Page 1

查询NCP1030供应商

NCP1030, NCP1031

Low Power PWM Controller

with On−Chip Power Switch

and Startup Circuits for

48V Telecom Systems

The NCP1030 and NCP1031 are a family of miniature high−voltage

monolithic switching regulators with on−chip Power Switch and Startup

Circuits. The NCP103x family incorporates in a single IC all the active

power, control logic and protection circuitry required to implement, with

minimal external components, several switching regulator applications,

such as a secondary side bias supply or a low power dc−dc converter.

This controller family is i deally s uited f or 4 8 V t elecom, 4 2 V a utomotive

and 12 V input applications. The NCP103x can be configured in any

single−ended topology such as forward or flyback. The NCP1030 is

targeted for applications requiring up to 3 W, and the NCP1031 is

targeted for applications requiring up to 6 W.

The internal error amplifier allows the NCP103x family to be easily

configured for secondary or primary side regulation operation in

isolated and non−isolated configurations. The fixed frequency o scillator

is optimized for operation up to 1 MHz and is capable of external

frequency synchronization, providing additional design flexibility. In

addition, the NCP103x incorporates individual line undervoltage and

overvoltage detectors, cycle by cycle current limit and thermal

shutdown to protect the controller under fault conditions. The preset

current limit thresholds eliminate the need for external sensing

components.

http://onsemi.com

8

1

8

1

1030/N1031 = Specific Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

Micro8

DM SUFFIX

CASE 846A

SO−8

D SUFFIX

CASE 751

MARKING

DIAGRAMS

8

1030

AYW

1

8

N1031

ALYW

1

Features

• On Chip High 200 V Power Switch Circuit and Startup Circuit

• Internal Startup Regulator with Auxiliary Winding Override

• Operation up to 1 MHz

• External Frequency Synchronization Capability

• Frequency Fold−down Under Fault Conditions

• Trimmed ± 2% Internal Reference

• Line Undervoltage and Overvoltage Detectors

• Cycle by Cycle Current Limit Using SENSEFET

• Active LEB Circuit

• Overtemperature Protection

• Internal Error Amplifier

T ypical Applications

• Secondary Side Bias Supply for Isolated dc−dc Converters

• Stand Alone Low Power dc−dc Converter

• Low Power Bias Supply

• Low Power Boost Converter

PIN CONNECTIONS

1

GND

2

C

T

3

V

FB

COMP

Device Package Shipping

NCP1030DMR2 Micro8 4000/Tape & Reel

NCP1031DR2 SO−8

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specification

Brochure, BRD8011/D.

4

(Top View)

ORDERING INFORMATION

8

V

DRAIN

7

V

CC

6

UV

5

OV

†

2500/Tape & Reel

Semiconductor Components Industries, LLC, 2004

August, 2004 − Rev. 4

1 Publication Order Number:

NCP1030/D

Page 2

NCP1030, NCP1031

GND

C

VFB

COMP

Internal Bias

T

10 V

Error Amplifier

10 V

10 V

I

I2 = 3I

−

+

+

2.5 V

−

2 k

1

1

Current Limit

Comparator

CT Ramp

+

3.0 V/3.5 V

One Shot

IO

−

Pulse

−

+

PWM Comparator

4.5 V

R

SENSE

LEB

−

+

+

50 mV

−

SQ

Reset

Dominant

Latch

R

PWM Latch

7.5 V/10 V

Thermal

Shutdown

Q

+

−

Reset

Dominant

Latch

−

+

−

+

S

R

Disable

+

2.5 V

−

10 V

+

−

−

+

+

−

+

10 V

10 V

6.5 V

−

I

START

16 V

V

DRAIN

V

CC

UV

OV

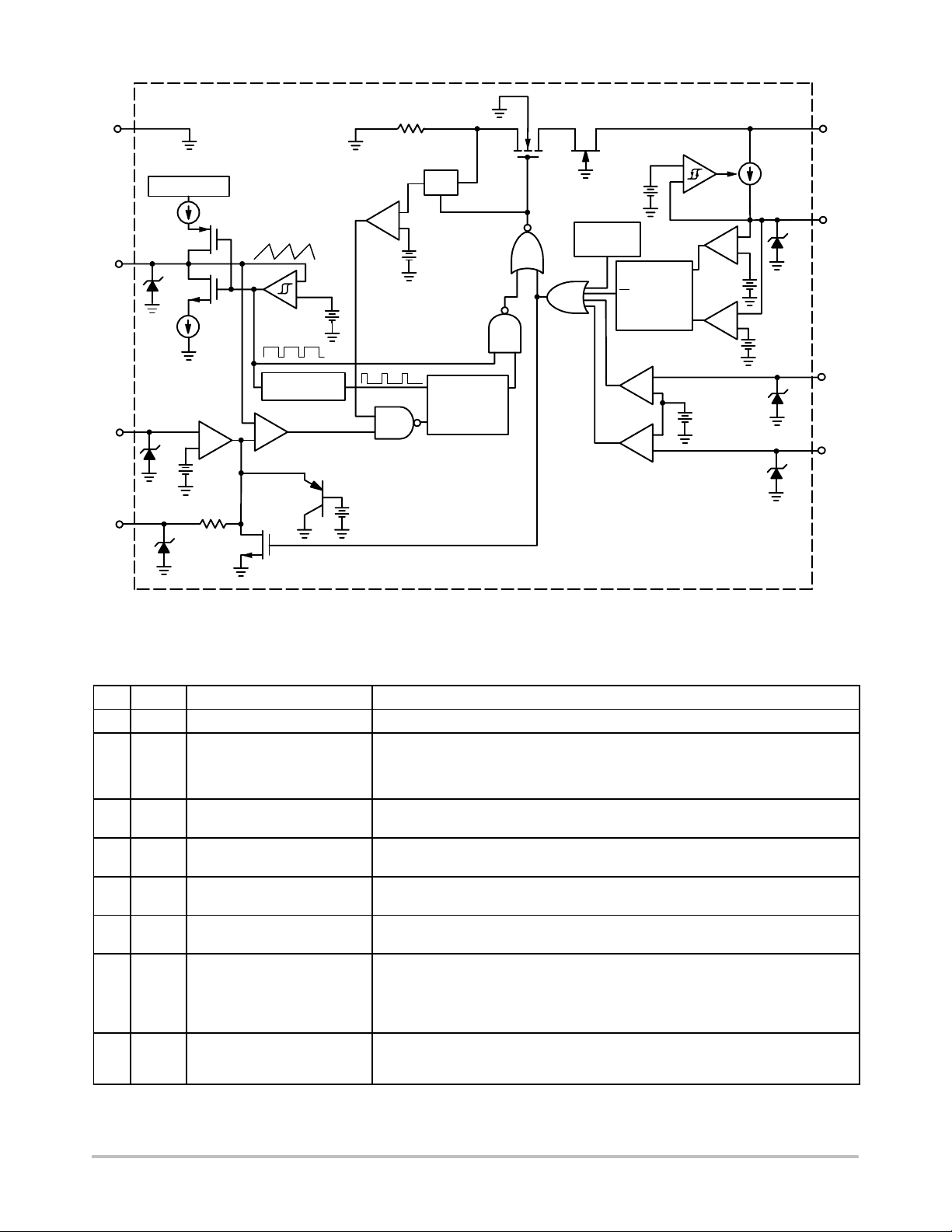

Figure 1. NCP1030/31 Functional Block Diagram

FUNCTIONAL PIN DESCRIPTION

Pin Name Function Description

1 GND Ground Ground reference pin for the circuit.

2 C

3 V

T

FB

4 COMP Error Amplifier Compensation Requires external compensation network between COMP and VFB pins. This pin is

5 OV Line Overvoltage Shutdown Line voltage (Vin) is scaled down using an external resistor divider such that the OV

6 UV Line Undervoltage Shutdown Line voltage is scaled down using an external resistor divider such that the UV

7 V

8 V

CC

DRAIN

Oscillator Frequency

Selection

An external capacitor connected to this pin sets the oscillator frequency up to 1 MHz.

The oscillator can be synchronized to a higher frequency by charging or discharging

C

to trip the internal 3.0 V/3.5 V comparator. If a fault condition exists, the power

T

switch is disabled and the frequency is reduced by a factor of 7.

