查询NCV7380供应商

NCV7380

Advance Information

LIN Transceiver

The NCV7380 is a physical layer device for a single wire data link

capable of operating in applications where high data rate is not

required and a lower data rate can achieve cost reductions in both the

physical media components and in the microprocessor which uses

the network. The NCV7380 is designed to work in systems

developed for LIN 1.3 or LIN 2.0. The IC furthermore can be used in

ISO9141 systems.

Because of the very low current consumption of the NCV7380 in

recessive state, it’s suitable for ECU applications with low standby

current requirements, whereby no sleep/wake−up control from the

microprocessor is necessary.

Features

• Operating Voltage V

• Low Current Consumption of Typ. 24 A

• LIN−Bus Transceiver:

♦ Slew Rate Control for Good EMC Behavior

♦ Fully Integrated Receiver Filter

♦ BUS Input Voltage −27 V to 40 V

♦ Integrated Termination Resistor for LIN Slave Nodes (30 k)

♦ Baud Rate up to 20 kBaud

♦ Will Work in Systems Designed for either LIN 1.3 or LIN 2.0

• Compatible to ISO9141 Functions

• High EMI Immunity

• Bus Terminals Protect Against Short−Circuits and Transients in the

Automotive Environment

• Bus Pin High Impedance During Loss of Ground and Undervoltage

Conditions

• Thermal Overload Protection

• High Signal Symmetry for use in RC–Based Slave Nodes up to 2%

Clock Tolerance when Compared to the Master Node

• 4.0 kV ESD Protection on all Pins

• NCV Prefix for Automotive and Other Applications Requiring Site

and Change Control

= 6.0 to 18 V

S

http://onsemi.com

MARKING

DIAGRAM

8

8

1

RxD

NC

VCC

TxD

ORDERING INFORMATION

Device Package Shipping†

NCV7380D SO−8 95 Units/Rail

NCV7380DR2 SO−8 2500 Tape & Reel

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

SO−8

D SUFFIX

CASE 751

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

PIN CONNECTIONS

18

2

3

4

(Top View)

V7380

ALYW

1

NC

7

VS

BUS

6

GND

5

This document contains information on a new product. Specifications and information

herein are subject to change without notice.

