Page 1

查询NCV7510供应商

NCV7510

FlexMOS Programmable

Peak and Hold PWM

MOSFET Predriver

The NCV7510 high side MOSFET predriver is a fully

programmable automotive grade product for driving solenoids or

other unipolar actuators. The product is optimized for common−rail

diesel fuel injection applications and includes an additional

synchronous clamp MOSFET predriver. Peak and hold currents, peak

dwell time and other features are programmable via the device’s SPI

port. Load current is continuously sampled and compared to the

programmable 7−bit peak/hold DAC values while the load

self−modulates to maintain the desired currents at each of the peak and

hold points. Passive fault diagnostics monitor and protect the

MOSFET s when a fault is detected. Fault data is available via SPI and

an open−drain FAULT output provides immediate fault notification to

a host controller.

The FlexMOS family of products offers application scalability

through choice of external MOSFETs.

Features

• 4 MHz 16−Bit SPI Communication

• 3.3 / 5.0 V Compatible Inputs

• Bootstrap for High Side MOSFET

• Synchronous Clamp Drive

• Cross Conduction Suppression

• Self−Protection

− Overcurrent and Overvoltage

− Antisaturation

• Fault Diagnostics

− Short to Battery/GND

− Open Circuit / Shorted Load

− Overvoltage

• Open−Drain FAULT Output

• Programmable

− Peak / Hold Current PWM Thresholds

− Overcurrent and Overvoltage

− Antisaturation Thresholds

− Peak Dwell Time

• NCV Prefix for Automotive and Other Applications Requiring Site

and Control Changes

Benefits

• Scalable by Choice of MOSFETs

• Reduced Load Power Consumption

• Low Host Controller Overhead

• Low Standby Current

http://onsemi.com

http://onsemi.com

MARKING DIAGRAM

20

20

1

SO−20L

DW SUFFIX

CASE 751D

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

PIN CONNECTIONS

120

ENA

CONTROL

PCLK

CSB

SCLK

SI

SO

LOOP

FAULT

OCP

ORDERING INFORMATION

Device Package Shipping

NCV7510DW SO−20L 37 Units/Rail

NCV7510DWR2 SO−20L

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specification

Brochure, BRD8011/D.