Feedback Input The regulated voltage is scaled down to 2.5 V by means of a resistor divider.

Regulation is achieved by comparing the scaled voltage to an internal 2.5 V reference.

effectively grounded if faults are present.

voltage reaches 2.5 V when line voltage reaches its maximum operating voltage.

voltage reaches 2.5 V when line voltage reaches its minimum operating voltage.

Supply Voltage This pin is connected to an external capacitor for energy storage. During Turn−On, the

startup circuit sources current to charge the capacitor connected to this pin. When the

, the startup circuit turns OFF and the power switch is

CC(on)

should not exceed 16 V.

CC

should not exceed 200 V.

DRAIN

Power Switch and

Startup Circuits

supply voltage reaches V

enabled if no faults are present. An external winding is used to supply power after

initial startup to reduce power dissipation. V

This pin directly connects the Power Switch and Startup Circuits to one of the

transformer windings. The internal High Voltage Power Switch Circuit is connected

between this pin and ground. V

http://onsemi.com

2

Page 3

NCP1030, NCP1031

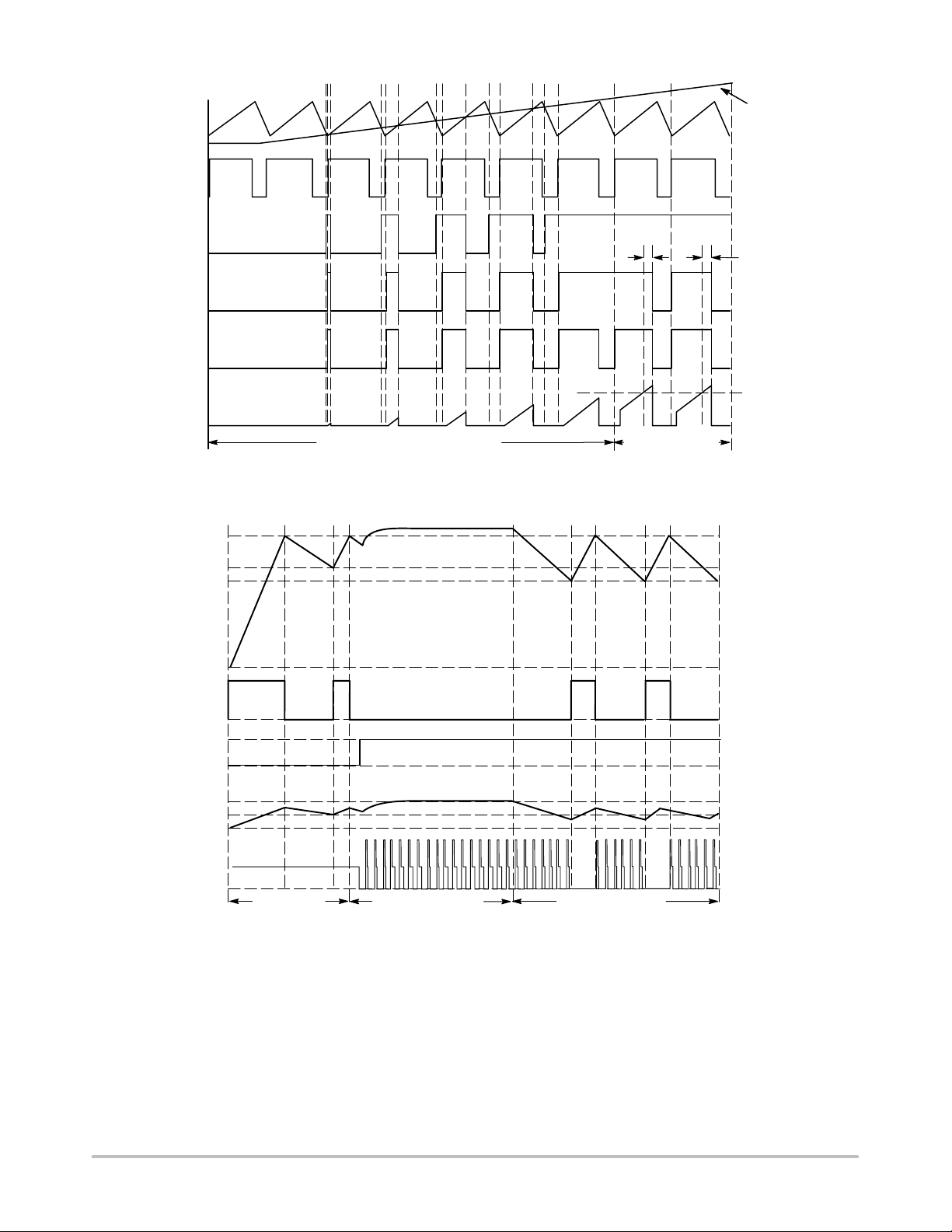

CT Ramp

C

Charge

T

Signal

PWM

Comparator

Output

PWM Latch

Output

Power Switch

Circuit Gate Drive

Leading Edge

Blanking Output

V

COMP Voltage

Current Limit

Propagation Delay

Current Limit

Threshold

Normal PWM Operating Range Output Overload

Figure 2. Pulse Width Modulation Timing Diagram

CC(on)

V

CC(off)

V

CC(reset)

