Page 1

NCV7683

s

Enhanced 100 mA Linear

Current Regulator and

Controller for Automotive

Sequenced LED Lighting

The NCV7683 consists of eight linear programmable constant

current sources. The part is designed for use in the regulation and

control of LED based Rear Combination Lamps and blinking

functions for automotive applications. System design with the

NCV7683 allows for two programmed levels for stop (100% Duty

Cycle) and tail illumination (programmable Duty Cycle), or an

optional external PWM control can be implemented.

LED brightness levels are easily programmed (stop is programmed

to the absolute current value, tail is programmed to the duty cycle)

with two external resistors. The use of an optional external ballast FET

allows for power distribution on designs requiring high currents. Set

back power limit reduces the drive current during overvoltage

conditions. This is most useful for low power applications when no

external FET is used.

Sequencing functionality is activated, controlled, and programmed

by individual pins. In addition to programming of the sequence

interval, the device can sequence 8 individual output channels, 4 pairs

of output channels, 2 quad output channels, or all 8 at once (for multi

IC use at high currents).

Enhanced features of this device are a global enable function and

display sequencing.

The device is available in a SSOP−24 package with exposed pad.

Features

• Constant Current Outputs for LED String Drive

• LED Drive Current up to 100 mA per Channel

• Open LED String Diagnostic with Open−Drain Output in All Modes

• Slew Rate Control Eliminates EMI Concerns

• Low Dropout Operation for Pre−Regulator Applications

• External Modulation Capable

• On−chip 800 Hz T ail PWM Dimming

• Single Resistor for Stop Current Set Point

• Single Resistor for Tail Dimming Set Point

• Overvoltage Set Back Power Limitation

• Improved EMC Performance

• Programmable Latch−Off function on Open String

♦ Restart Option of Unaffected Strings

• Over Temperature Fault Reporting

• Global Enable

• Display Sequencing

• SSOP−24 Fused Lead Package with Exposed Pad

• AEC−Q100 Qualified and PPAP Capable

• These are Pb−Free Devices

Applications

• Rear Combination Lamps (RCL)

• Daytime Running Lights (DRL)

• Fog Lights

• Center High Mounted Stop Lamps (CHMSL) Arrays

• Turn Signal and Other Externally Modulated Applications

• Signature Lamp

www.onsemi.com

MARKING DIAGRAM

NCV7683G

SSOP24 NB EP

CASE 940AP

NCV7683 = Specific Device Code

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

ORDERING INFORMATION

Device Package Shipping

NCV7683DQR2G SSOP24−EP

(Pb−Free)

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specification

Brochure, BRD801 1/D.

