RCL)

• Daytime Running Lights (DRL)

• Fog Lights

• Center High Mounted Stop Lamps (CHMSL) Arrays

• Turn Signal and Other Externally Modulated Applications

© Semiconductor Components Industries, LLC, 2017

October, 2020 − Rev. 2

1 Publication Order Number:

NCV7685/D

Page 2

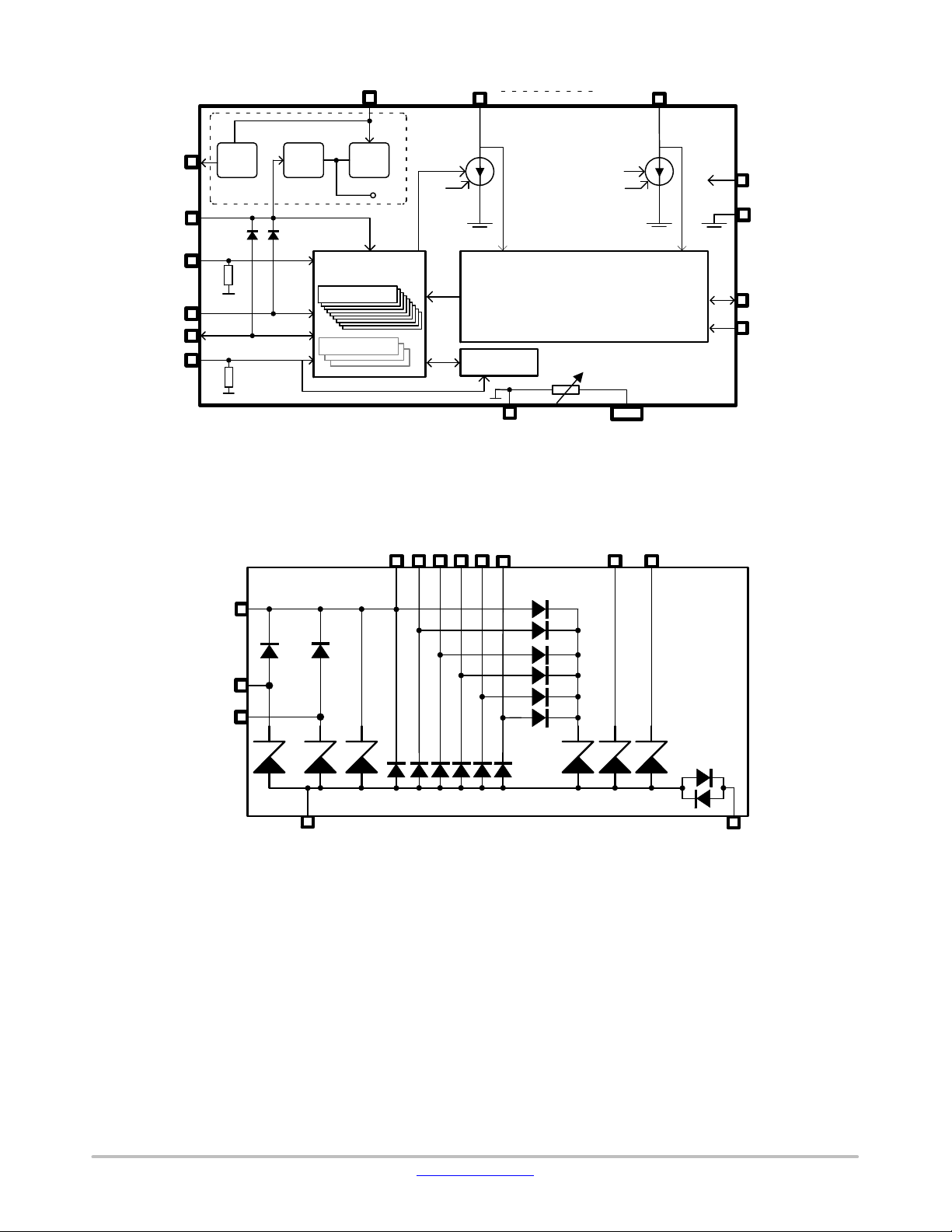

NCV7685

VCC

VDD

OEN

SCL

SDA

CONF

3V3

REG

Life Support

Vint.

REG

VS

Vint.

REG

Vint.

Registers

PWM Registers

OUT1

ctrl

Iset

60 mA

I2C

Diagnostic control

OTP

GND

Figure 1. Block Diagram

EXPOSED PAD

OUT12

ctrl

Iset

NCV7685

Iset

60mA

Iset

GNDP

DIAG

DIAGEN

VDD

SCL

SDA

GND

VS

OUTx

OEN

DIAG

DIAGEN

CONF

Figure 2. ESD Schematic

VCC

ISET

GNDP

www.onsemi.com

2

Page 3

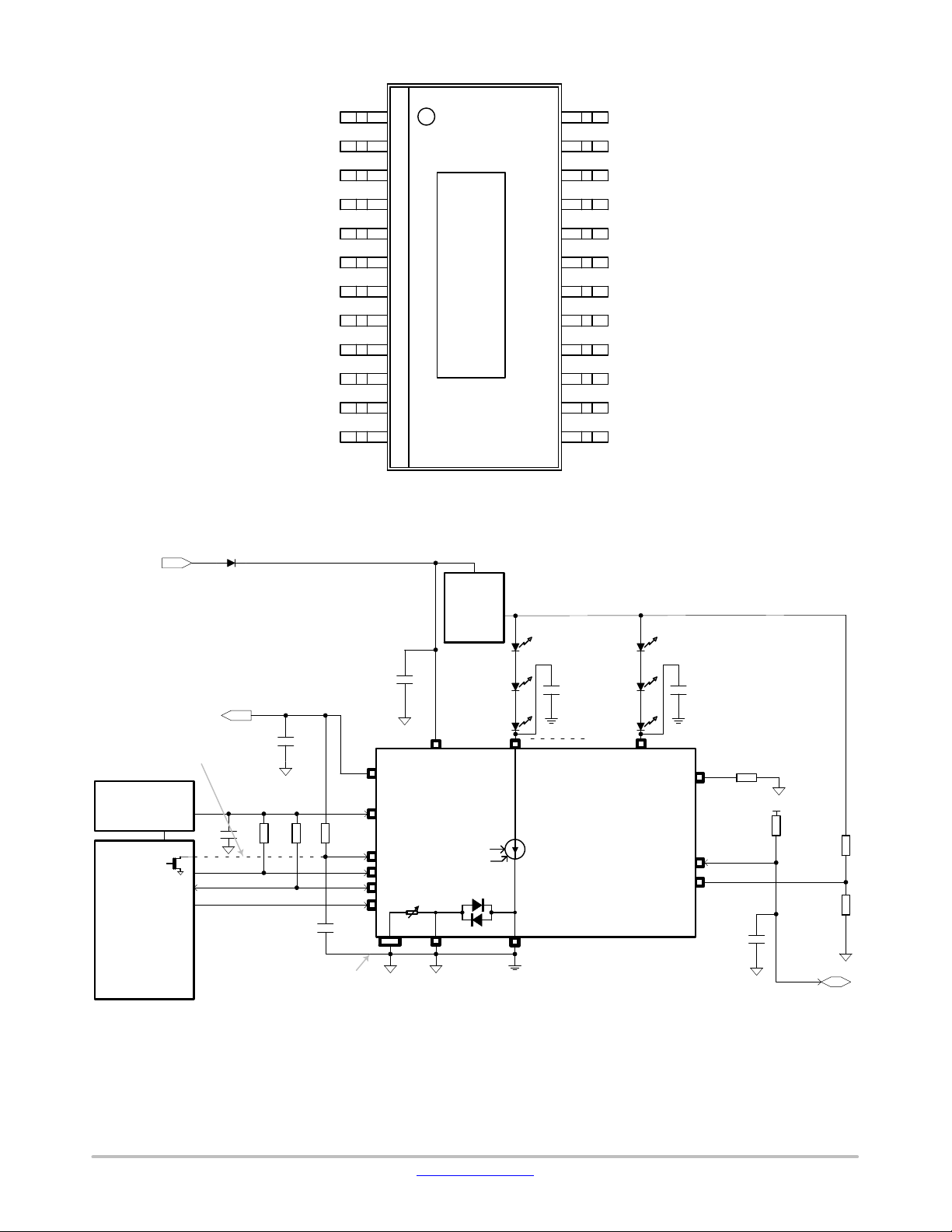

NCV7685

Vsupply

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT8

OUT9

OUT10

OUT11

OUT12

AWLYYWW

NCV7685

G

Figure 3. Pinout Diagram

VDD

SCL

SDA

OEN

DIAG

GNDP

DIAGEN

VS

V

CC

CONF

ISET

GND

MRA4003T3G

e.g. sensor

Optional connection if MCU

control of OEN input is required.

