Page 1

NCL30073LED4GEVB

15 W High Power Factor

LED Driver

Evaluation Board

User'sManual

Overview

This manual covers the specification, theory of operation,

testing and construction of the NCL30073LED4GEVB

evaluation board. The NCL30073 board demonstrates a

15 W high PF buck boost LED driver for a typical downlight

application.

Key Features

The key features of this evaluation board include:

• Low Parts Count

• TRIAC Dimmer Compatible

• High Power Factor

• Integrated Fault Protection

♦ Over Temperature on board (a PCB mounted PTC)

♦ Output Over Current

♦ Output Over Voltage

www.onsemi.com

EVAL BOARD USER’S MANUAL

Table 1. SPECIFICATIONS

Input voltage 207 − 253 V ac

Line Frequency 50 Hz

Power Factor (100% Load)

Output Voltage 72 V dc

Output Ripple 75% Pk − Pk

Output Current 200 mA dc ± 5%

Efficiency 88.5% Typ.

Start Up Time < 250 msec Typ.

0.9

Min

© Semiconductor Components Industries, LLC, 2017

July, 2017 − Rev. 0

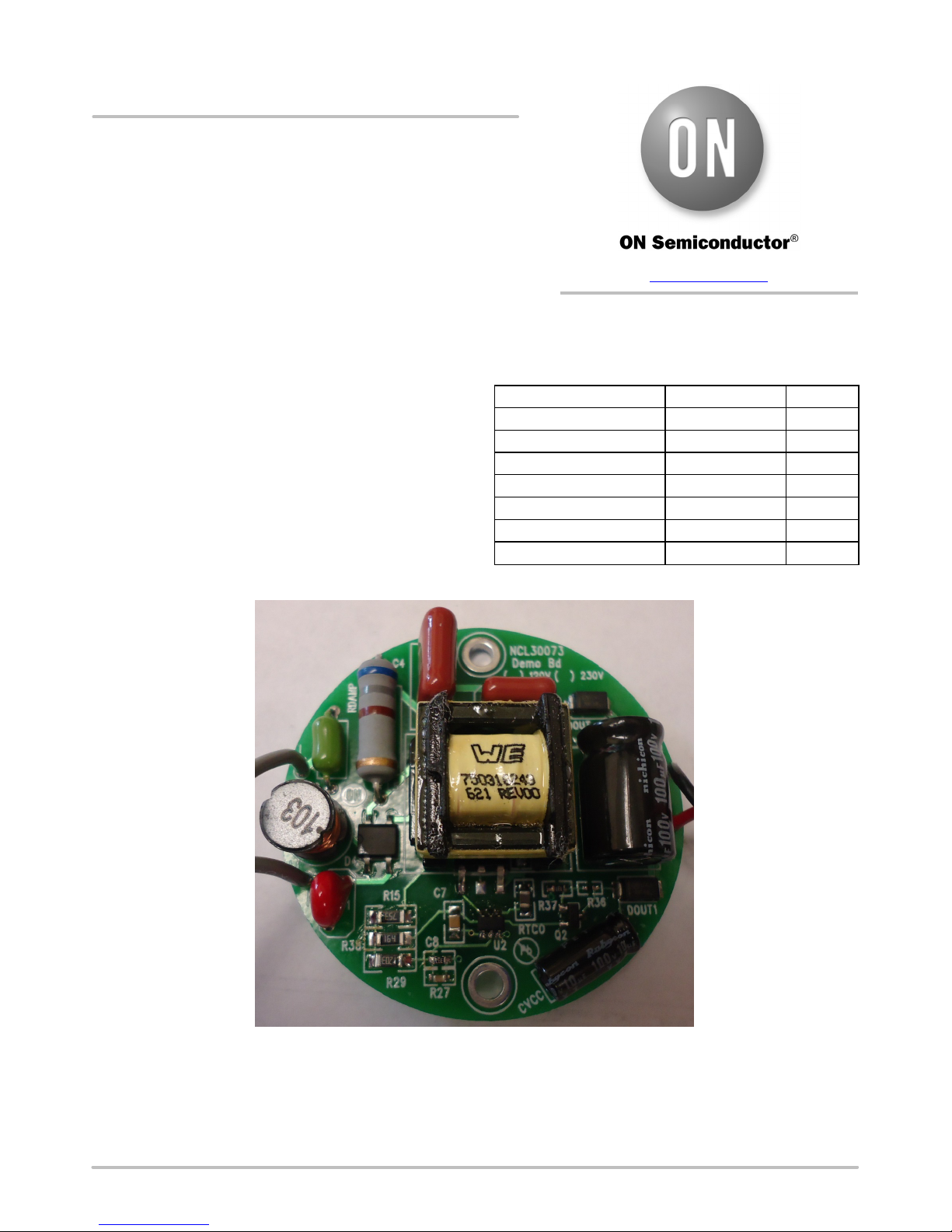

Figure 1. Evaluation Board Photo

1 Publication Order Number:

EVBUM2505/D

Page 2

NCL30073LED4GEVB

THEORY OF OPERATION

Power Stage

The power stage is a flying buck boost design. In this

configuration, drain of the switching FET is connected to the

rectified HVDC and the source is switching. This has many

benefits:

1. Direct output current sensing

2. Direct output voltage sensing

3. No Aux winding needed

The power stage operates as a fixed frequency DCM

power stage. The DCM allows for no forced commutation

of the output diode for good EMI performance. The fixed

current/fixed frequency provides for a constant power

control over a large portion of the input waveform. The

resistor divider of R27 and R29 provides some wave shaping

to improve the power factor. The input current waveform is

made to be square for maximum TRIAC dimmer

compatibility.