AWLYYWW

2500 /

Tape & Reel

†

© Semiconductor Components Industries, LLC, 2016

February, 2018 − Rev. 3

1 Publication Order Number:

NCV7683/D

Page 2

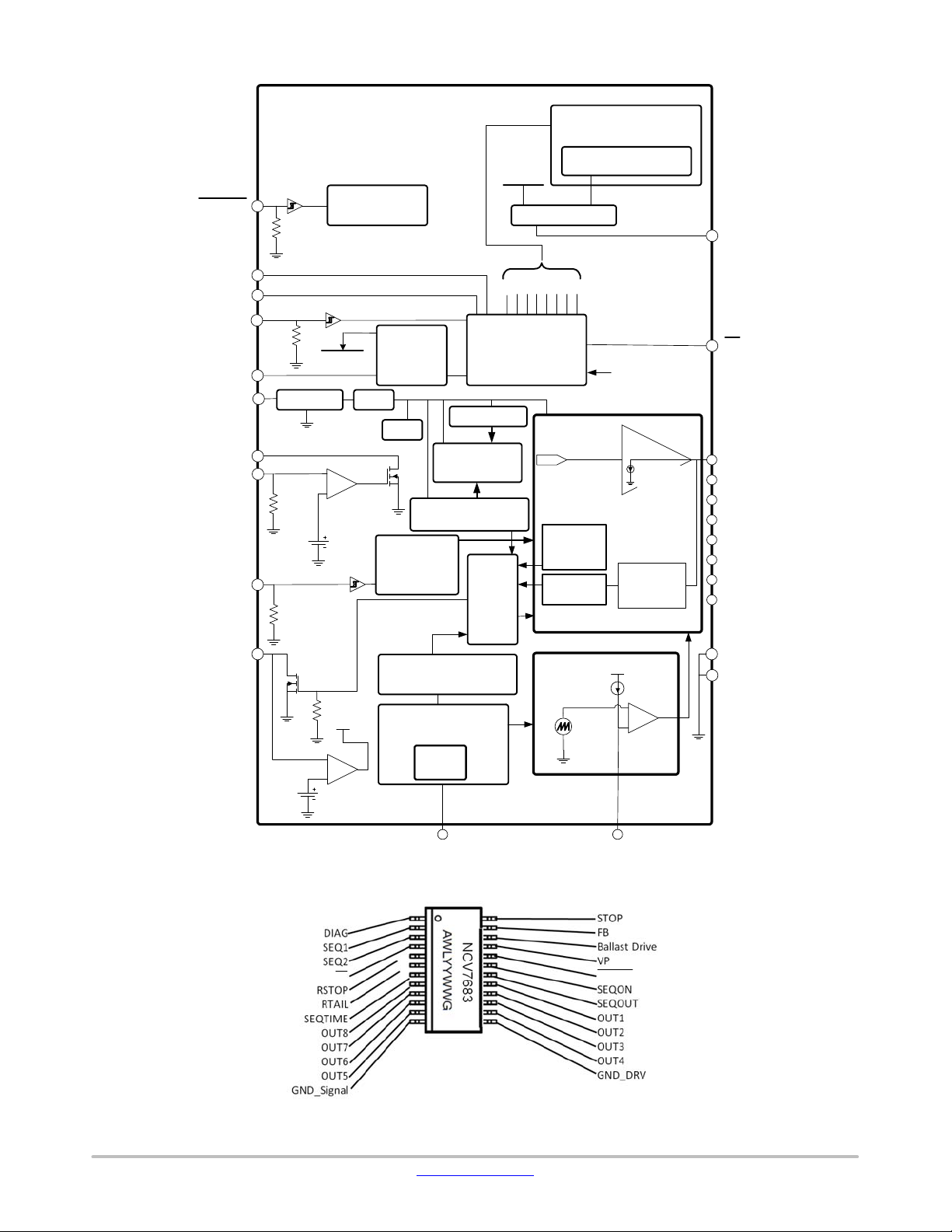

ENABLE

200k

Output

Drive Control

NCV7683

VP

Timer Circuit

Timer

Programming Current

Vref

SEQTIME

SEQ1

SEQ2

SEQON

SEQOUT

VP

Ballast

Drive

FB

STOP

DIAG

200k

DIAG

Interface

EMC Filter

200K

200K

1.8V

UVLO

−

+

FET Drive

1V

CC

−

+

Open

Circuit

Restart

SEQOUT

Open Load

Detection

Vreg

Over temperature &

Over voltage sense

Control Logic

I

RSTOP

V−I Converter

Pin

Current

Limit

8

Channel Control

Overvoltage

Soft Start,

Bias and

Reference

DIAG

Inverface

x 150

1

234567

CC

Channel

Control

Setback

Current

−20%

Output

Latch−Off

Oscillator

and PWM

2.2V

0.4V

50% IOUT

Open Load

Detect

Vreg

Irstop

−

+

Rtail

1 of 8

Output

Current

Drive

LO

Out1

Out2

Out3

Out4

Out5

Out6

Out7

Out8

GND_Signal

GND_DRV

LO

RSTOP

Figure 1. Block Diagram

Figure 2. Pinout Diagram

www.onsemi.com

2

RTAIL

ENABLE

Page 3

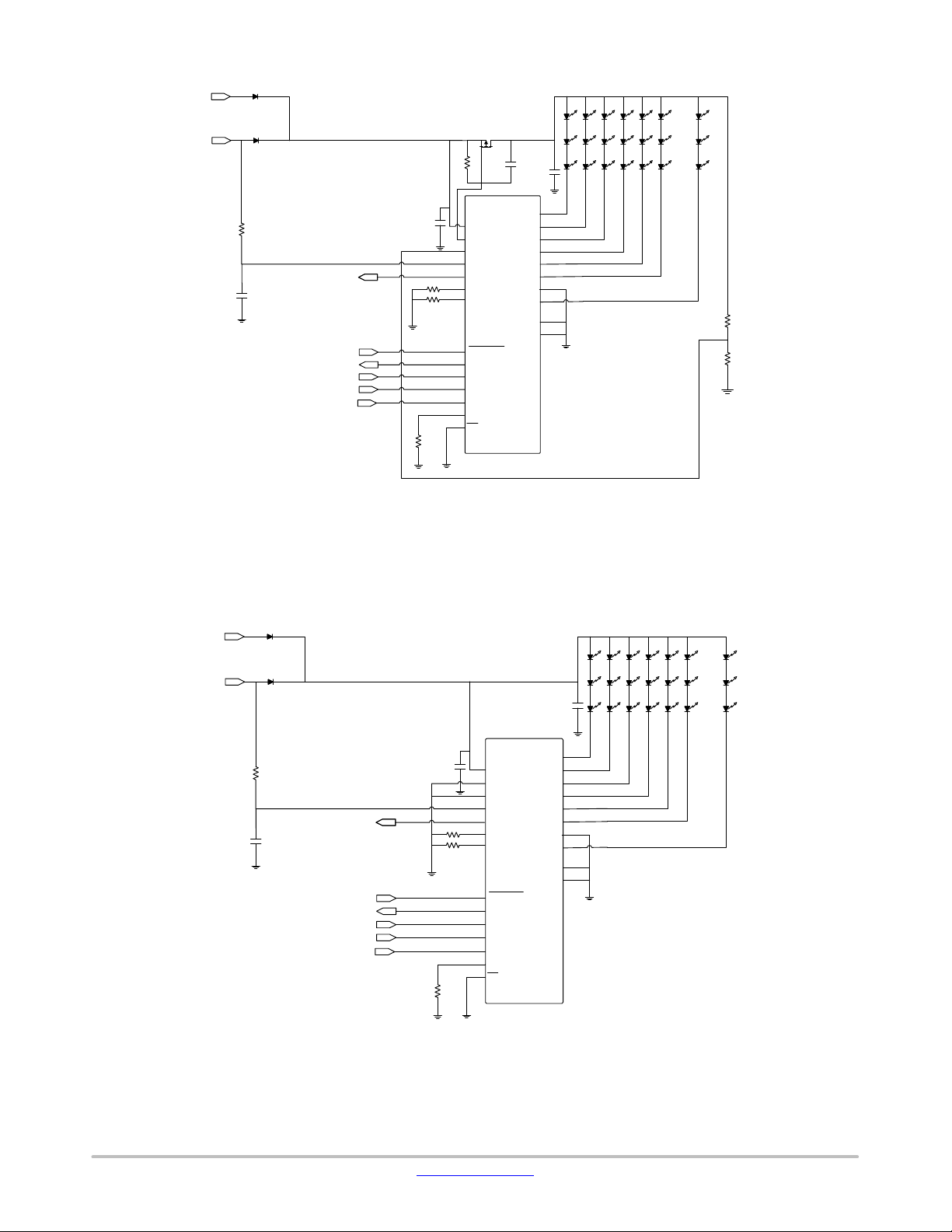

NCV7683

TAIL

STOP

MRA4003T3G

MRA4003T3G

R1

10K

C4

10nF

C1

0.68uF

R4, 3.01K

R5, 1.62K

R2

R3

1K

NTD2955

VP

Ballast

Drive

FB

STOP

DIAG

RSTOP

RTAIL

GND_Signal

GND_DRV

ENABLE

SEQOUT

SEQ1

SEQ2

SEQON

SEQTIME

LO

NCV7683

C2

0.22uF

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT8

C3

100nF

V

STRING

Figure 3. Application Diagram with External FET Ballast Transistor

R6

9.53K

R7

1K

R6 and R7 values shown yield 10.5 V regulation on V

STRING

.

C1 is for line noise and stability considerations.

C3 is for EMC considerations.

Unused OUTx channels should be shorted to ground as OUT7 shows in this example.

MRA4003T3G

TAIL

MRA4003T3G

STOP

R1

10K

C4

10nF

0.68uF

R4, 3.01K

R5, 1.62K

C1

VP

Ballast

Drive

FB

STOP

DIAG

RSTOP

RTAIL

GND_Signal

ENABLE

SEQOUT

SEQ1

SEQ2

SEQON

SEQTIME

LO

R2

NCV7683

100nF

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT8

GND_DRV

C3

V

STRING

Figure 4. Application Diagram without the FET Ballast Transistor

When using the NCV7683 without the FET ballast transistor, tie the FB pin and Ballast Drive pin to GND.

