Page 1

NCP1523

s

3 MHz, 600 mA,

High−Efficiency, Adjustable

Output Voltage Step−down

Converter

The NCP1523 step−down PWM DC−DC converter is optimized for

portable applications powered from 1−cell Li−ion or 3 cell

Alkaline/NiCd/NiMH batteries. The device is available in an

adjustable output voltage from 0.9 V to 3.3 V. It uses synchronous

rectification to increase efficiency and reduce external part count. The

device also has a built−in 3 MHz (nominal) oscillator which reduces

component size by allowing use of a small inductor and capacitors.

NCP1523 is available in automatic switching PWM/PFM

(NCP1523FCT2G) improving system efficiency and in PWM mode

only (NCP1523BFCT2G) offering a very efficient load transient

solution.

Additional features include integrated soft−start, cycle−by−cycle

current limiting and thermal shutdown protection. The NCP1523 is

available in a space saving, 8 pin chip scale package.

Features

• Sources up to 600 mA

• 3 MHz Switching Frequency

• Up to 93% Efficiency

• Synchronous rectification for higher efficiency

• Thermal limit protection

• Shutdown current consumption of 0.3 A

• These are Pb−Free Devices

Special Features for NCP1523FCT2G

• Auto PFM/PWM mode solution

• High efficiency at light load

http://onsemi.com

A1

FLIP−CHIP−8

CASE 766AE

NCPxxxx = Device Code

A = Assembly Location

Y = Year

WW = Work Week

G = Pb−Free Package

A1

B1

C1

D1

Top View

(Bumps Below)

xxxx = 1523 or 523B

PIN CONNECTIONS

A2

PIN: A1 − GND

B2

C2

D2

MARKING

DIAGRAM

NCPxxxxG

AYWW

A1

A2 − V

IN

B1 − SW

B2 − EN

C1 − GND

C2 − ADJ

D1 − V

OUT

D2 − FB

Special Features for NCP1523BFCT2G

• Load Transient Highly Efficient Solution

• Very small Output Voltage Ripple

• Adjustable Output Voltage from 0.9 V to 3.3 V

Typical Applications

• Cellular Phones, Smart Phones and PDAs

• Digital Still Cameras

• MP3 Players and Portable Audio Systems

• Wireless and DSL Modems

• Portable Equipment

© Semiconductor Components Industries, LLC, 2007

February, 2007 − Rev. 2

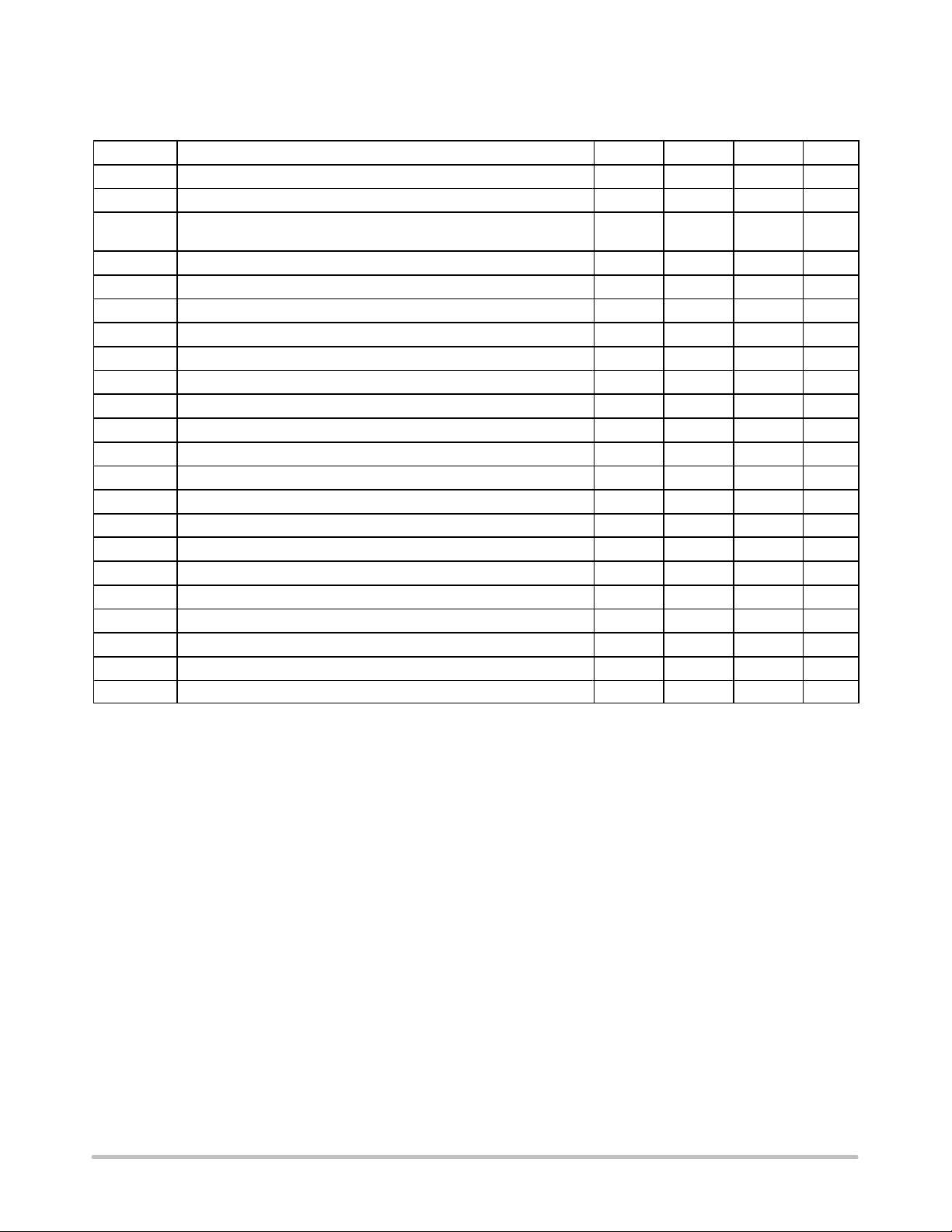

ORDERING INFORMATION

Device Package Shipping

NCP1523FCT2G

(NCP1523)

NCP1523BFCT2G

(NCP1523B)

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specification

Brochure, BRD8011/D.