Semiconductor Components Industries, LLC, 2004

May, 2004 − Rev. P3

1 Publication Order Number:

NCV7380/D

NCV7380

NCV7380

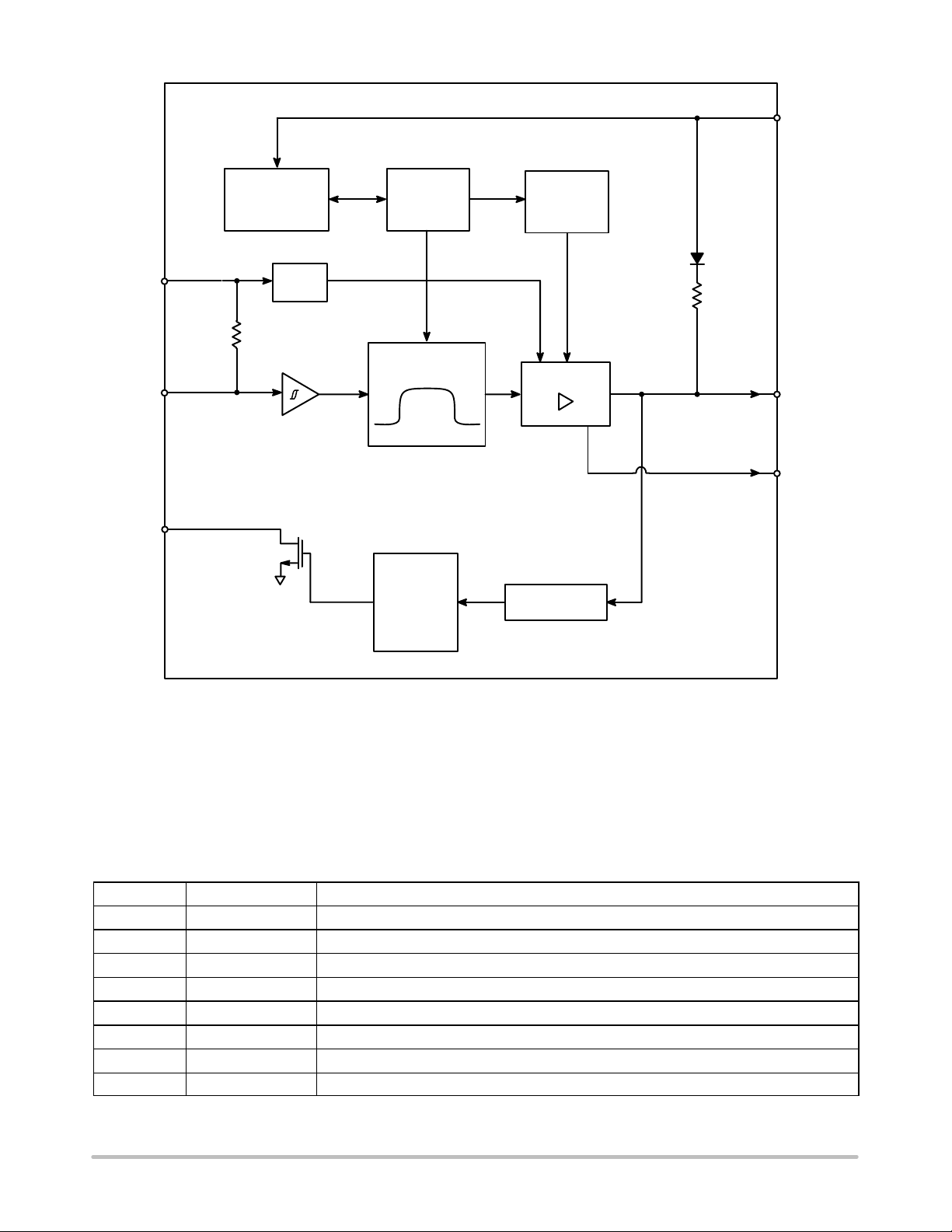

VS

VCC

TxD

RxD

Internal Supply

and

References

POR

15 K

Biasing &

Bandgap

SLEW RATE

CONTROL

Receive

Comparator

Thermal

Shutdown

30 K

BUS Driver

BUS

GND

Input

Filter

Figure 1. Block Diagram

P ACKAGE PIN DESCRIPTION

Pin Symbol Description

1 RXD Receive data from BUS to microprocessor, LOW in dominant state.

2 NC No connection.

3 VCC 5.0 V supply input.

4 TXD Transmit data from microprocessor to BUS, LOW in dominant state.

5 GND Ground

6 BUS LIN bus pin, LOW in dominant state.

7 VS Battery input voltage.

8 NC No connection.

http://onsemi.com

2

NCV7380

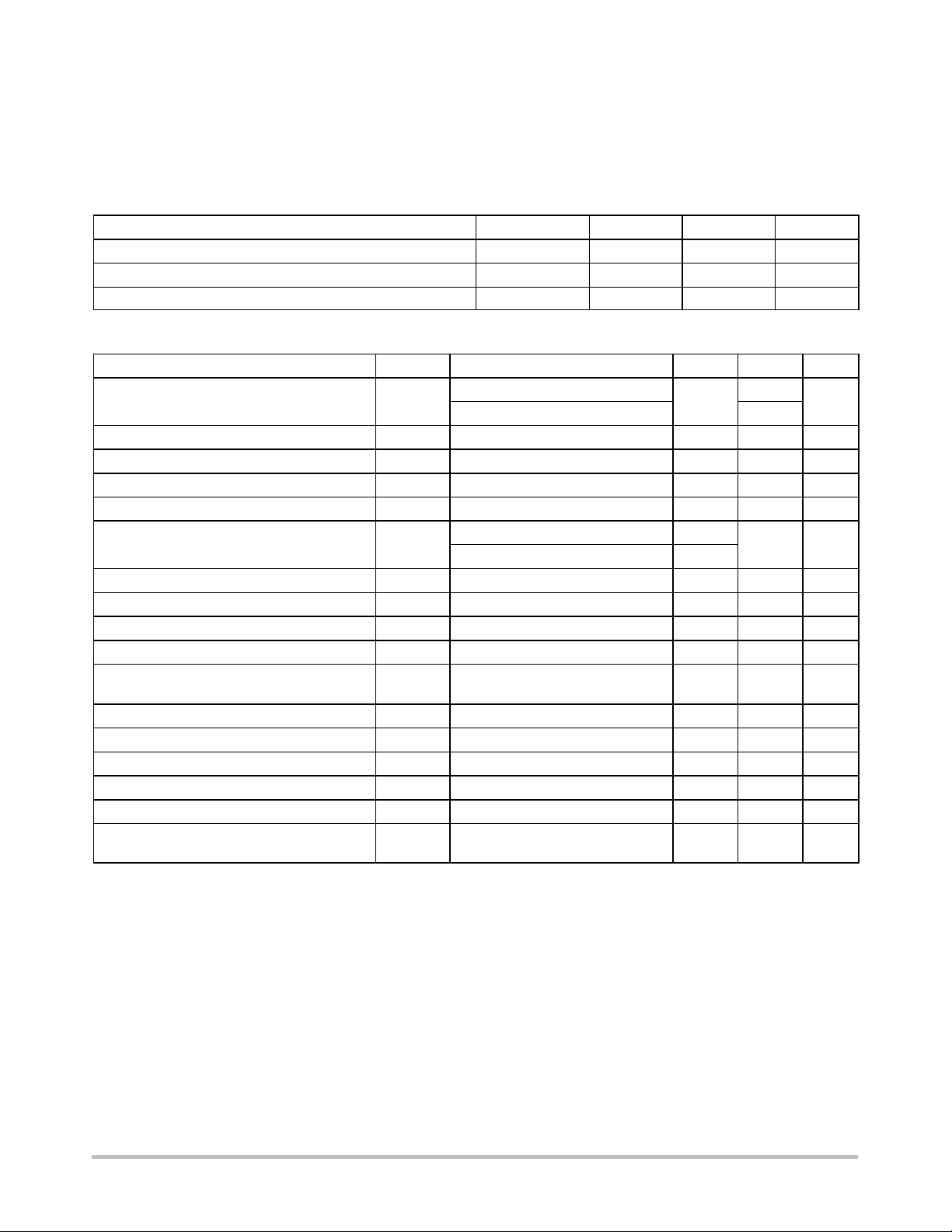

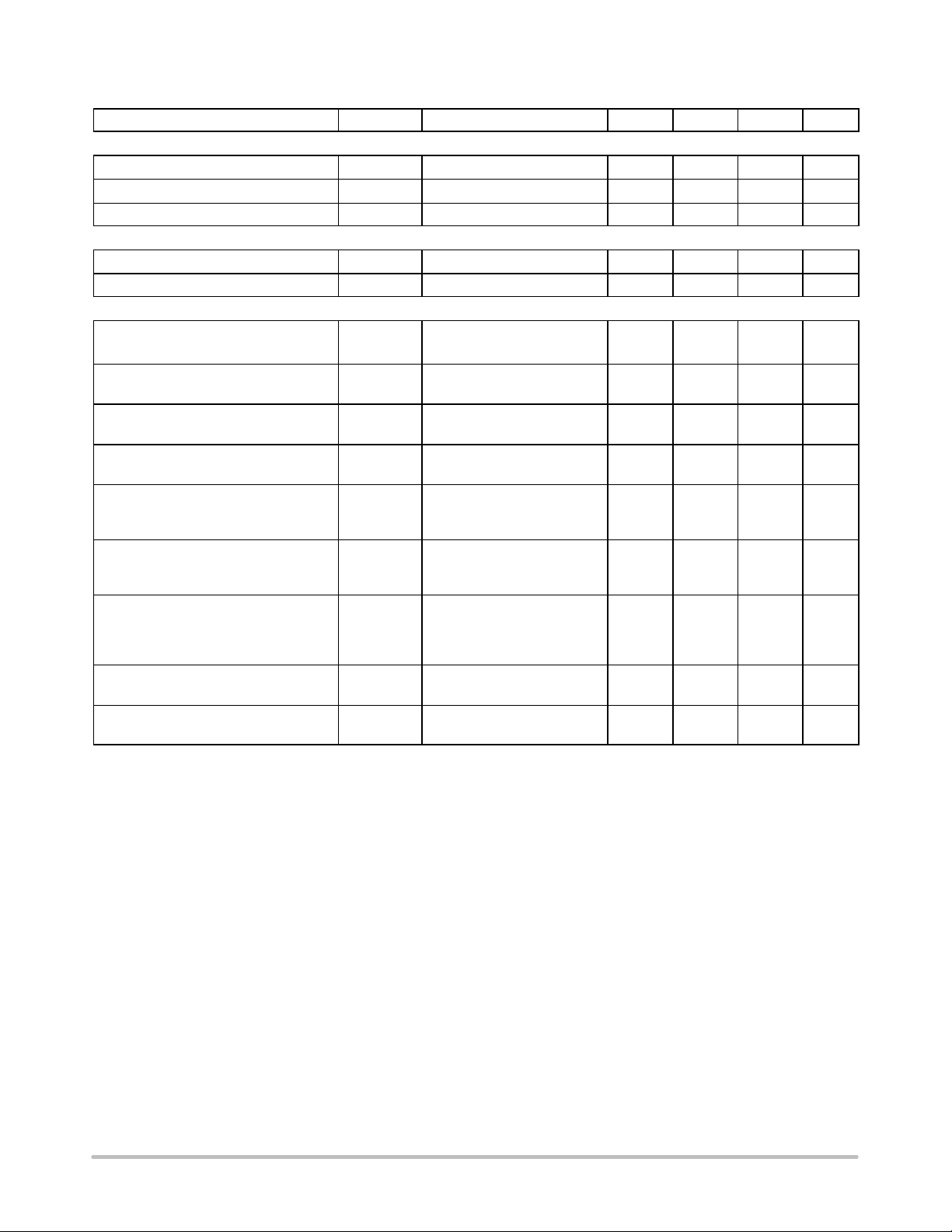

Electrical Specification

All voltages are referenced to ground (GND). Positive

currents flow into the IC.

The maximum ratings given in the table below are

limiting values that do not lead to a permanent damage of

OPERATING CONDITIONS

Characteristic Symbol Min Max Unit

