NCP1800

Single−Cell Lithium Ion

Battery Charge Controller

The NCP1800 is a constant current, constant voltage (CCCV)

lithium ion battery charge controller. The external sense resistor sets

the full charging current, and the termination current is 10% of the full

charge current (0.1 C). The voltage is regulated at ±1% during the

final charge stage. There is virtually zero drain on the battery when the

input power is removed.

Features

• Integrated Voltage and Programmable Current Regulation

• Integrated Cell Conditioning for Deeply Discharged Cell

• Integrated End of Charge Detection

• Better than 1% Voltage Regulation

• Charger Status Output for LED or Host Processor Interface

• Charge Interrupt Input

• Safety Shutoff for Removal of Battery

• Adjustable Charge Current Limit

• Input Over and Under Voltage Lockout

• Micro8 Package

Applications

• Cellular Phones, PDAs

• Handheld Equipment

• Battery Operated Portable Devices

8

PIN CONNECTIONS AND

ISNS

ISEL

COMP/DIS

GND

http://onsemi.com

Micro8

CASE 846A

DM SUFFIX

1

MARKING DIAGRAM

18

2

3

4

X = A for 41 Device

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

180X

AYW

B for 42 Device

OUT

V

7

CC

6

CFLG

5

VSNS

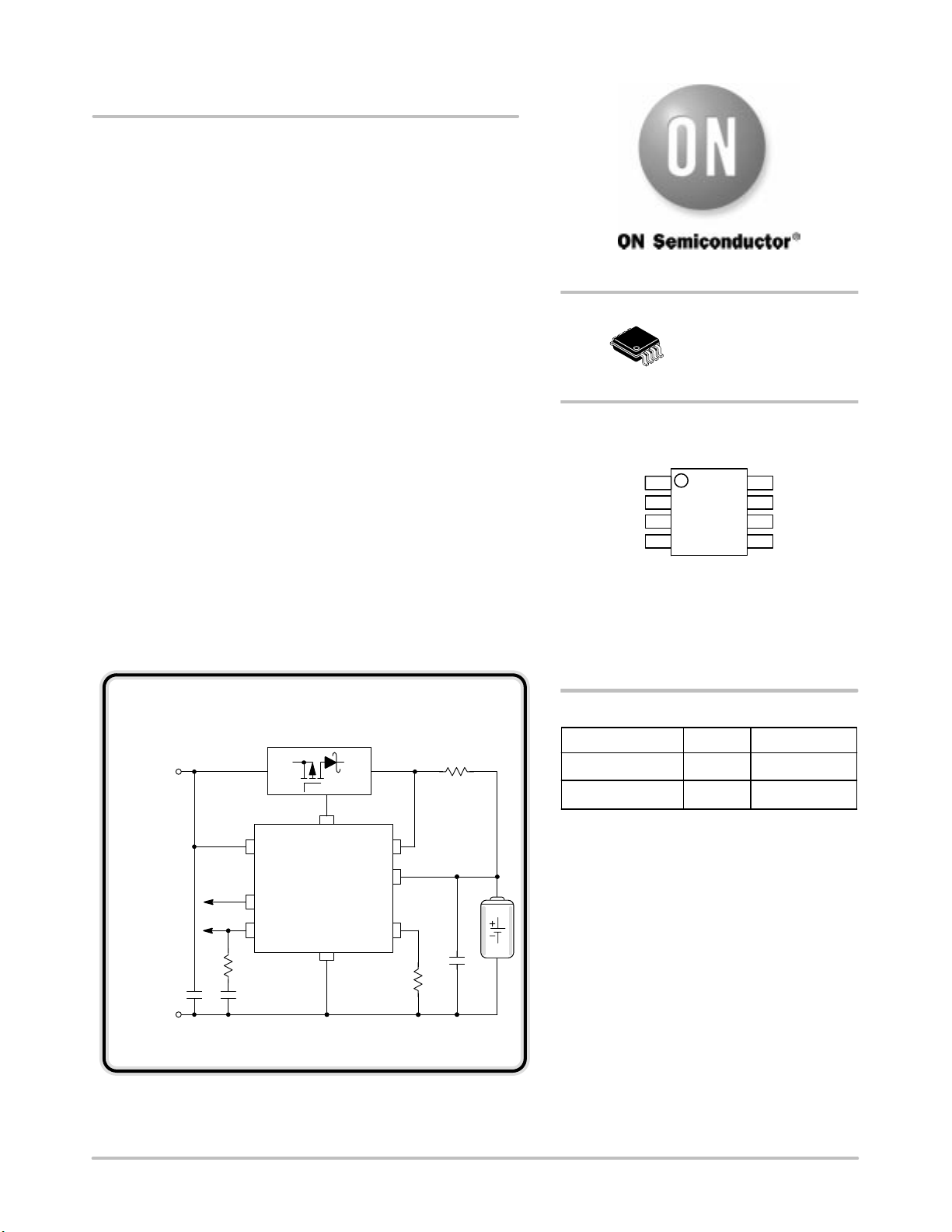

PMOS/Schottky (FETKY): NTHD4P02FT1 (ChipFET)