3.3V/5V

LDO

Open Drain

GPIO structure

2

I

C {

Micro−

controller

100nF

4.7K

CVDD

R5

This GND−track is exclusively

for COEN connection. (to avoid

common impedance coupling from

other GND−currents)

Figure 4. Application Diagram with Micro−controller (I2C Mode)

R6

4.7K

C2

1nF

R7

10K

COEN

10nF

VCC

VDD

OEN

SCL

SDA

CONF

EXPOSED

100 nF

PAD

C1

VS

LDO

or

DC/DC

OUT1

GND

ctrl

Iset

60 mA

GNDP

C

OUT1

(optional)

1nF

OUT12

V

STRING

ctrl

Iset

60mA

NCV7685

C

OUT12

(optional)

1nF

Iset

Iset

DIAG

DIAGEN

(optional)

C

R1

2.2K

DIAG

1nF

R4

10K

VCC

R2

10K

R3

2.2K

www.onsemi.com

3

Page 4

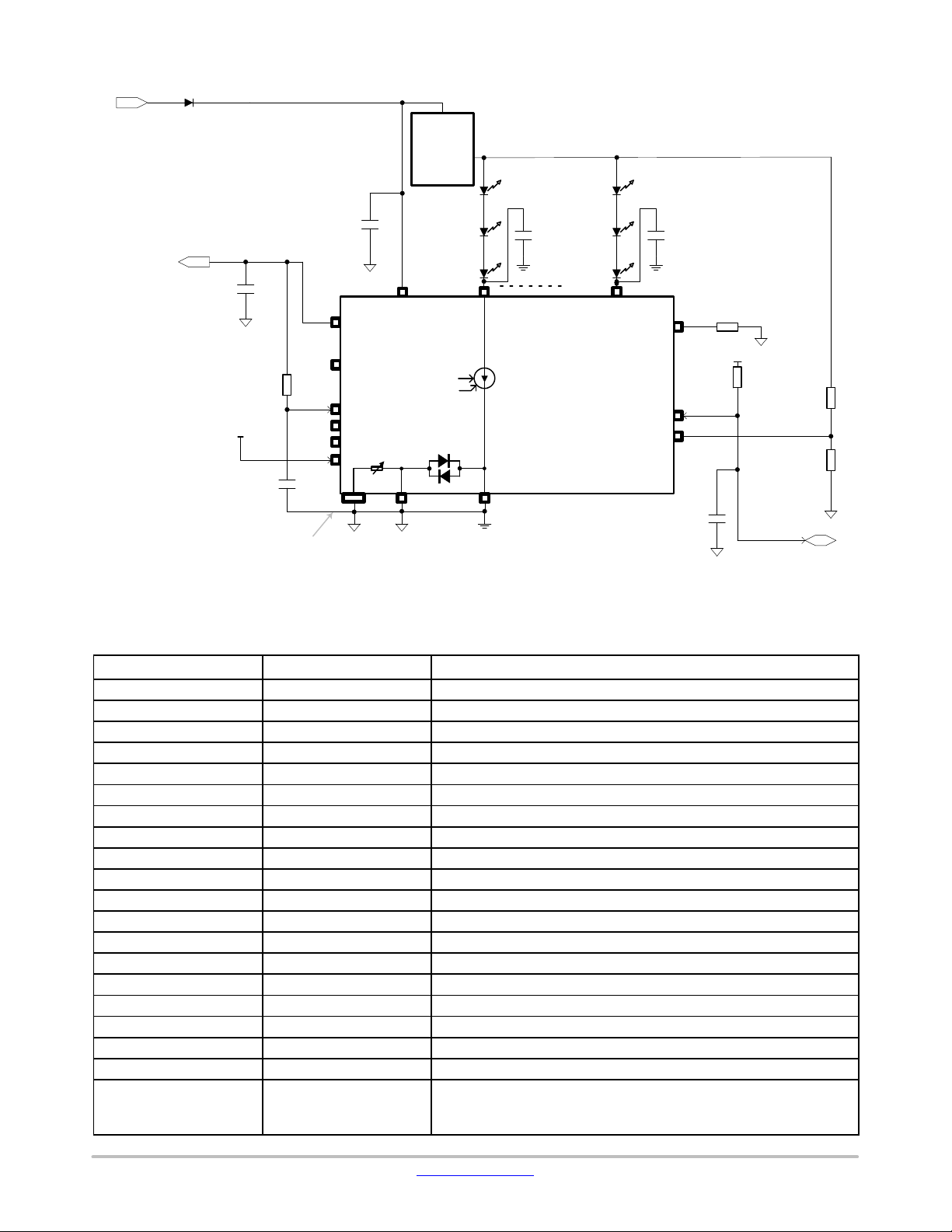

Vsupply

MRA4003T3G

NCV7685

LDO

or

DC/DC

V

STRING

C1

100nF

e.g. sensor

C2

1nF

VCC

VDD

R7

10 K

VS

C

10 nF

This GND−track is exclusively for

COEN connection. (to avoid

common impedance coupling from

other GND−currents)

Figure 5. Application Diagram without Micro−controller (Stand Alone Mode)

Table 1. PIN FUNCTION DESCRIPTION

Pin #

1 OUT1 Channel 1 Current Output to LED

2 OUT2 Channel 2 Current Output to LED

3 OUT3 Channel 3 Current Output to LED

4 OUT4 Channel 4 Current Output to LED

5 OUT5 Channel 5 Current Output to LED

6 OUT6 Channel 6 Current Output to LED

7 OUT7 Channel 7 Current Output to LED

8 OUT8 Channel 8 Current Output to LED

9 OUT9 Channel 9 Current Output to LED

10 OUT10 Channel 10 Current Output to LED

11 OUT11 Channel 11 Current Output to LED

12 OUT12 Channel 12 Current Output to LED

13 GND Signal Ground

14 ISET Current Setting/EoL Enable Pin

15 CONF Stand Alone Mode Selection Bank

16 VCC 3.3 V Voltage Reference Output (Needs External Decoupling Capacitor)

17 VS Supply Voltage Input

18 DIAGEN Diagnostic Voltage Sensing Node for V

19 GNDP Power Ground for output drivers

20 DIAG Open−drain diagnostic input/output.

OEN

OEN

SCL

SDA

CONF

EXPOSED

PAD

Label Description

VS

OUT1

ctrl

Iset

60 m A

C

OUT1

(optional)

1n F

OUT12

ctrl

Iset

60mA

C

OUT12

(optional)

1nF

Iset

Iset

DIAG

R1

2.2K

R4

10K

Vsupply

R2

10K

DIAGEN

R3

2.2K

NCV7685

GND GNDP

Reporting Open Circuit and thermal shutdown.