I

START

0 mA

3.0 V

2.5 V

V

DRAIN

0 V

V

UV

0 V

V

FB

0 V

0 V

Power−up &

Normal Operation

Output Overload

standby Operation

Figure 3. Auxiliary Winding Operation with Output Overload Timing Diagram

http://onsemi.com

3

Page 4

NCP1030, NCP1031

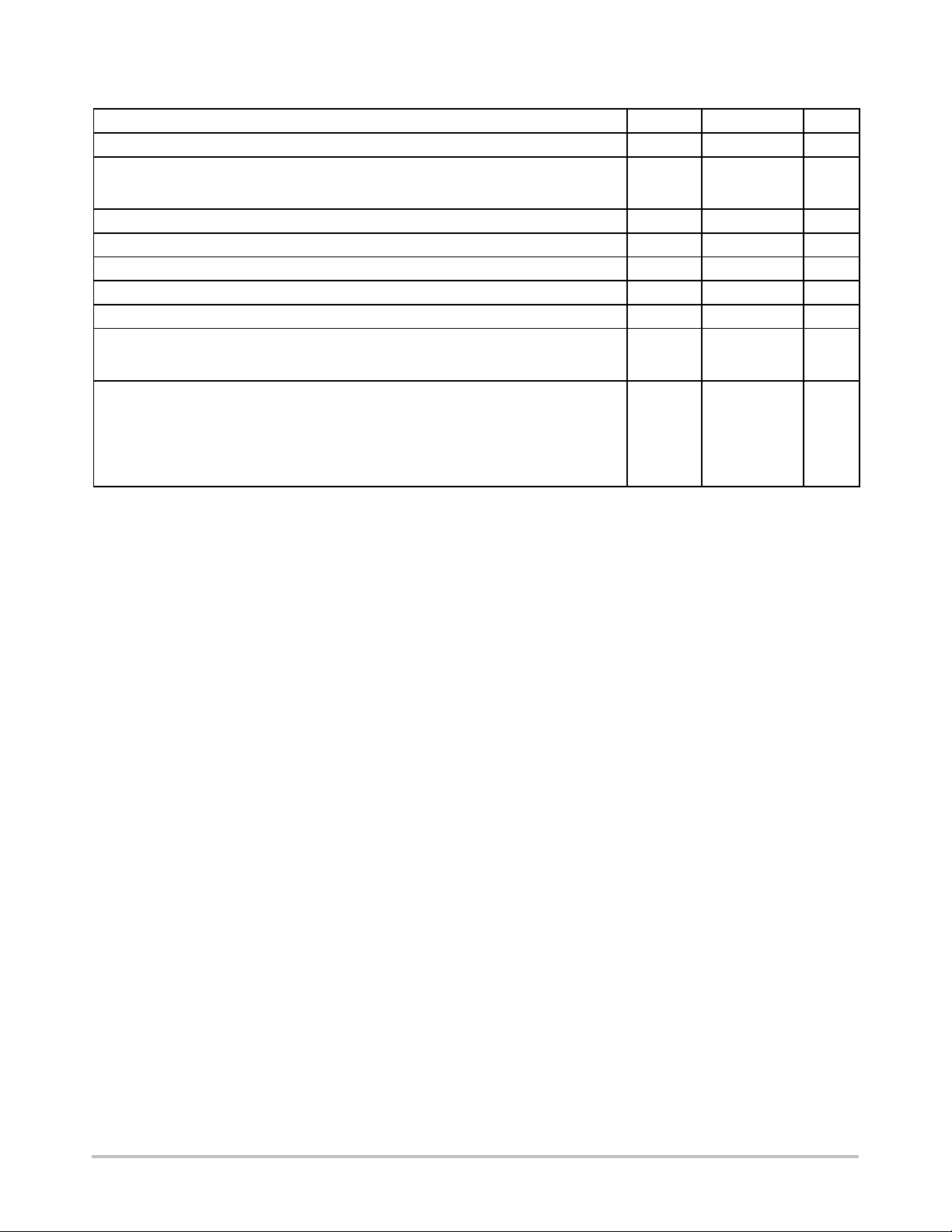

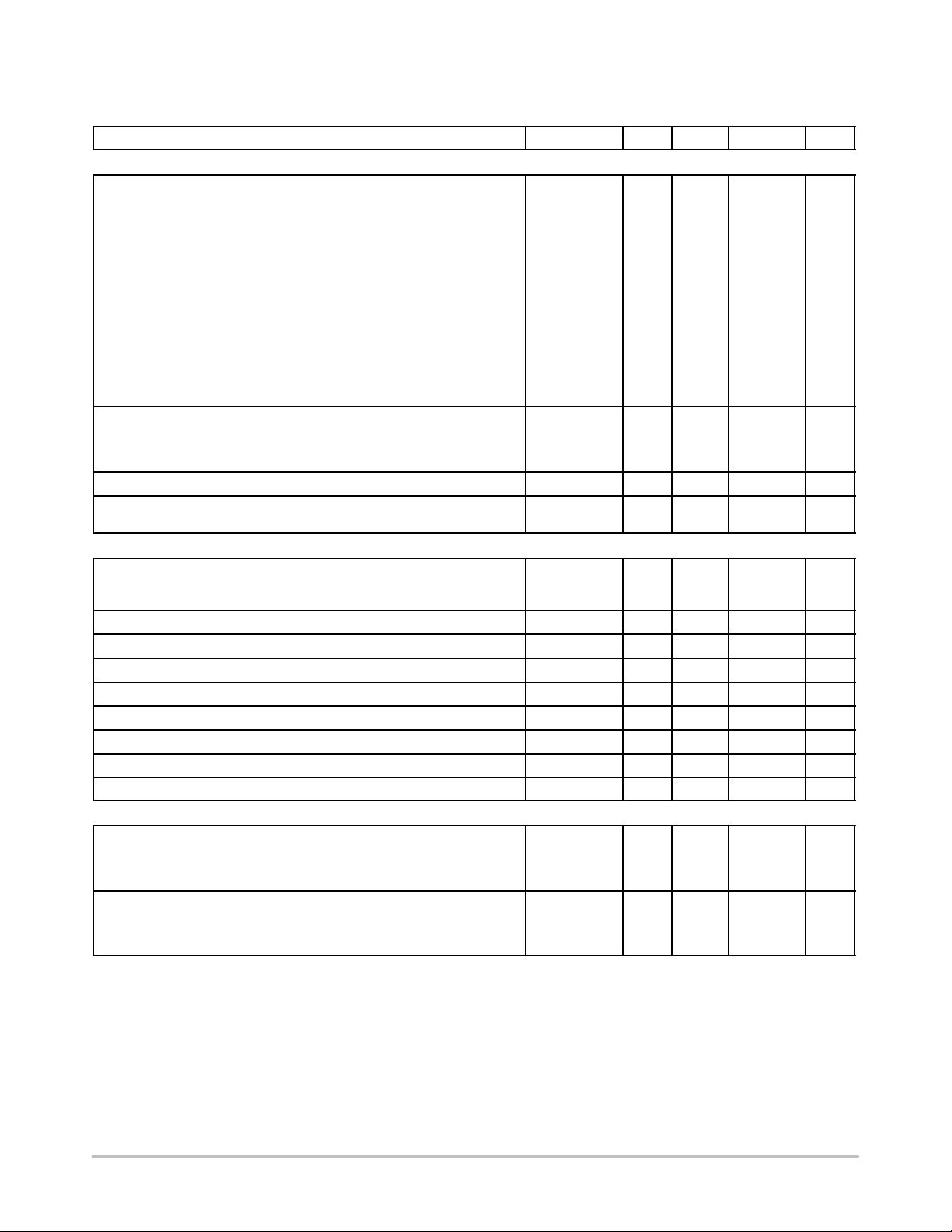

MAXIMUM RATINGS

Rating Symbol Value Unit

Power Switch and Startup Circuits Voltage V

Power Switch and Startup Circuits Input Current

− NCP1030

DRAIN

I

DRAIN

− NCP1031

VCC Voltage Range V

All Other Inputs/Outputs Voltage Range V

VCC and All Other Inputs/Outputs Current I

Operating Junction Temperature T

Storage Temperature T

CC

IO

IO

J

stg

Power Dissipation (TJ = 25°C, 2.0 Oz., 1.0 Sq Inch Printed Circuit Copper Clad)

DM Suffix, Plastic Package Case 846A

D Suffix, Plastic Package Case 751

Thermal Resistance, Junction to Air (2.0 Oz. Printed Circuit Copper Clad)

DM Suffix, Plastic Package Case 846A

R

JA

0.36 Sq. Inch

1.0 Sq. Inch

D Suffix, Plastic Package Case 751

0.36 Sq. Inch

1.0 Sq. Inch

Maximum ratings are those values beyond which device damage can occur. Maximum ratings applied to the device are individual stress limit

values (not normal operating conditions) and are not valid simultaneously . If these limits are exceeded, device functional operation is not implied,

damage may occur and reliability may be affected.

A.This device contains ESD protection circuitry and exceeds the following tests:

Pins 1−7: Human Body Model 2000V per MIL−STD−883, Method 3015.

Pins 1−7: Machine Model Method 200 V.

Pin 8 is connected to t he H igh Voltage Startup and Power Switch Circuits a nd rated only to the maximum voltage rating o f t he p art, or 2 00V.

B.This device contains Latchup protection and exceeds 100 mA per JEDEC Standard JESD78.

