NCP5010

e

500 mW Boost Converter for

White LEDs

The NCP5010 is a fixed frequency PWM boost converter with

integrated rectification optimized for constant current applications

such as driving white LEDs. This device features small size, minimal

external components and high−efficiency for use in portable

applications and is capable of providing up to 500 mW output power

to 2−5 series connected white LEDs. A single resistor sets the LED

current and the CTRL pin can be pulse width modulated (PWM) to

reduce the LED Current.

The device includes True−Cutoff circuitry to disconnect the load

from the battery when the device is put into standby mode. To protect

the device, an output overvoltage protection, and short circuit

protection have been incorporated. The NCP5010 is housed in a low

profile, space efficient 1.7 x 1.7 mm Flip−Chip package. The device

has been optimized for use with small inductors and ceramic

capacitors.

Features

• 2.7 to 5.5 V Input Voltage Range

• Efficiency: 84% for 5 LED (V

4.2 V V

IN

• Low Noise 1 MHz PWM DC−DC Converter

• Open LED Protection and Short Circuit Protection

• Serial LEDs Architecture for Uniform Current Matching

• 1 mA Shutdown Current Facility with True−Cutoff

• Very Small 8−Pin Flip−Chip 1.7 x 1.7 mm Package

• This is a Pb−Free Device

T ypical Applications

• White LED Backlighting for Small Color LCD Displays

• Cellular Phones

• Digital Cameras

• MP3 Players

• High Efficiency Step−up Converter

= 3.5 V by LED) at 30 mA and

F

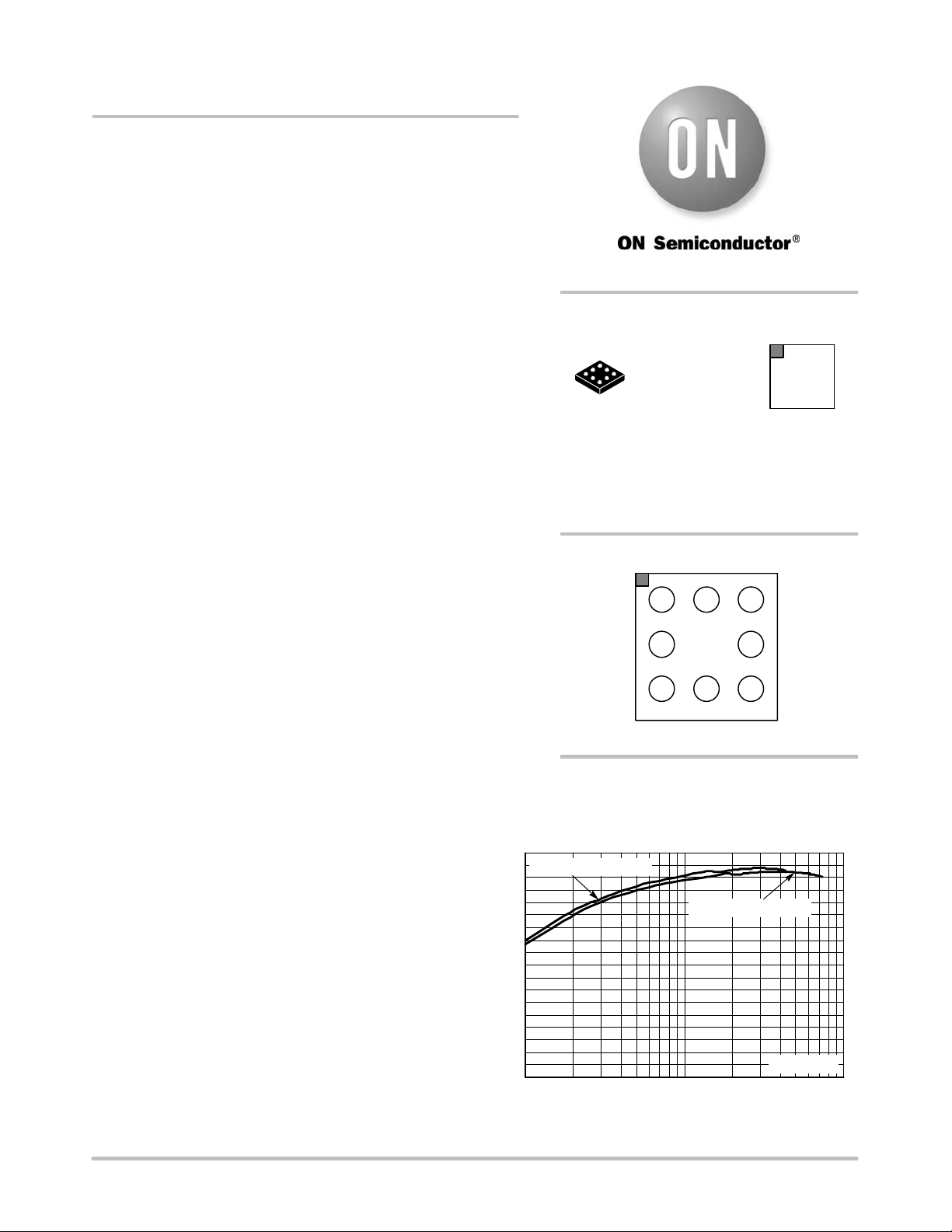

90

80

70

60

50

40

30

EFFICIENCY (%)

20

10

http://onsemi.com

MARKING

DIAGRAM

A1

8−Pin Flip−Chip

FC SUFFIX

1

See detailed ordering and shipping information in the packag

dimensions section on page 16 of this data sheet.

V

= 5 LED (18 V)

OUT

0

1 10 100

Figure 1. Efficiency vs. Output Current

CASE 499AJ

DAX = Specific Device Code

G = Pb−Free Package

A = Assembly Location

Y = Year

WW = Work Week

PIN CONNECTIONS

A1

A2 A3

AGND

CTRL NC

B1 B3

V

IN

C1 C2 C3

V

ORDERING INFORMATION

OUT

I

OUT

SW PGND

Top View

V

= 3 LED (11 V)

OUT

(mA)