Normal Operation = HIGH

C

DIAG

(optional)

1 nF

Via Resistor Divider

STRING

www.onsemi.com

4

Page 5

NCV7685

Table 1. PIN FUNCTION DESCRIPTION (continued)

Pin # DescriptionLabel

21 OEN Output Enable Input

22 SDA I2C Serial Data

23 SCL I2C Serial Clock

24 VDD Digital Supply Voltage Input

epad epad True Ground

Do NOT Connect to PCB Traces other than GND

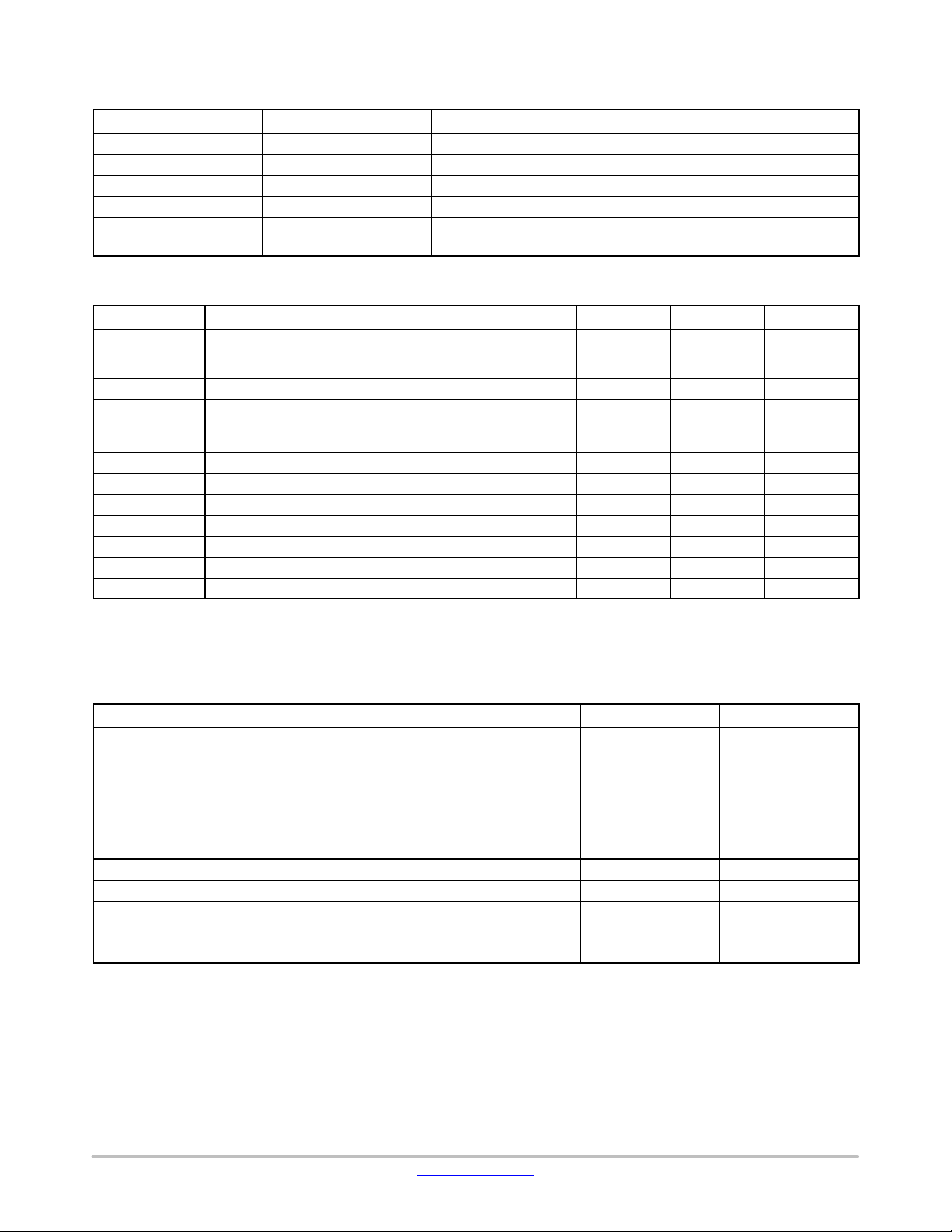

Table 2. ABSOLUTE MAXIMUM RATINGS

Symbol

V

_VS Power supply voltage:

MAX

Continuous supply voltage

Transient Voltage (t < 500 ms, “load dump”)

V

_INx Input pin voltage (DIAGEN, DIAG, CONF, OEN) −0.3 40 V

MAX

V

_OUTx Continuous Output Pin voltage

MAX

Transient Voltage (t < 500 ms, “load dump”) or during PWM

period = OFF

V

_VCC Stabilized supply voltage −0.3 3.6 V

MAX

V

_VDD Digital input supply voltage −0.3 5.5 V

MAX

V

_IO DC voltage at pins (VDD, SCL, SDA) −0.3 5.5 V

MAX

V

_ISET DC voltage at pin ISET −0.3 3.6 V

MAX

I

_GNDP Maximum Ground Current − 750 mA

MAX

T

JMAX

T

A_zap

Junction Temperature, T

OTP Zap Ambient Temperature 10 30 °C

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. Integrated protection functions are designed to prevent IC destruction under fault conditions described in the datasheet. Fault conditions are

considered as outside normal operating range. Protection functions are not designed for continuous repetitive operation.

Parameter Min Max Unit

−0.3

−0.3

−0.3

−0.3

J

−40 150 °C

28

40

28

40

V

V

V

V

Table 3. ATTRIBUTES

Parameter

ESD Capability (Note 2)

ESD Voltage, HBM (Human Body Model); (100 pF, 1500 W)

− All pins

− Output pins OUTx to GND

ESD according to CDM (Charge Device Model)

− All pins

− Comer pins

ESD according to MM (Machine Mode)

− All pins

Moisture sensitivity (SSOP24−EP) (Note 3) MSL2

Storage Temperature −55 to 150 °C

Package Thermal Resistance (SSOP24−EP) (Note 4)

− Junction to Ambient, R

− Junction to Board, R

− Junction to Case (Top), R

q

JA

q

JB

q

JC

2. This device series incorporates ESD protection and is tested by the following methods:

ESD HBM tested per AEC−Q100−002 (EIA/JESD22−A114)

ESD CDM tested per EIA/JES D22/C101, Field Induced Charge Model

ESD MM according to AEC−Q100

3. For additional information, see or download ON Semiconductor’s Soldering and Mounting Techniques Reference Manual, SOLDERRM/D,

and Application Note AND8003/D.

4. Values represent thermal resistances under natural convection are obtained in a simulation on a JEDEC−standard, 2S2P; High Effective

Thermal Conductivity Test Board as specified in JESD51−7, in an environment described in JESD51−2a.