1 Publication Order Number:

FLIP−CHIP−8

(Pb−Free)

FLIP−CHIP−8

(Pb−Free)

Tape & Reel

Tape & Reel

NCP1523/D

†

3000 /

3000 /

Page 2

NCP1523

V

BATTERY

4.7 F

V

A2

GND

C1

V

IN

C

IN

A2

C1

A1

V

IN

GND

GND

V

SW

OUT

ADJ

B1

D1

C2

L

V

OUT

C

OUT

R1

OFF ON

B2

EN

FB

D2

R2

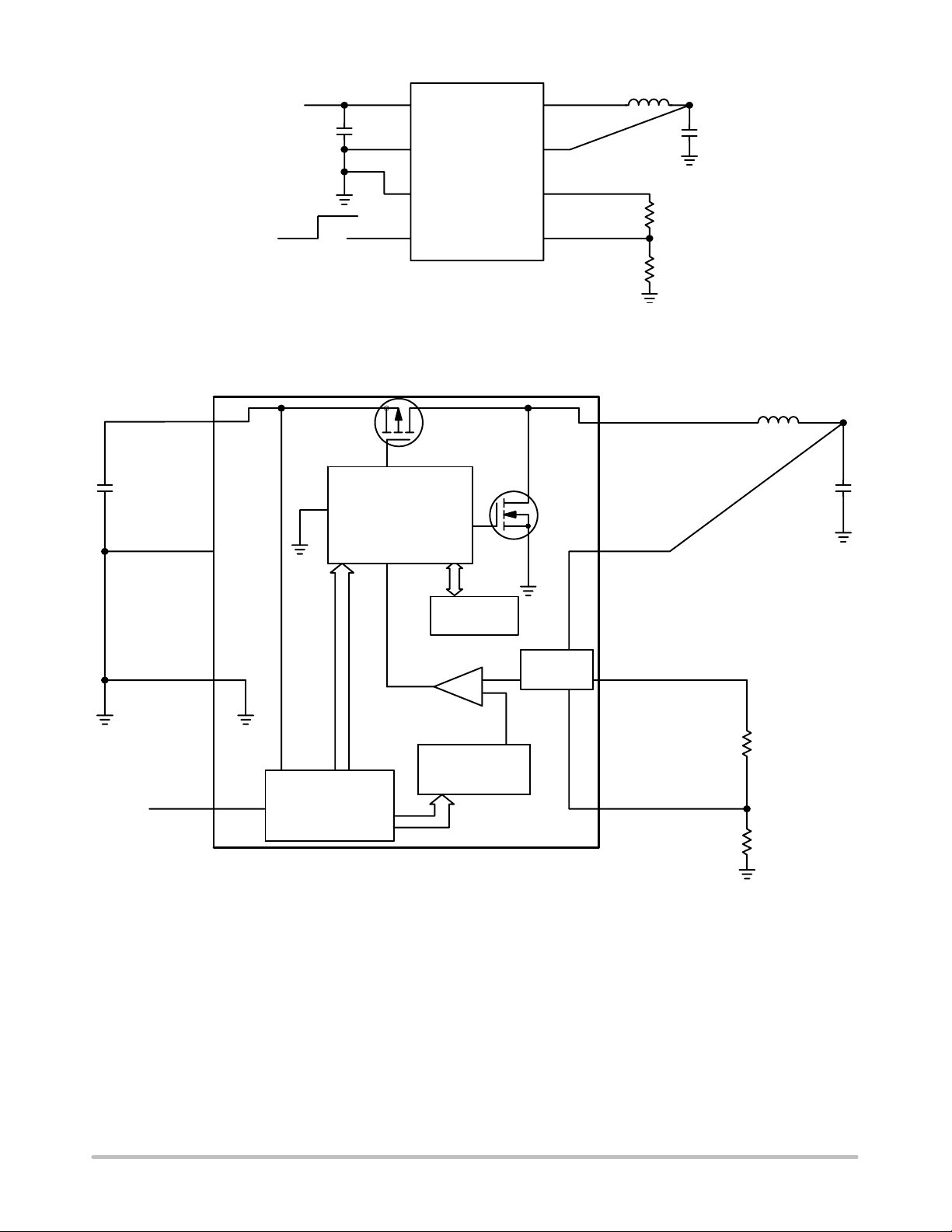

Figure 1. NCP1523 Typical Applications

TYPICAL APPLICATIONS

IN

Q1

Q2

Mode

Control

SW

B1

V

D1

2.2 H

4.7 F

OUT

Enable

GND

A1

EN

B2

I

Reference Voltage

Logic Control &

Thermal Shutdown

Figure 2. Simplified Block Diagram

LIMIT

Comp

ADJ

C2

R1

FB

D2

R2

http://onsemi.com

2

Page 3

NCP1523

PIN FUNCTION DESCRIPTION

Pin Pin Name Type Description

A1 GND Power Ground Ground connection for the NFET Power Stage and the analog sections.

A2 V

B1 S

IN

W

B2 EN Digital Input Enable for Switching Regulator. This pin is active high. This pin contains an internal

C1 GND Power Ground Ground connection for the NFET Power Stage and the analog sections.