1

NCV7510

AWLYYWW

V

B

DRN

GATE

SRC

CLAMP

PGND

SNS+

SNS−

DGND

V

DD

1000 Tape & Reel

†

Semiconductor Components Industries, LLC, 2005

January, 2005 − Rev. 0

1 Publication Order Number

NCV7510/D

Page 2

NCV7510

ENA

CONTROL

FAULT

CSB

SCLK

SO

PCLK

LOOP

DRN

POROVSD

V

DD

16−BIT

SPI

SI

8−BIT

TIMER

DIAGNOSTICS

VREF

FET

DRIVE

CONTROL

FAULT

7−BIT

DAC

HYSTERETIC

MUX

CONTROL

V

DD

CLAMP

DRIVE

GATE

DRIVE

ANTISAT

DETECTION

OVER

CURRENT

SENSE

AMP

4X

CLAMP

V

B

GATE

SRC

OCP

SNS+

SNS−

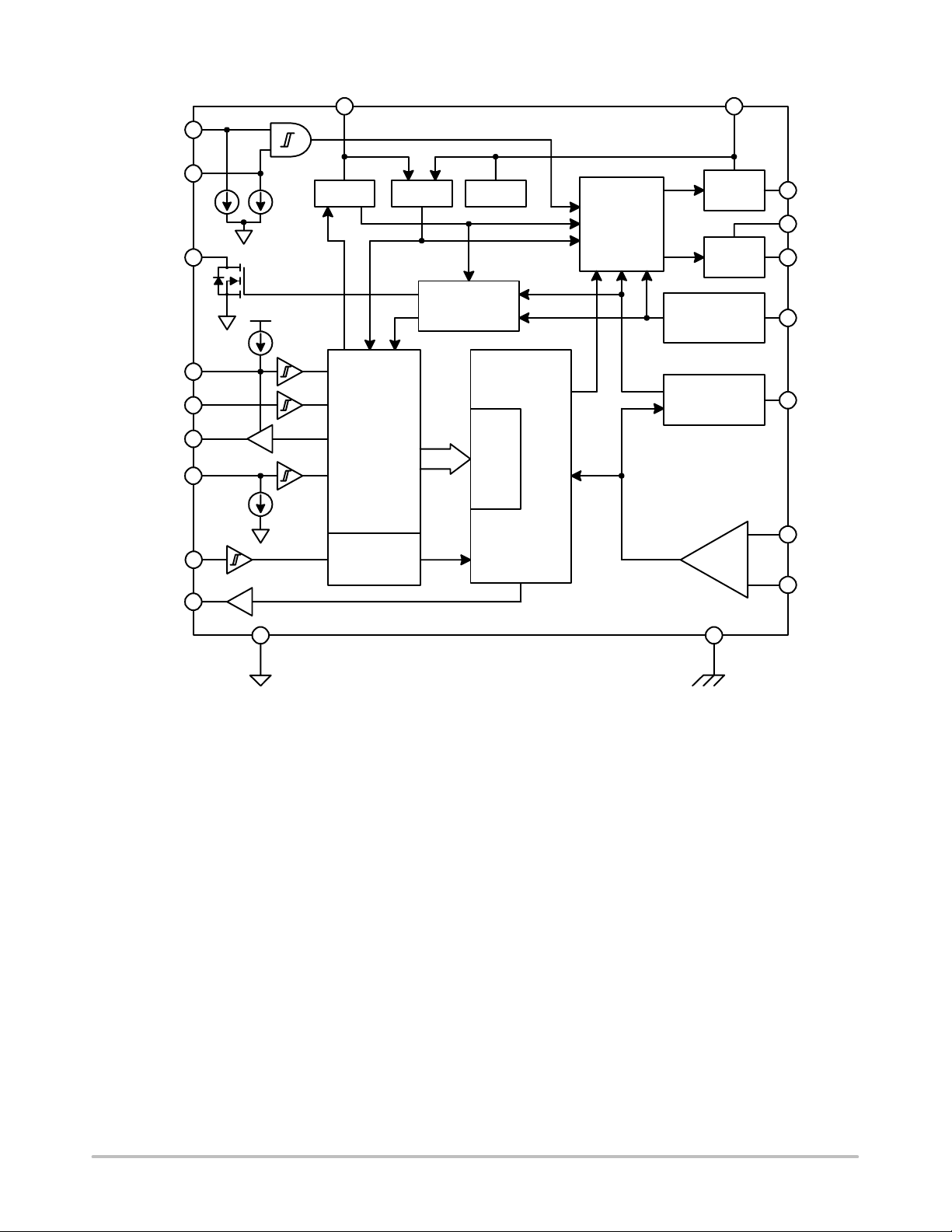

Figure 1. Block Diagram

PGNDDGND

http://onsemi.com

2

Page 3

SPI

HOST CONTROLLER

ENA

CONTROL

PCLK

CSB

SCLK

SI

SO

LOOP

FAULT

NCV7510

VB

DRN

GATE

SRC

CLAMP

PGND

NCV7510

SNS+

SNS−

DGND

BAT

D1

D2D3

RLIM

C

BOOT

M1

NTD32N06

RG

D4

+

MMBZ9V1

M2

NTD32N06

C

BULK2

RS

D5

D6

FILTER

+

C

BULK1

INJECTOR 1

INJECTOR 2

INJECTOR 3

INJECTOR 4

RSNS

NTD32N06

M6

NTD32N06

M5

NTD32N06

M4

NTD32N06

M3

OCP

VDD

RB

RA

RPU

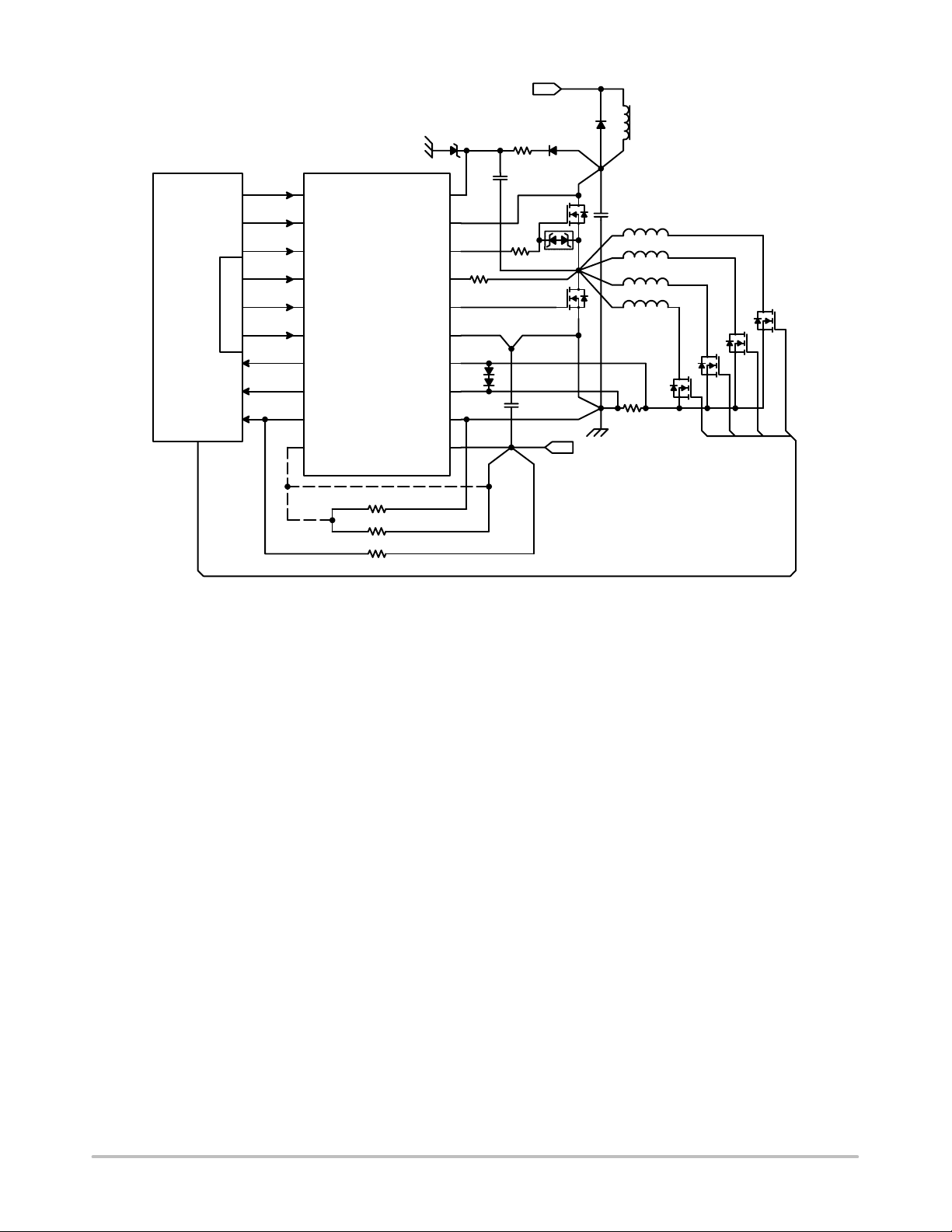

Figure 2. Application Diagram

+5V

http://onsemi.com

3

Page 4

NCV7510

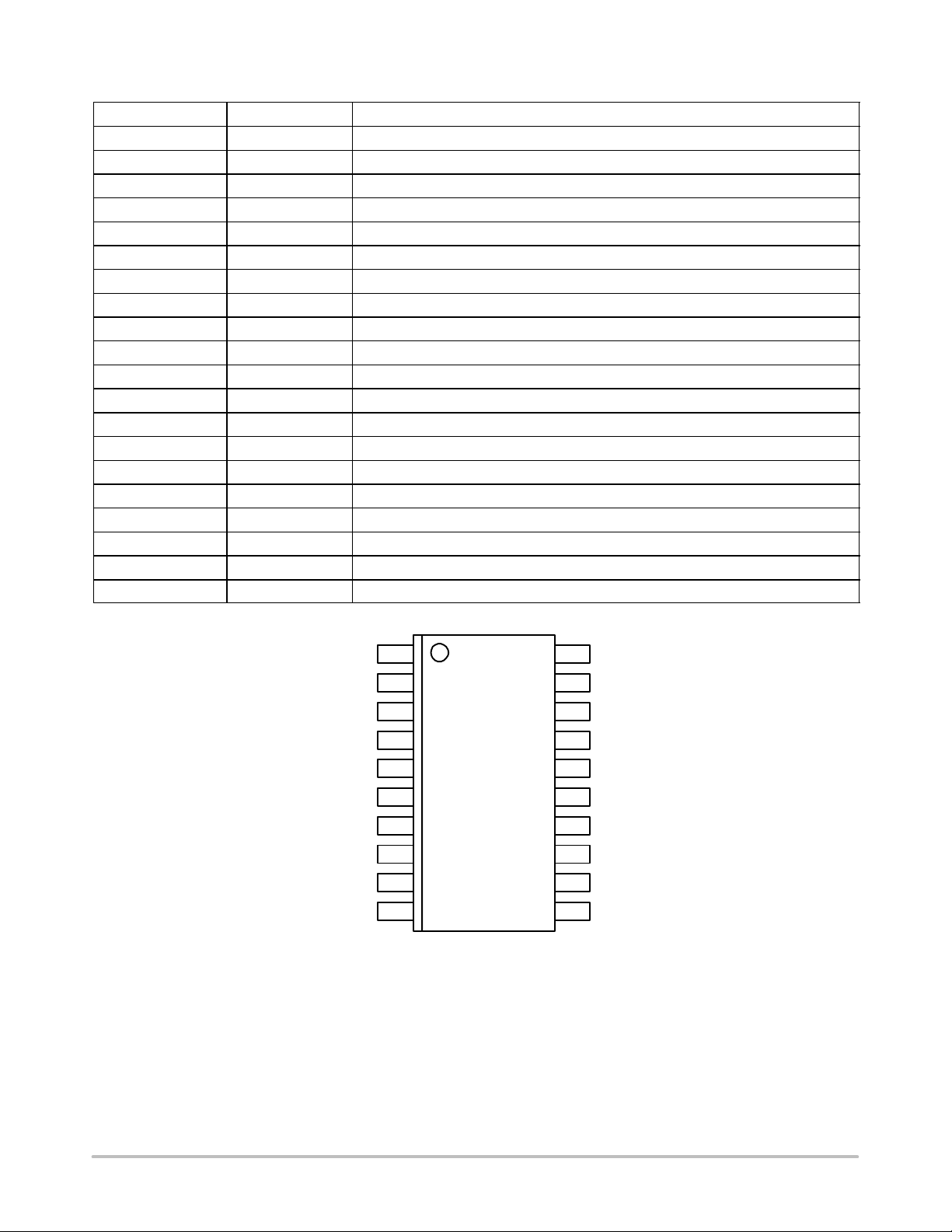

PACKAGE PIN DESCRIPTIONS

PACKAGE PIN# PIN SYMBOL FUNCTION

1 ENA Logic input for Enable.

2 CONTROL Logic input for PWM cycle control.

3 PCLK Logic input for clock or logic level control of Dwell timer.

4 CSB Logic input for active low chip select.

5 SCLK SPI clock input.

6 SI SPI serial data input.

7 SO SPI serial data output.

8 LOOP Control loop state output.

9 FAULT Open−drain fault output.

10 OCP Overcurrent program input.

11 V

12 DGND Supply return; device substrate.

13 SNS− Current sense negative input.

14 SNS+ Current sense positive input.

15 PGND High current supply return; CLAMP antisaturation reference node.

16 CLAMP Clamp MOSFET gate drive output.

17 SRC HS and CLAMP MOSFET antisaturation diagnostic input.

18 GATE HS MOSFET gate drive output.

19 DRN HS MOSFET drain antisaturation / overvoltage diagnostic input.

20 V

DD

B

Logic supply voltage input; CLAMP predriver voltage.

Bootstrapped GATE predriver voltage.

ENA

CONTROL

PCLK

CSB

SCLK

SO

LOOP

FAULT

OCP

120

V

B

DRN

GATE

SRC

CLAMP

SI

PGND

SNS+

SNS−

DGND

V

DD

http://onsemi.com

4

Page 5

NCV7510

Pin Function Descriptions

ENA: CMOS input with hysteresis logically ANDed with

the CONTROL input to command the predriver outputs.

This input has an active pulldown current source.

CONTROL: CMOS input with hysteresis logically ANDed

with the ENA input to command the predriver outputs. This

input has an active pulldown current source.

PCLK: Buffered CMOS input with hysteresis. This input

controls which DAC register pair is selected for load current

comparison. The input is programmed via Auxiliary register

($01) bit D

to respond to a clock signal (AUX D3=0 default

3

at POR) or a logic level (AUX D3=1.) The pin presents a

12 pF maximum load to the controller.

CSB: CMOS input with hysteresis. This input is the

active−low chip select input that enables serial data transfer

between the host controller and the device. This input has an

active pullup current source.

SCLK: Buffered CMOS input with hysteresis. This input

is the synchronizing clock input for serial data transfer

between the micro controller and the device. The pin

presents a 12 pF maximum load to the controller.

SI: Buffered CMOS input with hysteresis. This pin is the

data input to the device’s SPI shift register. Serial data

received at this input is transferred from the host controller

to the shift register under the control of the CSB and SCLK

inputs. The pin presents a 12 pF maximum load to the

controller. This input has an active pulldown current source.

SO: The CMOS compatible line driver at this pin is the data

output from the device’s SPI shift register. Serial data

transmitted at this output is transferred from the shift register

to the host controller under the control of the CSB and SCLK

inputs. The pin is capable of driving 200 pF at 4 MHz and

is HI−Z when the CSB input is high.

LOOP: The CMOS compatible driver at this pin reflects the

state of the control loop. A logic low indicates that load

current is less than the programmed DAC reference.

FAULT: An open−drain low voltage NMOS output at this

pin provides immediate fault indication to a connected host

controller. An external resistor is normally connected

between this pin and V

DD

.

DGND: Device substrate voltage and VDD return path for

mixed signal functions. This pin is the circuit common

reference point.

OCP: This analog comparator input supplies a reference

voltage to the device’s overcurrent fault detection. When the

voltage at this pin is less than 4.5 V, the applied voltage is the

overcurrent reference voltage. When the voltage is greater

than 4.5 V, an internal 3.0 V overcurrent reference is used.

The voltage at this pin must not exceed V

. Applying

DD

approximately VDD + 1.4 V will place the NCV7510 in test

mode and suspend normal operation. The user is advised to

avoid activating the test mode.