PMOS: NTGS3441T1 (TSOP 6)

Schottky: MBRM130L

V

in

CC

OUT

NCP1800

= 560 nF

COMP

ISNS

VSNS

ISEL

R

ISEL

60 k

Host or LED

Host

Processor

C

GND

V

CFLG

COMP/

DIS

R

COMP

R

COMP

C

COMP

= 15 , C

in

Figure 1. Typical Application

ORDERING INFORMATION

Device Package Shipping

R

SNS

C

out

NCP1800DM41R2 Micro8 4000 Units/Reel

NCP1800DM42R2 Micro8 4000 Units/Reel

Semiconductor Components Industries, LLC, 2003

May, 2003 - Rev. 4

1 Publication Order Number:

NCP1800/D

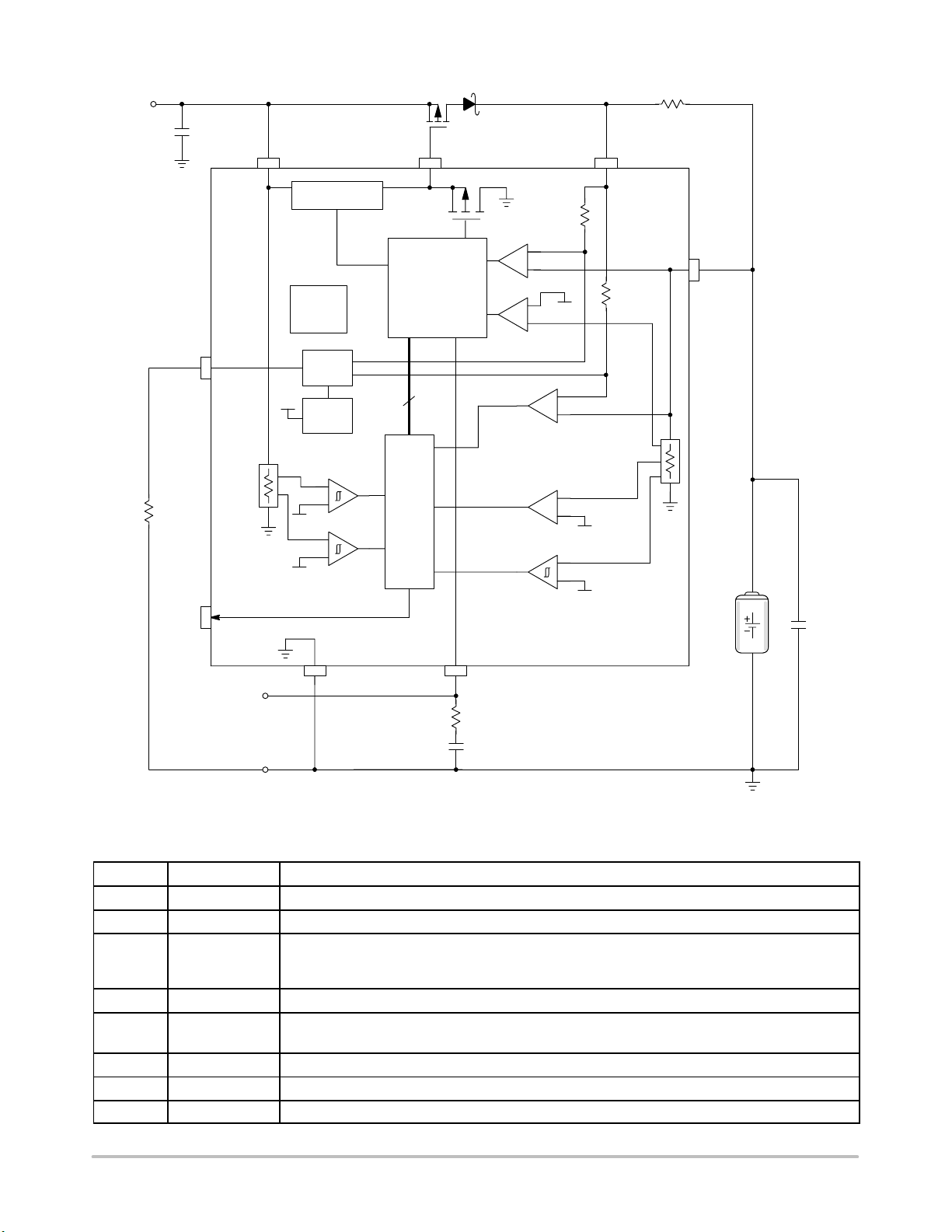

NCP1800

R

SNS

C

in

V

CC

Active Pullup

OUT

I

SNS

ISEL

R

ISEL

CFLG

CC

Chip

Enable

I

REF

V

REF

V

REF

CONTROL

CV

EOC

Detect

V

REF

EOC REF

V

SNS

Input UV

Lockout

LOGIC

V

REF

V

REF

Input OV

Lockout

Pre CHG

Complete

V

SNS

Overvoltage

V

REF

V

REF

C

out

GND COMP/DIS

Figure 2. NCP1800 Internal Block Diagram

PIN FUNCTION DESCRIPTIONS

Pin Symbol Description

1 I

SNS

This is one of the inputs to the current regulator and the end-of-charge comparator.

2 ISEL A resistor from this pin to ground pin sets the full charging current regulation level.

3 COMP/DIS This is a multifunctional pin that is used for compensation and can be used to interrupt charge with an

open drain/collector output from a microcontroller. When this pin is pulled to ground, the charge

current is interrupted.

4 GND This is the ground pin of the IC.

5 V

SNS

This is an input that is used to sense battery voltage and is the other input to the current regulator. It

also serves as the input to the battery overvoltage comparator.

6 CFLG An open drain output that indicates the battery charging status.

7 V

CC

This is a multifunctional pin that powers the device and senses for over and undervoltage conditions.