C2 ADJ Analog Input This pin is the compensation input. R1 is connected to this pin.

D1 V

OUT

D2 FB Analog Input Feedback voltage from the output of the power supply. This is the input to the error

MAXIMUM RATINGS

Minimum Voltage All Pins V

Maximum Voltage All Pins (Note 1) V

Maximum Voltage Enable, FB, SW V

Thermal Resistance, Junction−to−Air (Note 2)

Operating Ambient Temperature Range T

Storage Temperature Range T

Junction Operating Temperature T

Latch−up Current Maximum Rating TA = 85°C (Note 4) L

ESD Withstand Voltage (Note 3)

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

1. According to JEDEC standard JESD22−A108B

2. For the 8−Pin Chip Scale Package, the R

3. This device series contains ESD protection and exceeds the following tests:

Human Body Model (HBM) $2.0 kV per JEDEC standard: JESD22−A114

Machine Model (MM) $200 V per JEDEC standard: JESD22−A115

4. Latchup current maximum rating per JEDEC standard: JESD78.

Human Body Model

Machine Model

Power Input Power Supply Input for the PFET Power Stage and the Analog Sections of the IC.

Analog Output Connection from Power MOSFETs to the Inductor.

pulldown resistor.

Analog Input This pin is connected of the converter’s output. This is the sense of the output voltage.

amplifier.

Rating Symbol Value Unit

−0.3 V

7 V

VIN + 0.3 V

159 °C/W

−40 to 85 °C

−55 to 150 °C

−40 to 125 °C

"100 mA

2.0

V

R

MIN

MAX

MAX

JA

A

STG

J

U

ESD

200

is highly dependent of the PCB heatsink area. R

JA

= 159°C/W with 50 mm2 PCB heatsink area.

JA

kV

V

http://onsemi.com

3

Page 4

NCP1523

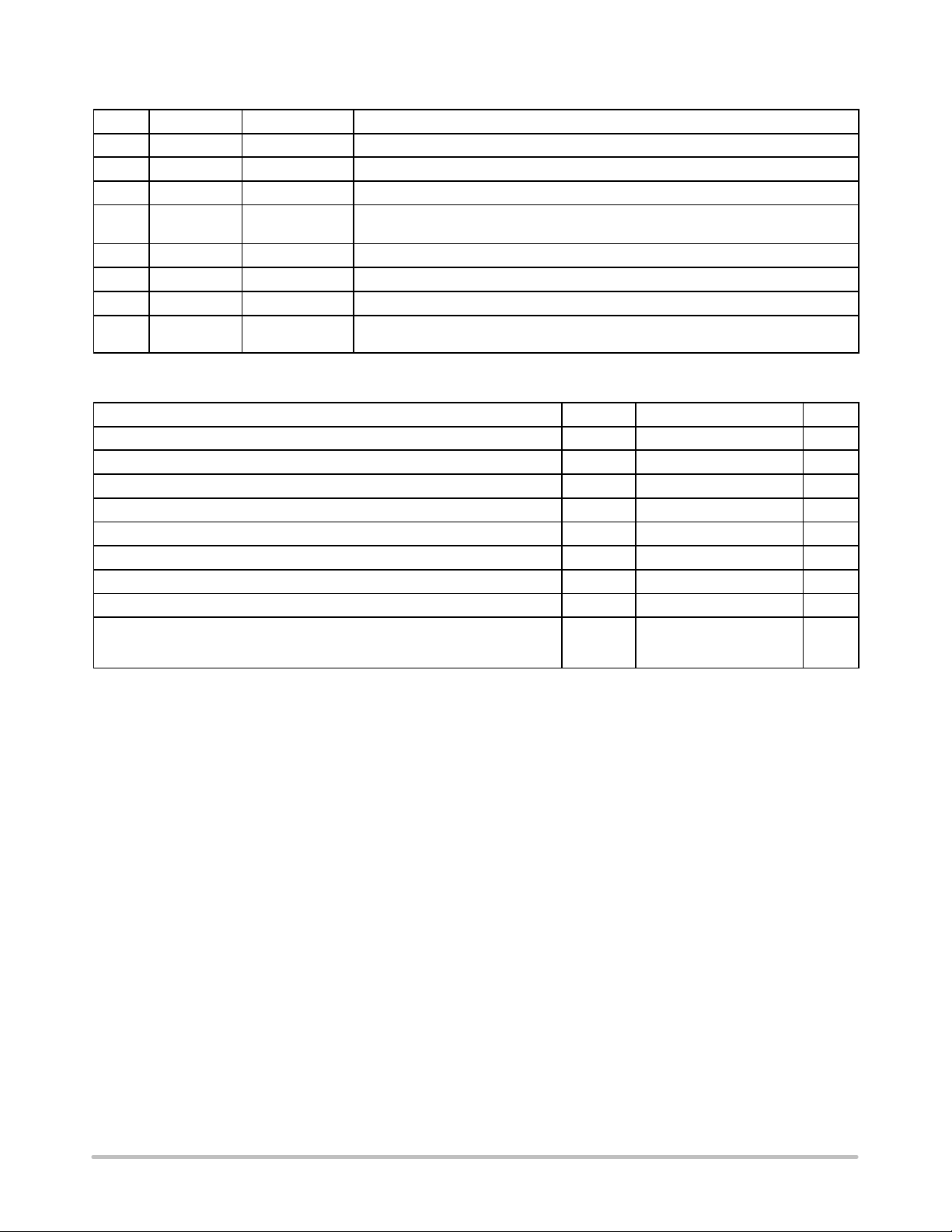

ELECTRICAL CHARACTERISTICS FOR NCP1523

(Typical values are referenced to TA = +25°C, Minimum and Maximum values are referenced −40°C to +85°C ambient temperature,