www.onsemi.com

3

Page 4

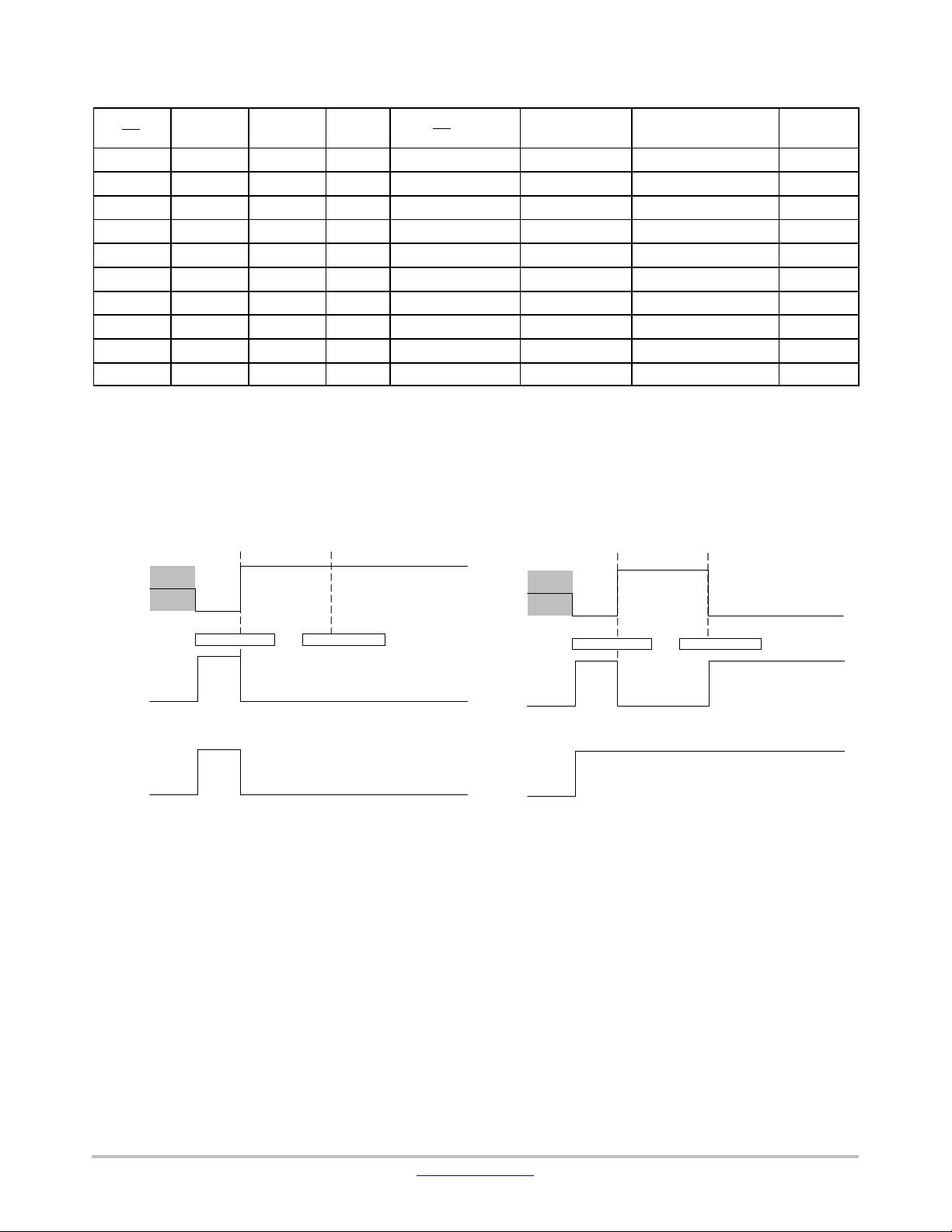

NCV7683

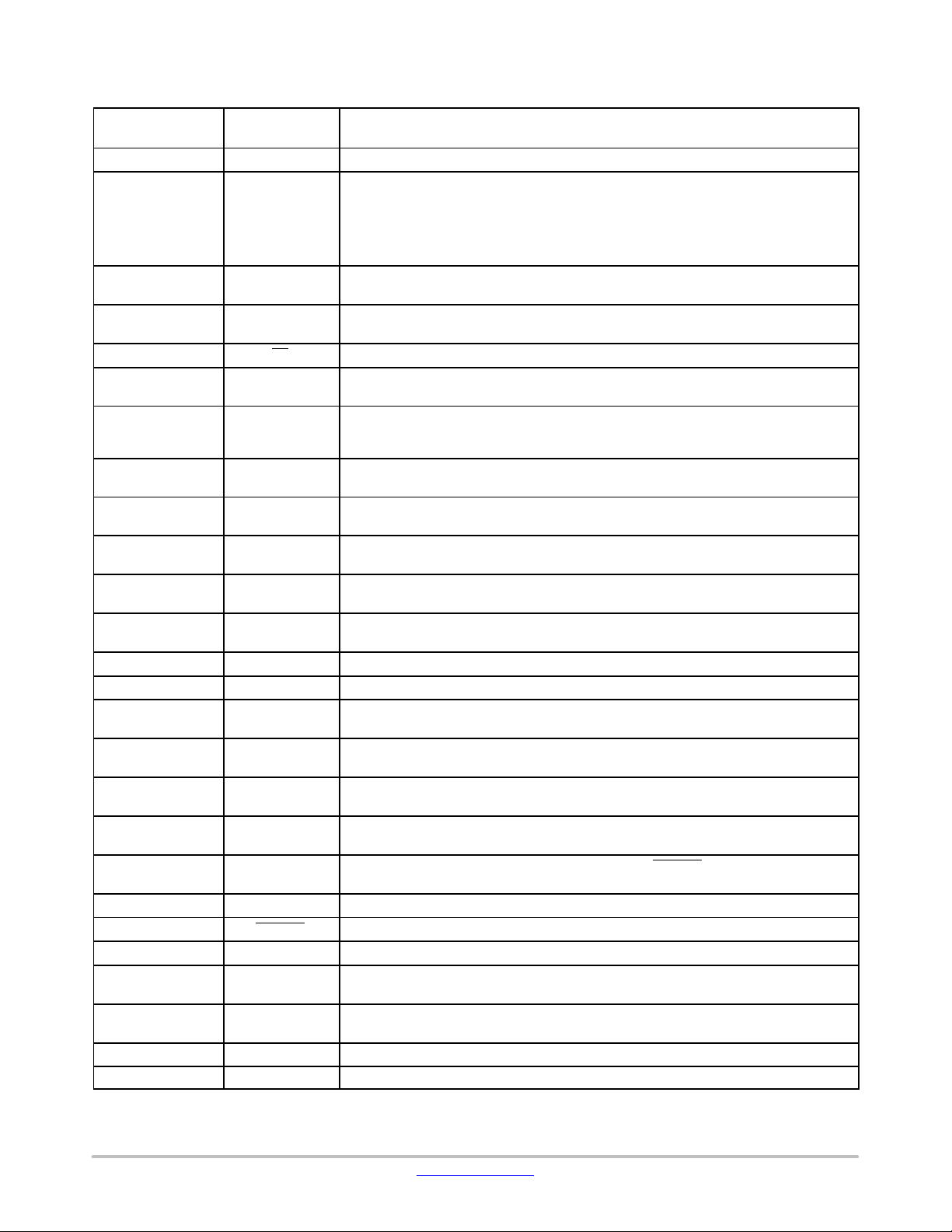

Table 1. APPLICATION I/O TRUTH TABLE

STOP

EN SEQON

INPUT

1 X X X no OFF − 1

0 0 0 0 no OFF − 1

0 0 1 X no I

0 0 1 X no I

0 0 1 X yes OFF OPEN CIRCUIT*** 1

0 0 0 1 no PWM NORMAL 0

0 0 0 1 no PWM OPEN CIRCUIT*** PWM

0 1 X X no I

0 1 X X no I

0 1 X X yes OFF OPEN CIRCUIT*** 1

Reference Figures below.

X = don’t care

0 = LOW

1 = HIGH

* Open Circuit, RSTOP Current Limit, Set Back Current Limit down 20%, and thermal shutdown

**Pull−up resistor to DIAG and SEQOUT required.

*** OPEN CIRCUIT = Any string or SEQOUT open.

TAIL

MODE

OUTx LATCH OFF

= GND)

(w/ LO

OUTX

CURRENT

STOP

STOP

STOP

STOP

FAULT

STATE*

NORMAL 0

OPEN CIRCUIT*** 1

NORMAL 0

OPEN CIRCUIT*** 1

DIAG

STATE**

DIAG

Open String Occurs

on

OUTx

Current

off

on

OUTx

Current

off

Outputs with no open string.

Figure 5. DIAG timing diagram WITH

Open String Latch Active

All outputs latch off.

Open String Removed

on

Current

off

on

Current

off

DIAG

Open String Occurs

OUTx

OUTx

Outputs with no open string.

Open String Removed

Figure 6. DIAG timing diagram WITHOUT

Open String Latch Active

No outputs are turned off.

DIAG will report the state.

www.onsemi.com

4

Page 5

NCV7683

Sequencing_on

Sequencing_on

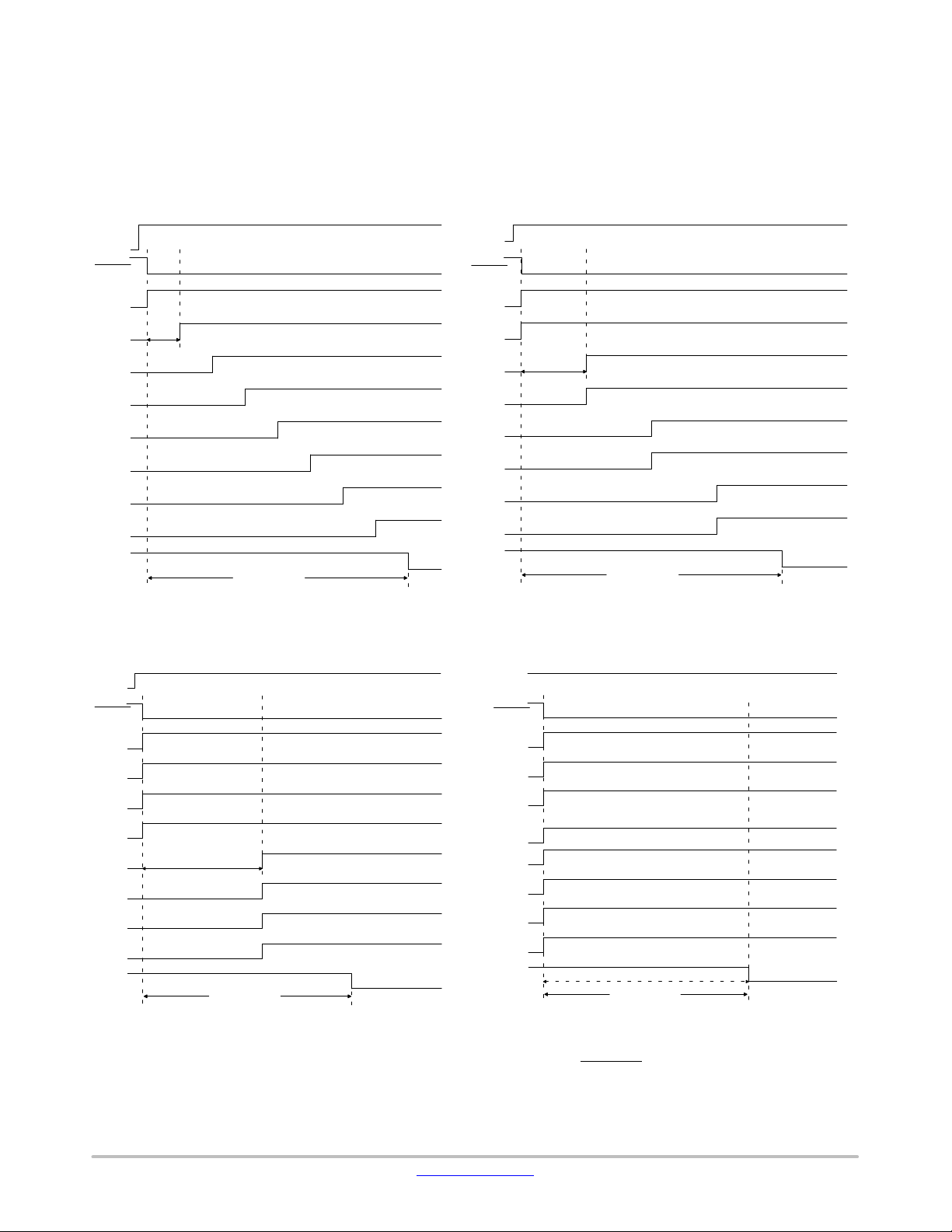

Sequence Programming Timing Diagrams

The four timing diagrams show the options available for sequencing of the 8 outputs dependent on the state of SEQ1 and SEQ2.

1. 8 individual sequence intervals.

2. 4 pairs of sequence intervals.

3. 2 quads of sequence intervals.

4. 1 single sequence interval.