−0.3 to 200 V

A

1.0

2.0

−0.3 to 16 V

−0.3 to 10 V

100 mA

−40 to 125 °C

−55 to 150 °C

W

0.69

0.93

°C/W

181

162

135

117

http://onsemi.com

4

Page 5

NCP1030, NCP1031

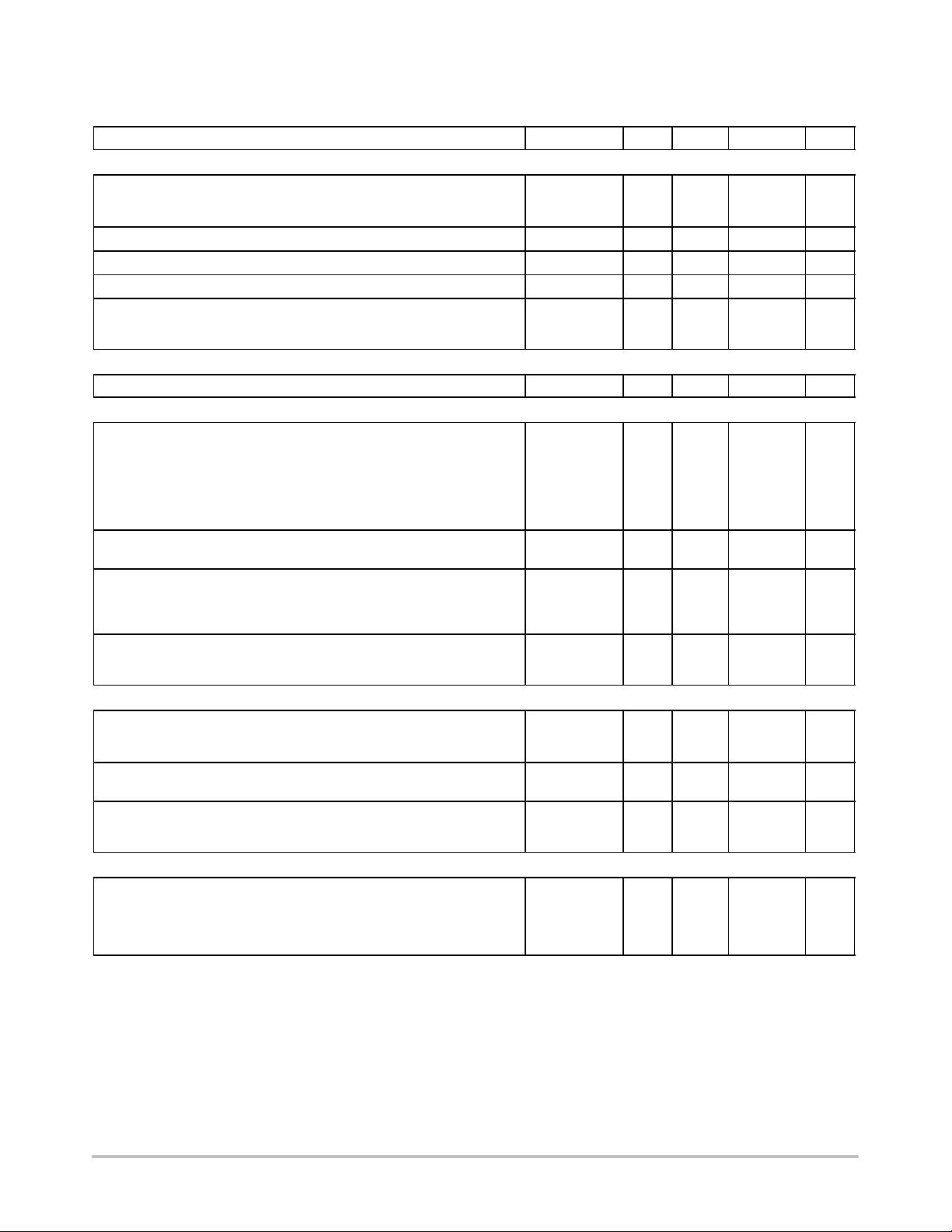

DC ELECTRICAL CHARACTERISTICS (V

V

= 2.5 V, TJ = −40°C to 125°C, typical values shown are for TJ = 25°C unless otherwise noted.) (Note 1)

COMP

Characteristics

= 48 V, VCC = 12 V, CT = 560 pF, VUV = 3 V, VOV = 2 V, VFB = 2.3 V,

DRAIN

Symbol Min Typ Max Unit

STARTUP CONTROL

Startup Circuit Output Current (VFB = V

NCP1030

T

= 25°C

J

T

= −40°C to 125°C

J

V

= 0 V

CC

= V

V

CC

= 0 V

V

CC

V

= V

CC

CC(on)

CC(on)

− 0.2 V

− 0.2 V

COMP

)

I

START

10

6.0

8.0

2.0

12.5

8.6

−

−

15

12

16

13

NCP1031

T

= 25°C

J

T

J

V

= 0 V

CC

V

= V

CC

= −40°C to 125°C

V

= 0 V

CC

= V

V

CC

CC(on)

CC(on)

− 0.2 V

− 0.2 V

13

8.0

11

4.0

16

12

19

16

−

−

21

18

VCC Supply Monitor (VFB = 2.7 V)

Startup Threshold Voltage (V

Minimum Operating V

Hysteresis Voltage

CC

Undervoltage Lockout Threshold Voltage, VCC Decreasing (VFB = V

Minimum Startup Voltage (Pin 8)

I

= 0.5 mA, VCC =V

START

Increasing)

CC

After Turn−on (VCC Increasing)

− 0.2 V

CC(on)

COMP

) V

V

V

CC(on)

V

CC(off)

V

CC(hys)

CC(reset)

START(min)

9.6

7.0

10.2

7.6

−

2.6

10.6

8.0

−

6.0 6.6 7.0 V

− 16.8 18.5

ERROR AMPLIFIER

Reference Voltage (V

TJ = 25°C

T

= −40°C to 125°C

J

Line Regulation (VCC = 8 V to 16 V, TJ = 25°C) REG

Input Bias Current (VFB = 2.3 V) I

COMP Source Current I

COMP Sink Current (VFB = 2.7 V) I

COMP Maximum Voltage (I

COMP Minimum Voltage (I

Open Loop Voltage Gain A

= VFB, Follower Mode)

COMP

= 0 A) V

SRC

= 0 A, VFB = 2.7 V) V

SNK

V

REF

LINE

VFB

SRC

SNK

C(max)

C(min)

VOL

2.45

2.40

2.5

2.5

2.55

2.60

− 1.0 5.0 mV

− 0.1 1.0 A

80 110 140 A

200 550 900 A

4.5 − − V

− − 1.0 V

− 80 − dB

Gain Bandwidth Product GBW − 1.0 − MHz

LINE UNDER/OVERVOLTAGE DETECTOR

Undervoltage Lockout (V

Voltage Threshold (Vin Increasing)

FB

= V

Voltage Hysteresis

Input Bias Current

Overvoltage Lockout (VFB = V

Voltage Threshold (Vin Increasing)

Voltage Hysteresis

Input Bias Current

COMP

COMP

)

V

V

UV(hys)

I

UV

UV

2.400

0.075

−

2.550

0.175

0

2.700

0.275

1.0

)

V

V

OV(hys)

I

OV

OV

2.400

0.075

−

2.550

0.175

0

2.700

0.275

1.0

1. Production testing for NCP1030DMR2 is performed at 25°C only; limits at −40°C and 125°C are guaranteed by design.

mA

V

V

V

V

V

A

V

V

A

http://onsemi.com

5

Page 6

NCP1030, NCP1031

DC ELECTRICAL CHARACTERISTICS (V

V

= 2.5 V, TJ = −40°C to 125°C, typical values shown are for TJ = 25°C unless otherwise noted.) (Note 2)

COMP

Characteristics

= 48 V, VCC = 12 V, CT = 560 pF, VUV = 3 V, VOV = 2 V, VFB = 2.3 V,

DRAIN

Symbol Min Typ Max Unit

OSCILLATOR

Frequency (CT = 560 pF, Note 3)

TJ = 25°C

T

= −40°C to 125°C

J

Frequency (CT = 100 pF) f

Charge Current (VCT = 3.25 V) I

Discharge Current (VCT = 3.25 V) I

f

OSC1

OSC2

CT(C) −

CT(D) −

275

260

300

−

− 800 − kHz

215 − A

645 − A

Oscillator Ramp

Peak

Valley

Vrpk

V

rvly

−

−

3.5

3.0

PWM COMPARATOR

Maximum Duty Cycle

DC

MAX

70 75 80 %

POWER SWITCH CIRCUIT

Power Switch Circuit On−State Resistance (I

NCP1030

T

= 25°C

J

T

= 125°C

NCP1031

J

T

= 25°C

J

= 125°C

T

J

Power Switch Circuit and Startup Circuit Breakdown Voltage

(ID = 100 A, TJ = 25°C)

Power Switch Circuit and Startup Circuit Off−State Leakage Current

(V

= 200 V, VUV = 2.0 V)

DRAIN

T

= 25°C

J

T

= −40 to 125°C

J

= 100 mA)

D

R

DS(on)

V

(BR)DS

I

DS(off)

−

−

−

−

4.1

6.0

2.1

3.5

200 − −

−

−

13

−

Switching Characteristics (VDS = 48 V, RL = 100 )

Rise Time

Fall Time

t

r

t

f

−

−

22

24

CURRENT LIMIT AND OVER TEMPERATURE PROTECTION

Current Limit Threshold (T

NCP1030 (di/dt = 0.5 A/s)

= 25°C)

J

NCP1031 (di/dt = 1.0 A/s)

Propagation Delay, Current Limit Threshold to Power Switch Circuit Output

(Leading Edge Blanking plus Current Limit Delay)