V

: +5.0 Vpower supply input. The voltage at this pin

DD

initiates power−on reset, supplies power to internal

mixed−signal functions and supplies gate charge to the

external CLAMP MOSFET. A low ESR external bulk

capacitor connected between VDD and PGND is

recommended to supply transient gate charge. Several

internal reference voltages are derived from V

DD

.

SNS−: The inverting input to the analog current sense

amplifier. This input should be Kelvin connected directly to

the external current sense resistor’s negative terminal.

SNS+: The noninverting input to the analog current sense

amplifier. This input should be Kelvin connected directly to

the external current sense resistor’s positive terminal.

PGND: Return path for the GATE and CLAMP predriver

transient currents and the lower input to the CLAMP

antisaturation detection comparator. This pin should be

star−connected to the CLAMP MOSFET’s source and the

external V

bulk charge capacitor’s negative terminal.

DD

CLAMP: External CLAMP MOSFET predrive output.

This output switches the CLAMP MOSFET’s gate between

V

and PGND.

DD

SRC: Lower input to the GATE antisaturation detection

comparator and upper input to the CLAMP antisaturation

detector.

GATE: External HS MOSFET predrive output. This output

switches the HS MOSFET’s gate between V

and PGND.

B

DRN: Upper input to the GATE antisaturation detection

comparator, overvoltage detection input, and powerup

interlock input. This pin should be connected directly to the

HS MOSFET’s drain terminal.

VB: Bootstrap or boost input voltage. This input supplies

gate charge to the external HS MOSFET.

http://onsemi.com

5

Page 6

NCV7510

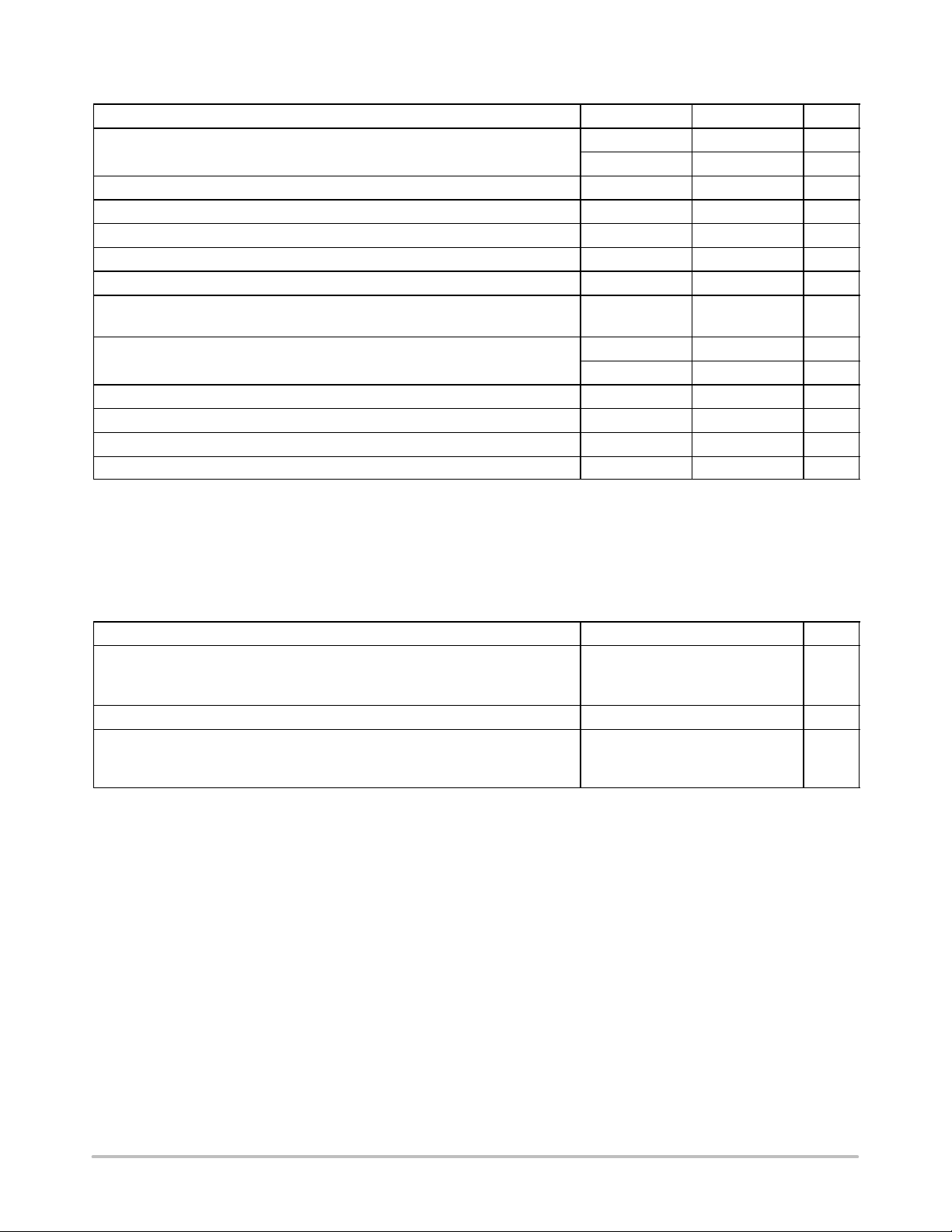

MAXIMUM RATINGS (Voltages are with respect to device substrate.)

Rating

DC Supply Voltage (Note 1)

VDRN Peak Transient Voltage (Note 2) VDRN

VB Pin Voltage V

GATE Pin Voltage V

VB to GATE Differential Voltage VB − V

SRC Pin Voltage V

Logic Level Input/Output Voltage

(SO, SI, SCLK, CSB, ENA, CONTROL, PCLK, FAULT, LOOP)

Sense Amplifier Input Voltage

Overcurrent Comparator Input Voltage V

Junction Temperature Tj 150 °C

Storage Temperature Range T

Peak Reflow Soldering Temperature: Lead−free (60 to 150 seconds at 217 °C) (Note 3) 265 peak °C

Maximum ratings are those values beyond which device damage can occur. Maximum ratings applied to the device are individual stress limit

values (not normal operating conditions) and are not valid simultaneously . If these limits are exceeded, device functional operation is not implied,

damage may occur and reliability may be affected.

1. Reverse VDRN protection must be included in the application circuit.

2. VDRN transient voltage suppression must be included in the application circuit.

3. For additional information, see or download ON Semiconductor’s Soldering and Mounting Techniques Reference Manual, SOLDERRM/D,

and Application Note AND8003/D.

Symbol Value Unit

VDRN −0.3 to 45 V

V

V

V

DD

B

GATE

SRC

V

I/O

SNS+

SNS−

OCP

stg

(PK)

GATE

−0.3 to 7.0 V

45 V

−2.0 to 50 V

−2.0 to 50 V

50 V

−2.0 to 45 V

−0.3 to 7.0 V

−0.3 to 45 V

−0.3 to 7.0 V

−0.3 to 7.0 V

−65 to 150 °C

ATTRIBUTES

Characteristic Value Unit

ESD Capability (All Pins)