ENABLE

OUT1

(current)

OUT2

(current)

OUT3

(current)

OUT4

(current)

OUT5

(current)

OUT6

(current)

OUT7

(current)

OUT8

(current)

SEQOUT

Figure 7. Sequencing Timing Diagram

Sequencing_on

ENABLE

OUT1

(current)

OUT2

(current)

OUT3

(current)

OUT4

(current)

OUT5

(current)

OUT6

(current)

OUT7

(current)

OUT8

(current)

SEQOUT

Figure 9. Sequencing Timing Diagram

Sequence

Interval

Sequence

Sequence Time

(SEQ1 = 0, SEQ2 = 0)

Interval

Sequence Time

(SEQ1 = 0, SEQ2 = 1)

ENABLE

OUT1

(current)

OUT2

(current)

OUT3

(current)

OUT4

(current)

OUT5

(current)

OUT6

(current)

OUT7

(current)

OUT8

(current)

SEQOUT

Sequencing_on

ENABLE

OUT1

(current)

OUT2

(current)

OUT3

(current)

OUT4

(current)

OUT5

(current)

OUT6

(current)

OUT7

(current)

OUT8

(current)

SEQOUT

Sequence

Interval

Sequence Time

Figure 8. Sequencing Timing Diagram

(SEQ1 = 1, SEQ2 = 0)

Sequence Time

Figure 10. Sequencing Timing Diagram

(SEQ1 = 1, SEQ2 = 1)

The sequencing function is triggered by a logic level high to low signal on the ENABLE pin.

0=ground

1=floating

www.onsemi.com

5

Page 6

NCV7683

Table 2. PIN FUNCTION DESCRIPTION

SSOP−24 Exposed

Pad Package

Pin # Label Description

1 DIAG Open−drain diagnostic output. Requires a pull−up resistor.

2 SEQ1 Grounding this pin changes the output sequencing.

3 SEQ2 Grounding this pin changes the output sequencing.

4 LO Latch Off. Ground this pin for latch off function.

5 RSTOP Stop current bias program resistor.

6 RTAIL Tail current duty cycle PWM program resistor.

7 SEQTIME Sequence Time program resistor.

8 OUT8 Channel 8 constant current output to LED.

9 OUT7 Channel 7 constant current output to LED.

10 OUT6 Channel 6 constant current output to LED.

11 OUT5 Channel 5 constant current output to LED.

12 GND_Signal Low Current Logic Ground.

13 GND_DRV High Current Driver Ground. Pin is fused to the epad.

14 OUT4 Channel 4 constant current output to LED.

15 OUT3 Channel 3 constant current output to LED.

16 OUT2 Channel 2 constant current output to LED.

17 OUT1 Channel 1 constant current output to LED.

18 SEQOUT Open−drain output. Requires a pull−up resistor. Follows ENABLE pin after delay of OUT8

19 SEQON High turns on 1−8 output sequencing.

20 ENABLE Global enable input. Low turns device on.

21 VP Supply voltage input.

22 Ballast Drive Gate drive for external power distribution PFET.

23 FB Feedback Sense node for VP regulation.

24 STOP Stop Logic Input. External Modulation Input when VP is high.

epad epad Ground. Do not connect to pcb traces other than GND.

Reporting Open Circuit, RSTOP Current Limit,

Set Back Current Limit down 20%, and thermal shutdown.

Normal Operation = LOW.

Open Load reset input.

Ground if not used (only if latchoff is not used).

Reference the sequencing section of the datasheet.

Reference the sequencing section of the datasheet.

Referenced to ground (pin 12).

Referenced to ground (pin 12).

Ground pin if using external modulation.

Referenced to ground (pin 12).

Unused pin should be grounded (pin 13).

Unused pin should be grounded (pin 13).

Unused pin should be grounded (pin 13).

Unused pin should be grounded (pin 13).

Unused pin should be grounded (pin 13).

Unused pin should be grounded (pin 13).

Unused pin should be grounded (pin 13).

Unused pin should be grounded (pin 13).

with SEQON high.

Ground if not used.

Use feedback resistor divider or connect to GND.

www.onsemi.com

6

Page 7

NCV7683

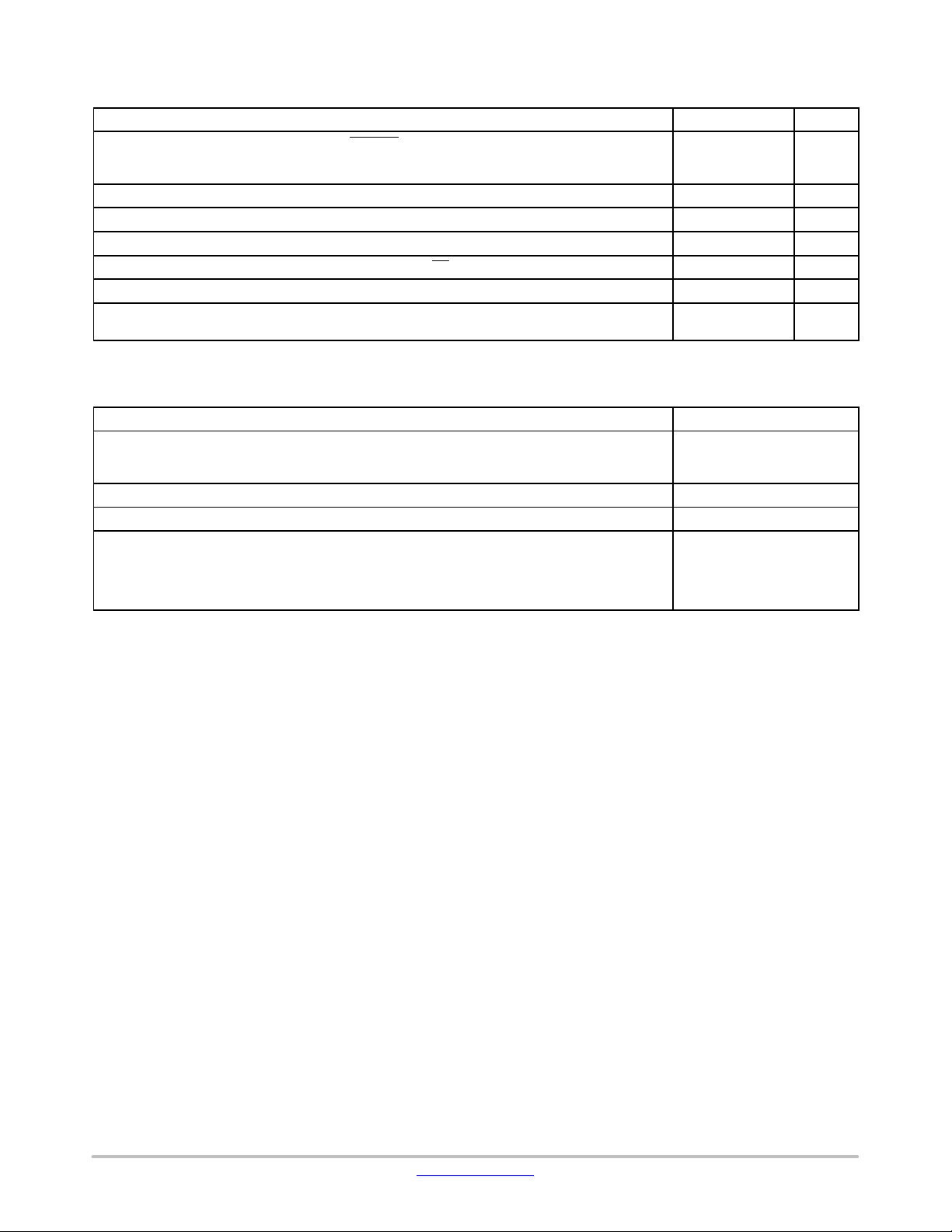

Table 3. MAXIMUM RATINGS (Voltages are with respect to device substrate.)

Rating

Supply Input (VP, Ballast Drive, STOP, DIAG, ENABLE, SEQON, SEQOUT)

DC

Peak Transient

Output Pin Voltage (OUTX) −0.3 to 40 V

Output Pin Current (OUTX) 200 mA

DIAG Pin Current 10 mA

Input Voltage (RTAIL, RSTOP, FB, SEQTIME, SEQ1, SEQ2, LO) −0.3 to 3.6 V

Junction Temperature, T

J

Peak Reflow Soldering Temperature: Lead−free

60 to 150 seconds at 217°C (Note 1)

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

Table 4. ATTRIBUTES

Characteristic Value

ESD Capability

Human Body Model

Machine Model

Moisture Sensitivity (Note 1) MSL3

Storage Temperature

Package Thermal Resistance (Note 2)

SSOP24

Junction–to–Board, R

Junction–to–Ambient, R

Junction–to–Lead, R

1. For additional information, see or download ON Semiconductor’s Soldering and Mounting Techniques Reference Manual, SOLDERRM/D,

and Application Note AND8003/D.

2. Values represent typical still air steady−state thermal performance on 1 oz. copper FR4 PCB with 645 mm

q

JB

q

JA

q

JL

Value Unit

−0.3 to 40

40

−40 to 150 °C

260 peak °C

≥ ± 4.0 kV

≥ ± 200 V

−55 to 150°C

18°C/W

78°C/W

54°C/W

2

copper area.

V

www.onsemi.com

7

Page 8

NCV7683

Table 5. ELECTRICAL CHARACTERISTICS

(4.5 V < VP < 16 V, STOP = VP, RSTOP = 3.01 kW, RTAIL = 1.62 kW, RSEQTIME = 4.99 kW, −40°C ≤ TJ ≤ 150°C, unless otherwise specified.)