Value Unit

±2

±4

±500

±750

±150

45.8

8.8

10.1

kV

kV

V

V

V

°C/W

°C/W

°C/W

www.onsemi.com

5

Page 6

NCV7685

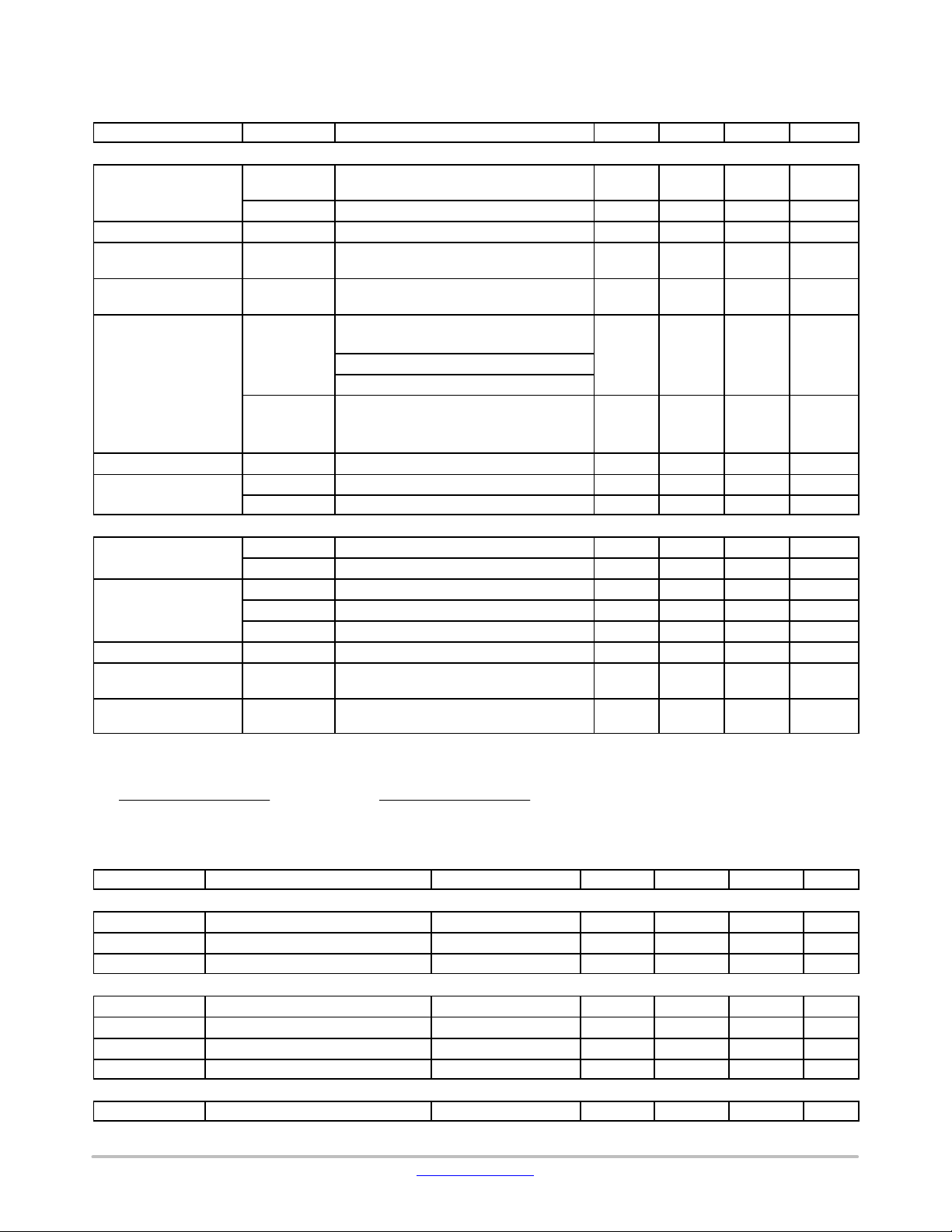

Table 4. ELECTRICAL CHARACTERISTICS

(5 V < VS < 18 V, 3.15 V < VDD < 5.5 V, R1 = 1.82 kΩ, −40°C ≤ T

Characteristic Symbol Test Conditions Min Typ Max Unit

GENERAL

Supply Voltage

Supply Under−Voltage VSUV VS rising 3.8 4.1 4.4 V

Supply range during

OTP zapping

Supply Under−Voltage

hysteresis

Supply Current (Vs) Is(error mode) all OUTx OFF except channel in open load

Digital supply current IDD I2C mode, VS = 12 V − 0.24 2 mA

VDD Under Voltage

detection

CURRENT SOURCE OUTPUTS

Output current

Current Matching from

channel to channel

Current Slew Rate ISRx 10% to 90% − 30 −

Open Circuit Detection

Threshold

Open load recovery in

auto−recovery mode

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

5. Matching formulas:

ƪ

2IOUTx(min)

IOUTx(min) ) IOUTx(max)

VS_EXT Functional extended range (limited temper-

VS_OP Parametric operation 5 − 18 V

VS_OTPzap 2.5 V ≤ ISET ≤ 3.3 V;

VSUVhys − 200 − mV

Is(active) Active Mode

VDDUV_R VDD rising − − 2.9 V

VDDUV_F VDD falling 2 − − V

IOUThot OUTx = 1 V, Tj = 150°C 50 55 60 mA

IOUTcold OUTx = 0.5 V, Tj = −40°C 50 55 60 mA

ImatchCold Tj = −40°C (Note 5) −7 0 7 %

Imatch Tj = 25°C (Note 5) −6 0 6 %

ImatchHot Tj = 150°C (Note 5) −5 0 5 %

OLDT IOUTx > 20mA 30 50 70 % of output

OLR 5 10 15 mA

* 1ƫ 100 and

ature)

VS current peak capability ≥ 70 mA

SCL = SDA = 0

Iout_VCC = 0 mA

Iout_VCC = 1 mA

VS = 16 V, Vcc unloaded

OUTx = 1 V, R1 = 2 kW

ƪ

IOUTx(min) ) IOUTx(max)

≤ 150°C, unless otherwise specified)

J

2IOUTx(max)

* 1ƫ 100

5 − 28 V

13 − 18 V

−

−

− 7 10 mA

1.2

2.2

1.5

2.5

mA

mA

mA/ms

current

Table 5. ELECTRICAL CHARACTERISTICS

(5 V < VS < 18 V, 3.15 V < V

Symbol

VOLTAGE REFERENCE

V_VCC Output Voltage Tolerance I_VCC ≤ 1 mA 3.20 3.30 3.45 V

Iout_VCC Output Current − − −1 mA

Cload_VCC Load Capacitor

INPUTS: OEN, CONF

VinL

VinH Input High Level − 1.25 1.66 V

Vin_hyst Input Hysteresis 100 250 400 mV

Rin_pd Input Pull−down Resistor 120 200 280

INPUTS: SCL, SDA

VinL Input Low Level − − 0.3×VDD V

Input Low Level 0.7 1.0 − V

< 5.5 V, R1 = 1.82 kΩ, −40°C ≤ TJ ≤ 150°C, unless otherwise specified)

DD

Parameter Test Conditions Min Typ Max Unit

ESR < 200 mW

0.9 1.0 2.5 nF

www.onsemi.com

6

kW

Page 7

NCV7685

Table 5. ELECTRICAL CHARACTERISTICS (continued)

(5 V < VS < 18 V, 3.15 V < V

Symbol UnitMaxTypMinTest ConditionsParameter

INPUTS: SCL, SDA

VinH

Vin_hyst Input Hysteresis 0.05×VDD − − V

Iout_SDA Output Current V (SDA) = 0.4 V 3 − − mA

DIAGEN PIN

VDiagenTH VS Diagnostic Enable Threshold 1.9 2.0 2.1 V

Rdiagen_pd Input Pull−down Resistor 120 200 280

DIAG PIN

VoutL Output Low Level Diagnostic Activated,

DiagRes Diagnostic Reset Voltage 1.65 1.80 1.95 V

tp_DIAG Filter Time to Set the DIAG Fail Pin in

DIAG_leak DIAG Output Leakage VDIAG = 5 V − − 10

ISET INPUT PIN

VISET Global Current Setting 0.94 1.0 1.06 V

K IOUT ISET Factor − 100 − −

tsetupISET Setup−up Time to 90% of the ISET

INTERNAL PWM CONTROL UNIT (OUT1− OUT12)

Symbol Parameter Test Conditions Min Ty p Max Unit

PWM1 PWM1 Frequency, I2C Mode Configuration Via I2C 132 150 168 Hz

PWM2 PWM2 Frequency, I2C Mode Configuration Via I2C 264 300 336 Hz

PWM3 PWM3 Frequency, I2C Mode Configuration Via I2C 528 600 672 Hz

PWM4 PWM4 Frequency, I2C Mode Configuration Via I2C 1056 1200 1344 Hz

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

Input High Level 0.7×VDD − − V

Failure Mode

Regulated Value

< 5.5 V, R1 = 1.82 kΩ, −40°C ≤ TJ ≤ 150°C, unless otherwise specified)

DD

Idiag = 1 mA

Idiag = 1 mA − 10 20

VS > 5 V − − 50

− 0.2 0.4 V

kW

ms

mA

ms

Table 6. THERMAL WARNING AND THERMAL SHUTDOWN PROTECTION

Symbol

Tjwar_on Thermal Warning Threshold (Junction Temperature) − TSD−30 − °C

TSD Thermal Shutdown Threshold (Junction Temperature)

Tjsd_hys Thermal Shutdown Hysteresis 10 − 15 °C

T

Increasing

J

General

The NCV7685 is a twelve channel LED driver. Each

output can drive currents up to 60 mA/channel and are

programmable via an external resistor. The target

applications for the device are in automotive rear lighting

systems and dashboard applications. The device can be used

with micro−controller applications using the I

stand−alone applications. In both cases it is mandatory to

supply the LED channels by an external ballast transistor, or

by an LDO or a DC/DC to have low voltage drop on the

outputs which will lead to a decrease in power dissipation in

the device. In order to have very low electromagnetic

emission, this device has an embedded spread spectrum

oscillator.