Human Body Model

Charged Device Model

Moisture Sensitivity (Note 3) MSL 1

Package Thermal Resistance

Junction–to–Ambient, R

Junction–to–Case, R

JA

JC

> 3.0

> 1.0

55

9.0

kV

kV

°C/W

°C/W

http://onsemi.com

6

Page 7

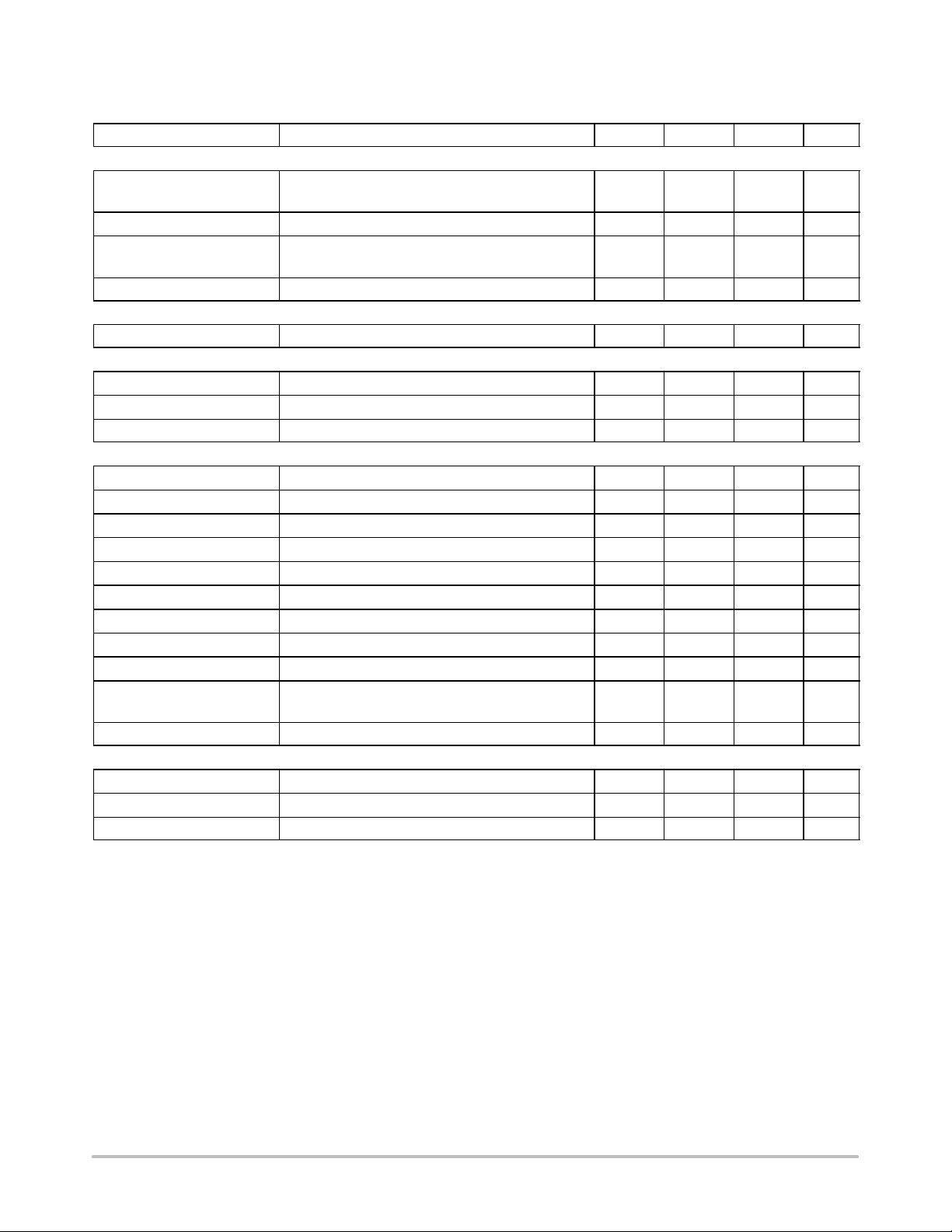

NCV7510

ELECTRICAL CHARACTERISTICS (5 V < V

)

(Note 4

< 26 V, 4.75 V < VDD < 5.25 V, −40°C < TJ < 125°C, unless otherwise specified.)

DRN

Characteristic Conditions Min Typ Max Unit

DRN Input

Input Current

= 12.8 V, VDD = 0 V

DRN

V

= 26 V, VDD =5.25 V

DRN

–

–

0.5

−

5.0

2.0

A

mA

V

Power−On Lockout Threshold VDD = 0 V, GATE predriver locked out – 0.7 1.5 V

Over−Voltage Lockout GATE predriver disabled, CLAMP predriver active

28 32 36 V

Auxiliary Register Bit 6 = 1

Over−Voltage Hysteresis 0.1 0.8 2.0 V

VB Input

Input Bias Current

V

= 24 V – 0.7 1.5 mA

B

VDD Supply

Operating Current

V

= 14 V 3.5 7.0 mA

DRN

Power−On Reset Threshold Predrivers disabled, VDD rising 3.0 3.5 4.4 V

Power−On Reset Hysteresis − 0.25 − V

Digital I/O

High ENA, CONTROL, SI, SCLK, CSB, PCLK 2.2 – – V

V

IN

VIN Low ENA, CONTROL, SI, SCLK, CSB, PCLK – – 0.8 V

VIN Hysteresis ENA, CONTROL, SI, SCLK, CSB, PCLK 0.6 1.2 V

Input Pulldown Current ENA, CONTROL, SI: V

Input Pullup Current CSB: V

SO Low Voltage I

SO High Voltage I

LOOP Low Voltage I

LOOP High Voltage I

LOOP Output Response Delay

(See Figure 3)

SINK

SOURCE

SINK

SOURCE

t

LOOP(HL)

t

LOOP(LH)

FAULT Low Voltage FAULT Active, I

= 0 V −25 – – A

IN

= 1 mA – – 0.4 V

= 1 mA V

= 0.1 mA – – 0.5 V

= 0.1 mA V

; C

LOOP

; C

LOOP

FAULT

= V

IN

DD

= 50 pF

= 50 pF

= 0.5 mA – 0.1 0.5 V

– – 25 A

− 1.0 – – V

DD

− 1.0 – – V

DD

–

–

0.5

0.5

1.2

1.2

s

s

PCLK Input

Input Capacitance

(Note 5) – – 12 pF

Clock Frequency Auxiliary Register Bit 3 = 0 (Note 5) 0 – 20 MHz

DAC Reference Select Delay Auxiliary Register Bit 3 = 1 (Note 5) – – 3.0 s

http://onsemi.com

7

Page 8

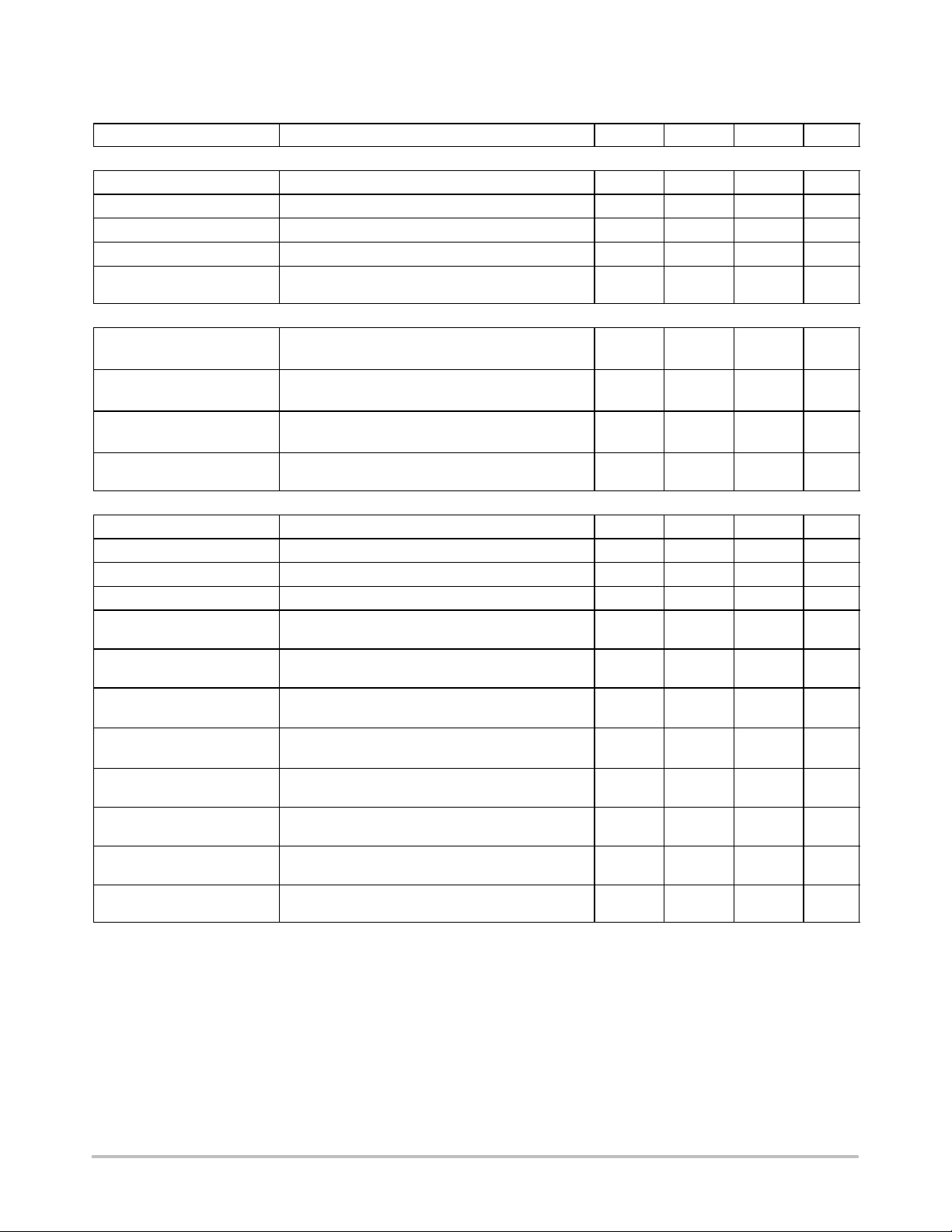

NCV7510

ELECTRICAL CHARACTERISTICS (continued) (5 V < VDRN < 26 V, 4.75 V < V

otherwise specified.) (Note 4

)

< 5.25 V, −40°C < TJ < 125°C, unless

DD

Characteristic Conditions Min Typ Max Unit

GATE and CLAMP Predrivers

GATE Output R

GATE Output R

High VB = 7.3 V, VB−V

DS(ON)

Low VB = 7.3 V, V

DS(ON)

GATE Output Delay

(See Figure 4)

GATE Response Delay

(See Figure 4)

GATE Output Low Hold Time

(See Figure 5)

GATE

t

; ENA or CONTROL High to GATE High

P(LH)

C

=2 nF

GATE

t

; ENA or CONTROL Low to GATE Low

P(HL)

C

=2 nF

GATE

t

;SNS+ Falling to GATE Rising

DLY(GR)

VDD=5.0 V, VDRN=10 V, VB=20 V,

V

Following V

SRC

t

;SNS+ Rising to GATE Falling

DLY(GF)

VDD=5.0 V, VDRN=10 V, VB=20 V,

Following V

V

SRC

VDD = 5.0 V, C

= 0.5 V – 20 50

GATE

= 0.5 V – 20 50

– 0.8 1.6 s

– 0.3 0.6 s

– 0.4 1.6 s

, V

GATE

=20% FS, C

DAC

GATE

=2 nF

– 0.4 1.6 s

, V

GATE

=2 nF 5.0 10 15 s

GATE

=80% FS, C

DAC

GATE

=2 nF

GATE Output Pulldown (HI−Z) 20 60 150 k

CLAMP Output R

CLAMP Output R

High VDD = 5.0 V, VDD−V

DS(ON)