Characteristic Conditions Min Typ Max Unit

GENERAL PARAMETERS

Quiescent Current (IOUTx = 50 mA)

STOP mode

Tail mode

Fault mode

Driver Ground Pin Current (pin12) IOUT1 to IOUT8 = 50 mA − 400 500 mA

Output Under Voltage Lockout VP Rising 3.8 4.1 4.4 V

Output Under Voltage Lockout

Hysteresis

Open Load Disable Threshold 7.2 7.7 8.2 V

Open Load Disable Hysteresis − 200 − mV

THERMAL LIMIT

Thermal Shutdown

Thermal Hysteresis (Note 3) − 15 − °C

CURRENT SOURCE OUTPUTS

Output Current

Maximum Regulated Output Current 0.5V to 16V 100 − − mA

Current Matching

Line Regulation 9 V ≤ VP ≤ 16 V – 1.2 6.0 mA

Open Circuit Detection Threshold 25 mA

Current Slew Rate Iout = 44 mA, 10% to 90% points − 6 15

Overvoltage Set Back Threshold @ 99% Iout 16.0 17.2 18.4 V

Overvoltage Set Back Current VP = 20 V (Note 4) − 78 − %Iout

Diag Reporting of Set Back Current − 80 − %Iout

Output Off Leakage EN = high − − 1

FET DRIVER

Ballast Drive

DC Bias

Sink Current

Ballast Drive Reference Voltage 0.92 1.00 1.08 V

STOP / ENABLE / SEQON LOGIC

Input High Threshold

Input Low Threshold 0.70 1.00 1.44 V

VIN Hysteresis 100 250 400 mV

Input Impedance Vin = 14 V 120 200 300

3. Designed to meet these characteristics over the stated voltage and temperature recommended operating ranges, though may not be 100%

parametrically tested in production.

4. The output current degrades at a rate of 8%/V.

VP = 16 V

VP = 16 V

VP = 16 V, STOP = 0 V, OUTx = 0 mA,

Disconnected output

(Note 3) 150 175 − °C

OUTX = 0.5 V

OUTX = 1 V, R

ƪ

IOUTx(min) ) IOUTx(max)

ƪ

IOUTx(min) ) IOUTx(max)

50 mA

FB = 1.5 V, Ballast Drive = 3 V

FB = 0.5 V, Ballast Drive = 3 V

= 1.5 K

STOP

2IOUTx(min)

2IOUTx(max)

* 1ƫ 100

* 1ƫ 100

−

−

−

− 200 − mV

45

90

−4 0 4 %

25

35

−

4

0.75 1.25 1.75 V

6

5

−

50

100

50

50

1.0

13

12

12

2.0

55

110

7565% of Output

2.4

20

mA

mA

Current

mA/ms

mA

mA

kW

www.onsemi.com

8

Page 9

NCV7683

Table 5. ELECTRICAL CHARACTERISTICS

(4.5 V < VP < 16 V, STOP = VP, RSTOP = 3.01 kW, RTAIL = 1.62 kW, RSEQTIME = 4.99 kW, −40°C ≤ TJ ≤ 150°C, unless otherwise specified.)

Characteristic UnitMaxTypMinConditions

SEQ1/SEQ2/LO LOGIC

Input High Threshold

Input Low Threshold 0.70 1.00 1.44 V

VIN Hysteresis 100 250 400 mV

Input Pull−up Current SEQx = 0 V 5 10 20

CURRENT PROGRAMMING

RSTOP Bias Voltage

Stop current programming voltage 0.94 1.00 1.06 V

RSTOP K multiplier

I

OUTX/IRSTOP

RSTOP Over Current Detection RSTOP = 0 V 0.70 1.00 1.45 mA

RTAIL Bias Current Tail duty cycle programming current 290 330 370

Duty Cycle RTAIL = 0.49 V

RTAIL = 0.76 V

RTAIL = 1.66 V

SEQTIME Voltage 0.94 1.00 1.06 V

DIAG / SEQOUT OUTPUT

Output Low Voltage

DIAG Output Leakage V

Output Active, I

= 5 V − − 10

DIAG

DIAG,SEGOUT

= 1 mA – 0.1 0.40 V

Open Load Reset Voltage on DIAG 1.6 1.8 2.0 V

SEQOUT Open Load Detection

Threshold Voltage

SEQOUT Open Load Detection Sink

Current

AC CHARACTERISTICS

Stop Turn−on Delay Time

V(STOP) > 1.75 V to I(OUTx) = 90% − 14 45

Stop Turn−off Delay Time V(STOP) < 0.75 V to I(OUTx) = 10% − 14 45

PWM Frequency STOP = 0 V 400 800 1200 Hz

Open Circuit to DIAG Reporting 4.8 mA pull−up to VP, V(DIAG) >1.5 V 1 2 4

Sequence Time / R

SEQTIME

Sequence Re−Enable

Time / R

SEQTIME

SEQTIME = 1K to 10K 45.5 49 52.5 msec

SEQTIME = 1K to 10K 45.5 49 52.5 msec

VP Turn−on Time 0.55 0.80 1.2 msec

3. Designed to meet these characteristics over the stated voltage and temperature recommended operating ranges, though may not be 100%

parametrically tested in production.

4. The output current degrades at a rate of 8%/V.

0.75 1.25 1.75 V

− 150 − −

3.5

17

59.5

20

70

5

6.5

23

80.5

0.70 0.8 0.90 V

10 20 35

msec

msec

kohm

kohm

mA

mA

%

mA

mA

ms

www.onsemi.com

9

Page 10

NCV7683

TYPICAL CHARACTERISTICS

100

90

80

70

60

50

40

30

20

Iout OUTPUT CURRENT (mA)

10

T = 25°C

0

Figure 11. Iout vs. RSTOP Figure 12. Iout vs. Temperature

100

90

80

70

60

50

40

30

DUTY CYCLE (%)

20

10

0

Figure 13. Duty Cycle vs. RTAIL Figure 14. Duty Cycle vs. V(RTAIL)

53

52

51

50

49

48

Iout, OUTPUT CURRENT (mA)

4810

RSTOP (kW)

RSTOP = 3.01 kW

RTAIL (kW)

97653210

DUTY CYCLE (%)

65743210

RSTOP = 3.01 kW

47

100

90

80

70

60

50

40

30

20

10

0

40 100 160

TEMPERATURE (°C)

V(RTAIL)

1401208060200−20−40

2.52.01.51.00.50

80

70

60

50

40

30

DUTY CYCLE (%)

20

10

0

Figure 15. Duty Cycle vs. Temperature

RTAIL = 5 kW

RTAIL = 2.3 kW

RTAIL = 1.5 kW

20 120 160

TEMPERATURE (°C)

1401008060400−20−40

www.onsemi.com

10

Page 11

NCV7683

TYPICAL CHARACTERISTICS

60

50

40

30

20

, OUTPUT CURRENT (mA)

10

OUT

I

0

Figure 16. I

60

50

40

30

51.0

50.8

50.6

50.4

50.2

50.0

49.8

49.6

, OUTPUT CURRENT (mA)

49.4

OUT

I

R

= 3.01 k

STOP

19 27

VP (V) V

vs. VP Figure 17. I

OUT

252321171513119

49.2

49.0

91316

OUT

60

50

40

30

(V)

OUT

Line Regulation

1514121110876

20

, OUTPUT CURRENT (mA)

10

OUT

I

0

Figure 18. I

14

12

10

8

6

VSTRING (V)

4

2

0

Figure 20. VSTRING vs. R6

V

OUT

R6 (W)

(V)

OUT

vs. V

OUT

14121086420

per eq. 1

R7 = 1 kW

12K10K 14K8K6K4K2K0

20

, OUTPUT CURRENT (mA)

10

OUT

I

16

0

500

450

400

350

300

250

200

TIME (msec)

150

100

50

0

Figure 21. (Sequence Time / Re−Enable Time)

0.40.30.20.10

V

(V)

OUT

Figure 19. I

3810

RSEQTIME (kW)

OUT

vs. V

OUT

0.5

97654210

vs. RSEQTIME

www.onsemi.com

11

Page 12

160

140

NCV7683

TYPICAL CHARACTERISTICS

100

R(t) (°C/W)

10

120

100

qJA (°C/W)

80

60

40

20

0

COPPER HEAT SPREADER AREA (mm2)

1 oz

2 oz

600500400 7003002001000

Figure 22. qJA Copper Spreader Area

50%

20%

10%

5%

2%

1%

1

0.1

1000

100

R(t) (°C/W)

0.1

10

1

Single Pulse

0.010.001 1000.10.00010.00001 100.000001 1 1000

PULSE TIME (sec)

Figure 23. Thermal Duty Cycle Curves on 645 mm2 Spreader Test Board

100 mm

0.010.001 1000.10.00010.00001 100.000001

PULSE TIME (sec)

1 1000

Figure 24. Single Pulse Heating Curve

2

50 mm

2

2

500 mm

www.onsemi.com

12

Page 13

NCV7683

DETAILED OPERATING DESCRIPTION

General

The NCV7683 device is an eight channel LED driver

whose output currents up to 100 mA/channel are

programmed by an external resistor. The target application

for the device is in automotive Rear Combination Lighting

(RCL) systems and blinking functions.