I

t

LIM

PLH

350

700

515

1050

− 100 −

Thermal Protection (Note 4)

Shutdown Threshold (TJ Increasing)

Hysteresis

T

SHDN

T

HYS

125

−

150

45

TOTAL DEVICE

Supply Current After UV Turn−On

Power Switch Enabled

Power Switch Disabled

Non−Fault condition (V

Fault Condition (V

FB

= 2.7 V, V

FB

= 2.7 V)

UV

= 2.0 V)

I

I

I

CC1

CC2

CC3

2.0

−

−

3.0

1.5

0.65

2. Production testing for NCP1030DMR2 is performed at 25°C only; limits at −40°C and 125°C are guaranteed by design.

3. Oscillator frequency can be externally synchronized to the maximum frequency of the device.

4. Guaranteed by design only.

325

kHz

325

V

−

−

7.0

12

3.0

6.0

V

A

25

50

ns

−

−

mA

680

1360

ns

°C

−

−

mA

4.0

2.0

1.2

http://onsemi.com

6

Page 7

NCP1030, NCP1031

TYPICAL CHARACTERISTICS

13.0

12.5

12.0

NCP1030

V

DRAIN

T

= 25°C

J

= 48 V

11.5

11.0

10.5

10.0

9.5

, STARTUP CURRENT (mA)

9.0

START

8.5

I

8.0

0

246810

VCC, SUPPLY VOLTAGE (V)

Figure 4. NCP1030 Startup Current vs. Supply

Voltage

20

18

16

14

12

10

8

6

, STARTUP CURRENT (mA)

4

START

2

I

VCC = V

CC(on)

0

−50 −25 0 25 50 150

TJ, JUNCTION TEMPERATURE (°C)

NCP1030

V

= 48 V

DRAIN

VCC = 0 V

− 0.2 V

75 100 125

20

19

18

NCP1031

V

= 48 V

DRAIN

T

= 25°C

J

17

16

15

14

13

, STARTUP CURRENT (mA)

12

START

11

I

10

0

246810

VCC, SUPPLY VOLTAGE (V)

Figure 5. NCP1031 Startup Current vs. Supply

Voltage

20

18

16

VCC = 0 V

14

12

10

VCC = V

CC(on)

− 0.2 V

8

6

, STARTUP CURRENT (mA)

4

START

2

I

0

−50 −25 0 25 50 150

, JUNCTION TEMPERATURE (°C)

T

J

NCP1031

V

DRAIN

75 100 125

= 48 V

Figure 6. NCP1030 Startup Current vs.

Junction Temperature

12

NCP1030

10

8

TJ = −40°C

TJ = 25°C

6

TJ = 125°C

, STARTUP CURRENT (mA)

2

START

I

0

0425 50 75 100 200

, DRAIN VOLTAGE (V)

V

DRAIN

VCC = V

CC(on)

125 150 175

− 0.2 V

Figure 8. NCP1030 Startup Current vs. Drain

Voltage

20

18

16

14

12

10

8

6

, STARTUP CURRENT (mA)

START

I

2

0

0425 50 75 100 200

http://onsemi.com

7

Figure 7. NCP1031 Startup Current vs.

Junction Temperature

NCP1031

TJ = −40°C

TJ = 25°C

TJ = 125°C

VCC = V

CC(on)

− 0.2 V

125 150 175

, DRAIN VOLTAGE (V)

V

DRAIN

Figure 9. NCP1031 Startup Current vs. Drain

Voltage

Page 8

NCP1030, NCP1031

0

TYPICAL CHARACTERISTICS

11.0

10.5

Startup Threshold

10.0

9.5

9.0

8.5

8.0

7.5

, SUPPLY VOLTAGE (V)

7.0

CC

V

Minimum Operating Threshold

6.5

6.0

−50 −25 0 50 150

T

, JUNCTION TEMPERATURE (°C)

J

75 100 12525

Figure 10. Supply V oltage Thresholds vs.

Junction Temperature

20.0

VCC = V

19.5

19.0

I

START

CC(on)

= 0.5 mA

18.5

18.0

17.5

17.0

16.5

16.0

, MINIMUM STARTUP VOLTAGE (V)

15.5

15.0

−25

−50 0 25 50 75 100 125 150

START(min)

V

TJ, JUNCTION TEMPERATURE (°C)

Figure 12. Minimum Startup Voltage vs.

Junction Temperature

− 0.2 V

6.80

6.75

6.70

6.65

6.60

6.55

6.50

THRESHOLD (V)

6.45

, UNDERVOLTAGE LOCKOUT

6.40

6.35

CC(reset)

6.30

V

−50 −25 0 25 50 15

T

, JUNCTION TEMPERATURE (°C)

J

75 100 125

Figure 11. Undervoltage Lockout Threshold

vs. Junction T emperature

2.70

2.65

2.60

2.55

2.50

2.45

2.40

2.35

, REFERENCE VOLTAGE (V)

2.30

REF

2.25

V

2.20

−25

−50 0 25 50 75 100 125 150

TJ, JUNCTION TEMPERATURE (°C)

Figure 13. Reference V oltage vs. Junction

Temperature

VCC = 12 V

145

140

135

VCC = 12 V

V

= 2.5 V

COMP

V

= 2.3 V

FB

130

125

120

115

110

105

, COMP SOURCE CURRENT (A)

100

SRC

I

95

−50 0 25 50 75 100 125 150

−25

, JUNCTION TEMPERATURE (°C)

T

J

Figure 14. COMP Source Current vs. Junction

Temperature

840

790

740

690

640

590

540

490

, COMP SINK CURRENT (A)

440

SNK

390

I

340

−50 0 25 50 75 100 125 150

http://onsemi.com

8

VCC = 12 V

V

= 2.5 V

COMP

V

= 2.7 V

FB

−25

, JUNCTION TEMPERATURE (°C)

T

J

Figure 15. COMP Sink Current vs. Junction

Temperature

Page 9

NCP1030, NCP1031

TYPICAL CHARACTERISTICS

2.600

2.575

2.550

2.525

2.500

2.475

2.450

2.425

2.400

2.375

2.350

−50 −25 0 50 15075 100 12525

TJ, JUNCTION TEMPERATURE (°C)

, LINE UNDER/OVERVOLTAGE THRESHOLDS (V)

Figure 16. Line Under/Overvoltage Thresholds

UV/OV

V

vs. Junction T emperature

1000

900

800

VCC = 12 V

T

J

700

600

500

400

300

200

, OSCILLATOR FREQUENCY (kHz)

100

OSC

0

f

0 200 400 600 800 1000

CT, TIMING CAPACITOR (pF)

= 25°C

220

210

200

190

180

170

160

, UNDER/OVERVOLTAGE

150

HYSTERESIS (mV)

140

130

UV/OV(hys)

V

120

−25

−50 0 25 50 75 100 125 150

T

, JUNCTION TEMPERATURE (°C)

J

Figure 17. Line Under/Overvoltage Hysteresis

vs. Junction T emperature

1100

1000

900

800

700

600

500

400

300

, OSCILLATOR FREQUENCY (kHz)

200

OSC

f

100

−50 −25 0 25 15050 75 100 125

T

CT = 47 pF

CT = 220 pF

CT = 1000 pF

, JUNCTION TEMPERATURE (°C)

J

VCC = 12 V

Figure 18. Oscillator Frequency vs. Timing

Capacitor

77.0

VCC = 12 V

76.5

76.0

75.5

f

OSC

= 200 kHz

75.0

74.5

74.0

f

= 1000 kHz

OSC

73.5

, MAXIMUM DUTY CYCLE (%)

73.0

MAX

72.5

DC

72.0

−50 −25 0 25 50 75

T

, JUNCTION TEMPERATURE (°C)

J

Figure 20. Maximum Duty Cycle vs. Junction

Temperature

100 125 150

http://onsemi.com

Figure 19. Oscillator Frequency vs. Junction

8

VCC = 12 V

7

I

= 100 mA

D

6

5

4

3

, POWER SWITCH CIRCUIT

2

ON RESISTANCE ()

1

DS(on)

R

0

−50 −25 0 25 50 75

T

, JUNCTION TEMPERATURE (°C)