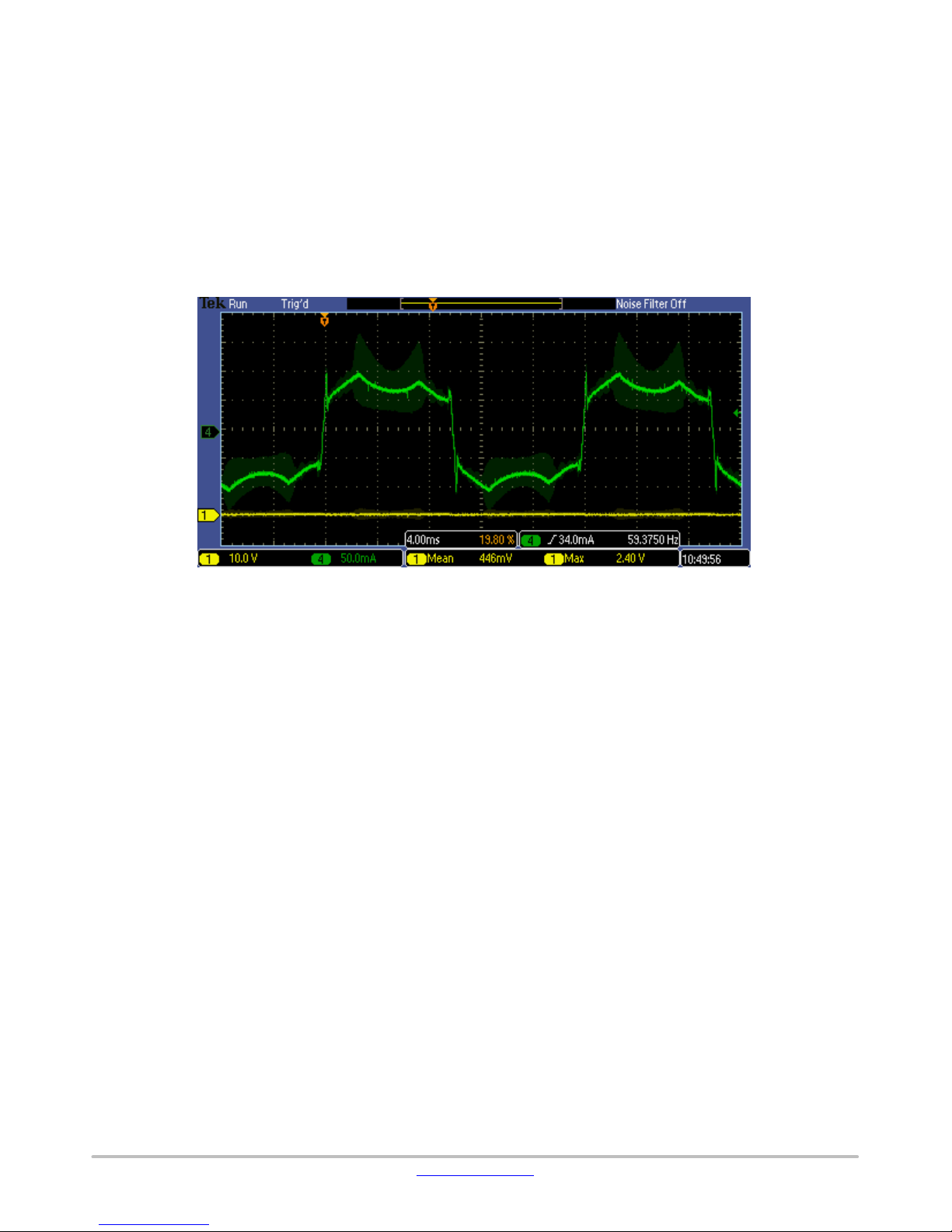

Figure 2.

Output Voltage Sense and Vcc generation

Dout1 is in parallel with the output during the off time of

the FET and stores energy in Cvcc. R36 and R37 divide the

output voltage and Q2 buffers it to provide Vcc power to the

controller. Since the divider is a fixed ratio, Vcc is a fixed

percentage of the output voltage. When Vcc rises above

25 V, the controller detects and OVP fault. The maximum

output voltage is set by adjusting the ratio of R36/R37.

In cases where the output has a lot of ripple current and the

LED has high dynamic resistance, the peak output voltage

can be much higher than the average output voltage. The

inductor winding will charge the Cvcc to the peak of the

output voltage which may trigger the OVP sooner than

expected so in this case the peak voltage of the LED string

is critical.

Protection

Thermal Protection

Rtco is a PTC connected between the CS pin and Rsens.

The controller creates and internal signal current from the

CS pin. As the resistance of Rtco becomes larger with

temperature, the signal level at the CS pin increases causing

the current to foldback with temperature.

Programmable OVP

R36 and R37 set Vcc as a fixed percentage of the output

voltage. The OVP threshold on the controller is 25 V. So the

ratio of R36/R37 is set to trip the Vcc OVP threshold at about

100 V output.

Overcurrent Protection

The controller has built in overcurrent limits.

Output Current

The output current is set by the value of Rsens. It’s

possible to adjust the output current by changing Rsens.

TRIAC Dimming Compatibility

The EMI filter components are selected to provide

optimum damping of the EMI filter to eliminate ringback of

the input current which will lead to loss of hold current in the

dimmer. The square nature of the input current makes the

best case for TRIAC holding current over the line cycle

while still maintaining power factor above 0.9.