The STOP logic input switches the two modes of the IC.

While in the STOP mode (high), the duty cycle of the outputs

is at 100%. When STOP is low, the duty cycle of the outputs

is programmed via an external resistor on the RTAIL pin.

A mixture of sequencing options is available using the

Sequencing ON, SEQ1, and SEQ2 pins. Sequencing options

include individual channels 1−8, 4 paired combinations, 2

quad combinations, and an all on delay. A logic output

(DIAG) communicates open circuit o f t he L ED d river o utputs

and SEQOUT back to the microprocessor. Both DIAG and

SEQOUT require a pull−up resistor for proper operation.

An optional external control for a ballast transistor helps

distribute the system power.

The part features an enable input logic pin.

LO (Latch Off) and DIAG

Automotive requirements sometime dictate all outputs

turn off if one of the outputs is an open circuit. This

eliminates driving with partial illuminated lights. The

module will either display all LED strings or no LED strings

at all. The option to turn all LED strings off with an open

circuit detect on any of the 8 outputs is programmed by

grounding the LO

pin. This pin should be left open if this

feature is not required.

Each output has its own sensing circuitry. An open string

detection on any output latches off all 8 outputs when

programmed (LO

= low). There are three means to reinitiate

the IC drivers.

1. Forcing the DIAG pin below the Open Circuit

Reset Voltage (1.8 V typical).

2. Toggling the ENABLE

input

3. A complete power down of the device below the

Under Voltage Lockout threshold including

hysteresis (3.9 V typical).

Open Load Detection

Open load detection has an under voltage lockout feature

to remove the possibility of turning off the device while it is

powering up. The Open Load Disable Threshold is 7.7 V

(typ). Open load detection becomes active above this

threshold. Current is monitored internal to the NCV7683

device and an open load is flagged when the current is 1/2

of the targeted output current.

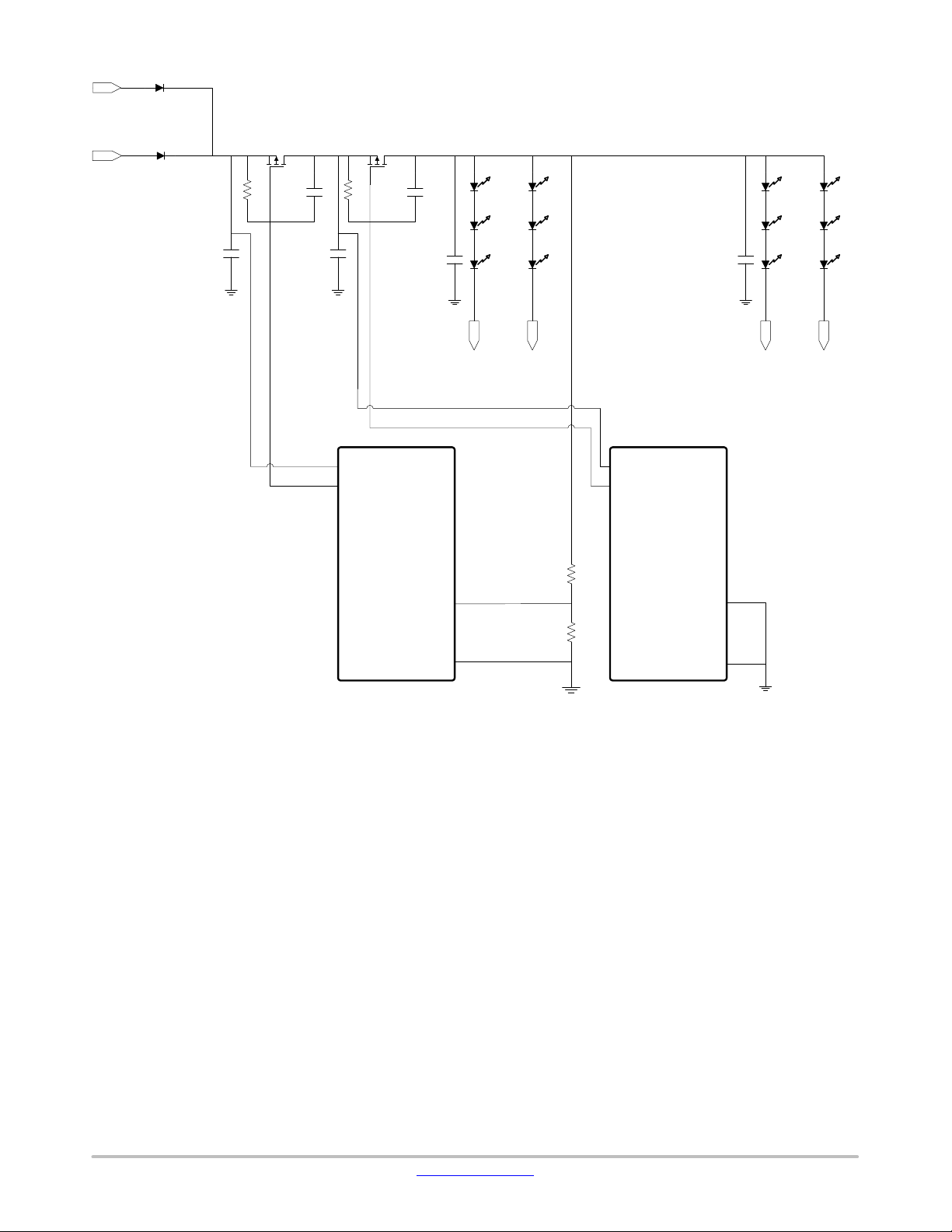

For multiple IC implementation of Open Load Detection

and preservation of the Latch Off feature, multiple ballast

transistors in series must be used as shown in Figure 25.

Interruption of any of the series devices will provide an all

off occurrence. The string voltage is set up by the feedback

in just the first device. Any subsequent devices should

connect their FB pin to ground. This will remove

competition of voltage regulation points of Vstring.

www.onsemi.com

13

Page 14

NCV7683

T

AIL

STOP

D1

MRA4003T3G

D2

MRA4003T3G

C1

0.68uF

Q1 Q2

NVD2955

R1

C2

1K

0.22uF

C3

0.68uF

VP VP

Ballast Drive

NVD2955

R2

0.22uF

1K

C4

C5

100nF

OUT1

---------

OUT8

V

STRING

D3

D4

D5 D8

OUT1-OUT8

D6 D9

D7

C6

100nF

OUT1

Ballast Drive

---------

OUT8

R3

9.53K

1 -8

D10

D11

OUT1-OUT8

D12

D13

D14

FBFB

GND

NCV7683 NCV7683

U1 U2

R4

1K

GND

Figure 25.

DIAG

The logic DIAG pins main function is to alert the

controlling microprocessor an open string has occurred on

one of the outputs (DIAG high = open string). Reference

Table1 for details on logic performance.

Open circuit conditions are reported when the outputs are

actively driven. When operating in STOP mode the DIAG

signal is a DC signal. When operating in TAIL the DIAG

signal is a PWM signal reporting open circuit when the

output drive is active.

Ballast Drive

The use of an external FET device (NTD2955) helps

distribute the system power. A DC voltage regulation system

is used which regulates the voltage at the top (anode) of the

LED strings (Vstring). This has the effect of limiting the

power in the NCV7683 by setting the voltage on the IOUTx

pins specific to each customer application. The Ballast Drive

pin provides the drive in the feedback loop from the FB pin.

In steady state, the voltage is regulated at the feedback

voltage (FB). A simple voltage divider helps set the voltage

at Vstring. Unlike other systems, the ballast drive current

does not turn off in a leakage state when turned of f (FB high),

but instead provides 1 mA of current providing a faster

response of the system loop. This sets the gate voltage of the

NTD2955 to 1 V at 25°C.

Parallel Outputs

The maximum rating per output is 100 mA. In order to

increase system level LED string current, parallel

combinations of any number of outputs is allowed.

Combining all 8 outputs will allow for a maximum system

level string current design of 800 mA.

www.onsemi.com

14

Page 15

NCV7683

Unused Outputs

Unused outputs should be shorted to ground. The

NCV7683 detects the condition during power−up using the

open load disable threshold and disables the open circuit

detection circuitry. The timing diagrams below highlight the

impacts in time with the sequencing function when an output

is not used. In this example (Figures 26 and 27), OUT7 is not

used and is grounded with SEQ1=0 and SEQ2=0. The

Sequencing_on

ENABLE

OUT1

(current)

OUT2

(current)

OUT3

(current)

OUT4

(current)

OUT5

(current)

OUT6

(current)

OUT7

(current)

OUT8

(current)

SEQOUT

Sequence

Interval

Sequence Time

*Sequence interval unaffected.

Figure 26. Unused Output time shift.