J

Figure 21. Power Switch Circuit On Resistance

vs. Junction T emperature

9

Temperature

NCP1030

NCP1031

100 125 150

Page 10

NCP1030, NCP1031

TYPICAL CHARACTERISTICS

1000

100

, OUTPUT CAPACITANCE (pF)

OUT

C

10

0 40 80 120 160 200

V

, DRAIN VOLTAGE (V)

DRAIN

NCP1031

NCP1030

Figure 22. Power Switch Circuit Output

Capacitance vs. Drain V oltage

600

575

Current Slew Rate = 500 mA/s

550

525

500

475

450

425

400

375

, CURRENT LIMIT THRESHOLD (mA)

350

LIM

I

−50 −25 0 25 50 75

TJ, JUNCTION TEMPERATURE (°C)

100 125 150

NCP1030

40

VCC = 12 V

35

30

25

20

15

10

5

, POWER SWITCH AND STARTUP

0

CIRCUITS LEAKAGE CURRENT (A)

0 50 100 150

DS(off)

I

V

TJ = −40°C

TJ = 25°C

TJ = 125°C

, DRAIN VOLTAGE (V)

DRAIN

Figure 23. Power Switch Circuit and Startup

Circuit Leakage Current vs. Drain Voltage

1200

1150

Current Slew Rate = 1 A/s

1100

1050

1000

950

900

850

800

750

, CURRENT LIMIT THRESHOLD (mA)

700

LIM

I

−50 −25 0 25 50 75

TJ, JUNCTION TEMPERATURE (°C)

200 250 300

NCP1031

100 125 150

Figure 24. NCP1030 Current Limit Threshold

vs. Junction T emperature

600

575

550

525

500

475

450

425

400

375

, CURRENT LIMIT THRESHOLD (mA)

350

LIM

I

TJ = 25°C

375 400 425 450 475 500

CURRENT SLEW RATE (mA/S)

Figure 26. NCP1030 Current Limit Threshold

vs. Current Slew Rate

NCP1030

http://onsemi.com

10

Figure 25. NCP1031 Current Limit Threshold

vs. Junction T emperature

1200

1150

1100

1050

1000

950

900

850

800

750

, CURRENT LIMIT THRESHOLD (mA)

700

LIM

I

TJ = 25°C

750 800 850 900 950 1000

CURRENT SLEW RATE (mA/S)

Figure 27. NCP1031 Current Limit Threshold

vs. Current Slew Rate

NCP1031

Page 11

NCP1030, NCP1031

TYPICAL CHARACTERISTICS

4.1

V

= 48 V

DRAIN

3.9

T

= 25°C

J

= 560 pF

C

T

3.7

3.5

3.3

3.1

2.9

2.7

, OPERATING SUPPLY CURRENT (mA)

2.5

10 11 12 13 14 15 16

CC1

I

VCC, SUPPLY VOLTAGE (V)

Figure 28. Operating Supply Current vs.

Supply Voltage

10

9

8

7

4.0

3.5

3.0

2.5

2.0

1.5

1.0

, SUPPLY CURRENT (mA)

CC

I

0.5

0

−50 −25 0 25 50 75 100

VUV = 3.0 V, VFB = 2.3 V

VUV = 3.0 V, VFB = 2.7 V

VUV = 2.0 V

TJ, JUNCTION TEMPERATURE (°C)

Figure 29. Supply Current vs. Junction

Temperature

TJ = 25 °C

VCC = 12 V

C

= 560 pF

T

125 150

6

5

3

, POWER SUPPLY CURRENT (mA)

CC

I

2

200 300 400 500 600 700 8004900 1000

f

, OSCILLATOR FREQUENCY (kHz)

OSC

NCP1031

NCP1030

Figure 30. Operating Supply Current vs.

Oscillator Frequency

http://onsemi.com

11

Page 12

NCP1030, NCP1031

+

V

in

−

+

V

out

−

SECONDARY

NCP103x

GND

C

T

V

FB

COMP

V

DRAIN

V

CC

UV

OV

SIDE CONTROL

V

BIAS

GND

Figure 31. Secondary Side Bias Supply Configuration

+

V

in

−

V

CC

NCP103x

V

GND

C

T

V

FB

COMP

DRAIN

V

UV

OV

CC

V

CC

Figure 32. Boost Circuit Configuration

+

V

out

−

http://onsemi.com

12

Page 13

NCP1030, NCP1031

OPERATING DESCRIPTION

Introduction

The NCP1030 and NCP1031 are a family of miniature

monolithic voltage−mode switching regulators designed for

isolated and non−isolated bias supply applications. The

internal startup circuit and the MOSFET are rated at 200 V,

making them ideal for 48 V telecom and 42 V automotive

applications. In addition, the NCP103x family can operate

from an existing 12 V supply. This controller family is

optimized for operation up to 1 MHz.

The NCP103x family incorporates in a single IC all the

active power, control logic and protection circuitry required

to implement, with a minimum of external components,

several switching regulator applications, such as a

secondary side bias supply or a low power dc−dc converter.

The NCP1030 is available in the space saving Micro8

package and is targeted for applications requiring up to 3 W.

The NCP1031 is targeted for applications up to 6 W and is

available in the SO−8 package.

The NCP103x includes an extensive set of features

including over temperature protection, cycle by cycle

current limit, individual line under and overvoltage

detection comparators with hysteresis, and regulator output

undervoltage lockout with hysteresis, providing full

protection during fault conditions. A description of each of

the functional blocks is given below, and the representative

block diagram is shown in Figure 2.

Forward:

V

C

CC

where, I

−1

cos

is the bias current supplied by the VCC capacitor

bias

1

OUTNP

DCVinN

including the IC bias current (I

S

2.6

L

OUTCOUT

CC1

I

bias

) and any additional

(eq. 1)

current used to bias the feedback resistors (if used).

After initial startup, the VCC pin should be biased above

V

using an auxiliary winding. This will prevent the

CC(off)

startup regulator from turning ON and reduce power

dissipation. Also, the load should not be directly connected

to the VCC capacitor. Otherwise, the load may override the

startup circuit. Figure 33 shows the recommended

configuration for a non−isolated flyback converter.

+

Vin

−

NCP103x

GND

CT

VFB

COMP

VDRAIN

VCC

UV

OV

+

V

out

−

Startup Circuit and Undervoltage Lockout

The NCP103x contains an internal 200 V startup regulator

that eliminates the need for external startup components.

The startup regulator consists of a constant current source

that supplies current from the input line (Vin) to the capacitor

on the V

pin (CCC). Once the VCC voltage reaches

CC

approximately 10 V, the startup circuit is disabled and the

Power Switch Circuit is enabled if no faults are present.

During this self−bias mode, power to the NCP103x is

supplied by the VCC capacitor. The startup regulator turns

ON again once V

reaches 7.5 V. This “7.5−10” mode of

CC

operation is known as Dynamic Self Supply (DSS). The

NCP1030 and NCP1031 startup currents are 12 mA and 16

mA, respectively.

If VCC falls below 7.5 V, the device enters a re−start mode.

While in the re−start mode, the V

capacitor is allowed to

CC

discharge to 6.5 V while the Power Switch is enabled. Once

the 6.5 V threshold is reached, the Power Switch Circuit is

disabled and the startup regulator is enabled to charge the

VCC capacitor. The Power Switch is enabled again once the

V

voltage reaches 10 V. Therefore, the external V

CC

CC

capacitor must be sized such that a voltage greater than 7.5

V is maintained on the VCC capacitor while the converter

output reaches regulation. Otherwise, the converter will

enter the re−start mode. Equation (1) provides a guideline

for the selection of the V

capacitor for a forward

CC

converter;

Figure 33. Non−Isolated Bias Supply Configuration

The maximum voltage rating of the startup circuit is

200 V. Power dissipation should be observed to avoid

exceeding the maximum power dissipation of the package.

Error Amplifier

The internal error amplifier (EA) regulates the output

voltage of the bias supply. It compares a scaled output

voltage signal to an internal 2.5 V reference (V

REF

connected to its non−inverting input. The scaled signal is fed

into the feedback pin (

V

) which is the inverting input of the

FB

error amplifier.