Battery Supply Voltage (Note 1) V

Supply Voltage V

Operating Ambient Temperature T

MAXIMUM RATINGS

Rating Symbol Condition Min Max Unit

Battery Supply Voltage V

Supply Voltage V

Transient Supply Voltage V

Transient Supply Voltage V

Transient Supply Voltage V

BUS Voltage V

Transient Bus Voltage V

Transient Bus Voltage V

Transient Bus Voltage V

DC Voltage on Pins TxD, RxD V

ESD Capability of Any Pin V

Maximum Latch−Up Free Current at Any Pin I

Maximum Power Dissipation P

Thermal Impedance

Storage Temperature T

Junction Temperature T

Lead Temperature Soldering

Reflow: (SMD styles only)

1. VS is the IC supply voltage including voltage drop of reverse battery protection diode, V

18 V .

2. ISO 7637 test pulses are applied to VS via a reverse polarity diode and > 2.0 F blocking capacitor.

3. ISO 7637 test pulses are applied to BUS via a coupling capacitance of 1.0 nF.

S

CC

S.tr1

S..tr2

S..tr3

BUS

BUS..tr1

BUS.tr2

BUS.tr3

DC

ESDHB

LATCH

tot

JA

stg

J

T

sld

the device but exceeding any of these limits may do so.

Long term exposure to limiting values may effect the

reliability of the device.