unless otherwise noted, operating conditions VIN = 3.6 V, V

Symbol Rating Min Typ Max Unit

V

IN

V

UVLO

I

q

I

STB

F

OSC

I

LIM

V

REF

V

FBtol

V

FB

V

OUT

V

OUT

V

OUT

V

OUT

V

LOADREG

Input Voltage Range 2.7 5.5 V

Under Voltage Lockout (VIN Falling) 2.4 V

Quiescent Current (Light Load Mode) 60 95

Standby Current, EN Low 0.3 1.2

Oscillator Frequency 2.400 3 3.600 MHz

Peak Inductor Current 1200 mA

Feedback Reference Voltage 0.6 V

FB Pin Tolerance Overtemperature −3 3 %

Reference Voltage Line Regulation 0.1 %

Output Voltage Accuracy (Note 5) −3% V

Minimum Output Voltage 0.9 V

Maximum Output Voltage 2.3 V

Output Voltage Line Regulation (VIN from 2.7 to 5.5) IO = 100 mA 0.1 %

Voltage Load Regulation (IO = 150 mA to 600 mA) 0.001 %/mA

Duty Cycle 100 %

R

SWH

R

SWL

I

LeakH

I

LeakL

V

ENH

V

ENL

T

START

P−Channel On−Resistance 300

N−Channel On−Resistance 300

P−Channel Leakage Current 0.05

N−Channel Leakage Current 0.01

Enable Pin High 1.2 V

Enable Pin Low 0.4 V

Soft Start Time 350 450

5. The overall output voltage tolerance depends upon the accuracy of the external resistor (R1, R2).

= 1.2 V unless otherwise noted)

OUT

nom

+3% V

A

A

m

m

A

A

s

http://onsemi.com

4

Page 5

NCP1523

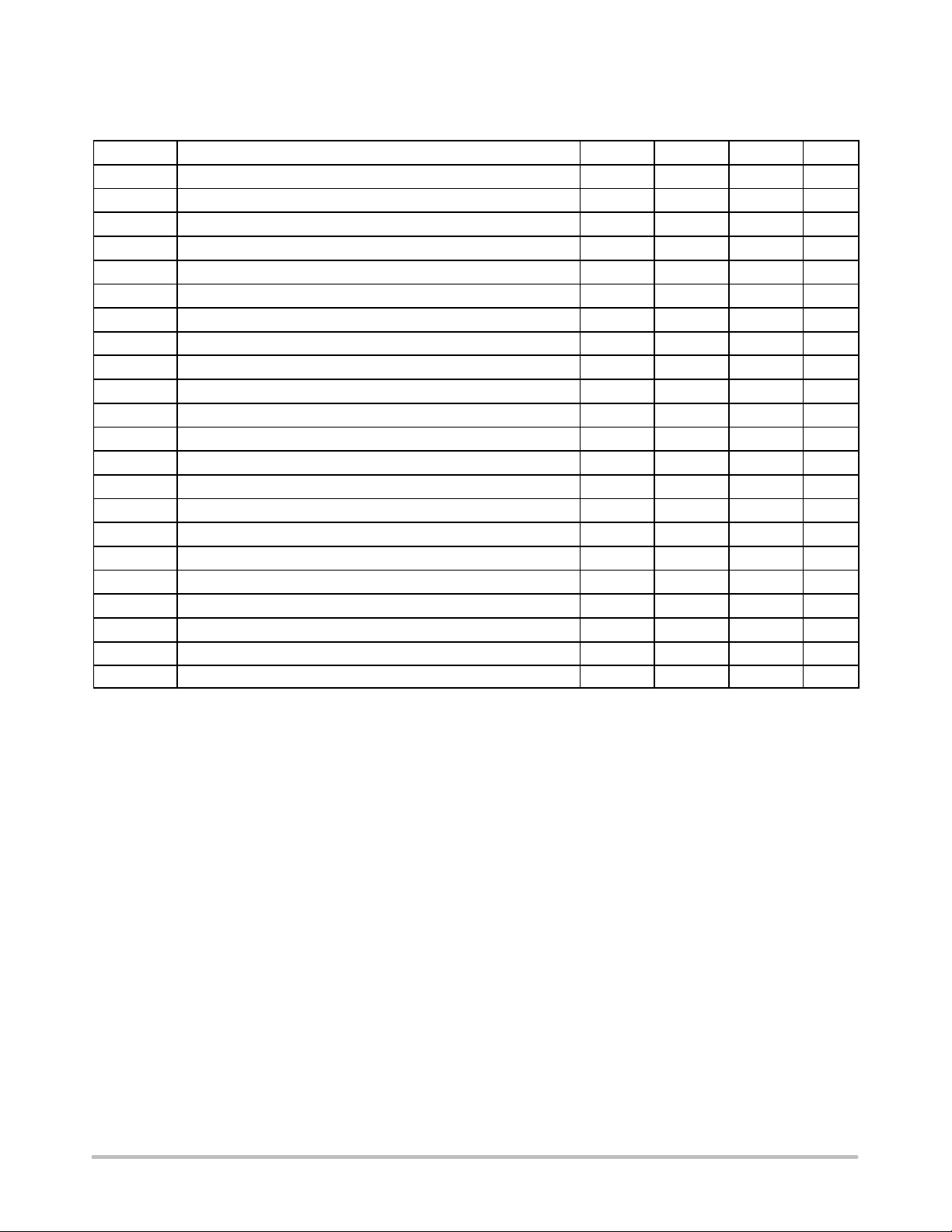

ELECTRICAL CHARACTERISTICS FOR NCP1523B

(Typical values are referenced to TA = +25°C, Minimum and Maximum values are referenced −40°C to +85°C ambient temperature,