DAXG

AYWW

FB

VIN = 4.2 V

© Semiconductor Components Industries, LLC, 2007

March, 2007 − Rev. 2

1 Publication Order Number:

NCP5010/D

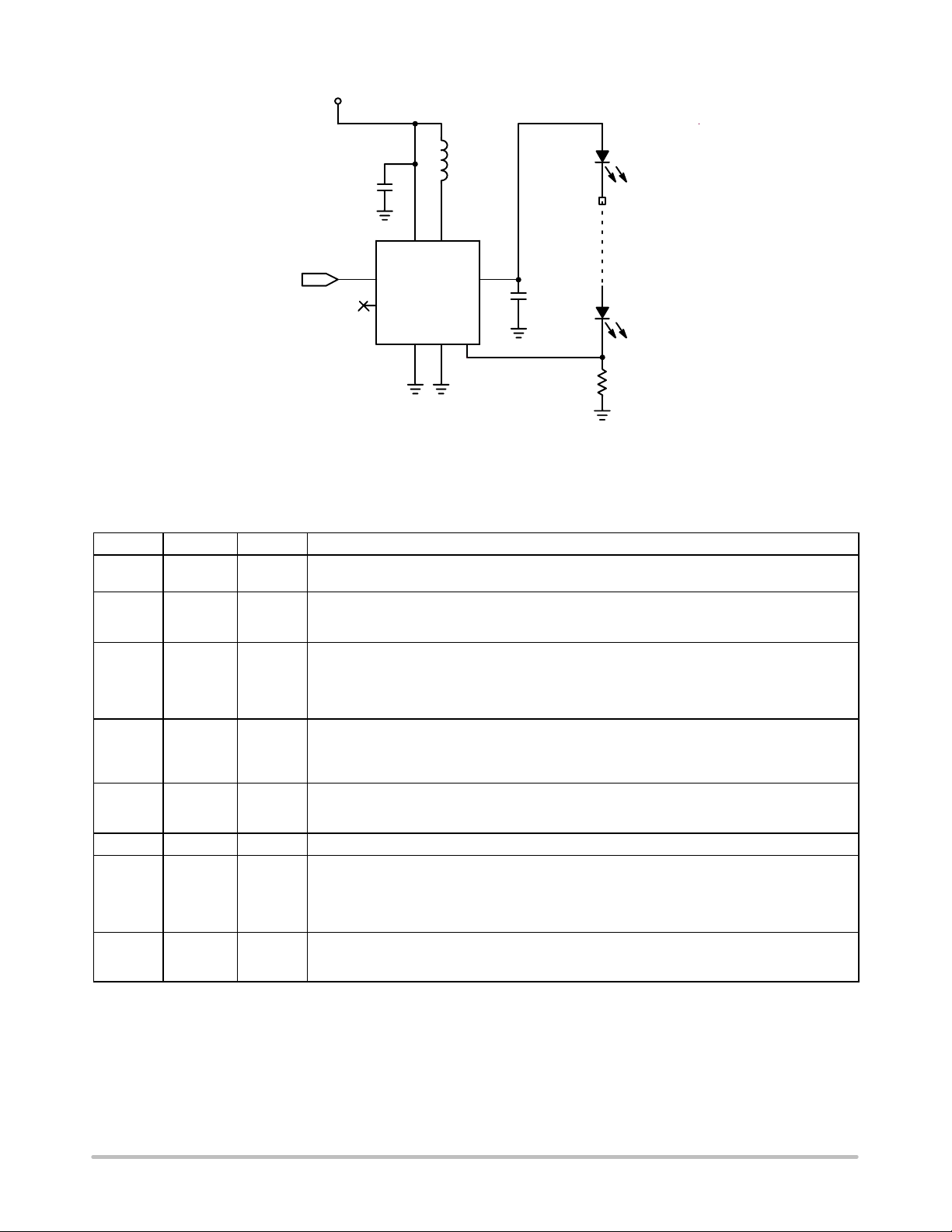

V

bat

2.7 to 5.5 V

NCP5010

C

in

4.7 mF 0603

L1

22 mH

LED

X5R 6.3V

C2

IN

SW

ENABLE

A2

CTRL

A3

NC

NCP5010

V

AGND

A1 B1

V

PGND

C3

OUT

B3

FB

C1

C

out

1 mF 0805

X5R 25V

R

24

LED

fb

2 to 5 LEDs

Figure 2. Typical Application Circuit

PIN FUNCTION DESCRIPTION

PIN PIN NAME TYPE DESCRIPTION

A1 AGND POWER System ground for the analog circuitry . A high quality ground must be provided to avoid spikes and/

B1 V

C1 V

IN

OUT

POWER Power Supply Input. A ceramic capacitor with a minimum value of 1 mF/6.3 V (X5R or X7R) must be

POWER DC−DC converter output. This pin should be directly connected to the load and a low ESR

A2 CTRL INPUT An Active High logic level on this pin enables the device. A built−in pulldown resistor disables the

C2 SW POWER Power switch connection for inductor. T ypical application will use a coil from 10 mH to 22 mH and

A3 NC N/A Not Connected

B3 FB INPUT Feedback voltage input used to close the loop by means of a sense resistor connected between the

C3 PGND POWER Power ground. A high quality ground must be used to avoid spikes and/or uncontrolled operation.

or uncontrolled operations. This pin is to be connected to the PGND pin.

connected to this pin. This capacitor should be placed as close as possible to this pin. In addition,

one end of the external inductor is to be connected at this point.

(<30 mW) 1 mF (min) 25 V bypass capacitor. This capacitor is required to smooth the current flowing

into the load, thus limiting the noise created by the fast transients present in this circuit. Since this is

a current regulated output, this pin has over voltage protection to protect from open load conditions.

Care must be taken to avoid EMI through the PCB copper tracks connected to this pin.

device if the pin is left open. This pin can also be used to control the average current into the load

by applying a low frequency PWM signal. If a PWM signal is applied, the frequency should be high

enough to avoid optical flicker but be no greater than 1 kHz.

must be able to handle at least 350 mA. If the desired output power is above 300 mW, the inductor

should have a DCR < 1.4 W.

primary LED branch and the ground. The output current tolerance is depends upon the accuracy of

this resistor and a ±5% or better accuracy metal film resistor is recommended. An analog dimming

signal can be applied to this point to reduce the output current. Please refer to the application

section for additional details.

Care must be taken to avoid high−density current flow in a limited PCB copper track. This pin is to

be connected to the AGND pin.

http://onsemi.com

2

NCP5010

MAXIMUM RATINGS

Rating Symbol Value Unit

Power Supply Voltage (Note 2) V

Over Voltage Protection V

IN

OUT

Human Body Model (HBM) ESD Rating (Note 3) ESD HBM 2000 V

Machine Model (MM) ESD Rating (Note 3) ESD MM 200 V

Digital Input Voltage

CTRL −0.3 < VIN < V

Digital Input Current

Power Dissipation @ TA = +85 °C P

Thermal Resistance Junction−to−Air

D

R

q

JA

8−Pin Flip−Chip Package

Operating Ambient Temperature Range T

Operating Junction Temperature Range T

Storage Temperature Range T

A

J

stg

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

1. Maximum electrical ratings are defined as those values beyond which damage to the device may occur at TA = 25°C.

2. According to JEDEC standard JESD22−A108B.

3. This device series contains ESD protection and passes the following tests:

Human Body Model (HBM) ±2.0 kV per JEDEC standard: JESD22−A114 for all pins.

Machine Model (MM) ±200 V per JEDEC standard: JESD22−A115 for all pins.

4. Latchup Current Maximum Rating: ±100 mA per JEDEC standard: JESD78.

5. Moisture Sensitivity Level (MSL): 1 per IPC/JEDEC standard: J−STD−020A.

6. For the 8−Pin Flip−Chip CSP Package, the R

50 mm total area and also 135°C/W with 500 mm. All the bumps have the same thermal resistance and need to be connected thereby optimizing

is highly dependent on the PCB Heatsink area. For example R

q

JA

the power dissipation.

7.0 V

24 V

+0.3

bat

1.0

mA

150 mW

°C/W

(Note 6)