The output of the error amplifier is available for frequency

compensation and connection to the PWM comparator

through the COMP pin. T o insure normal operation, the EA

compensation should be selected such that the EA frequency

response crosses 0 dB below 80 kHz.

The error amplifier input bias current is less than 1 A

over the operating range. The output source and sink

currents are typically 110 A and 550 A, respectively.

Under load transient conditions, COMP may need to

move from the bottom to the top of the C

Ramp. A large

T

current is required to complete the COMP swing if small

resistors or large capacitors are used to implement the

compensation network. In which case, the COMP swing will

)

http://onsemi.com

13

Page 14

NCP1030, NCP1031

be limited by the EA sink current, typically 110 A.

Optimum transient response is obtained if the compensation

components allow COMP to swing across its operating

range in 1 cycle.

Line Under and Overvoltage Detector

The NCP103x incorporates individual line undervoltage

(UV) and overvoltage (OV) shutdown circuits. The UV and

OV thresholds are 2.5 V. A fault is present if the UV is below

2.5 V or if the OV voltage is above 2.5 V. The UV/OV

detectors incorporate 175 mV hysteresis to prevent noise

from triggering the shutdown circuits.

The UV/OV circuits can be biased using an external

resistor divider from the input line as shown in Figure 34.

The UV/OV pins should be bypassed using a capacitor to

prevent triggering the UV or OV circuits during normal

switching operation.

V

in

R

1

+

R

2

+

V

OV

−

R

3

V

UV

−

Figure 34. UV/OV Resistor Divider

from the Input Line

The resistor divider must be sized to enable the controller

once V

is within the required operating range. While a UV

in

or OV fault is present, switching is not allowed and the

COMP pin is effectively grounded.

Either of these comparators can be used for a different

function if UV o r O V functions are not needed. For example,

the UV/OV detectors can be used to implement an enable or

disable function. If positive logic is used, the enable signal

is applied to the UV pin while the OV pin is grounded. If

negative logic is used, the disable signal is applied to the OV

pin while biasing the UV pin from V

using a resistor

CC

divider.

Oscillator

The oscillator is optimized for operation up to 1 MHz and

its frequency is set by the external timing capacitor (CT)

connected to the CT pin. The oscillator has two modes of

operation, free running and synchronized (sync). While in

free running mode, an internal current source sequentially

charges and discharges C

generating a voltage ramp

T

between 3.0 V and 3.5 V. Under normal operating

conditions, the charge (I

) and discharge (I

CT(C)

CT(D)

currents are typically 215 A and 645 A, respectively. The

charge:discharge current ratio of 1:3 discharges

CT in 25 %

of the total period. The Power Switch is disabled while C

is discharging, guaranteeing a maximum duty cycle of 75 %

as shown in Figure 35.

CT Ramp

Power Switch

Enabled

Charge

C

T

Signal

75%

Figure 35. Maximum Duty Cycle vs COMP

COMP

Duty Cycle

25 %

Figure 18 shows the relationship between the operating

frequency and CT. If an UV fault is present, both I

I

are reduced by a factor of 7, thus reducing the

CT(D)

operating frequency by the same factor.

The oscillator can be synchronized to a higher frequency

by capacitively coupling a synchronization pulse into the C

pin. In sync mode, the voltage on the C

pin needs to be

T

driven above 3.5 V to trigger the internal comparator and

complete the C

charging period. However, pulsing the C

T

pin before it reaches 3.5 V will reduce the p−p amplitude of

the CT Ramp as shown in Figure 36.

3.0 V/3.5 V

Comparator

Reset

T2 (f2)

Range in Sync

Sync Mode

3.5 V

C

Ramp

3.0 V

T

Free Running

Sync Pulse

T1 (f1) T2 (f2)

Mode

Figure 36. External Frequency Synchronization

Waveforms

The oscillator frequency should be set no more that 25%

below the target sync frequency to maintain an adequate

voltage range and provide good noise immunity. A possible

circuit to synchronize the oscillator is shown in Figure 37.

5 V

C

T

C1

R1

R2

)

Figure 37. External Frequency Synchronization

T

Circuit.

Max

C

C

T

2

Voltage

T

CT(C)

and

T

T

http://onsemi.com

14

Page 15

NCP1030, NCP1031

PWM Comparator and Latch

The Pulse Width Modulator (PWM) Comparator

compares the error amplifier output (COMP) to the C

Ramp and generates a proportional duty cycle. The Power

Switch is enabled while the CT Ramp is below COMP as

shown in Figure 35. Once the CT Ramp reaches COMP, the

Power Switch is disabled. If COMP is at the bottom of the

C

Ramp, the converter operates at minimum duty cycle.

T

While COMP increases, the duty cycle increases, until

COMP reaches the peak of the CT Ramp, at which point the

controller operates at maximum duty cycle.

The CT Charge Signal is filtered through a One Shot Pulse

Generator to set the PWM Latch and enable switching at the

beginning of each period. Switching is allowed while the C

Ramp is below COMP and a current limit fault is not present.

The PWM Latch and Comparator propagation delay is

typically 150 ns. If the system is designed to operate with a

minimum ON time less than 150 ns, the converter will skip

pulses. Skipping pulses is usually not a problem, unless

operating at a frequency close to the audible range. Skipping

pulses is more likely when operating at high frequencies

during high line and minimum load condition.

A series r esistor i s i ncluded f or E SD p rotection b etween t he

EA output a nd t he COMP pin. U nder n ormal o peration, a 2 20

mV offset is observed between the C

Ramp and the COMP

T

crossing points. This is not a problem as the series resistor

does not interact with the error amplifier transfer function.

Current Limit Comparator and Power Switch Circuit

The NCP103x monolithically integrates a 200 V Power

Switch Circuit with control logic circuitry. The Power

Switch Circuit is designed to directly drive the converter

transformer. The characteristics of the Power Switch Circuit

are well known. Therefore, the gate drive is tailored to

control switching transitions and help limit electromagnetic

interference (EMI). The Power Switch Circuit is capable of

switching 200 V.

The Power Switch Circuit incorporates SENSEFET

technology to monitor the drain current. A sense voltage is

generated by driving a sense element, R

, with a current

SENSE

proportional to the drain current. The sense voltage is

compared to an internal reference voltage on the

non−inverting input of the Current Limit Comparator. If the

sense voltage exceeds the reference level, the comparator

resets the PWM Latch and switching is terminated. The

NCP1030 and NCP1031 drain current limit thresholds are

0.5 A and 1.0 A, respectively.

Each time the Power Switch Circuit turns ON, a narrow

voltage spike appears across R

. The spike is due to the

SENSE

Power Switch Circuit gate to source capacitance,

transformer interwinding capacitance, and output rectifier

recovery time. This spike can cause a premature reset of the

PWM Latch. A proprietary active Leading Edge Blanking

(LEB) Circuit masks the current signal to prevent the

T

voltage spike from resetting the PWM Latch. The active

LEB masks the current signal until the Power Switch turn

ON transition is complete. The adaptive LEB period

provides better current limit control compared to a fixed

blanking period.

The current limit propagation delay time is typically

100 ns. This time is measured from when an overcurrent

fault appears at the Power Switch Circuit drain, to the start

of the turn−off transition. Propagation delay must be

factored in the transformer design to avoid transformer

saturation.

T

Thermal Shutdown

Internal Thermal Shutdown circuitry is provided to

protect the integrated circuit in the event the maximum

junction temperature is exceeded. When activated, typically

at 150C, the Power Switch Circuit is disabled. Once the

junction temperature falls below 105C, the NCP103x is

allowed to resume normal operation. This feature is

provided to prevent catastrophic failures from accidental

device overheating. It is not intended to be used as a

substitute for proper heatsinking.

Application Considerations

A 2 W bias supply for a 48 V telecom system was designed

using the NCP1030. The bias supply generates an isolated

12 V output. The circuit schematic is shown in Figure 38.

Application Note AND8119/D describes the design of the

bias supply.