8 OUT This is a current source driver for the pass transistor.

http://onsemi.com

2

NCP1800

Regulated Out ut Voltage NCP1800DM41

V

REG

4.059

4.1

4.141

V

MAXIMUM RATINGS

Rating Symbol Value Unit

Supply Voltage V

Voltage Range for:

CC

VSNS Input

ISNS Input

COMP/DIS Input

ISEL Input

CFLG Output

Out Output

OUT Sink Current Io 20 mA

Thermal Resistance, Junction to Air R

Operating Ambient Temperature T

Operating Junction Temperature T

Storage Temperature T

stg

JA

A

J

ATTRIBUTES

Characteristic Value

ESD Protection

Human Body Model (HBM) per JEDEC standard JESD22-A114

Machine Model (MM) per JEDEC standard JESD22-A114

Moisture Sensitivity, Indefinite Time Out of Drypack (Note 1) Level 1

Transistor Count 1015

Latch-up Current Maximum Rating per JEDEC standard JESD78 ≤ 150 mA

1. For additional information, see Application Note AND8003/D.

16 V

-0.3 to 6.0

-0.3 to 6.0

-0.3 to 6.0

-0.3 to 6.0

-0.3 to 6.0

-0.3 to V

CC

240

-20 to +85 °C

-20 to +150 °C

-55 to +150 °C

≤ 2 kV

≤ 200 V

V

°C/W

ELECTRICAL CHARACTERISTICS (T

Characteristic

Input Supply Voltage (Note 2) V

Input Supply Current I

Regulated Output Voltage NCP1800DM41 V

Full-Charge Current Reference Voltage

V

= 6.0 V, 3.0 V V

CC

Full-Charge Current Reference Voltage Temperature Coefficient

= 6.0 V, 3.0 V V

V

CC

Pre-Charge Current Reference Voltage

V

= 6.0 V, V

CC

3.0 V, R

SNS

Pre- Charge Current Reference Voltage Temperature Coefficient

V

= 6.0 V, V

CC

3.0 V, R

SNS

Pre-Charge Threshold Voltage NCP1800DM41

VCC Under Voltage Lockout Voltage V

Hysteresis of VCC Under Voltage Lockout (V

Hysteresis of VCC Under Voltage Lockout Voltage (V

4.2 V, R

SNS

4.2 V, R

SNS

= 60 K TA = 25°C

ISEL

= 60 K

ISEL

= 25°C for typical values, -20°C < TA < 85 °C for min/max values, unless otherwise noted.)