unless otherwise noted, operating conditions VIN = 3.6 V, V

Symbol Rating Min Typ Max Unit

V

IN

V

UVLO

I

q

I

STB

F

OSC

I

LIM

V

REF

V

FBtol

V

FB

V

OUT

V

OUT

V

OUT

V

OUT

V

LOADREG

Input Voltage Range 2.7 5.2 V

Under voltage Lockout (VIN Falling) 2.4 V

Quiescent Current − No Switching

Quiescent Current − Oscillator Running

Standby Current, EN Low 0.3 1.2

Oscillator Frequency 2.400 3 3.600 MHz

Peak Inductor Current 1200 mA

Feedback Reference Voltage 0.6 V

FB Pin Tolerance Overtemperature −3 3 %

Reference Voltage Line Regulation 0.1 %

Output Voltage Accuracy (Note 6) −3% V

Minimum Output Voltage (Note 7) 0.9 V

Maximum Output Voltage 3.3 V

Output Voltage Line Regulation (VIN = 2.7 – 5.2) IO = 100 mA (Note 7) 0.1 %

Voltage Load Regulation (IO = 1 mA to 600 mA) (Note 7) 0.001 %/mA

Duty Cycle 100 %

R

SWH

R

SWL

I

LeakH

I

LeakL

V

ENH

V

ENL

T

START

P−Channel On−Resistance 300

N−Channel On−Resistance 300

P−Channel Leakage Current 0.05

N−Channel Leakage Current 0.01

Enable Pin High 1.2 V

Enable Pin Low 0.4 V

Soft−Start Time 350 450

6. The overall output voltage tolerance depends upon the accuracy of the external resistor (R1, R2).

7. Electrical values are guaranteed for drop between input and output voltages less than 4.0 V (Page 13).

= 1.2 V unless otherwise noted)

OUT

250

2.5

nom

350

+3% V

A

mA

A

m

m

A

A

s

http://onsemi.com

5

Page 6

TABLE OF GRAPHS

Efficiency

Output Voltage vs. Temperature

Frequency Variation vs. Input Voltage 9, 10 19

Load Regulation

Line Regulation

Load Transient Response 15, 16 32, 33

Line Transient Response 31

Shutdown Current

Quiescent Current vs. Temperature 4 29

PWM Mode Operation 13 18

PFM Mode Operation 14

PFM/PWM Threshold vs. Input Voltage 12

Soft Start 17 30

V

F

V

V

V

V

T

OUT

OSC

OUT

OUT

OUT

OUT

I

stb

I

start

q

NCP1523

TYPICAL CHARACTERISTICS NCP1523FCT2G NCP1523BFCT2G

vs. Load Current 6, 7, 8 20, 21, 22

vs. Input Voltage 23

vs. Load Current 11 24

vs. Temperature 25

vs. Output Current 26

vs. Temperature 27

vs. Input Voltage 5

vs. Temperature 3 28

http://onsemi.com

6

Page 7

NCP1523

NCP1523 CHARACTERISTICS

100

90

80

70

60

50

40

30

20

, QUIESCENT CURRENT (A)

q

I

10

0

2.5 3.0 3.5 4.0 4.5 5.0 5.5

VIN, INPUT VOLTAGE (V)

EN = VIN

I

OUT

Figure 3. Quiescent Current vs. Supply

Voltage

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

SHUTDOWN CURRENT (A)

0.1

0

2.5 3.0 3.5 4.0 4.5 5.0 5.5

VIN, INPUT VOLTAGE (V)

Figure 5. Shutdown Current vs. Supply

Voltage

= 0 mA

EN = GND

I

= 0 mA

OUT

100

90

80

70

60

50

40

30

20

, QUIESCENT CURRENT (A)

q

I

10

0

−40 10 60 110

VIN = 5.5 V

TEMPERATURE (°C)

VIN = 2.7 V

Figure 4. Quiescent Current vs. Temperature

100

90

80

70

60

EFFICIENCY (%)

50

40

30

1 10 100 1000

−40°C

105°C

I

, OUTPUT CURRENT (mA)

OUT

25°C

Figure 6. Efficiency vs. Output Current

(V

= 1.8 V, VIN = 3.6 V)

OUT

100

90

80

70

60

EFFICIENCY (%)

50

40

30

1 10 100 1000

I

, OUTPUT CURRENT (mA)

OUT

−40°C

25°C

105°C

Figure 7. Efficiency vs. Output Current

(V

= 0.9 V, VIN = 3.6 V)

OUT

100

90

80

70

60

50

EFFICIENCY (%)

40

30

http://onsemi.com

7

−40°C

25°C

105°C

1 10 100 1000

I

, OUTPUT CURRENT (mA)

OUT

Figure 8. Efficiency vs. Output Current

(V

= 2.0 V, VIN = 3.6 V)

OUT

Page 8

NCP1523

NCP1523 CHARACTERISTICS

3.6

3.4

I

= 400 mA

3.2

3.0

2.8

FREQUENCY (MHz)

2.6

2.4

2.8 3.3 3.8 4.3 4.8 5.3

OUT

I

= 600 mA

OUT

VIN, INPUT VOLTAGE (V)

Figure 9. Frequency vs. Input Voltage

5.0

3.0

1.0

−1.0

LOAD REGULATION (%)

−3.0

−5.0

V

= 0.9 V

OUT

V

= 2.0 V

OUT

0 100 200 300 400 500 600

I

, OUTPUT CURRENT (mA)