Parameter Min Typ Max Unit

160 − 180 °C

Output Current Programming (I

SET/IOUTx

The maximum current can be defined with the Iset input

pin. The equations below can be used to calculate this

maximum output current:

Iset + 1VńR1

2

C bus or in

IOUTx + K Iset

Example:

R1 = 2 kΩ

using eq. 1 → Iset = 500 μA

and using eq. 2 → IOUTx = 50 mA

To avoid potential disturbances when all drivers are

activated at the same time, a typical activation delay of

400 ns between groups of 2 consecutive outputs is

implemented (see Figure 6).

)

(eq. 1)

(eq. 2)

www.onsemi.com

7

Page 8

NCV7685

PWM period counter

PWM signal

driver 1

driver 2

driver 3

driver 4

driver 5

driver 6

driver 7

driver 8

driver 9

driver 10

driver 11

driver 12

Power Supply and Voltage Reference (VS, VCC, VDD)

0123456789101112131415161718192021222324252627

Figure 6.

VS is the analog power supply input of the device. VS

supply is monitored with respect to the crossing of VSUV

level (typ. 4.1 V). When VS rises above VSUV, the device

starts the power−up state. When VS is above the VS_OP

minimum level (typ. 5 V), the device can work properly.

VCC is a voltage reference providing 3.3 V derived from

the VS main supply. It is able to deliver up to 1 mA and is

primarily intended to supply 3.3 V loads. If VCC output

reference is not used, then the VCC capacitor can be omitted.

VDD is the digital power supply input of the device.

5V

VS

Activation of the VDD can be

VDD

before or after VS supply

ISET resistor is connected to the I

pin, the access to the

SET

OTP registers is not possible. Zapping is only possible with

VS above 13 V. The outputs are disabled as soon as 2.5 V is

applied to the ISET pin. After the ID_LOCK_OTP I2C

message is properly received, no further OTP zapping is

possible.

Output Enable (OEN)

When the OEN input voltage is high, all output channels

are programmed according to the I2C or SAM

configuration. When OEN voltage is below 0.7 V, all

outputs are disabled in the SAM or I2C mode regardless on

the registers setting. If the OEN pin is left floating, the

internal pull down resistor will cause switching off all

channels. The OEN pin has to have max slope of 5 mV for

first 10 ms until VCC is activated. The recommended

examples are shown in Figure 4 and Figure 5. The Figure 11

shows the example of the driving multiple NCV7685 drivers

from one MCU.

*)VCC is internally

VCC

tsetupISET is up to 50

OEN

OEN pin has to have max slope of

5 mV/10 μs until VCC is activated.

Slope on the OEN pin has to be slower

than slope on the VS or slope on VDD

(depends on what comes first)

Figure 7. Power−up Sequence for OEN pin

Ground Connections (GND: Pin 13 and GNDP Pin 19)

μs

derived from VS

The device ground connection is split to two pins called

GND and GNDP. Both pins have to be connected on the

application PCB.

Chip Select for OTP Programing (Using I

SET

)

The device can be programmed using the I2C bus in End

of Line cases. When the voltage on the ISET pin is pulled

higher than 2.5 V, the device can be set in OTP control mode

via the I2C bus. During normal mode where only an external

www.onsemi.com

Configuration (CONF)

When the CONF input voltage will be below 0.7 V the

configuration 1 will be selected (One Time Programmable

OTP 1 register called SAM_CONF_1) and when the CONF

input voltage will be above 1.66 V the configuration 2 will

be selected (OTP 2 register called SAM_CONF_2). There

is ability to change the configuration in error mode (either

with CONF in SAM or through I

I2C Bus (SCL, SDA)

2

C in I2C mode).

The I2C bus consists of two wires, Serial Data (SDA) and

Serial Clock (SCL), carrying information between the

devices connected on the bus. Each device connected to the

bus is recognized by a unique address and operates as either

a transmitter or receiver, depending on the function of the

device. The NCV7685 can both receive and transmit data

with CRC8 error detection algorithm. The NCV7685 is a

slave device.

SDA is a bi−directional line connected to a positive supply

voltage via an external pull−up resistor. When the bus is free

both lines are HIGH. The output stages of the devices

connected to the bus must have an open drain to perform the

8

Page 9

NCV7685

wired−AND function. Data on the I2C bus can be transferred

up to 400 kb/s.

Diagnostic Enabling (DIAGEN)

The device is capable to detect for each independent

channel an open load condition. Versus the number of LEDs

and the Vstring voltage supply, a wrong open load condition

can be detected if the fault detection is activated when there

is not enough voltage across the LEDs. This threshold can

be programmable thanks to an external divider connected to

the DIAGEN pin. When the divided voltage is below a

typical value of 2 V, the LED diagnostic is disabled. When

the divided voltage is above the typical value of 2 V, the LED

diagnostic is enabled.

Diagnostic Feedback (DIAG)

The DIAG is an open drain output pin who can alert a

microcontroller as soon as one of the outputs is in error mode

(DIAG Low = open load or thermal shut−down or I

shorted). Forcing the DIAG pin below 1.8 V will force a

fault condition if the DIAGEN input pin is above a typical

value of 2 V. If the DIAGEN input pin is below the typical

value of 2 V then forcing the DIAG input pin will not have

any effect.

Due to certain sensitivity on the DIAG pin during the

startup, it is recommended to have the pull−up resistor

connected to the VCC supply. In case if the application

deviate from the proposal mentioned in the Figure 4 or

Figure 5, the power−up sequence has to follow the timing

diagrams in the Figure 8 or Figure 9.

5V

VS

DIAG

VCC

*) VCC is internally

derived from VS

SET

Figure 9. Power−up Sequence for DIAG pin. VDD is

supplied first, VS comes up later or equal.

Parallel Outputs

The maximum rating per output is 60 mA. In order to

increase system level LED string current, parallel

combinations of any number of outputs is allowed.

Combining all 12 outputs will allow for a maximum system

level string current design of 720 mA.

Required Time Delay for OTP Zapping

As soon as the ID_LOCK_OTP message is received, the

2

I

C acknowledge is immediately sent out to the MCU.

However, the internal circuitries still requires 500 ms time

delay to complete the OTP zapping of one OTP bit.

Therefore, no I2C confirmation is send. The number of OTP

bits that are zapped corresponds with each change from the

default values. It is needed 16.5 ms in total to successfully

finish the zapping sequence of all 32 customer bits + one

internal bit. The verification of the OTP banks can be done

by readout of the ID_READ_OTP I

2

C message after

zapping delay.