−40 to +85 °C

−40 to +125 °C

−65 to +150 °C

can be to 195°C/W with

q

JA

V

http://onsemi.com

3

NCP5010

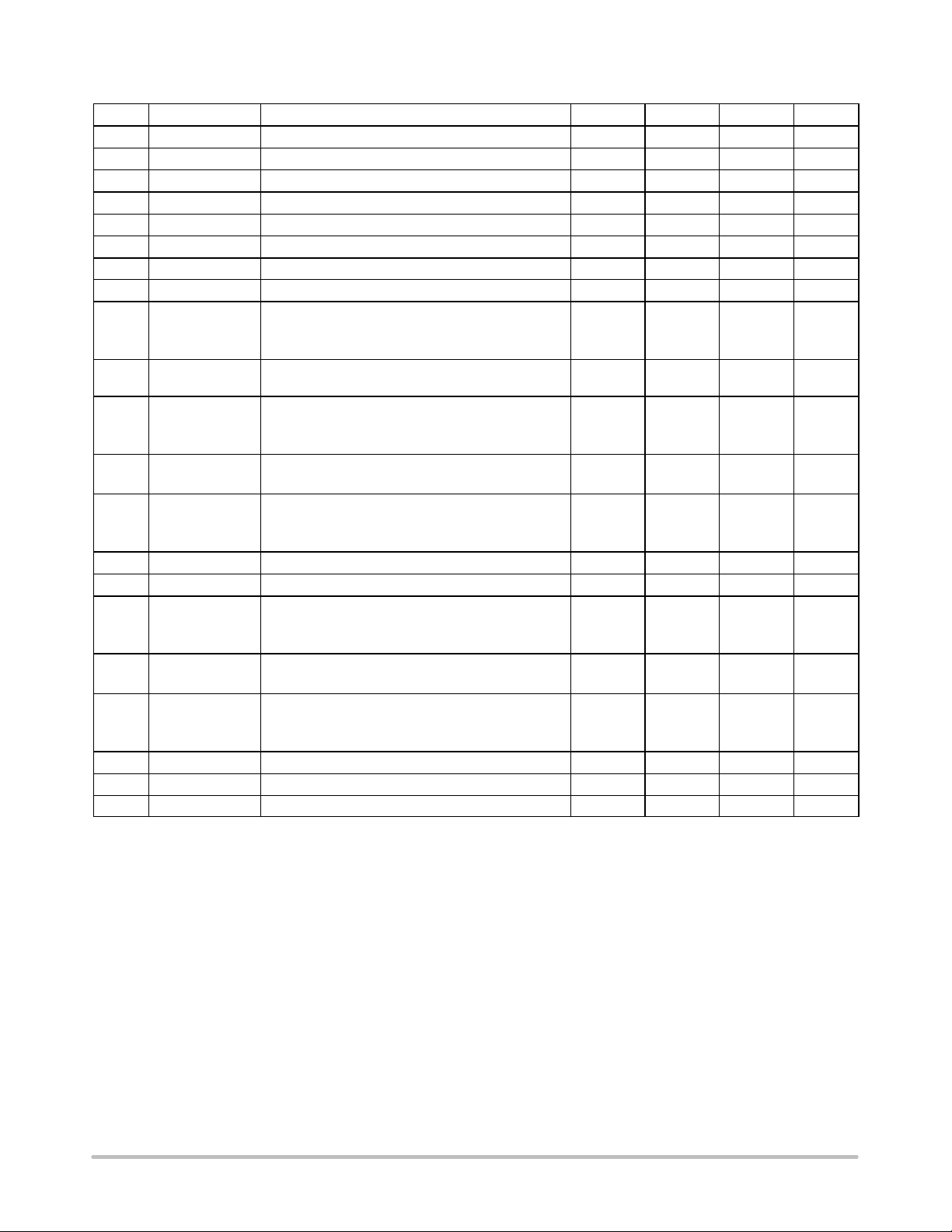

ELECTRICAL CHARACTERISTICS (Limits apply for T

between −40°C to +85°C and VIN = 3.6 V , unless otherwise noted)

A

Pin Symbol Rating Min Typ Max Unit

B1 V

C2 I

IN

PEAK_MAX

NMOS R

F

OSC

M

DUTY

E

FF

C1 OVP

C1 OVP

C1 P

C1 I

B3 F

C1 F

OUT

OUT

BV

BVLR

DS(on)

ON

H

Supply Voltage 2.7 5.5 V

Switch Current Limit 280 420 560 mA

Internal Switch On Resistor 0.6 1.0 W

PWM Oscillator Frequency 0.8 1.0 1.2 MHz

Maximum Duty Cycle 91 95 %

Efficiency (Note 7) 84 %

Overvoltage Clamp Voltage 20 22 V

Overvoltage Clamp Hysteresis 1.0 V

Output power (Note 8)

VIN = 3.1 V

VIN < 3.1 V

Minimum Output Current Controlled No Skip Mode

500

300

1.0 mA

(Note 9)

Feedback Voltage Threshold in Steady State

Overtemperature range

At 25°C

475

490

500

500

525

510

Feedback Voltage Line Regulation (Notes 9 and 10)

From DC to 100 Hz 0.2 0.5

B1 U

B1 U

C1 I

B1 S

VLO

VLOH

OUTSC

CPT

B1C2ISTDB Stand by Current, I

I

Q

A2 V

A2 V

A2 R

IL

IH

CTRL

7. Efficiency is defined by 100 * (P

VIN = 4.2 V with L= Coilcraft DT1608C−223

I

= 30 mA, Load = 5 LEDs (VF = 3.5 V per LED) bypassed by 1 mF X5R

OUT

VIN Undervoltage Lockout measured at 25°C

Threshold to Enable the Converter

Threshold to Disable the Converter

2.2

2.0

2.4

2.2

2.6

2.4

Undervoltage Lockout Hysteresis 200 mV

Short Circuit Output Current 20 mA

Short Circuit Protection Threshold

Detected

Released

V

bat

= 4.2 V

= 0 mA, CTRL = Low

OUT

35

47

50

67

65

87

2.0 mA

Quiescent Current

Device Not Switching (BF = VIN)

Device Switching (RFB disconnected)

0.4

1.0

Voltage Input Logic Low 0.3 V

Voltage Input Logic High 1.2 V

CTRL Pin Pulldown Resistance 175 370 kW

/ Pin) at 25°C

out

8. Guaranteed by design and characterized with L = 22 mH, DCR = 0.7 W max.

9. Load = 4 LEDs (VF = 3.5 V by LED), C

10.VIN = 3.6 V , Ripple = 0.2 V P−P, I

OUT

= 1 mF X5R, L= Coilcraft DT1608C−223.

OUT

= 15 mA.

mW

mV

%/V

V

% of V

mA

IN

http://onsemi.com

4

NCP5010

)

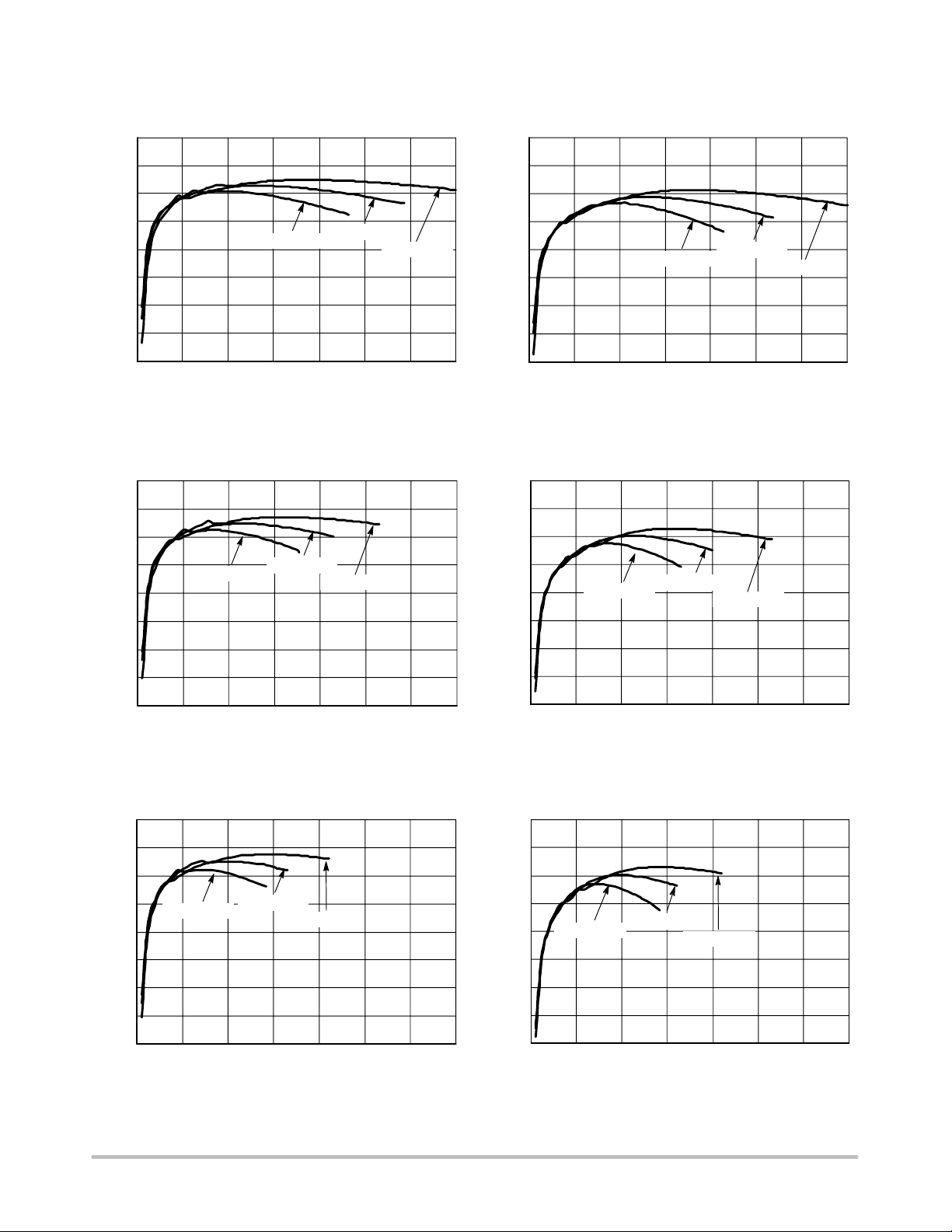

TYPICAL OPERATING CHARACTERISTICS

0

0

0

Condition: Efficiency = 100 x (Number of LED stacked x V

90

80

70

EFFICIENCY (%)