A

Symbol Min Typ Max Unit

2.5 - 16 V

- 140 250 A

4.059 4.1 4.141 V

4.158

4.2

4.242

210 240 270 mV

- -0.163 - %/°C

13.2 24 34.8 mV

- -0.180 - %/°C

2.78

2.85

2.93

3.0

3.08

3.15

3.43 3.56 3.69 V

= 60 K TA = 25°C

ISEL

= 60 K

ISEL

), TA = 25°C - 90 150 195 mV

UVLO

UVLO

NCP1800DM42

NCP1800DM42

) Temperature

CC

CC

REG

V

FCHG

TCV

FCHG

V

PCHG

TCV

PCHG

V

PCTH

UVLO

- - 0.261 - %/°C

V

Coefficient

End-of-Charge Voltage Reference

V

CC

= 6.0 V, V

4.2 V, R

SNS

= 60 K TA = 25°C

ISEL

End-of-Charge Voltage Reference Temperature Coefficient

V

= 6.0 V, V

CC

4.2 V, R

SNS

ISEL

= 60 K

V

TCV

EOC

EOC

20 24 28 mV

- -0.160 - %/°C

2. See the “External Adaptor Power Supply Voltage Selection” section of the application note to determine the minimum voltage of the charger

power supplies.

http://onsemi.com

3

NCP1800

ELECTRICAL CHARACTERISTICS (continued)

(TA = 25°C for typical values, -20°C < TA < 85 °C for min/max values, unless otherwise noted.)

Characteristic

Charge Disable Threshold Voltage (I

= 100 A min.) V

COMP

VCC Over Voltage Lockout V

Hysteresis of VCC Over Voltage Lockout (V

Hysteresis of VCC Over Voltage Lockout (V

V

Over Voltage Lockout NCP1800DM41

SNS

),TA = 25°C - 90 150 180 mV

OVLO

) Temperature Coefficient - - 0.39 - %/°C

OVLO

NCP1800DM42

Hysteresis of V

Hysteresis of V

= 25°C

T

A

Full Charge Current Range with R

Full Charge Current Range with R

Battery Drain Current (V

V

= Ground, V

CC

CFLG Pin Output Low Voltage (CFLG = LOW, I

Over Voltage Lockout (V

SNS

Over Voltage Lockout (V

SNS

SNS

SNS

+ I

SNS

SNS

= 4.2 V

SNS

), TA = 25°C - 40 70 100 mV

SOVLO

) Temperature Coefficient

SOVLO

= 0.4 I

= 0.8 I

)

= 5.0 mA) V

CFLG

CFLG Pin Leakage Current (CFLG = HIGH) I

Symbol Min Typ Max Unit

CDIS

OVLO

V

SOVLO

REG1

REG2

I

BDRN

CFLGL

CFLGH

- - 0.08 V

6.95 7.20 7.45 V

4.3

4.4

4.4

4.5

4.5

4.6

V

- - 0.52 - %/°C

600 - 1000 mA

300 - 600 mA

- - 0.5 A

- - 0.35 V

- - 0.1 A

http://onsemi.com

4

NCP1800

3.5

3

2.5

2

1.5

1

, PRE-CHARGE THRESHOLD VOLTAGE (V)

VCC, INPUT SUPPLY VOLTAGE (V)