VDD

t

setupISET

Figure 8. Power−up Sequence for DIAG pin. VS is

is up to 50 mst ≥ 0 ms

supplied first, VDD comes up later.

www.onsemi.com

9

Page 10

3.3V/5V

LDO

Open Drain

GPIO structure

I2C

Micro−

controller

V

BAT

MRA4003T3G

VCC_U1

C2

1nF

C

VDD

100nF

R5

4.7K

R6

4.7K

{

C

OEN

100nF

This GND−track is exclusively for

COEN connection. (to avoid

common impedance coupling from

other GND−currents)

Figure 10. Example of using Multiple NCV7685 Drivers Controlled from One MCU

NCV7685

V

SUPPLY

LDO

or

DC/DC

C1

100nF

R7

5K

R

59K

OEN

VCC

VDD

OEN

SCL

SDA

CONF

EP

VS

GND

V

STRING

C

OUT1

(optional)

1nF

OUT1 OUT12

NCV7685

DIAGEN

GNDP

Iset

DIAG

C

(optional)

1nF

VCC_U1

100K

C

33nF

U1

OUT12

2.2K

R4

DIAG

V

SUPPLY

C1

100nF

R1

_

R2

10K

R3

2.2K

C2

1nF

To VDD supply

R

C

VDD

100nF

OEN

59K

To MCU

C

OEN

100nF

This GND−track is exclusively

for COEN connection. (to avoid

common impedance coupling from

other GND−currents)

VCC

VDD

OEN

SCL

SDA

CONF

EP

VS

DIAG

V

STRING

C

(optional)

OUT1 OUT12

NCV7685

GND

GNDP

OUT1

1nF

ctrl

Iset

mA

DIAG

DIAGEN

(optional)

C

(optional)

1nF

U2

C

DIAG

1nF

OUT12

2.2K

R1

R2

10K

R3

2.2K

www.onsemi.com

10

Page 11

NCV7685

DIGITAL PART AND I2C REGISTERS

The I2C bus consists of two wires, serial data (SDA) and

serial clock (SCL), carrying information between the

devices connected on the bus. Each device connected to the

bus is recognized by a unique address. The NCV7685 can

both receive and transmit data with CRC8 error detection

Table 7. IDENTIFIER ADDRESSING (ID) MESSAGE

Name

ID_I2C_CONF 00 W I2C_CONF

ID_PWM 01 W PWM_DUTY

ID_PWM_CONF 02 W PWM_CONF, PWM_DUTY_EN

ID_PWM_ALL 03 W PWM_D1, PWM_D2, PWM_D3, PWM_D4, PWM_D5, PWM_D6,

ID_WRITEALL 04 W I2C_CONF, PWM_CONF, PWM_DUTY_EN

ID_STATUS 08 R I2C_STATUS

ID_FAULT 09 R FAULT_STATUS

ID_READALL 0A R I2C_CH_STATUS, I2C_STATUS, FAULT_STATUS

ID_SET_OTP 20 W SAM_CONF_1, SAM_CONF_2, ADD_SAM_SET

ID_LOCK_OTP 21 W SAM_CONF_1, SAM_CONF_2, ADD_SAM_SET

ID_READ_OTP 28 R ID_VERS_1, ID_VERS_2, SAM_CONF_1, SAM_CONF_2, ADD_SAM_SET

ID Access type Name of Register Addressed

PWM_D7, PWM_D8, PWM_D9, PWM_D10, PWM_D11, PWM_D12

algorithm. The NCV7685 is a slave device only. Generation

of the signals on the I

2

C bus is always the responsibility of

the master device.

They are multiple kinds of message structure possible

versus ID code received.

There are 3 kinds of registers, Hard Coding, OTP and

volatile registers.

Hard Coding

Registers:

ID_VERS_1

ID_VERS_2

OTP

Registers:

ADD_SAM_SET

SAM_CONF_1

Volatile

Registers:

I2C_CONF

I2C_STATUS

I2C_CH_STATUS

FAULT_STATUS

PWM_DUTY

PWM_D1 − PWM_D12

PWM_DUTY_EN

PWM_CONF

SAM_CONF_2

Format of the I2C frames

S 0 A ID A P

NCV7685 address NCV7685 address

‘0’ = Write

From master to NCV7685

From NCV7685 to master

S = Start condition

P = Stop condition

A = Acknowledge

A* = Not acknowledge

N bytes +

acknowledge

Figure 11. Format of I2C Write Access Frames

NCV7685

0 A CRC A*ID AA

NCV7685

address

Sr

NCV7685

addressaddress

1 A Data A PCRC A*S

CRC AData AA

‘0’ = Write

From master to NCV7685

From NCV7685 to master

Figure 12. Format of I2C Read Access Frames

Remark: CRC byte is not transmitted when CRC

protection is turned off (ERREN = 0)

www.onsemi.com

11

‘1’ = Read

S = Start condition

Sr = Repeated start condition

P = Stop condition

A = Acknowledge

A* = Not acknowledge

N bytes +

acknowledge

Page 12

NCV7685

P

CRC

P

P

CRC

CRC

PWM_D3

PWM_DUTY_EN[7:0]

CRC

CRC

CRC

FAULT_STATUS[7:0]

FAULT_STATUS[15:8]

I2C_STATUS

Acknowledges are ommited

S = Start condition

Sr = Repeated start condition

P = Stop condition

I2C_CH_STATUS[15:8] I2C_CH_STATUS[7:0]

P

CRC

CRC

SAM_CONF_2[7:0]SAM_CONF_2[15:8]

CRC

Acknowledges are ommited

S = Start condition

Sr = Repeated start condition

P = Stop condition

CRC

Sr P

Sr PCRC NCV7685 address 1 I2C_STATUSS NCV7685 address 0 ID_STATUS

PWM_DUTY_EN[15:8]

I2C_CONF[15:8] I2C_CONF[7:0]

NCV7685 address

NCV7685 address

S NCV7685 address 0 ID_I2C_CONF

S NCV7685 address 0 ID_PWM PWM_DUTY

S NCV7685 address 0 ID_PWM_CONF PWM_CONF PCRCNCV7685 address

PWM_D7 PWM_D8 PWM_D9 PWM_D10 PWM_D11 PWM_D12

...

NCV7685 address PWM_D4 PWM_D5 PWM_D6

S NCV7685 address 0 ID_PWM_ALL PWM_D1 PWM_D2

Sr PCRC NCV7685 address 1 FAULT_STATUS[15:8]S NCV7685 address 0 ID_FAULT FAULT_STATUS[7:0]

NCV7685 address

NCV7685 address

NCV7685 address

S NCV7685 address 0 ID_WRITEALL PWM_CONF PWM_DUTY_EN[15:8] PPWM_DUTY_EN[7:0]I2C_CONF[15:8] I2C_CONF[7:0]

CRC NCV7685 address 1

NCV7685 address

S NCV7685 address 0 ID_READALL

Figure 13. Format of I2C Frames

From master to NCV7685

From NCV7685 to master

ID_VERS_1 ID_VERS_2 SAM_CONF_1[15:8] SAM_CONF_1[7:0] ADD_SAM_SET

1

SAM_CONF_2[15:8] SAM_CONF_2[7:0] ADD_SAM_SET

SAM_CONF_1[15:8] SAM_CONF_1[7:0]

NCV7685 address

000

S NCV7685 address ID_SET_OTP

From master to NCV7685

Sr P

CRC NCV7685 address

SAM_CONF_1[15:8] SAM_CONF_1[7:0] PSAM_CONF_2[15:8] SAM_CONF_2[7:0] ADD_SAM_SET

NCV7685 address

NCV7685 address

S NCV7685 address ID_READ_OTP

S NCV7685 address ID_LOCK_OTP

From NCV7685 to master

Figure 14. Format of I2C OTP Frames

www.onsemi.com

12

Page 13

NCV7685

t

d

There is a safety mechanism implemented by repeating

the address. Since the I

2

C address is 7 bits long, first bit of

the second address byte starts with a “0” in the repeated byte

(see tables below).