www.onsemi.com

2

Page 3

NCL30073LED4GEVB

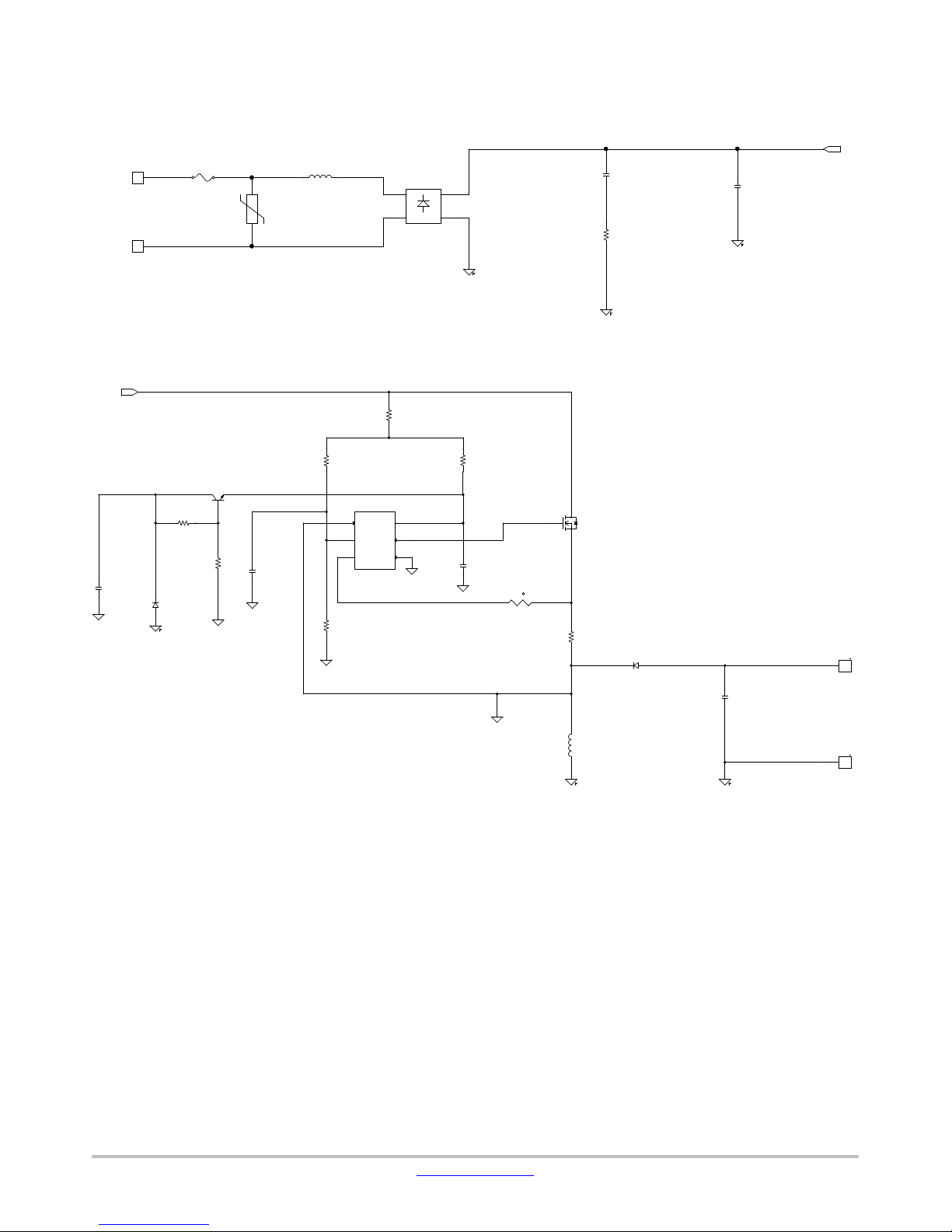

SCHEMATIC

+HVDC_iso

AC_L

AC_N

+HVDC_iso

CVcc

10uF 100V

1

1

Dout1

MURA160T3G

R36

301k

F2

0A5

R37

100k

Q2

MMBT5551LT1G

RV1

MOV 250V

C8

10nF

412k

R29

L1

10mH

1

OPP

2

FB

3

CS

NCL30073

R27

10k

D4

+

AC1

−

AC2

MB6S

Figure 3. Input Circuit

R15

143k

R38

220k

U2

6

Vcc

5

Gdrv

4

Gnd

1uF 50V

C7