PCTH

V

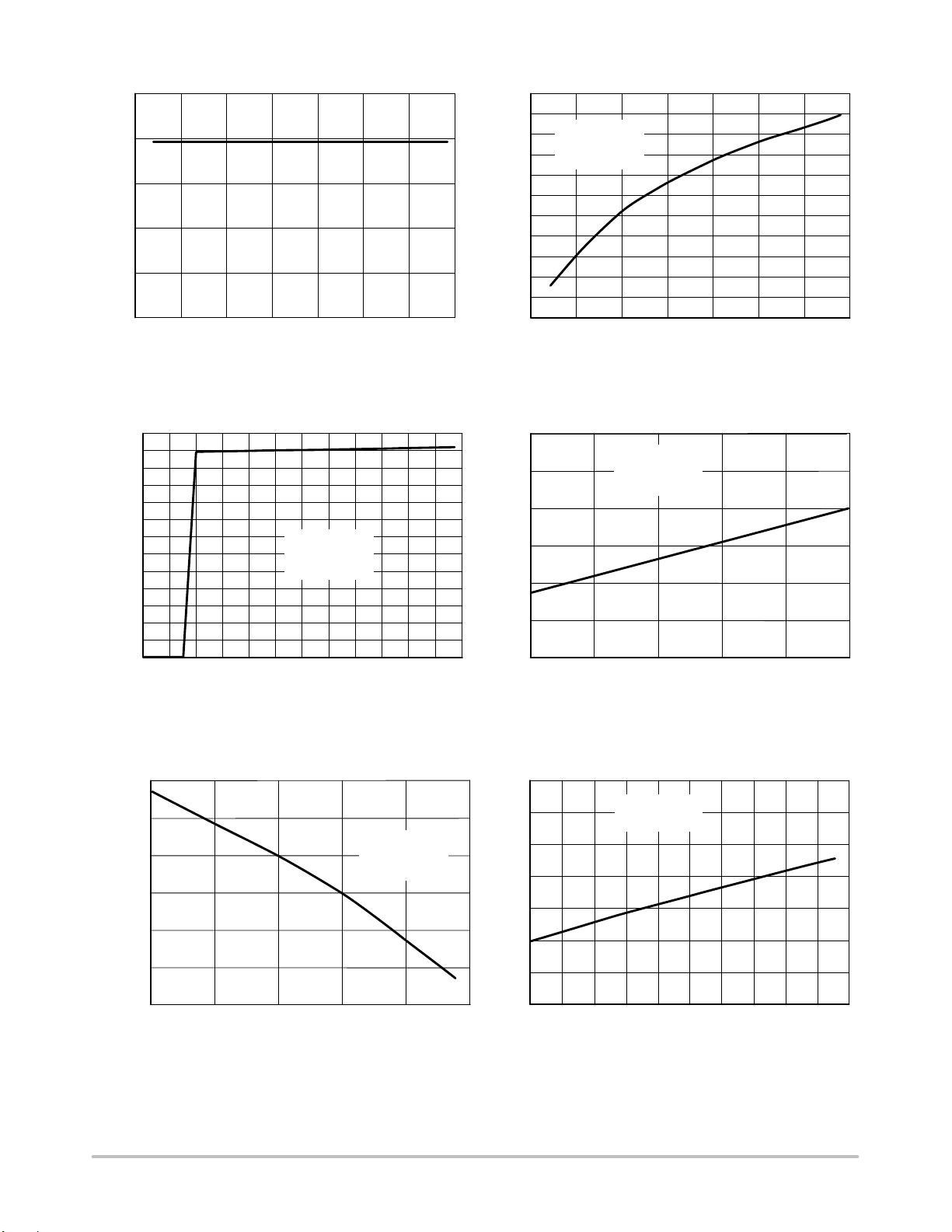

Figure 3. Pre-Charge Threshold Voltage versus

Input Supply Voltage

26

24

22

20

18

16

14

12

10

VCC = 5 V

= 60 k

R

ISEL

R

= 0.4

SNS

8

6

, PRE-CHARGE REFERENCE

4

PCHG

2

V

0

CURRENT THRESHOLD VOLTAGE (mV)

V

, BATTERY VOLTAGE (V)

SNS

Figure 5. Pre-Charge Current Reference

Voltage versus Battery Voltage

24.75

24.70

V

= 2.5 V

24.65

24.60

R

R

SNS

ISEL

SNS

= 60 k

= 0.4

24.55

24.50

24.45

24.40

, PRE-CHARGE CURRENT

24.35

24.30

REFERENCE VOLTAGE (mV)

PCHG

V

24.25

24.20

6.5 6.5

765.554.543.5

VCC, INPUT SUPPLY VOLTAGE (V)

Figure 4. Pre-Charge Current Reference Voltage

versus Input Supply Voltage

0.243

VCC = 5 V

R

0.2425

0.242

0.2415

0.241

0.2405

0.24

2.92.52.11.71.30.90.5

, FULL-CHARGE CURRENT REFERENCE VOLTAGE (V)

Figure 6. Full-Charge Current Reference Voltage

FCHG

V

= 60 k

ISEL

= 0.4

R

SNS

V

, BATTERY VOLTAGE (V)

SNS

versus Battery Voltage

765.554.543.5

4.24.03.83.63.43.2

0.2415

0.241

0.2405

0.24

0.2395

0.239

0.2385

, CHARGE CURRENT REFERENCE VOLTAGE (V)

FCHG

V

V

= 3.6 V

SNS

R

= 60 k

ISEL

= 0.4

R

SNS

VCC, INPUT SUPPLY VOLTAGE (V)

Figure 7. Full-Charge Current Reference

Voltage versus Input Supply Voltage

http://onsemi.com

76.565.554.5

5

24.5

24.4

24.3

24.2

24.1

24

23.9

23.8

, END OF CHARGE REFERENCE VOLTAGE (mV)

EOC

V

R

= 60 k

ISEL

R

= 0.4

SNS

VCC, INPUT SUPPLY VOLTAGE (V)

Figure 8. End of Charge Reference Voltage

versus Input Supply Voltage

76.565.554.5

NCP1800

0.48

0.44

VCC = 0

0.40

0.36

0.32

0.28

, BATTERY DRAIN CURRENT (A)

0.24

BDRN

0.2

I

3.1 3.9

, BATTERY VOLTAGE (V)

V

SNS

Figure 9. Battery Drain Current versus

Battery Voltage

1000

MEASURED

CALCULATED

I

, FULL-CHARGE CURRENT (mA)

REG

I

REG

, CURRENT PROGRAMMING RESISTANCE (k)

R

ISEL

(1.19 12e3)