60

50

010203040506070

VIN = 2.7 V

I

OUT

VIN = 3.3 V

VIN = 4.2 V

(mA)

Figure 3. Efficiency vs. Current @ 3 LEDS (10.5 V)

L = Coilcraft DT1608C−223

90

80

x I

LED

90

80

70

EFFICIENCY (%)

60

50

0 1020304050607

)/P

LED

IN

VIN = 2.7 V

I

(mA)

OUT

VIN = 3.3 V

VIN = 4.2 V

Figure 4. Efficiency vs. Current @ 3 LEDS (10.5 V)

L = TDK VLF4012AT−220

90

80

VIN = 2.7 V

70

EFFICIENCY (%)

60

50

0 10203040506070

VIN = 3.3 V

I

(mA)

OUT

VIN = 4.2 V

Figure 5. Efficiency vs. Current @ 4 LEDS (14 V)

L = Coilcraft DT1608C−223

90

80

VIN = 2.7 V

70

EFFICIENCY (%)

60

VIN = 3.3 V

VIN = 4.2 V

70

EFFICIENCY (%)

60

50

0 1020304050607

VIN = 2.7 V

VIN = 3.3 V

I

(mA)

OUT

VIN = 4.2 V

Figure 6. Efficiency vs. Current @ 4 LEDS (14 V)

L = TDK VLF4012AT−220

90

80

70

EFFICIENCY (%)

60

VIN = 2.7 V

VIN = 3.3 V

VIN = 4.2 V

50

0 10203040506070

I

(mA)

OUT

Figure 7. Efficiency vs. Current @ 5 LEDS (17.5 V)

L = Coilcraft DT1608C−223

http://onsemi.com

50

0 1020304050607

I

(mA)

OUT

Figure 8. Efficiency vs. Current @ 5 LEDS (17.5 V

L = TDK VLF4012AT−220

5

NCP5010

0

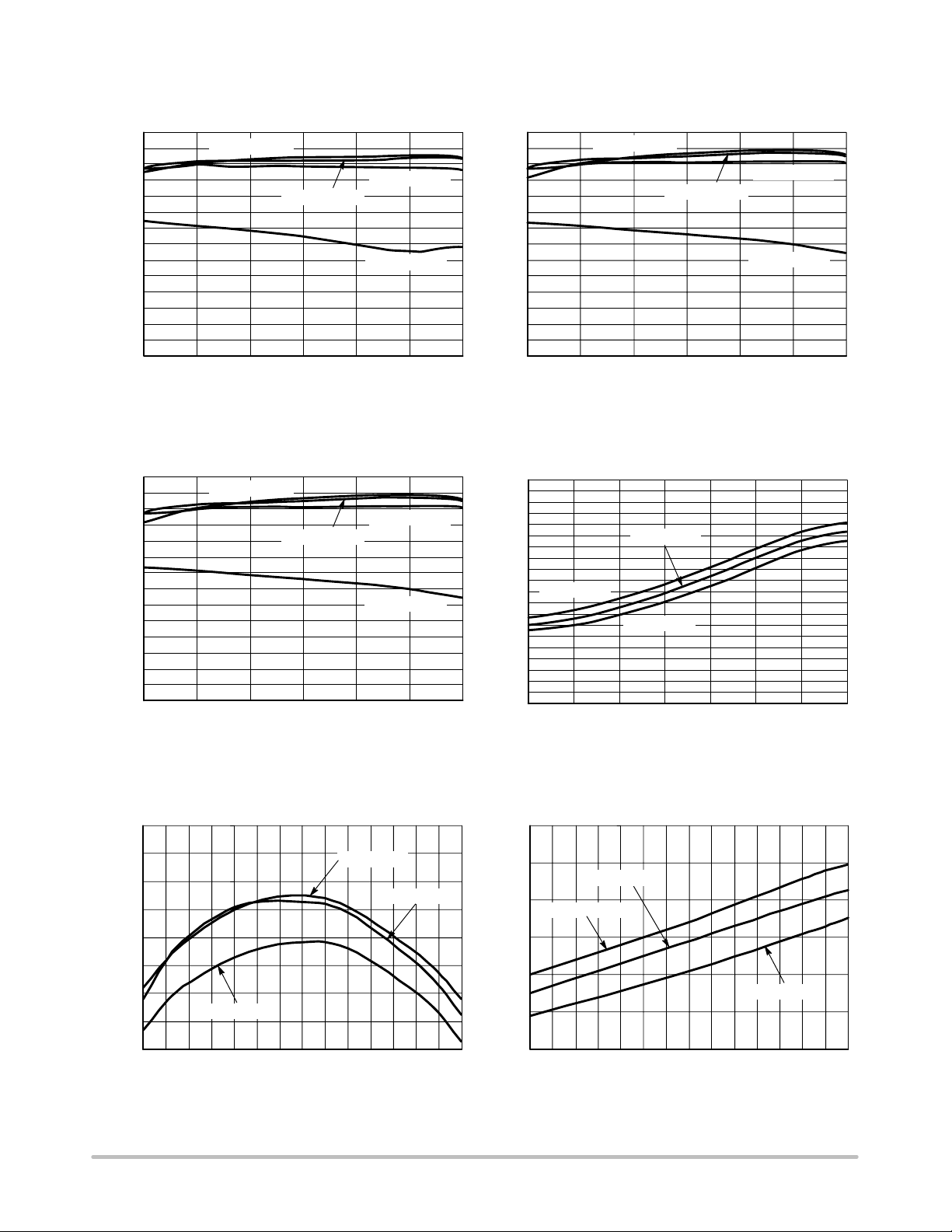

TYPICAL OPERATING CHARACTERISTICS

.5

00

Condition: Efficiency = 100 x (Number of LED stacked x V

90

I

= 33 mA

OUT

80

I

= 10 mA

70

I

OUT

= 23 mA

OUT

60

50

EFFICIENCY (%)

40

I

OUT

= 1 mA

30

20

2.5 3.0 3.5 4.0 4.5 5.0 5.5

VIN (V)

Figure 9. Efficiency vs. VIN @ 3 LEDS (10.5 V)

L = Coilcraft DT1608C−223

90

80

70

I

OUT

= 28 mA

I

OUT

= 23 mA

I

OUT

= 10 mA

x I

LED

)/P

IN

LED

90

I

= 33 mA

OUT

80

70

I

OUT

= 23 mA

I

OUT

60

50

EFFICIENCY (%)

40

I

OUT

30

20

2.5 3.0 3.5 4.0 4.5 5.0 5

VIN (V)

Figure 10. Efficiency vs. VIN @ 4 LEDS (14 V)

L = Coilcraft DT1608C−223

510

505

VIN = 3.6 V

= 10 mA

= 1 mA

60

I

50

EFFICIENCY (%)

40

OUT

= 1 mA

30

20

2.5 3.0 3.5 4.0 4.5 5.0 5.5

VIN (V)

Figure 11. Efficiency vs. V

@ 5 LEDS (17.5 V)

IN

L = Coilcraft DT1608C−223

1.04

VIN = 3.6 V

1.02

1.00

FREQUENCY (MHz)

0.98

VIN = 2.7 V

VIN = 5.5 V

VIN = 5.5 V

500

VIN = 2.7 V

495

FEEDBACK VOLTAGE (mV)

490

−40 −20 0 20 40 60 80 10

TEMPERATURE (°C)