Rtco

680 PTC

C4

100nF 400V

Rdamp

680

C6

33nF 400V

Q1

NDD60N900U1T4G

t

Rsens

1.13

Dout

MURA160T3G

1

LED−

Cout

100uF100V

Figure 4. Main Circuit

www.onsemi.com

3

L5

1.2mH

1

LED+

Page 4

NCL30073LED4GEVB

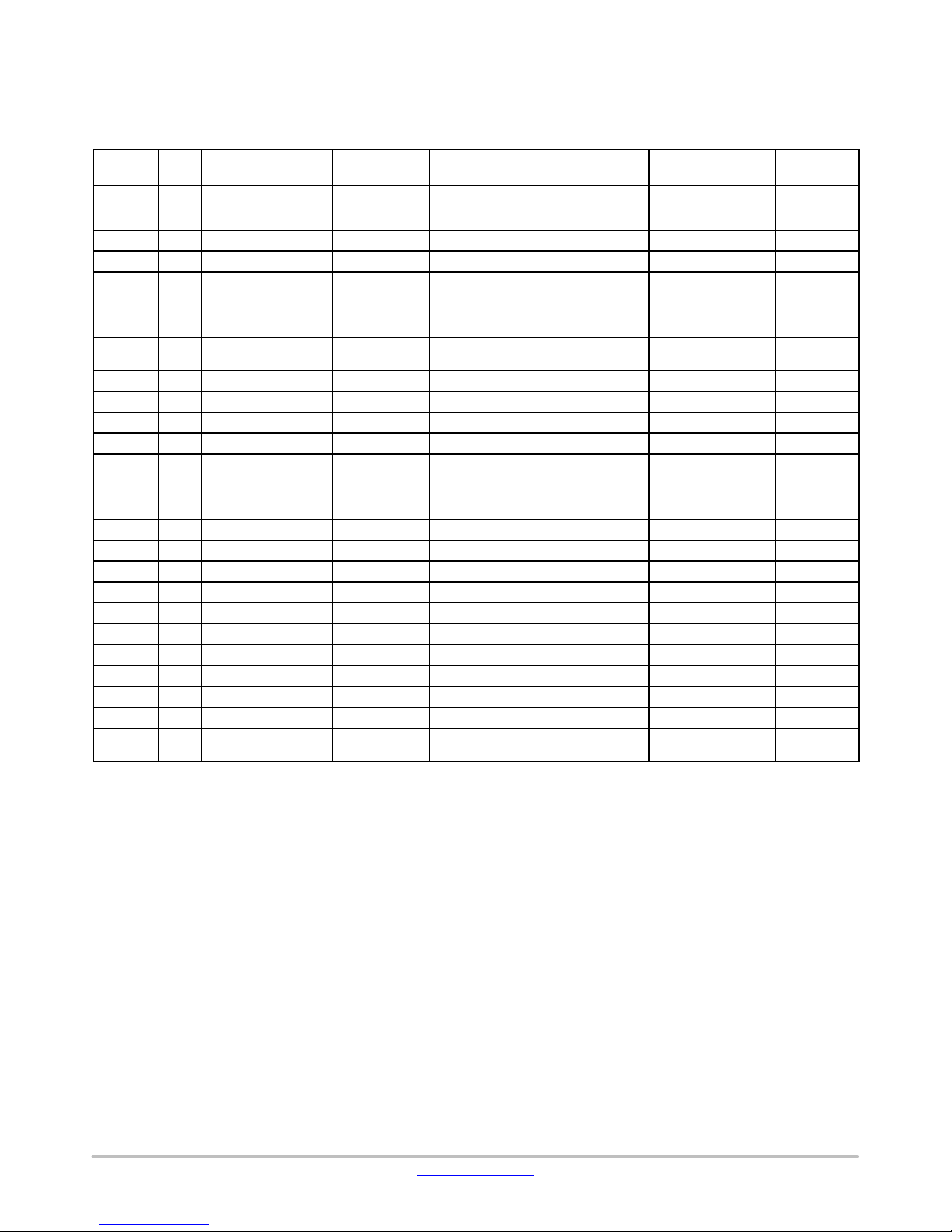

BILL OF MATERIAL

Table 2. BILL OF MATERIAL

Refer-

ence

CVcc 1

Cout 1

C4 1 100 nF 400 V Faratronic C212G104−4B****+++ Faratronic C212G104−4B****+++ Yes