(R

ISEL

R

SNS

Figure 11. Full-Charge Current versus

Current Programming Resistor

1000

VCC = 5 V

= 2.5 V

V

SNS

= 0.4

R

SNS

100

CALCULATED

10

, PRE-CHARGE CURRENT (mA)

I

PCHG

I

PCHG

(10 R

1

4.13.73.53.32.92.72.5

, CURRENT PROGRAMMING RESISTANCE (k)

R

ISEL

MEASURED

(1.19 12e3)

R

ISEL

SNS

)

100010010

Figure 10. Pre-Charge Current

versus Current Programming Resistor

VCC = 5 V

V

= 3.6 V

SNS

= 0.4

R

SNS

)

100010010

0.11

0.10

0.09

0.08

0.07

(V/V)

0.06

FCHG

0.05

/V

0.04

EOC

V

0.03

0.02

0.01

0100

R

ISEL

VCC = 5 V

R

= 0.4

SNS

75 150 175 225 275

, CURRENT PROGRAMMING RESISTANCE (k)

Figure 12. V

EOC/VFCHG

versus Current

3002502001251005025

Programming Resistor

, INPUT SUPPLY CURRENT (A)

I

250

V

= 4.7 V

SNS

200

V

Activated

SOVLO

150

V

< V

SNS

100

I

REG

SOVLO

= 0 A

50

CC

0

11109151413

VCC, INPUT SUPPLY VOLTAGE (V)

Figure 13. Input Supply Current versus Input

Supply Voltage

http://onsemi.com

6

16128765

NCP1800

Fault Detected

OR

= Low

V

CDIS

Pre- Charge

CFLG:High

OUT:0.1 I

V

SNS

< V

REG

PCTH

Fault Detected OR V

End of Charge

CFLG:Low

OUT:High

< VCC < V

V

UVLO

& V

< V

SNS

V

≥ V

SNS

PCTH

CDIS

OVLO

SOVLO

= Low

Fault Detected

V

OR

= Low

CDIS

Fault

Detected OR

V

= Low

CDIS

Full-Charge

CFLG:High

OUT:1 I

REG

V

< V

SNS

REG

Fault Modes:

1. Charger Low Output (V

2. Runaway Charger (V

3. Battery Removed (V

No Fault Detected

Trickle Charge

CFLG:Low

OUT:V

REG

V

≥ V

SNS

REG

I

SNS

≤ 0.1 I

I

CC

> V

CC

> V

SNS

REG

Final Charge

CFLG:High

OUT:V

REG

> 0.1 I

SNS

< V

OVLO

REG

UVLO

SOVLO

)

)

)

Figure 14. NCP1800 State Machine Diagram

http://onsemi.com

7

NCP1800

CHARGE

= I

Set I

Conditioning Phase

REG

/10

Fault Mode

Set CFLG LOW

Y

Start

OR

V

= LOW

CDIS

N

Set CFLG HIGH

Fault Mode

Y

OR

V

= LOW

CDIS

N

Y

V

SNS

< V

PCTH

N

Set I

CHARGE

= I

REG

Fault Modes:

1. Charger Low Output (V

2. Runaway Charger (V

3. Battery Removed (V

SNS

CC

CC

> V

> V

< V

UVLO

OVLO

SOVLO

Fault Mode

Y

OR

= LOW

V

CDIS

SNS

> V

N

REG

Current Regulation Phase

N

V

Y

Fault Mode

Y

OR

= LOW

V

CDIS

Voltage Regulation Phase

N

I

SNS

)

)

)

Set CFLG Low

< I

REG

N

Y

/10

Fault Mode

OR

Y

V

CDIS

= LOW

N

Figure 15. NCP1800 Charging Operational Flow Chart

http://onsemi.com

8

0.9 V

CFLG = High

Voltage

Current

0.1 x I

REG

I

REG

V

PCTH

NCP1800

V

REG

CFLG = Low

(I

< 0.1 X I

SNS

time

time

REG

)

Pre-Charge

Phase

Full-Charge

Phase

Final Charge

Phase

Figure 16. Typical Charging Algorithm

Charge Status

Conditions CFLG Pin

Pre-Charge, Full-Charge and Final Charge High-Z

End-of-Charge, Trickle Charge and Faults Low

Trickle Charge

Phase

http://onsemi.com

9

NCP1800

Operation Descriptions

The NCP1800 is a linear lithium ion (Li-ion) battery

charge controller and provides the necessary control

functions for charging Li-ion batteries precisely and safely.

It features the constant current and constant voltage method

(CCCV) of charging.

Conditioning and Pre-charge Phase

The NCP1800 initiates a charging cycle upon toggling the

COMP/DIS to LOW or application of the valid external

power source (i.e. V

VCC V

UVLO

OVLO

) with the

Li-ion battery present or when the Li-ion battery is inserted.