Figure 12. Feedback Voltage vs. Temperature

900

800

700

(mW)

DS(on)

600

500

NMOS R

400

VIN = 3.6 V

VIN = 2.7 V

VIN = 5.5 V

0.96

−40 −20 0 20 40 60 80 100

300

−40 −20 0 20 40 60 80 1

TEMPERATURE (°C)

Figure 13. Oscillator Frequency vs. Temperature Figure 14. NMOS R

http://onsemi.com

6

TEMPERATURE (°C)

vs. Temperature

DS(on)

NCP5010

TYPICAL OPERATING CHARACTERISTICS

I

(mA)

3

2

OUT

1

0

2.5 3.0 3.5 4.0 4.5 5.0 5.5

3 LEDs

VIN (V)

4 LEDs

5 LEDs

Figure 15. Typical Skip Mode Threshold vs. V

(C

= 1 mF X5R 25 V)

OUT

IN

Figure 16. Typical V

, 500 mV/div, AC 3 V

1 V

OUT

Ripple in OVP Conditions

OUT

, 5 V/div , DC

OUT

Figure 17. Continuous Current Mode (CCM)

1 SW, 5 V/div DC, 4 I

, 50 mA/div , DC, I

SW

OUT

Figure 19. Startup for LED Operating, 4 LEDS

= 22 W, 1 CTRL, 2 V/div DC, 2 FB, 500 mV/div DC,

R

BF

100 mA/div, T = 100 ms/div

4 I

L

= 15 mA

http://onsemi.com

7

Figure 18. Discontinuous Current Mode (DCM)

1 SW, 5 V/div DC, 4 ISW, 50 mA/div , DC, I

OUT

Figure 20. Duty Cycle Control Waveforms

1 CTRL, 2 V/div DC, 2 FB, 500 mV/div DC,

100 mA/div, T = 1 ms/div

4 I

L

= 1 mA

NCP5010

TYPICAL OPERATING CHARACTERISTICS

Figure 21. Typical Ripple for Voltage Operation

1 SW, 10 V/div DC, 2 FB, 500 mV/div DC, 3 V

20 mV/div AC, T = 500 ns/div

OUT

http://onsemi.com

8

NCP5010

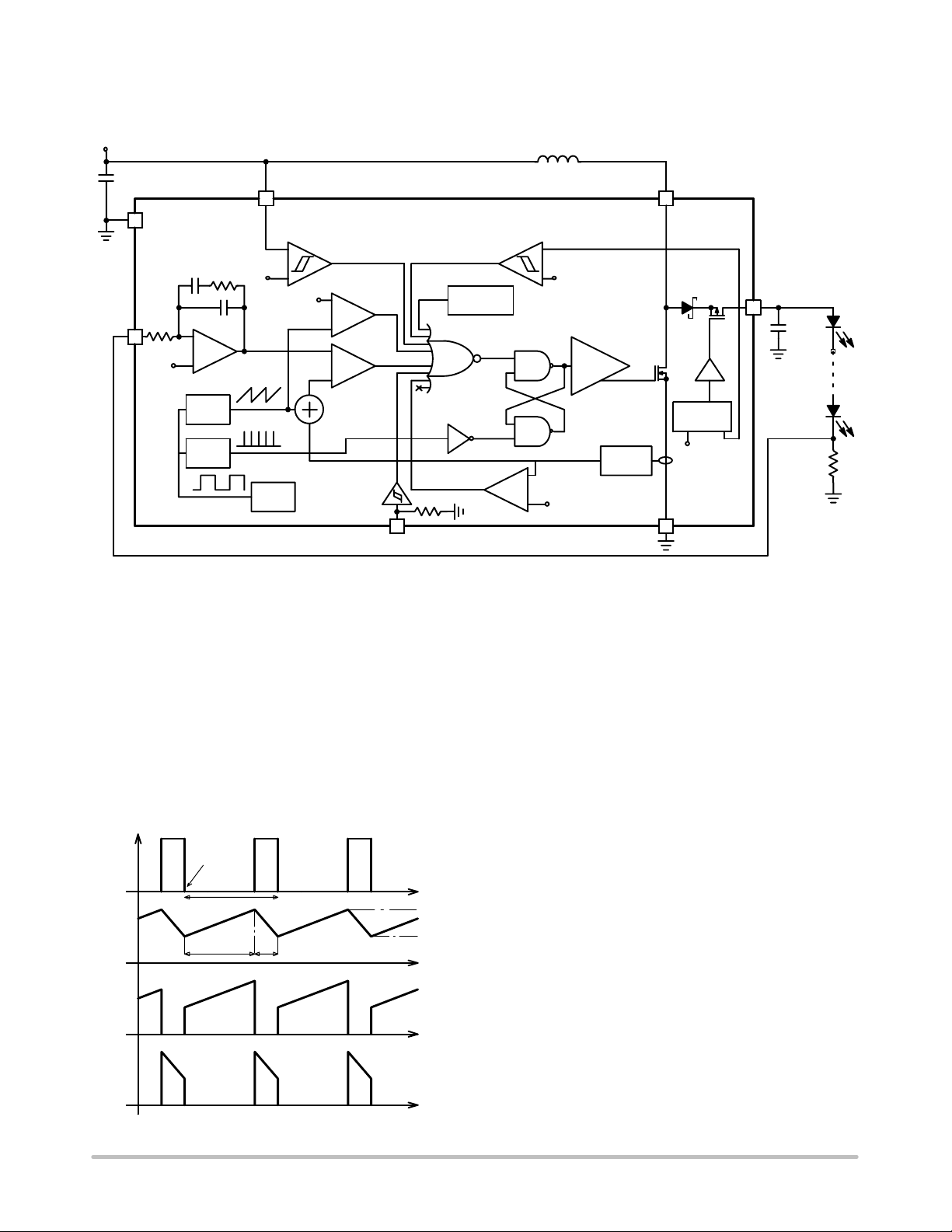

V

DETAIL OPERATING DESCRIPTION

Bat

2.7 to 5.5 V

C

in

1 mF, 6.3 V X5R 0603

A1

AGND

FB

B3

FB REF

CLOCK

−

ERROR

AMP

+

RAMP

COMP

ONE

SHOT

B1

UVLO REF

M DUTY REF

OSC

1 Mhz

L

IPEAK

COMP

22 mH

+

−

OVP REF

DRIVER

SENSE

+

−

IPEAK MAX

CURRENT

PGND

V

IN

UVLO

COMP

−

+

UVLO

MAX DUTY

CYCLE COMP

−

MAX D

+

−

PWM

COMP

+

CTRL

CTRL

IPEAK MAX

250 k

A2

OVP

COMP

OVP

THERMAL

PROTECTION

RST

SET

SW

C2

NMOS

SHORT

CIRCUIT

PROTECTION

V

C3

SC

IN

DRIVER

V

OUT

C1

X5R 0805

C

out

1 mF

25 V

Up to 22 V

R

FB

Figure 22. Functional Block Diagram

Operation

The NCP5010 DC−DC converter is based on a Current

Mode PWM architecture which regulates the feedback

voltage at 500 mV under normal operating conditions. The

boost converter operates in two separate phases (See

Figure 23). The first one is TON when the inductor is

charged by current from the battery to store up energy,

followed by T

step where the power is transmitted

OFF

through the internal rectifier to the load. The capacitor

C

is used to store energy during the T

OUT

supply current to the load during the TON stage thus

time and to

OFF

constantly powering the load.

Start

SW

IL

Cycle

1 MHz

I

peak

I

T

T

on

off

valley

The internal oscillator provides a 1 MHz clock signal to

trigger the PWM controller on each rising edge (SET signal)

which starts a cycle. During this phase the low side NMOS

switch is turne d on thus increasing the current through the

inductor. The switch current is measured by the SENSE

CURRENT and added to the RAMP COMP signal. Then

PWM COMP compares the output of the adder and the signal

from ERROR AMP. When the comparator threshold is

exceeded, the N M OS s w itch is turn ed off until the ris ing e dg e

of the next clock cycle. In addition, there are six functi ons

which can re set the flip −flop logic to swi tc h off the NMOS.