Low VDD = 5.0 V, V

DS(ON)

CLAMP

= 0.5 V – 20 50

CLAMP

= 0.5 V – 20 50

CLAMP Output Pulldown 50 200 500 k

CLAMP Output Delay ENA or CONTROL Input Low to CLAMP Output Low;

– – 3.0 s

(Note 5)

Current Sense Amplifier

Input Bias current

Input Common Mode Range V

SNS+, SNS− = 0 V (Each Input) −5.0 − – A

(SNS+,SNS−)

=750 mV −0.3 – 1.0 V

Current Sense Conversion (VDD = 5.0 V)

D/A Resolution

Referred to SNS+, SNS− Inputs 4.70 4.92 5.20 mV

Full Scale Value Referred to SNS+, SNS− Inputs 575 625 675 mV

Differential Non−Linearity – − ±0.75 LSB

DAC Offset DAC Code = 0 −5.0 − 5.0 mV

Trip Point Accuracy DAC Code = 3210 (25% FS) –12.5 − 12.5 mV

DAC Code = 6610 (50% FS) –12.5 − 12.5 mV

DAC Code = 9510 (75% FS) –12.5 − 12.5 mV

DAC Response Delay

(See Figure 6)

t

; CSB Rising to LOOP State Change

DAC

DAC Code = 12710 (Full Scale)

C

= 2 nF (Note 5)

GATE

– − 500 ns

http://onsemi.com

8

Page 9

NCV7510

ELECTRICAL CHARACTERISTICS (continued) (5 V < VDRN < 26 V, 4.75 V < V

otherwise specified.) (Note 4

)

< 5.25 V, −40°C < TJ < 125°C, unless

DD

Characteristic Conditions Min Typ Max Unit

Overcurrent Comparator

V

Input Bias Current

= 3.0 V – 0.26 3.0 A

OCP

Linear Input Voltage Range 1.0 – 3.0 V

Mode Select Threshold VDD = 5.0 V 4.2 4.5 4.8 V

Internal Overcurrent Reference V

Detection Blanking Time

= VDD = 5.0 V 2.7 3.0 3.3 V

OCP

Time to FAULT output low 1.25 2.5 5.0 s

(See Figure 7)

Antisaturation Detect

GATE MOSFET

Auxiliary Register Bit 5 = 0, VDRN−V

Auxiliary Register Bit 5 = 1, VDRN−V

CLAMP MOSFET Auxiliary Register Bit 4 = 0, V

Auxiliary Register Bit 4 = 1, V

SRC Input Bias Current V

Detection Blanking Time

V

SRC

SRC

= 14 V, V

= 0 V, V

GATE

GATE

= 14 V

= 0 V

Time to FAULT output low; GATE or CLAMP 5.0 10 20 s

SRC

SRC

SRC−VPGND

SRC−VPGND

0.96

1.92

0.2

0.4

–

−10

1.20

2.40

0.4

0.8

0.44

–

1.44

2.88

0.6

1.2

4.0

–

V

V

V

V

A

A

(See Figure 8)

Serial Peripheral Interface (VDRN = 14 V, V

SCLK Clock Period

= 5.0 V, Cso = 200 pF) (Figure 9)

DD

250 – – ns

Maximum Input Capacitance Sl, SCLK; (Note 5) – – 12 pF

SCLK High Time f

SCLK Low Time f

Sl Setup Time Sl = 0.8 V/2.0 V to SCLK = 2.0 V

Sl Hold Time SCLK = 2.0 V to Sl = 0.8 V/2.0 V

SO Rise Time (10% VSO to 90% VDD)

SO Fall Time (90% VSO to 10% VDD)

CSB Setup Time CSB = 0.8 V to SCLK = 2.0 V

= 4.0 MHz, SCLK = 2.0 V to 2.0 V 125 – – ns

sclk

= 4.0 MHz. SCLK = 0.8 V to 0.8 V 125 – – ns

sclk

25 – – ns

f

= 4.0 MHz (Note 5)

SCLK

25 – – ns

f

= 4.0 MHz (Note 5)

SCLK

– 25 50 ns

C

= 200 pF (Note 5)

so

– – 50 ns

C

= 200 pF (Note 5)

so

60 – – ns

(Note 5)

CSB Hold Time SCLK = 0.8 V to CSB = 2.0 V

75 – – ns

(Note 5)

SO Delay Time SCLK = 0.8 V to SO Data Valid

f

= 4.0 MHz (Note 5)

SCLK

Transfer Delay Time CSB rising edge to next falling edge.

– 65 125 ns

1.0 – – s

(Note 5)

4. Designed to meet these characteristics over the stated voltage and temperature recommended operating ranges, though may not be 100%

parametrically tested in production.

5. Guaranteed by design.

http://onsemi.com

9

Page 10

NCV7510

)

TIMING WAVEFORMS

CONTROL

GATE

t

P(LH)

50%

20%

80%

t

P(HL)

V

DD

V

B

t

LOOP(HL)

50%

50%

SNS+

LOOP

Figure 3. LOOP Output Response Delay

V

DD

CONTROL

SNS+

V

t

B

HLD

GATE

V

80%

PGND

t

LOOP(LH)

HI−Z

V

DAC(FS)

V

DD

V

SNS+

GATE

CSB

LOOP 50%

DAC(FS)

(DAC CODE =

SI

FULL SCALE OR ZERO)

SNS+

t

DLY(GR)

50%

20%

Figure 4. Gate Output Delay

50%

(DAC CODE =

ZERO OR FULL SCALE)

V

DAC(FS)

V

DLY(GF)

B

V

DD

V

DD

V

DAC(FS)

V

DAC(ZERO

80%

t

t

DAC

Figure 5. Gate Output Low Hold Time

(Gate Switched by CONTROL or SNS+)

V

OCP

SNS+

FAULT

GATE &

CLAMP

(REFERENCE ONLY)

t

OCB

V

50%

DD

Figure 7. Overcurrent Detection Blanking Time

http://onsemi.com

Figure 6. DAC Response Delay

(GATE MOSFET)

(CLAMP MOSFET)

t

ASB

SRC

FAULT

GATE &

CLAMP

V

(DRN−SRC)

V

(SRC−PGND)

(REFERENCE ONLY)

Figure 8. Antisaturation Detection Blanking Time

10

V

50%

V

DRN

V

PGND

DD

Page 11

NCV7510

CSB

SCLK

SI

SO

SI

SETUP

SI

HOLD

CSB

SETUP

1

MSB IN LSB IN

MSB OUT LSB OUT

Note: Not defined but usually MSB of data just received.

BITS 14...1

SO

DELAY

BITS 14...1

Figure 9. SPI Timing

TRANSFER

DELAY

CSB

HOLD

16

SO

RISE,FALL

90% V

10% V

DD

DD

SEE

NOTE

http://onsemi.com

11

Page 12

NCV7510

BASIC OPERATING DESCRIPTION

Introduction

The NCV7510 is designed for use as a predriver for

solenoids or other inductive loads requiring a “peak and

hold” function. It contains all the necessary circuitry for

programming various attributes of the peak and hold events.

These attributes include the current levels of the peak (or

pull−in) event, the current levels of the hold event and the

dwell time of the pull−in event (See Figure 10 Waveforms).

The attribute values are written into appropriate registers in

the NCV7510 via a 16−bit SPI interface. The peak and hold

event is directly initiated and determined by the inputs to the

ENA and CONTROL pins. By applying a logic high level to

these inputs, the user has precise control over how long the

solenoid will be activated.

CONTROL

Input

Solenoid

Current

Dwell

Timer

Programmable Peak

Programmable

Pull−In Time

The dwell time base for the pull−in event is provided to the

IC’s PCLK input by the user, and may be programmed by a

register bit to either be derived from a clock signal or be level

controlled. When driven by a clock signal, the drive mode

will automatically change from the peak to the hold event

when the dwell time expires. When level controlled, the

drive mode will change according to the logic state of the

PCLK input. Bringing the ENA or CONTROL input low

before the dwell time expires will terminate the peak event

and turn off the predrivers. Figure 10 shows the general

behavior of the NCV7510.

Programmable Hold

GATE

Predrive

CLAMP

Predrive

Figure 10. Idealized Waveforms

http://onsemi.com

12

Page 13

NCV7510

BASIC OPERATING DESCRIPTION (continued)

Hysteretic Control

The NCV7510 employs hysteretic control to achieve the

programmed peak and hold currents. The IC measures the

load current via an external sense resistor (See Functional

Block Diagram on page 2 and Application Diagram on

page 3). This voltage is applied to a differential amplifier’s

SNS+ and SNS− inputs. The amplified signal is then

compared to the programmed peak and hold reference levels

generated from the 7−bit D/A converter. (Refer to Figure 1 1)

During the peak event, the load current is compared to the

programmed values in the peak high and peak low registers

for the duration of the programmed dwell time. The

hysteretic controller will switch between the programmed

peak high and peak low values at a PWM rate determined by

the load supply voltage, the load characteristics, the peak

and valley current levels, and the response times of the

NCV7510 and external MOSFETs. When the dwell time h as

been reached, the controller will select the programmed

values in the hold high and hold low registers and the load

current will then be compared to these values. The hysteretic

PWM rate for the hold event is dependent on the same

factors as the peak event.