OUT

Figure 11. Load Regulation

3.6

3.4

I

= 400 mA

I

OUT

OUT

= 600 mA

3.2

3.0

2.8

FREQUENCY (MHz)

2.6

2.4

−40 −20 0 20 40 60 80

TEMPERATURE (°C)

Figure 10. Frequency vs. Temperature

300

250

200

150

100

, OUTPUT CURRENT (mA)

50

OUT

I

0

2.7 3.2 3.7 4.2 4.7 5.2

VIN, INPUT VOLTAGE (V)

Figure 12. PFM/PWM Threshold vs. Input

Voltage

Figure 13. Step Down Converter PFM Mode

Operation

Figure 14. Step Down Converter PWM Mode

Operation

http://onsemi.com

8

Page 9

NCP1523

NCP1523 CHARACTERISTICS

Figure 15. Load Transient Response in PFM

Operation (10 mA to 100 mA)

Figure 17. Soft Start Time (VIN = 3.6 V)

Figure 16. Load Transient Response Between

PFM and PWM Operation (100 mA to 200 mA)

http://onsemi.com

9

Page 10

V

2 V/Div

V

2 V/Div

V

OUT

10 mV/Div

I

OUT

200 mA/Div

LX

IN

Figure 18. PWM Mode of Operation

(V

= 3.6 V, V

IN

OUT

= 1.2 V, I

NCP1523

NCP1523B CHARACTERISTICS

3.6

3.5

3.4

3.3

3.2

3.1

3.0

2.9

2.8

FREQUENCY (MHz)

2.7

2.6

2.5

2.4

= 300 mA, 255C)

OUT

2.8 3.3 4.3 5.3

3.8 4.8

Vin, INPUT VOLTAGE (V)

Figure 19. Switching Frequency vs. Input

Voltage (V

= 1.2 V, I

OUT

= 300 mA, 255C)

OUT

100

2.7 V

3.6 V

Vin = 5.2 V

0 100 200 300 400 500 600

I

, OUTPUT CURRENT (mA)

OUT

EFFICIENCY (%)

90

80

70

60

50

40

30

Figure 20. Efficiency vs. Output Current

(V

= 1.2 V, 255C)

OUT

100

90

80

70

60

3.3 V

1.2 V

0.9 V

90

80

70

EFFICIENCY (%)

60

50

0 100 200 600

I

, OUTPUT CURRENT (mA)

OUT

25°C

300 400 500

−40°C

85°C

Figure 21. Efficiency vs. Output Current

(V

= 1.2 V, VIN = 3.6 V)

OUT

100

90

80

70

60

25°C

−40°C

85°C

EFFICIENCY (%)

50

40

30

0 100 200 600

I

, OUTPUT CURRENT (mA)

OUT

300 400 500

Figure 22. Efficiency vs. Output Current

(V

= 3.6 V, 255C)

IN

EFFICIENCY (%)

50

40

30

http://onsemi.com

10

2.5 3.0 3.5 5.5

VIN, INPUT VOLTAGE (V)

4.0 4.5 5.0

Figure 23. Efficiency vs. Input Current

(V

OUT

= 1.2 V, I

= 100 mA)

OUT

Page 11

NCP1523

NCP1523B CHARACTERISTICS

6

4

2

0

−2

LOAD REGULATION (mV)

−4

−6

0 100 200 300 400 600

I

(mA)

OUT

3.6 V

Vin = 5.5 V

Figure 24. Load Regulation vs. Input Voltage

(V

= 1.2 V, 255C)

OUT

6

5

4

3

I

= 600 mA

OUT

2

1

0

100 mA

−1

−2

−3

LINE REGULATION (mV)

−4

−5

−6

2.5 3.0 3.5 4.0 4.5 5.0 5.5

1 mA

Vin (V)

Figure 26. Line Regulation vs. Output Current

(V

= 1.2 V, 255C)

OUT

500

2.7 V

4

3

2

1

0

−1

−2

LOAD REGULATION (mV)

−3

−4

0 100 200 300 400 500 600

I

(mA)

out

Figure 25. Load Regulation vs. Temperature

(V

= 3.6 V, V

IN

6

5

4

3

2

1

−40°C

0

85°C

−1

−2

−3

LINE REGULATION (mV)

−4

−5

−6

2.5 3.0 3.5 4.0 4.5 5.5

25°C

Vin, INPUT VOLTAGE (V)

OUT

= 1.2 V)

Figure 27. Line Regulation vs. Temperature

(V

= 1.2 V, I

OUT

= 100 mA)

OUT

−40°C

25°C

85°C

5.0

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

, SHUTDOWN CURRENT

0.10

stb

I

0.05

0

−40 −15 10 35 60 85

TEMPERATURE (°C)

Figure 28. Shutdown Current vs. Temperature

(V

= 3.6 V)

OUT

3.9

3.7

3.5

3.3

3.1

2.9

, QUIESCENT CURRENT

q

I

2.7

2.5

−40 −15 10 35 85

http://onsemi.com

11

Vin = 4.2 V

2.7 V

3.6 V

60

TEMPERATURE (°C)

Figure 29. Quiescent Current vs. Temperature

Page 12

NCP1523

NCP1523B CHARACTERISTICS

500 mV/Div

V

V

OUT

I

OUT

OUT

EN

(V

= 3.6 V, V

IN

20 mV/Div

2 V/Div

200 mA/Div

Figure 30. Soft Start Time

16 mV

= 1.2 V, I

OUT

= 600 mA)

OUT

V

V

OUT

V

OUT

IN

20 mV/Div

500 mV/Div

Figure 31. Line Transient Response

(VIN step = 600 mV, V

50 mV/Div

45 mV

OUT

= 1.2 V)

I

OUT

50 mA/Div

Figure 32. Load Transient Response

(V

= 3.6 V, V

IN

= 1.2 V, 0 mA to 95 mA step)

OUT

I

OUT

(VIN = 3.6 V, V

200 mA/Div

Figure 33. Load Transient Response

= 1.2 V, 0 mA to 400 mA step)

OUT

http://onsemi.com

12

Page 13

NCP1523

OPERATION DESCRIPTION

Overview

The NCP1523 uses a constant frequency, voltage mode

step−down architecture. Both the main (P−channel

MOSFET) and synchronous (N−channel MOSFET)

switches are internal.