The MAX DUTY CYCLE COMP moni tors the pulse width

and if it exceeds 95% (nom) of the cycle ti me the sw itch will

be turned off. Thi s lim it s the swit ch from bei ng on for more

than one cycle. Due t o IP EAK COMP, the current through the

inductor is monitored and compared with the I

PEAK_MAX

threshold set at 440 mA (nom). If the current exceeds this

value, the controller is will turn off the NMOS sw itch for the

remainder of t he c ycle. T his is a safety f unction t o p revent a ny

excessive current that could ove rload the induct or and the

power stage. The four other safety circuits are SHORT

I

SW

CIRCUIT PROTECTION, OVP, UVLO, and THERMAL

PROTECTION. Please refer to the detail in following

sections.

The loop stability is compensated by the ERROR AMP

I

out

built in integrator. The gain and the loop bandwidth are

fixed internally and provides a phase margin greater than

45° whatever the current supplied.

Figure 23. Basic DC−DC Operation

http://onsemi.com

9

NCP5010

LED Current Selection

The feedback resistor (RFB) determines the average

maximum current through the LED string. The control loop

regulated the current such that the average voltage at the FB

input is 500 mV (nom). For example, should one need a

20 mA output current in the primary branch, RFB should be

selected according to the following equation:

FB

+

F

I

OUT

R

BV

+

500 mV

20 mA

+ 25 W

In white LED applications it is desirable to operate the

LEDs at a specific operating current as the color will shift

as the bias current is changed. As a result of this effect, it

is recommended to dim the LED string by a pulse width

modulation techniques. A low frequency PWM signal can

be applied to the CTRL input and by varying the duty cycle

the brightness of the LED can be changed. To avoid any

optical flicker, the frequency must be higher than 100 Hz

and preferably less than 1 kHz. Due to the soft−start

function set at 600 ms (nom) with higher frequency the

device remains active but the brightness can decrease.

Nevertheless in this case, a dimming control using a

filtered PWM signal (See Figure 33) can be used. Also for

DC voltage control the same technique is suitable and the

filter is takes away.

Inductor Selection

To choose the inductor there are three dif ferent electrical

parameters that need to be considered, the absolute value

of the inductor, the saturation current and the DCR. In

normal operation, this device is intended to operate in

Continuous Conduction Mode (CCM) so the following

equation below can be used to calculate the peak current:

I

+

(

h

1 * D

OUT

I

PEAK

In the equation above, VIN is the battery voltage, I

VIND

)

)

2LF

is

OUT

the load current, L the inductor value, F the switching

frequency, and the duty cycle D is given by:

V

IN

D +ǒ1 *

V

Ǔ

OUT

h is the global converter efficiency which can vary with

load current (see Figure 3 thru Figure 8). A good

approximation is to use h = 0.8. Figure 24 − Figure 26 are

a graphical representation of the above equations, as a

function of the desired I

, VIN, and number of LEDs in

OUT

series (VF = 3.5 V nominal). The curves are limited to an

I

PEAK_MAX

of 300 mA. It is important to analyze this at

worst case Vf conditions to ensure that the inductor current

rated is high enough such that it not saturate.

The recommended inductor value should range between

10 mH and 22 mH. As can be seen from the curves, as the

inductor size is reduced, the peak current for a given set of

conditions increases along with higher current ripple so it

is not possible to deliver maximum output power at lower

inductor values.

300

L = 10 mH

250

200

(mA)

150

PEAK

I

100

50

10 20 30 40 50 60 70 80

Figure 24. Peak Inductor Currents vs. I

L = 15 mH

L = 22 mH

I

OUT

(mA)

VIN = 3.1 V

V

IN

OUT

@ 3 LEDs, 10.5 V

300

L = 10 mH

250

200

(mA)

150

PEAK

I

L = 15 mH

100

50

10 20 30 40 50 60 70 80

L = 22 mH

I

OUT

(mA)

Figure 25. Peak Inductor Currents vs. I

VIN = 3.1 V

IN

OUT

@ 4 LEDs, 14 V

300

250

200

(mA)

150

PEAK

I

100

50

10 20 30 40 50 60 70 80

L = 10 mH

L = 15 mH

L = 22 mH

I

OUT

(mA)

VIN = 3.1 V

= 4.2 VV

IN

Figure 26. Peak Inductor Currents vs. I

@ 5 LEDs, 17.5 V

= 4.2 V

(mA)

= 4.2 VV

(mA)

OUT

(mA)

http://onsemi.com

10

NCP5010

Finally an acceptable DCR must be selected regarding

losses in the coil and must be lower than 1.4 W to limit

excessive voltage drop. In addition, as DCR is reduced,

overall efficiency will improve. Some recommended

inductors include but are not limited to:

TDK VLF4012AT−220MR51

TDK VLP4612T−220MR34

TDK VLP5610T−220MR45

Coilcraft LPO6610−223M

Coilcraft DO1605T−223MX

Coilcraft DT1608C−223

Capacitor Selection

To minimize the output ripple, a low ESR multi−layer

ceramic capacitor type X5R or equivalent should be

selected. For LED driver applications a 1 mF (min) 25 V is

adequate. The NCP5010 can be operated in a voltage mode

configuration (see Figure 34) for applications such as

OLED power. Under these conditions, C

OUT

can be

increased to 2.2 mF, 25 V or more to reduce the output

ripple.

The input needs to be bypassed by a X5R or an equivalent

low ESR ceramic capacitor near the VIN pin. A 1 mF, 6.3 V

is enough for most applications. However, if the connection

between VIN and the battery is too long then a 4.7 mF or

higher ceramic capacitor may be needed. Some

recommended capacitors include but are not limited to:

TDK C1608X5R1E105MT

TDK C2012X5R1E105MT

TDK C1608X5R0J105MT

TDK C2012X5R1E225MT

Murata GRM185R61A105KE36D

Murata GRM188R60J475KE19D

Murata GRM216R61E105KA12D

Short−Circuit Protection

If V

is falls below 50% of VIN then a short−circuit

OUT

condition is detected. When this event is detected, the

PWM circuitry is disabled and the NMOS power switch is

not turned on. Power will be supplied to the load through

the inductor, rectifier and high side switch. Once V

OUT

reaches 66% of VIN, then the PWM circuitry is enabled. In

normal conditions when the device is enabled by an active

high signal on CTRL, the short circuit condition continues

until the output capacitor is charged by the limited current

up to 66% of VIN.

V

OUT

2/3 V

IN

1/2 V

IN

Normal

Running

Figure 27. Example of the V

When Short−Circuit Arises

Overvoltage Protection (OVP)

Short−Circuit Condition

SC

Current limited at 20mA

Occurs

Converter in Standby

End of Short−Circuit

Detected Converter

Starts Again

Voltage Behavior

OUT

If there is an open load condition such as a loose

connection to the White LED string, the converter will

provide current to the C

capacitor and the voltage at the

out

output will rise rapidly. This could cause damage to the part

if there was not some external clamping Zener clamping

circuit. To eliminate the need for these external

components, the NCP5010 incorporates an OVP circuit

which monitors the output voltage with a resistive divider

network and a comparator and voltage reference. If the

output reaches 22 V (nominal), the OVP circuit will detect

a fault and inhibit PWM operation. This comparator has

1 V of hysteresis so when the load is reconnected and the

voltage drops below 21 V, the PWM operation will resume

automatically. The 22 V OVP threshold allows the use of

25 V ceramic capacitors for the output filter capacitor.

Undervoltage Lock Out (UVLO)

To ensure proper operation under all conditions, the

device has a built−in undervoltage lock out (UVLO)

circuit. During power−up, the device will remain disabled

until the input voltage exceeds 2.4 V nominal. This circuit

has 200 mV of hysteresis to provide noise immunity to

transient conditions.