S

CC

A

t < 1 min

Load Dump, t < 500 ms

− −0.3 +7.0 V

ISO 7637/1 Pulse 1 (Note 2) −150 − V

ISO 7637/1 Pulses 2 (Note 2) − 100 V

ISO 7637/1 Pulses 3A, 3B −150 150 V

t < 500 ms , Vs = 18 V −27

t < 500 ms ,Vs = 0 V −40

ISO 7637/1 Pulse 1 (Note 3) −150 − V

ISO 7637/1 Pulses 2 (Note 3) − 100 V

ISO 7637/1 Pulses 3A, 3B (Note 3) −150 150 V

− −0.3 7.0 V

Human body model, equivalent to

discharge 100 pF with 1.5 k

− −500 500 mA

At TA = 125°C − 197 mW

In Free Air − 152 °C/W

− −55 +150 °C

− −40 +150 °C

60 second maximum above 183°C

−5°C/+0°C allowable conditions

DROP

6.0 18 V

4.5 5.5 V

−40 +125 °C

= 0.4 to 1.0 V , V

−0.3

40

40

−4.0 4.0 kV

− 240 peak °C

voltage range is 7.0 to

BAT_ECU

30 V

V

http://onsemi.com

3

NCV7380

ELECTRICAL CHARACTERISTICS (V

= 6.0 to 18 V , V

S

= 4.5 to 5.5 V and T

CC

= −40 to 125°C unless otherwise noted.)

A

Characteristic Symbol Condition Min Typ Max Unit

GENERAL

V

Undervoltage Lockout V

CC

Supply Current, Dominant I

Supply Current, Dominant I

Supply Current, Recessive I

Supply Current, Recessive I

Supply Current, Recessive I

Sr +

CC_UV

Sd

CCd

Sr

CCr

I

CCr

VS > 6.0 V, TxD = L, EN = H 2.75 − 4.3 V

VS = 18 V , VCC = 5.5 V , TxD = L − 1.0 3.0 mA

VS = 18 V , VCC = 5.5 V , TxD = L − 0.8 1.5 mA

VS = 18 V , VCC = 5.5 V , TxD = Open − 10 20 A

V

= 18 V , VCC = 5.5 V , TxD = Open − 14 30 A

S

V

= 12 V , VCC = 5.0 V , TxD = Open,

S

T

= 25°

A

− 24 − A

Thermal Shutdown Tsd (Note 4) − 155 − 180 °C

Thermal Recovery T

(Note 4) − 126 140 150 °C

hys

BUS − Transmit

Short Circuit Bus Current I

BUS_LIM

V

= VS, Driver On − 120 200 mA

BUS

(Notes 5 and 6)

Pull Up Current Bus I

BUS_PU

V

BUS

= 0, V

= 12 V, Driver Off −600 − −200 A

S

(Notes 5 and 6)

Bus Reverse Current,

Recessive

Bus Reverse Current Loss of

Battery

Bus Current During Loss of

Ground

Transmitter Dominant V oltage V

Transmitter Dominant V oltage V

I

BUS_PAS_rec

(Notes 5 and 6)

I

BUS_LOG

(Notes 5 and 6)

I

BUS_LOG

(Notes 5 and 6)

BUSdom_DRV_1

BUSdom_DRV_2

V

> VS, 6.0 V < V

BUS

Driver Off

V

= 0 V , 0 V < V

S

V

= 12 V , 0 < V

S

BUS

Load = 40 mA − − 1.2 V

V

= 6.0 V , Load = 500 − − 1.2 V

S

< 18 V ,

BUS

< 18 V − − 5.0 A

BUS

< 18 V −1.0 − 1.0 mA

− − 5.0 A

(Note 5)

Transmitter Dominant V oltage V

BUSdom_DRV_3

V

= 18 V , Load = 500 − − 2.0 V

S

(Note 5)

Bus Input Capacitance C

(Note 4) Pulse Response via 10 k

BUS

V

= 12 V , VS = Open

PULSE

− 25 35 pF

BUS − Receive

Receiver Dominant Voltage V

ilBUS

− 0.4 *V

S

− − V

(Notes 5 and 6)

Receiver Recessive Voltage V

ihBUS

− − − 0.6 *V

S

(Notes 5 and 6)

Center Point of Receiver

Threshold

(Notes 5 and 6)

Receiver Hysteresis V

V

BUS_CNT

iBUS_HYS

V

BUS_CNT

V

BUS_CNTt

= (V

= (V

ilBUS

ihBUS

and V

− V

)/2 0.487

ihBUS

) − 0.16 *V

ilBUS

*V

S

0.5 *V

0.512

S

*V

S

− V

S

(Notes 5 and 6)