16−Bit

SPI

Registers

5−Bit Fault

7−Bit Peak High

7−Bit Hold High

7−Bit Peak Low

7−Bit Hold Low

7−Bit Auxiliary

8−Bit Dwell

MUX

MUX

Down

Counter

When the ENA and CONTROL inputs are brought high,

the dwell timer is initialized and the MOSFET drive control

circuit selects the GATE predrive output, activating the high

side MOSFET and allowing current to increase in the load.

When the peak high current level is reached, the MOSFET

drive control circuit will turn off the GATE predrive and then

turn on the CLAMP predrive. With the high side MOSFET

turned off, current in the load will begin to decrease. When

the peak low current level is reached, the MOSFET drive

control circuit will turn off the CLAMP predrive and then

turn on the GATE predrive. The peak event may be

terminated before the end of the programmed dwell time by

bringing either the ENA or CONTROL input low.

Otherwise, the peak high/low cycle repeats for the duration

of the peak dwell time.

Once the peak dwell time has been reached, the hysteretic

MUX control circuit will switch from the peak high and peak

low registers and now use the hold high and hold low

registers. Operation in this mode is quite the same as

described above for the peak event, except that the

programmed hold currents are now used to reduce power

dissipation in the load. The complete peak and hold event is

terminated when ENA or CONTROL is brought low.

V

BAT

V

R

A

R

B

7−Bit

DAC

Peak/Hold

Comparator

Overcurrent

Comparator

C2

3V REF

Sense

Amp

OCP

Select

C3

V

DD

GATE

Predriver

CLAMPC1

A1

4.5V

V

B

DD

OCP

L

R

SNS

PCLK

÷20

Prescaler

Figure 11. Hysteretic MUX Control Block Diagram

http://onsemi.com

13

Page 14

NCV7510

DETAILED OPERATING DESCRIPTION

Power Up/Down Control

The NCV7510 powerup control prevents spurious output

operation by interlocking the V

supplies. At the system level, it is assumed that the V

and VDD power

BAT

BAT

voltage is available before the VDD voltage. The Power−On

Reset (POR) interlock circuit derives an output disable

signal from the V

voltage at the DRN input and causes

BAT

the GATE and CLAMP outputs to be kept at the PGND

potential. Application of the VDD power supply allows the

outputs to subsequently be enabled when the VDD voltage

exceeds the POR threshold. All internal registers are then

initialized to their default states, fault data is cleared and the

GA TE and CLAMP outputs are held low (external MOSFET

V

approximately 0 V.) When the VDD voltage falls below

GS

the POR threshold during power down, the GATE and

CLAMP outputs are driven and held low until V

BAT

falls

below about 1.2 volts.

SPI Communication

The NCV7510 is a 16−bit SPI slave device. Fault data is

simultaneously sent from the device’s SO pin while

command data is received at the SI pin under synchronous

control of the master’s SCLK signal. No parity or buffer

under/over run detection circuitry is employed; therefore a

valid CSB frame must contain exactly 16 SCLK cycles for

each CSB high–low–high transition.

The host initiates communication when the CSB input is

driven low. Present fault data is latched in the device’s SPI

shift register when CSB goes low. Fault data, sent MSB first

at the SO output, changes on the falling edge of SCLK and

is guaranteed valid before the next rising edge of SCLK. The

data at the SI input is received MSB first and must be valid

before the rising edge of SCLK. The 16 bits received at the

SI input before CSB is driven high will be translated as the

current command.

SPI communication between the host and the NCV7510

may either be parallel via individual CSB addressing or

daisy−chained through other devices using a compatible SPI

protocol.

Command and Register Structure

The 16−bit command data received by the NCV7510 is

decoded into 8−bit address and 8−bit data words. The upper

byte, beginning with the received MSB, is bit−wise decoded

to address one of six internal registers and the lower byte is

decoded into program data for the addressed register. A

dummy address ($00) can also be sent to retrieve fault data.

Note that the register addresses are not fully decoded.

Sending an address combining more than one address bit

will result in the same data being sent to more than one

register. Bits A

and A

7

select internal test modes and should

6

always be set to 0. Figure 12 describes the general 16−bit SPI

word format and valid register addresses. Each register is

next described in detail.

MSB LSB

A7A6A5A4A3A2A1A0D7D6D5D4D3D2D1D

ADDRESS DATA

$01 AUX

$02 HDLO

$04 HDHI

$08 PKLO

$10 PKHI

$20 DWELL

Figure 12. 16−bit SPI Word Format and Valid Register

Auxiliary Register [$01]

D7D6D5D4D3D2D1D

D7D6D5D4D3D2D1D

D7D6D5D4D3D2D1D

D7D6D5D4D3D2D1D

D7D6D5D4D3D2D1D

D7D6D5D4D3D2D1D

Addresses

0

0

0

0

0

0

0

The AUX register is used to program several diagnostic

features and the behavior of the dwell timer under control of

the PCLK input and the DWELL timer register. This

register is initialized to $00 at POR. Bit definitions are

shown for this register in Figure 13.

$01 AUX

D7D6D5D4D3D2D1D

Figure 13. AUX Register Bit Definitions

0

DWELL TIME PRE−SCALE

PCLK INPUT MODE

CLAMP ANTI−SAT THRESHOLD

GATE ANTI−SA T THRESHOLD

OVERVOLTAGE ENABLE

Bit D7 selects an internal test mode and should always be

set to 0. Bit D6 controls interruption of load current by the

overvoltage detection function. At POR, the overvoltage

interrupt function is disabled. Programming D

=1 enables

6

overvoltage interrupt and will cause the FAULT output to

respond to an overvoltage event. Overvoltage events are

reported via the SPI shift register regardless of the state of

AUX D

.

6

http://onsemi.com

14

Page 15

NCV7510

DETAILED OPERATING DESCRIPTION (continued)

Bits D5 and D4 program the respective antisaturation

detection thresholds for the GATE (high side) and CLAMP

MOSFET s. A t POR, the GATE threshold is nominally set to

1.2 V and the CLAMP to 0.4 V . Programming the respective

bits to 1 nominally sets the GATE threshold to 2.4 V and the

CLAMP to 0.8 V.

Bit D

selects the functional mode for the PCLK input. At

3

POR, D3=0 and the PCLK input is configured to accept a

clock signal as the time base for an internal programmable

dwell timer. The dwell timer determines when to change

modes from peak to hold. Setting D

=1 configures the

3

PCLK input to accept a logic−level input which then directly

controls the selection of the peak or hold mode. When D3=1,

PCLK=0 selects the peak mode and PCLK=1 selects the

hold mode.

Bits D

program the dwell timer prescaler to divide

2−D0

the incoming clock signal at the PCLK input when AUX bit

D3=0. Refer to the Dwell Timer register description for

additional programming details.

Peak/Hold DAC Registers [$10,$08,$04,$02]

The peak and hold registers program the DAC reference

pairs for the peak and hold load currents. Each 8−bit register

uses only the 7 lower bits, and bit 8 must always be set to 0.

At POR, the registers are set to $00.

The PKHI ($10) and PKLO ($08) register pair contents

are the DAC reference values used during the peak mode of

the control cycle. The HDHI ($04) and HDLO ($02) register

pair contents are the DAC reference values used during the

hold mode of the control cycle. The peak or hold mode is

determined by the state of the internal dwell timer or the

logic level at the PCLK input. Refer to the AUX register and

Dwell Timer register descriptions for additional details. The

register values for the load currents can be determined with

the following equation:

IL R

VAL

10

where IL is the desired load current, R

SNS

4.92 mV

LSBs

is the current sense

SNS

(eq. 1)

resistor, and 4.92 mV is the nominal D/A resolution. The

maximum value of load current that can be programmed for

a given R

resistor can be found by:

SNS

I

L(MAX)

625 mV

R

SNS

(eq. 2)

where 625 mV is the nominal D/A full−scale value.

Dwell Time Register [$20]

The 8−bit dwell timer register value determines when the

programmed DAC reference pairs change from the peak

mode to the hold mode. Dwell timer operation is also

dependant upon the value of AUX register bits D

3−D0

(refer

to the Auxiliary register description.) Figure 14 shows a

detailed block diagram of the dwell timer.

$01 D7D6D5D4D3D2D1D

PCLK

÷20

4−20MHz Clock

(10µS Time Base)

$20 D7D6D5D4D3D2D1D

Down Counter

Figure 14. Dwell Timer Block Diagram

3−bit

Prescale

Divider

8−bit

0

Peak

Dwell

Time

0

When AUX D3=0, the dwell timer register value is

combined with the AUX D

prescale value to generate

2−D0

a dwell time based on the clock signal applied to the PCLK

input. The timer is designed to produce dwell times from 0

to 2.55 ms with 10 s resolution for popular host controller

clock rates. Figure 15 illustrates the prescale divisor truth

table for some common clock rates.

$01 D

D6D5D

7

÷

Figure 15. AUX Register Prescale Divisors

÷

÷

÷

÷

÷

÷

÷

10

2

3

4

5

6

7

8

D3D2D1D

4

0 0 0 0

0 0 0 1

0 0 1 0

0 0 1 1

0 1 0 0

0 1 0 1

0 1 1 0

0 1 1 1

1 X X XDIRECT IN

PCLK (MHz)

0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

20.0

Logic Level

A general formula for determining dwell time based on

the clock frequency applied to the PCLK input is:

where t

(

DIV 20 N

t

DWELL

DWELL

PCLK

is the dwell time in s, DIV is the pre−scale

10

)

20

(eq. 3)

divisor, PCLK is the clock frequency in MHz, and N10 is the

content of the DWELL time register.