It delivers a constant voltage from either a single Li−Ion

or three cell NiMH/NiCd battery to portable devices such as

cell phones and PDA. The output voltage is sets by external

resistor divider and has a voltage tolerance of ±3% with 90%

efficiency or better. The NCP1523 sources up to 600 mA

depending on external components chosen.

Additional features include soft−start, under voltage

protection, current overload protection, and thermal

shutdown protection. As shown in Figure 1, only six

external components are required for implementation. The

part uses an internal reference voltage of 0.6 V. It is

recommended to keep the part in shutdown until the input

voltage is 2.7 V or higher.

PWM Operating Mode: NCP1523 & NCP1523B

In this mode, the output voltage of the NCP1523 is

regulated by modulating the on−time pulse width of the

main switch Q1 at a fixed frequency of 3 MHz. The

switching of the PMOS Q1 is controlled by a flip−flop

driven by the internal oscillator and a comparator that

compares the error signal from an error amplifier with the

PWM ramp. At the beginning of each cycle, the main switch

Q1 is turned ON by the rising edge of the internal oscillator

clock. The inductor current ramps up until the sum of the

current sense signal and compensation ramp becomes higher

than the amplifier’s error voltage. Once this has occurred,

the PWM comparator resets the flip−flop, Q1 is turned OFF

and the synchronous switch Q2 is turned ON. Q2 replaces

the external Schottky diode to reduce the conduction loss

and improve the efficiency. To avoid overall power loss, a

certain amount of dead time is introduced to ensure Q1 is

completely turned OFF before Q2 is being turned ON.

PFM Operating Mode at Light Load: NCP1523 Only

The NCP1523FCT2G works with two mode of operation

PWM/PFM depending on the current required. Under light

load conditions, the NCP1523FCT2G enters in low current

PFM mode of operation to reduce power consumption (IQ =

60 A typ). The output regulation is implemented by pulse

frequency modulation. If the output voltage drops below the

threshold of PM comparator (typically V

−2%), a new

nom

cycle will be initiated by the PM comparator to turn on the

switch Q1. Q1 remains ON until the peak inductor current

reaches 200 mA (nom). Then I

comparator goes high to

LIM

switch OFF Q1. After a short dead time delay, switch

rectifier Q2 is turn ON. The Negative current detector

(NCD) will detect when the inductor current drops below

zero and the output voltage decreases through discharging

the output capacitor. When the output voltage falls below the

threshold of the PFM comparator, a new cycle starts

immediately.

PWM Operating Mode at Light Load: NCP1523B Only

At low light conditions, NCP1523BFCT2G works also in

PWM mode offering very good load transient results from

light load to full charge. When there is no load on the output,

the PMOS Q1 remains ON during a small pulse according

to the flip−flop driven by the internal oscillator and the error

comparator. If the drop between input and output voltage is

higher than 4.0 V, the structure reaches the minimum ON

time (T

). In this particular case, the part can not supply

ONmin

correctly the desired output voltage and shows a small

output voltage deregulation. For an output voltage

configured to 0.9 V, 4.9 V is the maximum input voltage

which guarantees the correct output value; for an output set

to 1.5 V, the maximum input is 5.5 V.

Cycle−by−Cycle Current Limitation

From the block diagram (Figure 3), an I

comparator is

LIM

used to realize cycle−by−cycle current limit protection. The

comparator compares the SW pin voltage with the reference

voltage, which is biased by a constant current. If the inductor

current reaches the limit, the I

comparator detects the

LIM

SW voltage falling below the reference voltage and releases

the signal to turn off the switch Q1. The cycle−by−cycle

current limit is set at 1200 mA (nom).

Soft Start

The NCP1523 uses soft−start to limit the inrush current

when the device is initially powered up or enabled.

Soft−start is implemented by gradually increasing the

reference voltage until it reaches the full reference voltage.

During startup, a pulsed current source charges the internal

soft−start capacitor to provide gradually increasing

reference voltage. When the voltage across the capacitor

ramps up to the nominal reference voltage, the pulsed

current source will be switched off and the reference voltage

will switch to the regular reference voltage.

Shutdown Mode

When a voltage less than 0.4 V is applied on the EN pin,

the NCP1523 will be disabled. In shutdown mode, the

internal reference, oscillator and most of the control

circuitries are turned off. Therefore, the typical current

consumption will be 0.3 A (typical value). Applying a

voltage above 1.2 V to EN pin will enable the device for

normal operation. The device will go through soft−start to

normal operation. EN pin should be activated after the input

voltage is applied.

Thermal Shutdown

Internal Thermal Shutdown circuitry is provided to

protect the integrated circuit in the event that the maximum

junction T emperature is exceeded. I f t he j unction t emperature

exceeds 160_C, the device shuts down. In this mode switch

Q1 and Q2 and the control circuits are all turned off. The

device restarts in soft start after the temperature drops below

135°C. This feature is provided to prevent catastrophic

failures from accidental device overheating.

http://onsemi.com

13

Page 14

NCP1523

APPLICATION INFORMATION

Output Voltage Selection

The output voltage is programmed through an external

resistor divider connected from ADJ to FB then to GND. For

low power consumption and noise immunity, the resistor

from FB to GND (R2) should be in the [100 k − 600 k]

range. If R2 is 200 k given the VFB is 0.6 V, the current

through the divider will be 3 A.