Table 8.

s

1

byte

7 6 5 4 3 2 1 0

I2C device Address R/W Bit

n

2

byte

7 6 5 4 3 2 1 0

I2C device Address 0

CRC ERROR DETECTION ALGORITHM

The CRC protection is turned off by default. It can be

enabled by activation of the OTP ERREN bit (ERREN = 1).

The every I

2

C byte including both addresses with R/W flag

Example of the CRC used in the I

I2C_CONF byte = 0xCFFF and with I

(0xC0) is 0x2E.

2

C message with

2

C address 0x60

are calculated using CRC8 algorithms. The CRC

8

polynomial is following: x

+ x5 + x3 + x2 + x + 1.

HARD CODING REGISTERS

Table 9. HARD CODING REGISTERS

Bit

ID_VERS_1

Access type

Bit name ID1[7:0]

Reset value 0 1 0 0 0 0 1 1

ID_VERS_2

Access type

Bit name ID2[7:0]

Reset value 0 0 0 0 0 1 0 0

1. ID1[7:0] = 43h (ON Semiconductor device identifier)

ID2[7:0] = 04h (The actual version)

D7 D6 D5 D4 D3 D2 D1 D0

R R R R R R R R

R R R R R R R R

OTP REGISTERS

Table 10. ADD_SAM_SET

Bit

Access type R/W R/W R/W R/W R/W R/W R/W R/W

Bit name AUTOR DETONLY ERREN ADD[4:0]

Reset value 0 1 0 0 0 0 0 0

ADD[4:0] are the programmable BUS address registers

(in I2C mode ADD[6:5] = 11).

AUTOR: When AUTOR=1 (and DIAGEN is high), open

load diagnosis is performed. When a fault is detected, the

DIAG pin is set and LED driver imposes a low current on the

faulty branch alone, switching off the others. When fault is

recovered, LED driver returns to normal operation after

resetting the DIAG pin. If the DIAG pin is triggered

externally, LED driver outputs are switched off and the low

power mode is entered.

D7 D6 D5 D4 D3 D2 D1 D0

DETONLY: When DETONLY=1, open load diagnostic is

performed. When a fault is detected, the DIAG pin is set

without taking any action on the current regulation. When

fault is recovered, DIAG is reset. If the DIAG pin is

triggered externally, no action is taken.

When AUTOR = DETONLY = 0, no diagnostic performed

When AUTOR = DETONLY = 1, no change

(same as previously setting).

ERREN: When ERREN = 1, CRC error detection

2

C communication.

www.onsemi.com

algorithm is activated for I

13

Page 14

NCV7685

Table 11. SAM_CONF

Bit

SAM_CONF_1

Access type

Bit name − − − − SAM1conf[11:0]

Reset value 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

SAM_CONF_2

Access type

Bit name − − − − SAM2conf[11:0]

Reset value 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1

1. SAM1conf[x] = 0 means channel is OFF and SAM1conf[x] = 1 means channel is ON

SAM2conf[x] = 0 means channel is OFF and SAM2conf[x] = 1 means channel is ON

VOLATILE REGISTERS

Table 12. I2C_CONF

Bit

Access type W W W W W W W W W W W W W W W W

Bit name I2CFLAG I2CautoR I2CdOnly PWMEN I2Cconf[11:0]

Reset value 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

R R R R R/W R/W R/W R/W R/W R/W R/W R/W R/W R/W R/W R/W

R R R R R/W R/W R/W R/W R/W R/W R/W R/W R/W R/W R/W R/W

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

I2CFLAG: the I2CFLAG should be reset whenever

standalone mode is entered. When I2CFLAG=1 and when

VDD is high, the I2C mode is activated, in all other

conditions the device is in Stand Alone Mode.

I2CautoR: When I2CautoR=1 (and DIAGEN is high),

open load diagnosis is performed. When a fault is detected,

the DIAG pin is set and LED driver imposes a low current

on the faulty branch alone, switching off the others. When

fault is recovered, LED driver returns to normal operation

after resetting the DIAG pin. If the DIAG pin is triggered

externally, LED driver outputs are switched off and the low

power mode is entered. Whenever the device is configured

in autorecovery (AUTOR in standalone mode or I2CautoR

in I2C mode), it is not allowed to put PWMDUTY = 0 or

I2CdOnly: When I2CdOnly =1, open load diagnostic is

performed. When a fault is detected, the DIAG pin is set

without taking any action on the current regulation. When

fault is recovered, DIAG is reset. If the DIAG pin is

triggered externally, no action is taken.

When I2CautoR = I2CdOnly = 0, no diagnostic

performed.

When I2CautoR = I2CdOnly = 1, no change (same as

previously setting).

PWMEN: When PWMEN = 1, PWM is activated, when

PWMEN = 0 the content of the complete register

PWM_DUTY_EN is not reset and PWM is disabled.

I2Cconf[x] = 0 means channel is OFF and I2Cconf[x] = 1

means channel is ON.

PWMDx = 0 to a channel which has detected an open load.

Table 13. I2C_STATUS

Bit

Access type R R R R R R R R

Bit name SC_Iset I2Cerr UV diagRange TW TSD DIAGERR OL

Reset value 0 0 0 0 0 0 0 0

SC_Iset: SC_Iset = 1 means there is short−circuit on the

external resistor on I

and DIAG pin is set. SC_Iset=0 no short−circuit.

I2Cerr: I2Cerr=1 means an error has been detected during

the I2C communication, I2Cerr=0 means no error during

I2C communication has been detected.

UV: the device is in under voltage condition (VS is below

VSUV threshold, all channels OFF).

D7 D6 D5 D4 D3 D2 D1 D0

diagRange: when diagRange = 1 the divided voltage is

pin and drivers are switched OFF

SET

above the typical value of 2 V (LED diagnostic is enabled),

diagRange = 0 means the divided voltage is below the

typical value of 2 V (LED diagnostic is disabled).

TW: when TW=1 the device is in the thermal warning

range (typ 140°C), this flag is just a warning no action is

foreseen on the output drivers. TW=0 means the device is

below the thermal warning range.

www.onsemi.com

14

Page 15

NCV7685

TSD: when TSD = 1 the device is in the Thermal shutdown

range, TSD = 0 means the device is below the thermal

shutdown range.

DIAGERR: DIAGERR = 1 means an error is detected by

DIAG pin forced externally.

Table 14.

SC_Iset

set when a short−circuit on the external resistor on I

Reset in case of short−circuit disappear permanently for at least 10ms.

I2Cerr

set if an error has been detected during the I2C communication.

Reset on register reading.

UV

diagRange

set when device is in under voltage condition (VS is below VSUV, all channels OFF).

set when divided voltage is above the VDiagenTH threshold.

Reset when the divided voltage is below the VDiagenTH threshold.

TW

set when junction temperature is above the Tjwar_on threshold.

Reset on register reading AND temperature is below the (Tjwar_on − Tjsd_hys) threshold

TSD

set when junction temperature is above the TSD threshold.

Reset on register reading AND temperature is below the TSD − Tjsd_hys) threshold

DIAGERR

set by DIAG pin forced low externally, latched if permanent after 10 ms.

Reset in case DIAG pin is not forced permanently for at least 10 ms.

OL

set in Open Load condition and DIAGEN is high, latched if permanent after 10 ms.

Reset if Open Load disappear permanently for at least 10 ms.

Fault information is maintained on falling DIAGEN threshold exceeded

OL: OL = 1 means at least one channel is in Open Load

condition, OL = 0 no Open Load.

pin, latched if permanent after 10 ms.

SET

Table 15. I2C_CH_STATUS

Bit D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Access type R R R R R R R R R R R R R R R R

Bit name I2CFLAG I2CautoR I2CdOnly PWMEN I2C_CH_STATUS[11:0]

Reset value 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

I2CFLAG: same as I2C_CONF register

I2CautoR: same as I2C_CONF register

I2CdOnly: same as I2C_CONF register

Remark: When NCV7685 is configured in I2C mode and

output channel OUTx is configured to operate in PWM

mode, I2C_CH_STATUS[x] shall contain value ‘1’.