Before a charge cycle can begin, the battery conditions are

verified to be within safe limits. The battery will not be

charged when its voltage is less than 0.9 V or higher than

V

SOVLO

.

Li-ion batteries can be easily damaged when fast charged

from a completely discharged state. Also, a fully discharged

Li-ion battery may indicate an abnormal battery condition.

With the built-in safety features of the NCP1800, the Li-ion

battery pre-charges (Pre-Charge Phase) at 10% of the full

rated charging current (I

lower than V

and the CFLG pin is HIGH. T ypically, the

PCTH

battery voltage reaches V

) when the battery voltage is

REG

in a few minutes and then the

PCTH

Full Charge phase begins.

Full Charge (Current Regulation) Phase

When the battery voltage reaches V

, the NCP1800

PCTH

begins fast charging the battery with full rate charging

current I

at the I

sense resistor, R

at I

REG

. The NCP1800 monitors the charging current

REG

input pin by the voltage drop across a current

SNS

, and the charging current is maintained

SNS

by the pass transistor throughout the full charge

phase.

I

is determined by R

REG

SNS

and R

with the following

ISEL

formula:

(1.19 12 k)

(R

ISEL

R

= 0.4 , I

SNS

SNS)

REG

= 0.6 A.

And with R

I

REG

= 60 k and R

ISEL

Since the external P channel MOSFET is used to regulate

the current to charge the battery and operates in linear mode

as a linear regulator, power is dissipated in the pass

transistor. Designing with a very well regulated external

adaptor (e.g. 5.1 V ±1%) can help to minimize the heat

dissipation in the pass transistor. Care must be taken in heat

sink designing in enclosed environments such as inside the

battery operated portables or cellular phones.

The Full Charge phase continues until the battery voltage

reaches V

V

thresholds of 4.1 and 4.2 V.

REG

Final Charge (Voltage Regulation) Phase

Once the battery voltage reaches V

. The NCP1800 comes in two options with

REG

, the pass transistor

REG

is controlled to regulate the voltage across the battery and the

Final Charge phase (constant voltage mode) begins. Once

the charger is in the Final Charge phase, the charger

maintains a regulated voltage and the charging current will

begin to decrease and is dependent on the state of the charge

of the battery. As the battery approaches a fully charged

condition, the charge current falls to a very low value.

Trickle Charge Phase

During the Final Charge phase, the charging current

continues to decrease and the NCP1800 monitors the

charging current through the current sense resistor R

When the charging current decreases to such a level that I

< 0.1 X I

, the CFLG pin is set to LOW and the Trickle

REG

SNS

SNS

Charge phase begins. The charger stays in the Trickle

Charge phase until any fault modes are detected or the

COMP/DIS pin is pulled low to start over the charging cycle.

.

http://onsemi.com

10

NCP1800

Vin = 5.2 V

NTHD4P02FT1

R

SNS

2.0

120 mA

OUT VCCCFLG V

SNS

NCP1800

COMP/

DIS

R

15

GND

COMP

C

COMP

C

out

10

Li-ion

GND

C

in

10 n

I

SNSISEL

R

ISEL

60 k

560 n

Figure 17. Typical Application Circuit for Lower Capacity Batteries (120 mAh shown here)

V

in

NTGS3441T1 & MBRM130L

= 5.2 V

-OR-

NTHD4P02FT1

R

SNS

0.4

OUT VCCCFLG V

SNS

NCP1800

600 mA

COMP/

DIS

R

15

GND

COMP

C

COMP

C

out

10

Li-ion

GND

C

in

10 n

I

SNSISEL

R

ISEL

60 k

560 n

Figure 18. Typical Application Circuit for Higher Capacity Batteries (600 mAh shown here)

http://onsemi.com

11

NCP1800

S

(

Selecting External Components

External Adaptor Power Supply Voltage Selection

Since the NCP1800 is using a linear, charging algorithm,

the efficiency is lower. Adapter voltage selection must be

done carefully in order to minimize the heat dissipation. In

general, the power supply input voltage should be around

5.0 to 6.0 V. The minimum input voltage should be chosen

to minimize the heat dissipation in the system. Excessively

high input voltages can cause too much heat dissipation and

will complicate the thermal design in applications like

cellular phones. With the overvoltage protection feature of

the NCP1800, input voltages higher than 7.0 V will activate

the overvoltage protection circuit and disconnect the power

supply input to the battery and other circuitry.