The formula below gives the value of V

, given the

OUT

desired R1 and the R1 value,

V

+ V

OUT

• V

• V

: output voltage (volts)

OUT

: feedback voltage = 0.6 V

FB

FB

• R1: feedback resistor from V

ǒ

OUT

1 )

R2

to FB

Ǔ

R1

• R2: feedback resistor from FB to GND

Input Capacitor Selection

In PWM operating mode, the input current is pulsating

with large switching noise. Using an input bypass capacitor

can reduce the peak current transients drawn from the input

supply source, thereby reducing switching noise

significantly. The capacitance needed for the input bypass

capacitor depends on the source impedance of the input

supply.

The maximum RMS current occurs at 50% duty cycle

with maximum output current, which is IO, max/2.

For NCP1523, a low profile ceramic capacitor of 4.7 F

should be used for most of the cases. For effective bypass

results, the input capacitor should be placed as close as

possible to the VIN Pin.

Table 1. LIST OF INPUT CAPACITOR

Murata

Taiyo Yuden JMK212BY475MG

TDK

Output L−C Filter Design Considerations:

The NCP1523 is built in 3 MHz frequency and uses

voltage mode architecture. The correct selection of the

output filter ensures good stability and fast transient

response.

Due to the nature of the buck converter, the output L−C

filter must be selected to work with internal compensation.

For NCP1523, the internal compensation is internally fixed

and it is optimized for an output filter of L = 2.2 H and

C

= 4.7 F

OUT

The corner frequency is given by:

f

+

c

1

Ǹ

2 L C

OUT

GRM188R60J475KE

GRM21BR71C475KA

C2012X5R0J475KT

C1608X5R0J475KT

+

2 2.2 H 4.7 F

1

Ǹ

+ 49.5 KHz

The device operates with inductance value between 1 H

and maximum of 4.7 H.

If the corner frequency is moved, it is recommended to

check the loop stability depending of the output ripple

voltage accepted and output current required. For lower

frequency, the stability will be increase; a larger output

capacitor value could be chosen without critical effect on the

system. On the other hand, a smaller capacitor value

increases the corner frequency and it should be critical for

the system stability. Take care to check the loop stability.

The phase margin is usually higher than 45°.

Table 2. L−C FILTER EXAMPLE

Inductance (L) Output Capacitor (C

1 H 10 F

2.2 H 4.7 F

4.7 H 2.2 F

Inductor Selection

OUT

)

The inductor parameters directly related to device

performances are saturation current and DC resistance and

inductance value. The inductor ripple current (IL)

decreases with higher inductance:

I

V

OUT

+

L

L f

SW

V

OUT

ǒ

1−

Ǔ

V

IN

IL = peak to peak inductor ripple current

L = inductor value

fSW = Switching frequency

The Saturation current of the inductor should be rated

higher than the maximum load current plus half the ripple

current:

I

)

L

2

I

L(MAX)

I

O(MAX)

I

L(MAX)

+ I

O(MAX)

Maximum inductor current

Maximum Output current

The inductor’s resistance will factor into the overall

efficiency of the converter. For best performances, the DC

resistance should be less than 0.3 for good efficiency.

Table 3. LIST OF INDUCTOR

FDK MIPW3226 Series

TDK

Taiyo Yuden LQ CBL2012

Coil Craft

VLF3010AT Series

TFC252005 Series

DO1605−T Series

LPO3010

http://onsemi.com

14

Page 15

NCP1523

Output Capacitor Selection

Selecting the proper output capacitor is based on the

desired output ripple voltage. Ceramic capacitors with low

ESR values will have the lowest output ripple voltage and

are strongly recommended. The output capacitor requires

either an X7R or X5R dielectric.

The output ripple voltage in PWM mode is given by:

V

OUT

+ I

ǒ

L

4 fSW C

1

OUT

) ESR

Ǔ

In PFM mode (at light load), the output voltage is

regulated by pulse frequency modulation. The output

voltage ripple is independent of the output capacitor value.

It is set by the threshold of PM comparator.

Table 4. LIST OF OUTPUT CAPACITOR ROHS

Murata

Taiyo Yuden

TDK

GRM188R60J475KE 4.7 F

GRM21BR71C475KA

GRM188R60OJ106ME

JMK212BY475MG

JMK212BJ106MG

C2012X5R0J475KT 4.7 F

C1608X5R0J475KT

C2012X5R0J106KT

10 F

4.7 F

10 F

10 F

http://onsemi.com

15

Page 16

NCP1523

PACKAGE DIMENSIONS

8 PIN FLIP−CHIP, 2.05x1.05, 0.5P

CASE 766AE−01

ISSUE C

2X

TERMINAL A1

LOCATOR

2X

8X

NOTE 3

8X

0.03 C

0.10 C

0.10 C

0.05 C

b

A0.05 BC

0.10 C

1

2

BOTTOM VIEW

D

TOP VIEW

SIDE VIEW

D1

AB

C

A

A2

B

E

A1

C

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. COPLANARITY APPLIES TO SPHERICAL

CROWNS OF SOLDER BALLS.

MILLIMETERS

DIMAMIN MAX

−−−

A1

A2 0.335 0.385

b 0.290 0.340

D 2.050 BSC

D1

E

e 0.500 BSC

0.655

0.210 0.270

1.500 BSC

1.050 BSC

A

SEATING

PLANE

e

e/2

D

e

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5773−3850

http://onsemi.com

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

NCP1523/D

16

Loading...

Loading...