C6 1 33 nF 400 V Faratronic C212G333−3A****+++ Faratronic C212G333−3A****+++ Yes

C7 1

C8 1 10 nF Yageo CC0603KRX7R9BB1

Dout1,

Dout

D4 1 MB6S MCC MB6S Digikey MB4S−TPMSCT−ND Yes

F2 1 0A5 Littelfuse 0263.500WRT1L Digikey F1999CT−ND Yes

L1 1 10 mH Wurth 744772103 Digikey 732−3791−ND Yes

L5 1 1.2 mH Wurth 750316243 Wurth 750316243 Yes

Q1 1 NDD60N900U1T4G ON

Q2 1 MMBT5551LT1G ON

RV1 1 MOV 250V Littelfuse V390ZA05P Digikey F3361−ND Ye s

Rdamp 1 680 Yageo RSF200JB−73−680R Digikey 680W−2−ND Yes

Rsens 1 1.13 Yageo RC1206FR−071R13L Digikey 311−1.13FRCT−ND Ye s

Rtco 1 680 PTC Epcos B59721A90A62 Digikey 495−4312−1−ND Ye s

R15 1 143k Yageo RC1206FR−07143KL Digikey 311−143KFRCT−ND Ye s

R27 1 10k Yageo RC0603FR−0710k0L Digikey 311−10.0KHRCT−ND Yes

R29 1 412k Yageo RC1206FR−07412KL Digikey 311−412KFRCT−ND Ye s

R36 1 301k Yageo RC0603FR−07301KL Digikey 311−301KHRCT−ND Yes

R37 1 100k Yageo RC0603FR−07100KL Digikey 311−100KHRCT−ND Yes

R38 1 220k Yageo RC1206FR−07220KL Digikey 311−220KFRCT−ND Ye s

U2 1 NCL30073 ON

Qty Part Distributor

10 mF 100 V

100 mF 100 V

1 mF 50 V

2 MURA160T3G ON

Rubycon 100YXJ10M5X11 Digikey

Nichicon UVK2A101MPD Digikey

Yageo CC0805KKX7R9BB1

Semiconductor

Semiconductor

Semiconductor

Semiconductor

Distributor

Part Number

05

03

MURA160T3G ON

NDD60N900U1T4G ON

MMBT5551LT1G ON

NCL30073 ON

Manufacturer

Digikey 311−1886−1−ND Yes

Digikey 311−1085−1−ND Yes

Semiconductor

Semiconductor

Semiconductor

Semiconductor

Manufacturer

Part Number

1189−2150−ND

UVK2A101MPD−ND

MURA160T3G No

NDD60N900U1T4G No

MMBT5551LT1G No

NCL30073 No

Substitution

Allowed

Yes

Yes

NOTE: All components to comply with RoHS 2002/95/EC

www.onsemi.com

4

Page 5

NCL30073LED4GEVB

GERBER VIEWS

Figure 5. Top Side PCB

www.onsemi.com

5

Page 6

NCL30073LED4GEVB

Circuit Board Fabrication Notes

1. Fabricate per IPC−6011 and IPC6012. Inspect to

IPA−A−600 Class 2 or updated standard.

2. Printed Circuit Board is defined by files listed in

fileset.

3. Modification to copper within the PCB outline is

not allowed without permission, except where

noted otherwise. The manufacturer may make

adjustments to compensate for manufacturing

process, but the final PCB is required to reflect the

associated gerber file design ± 0.001 in. for etched

features within the PCB outline.