4. No production test, guaranteed by design and qualification.

5. In accordance to LIN physical layer specification 1.3.

6. In accordance to LIN physical layer specification 2.0.

V

V

http://onsemi.com

4

NCV7380

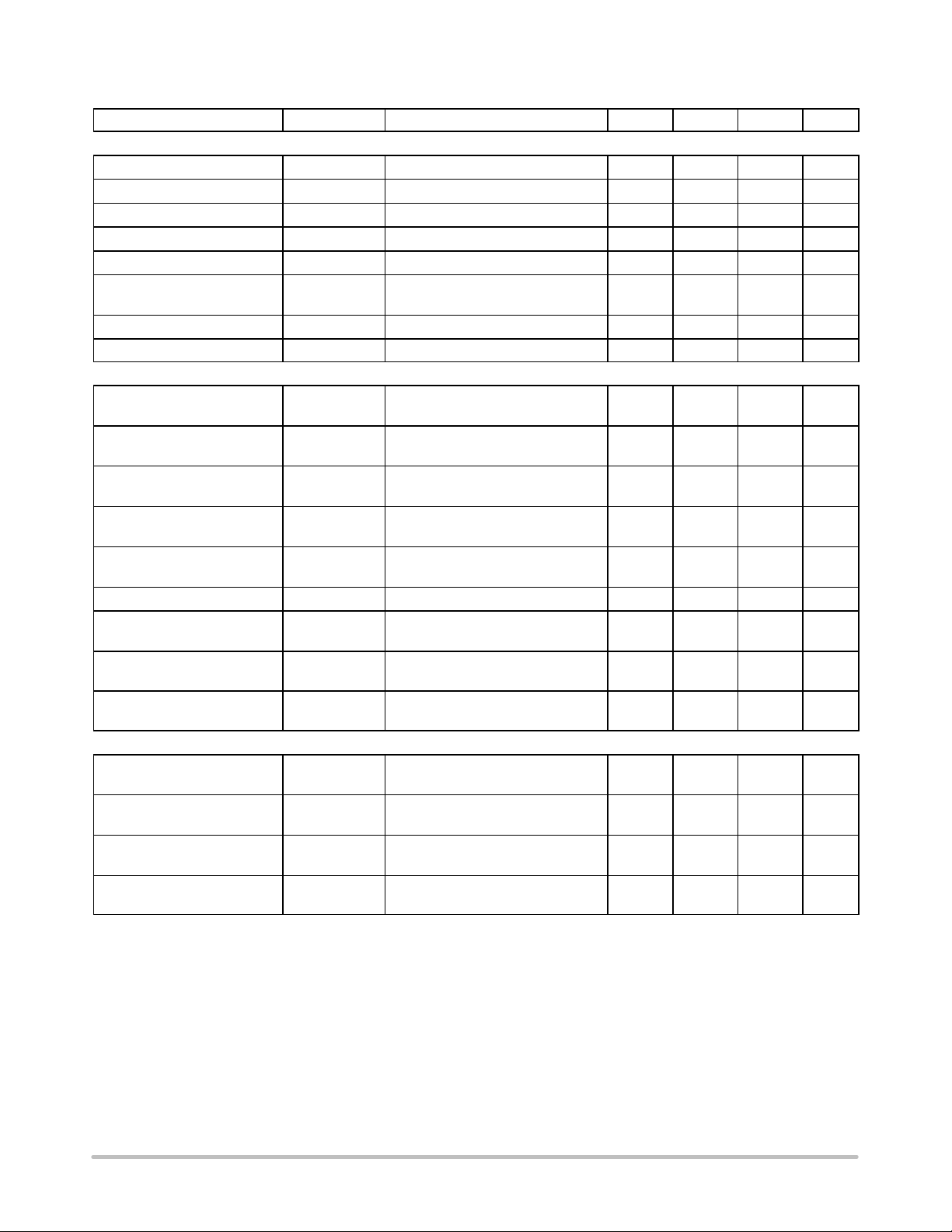

ELECTRICAL CHARACTERISTICS (continued) (V

= 6.0 to 18 V, V

S

= 4.5 to 5.5 V and T

CC

= −40 to 125°C unless otherwise noted.)

A

Characteristic Symbol Condition Min Typ Max Unit

TXD

High Level Input Voltage V

Low Level Input Voltage V

TxD Pull Up Resistor R

IH_TXD

ih

il

Rising Edge − − 0.7*V

Falling Edge 0.3*V

V

= 0 V 10 15 20 k

TxD

CC

− − V

CC

RXD

Low Level Output Voltage V

Leakage Current V

ol_rxd

leak_rxd

I

= 2.0 mA − − 0.9 V

RxD

V

= 5.5 V, Recessive −1.0 − 1.0 A

RxD

AC CHARACTERISTICS

Propagation Delay Transmitter

(Notes 9 and 11)

Propagation Delay Transmitter Symmetry

t

trans_pdf

t

trans_pdr

t

trans_sym

Bus Loads: 1.0 K/1.0 nF,

660 /6.8 nF, 500 /10 nF

Calculate t

trans_pdf

− t

trans_pdr

− − 5.0 s

−2.0 − 2.0 s

(Notes 7 and 11)

Propagation Delay Receiver

(Notes 7, 8, 9, 1 1 and 14)

Propagation Delay Receiver Symmetry

t

rec_pdf

t

rec_pdr

t

rec_sym

C

= 20 pF − − 6.0 s

RxD

Calculate t

trans_pdf

− t

trans_pdr

−1.5 − 1.5 s

(Notes 7 and 8)

Slew Rate Rising and Falling Edge,

High Battery (Notes 7 and 12)

t

SR_HB

Bus Loads: VS = 18 V ,

1.0 K/1.0 nF, 660 /6.8 nF,

1.0 2.0 3.0 V/s

500 /10 nF

Slew Rate Rising and Falling Edge,

Low Battery (Notes 7 and 12)

t

SR_LB

Bus Loads: VS = 7.0 V ,

1.0 K/1.0 nF, 660 /6.8 nF,

0.5 2.0 3.0 V/s

500 /10 nF

Slope Symmetry, High Battery

(Notes 7 and 12)

t

ssym_HB

Bus Loads: VS = 18 V ,

1.0 K/1.0 nF, 660 /6.8 nF,

−5.0 − 5.0 s

500 /10 nF, Calculate

t

sdom−tsrec

Bus Duty Cycle (Notes 8 and 15) D1

D2

Receiver Debounce Time

t

rec_deb

Calculate t

Calculate t

BUS_rec(min)

BUS_rec(max)

/100 s

/100 s

0.396

−

−

−

−

0.581

BUS Rising and Falling Edge 1.5 − 4.0 s

(Notes 10, 13 and 14)

7. In accordance to LIN physical layer specification 1.3.

8. In accordance to LIN physical layer specification 2.0.

9. Propagation delays are not relevant for LIN protocol transmission, only symmetry.

10.No production test, guaranteed by design and qualification.