For the application shown in Figure 18 (assuming

NTGS3441 and MBRM130L):

V

Li- ion regulated voltage,

IN(min)

V

(0.6 A)(R

REG

VFof Schottky Diode voltage drop of R

4.2 V (0.6 A) (100 m) 0.38 V

0.6 A)(0.4 ) 4.88 V 4.9 V

DS(ON)

)

SN

Therefore, for the application shown in Figure 17

(assuming NTHD4P01FT1):

V

Li- ion regulated voltage

IN(min)

4.2 V (0.12 A)(130m) 0.43

(0.12 A)(2.0 ) 4.89 V 4.9 V

If the output voltage accuracy is 5%, then a typ. 5.2 V

5% output voltage adaptor must be used.

And for a very good regulated adaptor of accuracy 1%, 5.0

V ±1% output voltage adaptor can then be used. It is obvious

that if tighter tolerance adaptors are used, heat dissipation

can be minimized by using lower nominal voltage adaptors.

Pass Element Selection

The type and size of the pass transistor is determined by

input-output differential voltage, charging current, current

sense resistor and the type of blocking diode used.

The selected pass element must satisfy the following

criteria:

Drop across pass element =

V

IN(min)

Li- ion regulated voltage VF I

REG

R

SNS

With:

V

IN(min)

V

REG

I

R

REG

SNS

5.0 V

4.2 V

0.6 A

0.4

Dropout across pass element =

5.0 V 4.2 V 0.38 V (0.6 A) (0.4 ) 0.18 V

Maximum R

should be less than (0.18 V)/(0.6 A) =

DS(on)

0.3 at 0.6 A.

V

IN(min)

V

REG

I

R

REG

SNS

5.0 V

4.2 V

0.12 A

2.0

Dropout across pass element = 5.0 V - 4.2 V - 0.43 V -

(0.12)(2.0 V

Therefore, maximum R

should be less than

DS(on)

(0.13 V)/(0.12 A) = 1.08 at 0.12 A.

External Output Capacitor

Any good quality output filter can be used, independent of

the capacitor’s minimum ESR. However, a 10 F tantalum

capacitor or electrolytic capacitor is recommended at the

output to suppress fast ramping spikes at the V

input and

SNS

to ensure stability for 1.0 A at full range. The capacitor

should be mounted with the shortest possible lead or track

length to the VSNS and GND pins.

Current Sense Resistor

The charging current can be set by the value of the current

sense resistor as in the previous formula. Proper de-rating

is advised when selecting the power dissipation rating of the

resistor. If necessary, R

selection of the R

SNS

can also be changed for proper

ISEL

values. T ake note of the recommended

full-charge current ranges specified in the electrical

characteristics section. Also notice the effect of RISEL on

the accuracy of pre-charge current and end-of-charge

detection as noted in Figures 10 and 12, respectively.

http://onsemi.com

12

NCP1800

PACKAGE DIMENSIONS

Micro8

DM SUFFIX

CASE 846A-02

ISSUE F

SEATING

PLANE

-T-

0.038 (0.0015)

PIN 1 ID

-A-

K

G

-B-

8 PL

D

0.08 (0.003) A

M

T

S

B

S

C

H

J

L

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A DOES NOT INCLUDE MOLD FLASH,

PROTRUSIONS OR GATE BURRS. MOLD FLASH,

PROTRUSIONS OR GATE BURRS SHALL NOT

EXCEED 0.15 (0.006) PER SIDE.

4. DIMENSION B DOES NOT INCLUDE INTERLEAD

FLASH OR PROTRUSION. INTERLEAD FLASH OR

PROTRUSION SHALL NOT EXCEED 0.25 (0.010)

PER SIDE.

5. 846A−01 OBSOLETE, NEW STANDARD 846A−02.

DIM MIN MAX MIN MAX

A 2.90 3.10 0.114 0.122

B 2.90 3.10 0.114 0.122

C −−− 1.10 −−− 0.043

D 0.25 0.40 0.010 0.016

G 0.65 BSC 0.026 BSC

H 0.05 0.15 0.002 0.006

J 0.13 0.23 0.005 0.009

K 4.75 5.05 0.187 0.199

L 0.40 0.70 0.016 0.028

INCHESMILLIMETERS

http://onsemi.com

13

NCP1800

ChipFET is a trademark of Vishay Siliconix.

FETKY and Micro8 are trademarks of International Rectifier Corporation.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make

changes without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any

particular purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all

liability, including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death

may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303-675-2175 or 800-344-3860 Toll Free USA/Canada

Fax: 303-675-2176 or 800-344-3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

N. American Technical Support: 800-282-9855 Toll Free USA/Canada

http://onsemi.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

2-9-1 Kamimeguro, Meguro-ku, Tokyo, Japan 153-0051

Phone: 81-3-5773-3850

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

NCP1800/D

14

WWW.ALLDATASHEET.COM

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...