4. Material in accordance with IPC−4101/21, FR4,

Tg 125°C min.

5. Layer to layer registration shall not exceed

± 0.004 in.

6. External finished copper conductor thickness shall

be 0.0026 in. min. (ie 2oz)

7. Copper plating thickness for through holes shall be

0.0013 in. min. (ie 1oz)

8. All holes sizes are finished hole size.

9. Finished PCB thickness 0.062 in.

10. All un-dimensioned holes to be drilled using the

NC drill data.

Figure 6. PCB Outline

11. Size tolerance of plated holes: ± 0.003 in. :

non−plated holes ± 0.002 in.

12. All holes shall be ± 0.003 in. of their true position

U.D.S.

13. Construction to be SMOBC, using liquid photo

image (LPI) solder mask in accordance with

IPC−SM−B40C, Type B, Class 2, and be green in

color.

14. Solder mask mis-registration ± 0.004 in. max.

15. Silkscreen shall be permanent non−conductive

white ink.

16. The fabrication process shall be UL approved and

the PCB shall have a flammability rating of

UL94V0 to be marked on the solder side in

silkscreen with date, manufactures approved logo,

and type designation.

17. Warp and twist of the PCB shall not exceed

0.0075 in. per in.

18. 100% electrical verification required.

19. Surface finish: electroless nickel immersion gold

(ENIG)

20. RoHS 2002/95/EC compliance required.

www.onsemi.com

6

Page 7

NCL30073LED4GEVB

ECA PICTURES

Figure 7. Top View

www.onsemi.com

7

Page 8

NCL30073LED4GEVB

TEST PROCEDURE

Equipment Needed

• AC Source – 200 to 260 V ac 50 Hz Minimum 100 W

capability

• AC Wattmeter – 100 W Minimum, True RMS Input

Voltage, Current, Power Factor, and THD 0.2%

accuracy or better

• DC Voltmeter – 300 V dc minimum 0.1% accuracy or

better

• DC Ammeter – 1 A dc minimum 0.1% accuracy or

better

• LED Load – 70 V – 80 V @ 110 mA

AC Power

Source

Note: Unless otherwise specified, all voltage measurements are taken at the terminals of the UUT.

Functional Test Procedure

1. Set the LED Load for 75 V output.

2. Set the input power to 230 V 50 Hz.

Caution: Do not touch the ECA once it is

energized because there are hazardous voltages

present.

AC

Wattmeter

Figure 8. Test Set Up

Test Connections

1. Connect the LED Load to the red(+) and black(−)

2. Connect the AC power to the input of the AC

3. Connect the DC voltmeter as shown in Figure 8.

UUT

Regulation

230 V / Max Load

leads through the ammeter shown in Figure 10.

Caution: Observe the correct polarity or the

load may be damaged.

wattmeter shown in Figure 8. Connect the white

leads to the output of the AC wattmeter

DC Ammeter

DC Voltmeter

LED Test

Load

Table 3.

207 V

230 V

253 V

Efficiency +

Vout Iout

Pin

Output Current Output Power Power Factor THD

100%

www.onsemi.com

8

Page 9

NCL30073LED4GEVB

TEST DATA

Figure 9. Power Factor Over Line

Figure 10. THD Over Line

www.onsemi.com

9

Page 10

NCL30073LED4GEVB

Figure 11. Efficiency

Figure 12. Regulation Over Line

www.onsemi.com

10

Page 11

NCL30073LED4GEVB

Figure 13. Start Up with AC Applied 230 V

Figure 14. Output Ripple 75% Pk − Pk

www.onsemi.com

11

Page 12

NCL30073LED4GEVB

Figure 15.

Q1

R15, R29, R38

Figure 16. Thermal Image SMT Side

www.onsemi.com

12

Page 13

NCL30073LED4GEVB

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

19521 E. 32nd Pkwy, Aurora, Colorado 80011 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

◊

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

www.onsemi.com

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

EVBUM2505/D

13

Loading...

Loading...