11.See Figure 2 − Input/Output Timing.

12.See Figure 7 − Slope Time Calculation.

13.See Figure 3 − Receiver Debouncing.

14.This parameter is tested by applying a square wave to the bus. The minimum slew rate for the bus rising and falling edges is 50 V/s.

15.See Figure 8 − Duty Cycle Measurement and Calculation.

V

s/s

s/s

http://onsemi.com

5

NCV7380

TIMING DIAGRAMS

TxD

BUS

RxD

50%

t

trans_pdf

V

BUS

95%

100%

50%

t

trans_pdr

50%

5%

0%

t

rec_pdf

t

rec_pdr

50%

Figure 2. Input/Output Timing

t < t

rec_deb

t < t

rec_deb

V

BUS

60%

40%

t

V

RxD

50%

t

Figure 3. Receiver Debouncing Filter

http://onsemi.com

6

NCV7380

TEST CIRCUITS FOR DYNAMIC AND STATIC CHARACTERISTICS

NCV7380

VSUP

R

C

100 nF

L

BUS

L

GND

VCC

TxD

RxD

Figure 4. Test Circuit for Dynamic Characteristics

NCV7380

500

2 F

VSUP

+

VCC

100 nF

2.7 K

20 pF

100 nF

BUS

1 nF

GND

Schaffner−

Generator

Puls3a,3b

Puls1,2,4

TxD

RxD

Figure 5. Test Circuit for Automotive Transients

12 V

Oscilloscope

+

−

http://onsemi.com

7

NCV7380

Functional Description

Initialization

After power on, the chip automatically enters the

recessive state (TxD = Open). Both VCC and VS must be

present.

Operating Modes

All operation modes will be handled from the NCV7380

automatically.

Normal Mode

After power on, the IC switches automatically to normal

mode. Bus communication is possible. If there is no

communication on the bus line the power consumption of

the IC is very low and does not require microprocessor

control.

Thermal Shutdown Mode

If the junction temperature TJ is higher than 155°C, the

NCV7380 could be switched into the thermal shutdown

mode (bus driver will be switched off, receiver is on).

If TJ falls below the thermal shutdown temperature (typ.

140°C) the NCV7380 will be switched to the normal mode.

LIN BUS Transceiver

The transceiver consists of a bus−driver (1.2 V @

40 mA) with slew rate control and current limit, and a

receiver with a high voltage comparator with filter

circuitry.

BUS Input/Output

The recessive BUS level is generated from the integrated

30 k pull up resistor in series with a diode. The diode

prevents reverse current on V

BUS

when V

BUS

> V

.

S

No additional termination resistor is necessary to use the

NCV7380 on LIN slave nodes. If this IC is used for LIN

master nodes, it is necessary to terminate the bus with an

external 1.0 k resistor in series with a diode to VBAT

(Figure 9).

TxD Input

During transmission the signal on TxD will be

transferred to the BUS driver for generating a BUS signal.

To minimize the electromagnetic emission of the bus line,

the BUS driver has integrated slew rate control and wave

shaping.

Transmitting will be interrupted if thermal shutdown is

active.

The CMOS compatible input TxD directly controls the

BUS level:

TxD = low → BUS = low (dominant level)

TxD = high → BUS = high (recessive level)

The TxD pin has an internal pull up resistor connected to

VCC. This secures that an open TxD pin generates a

recessive BUS level.

RxD Output

The signal on the BUS pin will be transferred

continuously to the RxD pin. Short spikes on the bus signal

are filtered with internal circuitry (Figure 3 and Figure 6).

BUS

RxD

VS

60%

50%

40%

V

BUS_CNT_max

V

BUS_CNT_min

V

hHYS

t < t

rec_deb

Figure 6. Receive Impulse Diagram

t < t

rec_deb

http://onsemi.com

8

NCV7380

The receive threshold values V

V

BUS_CNT_min

of 0.16*V

are symmetrical to 0.5*VS with a hysteresis

(typ). The LIN specific receive threshold is

S

BUS_CNT_max

and

between 0.4*VS and 0.6*VS.

The received BUS signal will be output to the RxD pin:

BUS < V

BUS_CNT

– 0.5 * V

HYS

→ RxD = low (BUS dominant)

BUS > V

BUS_CNT

+ 0.5 * V

HYS

→ RxD = high, floating (BUS recessive)

RxD is a buffered open drain output with a typical load

of:

Resistance: 2.7 k

Capacitance: < 20 pF

Data Rate

The NCV7380 is a constant slew rate transceiver. The

bus driver operates with a fixed slew rate range of 1.0 V/s

V/T 3.0 V/s. This principle provides very good

symmetry of the slope times between recessive to dominant

and dominant to recessive slopes within the LIN bus load

range (C

BUS

, R

term

).

The NCV7380 guarantees data rates up to 20 kbit within

the complete bus load range under worst case conditions.

The constant slew rate principle holds appropriate voltage

levels and can operate within the LIN Protocol

Specification for RC oscillator systems with a matching

tolerance up to 2%.