Fault Reporting

When a fault occurs, the open−drain FAULT flag is

latched low and fault information is latched and transferred

into the SPI shift register while CSB is high.

The host controller initiates SPI communication when

CSB goes low, and current fault information can then be

shifted out of the NCV7510’s SO output. While CSB is low,

transfer of new fault information is blocked. The FAULT

flag and fault data are cleared by the rising edge of CSB.

http://onsemi.com

15

Page 16

NCV7510

DETAILED OPERATING DESCRIPTION (continued)

Bits D4−D0 of the 16−bit SO word indicate detected faults

such that DX = 1 when a fault is detected. Figure 16 describes

the fault bit definitions. At POR, the register bits are cleared

to $00. Refer to the Fault Diagnosis description for details

regarding the NCV7510’s fault strategies and behaviors,

discussed in the next section.

SO FAULT DATA

OVERVOLTAGE

SHORT TO GND SHORT TO BATTER Y

D15− D5 = DON’T CARE; D4 − D0: 1 = FAULT, 0 = NO FAULT

Figure 16. SO Fault Bit Definitions

D4D3D2D1D

OVERCURRENT

0

OPEN LOAD

Fault Diagnosis and Protection Behavior

General

The NCV7510 continuously monitors the load supply

voltage, external MOSFETs, the load current, and the

control loop state during a control cycle for fault conditions.

Faults are managed on a cycle−by−cycle basis with regard

to the CONTROL and ENA inputs and are recoverable

(automatic fault re−try) such that the NCV7510 will attempt

to properly drive the load during the next control cycle.

Attention is focused on faults that may cause destructive

failure of the load, the external MOSFETs, or the sense

resistor.

Overcurrent faults are detectable regardless of the

CONTROL and ENA input states. Short to battery and short

to GND (antisaturation) faults are detectable when the

CONTROL and ENA inputs are high. Destructive fault

types are managed when possible to prevent failure by

latching both predriver outputs off. Fault reporting for these

types is priority encoded such that the first detected fault

locks out subsequent fault reporting bits. These faults cause

the FAULT flag to be set and latched low.

Non−destructive open load faults require no intervention

and are detectable at the end of a control cycle when

CONTROL or ENA goes low. This fault type has no priority

and is reported if no other fault has been detected, and does

not set the FAULT flag.

Overvoltage faults are detected without regard to the

CONTROL and ENA inputs. Management, reporting and

FAULT flag behavior for this fault type is dependent upon

the state of AUX register bit D

.

6

Reset of fault protection, and clearing of fault data and the

FAULT flag are independent. Protection circuitry is reset on

the rising edge of either the CONTROL or ENA inputs.

Fault data and the FAULT flag are cleared by the rising edge

of CSB. At power−on reset, all fault protection, fault data,

and the FAULT flag are cleared.

Fault detection, protection and reporting are detailed in

the following sections and are summarized in Table 1.

Overvoltage

The load supply voltage is monitored at the DRN pin for

overvoltage faults, and fault detection occurs regardless of

the states of CONTROL and ENA inputs. The interruption

of load current by the overvoltage detection circuit can be

programmed by bit D

in the AUX register. At POR, the

6

overvoltage interrupt default state is disabled (AUX D6=0).

When AUX D

=0 an overvoltage fault has no priority and

6

is reported if no other fault has been detected. The predrivers

and the FAULT flag are unaffected.

Programming AUX D6=1 enables overvoltage interrupt.

When CONTROL and ENA are high, an overvoltage fault

will cause the GATE output to be latched off, the CLAMP

output to be latched on, and the FAULT flag to be latched

low. The fault is given reporting priority and locks out

subsequent fault reporting bits. Overvoltage protection is

reset when CONTROL or ENA is brought low and then high

again.

Avalanche of the high side (HS) MOSFET may occur

when the CLAMP MOSFET is on during an overvoltage

fault (overvoltage enabled.) Avalanche of both the HS and

CLAMP MOSFETs may occur (overvoltage disabled) if the

overvoltage amplitude exceeds the combined avalanche

voltages of both MOSFETs. The devices should be carefully

chosen for proper avalanche voltage and avalanche energy

rating suitable to the application and its operating

environment.

Note that the NCV7510 requires transient overvoltage

suppression in accordance with the specifications in the

Maximum Ratings table.

Overcurrent

Load current (converted to a voltage by external sense

resistor R

) is monitored at the SNS+ and SNS−

SNS

differential inputs. A fault is detected when the amplified

differential voltage exceeds the overcurrent reference. A

nominal 2.5 s filter is used to help prevent false overcurrent

detection.

Overcurrent detection occurs regardless of the states of

the CONTROL and ENA inputs. This fault has reporting

priority and will latch the FAULT flag low. If overcurrent is

detected when CONTROL and ENA are high, both GATE

and CLAMP outputs are latched off. Overcurrent protection

is reset when the CONTROL or ENA input is brought low

and then high again.

http://onsemi.com

16

Page 17

NCV7510

DETAILED OPERATING DESCRIPTION (continued)

An overcurrent comparator input pin (OCP) is provided to

program a current limit reference value. When the voltage

at the OCP input is less than 4.5 V, the applied voltage is the

overcurrent reference voltage. When the voltage is greater

than 4.5 V, an internal 3.0 V overcurrent reference is used.

The voltage at OCP pin must not exceed V

approximately VDD + 1.4 V will place the NCV7510 in test

mode and suspend normal operation. The user is advised to

avoid activating the test mode.

The OCP reference can be programmed via an external

voltage divider placed between the V

illustrated by resistors RA and RB in the Hysteretic MUX

Block and Application diagrams. The following formulas

can be used to dimension the resistors:

V

RA R

I

OC

where 4 is the nominal sense amplifier gain and R

external load current sense resistor.

Overcurrent faults may be detected when the load is

shorted, when the SNS+ input is shorted to V

sense resistor is open, or when the peak or hold currents are

programmed higher than the overcurrent reference.

Open−circuit failure of the sense resistor may produce

voltages in excess of the NCV7510’s SNS+ input Maximum

Rating. This condition can be avoided by series connection

of a pair of diodes across the sense resistor (see Application

Diagram – D5 , D 6 ) t o p r o v i d e a p a t h f or the l o a d c urrent. The

diodes must be capable of carrying the maximum expected

load current and should be energy−rated for the application.

Open Load

To maintain the scalable flexibility of the NCV7510, the

states of the CLAMP predriver output and the ENA and

CONTROL inputs are monitored to determine an open load

condition as opposed to the detection of an absolute value of

minimum load current. It is expected that during normal

operation, a state change will occur at the CLAMP output as

a result of load current modulation between the peak high

and peak low program points while ENA and CONTROL

are high. Open load detection relies on the occurrence of a

control loop state change before the ENA or CONTROL

input goes low.

B

IOC 4 R

RA R

DD

R

B

B

and DGND pins, as

DD

SNS

V

DD

4 R

SNS

1

. Applying

DD

BAT

(eq. 4)

(eq. 5)

is the

SNS

, when the

If a control loop state change has not occurred during the

time that ENA and CONTROL were high, an open load fault

is detected. When an open load fault is detected, no

intervention is required. This fault type has no priority and

is reported if no other fault has been detected, and does not

set the FAULT flag. Open load fault data is cleared by the

rising edge of CSB.

Open load faults may be detected when the load is open,

when the sense resistor is shorted, or when the load current

is unable to reach the programmed peak or hold high current

value.

False open load faults may be indicated during engine

cranking when battery voltage can initially dip to about 5−6

volts. The programmed current may not be reached and a

state change in the control loop may not occur, thus

producing a false open load indication.

Antisaturation

Each of the high side and clamp MOSFET’s

drain−to−source voltages is separately monitored and

compared to an independently programmable saturation

detection threshold voltage. The detection thresholds are

programmed via the AUX D

the thresholds default nominally to 1.2 V for the high side

MOSFET and to 0.4 V for the clamp MOSFET. Setting

AUX D

threshold to nominally 2.4 V. Similarly, setting AUX D4=1

programs the clamp antisaturation detection threshold to

nominally 0.8 V. Each of the antisaturation detectors

employs a nominal 10 s filter to help prevent false anti−sat

fault detection.

circuitry monitors the voltage between the DRN and SRC

pins (high side) if the GATE output is on and monitors the

voltage between the SRC and PGND pins if the CLAMP

output is on.

ground fault at the SRC pin exists. Clamp saturation may be

detected when a short to battery fault at the SRC pin exists.

The GATE and CLAMP outputs are latched off and the

FAULT flag is set if either of these faults is detected.

that the first detected fault locks out subsequent fault

reporting bits. Antisaturation protection is reset when the

CONTROL or ENA input is brought low and then high

again.

=1 programs the high side antisaturation detection

5

When CONTROL and ENA are high, the antisaturation

High side saturation may be detected when a short to

Fault reporting for these types is priority encoded such

and D4 register bits. At POR,

5

http://onsemi.com

17

Page 18

NCV7510

DETAILED OPERATING DESCRIPTION (continued)

T able 1. Fault Types, Management and Reporting

Fault Type

CONTROL ENA AUX D

Overcurrent X X X OFF OFF D0 YES YES

Open Load HL 1 X OFF OFF D1 NO NO 1

Short to BAT 1 1 X OFF OFF D2 YES YES 2

Short to GND 1 1 X OFF OFF D3 YES YES 3

Overvoltage

†Output states after detection of a fault. Protection is reset on the rising edge of the CONTROL or ENA inputs.