2.2

+

0.033

2.2

NCP1030

GND

CT

VFB

COMP

680p

10k

35−76V

−

0.022

680p

Figure 38. 2 W Isolated Bias Supply Schematic

499

MURA110T3

VDRAIN

VCC

UV

OV

0.01

1M

100 p

45k3

34k

1:2.78

MBRA160T3

0.01

MBRA160T3

2.2

22

12V

4k99

1k30

+

−

10

http://onsemi.com

15

Page 16

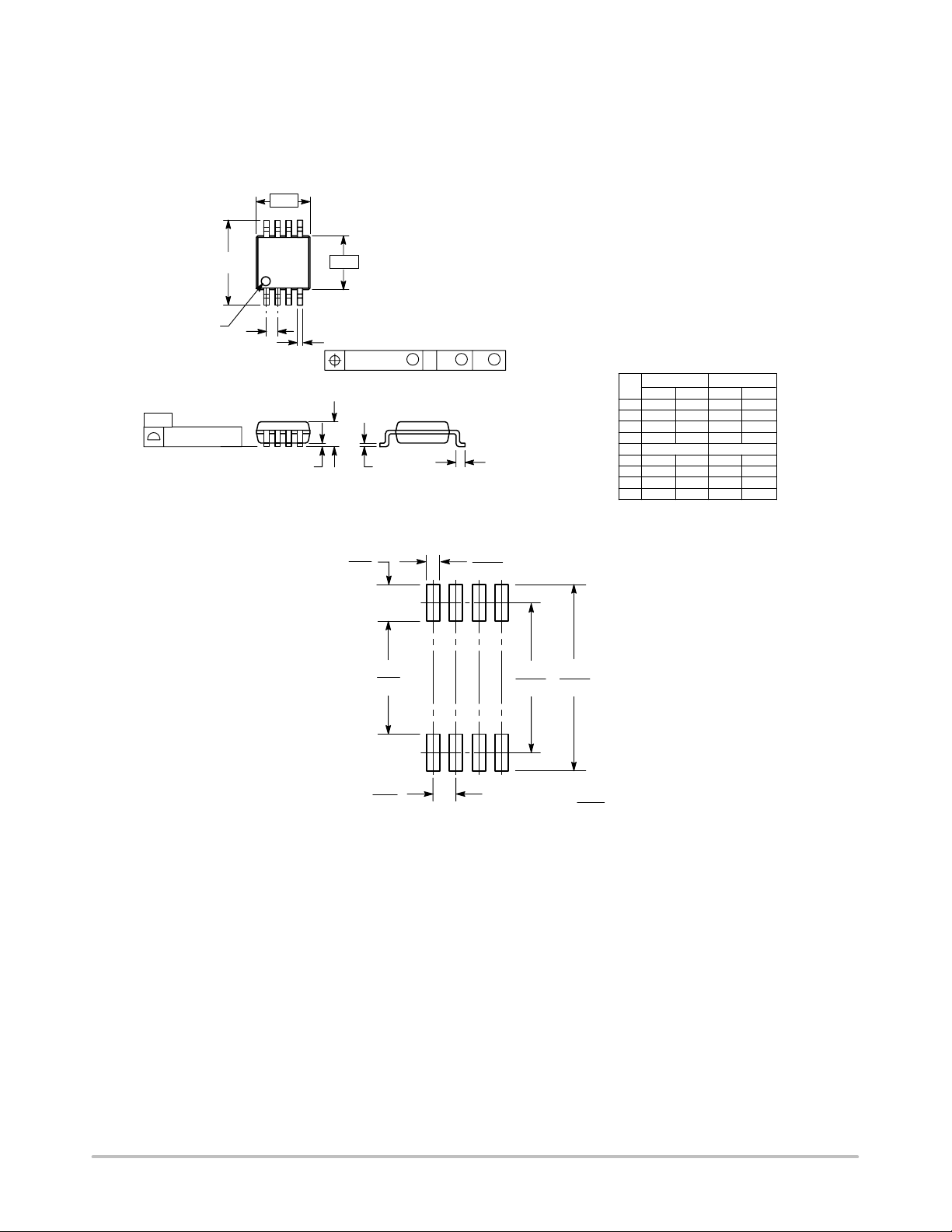

SEATING

PLANE

−T−

0.038 (0.0015)

PIN 1 ID

NCP1030, NCP1031

PACKAGE DIMENSIONS

Micro8

DM SUFFIX

CASE 846A−02

ISSUE F

−A−

−

K

G

−B−

8 PL

D

0.08 (0.003) A

M

T

S

B

S

C

H

J

L

NOTES:

1. DIMENSIONING AND TOLERANCING

PER ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION:

MILLIMETER.

3. DIMENSION A DOES NOT INCLUDE

MOLD FLASH, PROTRUSIONS OR GATE

BURRS. MOLD FLASH, PROTRUSIONS

OR GATE BURRS SHALL NOT EXCEED

0.15 (0.006) PER SIDE.

4. DIMENSION B DOES NOT INCLUDE

INTERLEAD FLASH OR PROTRUSION.

INTERLEAD FLASH OR PROTRUSION

SHALL NOT EXCEED 0.25 (0.010) PER

SIDE.

5. 846A−01 OBSOLETE, NEW STANDARD

846A−02.

DIM MIN MAX MIN MAX

A 2.90 3.10 0.114 0.122

B 2.90 3.10 0.114 0.122

C −−− 1.10 −−− 0.043

D 0.25 0.40 0.010 0.016

G 0.65 BSC 0.026 BSC

H 0.05 0.15 0.002 0.006

J 0.13 0.23 0.005 0.009

K 4.75 5.05 0.187 0.199

L 0.40 0.70 0.016 0.028

INCHESMILLIMETERS

8X

SOLDERING FOOTPRINT

1.04

0.041

3.20

0.126

0.65

6X

0.0256

0.38

0.015

8X

4.24

0.167

SCALE 8:1

5.28

0.208

inches

mm

http://onsemi.com

16

Page 17

−Y−

−Z−

NCP1030, NCP1031

PACKAGE DIMENSIONS

SO−8

D SUFFIX

CASE 751−07

ISSUE AC

−X−

B

H

A

58

1

4

G

D

0.25 (0.010) Z

M

S

Y

SXS

0.25 (0.010)

C

SEATING

PLANE

M

Y

0.10 (0.004)

M

K

N

X 45

M

J

NOTES:

1. DIMENSIONING AND TOLERANCING

PER ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION:

MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15

(0.006) PER SIDE.

5. DIMENSION D DOES NOT INCLUDE

DAMBAR PROTRUSION. ALLOWABLE

DAMBAR PROTRUSION SHALL BE 0.127

(0.005) TOTAL IN EXCESS OF THE D

DIMENSION AT MAXIMUM MATERIAL

CONDITION.

6. 751−01 THRU 751−06 ARE OBSOLETE.

NEW STANDARD IS 751−07.

MILLIMETERS

DIMAMIN MAX MIN MAX

4.80 5.00 0.189 0.197

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.053 0.069

D 0.33 0.51 0.013 0.020

G 1.27 BSC 0.050 BSC

H 0.10 0.25 0.004 0.010

J 0.19 0.25 0.007 0.010

K 0.40 1.27 0.016 0.050

M 0 8 0 8

N 0.25 0.50 0.010 0.020

S 5.80 6.20 0.228 0.244

INCHES

SOLDERING FOOTPRINT

7.0

0.275

0.6

0.024

1.52

0.060

4.0

0.155

1.270

0.050

SCALE 6:1

inches

mm

http://onsemi.com

17

Page 18

NCP1030, NCP1031

Micro8 is a trademark of International Rectifier. SENSEFET is a trademark of Semiconductor Components Industries, LLC.

The products described herein (NCP1030 and NCP1031) may be covered by one or more of the following U.S. patents: 5,418,410; 5,477,175.

There may be other patents pending.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 61312, Phoenix, Arizona 85082−1312 USA

Phone: 480−829−7710 or 800−344−3860 Toll Free USA/Canada

Fax: 480−829−7709 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Japan: ON Semiconductor, Japan Customer Focus Center

2−9−1 Kamimeguro, Meguro−ku, Tokyo, Japan 153−0051

Phone: 81−3−5773−3850

http://onsemi.com

ON Semiconductor Website: http://onsemi.com

Order Literature: http://www.onsemi.com/litorder

For additional information, please contact your

local Sales Representative.

NCP1030/D

18

Loading...

Loading...