Operating Under Disturbance

Loss of Battery

If VS and VCC are disconnected from the battery, the bus

pin is in high impedance state. There is no impact to the bus

traffic.

Loss of Ground

In case of an interrupted ground connection from VS and

VCC, there is no influence to the bus line.

Short Circuit BUS to Battery

The transmitter output current is limited to 200 mA

(max) in case of short circuit to battery.

Short Circuit BUS to Ground

Negative voltages on the bus pin are limited to current

through the internal 30 k resistor and series diode from VS.

Thermal Overload

The NCV7380 is protected against thermal overloads. If

the chip temperature exceeds the thermal shutdown

threshold, the transmitter is switched off until thermal

recovery. The receiver continues to work during thermal

shutdown.

Undervoltage V

CC

The VCC undervoltage lockout feature disables the

transmitter until it is above the undervoltage lockout

threshold to prevent undesirable bus traffic.

Application Hints

LIN System Parameter

Bus Loading Requirements

Parameter Symbol Min Typ Max Unit

Operating Voltage Range V

Voltage Drop of Reverse Protection Diode V

Voltage Drop of Bus Decouple Diode in the Master Node V

Battery Offset Voltage V

Ground Offset Voltage V

Master Termination Resistor R

Slave Termination Resistor R

Number of System Nodes N 2 − 16 −

Network Distance between any two ECU Nodes B

Line Capacitance C

Capacitance of Master Node C

Capacitance of Slave Node C

Network Total Capacitance C

Network Total Resistance R

Time Constant of Overall System τnet 1.0 − 5.0 s

BAT

Drop_rev

Drop_dec

batoff

goff

pu_master

pu_slave

US_length

LINE

Master

Slave

t1

t1

8.0 − 18 V

0.4 − 1.0 V

0.4 − 1.0 V

− − 0.1 V

− − 0.1 V

900 1000 1100

20 30 60 k

− − 40 m

− 100 150 pF/m

− 220 − pF

195 220 300 pF

1.0 4.0 10 nF

537 − 863

BAT

BAT

http://onsemi.com

9

NCV7380

Recommendations for System Design

The goal of the LIN physical layer standard is to have a

universal definition of the LIN system for plug and play

solutions in LIN networks up to 20 kbd bus speeds.

In case of small and medium LIN networks, it’s

recommended to adjust the total network capacitance to at

least 4.0 nF for good EMC and EMI behavior. This can be

done by setting only the master node capacitance. The

slave node capacitance should have a unit load of typically

220 pF for good EMC/EMI behavior.

In large networks with long bus lines and the maximum

number of nodes, some system parameters can exceed the

defined limits and the LIN system designer must intervene.

The whole capacitance of a slave node is not only the unit

load capacitor itself. Additionally, there is the capacitance

of wires and connectors, and the internal capacitance of the

LIN transmitter. This internal capacitance is strongly

dependent on the technology of the IC manufacturer and

should be in the range of 30 pF to 150 pF. If the bus lines

have a total length of nearly 40m, the total bus capacitance

can exceed the LIN system limit of 10 nF.

A second parameter of concern is the integrated slave

termination resistor tolerance. If most of the slave nodes

have a slave termination resistance at the allowed

maximum of 60 k, the total network resistance is more

than 700 . Even if the total network capacitance is below

or equal to the maximum specified value of 10 nF, the

network time constant is higher than 7.0 s.

This problem can be solved only by adjusting the master

termination resistor to the required maximum network time

constant of 5.0 s (max).

The LIN bus output driver of the NCV7380 provides a

higher drive capability than necessary (40 mA @ 1.2 V)

within the LIN standard (33.6 mA @ 1.2 V). With this

driver stage the system designer can increase the maximum

LIN networks with a total network capacitance of more

than 10 nF. The total network resistance can be decreased

to:

R

(V

tl_min

Bat_max

(18 V 1.2 V)40 mA 420

V

BUSdom

)I

BUS_max

NOTE: The NCV7380 meets the requirements for

implementation in RC−based slave nodes. The LIN

Protocol Specification requires the deviation of the slave

node clock to the master node clock after synchronization

must not differ by more than 2%.

Setting the network time constant is necessary in large

networks (primarily resistance) and also in small networks

(primarily capacitance).

MIN/MAX SLOPE TIME CALCULATION

(In accordance to the LIN System Parameter Table)

V

BUS

100%

60%

40%

0%

t

sdom

Figure 7. Slope Time and Slew Rate Calculation

(In accordance to LIN physical layer specification 1.3)

The slew rate of the bus voltage is measured between

40% and 60% of the output voltage swing (linear region).

The output voltage swing is the difference between

dominant and recessive bus voltage.

dVdt 0.2 * V

swing

(t

40%−t60%

)

The slope time is the extension of the slew rate tangent

until the upper and lower voltage swing limits:

t

slope

5*(t

40%−t60%

)

60%

40%

V

dom

t

srec

The slope t ime of the recessive to d ominant e dge i s d irectly

determined by the slew rate control of the transmitter:

t

slope

V

swing

dVdt

The dominant to recessive edge is influenced from the

network time constant and the slew rate control, because it’s

a passive edge. In case of low battery volt ages and high bus

loads t he rising edge is only determined by t he network. If the

rising edge slew rate exceeds the value of the dominant one,

the slew ra t e cont rol det e rmi ne s the ri sing edge .

http://onsemi.com

10

NCV7380

TxD

V

BUS

GND

RxD

SUP

100%

0%

58.1%

28.4%

t

Bit

t

dom(max)

t

dom(min)

74.4%

42.2%

t

Bit

t

rec(min)

58.1%

t

rec(max)

28.4%

Figure 8. Duty Cycle Measurement and Calculation in Accordance to LIN Physical Layer Specification 2.0

Duty Cycle Calculation

With the timing parameters shown in Figure 8 two duty

cycles, based on t

rec(min)

and t

can be calculated as

rec(max)

follows:

D1* = t

D2* = t

rec(min)

rec(max)

/(2 x t

/(2 x t

Bit

Bit

)

)

For proper operation at 20 KBit/s (bit time is 50 s) the

LIN driver has to fulfill the duty cycles specified in the AC

characteristics for supply voltages of 7...18 V and the three

defined standard loads.