(SEQ1=0, SEQ2=0)

*

*

subsequent output (OUT8) has been pulled in (in time) as

shown by the 1st arrow. The 2nd arrow shows the SEQOUT

signal has also been pulled in (in time). For instances which

are coupled with others (in time) (e.g. SEQ1=1 and SEQ2=0

with OUT7 GND), there is no change in the ensuing

waveforms. Figure 27 shows there is no impact for channel

8 when OUT7 is not used.

Sequencing_on

ENABLE

OUT1

(current)

OUT2

(current)

OUT3

(current)

OUT4

(current)

OUT5

(current)

OUT6

(current)

OUT7

(current)

OUT8

(current)

SEQOUT

Sequence

Interval

Sequence Time

Figure 27. Unused Output No Time Shift.

(SEQ1=1, SEQ2=0)

Sequencing

Output sequencing is controlled by the SEQON,

SEQTIME, SEQ1 , and SEQ2 pins. The SEQON pin must be

high to enable any of the sequencing functions. With the

SEQON pin in a low state, all 8 outputs turn on at the same

time and SEQOUT remains high all the time (via the

external pull−up resistor). The SEQ1 and SEQ2

programming pins are utilized by grounding them or leaving

them floating. They follow Table 6 (reference timing

diagrams in Figure 7, Figure 8, Figure 9, and Figure 10). The

sequence interval is defined by the delay of the ENABLE

pin

going low to OUT2 turning on (OUT1 turns on coincident

with ENABLE

). The same sequence time interval is present

for each additional sequential turn−on output of the IC.

Forcing an ENABLE

high or SEQON low will cause a

device which is operating in the sequence mode to leave the

sequence mode. ENABLE

going from low to high

(Figure 28) will turn off all outputs. With SEQON going

high to low (Figure 29 and Figure 30), operation will

continue as a device which is not using the sequence mode

feature. A device which was previously in TAIL mode

(STOP=0) (Figure 29) will revert to TAIL mode. A device

which was previously in STOP mode (STOP=1) Figure 30

will revert to STOP mode.

Before a sequence event, SEQOUT is high impedance.

After a sequence event, SEQOUT is high impedance.

Sequence and Re−Enable Time Programming

Sequence time is programmed using a resistor from the

SEQTIME pin to ground. Figure 21 displays the expected

time using the program resistor. Acceptable values for the

resistor are between 1 K and 10 K. These provide 49 msec

and 490 msec times respectively.

The Sequence Re−Enable Time uses the same internal

timer as the Sequence Time. The Sequence Re−Enable Time

is provided to prevent an immediate feedback triggering in

a daisy chain setup. Reference Figures 33 and Figure 36 for

details.

The program resistor used can be calculated by using the

electrical parameters

1. Sequence Time / R

2. Sequence Re−Enable Time / R

SEQTIME

SEQTIME

www.onsemi.com

15

Page 16

NCV7683

Sequence Time +

Sequence_Time

R

SEQTIME

@ R

SEQTIME

Sequence ReEnable_Time +

Sequence ReEnable_Time

R

SEQTIME

@ R

SEQTIME

Table 6. SEQUENCING COMBINATIONS

SEQ1 SEQ2 Sequencing Functionality

1

1

0

0

0 = ground

1 = floating*

SEQON = 1

*Internal pull−up to the internal power supply .

STOP

1

0

1

0

Dual Output Combination

Full 8 Channel Sequencing

All On

Quad Combination

Example:

Electrical Parameter (typ)

Sequence Time / R

R

SEQTIME

= 1 kW

SEQTIME

Sequence Time = 49 * 1 = 49 msec

SEQON

ENABLE

OUTx (V)

SEQOUT

Figure 28. Sequence Interrupt from EN

STOP

= 49 msec/kW

SEQON

ENABLE

OUTx (V)

SEQOUT

Figure 29. Sequence Interrupt from SEQON

(STOP=0)

Daisy Chain

NCV7683 devices can be daisy−chained as shown in

Figure 32. Connections allow for a continuous stream of

devices including all delays attributed to the previous

sequence timing events from the previous integrated

circuits. This setup ripples the signal through all devices

until all devices are on. The example shows 3 devices, but

as many devices as desired may be used.

For retriggerable functionality such that once a signal

reaches the end of the daisy chain string, all devices turn off,

and the sequence starts again refer to Figure 33 or Figure 35.

The NCV7683 device utilizes a Sequence Re−Enable time

whereby a device turned off via the ENABLE

pin will not

turn back on until the Sequence Re−Enable time has passed.

This allows all devices to turn off for a discernible time

before reinitiating the sequence. Additional time at the end

SEQON

ENABLE

OUTx (V)

SEQOUT

Figure 30. Sequence Interrupt from SEQON

(STOP=1)

of the sequence can be achieved through the use of an

optional capacitor. If the optional capacitor does not provide

sufficient time at the end of the sequence, an NCV303

Voltage Detector can be added as shown in Figure 34.

Figure 36 shows the timing diagram associated with the

setup shown in Figure 33. As each NCV7683 device

receives a turn on signal through its ENABLE

pin, the output

turns on an LED. There is an internal delayed response for

the SEQOUT pin to go low which delays the turn−on of the

next sequential LED. An alternative setup using NFET

transistors instead of PFET transistors is shown in

Figure 35.

An open circuit detection circuit is implemented (refer to

Figure 31) on the SEQOUT pin to enable the detection of the

condition (open circuit), report the condition back to the

www.onsemi.com

16

Page 17

NCV7683

controller via the DIAG pin, and turn off all driver ICs in the

daisy chain eliminating any spurious lighting events.

+

Open Load

detection

NCV7683

−

Electronic module 1

Vol

Sequence Output

Iol

Output

Turn−on

Control

Sequence

Output

GND

IC1

SEQOUT is not active during STOP/TAIL modes

(SEQOUT=0).

VS

Input Control

NCV7683

Electronic module 2

ENABLE

R1

10K

Figure 31. Daisy Chain Interface between Multiple ICs

Table 7. APPLICATION SPECIFIC TRUTH TABLE

Input Fault State

ENB SEQON STOP LO Condition DIAG

OFF

1

TURN

0

0 1 X X BIAS ERROR 1 ACTIVE SEQUENCING

0 1 X OPEN OPEN CIRCUIT 1 ACTIVE SEQUENCING

0 1 X X TSD 1 Hi Z ALL OFF

0 1 X SHORT T O GROUND OPEN CIRCUIT 1 Hi Z ALL OFF

0 1 X X SEQOUT OPEN 1 Hi Z SEQUENCING

STOP

0

0 0 1 X BIAS ERROR 1 0 ALL ON

0 0 1 OPEN OPEN CIRCUIT 1 0 ALL ON

0 0 1 X TSD 1 0 ALL OFF

0 0 1 SHORT TO GROUND OPEN CIRCUIT 1 0 ALL OFF

TAIL

0

0 0 0 X BIAS ERROR 1 0 ALL PWM

0 0 0 OPEN OPEN CIRCUIT PWM 0 ALL PWM

0 0 0 X TSD 1 0 ALL OFF

0 0 0 SHORT TO GROUND OPEN CIRCUIT 1 0 ALL OFF

BIAS ERROR = 20% current foldback (via overvoltage on VP and/or over temperature) or RSTOP current limit.

X X X X 1 Hi Z ALL OFF

1 X X NORMAL 0 ACTIVE SEQUENCING

0 1 X NORMAL 0 0 ALL ON

0 0 X NORMAL 0 0 ALL PWM

SEQOUT

Current Sources

IC2

Status

www.onsemi.com

17

Page 18

NCV7683

VBAT

OUT OUT OUT

R7, 10k

(Turn Control)

ENABLE SEQOUT

5V

R8

10k

R1

10k

R4

10k

10K 10K

ENABLE SEQOUT ENABLE SEQOUT

NCV7683

IC1 IC2 IC3

NCV7683 NCV7683

Figure 32. Daisy Chain Sequencing

VBAT

OUT OUT OUT

R2

10k

ENABLE

SEQON SEQON

SEQOUT

NCV7683

IC1 IC2 IC3

R5

10k

ENABLE

SEQOUT

NCV7683

R3

10k

R6

10k

ENABLE

SEQON

NCV7683

SEQOUT

10K

R9

3.9k

(optional)

5V

Figure 33. Retriggerable Daisy Chain Sequencing using the Sequence Re−Enable Time

www.onsemi.com

18

Page 19

NCV7683

R7, 10k

(Turn Control)

5V

VBAT

5V

R4

10k

STOP

TAIL

TURN

VBAT

R8

10k

OUT OUT OUT

R7

10k

ENABLE

SEQON SEQON

SEQOUT

NCV7683

IC1 IC2 IC3

Figure 34. Extending the End of Sequence Time

R2

10k

R5

10k

ENABLE

NCV7683

SEQOUT

R3

10k

R6

10k

ENABLE

SEQON

NCV7683

SEQOUT

R9

10k

Reset

Input

NCV303

CD

OUT OUT OUT

R7

10k

R4

10k

R2

10k

ENABLE

SEQON SEQON

SEQOUT

NCV7683

IC1 IC2 IC3

R5

10k

ENABLE

NCV7683

SEQOUT

R3

10k

R6

10k

ENABLE

SEQON

NCV7683

SEQOUT

Figure 35. Alternate Retriggerable Daisy Chain Sequencing using Sequence Re−Enable Time

R9

10k

www.onsemi.com

19

Page 20

IC1

TURN

ENABLE1

I

out1−4

I

out5−8

NCV7683

Re−Enable Time

SEQOUT

ENABLE2

IC2

SEQOUT

ENABLE3

Sequence

Interval

I

out1−4

I

out5−8

I

out1−4

Sequence

Interval

1

2

IC3

I

out5−8

SEQOUT

3

Figure 36. Sequencing Timing Diagram with Re−Enable Time Delay

www.onsemi.com

20

Page 21

NCV7683

Programmability

Strings of LEDs are a common configuration for RCL

applications. The NCV7683 provides eight matched outputs

allowing individual string drive with current set by a single

resistor. Output currents are mirrored and matched within

±4% at hot temperature.