T

http://onsemi.com

11

NCP5010

Layout Recommendations

As with all switching DC/DC converter, care must be

observed to the PCB board layout and component

placement. To prevent electromagnetic interference (EMI)

problems and reduce voltage ripple of the device any

copper trace which see high frequency switching path

should be optimized. So the input and output bypass

ceramic capacitor, CIN and C

be placed as close as possible the NCP5010 and connected

directly between pins and ground plane. In additional, the

track connection between the inductor and the switching

input, SW pin must be minimized to reduce EMI radiation.

Finally it is always good practice to keep way sensitive

tracks such as feedback connection from switched signal

like SW or VOUT connections. Figure 28 shown an

example of optimized PCB layout.

as depicted Figure 2 must

OUT

Figure 28. Recommended PCB Layout

http://onsemi.com

12

NCP5010

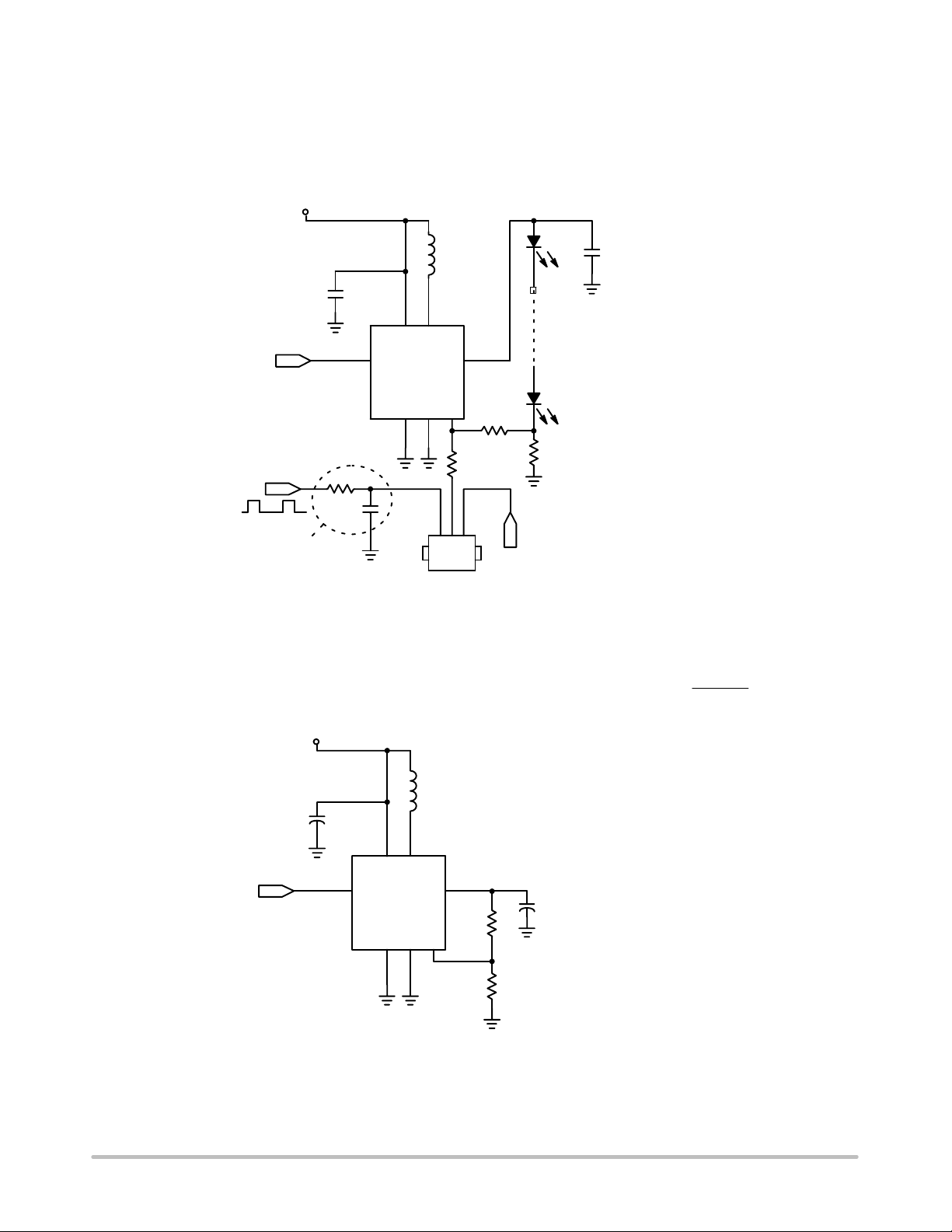

TYPICAL APPLICATION CIRCUITS

Basic Feedback

Figure 29 is a basic application where a regulated courant

is drive in a string of LEDs. A 20.8 mA current is fixed by

R1 and LEDs are dim with PWM apply on CTRL pin.

V

Bat

2.7 to 5.5 V

L1

B1

IN

V

AGND

A1

C2

SW

V

OUT

PGND

C3

22 mH

C1

FB

B3

C

in

4.7 mF 0603

X5R 6.3 V

PWM

A2

NCP5010

CTRL

LED

2 to 5 LEDs

LED

R1

24

C2

1 mF 0805

X5R 25 V

L1: TDK VLF4012A T−220MR51

C1: TDK C1608X5R0J475MT

C2: TDK C2012X5R1E105MT

Figure 29. Typical Semi−Pulsed Mode of Operation

Different Supply

The NCP5010 can operate from two different supply:

One end of the inductor (V

) can be directly connected

BAT

to a battery like 4 cell alkaline or 2 cell Li−Ion. And VIN pin

V

Bat

V

in

C

4.7 mF 0603

X5R 6.3 V

ENABLE

2.7 to 5.5 V

in

A2

CTRL

NCP5010

Figure 30. Operate from Different Supply

B1

IN

V

AGND

A1

C2

SW

V

OUT

PGND

C3

L1

22 mH

C1

FB

B3

need a power delivered for example from an LDO. Care

must be observed to have always V

minimum output voltage range will be V

LED

LED

R1

24

C2

1 mF 0805

X5R 25 V

2 to 5 LEDs

L1: TDK VLF4012A T−220MR51

C1: TDK C1608X5R0J475MT

C2: TDK C2012X5R1E105MT

above VIN and

BAT

voltage.

BAT

http://onsemi.com

13

NCP5010

Multiple LEDs String

Since the output voltage in limited at 22 V (nom.), one

can arrange the LEDs in 2 or more string. Figure 31 shows

V

Bat

2.7 to 5.5 V

L1

C1

4.7 mF 0603

X5R 6.3 V

ENABLE

X5R 6.3 V

A2

CTRL

NCP5010

ENABLE SECONDARY BRANCH

Figure 31. Multiple LED String Application

22 mH

C2

IN

SW

V

AGND

A1 B1

C3

PRIMARY BRANCH

V

OUT

PGND

B3

C1

FB

two LEDs branches where the constant current is regulated

in primary branch and the secondary branch is selected by

Q1. The number of LED in each string have to be the same.

LED

2 to 5 LEDs

LED

R1

24

LED

LED

R2

24

Q1

N

C2

1 mF 0805

X5R 25 V

L1: TDK VLF4012A T−220MR51

C1: TDK C1608X5R0J475MT

C2: TDK C2012X5R1E105MT

Matched LEDs Branches

Should one need to control precisely the current in two

LEDs branches the schematic Figure 32 can be used. An

dual NPN BC847BD is used to form a current mirror Q1

V

Bat

2.7 to 5.5 V

L1

C1

4.7 mF 0603

X5R 6.3 V

ENABLE

X5R 6.3 V

A2

NCP5010

CTRL

IN

V

AGND

A1 B1

C2

SW

V

OUT

PGND

C3

22 mH

FB

B3

C1

I1 I2

R1

24

like this the current in the secondary branch I2 equal the

current in primary branch I1. Thank to this current mirror

the number of LEDs in secondary branch could be lower or

equal than primary one.