Due to this simple definition there is no need to measure

slew rates, slope times, transmitter delays and dominant

voltage levels as specified in the LIN physical layer

specification 1.3.

The devices within the D1/D2 duty cycle range also

operates in applications with reduced bus speed of

10.4 KBit/s or below.

In order to minimize EME, the slew rates of the

transmitter can be reduced (by up to 2 times). Such

devices have to fulfill the duty cycle definition D3/D4 in

the LIN physical layer specification 2.0. Devices within

this duty cycle range cannot operate in higher frequency

20 KBit/s applications.

*D1 and D2 are defined in the LIN protocol specification 2.0.

http://onsemi.com

11

NCV7380

Ignition

Car Battery

1N4001

V

BAT

10 F

100 nF

V

OUT

V

Voltage

Regulator

NCV8502

10 k

P

GND

LIN BUS

2.2 F

IN

100 nF

Reset

47 nF

2.7 K

VCC VS

RxD

TxD

BUS

NCV7380

GND

Slave

ECU

220 pF

LIN Bus

to Single Wire

ECU Connector

*

BUS

2.2 F

100 nF

47 nF

220 pF

Master

ECU

1 K

LIN Bus

to Single Wire

ECU Connector

1N4001

V

BAT

V

OUT

10 F

100 nF

V

Voltage

Regulator

NCV8501

10 k

P

GND

IN

2.7 K

10 k

VCC VS

INH

RxD

NCV7382

TxD

EN

GND

ENABLE

Reset

47 nF

*The NCV7382 is a pin compatible transceiver with INH control.

Figure 9. Application Circuitry

http://onsemi.com

12

NCV7380

ESD/EMC Remarks

General Remarks

Electronic semiconductor products are sensitive to

Electro Static Discharge (ESD). Always observe Electro

Static Discharge control procedures whenever handling

semiconductor products.

POWER SUPPLY PIN VS

Test Pulse Condition Duration

1 t1 = 5.0 s/US = −100 V/tD = 2.0 ms 5000 Pulses

2 t1 = 0.5 s/US = 100 V/tD = 0.05 ms 5000 Pulses

3a/b US = −150 V/US = 100 V

Burst 100 ns/10 ms/90 ms Break

5 Ri = 0.5 , tD = 400 ms

tr = 0.1 ms/UP + US = 40 V

DATA AND SIGNAL PINS BUS

Test Pulse Condition Duration

1 t1 = 5.0 s/US = −100 V/tD = 2.0 ms 1000 Pulses

2 t1 = 0.5 s/US = 100 V/tD = 0.05 ms 1000 Pulses

3a/b US = −150 V/US = 100 V

Burst 100 ns/10 ms/90 ms Break

ESD Test

The NCV7380 is tested according to MIL883D (human

body model).

EMC

The test on EMC impacts is done according to ISO

7637−1 for power supply pins and ISO 7637−3 for data and

signal pins.

1 h

10 Pulses Every 1 Min

1000 Burst

http://onsemi.com

13

−Y−

−Z−

NCV7380

PACKAGE DIMENSIONS

SO−8

CASE 751−07

ISSUE AB

−X−

B

H

A

58

1

4

G

D

0.25 (0.010) Z

M

S

Y

0.25 (0.010)

C

SEATING

PLANE

SXS

M

0.10 (0.004)

M

Y

K

N

X 45

M

J

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. 751−01 THRU 751−06 ARE OBSOLETE. NEW

STANDARD IS 751−07.

MILLIMETERS

DIMAMIN MAX MIN MAX

4.80 5.00 0.189 0.197

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.053 0.069

D 0.33 0.51 0.013 0.020

G 1.27 BSC 0.050 BSC

H 0.10 0.25 0.004 0.010

J 0.19 0.25 0.007 0.010

K 0.40 1.27 0.016 0.050

M 0 8 0 8

N 0.25 0.50 0.010 0.020

S 5.80 6.20 0.228 0.244

INCHES

SOLDERING FOOTPRINT*

1.52

0.060

7.0

0.275

0.6

0.024

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any

liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental

damages. “Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over

time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under

its patent rights nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body,

or other applications intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death

may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees,

subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of

personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part.

SCILLC is an Equal Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

4.0

0.155

1.270

0.050

SCALE 6:1

inches

mm

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Japan: ON Semiconductor, Japan Customer Focus Center

2−9−1 Kamimeguro, Meguro−ku, Tokyo, Japan 153−0051

Phone: 81−3−5773−3850

http://onsemi.com

14

ON Semiconductor Website: http://onsemi.com

Order Literature: http://www.onsemi.com/litorder

For additional information, please contact your

local Sales Representative.

NCV7380/D

Loading...

Loading...