‡ Fault data and the flag are cleared by the rising edge of the CSB input.

1. If detected, fault is reported after the falling edge of the CONTROL (or ENA) input.

2. Detection via CLAMP antisaturation.

3. Detection via GATE antisaturation.

4. When AUX D

= 0, overvoltage will be reported along with priority faults; outputs are unchanged.

6

Input States †Output States ‡Fault Data

GATE CLAMP Report Bit Priority

6

X X 0 — —

0 1 1 OFF OFF YES YES

1 1 1 OFF ON YES YES

D4

NO NO 4

‡FAULT

Flag Set

Note

http://onsemi.com

18

Page 19

NCV7510

DETAILED OPERATING DESCRIPTION (continued)

Operational Behavior

General

The NCV7510 is designed to maintain the programmed

load current at the PKHI and PKLO or at the HDHI and

HDLO reference values. While the device’s flexibility

allows all of these to be programmed to the same value, a

non−zero value is nonetheless required and the minimum

value is constrained by the NCV7510’s DC and AC

capabilities. It is also possible to reverse the order of the

PKHI|PKLO and HDHI|HDLO register values such that the

HI value is less than the LO value. While this is unlikely to

result in damage to the application, it will certainly lead to

bizarre behavior.

As previously noted, the PKHI program value may not be

reached during engine cranking when battery voltage may

initially dip to about 5−6 volts, particularly when driving

low resistance loads. This has additional implications for

both the external bootstrap circuitry (duty cycle 100%)

and open−load detection behavior, both of which are

discussed in other sections of this data sheet.

The NCV7510’s ability to maintain the programmed load

currents is constrained by the total of the NCV7510’s

inherent DC accuracy and loop response delay, the load

characteristics, and any additional delays imposed by

external compensation circuitry, whether slew−rate limiting

or other filtering designed to attenuate the egress or ingress

of radiated or conducted EMI.

Mode Control

The dwell timer selects which pair of the peak or hold

registers is setting the internal DAC and thus determines

whether the device is operating in the peak mode or the hold

mode. Bit D

of the AUX register determines whether a

3

logic level at the PCLK input directly controls the dwell time

or whether the internal dwell timer divides down an external

clock signal at the PCLK input.

When AUX D

=1, the control loop will be placed in the

3

peak mode when PCLK=0 and in the hold mode when

PCLK=1. When AUX D3=0, the control loop state will be

determined by the state of the dwell timer. The dwell time is

programmed via prescale divisor AUX register bits D

2−D0

and by the 8−bit DWELL timer register.

In the following sections, “dwell timer” means either the

state of the logic level at the PCLK input or the state of the

internal dwell timer.

Output Control

The state of the GATE and CLAMP outputs is determined

by the ENA and CONTROL inputs and by the state of the

control loop. In the absence of any faults, the state of the

control loop is determined by the contents of the peak and

hold registers, the state of the dwell timer , and the magnitude

of the load current.

The output control cycle begins when both the ENA and

CONTROL logic inputs are asserted high and ends when

either input is asserted low. At the beginning of each control

cycle the dwell timer and protection circuitry are initialized,

and the internal DAC is initialized to the PKHI register value

(if the dwell time register content is non−zero or if AUX

D

=1 and PCLK=0) or to the HDHI register value (if the

3

dwell time register content is null or if AUX D3=1 and

PCLK=1). The GATE and CLAMP output states will be

determined by the state of the control loop. At the end of

each control cycle the GATE and CLAMP outputs are driven

low, the dwell timer is reset, and open load fault data is

transferred into the SPI shift register if an open load fault

exists.

Control Loop

Load current is converted to a voltage via an external

sense resistor and compared with the programmed internal

DAC voltages. During the dwell time, the load current is

compared to the DAC voltages set by the peak high and peak

low register values. When the dwell time expires, the load

current is compared to the DAC voltages set by the hold high

and hold low register values. The state of the control loop is

reflected at the LOOP output such that a logic low indicates

that load current is less than the programmed DAC

reference.

When the load current is less than the peak or hold high

current, the GATE output is at the V

potential and the

B

CLAMP output is at PGND. When the load current is greater

than the peak or hold HI current, the DAC voltage is set to

the peak or hold LOW register value, the GATE output is

driven to PGND and the CLAMP output is driven to V

DD

When the load current is less than the peak or hold low

current, the DAC voltage is set to the peak or hold HIGH

register value, the GATE output is driven to VB and the

CLAMP output is driven to PGND.

.

http://onsemi.com

19

Page 20

NCV7510

DETAILED OPERATING DESCRIPTION (continued)

MOSFET Predrivers

The NCV7510 employs cross−conduction suppression

for the external high side and clamp MOSFETs. The

CLAMP antisaturation circuitry is used to detect the

turn−off of the high side MOSFET and the voltage at the

CLAMP pin is monitored to detect turn−off of the CLAMP

MOSFET. Figure 17 shows the simplified predriver circuits.

The high side predriver is designed to allow external

system level diagnostics to be implemented at the SRC pin.

The driver is constructed to provide a typical 20 discharge

path for 10 s at turn−off and a 60 k gate−source bleed

resistance to help prevent MOSFET turn−on from leakage

or noise. The R

resistor must be carefully chosen to ensure

G

full depletion of the high side MOSFET’ s gate char ge in less

than 10 s.

Current for the GATE predrive output is supplied from the

V

voltage developed by an external bootstrap circuit or

B

boost power supply. Current for the CLAMP predrive output

is supplied from the VDD power supply.

While the IC contains no slew rate control circuitry, slew

rate control of the high side MOSFET can be achieved by the

use of a series gate resistor (R

.) Since the body diode of the

G

CLAMP MOSFET conducts the load current immediately

after high side turn off, slew rate control of the CLAMP

MOSFET gives no benefit and the use of a series gate

resistor will interfere with cross−conduction suppression.

Bootstrap Circuit

A bootstrap circuit can be constructed using a diode,

resistor, and capacitor to generate the VB voltage necessary

to put the external high side MOSFET in full conduction

(refer to Figure 17). The circuit charges C

and R

when the SRC pin is low. The charge is then

LIM

BOOT

through D2

transferred to the high side MOSFET when M1 in the GATE

predriver is turned on, and the capacitor rides up with the

voltage at the SRC pin. The charge is continually refreshed

as a result of alternate switching of the high side and clamp

MOSFET s. A clamp diode at the V

input (see Application

B

Diagram – Diode D3) may be needed to keep the NCV7510

within its maximum ratings during overvoltage transients.

D4 ensures that the high side MOSFET’s maximum VGS is

not exceeded (refer to Figure 17).

While simple and straightforward in operation, a

bootstrap circuit depends on periodic refresh and thus

cannot run at 100% duty cycle. During engine cranking, the

PKHI program value may not be reached and a state change

in the control loop may not occur, possibly fully depleting

(and preventing recharge) of the bootstrap capacitor.

With the use of logic−level MOSFETs and careful design,

sufficient V

should be available during start up. Attention

GS

to leakage paths (such as external gate−source bleed

resistors) and the VB input bias current will help ensure that

gate charge is available when recharge does not occur.

VBAT

V

B

I

M3

VB

60 k

M4

M5

20

20

M1

20

M2

20

V

DD

200 k

C

BOOT

GATE

R

SRC

CLAMP

PGND

G

IN

10 s

Q

D2

R

LIM

M

HS

D4

L

SOL

R

SOL

M

CL

R

SNS

Figure 17. Simplified GATE and CLAMP Predrivers

http://onsemi.com

20

Page 21

NCV7510

PACKAGE DIMENSIONS

SO−20L

DW SUFFIX

CASE 751D−05

ISSUE G

H10X

M

B

M

0.25

D

20

1

B20X

M

SAS

T

0.25

18X

e

A

11

E

10

h X 45

B

B

A

SEATING

PLANE

A1

T

NOTES:

1. DIMENSIONS ARE IN MILLIMETERS.

2. INTERPRET DIMENSIONS AND TOLERANCES

PER ASME Y14.5M, 1994.

3. DIMENSIONS D AND E DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE PROTRUSION

SHALL BE 0.13 TOTAL IN EXCESS OF B

DIMENSION AT MAXIMUM MATERIAL

CONDITION.

MILLIMETERS

DIM MIN MAX

A 2.35 2.65

A1 0.10 0.25

B 0.35 0.49

C 0.23 0.32

D 12.65 12.95

E 7.40 7.60

e 1.27 BSC

L

C

H 10.05 10.55

h 0.25 0.75

L 0.50 0.90

0 7

http://onsemi.com

21

Page 22

NCV7510

FlexMOS is a trademark of Semiconductor Components Industries, LLC.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 61312, Phoenix, Arizona 85082−1312 USA

Phone: 480−829−7710 or 800−344−3860 Toll Free USA/Canada

Fax: 480−829−7709 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Japan: ON Semiconductor, Japan Customer Focus Center

2−9−1 Kamimeguro, Meguro−ku, Tokyo, Japan 153−0051

Phone: 81−3−5773−3850

http://onsemi.com

22

ON Semiconductor Website: http://onsemi.com

Order Literature: http://www.onsemi.com/litorder

For additional information, please contact your

local Sales Representative.

NCV7510/D

Loading...

Loading...