PWMEN: same as I2C_CONF register

I2C_CH_STATUS[11:0]: same as I2C_CONF[11:0] bits

in I2C mode or same as SAM_CONF_1[11:0],

SAM_CONF_2[11:0] bits in Standalone mode.

Table 16. FAULT_STATUS

Bit

Access type R R R R R R R R R R R R R R R R

Bit name − − − − FAULT[11:0]

Reset value 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

FAULT[11:0]: when FAULT[x] = 1 the OUTx channel is

in fault mode (Open Load latched when the duration is

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

is working properly. The register is reset on each read

operation.

longer than 10 ms), when FAULT[x] = 0 the OUTx channel

www.onsemi.com

15

Page 16

NCV7685

Table 17. PWM_DUTY

Bit

Access type − W W W W W W W

Bit Name − PWMDUTY[6:0]

Reset Value 0 0 0 0 0 0 0 0

D7 D6 D5 D4 D3 D2 D1 D0

PWMDUTY[6:0]: logarithmic (or linear) common

dimming for all channels via embedded PWM generator

(128 steps). Following formula applies when logarithmic

dimming is selected: Duty_Cycle_Percent = 100 × α

(N−i)

where α = 0.9471 and N = 127 rounded with an accuracy

of 400 ns.

When PWMDUTY = 127 all channels ar fully switched

When PWMDUTY = 0 all channels are switched off.

Whenever the device is configured in autorecovery

(AUTOR in standalone mode or I2CautoR in I2C mode), it

is not allowed to put PWMDUTY = 0 or PWMDx = 0 to a

channel which has detected an open load.

Transmitting PWM_DUTY via I

2

C will cause setting the

value to all channels.

on.

Table 18. PWM_Dx

Bit

Access type − W W W W W W W

Bit Name − PWMDx[6:0]

Reset Value 0 0 0 0 0 0 0 0

PWMDx[6:0]: logarithmic (or linear) independent PWM

dimming for each OUTx channel via embedded PWM

generator (128 steps). Following formula applies when

logarithmic dimming is selected: Duty_Cycle_Percent =

100 × α

(N−i)

an accuracy of 400 ns.

When PWMDx = 127 the OUTx channel is fully switched

on.

When PWMDx = 0 the OUTx channel is switched off.

D7 D6 D5 D4 D3 D2 D1 D0

Whenever the device is configured in autorecovery

(AUTOR in standalone mode or I2CautoR in I2C mode), it

is not allowed to put PWMDUTY = 0 or PWMDx = 0 to a

channel which has detected an open load.

where α = 0.9471 and N = 127 rounded with

To set independent PWM Duty Cycle value to each

channel simultaneously, all twelve PWM_Dx bytes has to be

transferred via I

2

C bus in ID_PWM_ALL message. If

PWM_DUTY register is updated, all PWM_Dx bytes will

be overwritten by the same value from PWM_DUTY

register.

Table 19. PWM_DUTY_EN

Bit

Access type − − − − W W W W W W W W W W W W

Bit name − − − − PWMDUTYen[11:0]

Reset value 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

PWMDUTYen[11 :0] : when PWMDUTYen[x] = 1,

PWM dimming is enabled for OUTx channel, when

PWMGAINen[x] = 0 means PWM dimming is disabled for

Table 20. PWM_CONF

Bit

Access type W W W W W W W W

Bit Name − − − − − PWMLIN PWMF2 PWMF1

Reset Value 0 0 0 0 0 0 0 0

PWMLIN bit shall select between between logarithmic

(PWMLIN=0) and linear (PWMLIN=1) translation of

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

OUTx channel. When the PWM dimming is disabled, the

output channel is programmed according to the I2Cconf[x]

settings.

D7 D6 D5 D4 D3 D2 D1 D0

PWMF2 and PWMF1 bits set typical PWM frequency

settings according to the Table 21.

PWMDUTY bits to duty cycle of internal PWM signal.

www.onsemi.com

16

Page 17

Table 21. TYPICAL PWM FREQUENCY SETTINGS

PWMF2

0 0 150

0 1 300

1 0 600

1 1 1200

NCV7685

PWMF1 typ. PWM frequency [Hz]

Figure 15. Output Duty Cycle vs. Register Setting Figure 16. Output Duty Cycle vs. Register Setting

− Detail

ON Semiconductor is licensed by Philips Corporation to carry the I2C Bus Protocol.

www.onsemi.com

17

Page 18

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 1:1

2X

NOTE 4

D

A

B

TOP VIEW

SIDE VIEW

NOTE 8

D2

BOTTOM VIEW

3.00

13

24X

A1

EE1

2X 12 TIPS

b

M

0.12 DC

A2

C

E2

NOTE 8

2X

0.20 C

24X

NOTE 5

PIN 1

REFERENCE

0.10 C

0.10

C

0.15 DC

NOTE 6

24

112

e

NOTE 6

A

M

A-B

RECOMMENDED

SOLDERING FOOTPRINT*

SSOP−24 NB EP

CASE 940AQ

A-B0.20

C

D

H

A1

0.20 C

A-B

h

SEATING

PLANE

M

0.15 DC

ISSUE O

L1

L

DETAIL A

NOTE 7

c

END VIEW

A-B

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b DOES NOT INCLUDE DAMBAR

PROTRUSION. DAMBAR PROTRUSION SHALL

BE 0.10 MAX. AT MMC. DAMBAR CANNOT BE

L2

GAUGE

PLANE

SEATING

C

PLANE

DETAIL A

h

LOCATED ON THE LOWER RADIUS OF THE

FOOT. DIMENSION b APPLIES TO THE FLAT

SECTION OF THE LEAD BETWEEN 0.10 TO 0.25

FROM THE LEAD TIP.

4. DIMENSION D DOES NOT INCLUDE MOLD

FLASH, PROTRUSIONS OR GATE BURRS. MOLD

FLASH, PROTRUSIONS OR GATE BURRS SHALL

NOT EXCEED 0.15 PER SIDE. DIMENSION D IS

DETERMINED AT DATUM PLANE H.

5. DIMENSION E1 DOES NOT INCLUDE INTERLEAD

FLASH OR PROTRUSION. INTERLEAD FLASH

OR PROTRUSION SHALL NOT EXCEED 0.25 PER

SIDE. DIMENSION E1 IS DETERMINED AT DATUM PLANE H.

6. DATUMS A AND B ARE DETERMINED AT DATUM

PLANE H.

7. A1 IS DEFINED AS THE VERTICAL DISTANCE

FROM THE SEATING PLANE TO THE LOWEST

POINT ON THE PACKAGE BODY.

8. CONTOURS OF THE THERMAL PAD ARE UNCONTROLLED WITHIN THE REGION DEFINED

BY DIMENSIONS D2 AND E2.

M

MILLIMETERS

DIM MIN MAX

---

A 1.75

A1 0.00 0.10

A2 1.651.10

b 0.19 0.30

c 0.09 0.20

D 8.64 BSC

D2 2.50 2.70

E 6.00 BSC

E1 3.90 BSC

E2 1.80 2.00

e 0.65 BSC

h 0.25 0.50

L 0.40 0.85

L1 1.00 REF

L2 0.25 BSC

M 0 8

__

GENERIC

MARKING DIAGRAM*

XXXXXXXXXG

AWLYYWW

DATE 18 AUG 2017

24X

1.15

2.20

6.40

XXXX = Specific Device Code

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

1

24X

0.40

0.65

PITCH

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

G = Pb−Free Package

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present. Some products

may not follow the Generic Marking.

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98AON73645G

SSOP−24 NB EP

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

Page 19

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...