LED

2 to 5 LEDs

LED

LED

LED

Q1

R2

24

C2

1 mF 0805

X5R 25 V

NPN Duals

Q1: ON SEMICONDUCTOR BC847BDW1T1

L1: TDK VLF4012A T−220MR51

C1: TDK C1608X5R0J475MT

C2: TDK C2012X5R1E105MT

Figure 32. Matched 2 Branches of LEDs

http://onsemi.com

14

NCP5010

Analog Dimming Control

When the NCP5010 is in steady state the output voltage

is controlled in order to have 500 mV to the feedback input

(FB pin). The principle of this schematic is bias by a

resistive network R2/R3 the feedback voltage. If not any

V

Bat

2.7 to 5.5 V

22 mH

C1

4.7 mF 0603

ENABLE

PWM SIGNAL

Average Network

Figure 33. Dimming Control Using a Filtered PWM Signal or a DC Voltage

X5R 6.3 V

A2

NCP5010

R1 10 k

CTRL

IN

V

AGND

A1 B1

C3

470 nF

C2

SW

V

OUT

PGND

C3

Select

L1

signal is put from outside to R2 there is no voltage drop

across R3 and I

= VFB/R4. When the voltage put to R2

OUT

is increasing the loop balance output voltage to get always

500 mV to FB pin. Thereby voltage across R4 decreases

like this the current in the string of LEDs.

C2

1 mF 0805

X5R 25 V

2 to 5 LEDs

L1: TDK VLF4012A T−220MR51

C1: TDK C1608X5R0J475MT

C2: TDK C2012X5R1E105MT

C3: Standard Capacitor

FB

B3

R2

100 k

C1

R3

18 k

DC VOLTAGE

LED

LED

R4

24

DC/DC Boost Application

The NCP5010 can be used as DC/DC Boost converter to

deliver constant voltage to powering load like OLED or

V

Bat

2.7 to 5.5 V

L1

IN

V

AGND

A1 B1

C2

SW

V

OUT

PGND

C3

22 mH

FB

B3

C1

4.7 mF 0603

X5R 6.3 V

ENABLE

A2

CTRL

NCP5010

Figure 34. OLED or LCD Bias Supply

LCD biasing. An external resistive network is connected to

sense the output voltage and close the loop.

R1 ) R2

C1

R

290 k

R

10 k

15 V / 35 mA

C2

2.2 mF 0805

X5R 25 V

V

+ 0.5

out

L1: TDK VLF4012A T−220MR51

C1: TDK C1608X5R0J475MT

C2: TDK C2012X5R1E225MT

ǒ

R1

Ǔ

http://onsemi.com

15

NCP5010

ORDERING INFORMATION

Device Marking Operating T emperature Range Package Shipping

NCP5010FCT1G DAX −40°C to +85°C 8−Pin Flip−Chip CSP

(Pb−Free)

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

3000 Tape and Reel

†

Two type of demo boards available:

• The NCP5010EVB board which configures the device driving a string of 2−5 White LEDs in series.

• The NCP5010BIASEVB board for applications such as powering an OLED panel or LCD biasing.

Finally in addition to these demo boards, Application Note “ANDXXXX/D” deals with configuring the NCP5010 with a

high side sense resistor.

http://onsemi.com

16

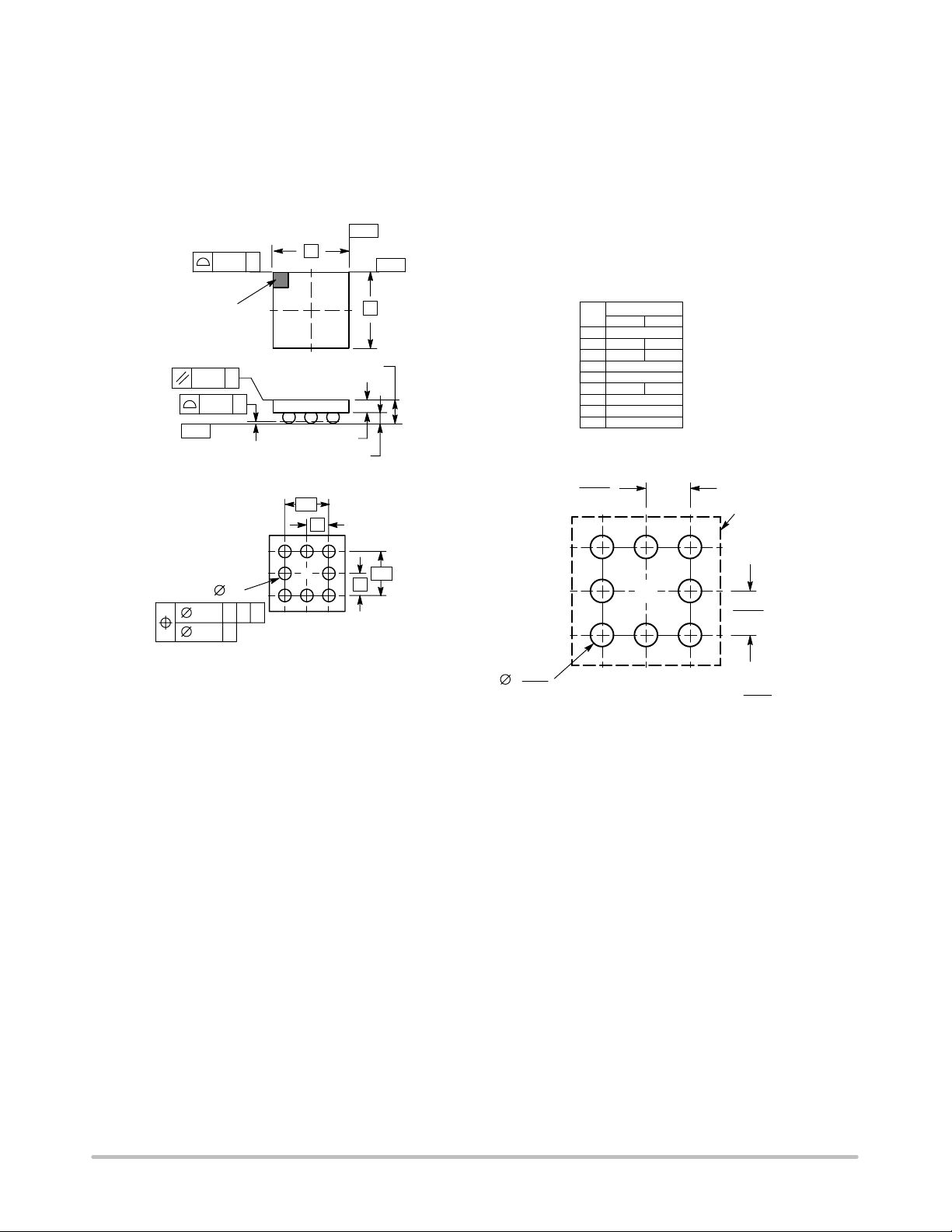

NCP5010

PACKAGE DIMENSIONS

8−PIN FLIP−CHIP

FC SUFFIX

CASE 499AJ−01

ISSUE A

PIN 1

INDICATOR

0.10 C

0.05 C

−C−

SEATING

PLANE

8X b

0.05 C

0.03 C

4 X

0.10 C

A B

D

TOP VIEW

SIDE VIEW

D1

e

C

B

A

12 3

BOTTOM VIEW

A2

−A−

A1

e

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

−B−

E

A

2. CONTROLLING DIMENSION: MILLIMETERS.

3. COPLANARITY APPLIES TO SPHERICAL

CROWNS OF SOLDER BALLS.

MILLIMETERS

DIM MIN MAX

A 0.6 BSC

A1 0.210 0.270

A2

0.330 0.390

D 1.70 BSC

E

1.70 BSC

b 0.290 0.340

e 0.500 BSC

D1 1.000 BSC

E1 1.000 BSC

SOLDERING FOOTPRINT

0.50

E1

0.265

0.01

0.0197

SCALE 20:1

DIE SIZE MAY VARY

0.50

0.0197

mm

ǒ

Ǔ

inches

http://onsemi.com

17

NCP5010

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any

liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental

damages. “Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over

time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under

its patent rights nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body,

or other applications intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death

may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees,

subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of

personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part.

SCILLC is an Equal Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5773−3850

http://onsemi.com

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

NCP5010/D

18

Loading...

Loading...