A high STOP condition sets the output current using

equation 1 below.

A low STOP condition, modulates the output currents at

a duty cycle (DC) programmed using equation 2 below.

Note, current limiting on RSTOP limits the current which

can be referenced from the RSTOP Pin. Exceeding the

RSTOP Current Limit will set the output current to less than

100 mA, and the DIAG Pin will go high. This helps limit

output current (brightness and power) for this type of fault.

The average ISTOP Duty Cycle current provides the

dimmed tail illumination function and assures a fixed

brightness level for tail. The PWM generator’s fixed

frequency (800 Hz typ.) oscillator allows flicker−free

illumination. PWM control is the preferred method for

dimming LEDs.

The diagnostic function allows the detection of an open in

any one of the output circuits. The active−low diagnostic

output (DIAG) i s c oincident w ith t he STOP input a nd t he O N

state in the tail mode. DIAG remains high (pulled up) if an

open load is detected in any LED string when STOP is high.

Output Current Programming

Reference Figure 11 (typ performance graph) to choose

programming resistor (RSTOP) value for stop current.

Reference Figure 13 Typical Performance Graph (Duty

Cycle vs. RTAIL) to choose a typical value programming

resistor for output duty cycle (with a typical RSTOP value

of 3.01 kW). Note the duty cycle is dependent on both

RSTOP and RTAIL values. RSTOP should always be

chosen first as the stop current is only dependent on this

value.

Alternatively, the equations below can be used to calculate

a typical value and used for worst case analysis.

Set the Stop Current using RSTOP

I

OUTX

+ 150@

RSTOP_Bias_Voltage

RSTOP

(eq. 1)

RSTOP Bias Voltage = 1 V (typ)

Set the Duty Cycle (DC) using RTAIL

RTAIL + 1.8 @ RSTOP(DC ) 0.22)

(eq. 2)

DC = duty cycle expressed in fractional form. (e.g. 0.50

is equivalent to 50% duty cycle) (ground RTAIL when using

external modulation)

Output Current is directly tested per the electrical

parameter table to be ±10% (with RSTOP = 3.01 KW) or

45 mA (min), 50 mA (typ), 55 mA (max) at room and hot

temperature.

Duty Cycle will vary according to the changes in RTAIL

Voltage and RTAIL Bias Current (generated from the current

through RSTOP).

Voltage errors encompass generator errors (0.4 V to

2.2 V) and comparator errors and are included in testing as

the Duty Cycle. Typical duty cycle measurements are 5%

with RTAIL = 0.49 V and 70% with RTAIL = 1.66 V.

RTAIL Bias Current errors are measured as RTAIL Bias

Current and vary as 290 mA (min), 330 mA (typ), and 370 mA

(max) with RSTOP = 3.01 kW.

The error duality o riginating f rom b oth t he i nternal c urrent

source generated on the RSTOP pin and the comparator

voltage thresholds of the RTAIL pin combined with the

choice of duty cycle levels make it difficult to specify duty

cycle minimum and maximum limits, but worst case

conditions can be calculated when considering the variation

in the voltage threshold and current source. Duty Cycle

variation must include the direct duty cycle as specified in

the electrical parameter table plus an additional error due to

the Irstop current which generates this voltage in the system.

RSTOP Over Current Protection

Over Current protection has been included for the RSTOP

pin. W ithout protection, the device performance could cause

excessive high current and potential damage to the external

LEDs. Detection of the RSTOP over current event (RSTOP

to ground) is 1 mA (typ) and is current limited to 2.2 mA

(typ). Output drive currents will limit to typically 65 mA.

Note – A feature of the NCV7683 device includes

operation of the device during a short circuit on the RSTOP

pin. Iout is decreased during the STOP condition and the

TAIL duty cycle is reduced to less than 40% by reducing the

voltage on the RTAIL pin to 2/3 of normal operation.

Set Back Current

Automotive battery systems have wide variations in line

supply voltage. Low dropout is a key attribute for providing

consistent LED light output at low line voltage. Unlike

adjustable regulator based constant current source schemes

where the set point resistor resides in the load path, the

NCV7683’s set point resistor lies outside the LED load path,

and aids in the low dropout capability.

Setback Current Limit is employed during high voltage.

During a Setback Current Limit event, the drive current is

reduced resulting in lower power dissipation on the IC. This

occurs during high battery voltage (VP > 16 V). In this way

the NCV7683 can operate in extreme conditions and still

provide a controlled level of light output The Setback

Current (−20%) condition is reported on the DIAG Pin.

Activation of the set back current feature provides a

roll−off rate of −8%/V.

www.onsemi.com

21

Page 22

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 1:1

2X

NOTE 4

D

A

B

TOP VIEW

SIDE VIEW

NOTE 8

D2

BOTTOM VIEW

2.72

13

24X

A1

EE1

b

M

0.12 DC

E2

NOTE 8

2X

0.20 C

24X

NOTE 5

PIN 1

REFERENCE

0.10 C

0.10

C

0.15 DC

NOTE 6

24

112

e

NOTE 6

A

M

A-B

RECOMMENDED

SOLDERING FOOTPRINT

SSOP24 NB EP

CASE 940AP

A-B0.20

C

D

H

A1

0.20 C

2X 12 TIPS

A-B

A2

SEATING

C

PLANE

M

0.15 DC

ISSUE O

L

DETAIL A

NOTE 7

h

c

END VIEW

A-B

L1

DATE 05 MAR 2015

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b DOES NOT INCLUDE DAMBAR

PROTRUSION. DAMBAR PROTRUSION SHALL

BE 0.10 MAX. AT MMC. DAMBAR CANNOT BE

L2

GAUGE

PLANE

SEATING

C

PLANE

DETAIL A

h

LOCATED ON THE LOWER RADIUS OF THE

FOOT. DIMENSION b APPLIES TO THE FLAT

SECTION OF THE LEAD BETWEEN 0.10 TO 0.25

FROM THE LEAD TIP.

4. DIMENSION D DOES NOT INCLUDE MOLD

FLASH, PROTRUSIONS OR GATE BURRS. MOLD

FLASH, PROTRUSIONS OR GATE BURRS SHALL

NOT EXCEED 0.15 PER SIDE. DIMENSION D IS

DETERMINED AT DATUM PLANE H.

5. DIMENSION E1 DOES NOT INCLUDE INTERLEAD

FLASH OR PROTRUSION. INTERLEAD FLASH

OR PROTRUSION SHALL NOT EXCEED 0.25 PER

SIDE. DIMENSION E1 IS DETERMINED AT DATUM PLANE H.

6. DATUMS A AND B ARE DETERMINED AT DATUM

PLANE H.

7. A1 IS DEFINED AS THE VERTICAL DISTANCE

FROM THE SEATING PLANE TO THE LOWEST

POINT ON THE PACKAGE BODY.

8. CONTOURS OF THE THERMAL PAD ARE UNCONTROLLED WITHIN THE REGION DEFINED

BY DIMENSIONS D2 AND E2.

M

MILLIMETERS

DIM MIN MAX

---

A 1.75

A1 0.00 0.10

A2 1.651.10

b 0.19 0.30

c 0.09 0.20

D 8.64 BSC

D2 2.37 2.67

E 6.00 BSC

E1 3.90 BSC

E2 1.79 1.99

e 0.65 BSC

h 0.25 0.50

L 0.40 0.85

L1 1.00 REF

L2 0.25 BSC

M 0 8

__

GENERIC

MARKING DIAGRAM*

XXXXXXXXXG

AWLYYWW

24X

1.15

2.19

6.40

XXXX = Specific Device Code

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

24X

0.40

1

0.65

PITCH

DIMENSIONS: MILLIMETERS

not follow the Generic Marking.

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98AON96176F

SSOP24 NB EP

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

Page 23

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor ’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...